Acoustic-Based Machine Main State Monitoring for High-Speed CNC Drilling

Abstract

1. Introduction

2. State of the Art

2.1. AI-Driven Process Optimization for CNC Drilling Machines in Industry 4.0

2.2. Real-Time Data Integration and Simulation in CNC Drilling

3. Materials and Methods

3.1. Integrating Acoustic Wave and Mechanical Analysis

3.2. Acoustic Wave Propagation in Drilling Process

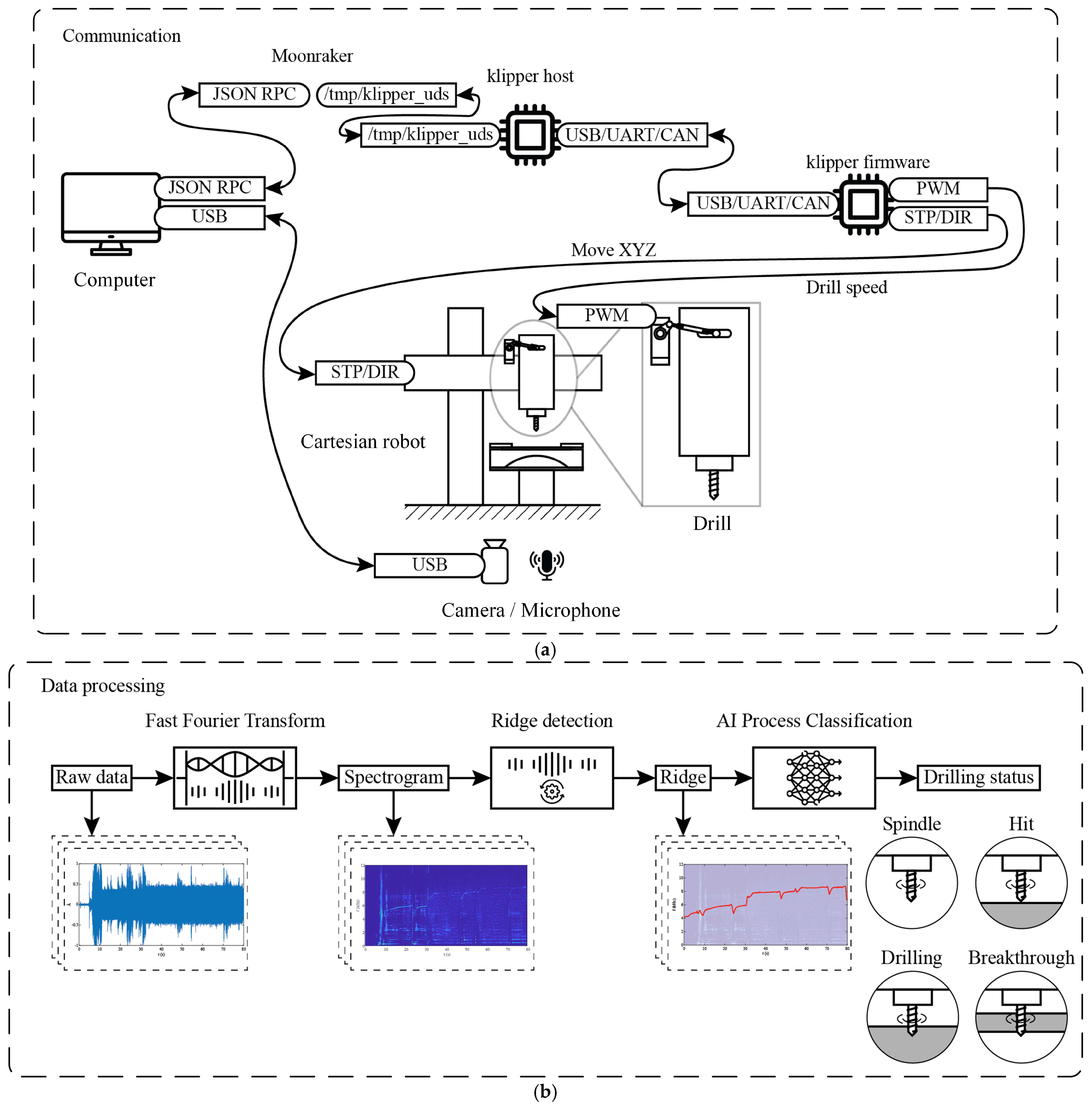

3.3. Optimizing CNC Drilling Performance with Klipper and AI-Enhanced Data Processing

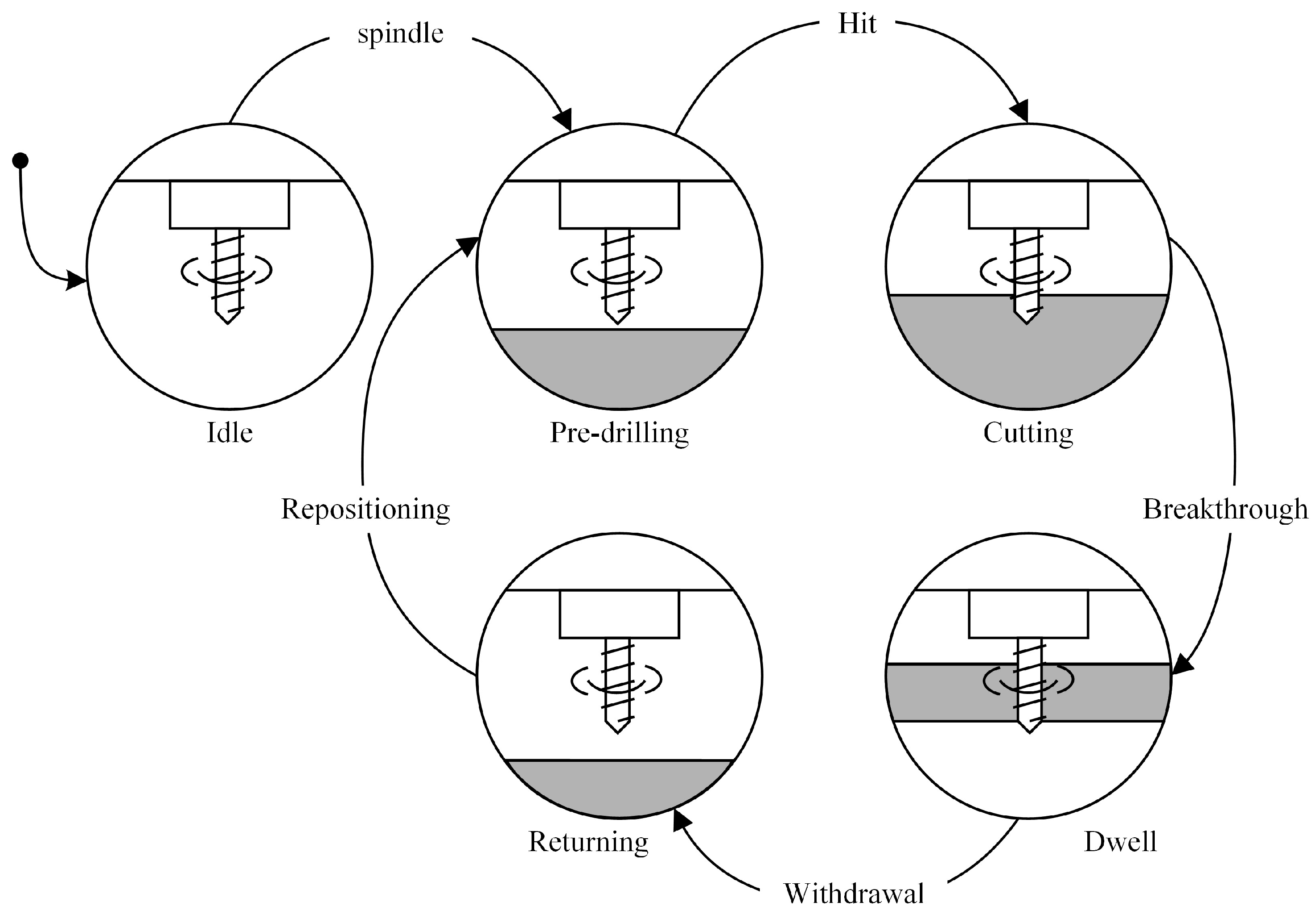

3.4. Finite State Machine Approach to Drilling Automation

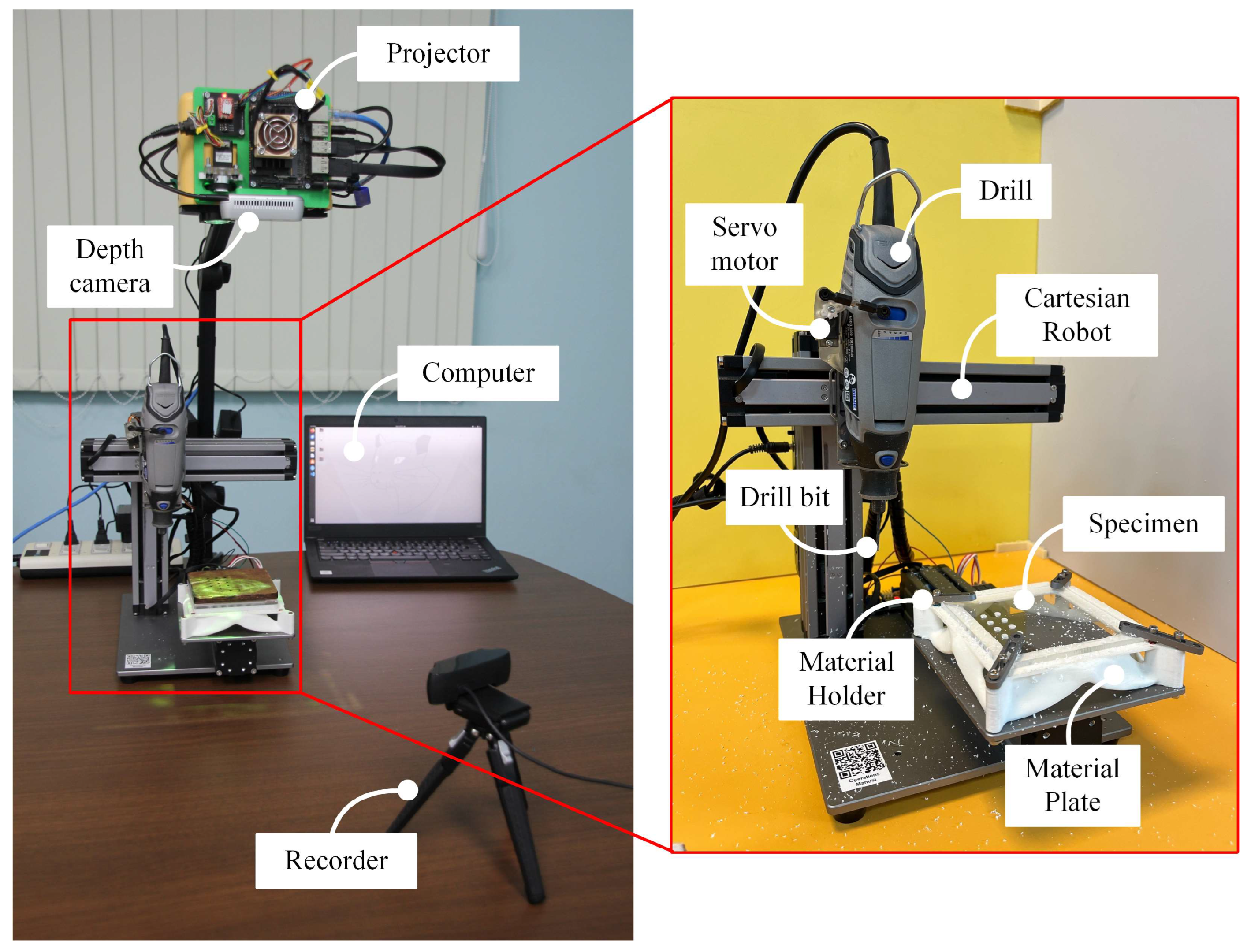

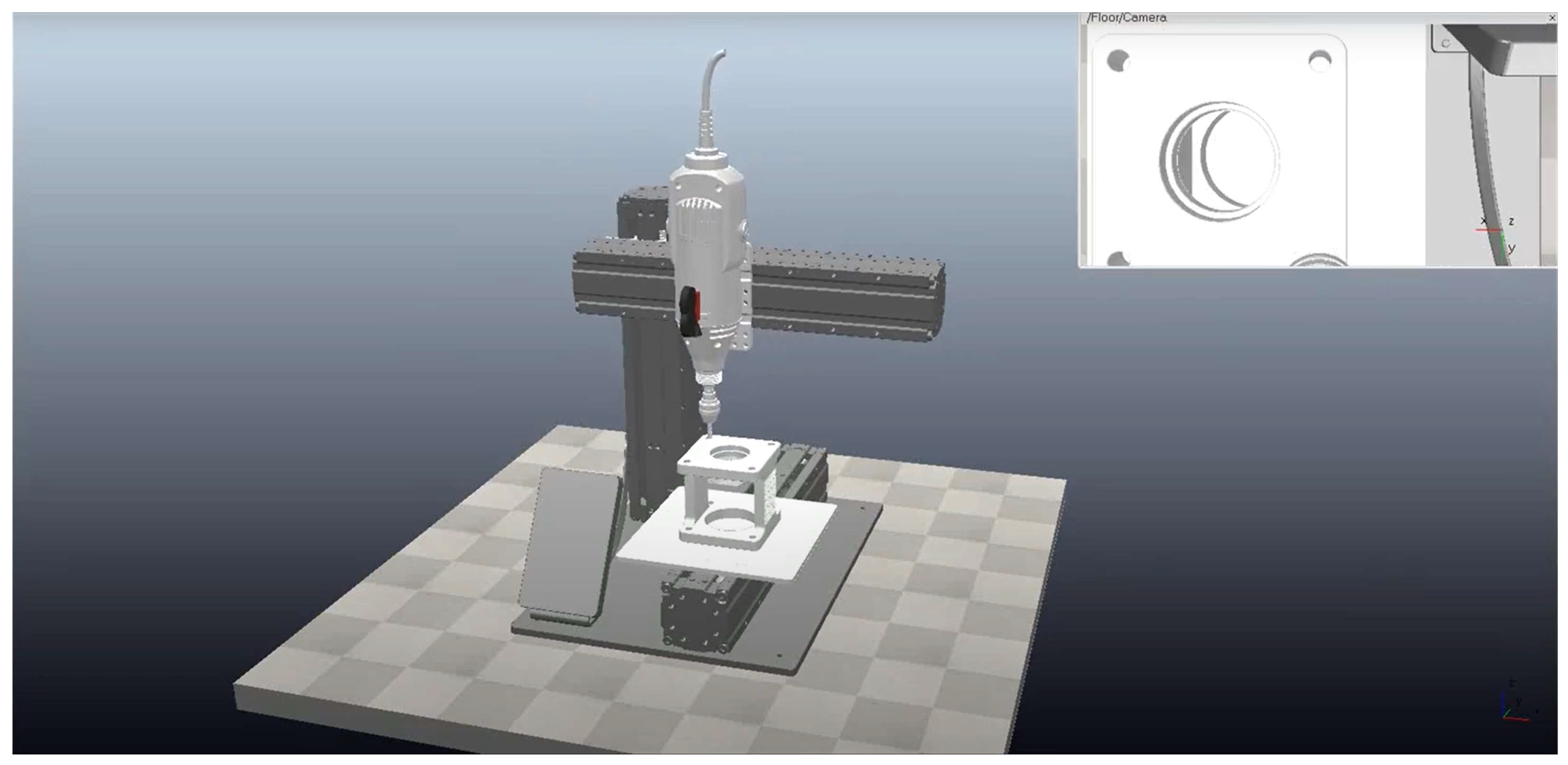

3.5. Experimental Setup

4. Results

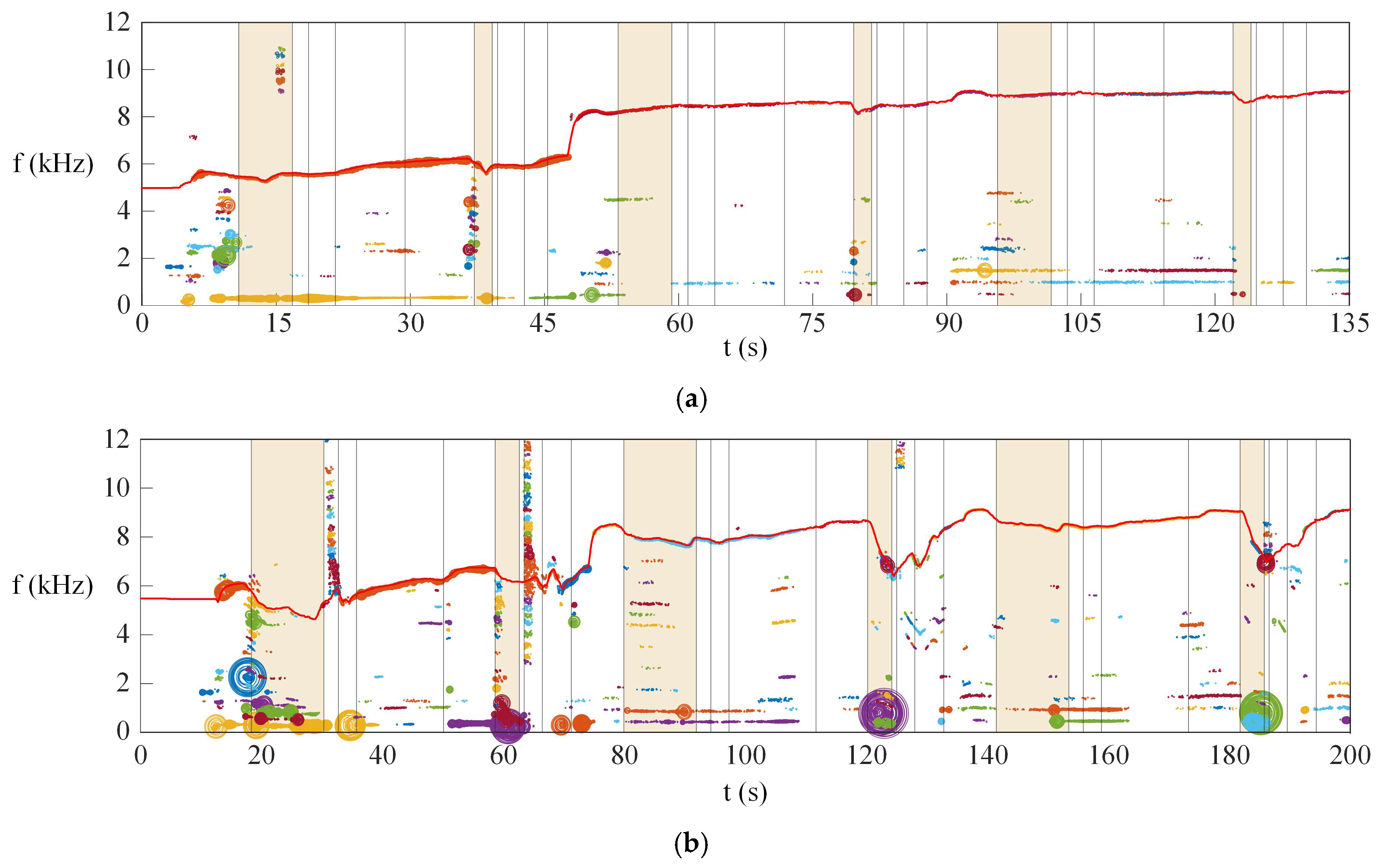

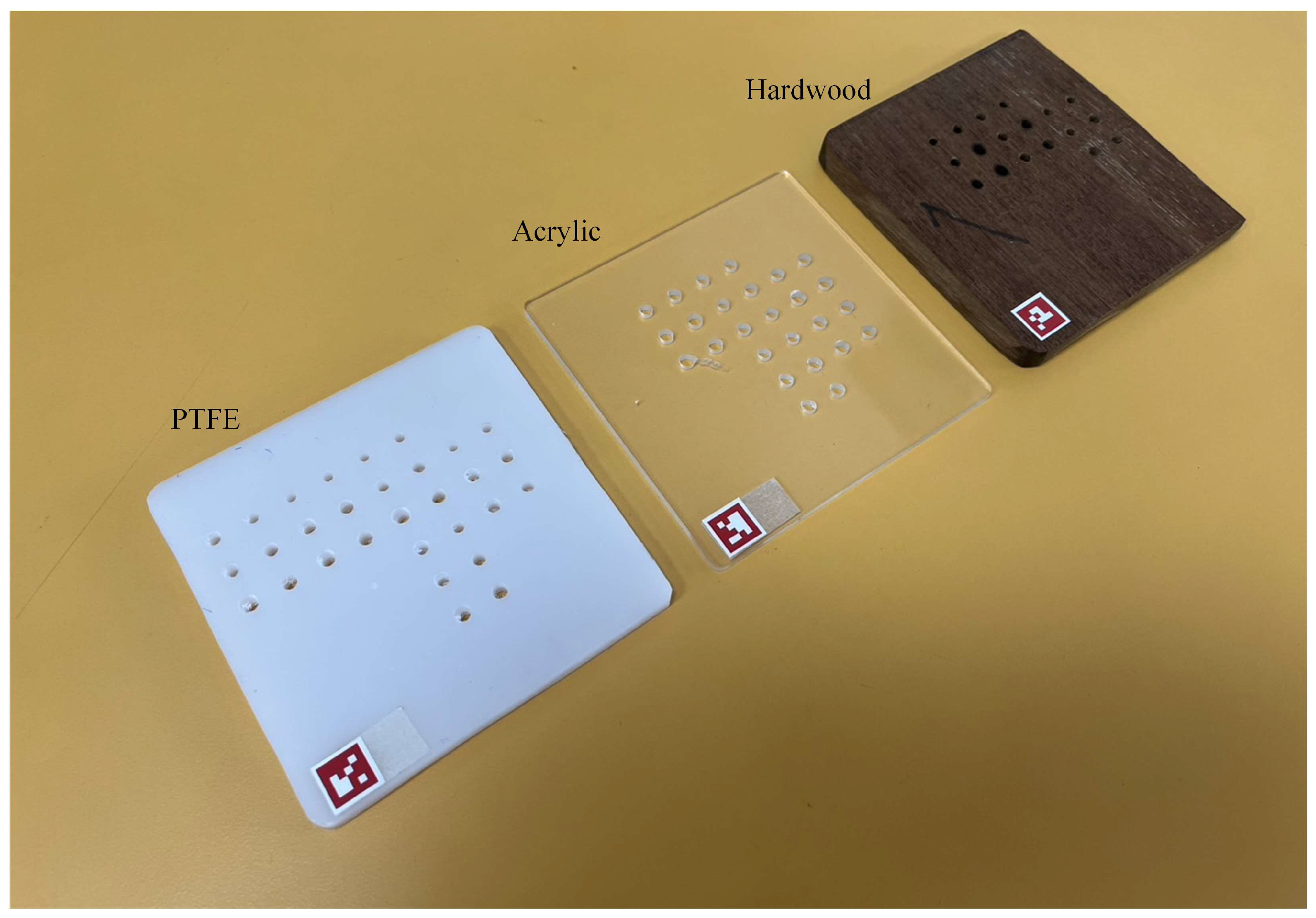

4.1. Acoustic Characteristics of Materials Drilling

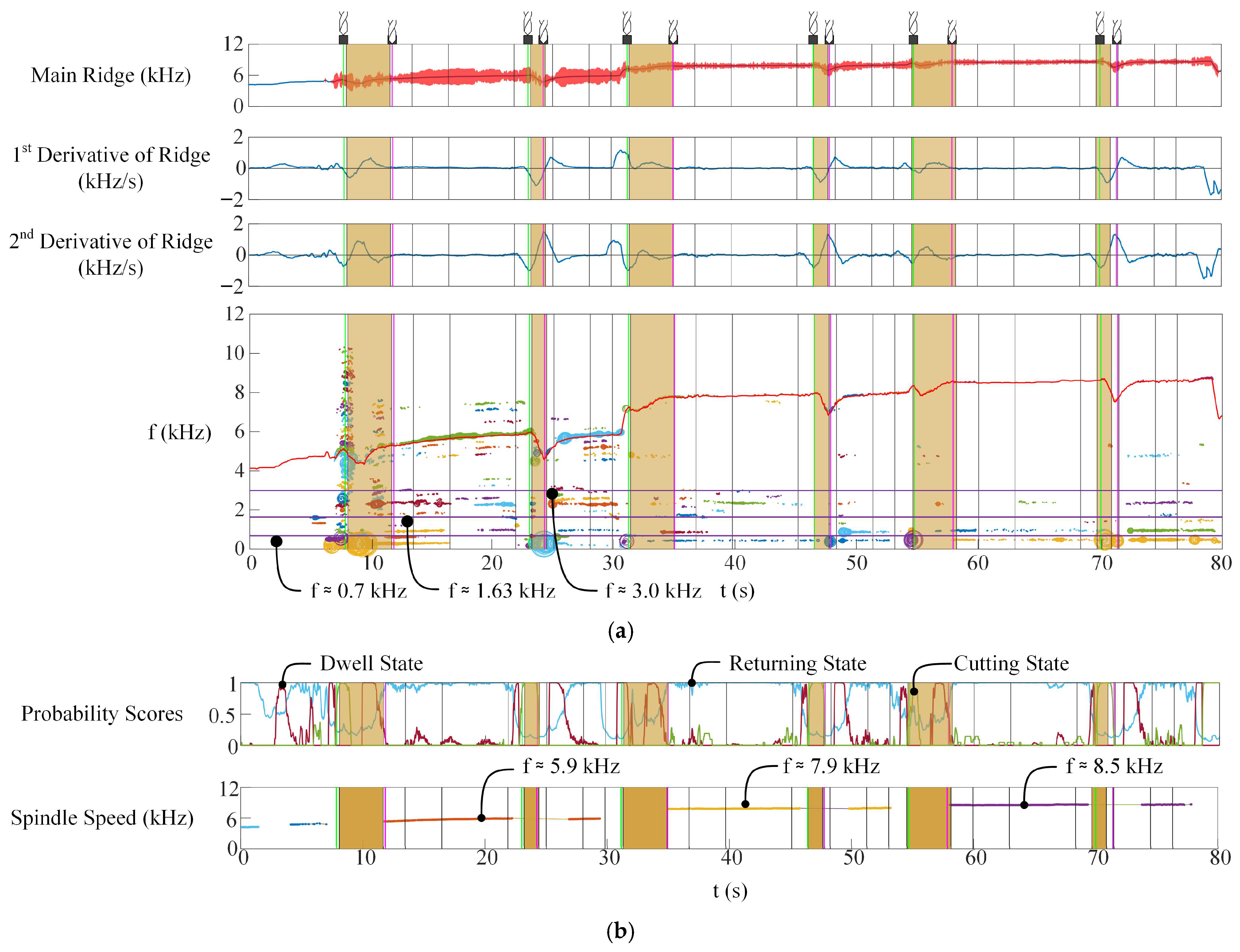

4.2. Analysis for Drilling Process Characterization

5. Discussion

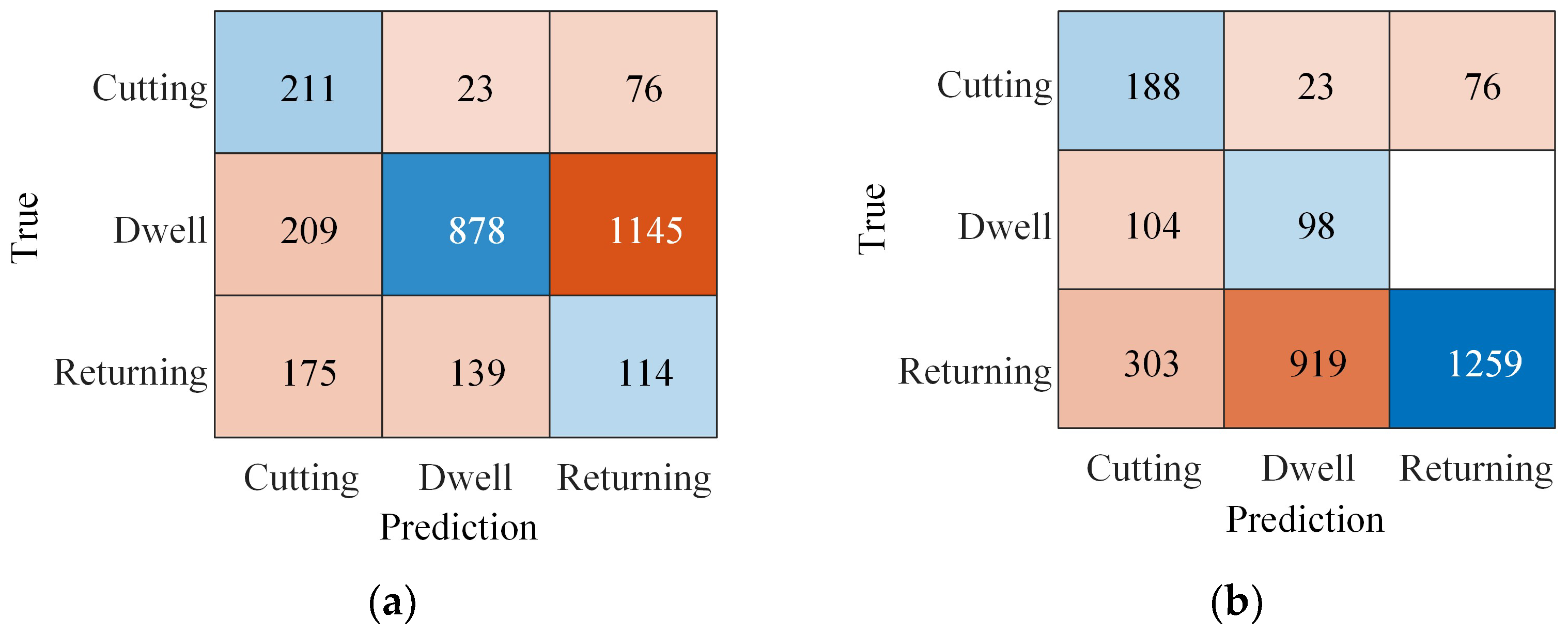

5.1. Accuracy Analysis for State Prediction

5.2. Open Sound Library

5.3. Potential for Other Canned Cycle

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Chaiprabha, K.; Chanchareon, R. Innovative Smart Drilling with Critical Event Detection and Material Classification. J. Manuf. Mater. Process. 2023, 7, 155. [Google Scholar] [CrossRef]

- Szwajka, K.; Zielińska-Szwajka, J.; Trzepieciński, T. Experimental Analysis of Smart Drilling for the Furniture Industry in the Era of Industry 4.0. Materials 2024, 17, 2033. [Google Scholar] [CrossRef] [PubMed]

- Yue, X.; Yue, Z.; Yan, Y.; Li, Y. Experimental study on predicting rock properties using sound level characteristics along the borehole during drilling. Bull. Eng. Geol. Environ. 2023, 82, 310. [Google Scholar] [CrossRef]

- Govekar, E.; Gradišek, J.; Grabec, I. Analysis of acoustic emission signals and monitoring of machining processes. Ultrasonics 2000, 38, 598–603. [Google Scholar] [CrossRef]

- Hase, A. In Situ Measurement of the Machining State in Small-Diameter Drilling by Acoustic Emission Sensing. Coatings 2024, 14, 193. [Google Scholar] [CrossRef]

- Uhlmann, E.; Holznagel, T. Acoustic emission-based process monitoring in the milling of carbon fibre-reinforced plastics. CIRP J. Manuf. Sci. Technol. 2022, 37, 464–476. [Google Scholar] [CrossRef]

- Chacón, J.L.F.; de Barrena, T.F.; García, A.; de Buruaga, M.S.; Badiola, X.; Vicente, J. A novel machine learning-based methodology for tool wear prediction using acoustic emission signals. Sensors 2021, 21, 5984. [Google Scholar] [CrossRef] [PubMed]

- Mohammad, A.; Belayneh, M. Field Telemetry Drilling Dataset Modeling with Multivariable Regression, Group Method Data Handling, Artificial Neural Network, and the Proposed Group-Method-Data-Handling-Featured Artificial Neural Network. Appl. Sci. 2024, 14, 2273. [Google Scholar] [CrossRef]

- Kasiviswanathan, S.; Gnanasekaran, S.; Thangamuthu, M.; Rakkiyannan, J. Machine-Learning- and Internet-of-Things-Driven Techniques for Monitoring Tool Wear in Machining Process: A Comprehensive Review. J. Sens. Actuator Netw. 2024, 13, 53. [Google Scholar] [CrossRef]

- Hase, A.; Wada, M.; Koga, T.; Mishina, H. The relationship between acoustic emission signals and cutting phenomena in turning process. Int. J. Adv. Manuf. Technol. 2014, 70, 947–955. [Google Scholar] [CrossRef]

- Elhadi, A.; Slamani, M.; Amroune, S.; Arslane, M.; Chatelain, J.F.; Jawaid, M.; Bidi, T. Precision drilling optimization in jute/palm fiber reinforced hybrid composites. Meas. J. Int. Meas. Confed. 2024, 236, 115066. [Google Scholar] [CrossRef]

- Velayudham, A.; Krishnamurthy, R.; Soundarapandian, T. Acoustic emission based drill condition monitoring during drilling of glass/phenolic polymeric composite using wavelet packet transform. Mater. Sci. Eng. A 2005, 412, 141–145. [Google Scholar] [CrossRef]

- Marinescu, I.; Axinte, D.A. A critical analysis of effectiveness of acoustic emission signals to detect tool and workpiece malfunctions in milling operations. Int. J. Mach. Tools Manuf. 2008, 48, 1148–1160. [Google Scholar] [CrossRef]

- Iatsenko, D.; McClintock, P.V.E.; Stefanovska, A. Extraction of instantaneous frequencies from ridges in time–frequency representations of signals. Signal Process. 2016, 125, 290–303. [Google Scholar] [CrossRef]

- Bai, X.; Qiao, G.; Liu, Z.; Zhu, W. Investigation of transient machining in the cortical bone drilling process by conventional and axial vibration-assisted drilling methods. Proc. Inst. Mech. Eng. Part H J. Eng. Med. 2023, 237, 489–501. [Google Scholar] [CrossRef]

- Retiti Diop Emane, C.; Song, S.; Lee, H.; Choi, D.; Lim, J.; Bok, K.; Yoo, J. Anomaly Detection Based on GCNs and DBSCAN in a Large-Scale Graph. Electronics 2024, 13, 2625. [Google Scholar] [CrossRef]

- Kanyama, M.N.; Bhunu Shava, F.; Gamundani, A.M.; Hartmann, A. Machine learning applications for anomaly detection in Smart Water Metering Networks: A systematic review. Phys. Chem. Earth 2024, 134, 103558. [Google Scholar] [CrossRef]

- Cheng, Y.; Li, Y.; Li, G.; Liu, X.; Xia, J.; Liu, C.; Hao, X. Tool breakage monitoring driven by the real-time predicted spindle cutting torque using spindle servo signals. Robot. Comput. Integr. Manuf. 2025, 92, 102888. [Google Scholar] [CrossRef]

- Hagag, A.M.; Yousef, L.S.; Abdelmaguid, T.F. Multi-Criteria Decision-Making for Machine Selection in Manufacturing and Construction: Recent Trends. Mathematics 2023, 11, 631. [Google Scholar] [CrossRef]

- Bustillo, A.; Urbikain, G.; Perez, J.M.; Pereira, O.M.; Lopez de Lacalle, L.N. Smart optimization of a friction-drilling process based on boosting ensembles. J. Manuf. Syst. 2018, 48, 108–121. [Google Scholar] [CrossRef]

- Everson, C.E.; Hoessein Cheraghi, S. The application of acoustic emission for precision drilling process monitoring. Int. J. Mach. Tools Manuf. 1999, 39, 371–387. [Google Scholar] [CrossRef]

- Xu, N.; Li, M.; Fang, S.; Huang, C.; Chen, C.; Zhao, Y.; Mao, F.; Deng, T.; Wang, Y. Research on the detection of the hole in wood based on acoustic emission frequency sweeping. Constr. Build. Mater. 2023, 400, 132761. [Google Scholar] [CrossRef]

- Du, S.; Huang, C.; Ma, X.; Fan, H. A Review of Data-Driven Intelligent Monitoring for Geological Drilling Processes. Processes 2024, 12, 2478. [Google Scholar] [CrossRef]

- Yadav, A.; Garg, R.K.; Sachdeva, A. Artificial intelligence applications for information management in sustainable supply chain management: A systematic review and future research agenda. Int. J. Inf. Manag. Data Insights 2024, 4, 100292. [Google Scholar] [CrossRef]

- Pacheco, D.A.D.J.; Iwaszczenko, B. Unravelling human-centric tensions towards Industry 5.0: Literature review, resolution strategies and research agenda. Digit. Bus. 2024, 4, 100090. [Google Scholar] [CrossRef]

- Reeber, T.; Henninger, J.; Weingarz, N.; Simon, P.M.; Berndt, M.; Glatt, M.; Kirsch, B.; Eisseler, R.; Aurich, J.C.; Möhring, H.C. Tool condition monitoring in drilling processes using anomaly detection approaches based on control internal data. Procedia CIRP 2024, 121, 216–221. [Google Scholar] [CrossRef]

- Rahman, M.A.; Saleh, T.; Jahan, M.P.; McGarry, C.; Chaudhari, A.; Huang, R.; Tauhiduzzaman, M.; Ahmed, A.; Mahmud, A.A.; Bhuiyan, M.S.; et al. Review of Intelligence for Additive and Subtractive Manufacturing: Current Status and Future Prospects. Micromachines 2023, 14, 508. [Google Scholar] [CrossRef]

- Peña, B.; Aramendi, G.; Rivero, A.; De Lacalle, L.N.L. Monitoring of drilling for burr detection using spindle torque. Int. J. Mach. Tools Manuf. 2005, 45, 1614–1621. [Google Scholar] [CrossRef]

- López De Lacalle, L.N.; Pérez-Bilbatua, J.; Sánchez, J.A.; Llorente, J.I.; Gutiérrez, A.; Albóniga, J. Using high pressure coolant in the drilling and turning of low machinability alloys. Int. J. Adv. Manuf. Technol. 2000, 16, 85–91. [Google Scholar] [CrossRef]

- Bunian, S.; Al-Ebrahim, M.A.; Nour, A.A. Role and Applications of Artificial Intelligence and Machine Learning in Manufacturing Engineering: A Review. Eng. Sci. 2024, 29, 1088. [Google Scholar] [CrossRef]

- Presciuttini, A.; Cantini, A.; Costa, F.; Portioli-Staudacher, A. Machine learning applications on IoT data in manufacturing operations and their interpretability implications: A systematic literature review. J. Manuf. Syst. 2024, 74, 477–486. [Google Scholar] [CrossRef]

- Basavarajappa, S.; Chandramohan, G.; Davim, J.P. Some studies on drilling of hybrid metal matrix composites based on Taguchi techniques. J. Mater. Process. Technol. 2008, 196, 332–338. [Google Scholar] [CrossRef]

- Bakkal, M.; Shih, A.J.; McSpadden, S.B.; Liu, C.T.; Scattergood, R.O. Light emission, chip morphology, and burr formation in drilling the bulk metallic glass. Int. J. Mach. Tools Manuf. 2005, 45, 741–752. [Google Scholar] [CrossRef]

- López de Lacalle, L.N.; Lamikiz, A.; Muñoa, J.; Salgado, M.A.; Sánchez, J.A. Improving the high-speed finishing of forming tools for advanced high-strength steels (AHSS). Int. J. Adv. Manuf. Technol. 2006, 29, 49–63. [Google Scholar] [CrossRef]

- Drumheller, D.S.; Knudsen, S.D. The propagation of sound waves in drill strings. J. Acoust. Soc. Am. 1995, 97, 2116–2125. [Google Scholar] [CrossRef]

- Wang, Q.; Bi, C.; Zhang, J.; Wang, H.; Guan, Z. Experimental Study on Downhole Acoustic Wave Propagation Characteristics in Curved Drill String. Processes 2023, 11, 1525. [Google Scholar] [CrossRef]

- Daraba, D.; Pop, F.; Daraba, C. Digital Twin Used in Real-Time Monitoring of Operations Performed on CNC Technological Equipment. Appl. Sci. 2024, 14, 10088. [Google Scholar] [CrossRef]

- Birkelid, A.H.; Eikevåg, S.W.; Elverum, C.W.; Steinert, M. High-performance polymer 3D printing—Open-source liquid cooled scalable printer design. HardwareX 2022, 11, e00265. [Google Scholar] [CrossRef] [PubMed]

- Avni, Y.; Danial-Saad, A.; Sheidin, J.; Kuflik, T. Enhancing museum accessibility for blind and low vision visitors through interactive multimodal tangible interfaces. Int. J. Hum. Comput. Stud. 2025, 198, 103469. [Google Scholar] [CrossRef]

- Tůma, P. Advances in the design and application of contactless conductivity detectors for separation, flow-through, microfluidic and sensing techniques: A review. Anal. Chim. Acta 2025, 1337, 343325. [Google Scholar] [CrossRef]

- Dávila, J.L.; Manzini, B.M.; Lopes da Fonsêca, J.H.; Mancilla Corzo, I.J.; Neto, P.I.; Aparecida de Lima Montalvão, S.; Annichino-Bizzacchi, J.M.; Akira d’Ávila, M.; Lopes da Silva, J.V. A parameterized g-code compiler for scaffolds 3D bioprinting. Bioprinting 2022, 27, e00222. [Google Scholar] [CrossRef]

- Kumar, S.; Sayyad, S.; Bongale, A. Fault Classification of 3D-Printing Operations Using Different Types of Machine and Deep Learning Techniques. AI 2024, 5, 1759–1778. [Google Scholar] [CrossRef]

- Hu, Z.; Wang, J.; Wang, G.; Wen, S.; Li, Z. Extraction of time-frequency ridge line based on automatic peak search and curve fitting. Eng. Res. Express 2024, 6, 025502. [Google Scholar] [CrossRef]

- Ryalat, M.; Franco, E.; Elmoaqet, H.; Almtireen, N.; Al-Refai, G. The Integration of Advanced Mechatronic Systems into Industry 4.0 for Smart Manufacturing. Sustainability 2024, 16, 8504. [Google Scholar] [CrossRef]

- Moreira, M.V.; Landon, Y.; Araujo, A.C. A Timed Automaton Model with Timing Intervals and Outputs for Fault Diagnosis of the Drilling Process on a CNC Machine. J. Control Autom. Electr. Syst. 2023, 34, 1207–1219. [Google Scholar] [CrossRef]

- Sun, J.; Xi, R.; Jiang, Z.; Xia, G.; Dai, Y.; Zhang, J. Auditory perception based milling posture detection and depth control enhancement for orthopedic robots. Measurement 2025, 239, 115448. [Google Scholar] [CrossRef]

- Damilos, S.; Saliakas, S.; Karasavvas, D.; Koumoulos, E.P. An Overview of Tools and Challenges for Safety Evaluation and Exposure Assessment in Industry 4.0. Appl. Sci. 2024, 14, 4207. [Google Scholar] [CrossRef]

- Wang, T.; Li, J.; Kong, Z.; Liu, X.; Snoussi, H.; Lv, H. Digital twin improved via visual question answering for vision-language interactive mode in human–machine collaboration. J. Manuf. Syst. 2021, 58, 261–269. [Google Scholar] [CrossRef]

- Ntemi, M.; Paraschos, S.; Karakostas, A.; Gialampoukidis, I.; Vrochidis, S.; Kompatsiaris, I. Infrastructure monitoring and quality diagnosis in CNC machining: A review. CIRP J. Manuf. Sci. Technol. 2022, 38, 631–649. [Google Scholar] [CrossRef]

- Stradovnik, S.; Hace, A. Workpiece Placement Optimization for Robot Machining Based on the Evaluation of Feasible Kinematic Directional Capabilities. Appl. Sci. 2024, 14, 1531. [Google Scholar] [CrossRef]

| Variable | Description |

|---|---|

| Total, constant and amplitude of cyclic force | |

| Cyclic function representing the periodic behavior of the force | |

| Frequency of the cyclic force | |

| Amplitude and phase of the nth sinusoidal component in Fourier expansion | |

| Displacement of the surface that produces mechanical wave as a function of time | |

| Mass of the system | |

| Damping coefficient | |

| Stiffness of the system | |

| Pressure at position x and time t and maximum pressure at the source of a sound | |

| Attenuation coefficient | |

| Distance the sound wave has traveled | |

| Motor’s torque of drilling machine. | |

| Motor’s torque constant. | |

| Resistance of the motor. | |

| Input voltage to the motor. | |

| Motor’s speed constant. | |

| Angular velocity of the spindle. | |

| Moment of inertia of the spindle system. | |

| Resistive torque in drilling process. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Piankitrungreang, P.; Chaiprabha, K.; Chungsangsatiporn, W.; Ratanasumawong, C.; Chancharoen, P.; Chancharoen, R. Acoustic-Based Machine Main State Monitoring for High-Speed CNC Drilling. Machines 2025, 13, 372. https://doi.org/10.3390/machines13050372

Piankitrungreang P, Chaiprabha K, Chungsangsatiporn W, Ratanasumawong C, Chancharoen P, Chancharoen R. Acoustic-Based Machine Main State Monitoring for High-Speed CNC Drilling. Machines. 2025; 13(5):372. https://doi.org/10.3390/machines13050372

Chicago/Turabian StylePiankitrungreang, Pimolkan, Kantawatchr Chaiprabha, Worathris Chungsangsatiporn, Chanat Ratanasumawong, Peemdej Chancharoen, and Ratchatin Chancharoen. 2025. "Acoustic-Based Machine Main State Monitoring for High-Speed CNC Drilling" Machines 13, no. 5: 372. https://doi.org/10.3390/machines13050372

APA StylePiankitrungreang, P., Chaiprabha, K., Chungsangsatiporn, W., Ratanasumawong, C., Chancharoen, P., & Chancharoen, R. (2025). Acoustic-Based Machine Main State Monitoring for High-Speed CNC Drilling. Machines, 13(5), 372. https://doi.org/10.3390/machines13050372