1. Introduction

Rolling bearings are essential components in rotating machinery often exposed to high-speed operations and localized stresses that may result in operational failures. Consequently, the regular monitoring of bearing health to prevent severe damage has garnered significant attention among researchers [

1]. However, practical operating environments are often compromised by intense background noise, attributable to equipment instability, environmental fluctuations, and electromagnetic disturbances [

2,

3]. These disturbances cause the collected data to deviate from actual values, masking meaningful fault characteristics and thereby increasing the complexity of bearing fault diagnosis (BFD) [

4]. Therefore, a key challenge in BFD is developing denoising and feature extraction techniques that can effectively extract transient fault pulses from noise-contaminated signals, ensuring accurate and reliable fault identification.

Over the years, significant efforts have been devoted to reducing noise interference and extracting meaningful fault features [

5,

6,

7]. Various signal denoising techniques have been explored, including empirical mode decomposition (EMD) [

8,

9], variational mode decomposition (VMD) [

10,

11], and wavelet transform (WT) [

12,

13]. While EMD decomposes signals into intrinsic mode functions (IMFs) for denoising but may suffer from mode mixing, where IMFs contain mixed frequencies, especially when noise overlaps with useful signals. VMD decomposes signals into sparsity-based modes but requires predefined mode numbers and is noise-sensitive. WT performs multiscale decomposition, removing high-frequency noise while preserving low- or mid-frequency signals, enabling effective denoising. Donoho et al. [

14] combined the soft thresholding technique with wavelet transform, effectively removing noise components with wavelet coefficients smaller than the threshold while preserving the main features of the signal. However, wavelet thresholding methods overlook signal sparsity. To enhance sparsity, Selesnick et al. [

15] proposed the overlapping group shrinkage (OGS) method, which achieves promising results for group-sparse signals. Wang et al. [

16] applied OGS in fractional spline wavelet domains for bearing fault signal extraction. Zhao et al. [

17] used OGS with shift-invariant wavelet transforms for electrocardiogram denoising. OGS has been successfully applied to bearing fault diagnosis due to the group-sparse nature of wavelet coefficients [

18,

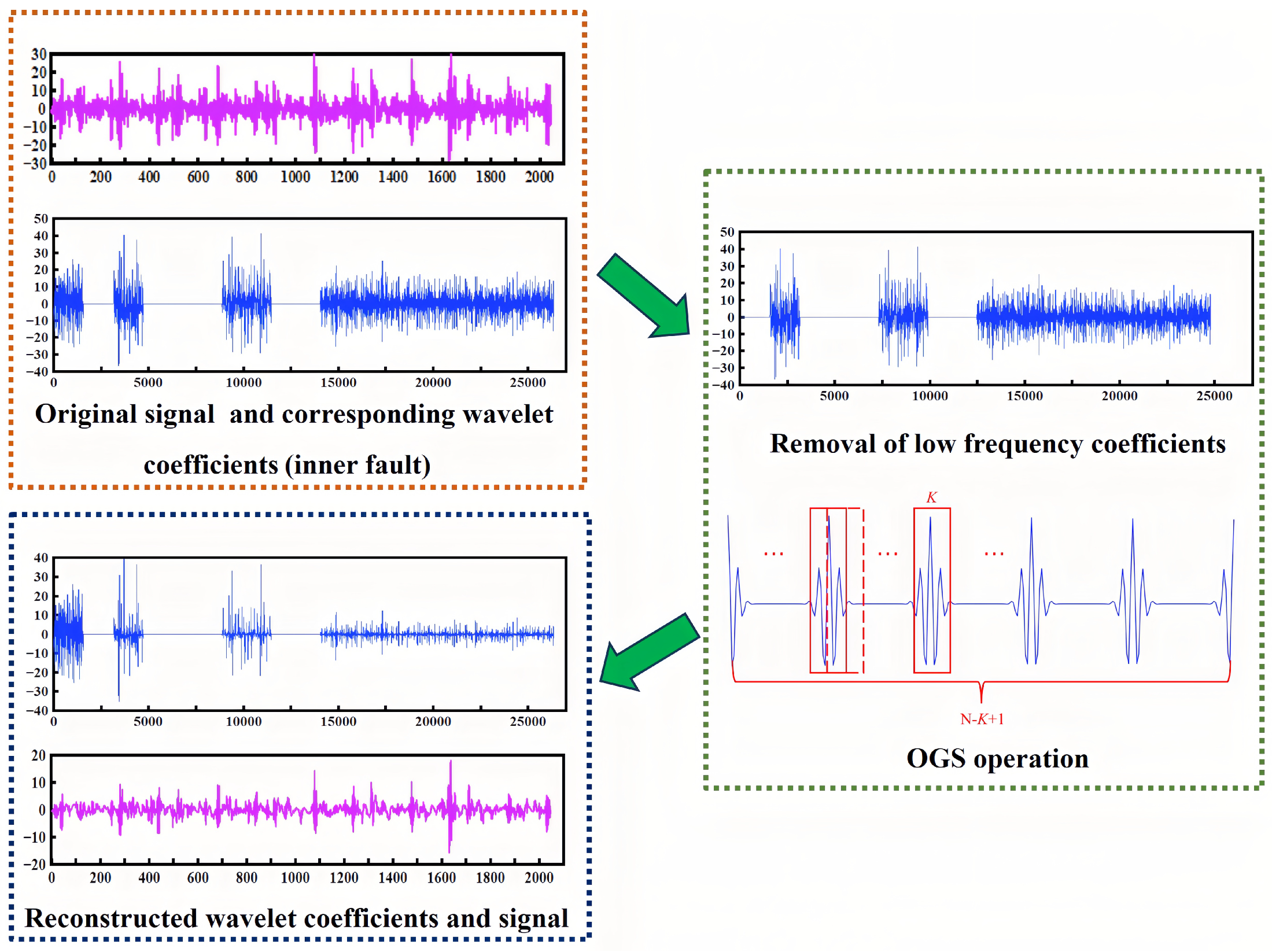

19]. The OGS relies on prior statistical models, such as Gaussian or Laplace distributions, and it requires detailed statistical analysis and parameter estimation for each wavelet coefficient. This dependence on statistical modeling introduces prior assumptions and computational complexity. To address these issues, this paper proposes a WOGS method, which is crucial for overcoming the challenge of strong background noise in fault diagnosis. WOGS directly adjusts the shrinkage parameters based on the

norms energy relationships at the group level without prior modeling assumptions, thus reducing computational complexity. It effectively preserves key high-frequency information related to periodic event extraction, improving denoising performance.

After denoising, feature extraction from bearing vibration signals is a key step in fault diagnosis [

20]. Periodic pulse information often serves as a crucial indicator of fault characteristics, and the ability to accurately extract these features directly determines the effectiveness of the final diagnosis. However, bearing vibration signals are complex, which makes it difficult to directly extract fault information. As a key parameter in mechanical dynamics, entropy features can characterize the modal periodicity and the orderliness, or disorderliness, of pulse sequences in faulty bearing vibration signals. Civera et al. [

21] proposed instantaneous spectral entropy (ISE) and continuous wavelet transform for anomaly detection and fault diagnosis, in which ISE is highlighted as being particularly sensitive to fault signals and potentially suitable for real-time monitoring. Zhuang et al. [

22] proposed a feature extraction method based on VMD and sample entropy (SE), where SE quantifies the probability of changes in the time series due to variations in data positions, effectively capturing the characteristics of fault signals. Compared to ISE, which struggles to characterize system nonlinearity, and SE, which is unstable for short sequences, PE is widely used in BFD due to its simplicity and sensitivity to regular impulses, effectively measuring randomness and capturing signal fluctuations [

23]. However, PE only analyzes single-scale time series and cannot assess fault information in complex signals. To address this, Bie et al. [

24] proposed multiscale permutation entropy (MPE) to extract periodic pulse features from bearing fault signals. However, MPE overlooks fault information in high-frequency components. Li et al. [

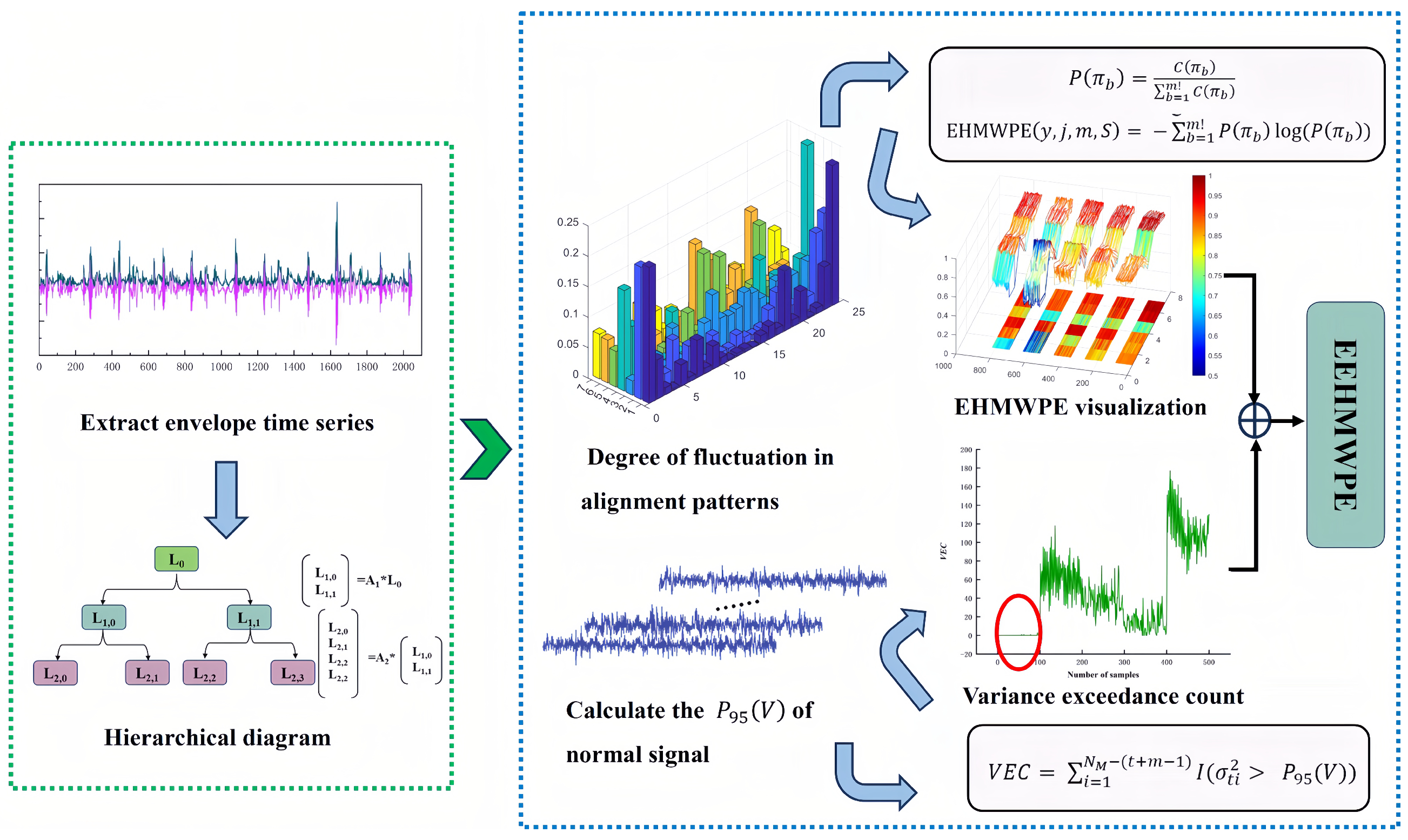

25] introduced hierarchical permutation entropy (HPE) to separate low- and high-frequency components, enhancing fault information extraction. However, HPE may lead to information loss. Yang et al. [

26] proposed hierarchical multiscale permutation entropy (HMPE), combining hierarchical and multiscale coarse-graining strategies. Wan et al. [

27] used multiscale-weighted permutation entropy (MWPE) to represent periodic pulses in wind turbine bearings and local linear embedding for degradation analysis. However, HMPE and MWPE do not fully consider class separability, which may impact feature discrimination and diagnostic accuracy. Additionally, envelope signals, rich in pulse information, enhance fault feature changes and improve fault recognition reliability [

28]. This paper proposes an EEHMWPE feature vector, combining enveloped hierarchical multiscale-weighted permutation entropy (EHMWPE) with extended statistical features. The EEHMWPE based on envelope signals considers the probability of the same pattern with different state vector amplitudes in coarse-grained time series, which improves upon HMPE’s limitations. Extended statistical features enhance EHMWPE’s robustness and class separability. Finally, a BFD strategy based on WOGS and EEHMWPE was applied to rolling bearing experimental datasets.

The innovative contributions of this article are as follows:

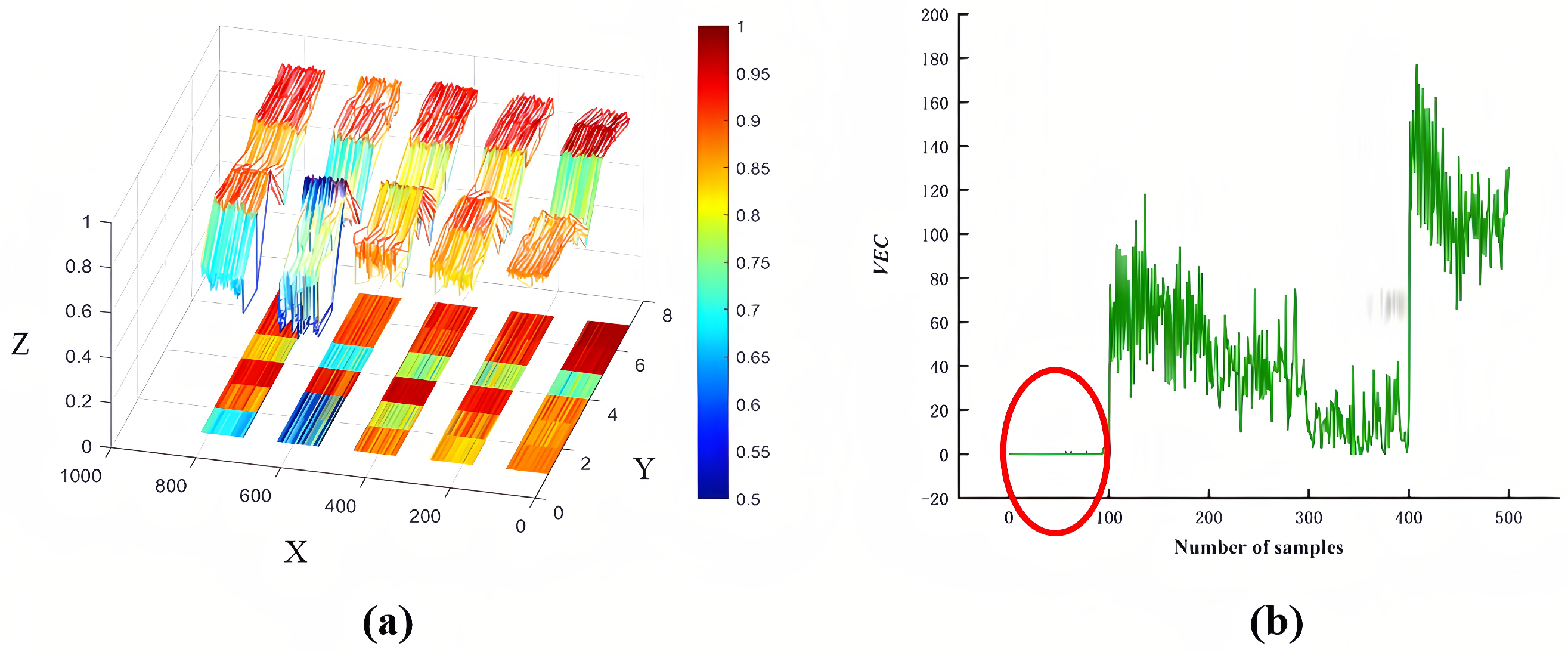

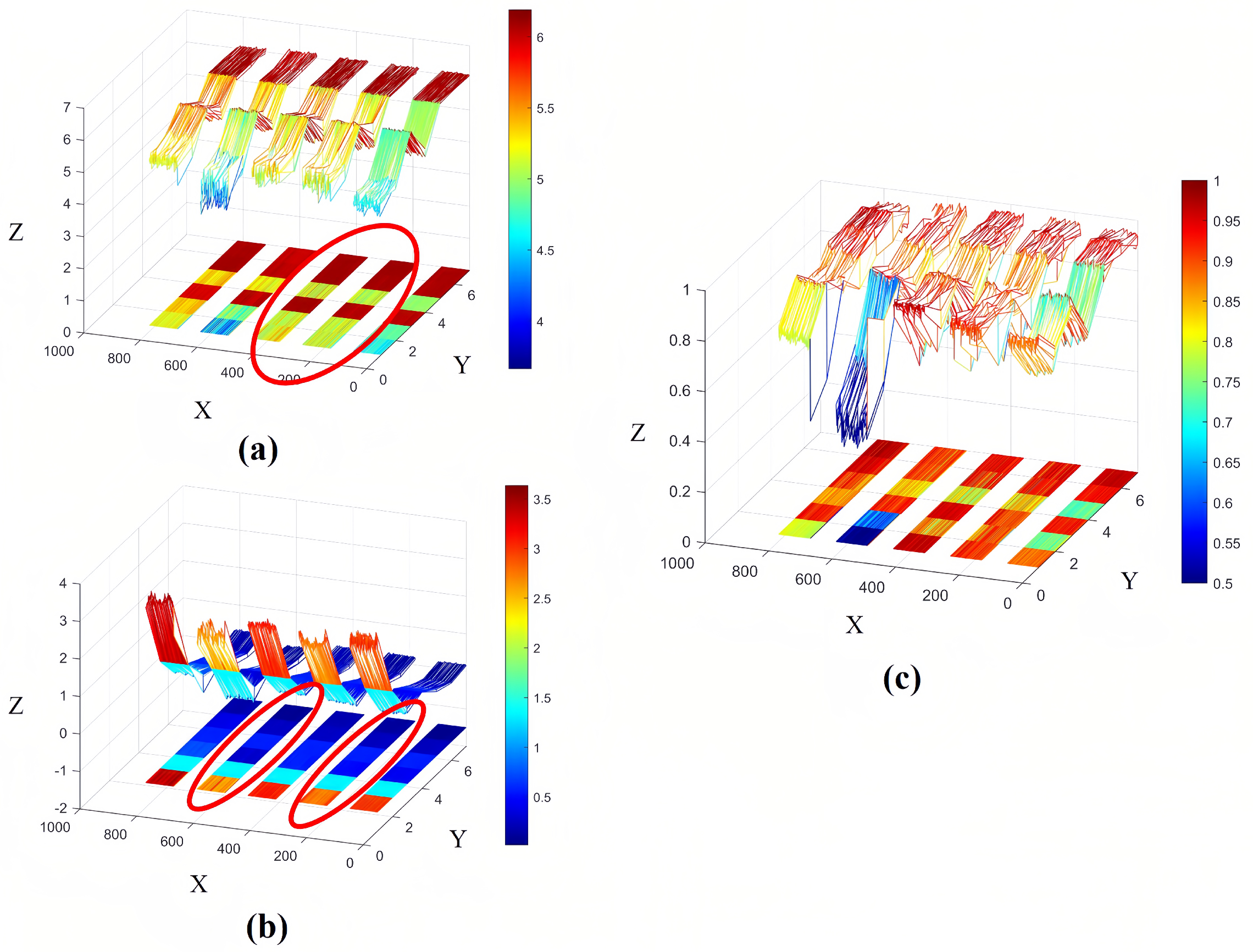

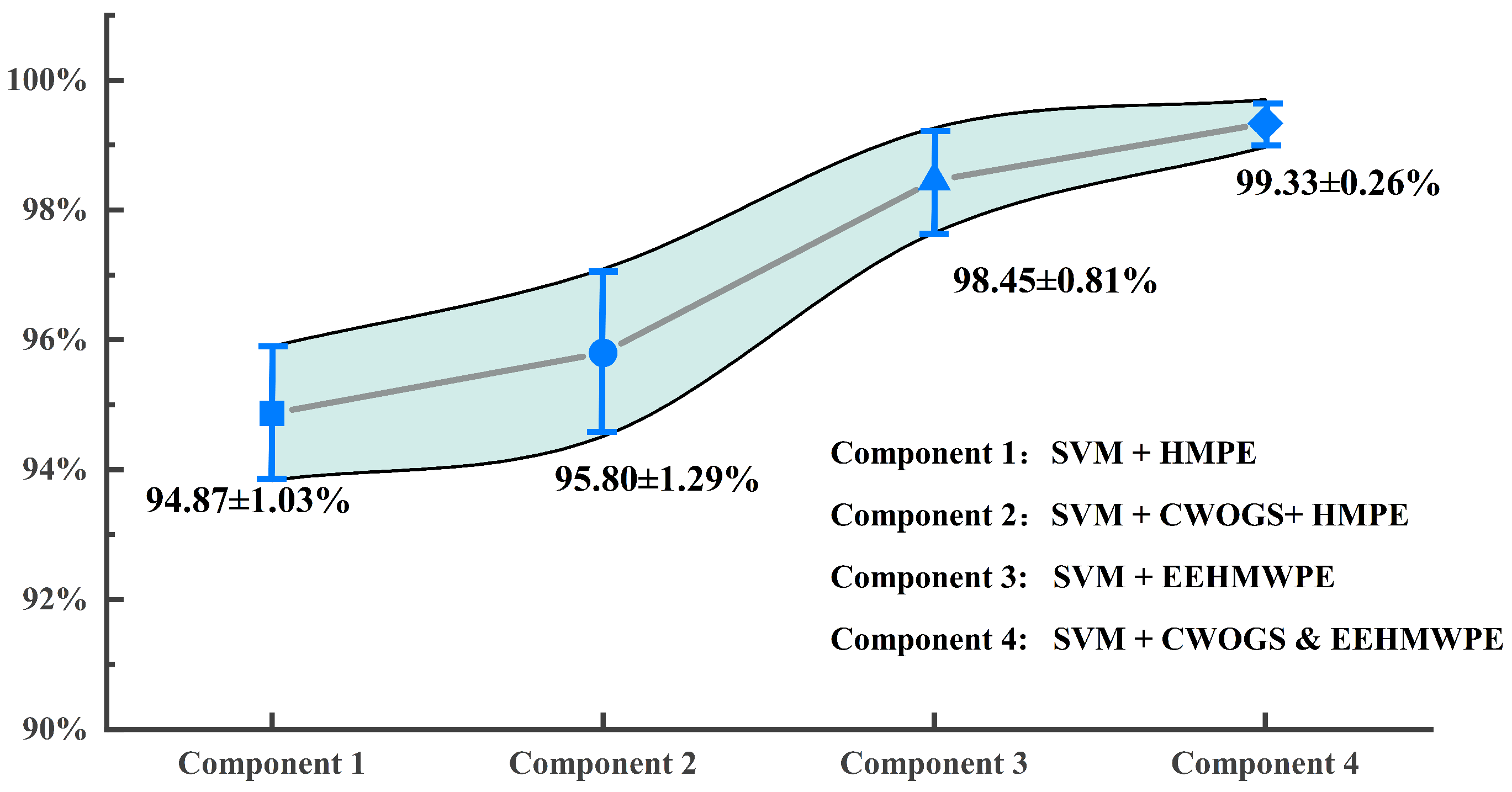

(1) A novel and efficient denoising method, WOGS, is proposed that adaptively adjusts the shrinkage level based on the energy relationships within wavelet coefficient groups. It retains normal signal information while enhancing the periodic pulse information from fault signals.

(2) A feature vector EEHMWPE was constructed to quantify the complexity of time series, effectively enhancing the inter-class distance between normal and faulty signals by integrating envelope information, weighting, and extended statistical features. It provides more discriminative features for classification models.

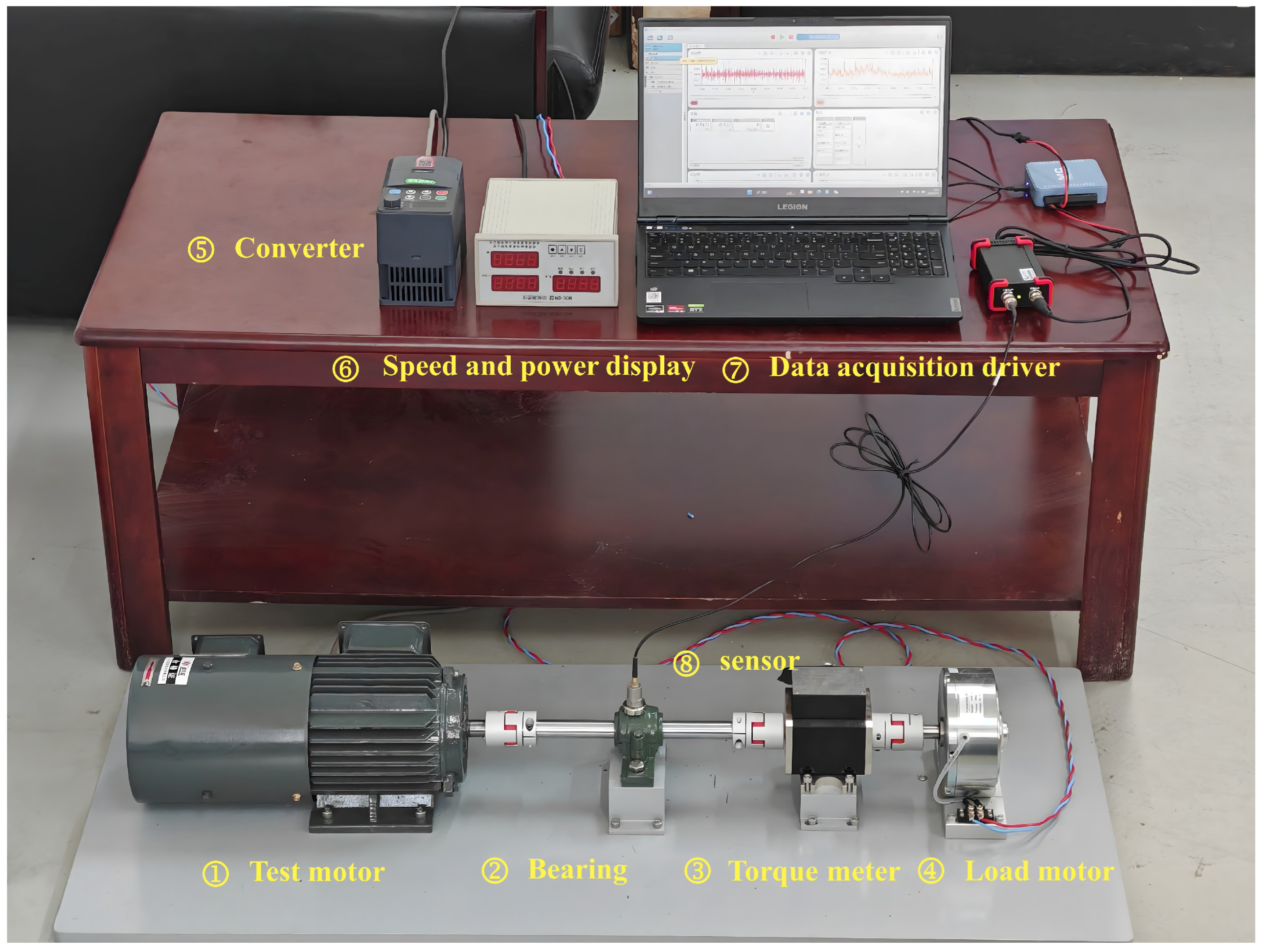

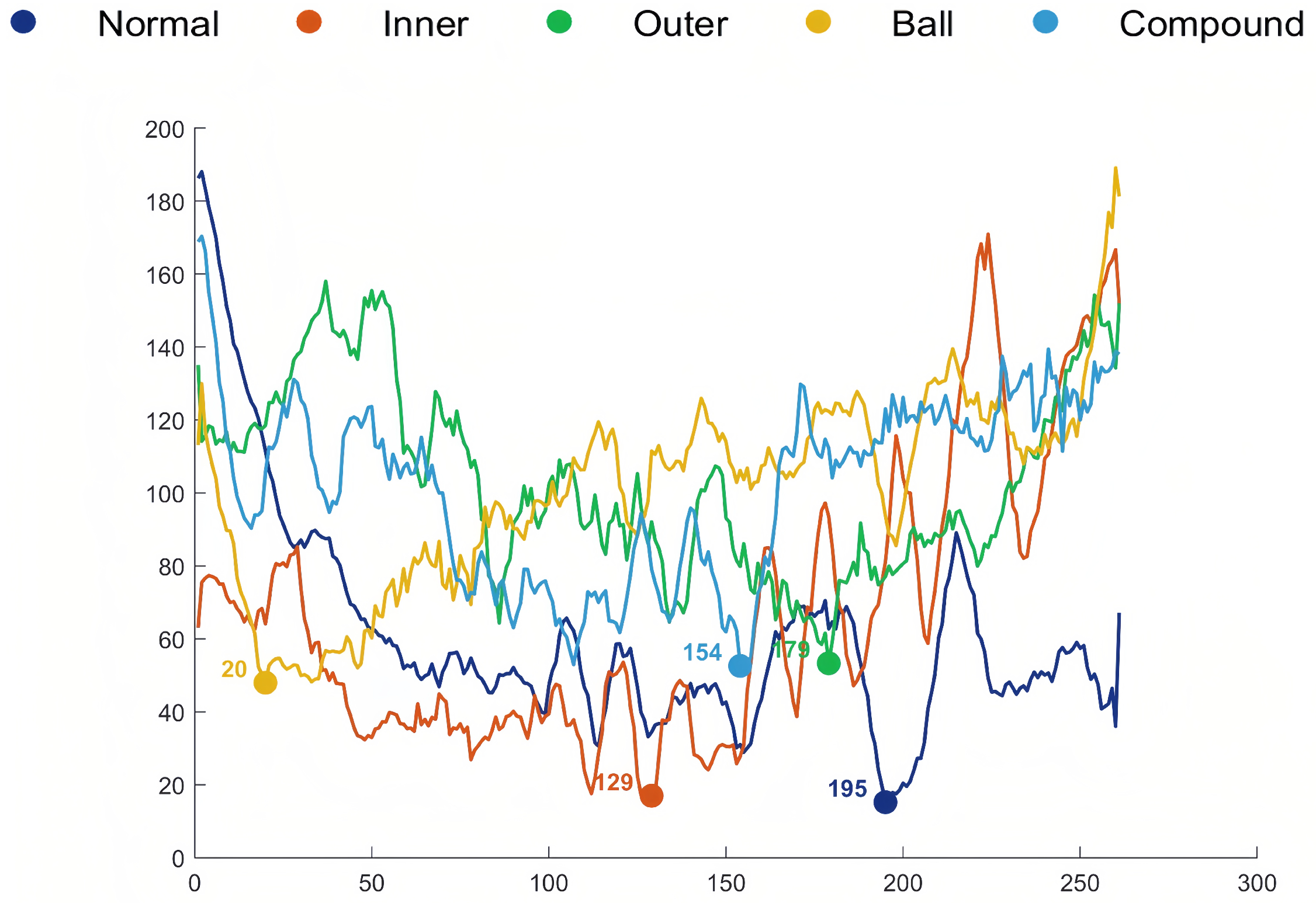

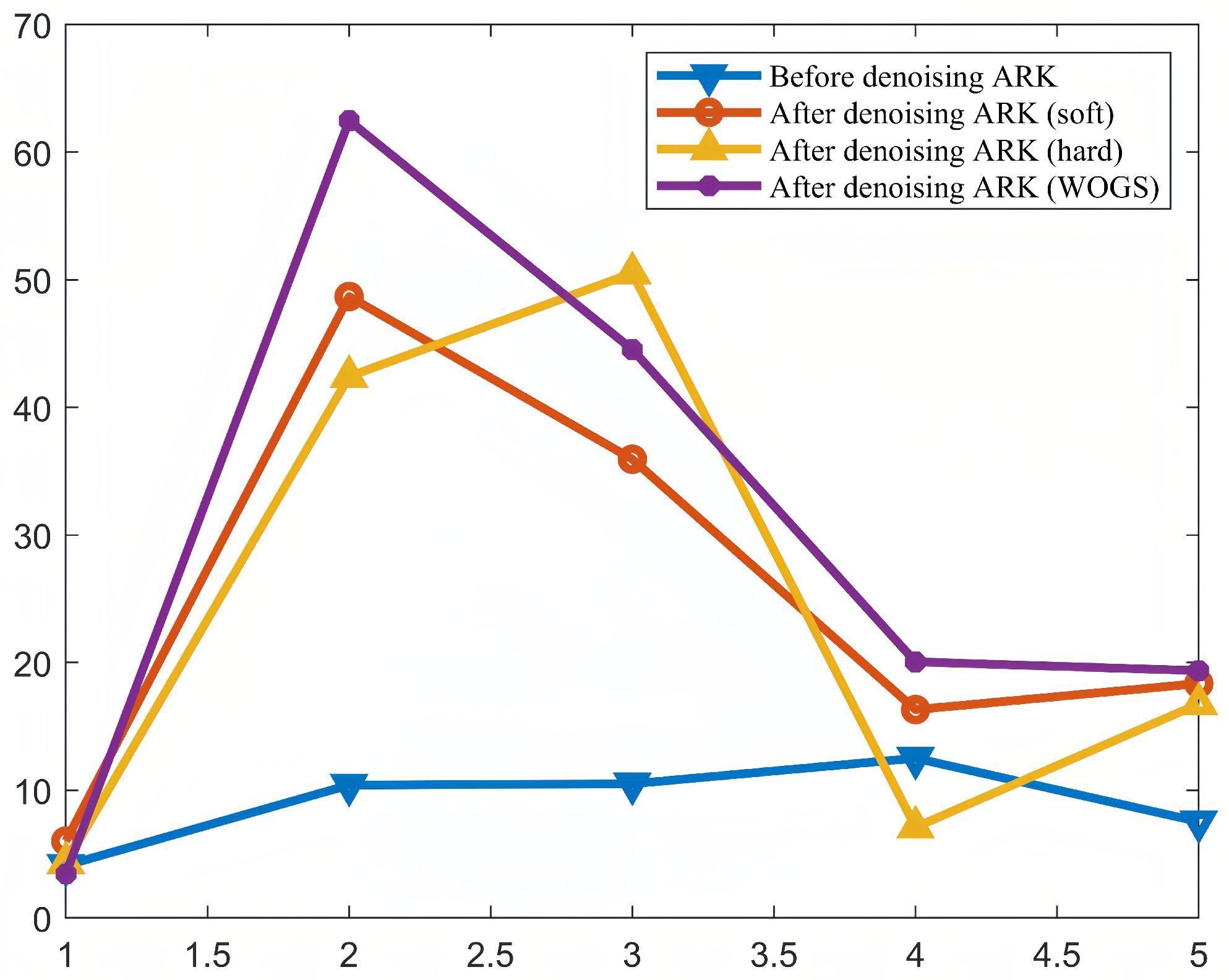

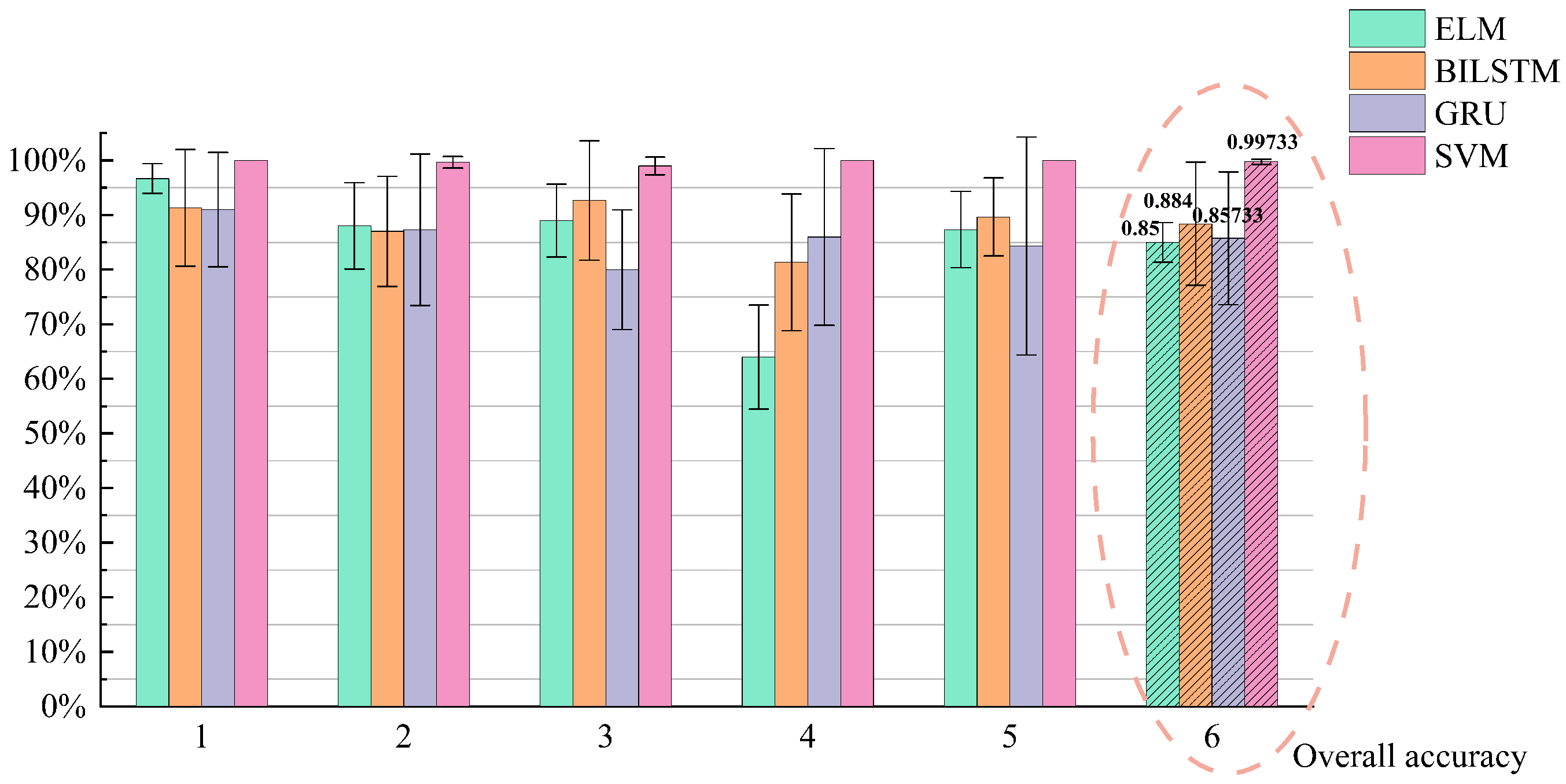

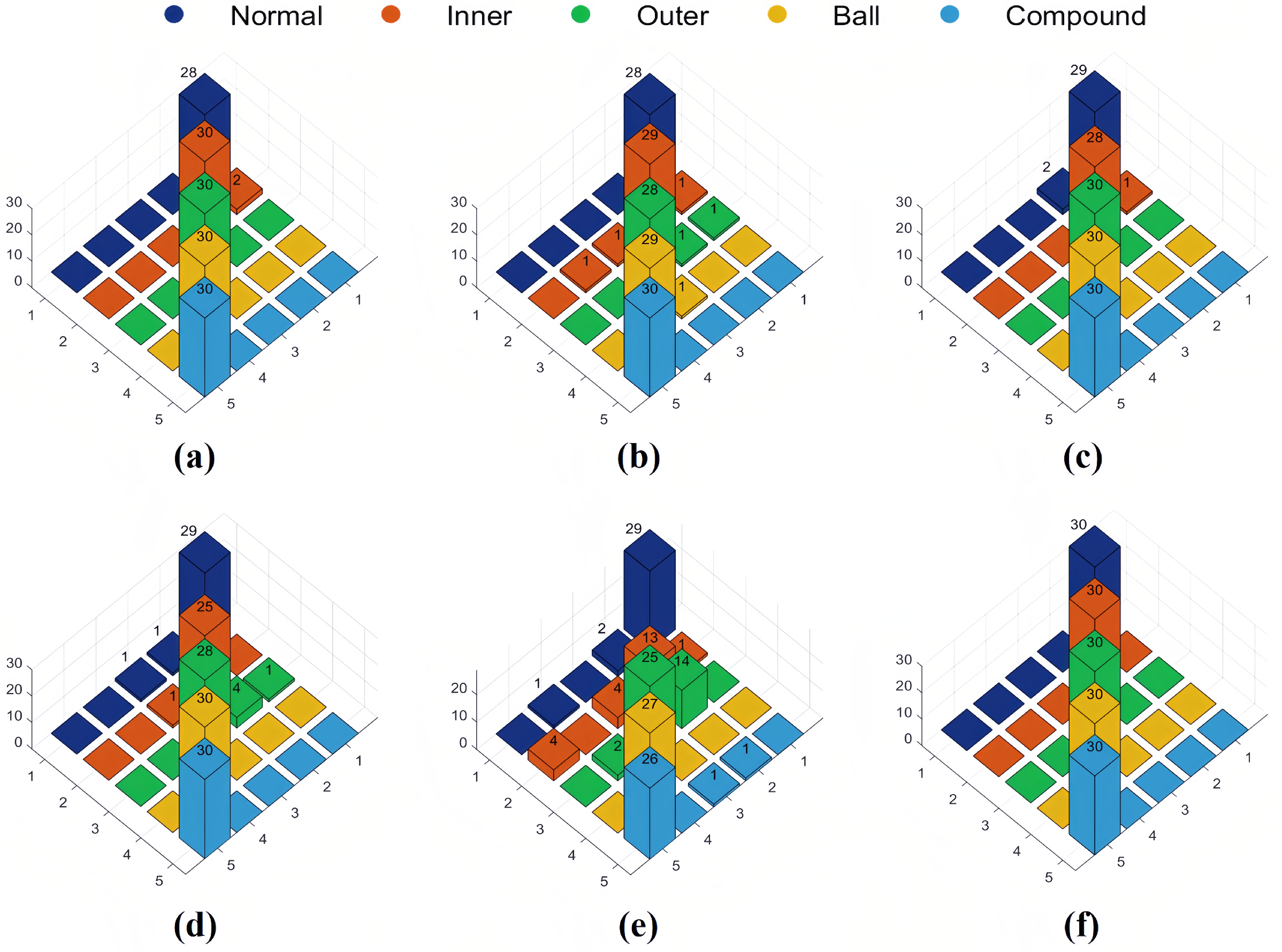

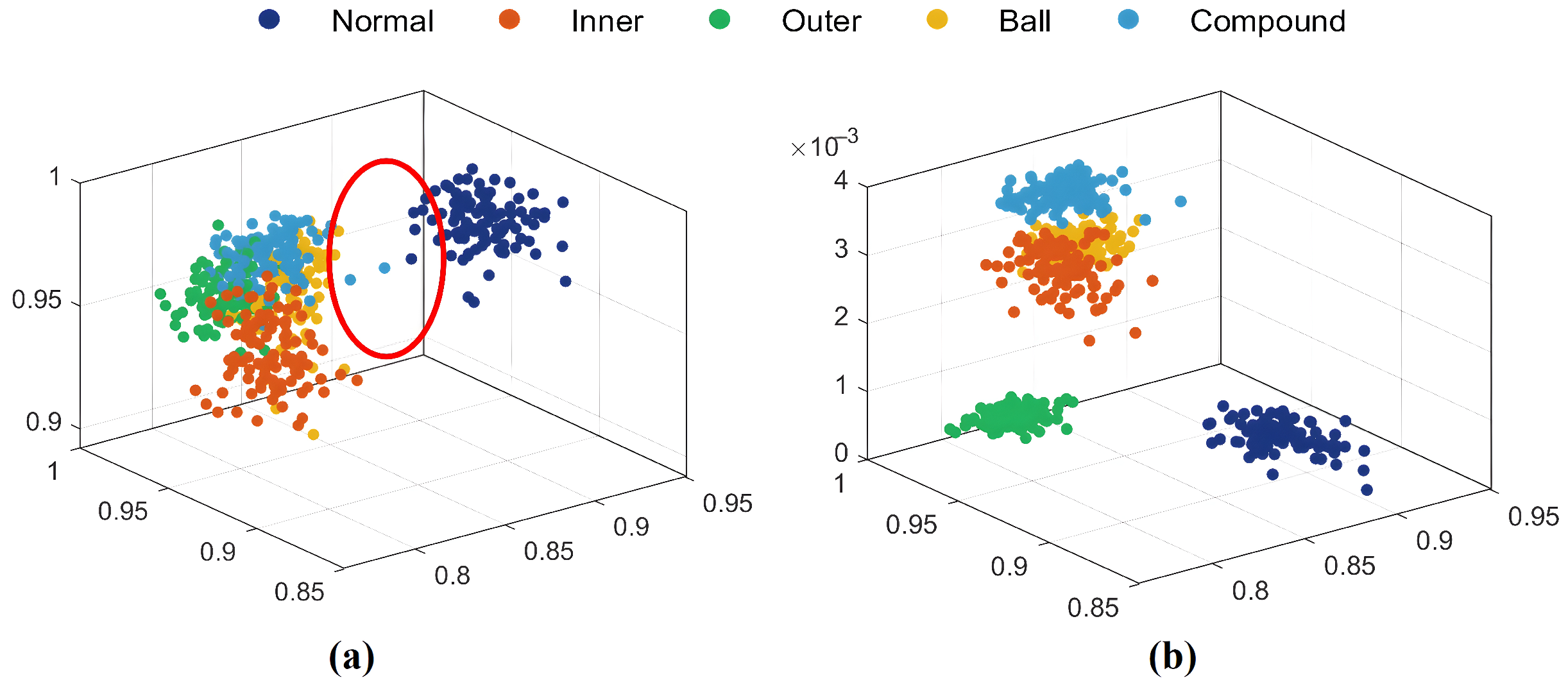

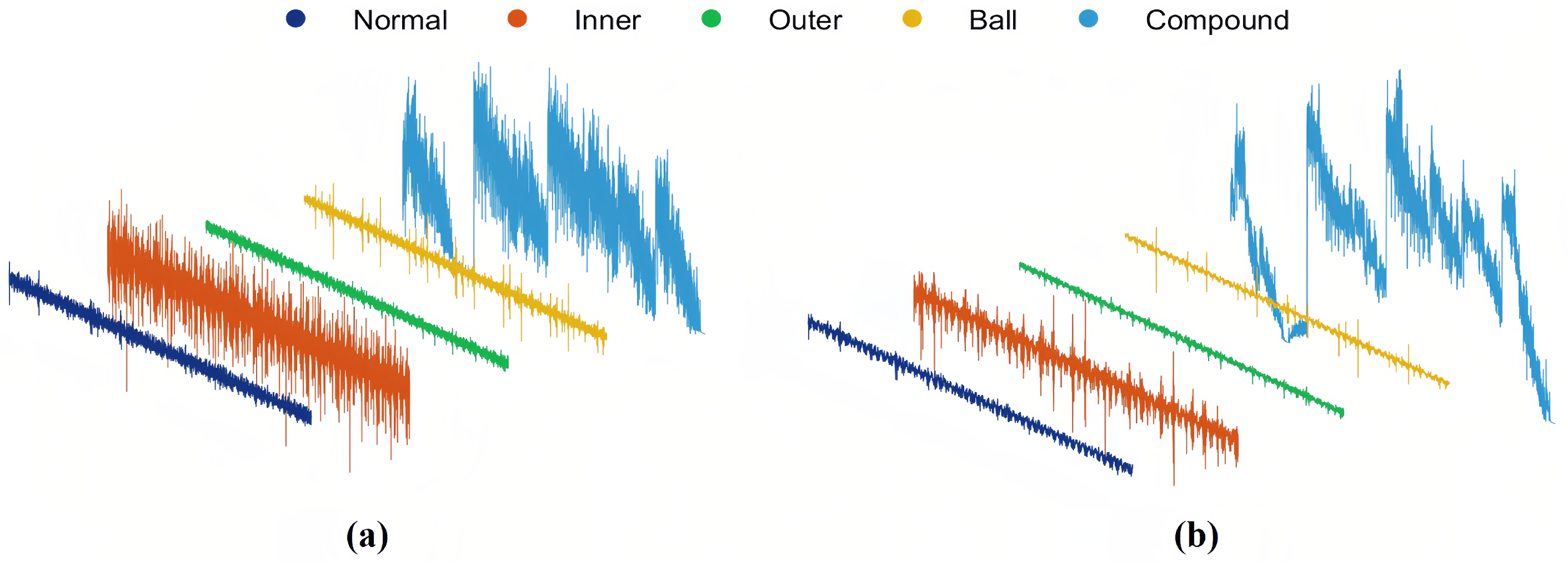

(3) The WOGS-EEHMWPE strategy’s advantages in feature extraction were validated using datasets from a bearing test rig and the CWRU dataset. Classification results with a standard classifier showed that the WOGS-denoised signals significantly enhance EEHMWPE’s feature extraction performance, with WOGS-EEHMWPE achieving the highest fault feature extraction capability.

The remainder of this article is organized as follows:

Section 2 introduces the theoretical background of wavelet overlap shrinkage denoising and extended envelope layered multi-scale weighted permutation entropy.

Section 3 provides a detailed introduction to the proposed WOGS denoising method and the EEHMWPE feature vector.

Section 4 demonstrates the effectiveness of the proposed strategy through experiments.

Section 5 further verified the performance of this strategy on the CWRU dataset and the HSUT dataset. Finally,

Section 6 concludes the paper and discusses future directions.