Abstract

Functionally graded materials (FGMs) are a class of advanced materials characterized by spatially varying properties, offering significant advantages in aerospace, automotive, and biomedical industries. The integration of additive manufacturing (AM) has revolutionized the fabrication of FGMs, enabling precise control over material gradients and complex geometries. This review presents a comprehensive bibliometric and content analysis of 3D-printed FGMs, focusing on materials, processing techniques, mechanical properties, and application trends. The findings highlight the growing research interest in FGMs since 2016, with a peak in 2021, and the dominant contributions from the USA and China. Key research trends include advancements in selective laser melting and direct energy deposition techniques, which have enhanced mechanical performance by improving wear resistance, tensile strength, and elasticity. Despite these advancements, challenges such as residual stresses, interfacial bonding weaknesses, and material anisotropy persist. Future research should focus on optimizing AM processes to enhance material homogeneity, developing eco-friendly materials to align with sustainability goals, and establishing standardized testing methods for FGMs to ensure their reliability in industrial applications.

1. Introduction

A functionally graded material (FGM) is a type of material in which the composition and/or structure varies gradually throughout its volume, leading to corresponding changes in its properties [1,2,3]. The concept of FGMs was first introduced by researchers in Japan in 1984 [1]. FGMs represent a remarkable advancement in material science, offering the ability to seamlessly transition properties across their structure. This unique characteristic enables FGMs to address specific challenges in high-performance applications, including manufacturing (cutting tools) [4,5], aerospace [6,7,8,9], biomedical [10,11,12,13,14,15,16], automobile [17,18,19,20,21,22], and energy sectors [23].

Research and development into FGMs has significantly advanced, with a focus on innovative strategies. These strategies include combining different materials such as polymers, composites, ceramics, and metals, either separately or in various combinations [24].

FGMs exhibit spatially varying properties, which are tailored for specific applications by adjusting their composition and microstructure. The properties of FGMs are heavily influenced by the material composition and structure, as gradients in composition affect mechanical, thermal, and electrical performance. Variations in grain size, phase distribution, and porosity can significantly alter the material’s strength and thermal conductivity [25].

The processing techniques employed in the fabrication of FGMs also play a critical role in determining the uniformity and properties of the final material. Methods such as additive manufacturing or powder metallurgy, for example, can introduce defects like porosity or uneven phase distribution if not carefully controlled. These defects can negatively impact the material’s mechanical performance, including its strength and fatigue resistance. Proper optimization of processing parameters is thus essential to achieve a consistent gradient of properties across the material [26].

Furthermore, external factors like temperature and loading conditions have a profound effect on the behavior of FGMs. The mechanical properties, including tensile strength and hardness, can vary depending on the environmental conditions in which the material operates. The study [27] showed that in certain FGMs, such as Ni-Al alloys, the mechanical properties like Young’s Modulus, plasticity, and yield strength change significantly with temperature, highlighting the need to consider operational conditions when designing FGMs. Also, the analysis of FGM structures requires the implementation of sophisticated mechanical behavior simulation tools, and the interaction between design and manufacturing and the risks associated with cracks play an important role in understanding the mechanical behavior of crack structures [28].

Recent research has demonstrated that FGMs exhibit complex responses to thermal and hygrothermal environments, necessitating advanced modeling techniques for accurate analysis. Tian et al. [29] investigated the thermal behavior of functionally graded plates with variable gradients under linear heat sources, highlighting the need for hybrid numerical methods to predict temperature distributions effectively. Han et al. [30] further examined heat conduction and cracking in FGMs using an FDEM-based thermo-mechanical coupling model, revealing that thermal stress gradients significantly influence material integrity. In the context of dynamic behavior, Inala [31] analyzed the influence of hygrothermal conditions on the natural frequency and stability of FG plates, demonstrating that moisture absorption and temperature fluctuations alter vibrational characteristics. Additionally, Zenkour [32] explored the hygro-thermo-mechanical response of FG plates resting on elastic foundations, concluding that both temperature and humidity affect stiffness and load-bearing capacity. Similarly, Shariyat and Ghafourinam [33] studied the creep and stress redistribution in thick-walled FGM spheres with temperature- and moisture-dependent material properties, emphasizing the role of inelastic deformations under prolonged environmental exposure. Lastly, Pal et al. [34] investigated the dynamic response of FG plates under hygrothermal loading, reinforcing the critical need to account for these environmental factors in practical applications. Collectively, these studies underscore the necessity of incorporating hygrothermal effects, porosity considerations, and thermal moments into the boundary conditions when analyzing FG structures for high-temperature and humid environments.

The integration of nanomaterials into FGMs has led to significant advancements in mechanical, thermal, and functional properties, enabling their use in various high-performance applications [35]. Recent studies have explored different nanostructures, such as nanoparticles and graphene, as reinforcement phases within FGMs, demonstrating their effectiveness in enhancing material properties.

Kwon et al. [36] investigated dual-nanoparticulate-reinforced aluminum matrix composites, highlighting the potential of combining two distinct nanoparticles to achieve superior strength and thermal stability. Expanding on this work, Kwon et al. [37] further explored the fabrication of functionally graded aluminum matrix composites using spark plasma sintering. In the context of graphene-reinforced FGMs, Gantayat et al. [38] conducted a finite element analysis on functionally graded beams reinforced with graphene, showing improved dynamic characteristics and structural integrity. Additionally.

Selecting the appropriate manufacturing method for FGM is very important, considering both economic factors and environmental concerns. Traditional manufacturing methods, such as vapor deposition [39,40,41,42], thermal spraying [43,44,45,46], powder metallurgy [47,48,49,50,51], spark plasma sintering [52,53,54,55], and centrifugal casting [56,57,58,59,60] are widely used. However, these methods come with several drawbacks, including limitations in the complexity and size of the parts they can produce, density restrictions, high energy consumption, and negative environmental impacts such as excessive resource consumption and pollutant emissions, which restrict their efficiency and scalability [61].

On the other hand, additive manufacturing (AM) presents a revolutionary alternative. Unlike conventional techniques, AM allows for the production of intricate geometries in a single step, with a high degree of precision and minimal design constraints [62]. Additionally, AM eliminates the need for multi-part assemblies by producing complex, integrated components, which reduces both production time and cost. Furthermore, the ability to manufacture parts on demand not only cuts down on storage and transportation needs but also contributes to a longer service life and sustainability of the components [25,63]. Given these advantages, AM holds significant promise for the future of gradient material fabrication. According to [24,25,64,65], the synergy between FGMs and AM has unlocked unprecedented possibilities in tailoring material functionality.

Various additive manufacturing processes have been explored for fabricating FGMs. For polymer materials, processes such as fused deposition modeling (FDM) [66,67,68] and selective laser sintering (SLS) [69,70] are commonly used, while metal materials are typically produced using laser-engineered net shaping (LENS) [71,72,73], selective laser melting (SLM) [74,75,76,77], and electron beam melting (EBM) [78,79,80].

The gradation in FGM plays an essential role in minimizing residual stresses, which in turn improves their mechanical and physical properties [64,81,82,83].

The environmental implications of FGM production are increasingly being scrutinized, particularly considering global sustainability goals. Additive manufacturing processes inherently minimize material waste by adopting a layer-by-layer approach, which contrasts starkly with the inefficiencies of subtractive methods [84]. Additionally, FGMs reduce the need for energy-intensive joining and assembly processes by integrating multiple functions within a single material [25]. However, challenges such as the recyclability of FGMs and the carbon footprint associated with raw material extraction persist [85]. The development of eco-friendly feedstock materials and energy-efficient fabrication processes is critical for advancing FGMs within a sustainable framework [25,86].

Several review articles have explored FGMs, discussing their fabrication methods, properties, and applications. However, most of these reviews primarily focus on conventional processing techniques such as powder metallurgy, centrifugal casting, and thermal spraying. In contrast, this review specifically examines FGMs manufactured through additive manufacturing techniques, offering a comprehensive overview of the field. It begins by discussing strategies employed for processing and constructing FGMs, emphasizing both conventional methods and advanced approaches, particularly additive manufacturing processes. Techniques for evaluating the properties and performance of FGMs, and ensuring their alignment with application-specific requirements, are also examined.

The review further explores a wide range of application sectors where FGMs are utilized. A bibliometric analysis is conducted to track the evolution of research over the years, highlighting key milestones, publication trends, and the most prolific contributors to the field. Additionally, keyword analysis sheds light on the primary research themes, emerging topics, and evolving priorities in the development of FGMs.

This bibliometric perspective, combined with the content analysis, offers a comprehensive understanding of FGMs developed using additive manufacturing techniques, providing valuable insights for advancing research and practical applications.

2. Overview of FGM

2.1. FGM Classification

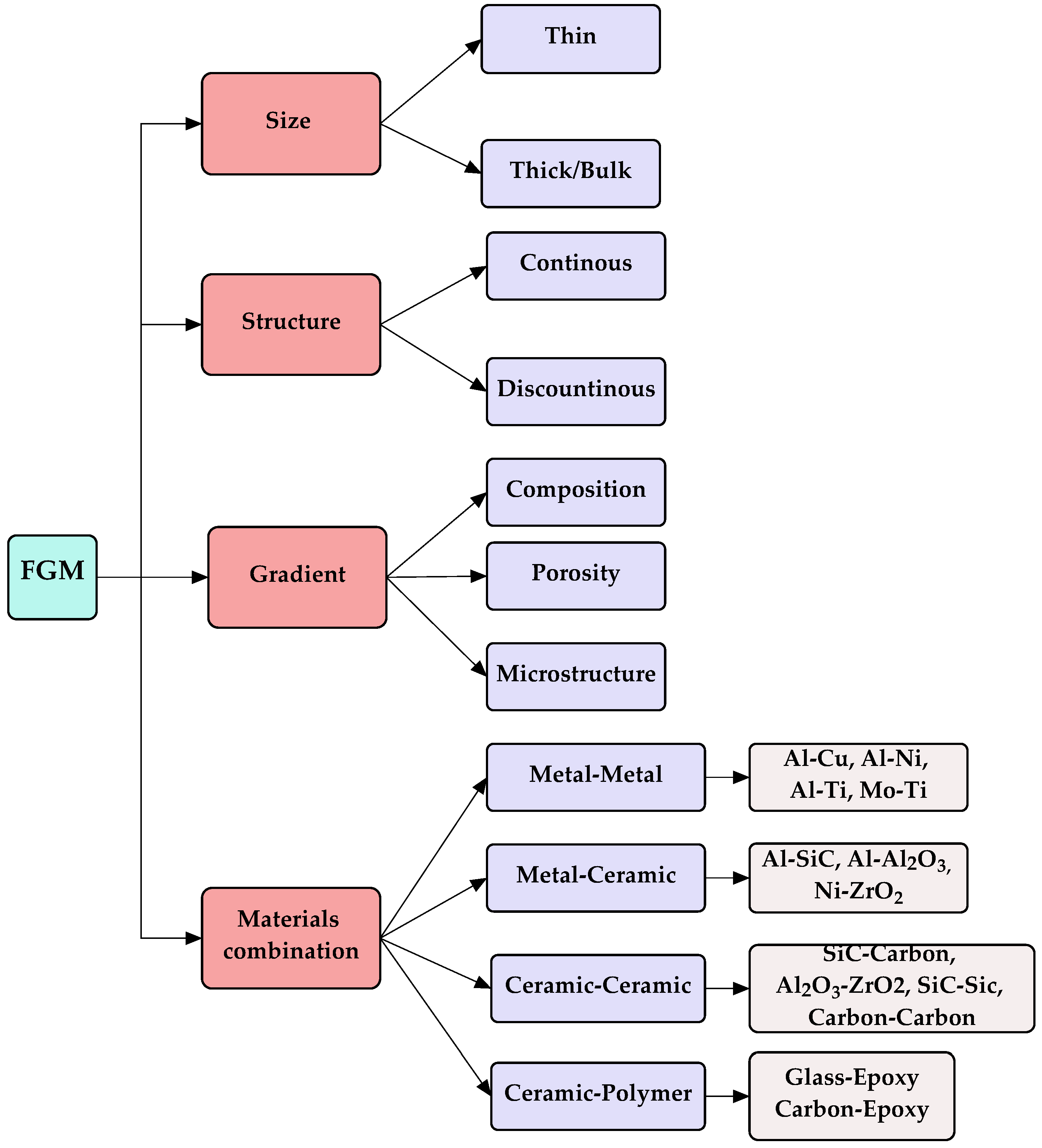

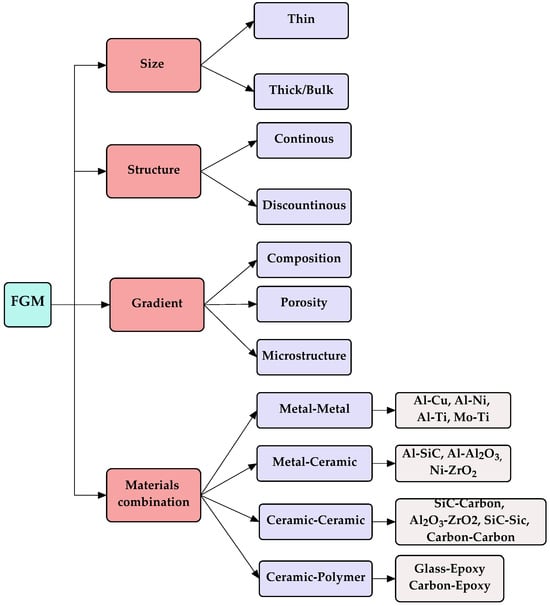

FGMs can be classified based on various characteristics, including size, structure, gradient type, and material combinations, as seen in Figure 1 and Figure 2.

Figure 1.

FGMs classification.

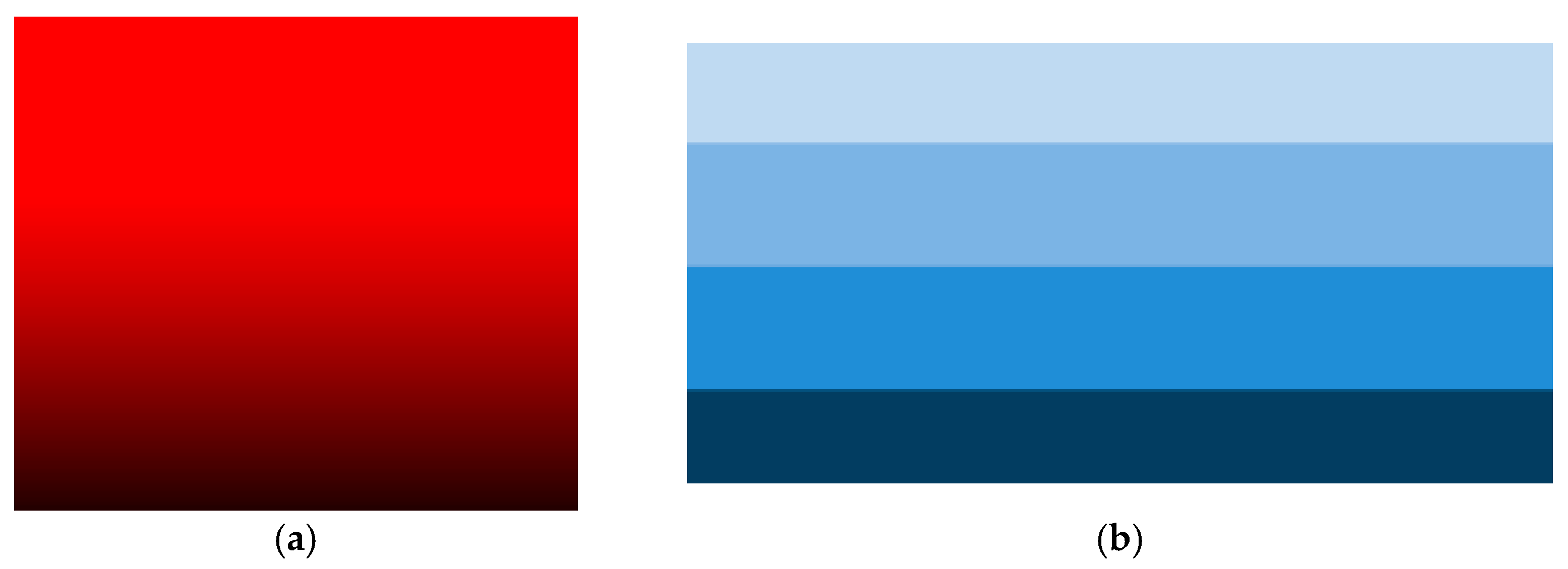

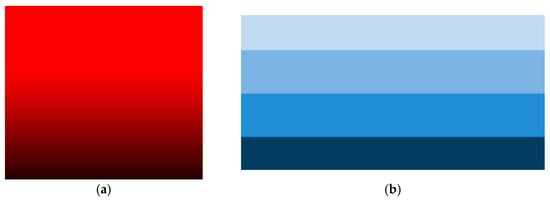

Figure 2.

FGMs structure types: (a) continuous FGM; (b) stepwise FGM.

Firstly, FGMs can be categorized by size, which refers to their physical dimensions. They may be produced as thin films or coatings for applications requiring surface-specific properties, such as wear resistance or thermal protection. Alternatively, FGMs can be fabricated as thick or bulk materials, suitable for load-bearing applications or thermal barriers [87].

Secondly, the structure of FGMs plays a critical role in their performance. FGMs with a continuous structure have a seamless transition of properties across the gradient, ensuring uniform behavior. In contrast, discontinuous structures feature distinct layers or regions with abrupt changes in material properties, making them useful for applications where sharp property changes are necessary [26].

Another important classification factor is the type of gradient present in the material [1]. FGMs can exhibit gradients in composition, where the material constituents vary across the structure. Alternatively, a gradient in porosity is designed to control density and mechanical properties. Furthermore, FGMs may have a microstructural gradient, with variations in grain size, phase distribution, or crystal orientation, enabling unique mechanical or thermal behavior.

Lastly, FGMs are classified based on their material combination, which determines their functional properties. Metal-metal FGMs, such as Al-Cu, Al-Ni, Al-Ti, and Mo-Ti, are primarily used for high-temperature or structural applications [88]. Metal-ceramic FGMs, including Al-SiC, Al-Al2O3, and Ni-ZrO2, offer a combination of strength and thermal resistance. For applications requiring high wear resistance or thermal stability, ceramic-ceramic FGMs, such as SiC-carbon, Al2O3-ZrO2, and SiC-SiC, are ideal. The performed studies showed that a high ceramic volume fraction improves hardness and wear resistance, but too many reinforcing particles can reduce tensile properties and cause premature failure due to coarse dendritic phases and unmelted particles [61].

Finally, ceramic-polymer FGMs, like glass-epoxy and carbon-epoxy, provide lightweight and flexible solutions for aerospace or biomedical applications [14].

2.2. Applications of FGMs Across Different Industries

FGMs have garnered significant attention across various industries due to their unique property gradients, which offer tailored solutions for specific engineering challenges. This section delves into the diverse applications of FGMs, highlighting specific case studies that demonstrate their practical implementations and benefits.

2.2.1. Aerospace Industry

In aerospace, FGMs are utilized to manage extreme thermal gradients and mechanical stresses. Some examples of aerospace applications of FGMs include engine parts, turbine blades, and thermal and acoustic insulations [7,8,9].

2.2.2. Biomedical Field

FGMs have found applications in the biomedical field [10,11,12,14,15,89], particularly in the development of implants and prosthetics. By mimicking the natural gradation found in bones and teeth, FGMs enhance compatibility and performance.

2.2.3. Automotive Sector

In the automotive industry, FGMs contribute to the development of components that can withstand high temperatures and mechanical loads. For example, engine components, combustion chambers, cylinder liners, panels, chassis, flywheels, shock absorbers, brake discs, pistons, and drive shafts benefit from the unique properties of FGMs, enhancing performance, durability, and overall efficiency [19,20,22,90].

2.2.4. Energy Sector

FGMs are employed in the energy sector for applications such as heat exchanger tubes and thermal barrier coatings. Their ability to manage thermal stresses and resist high temperatures makes them ideal for improving the efficiency and lifespan of energy conversion systems [91,92,93,94].

2.2.5. Defense Applications

The defense industry utilizes FGMs for their crack-inhibiting properties, making them suitable for penetration-resistant materials used in armor plates and bullet-proof vests [95,96,97,98,99,100,101]. The gradual transition in material properties helps in absorbing and dissipating impact energy effectively.

2.2.6. Manufacturing

In the manufacturing industry, FGMs are increasingly utilized to enhance the performance and longevity of various tools and components, such as cutting tools, grinding tools, molds, and dies [5,102,103]. These materials are particularly valuable in applications that require high wear resistance, thermal stability, and the ability to withstand mechanical stresses.

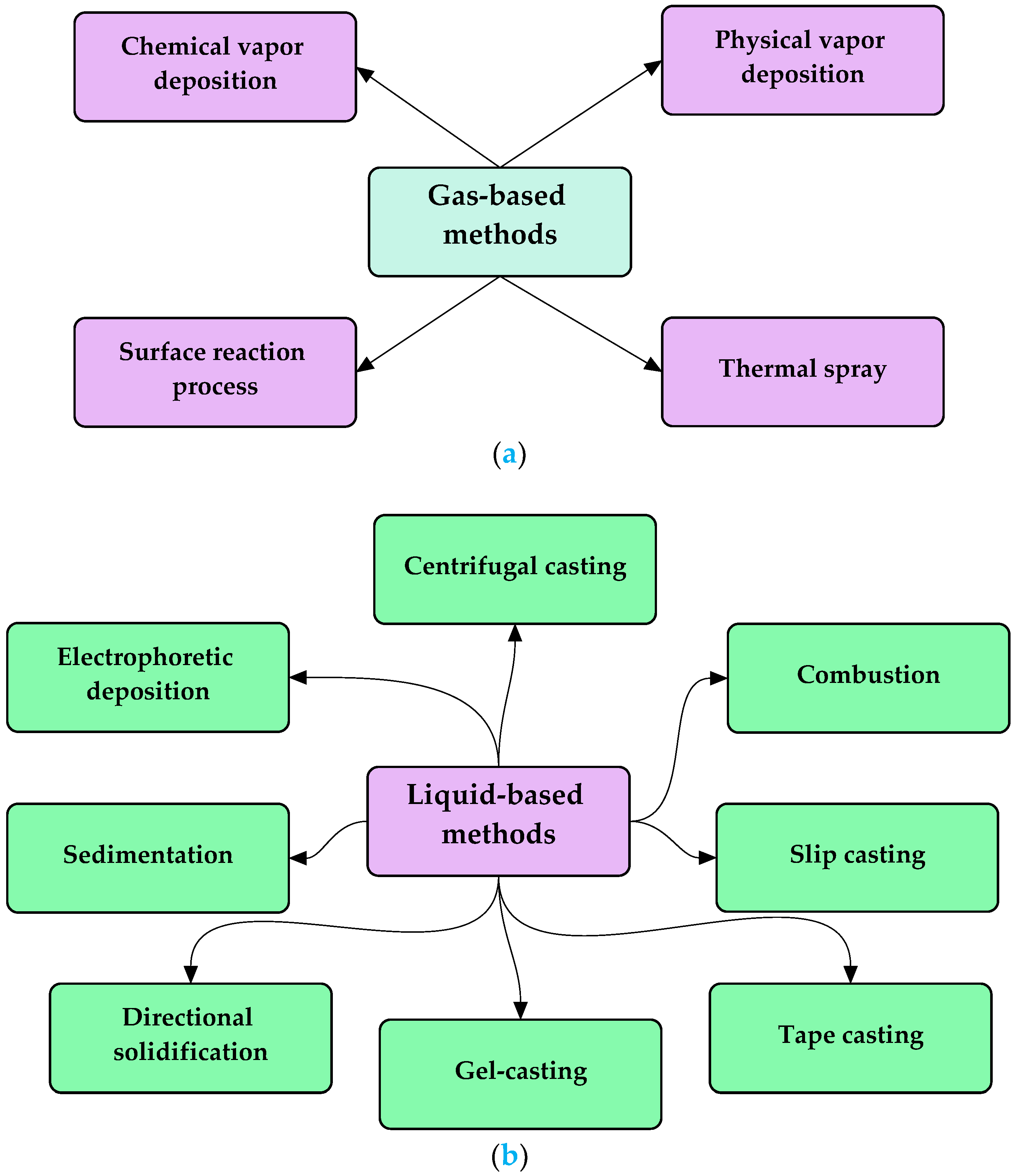

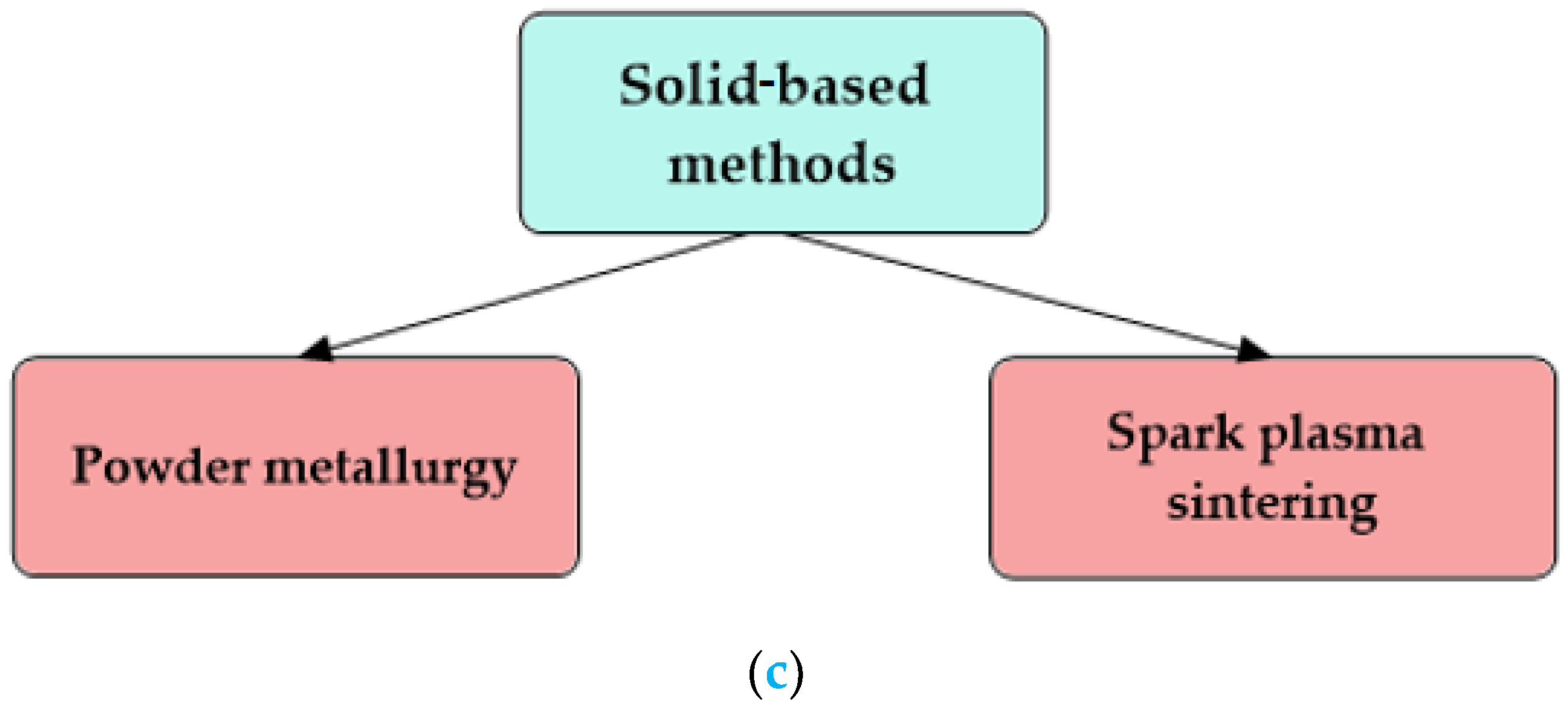

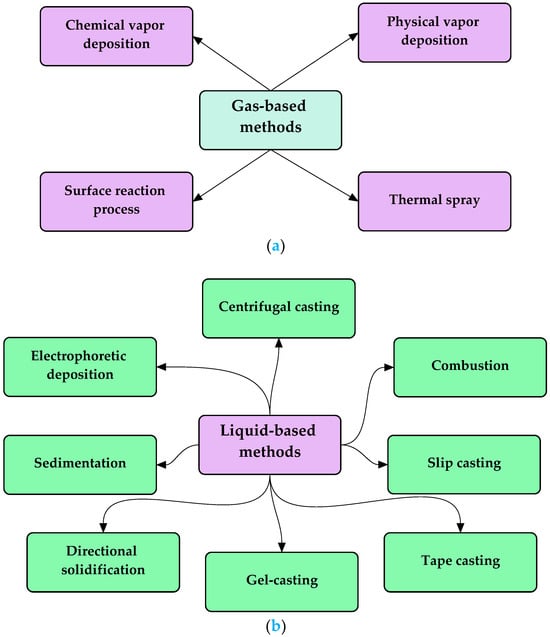

2.3. Conventional Manufacturing Methods of FGM

FGMs are produced using various fabrication techniques, which can be broadly classified into gas-based, liquid-based, and solid-based methods (see Figure 3). Each method offers unique advantages depending on the desired gradient structure and application, as shown in Table 1. On the other hand, there are limitations such as the growth patterns, the diverse types of materials that can be utilized due to ranked boundaries, structural considerations, constraint forces, and issues related to porosity [104].

Figure 3.

Main conventional fabrication methods of FGM: (a) gas-based; (b) liquid-based; and (c) solid-based.

Different conventional manufacturing methods contribute to varying types of gradients in FGMs. For instance, chemical vapor deposition (CVD) and thermal spray allow precise control over composition and microstructure. Centrifugal casting effectively generates composition gradients by leveraging material density differences, whereas combustion methods introduce porosity due to their rapid reaction kinetics. Solid-state techniques such as powder metallurgy and spark plasma sintering (SPS) enable microstructural refinement and controlled porosity through precise sintering mechanisms. These distinctions are further detailed in Table 1.

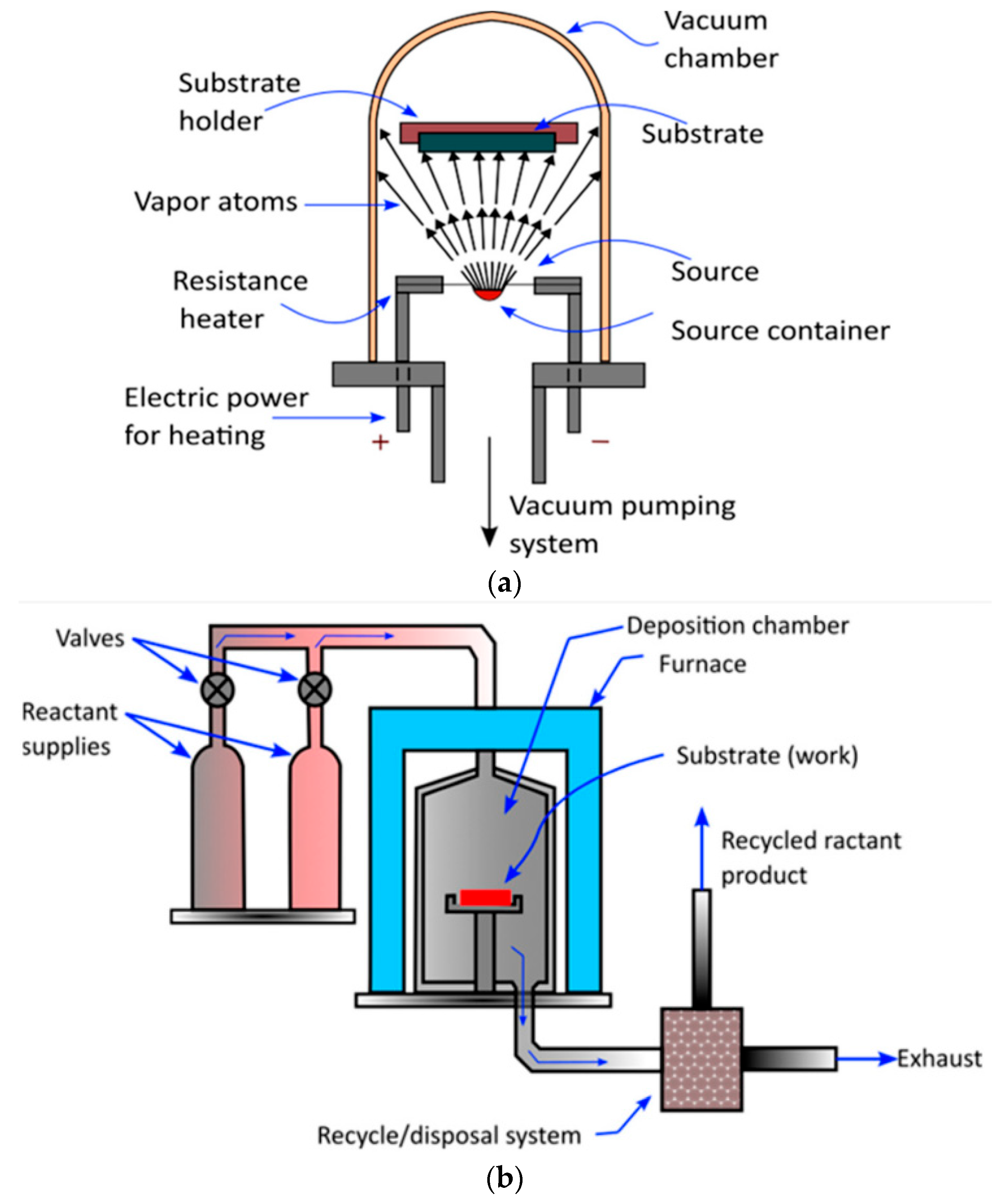

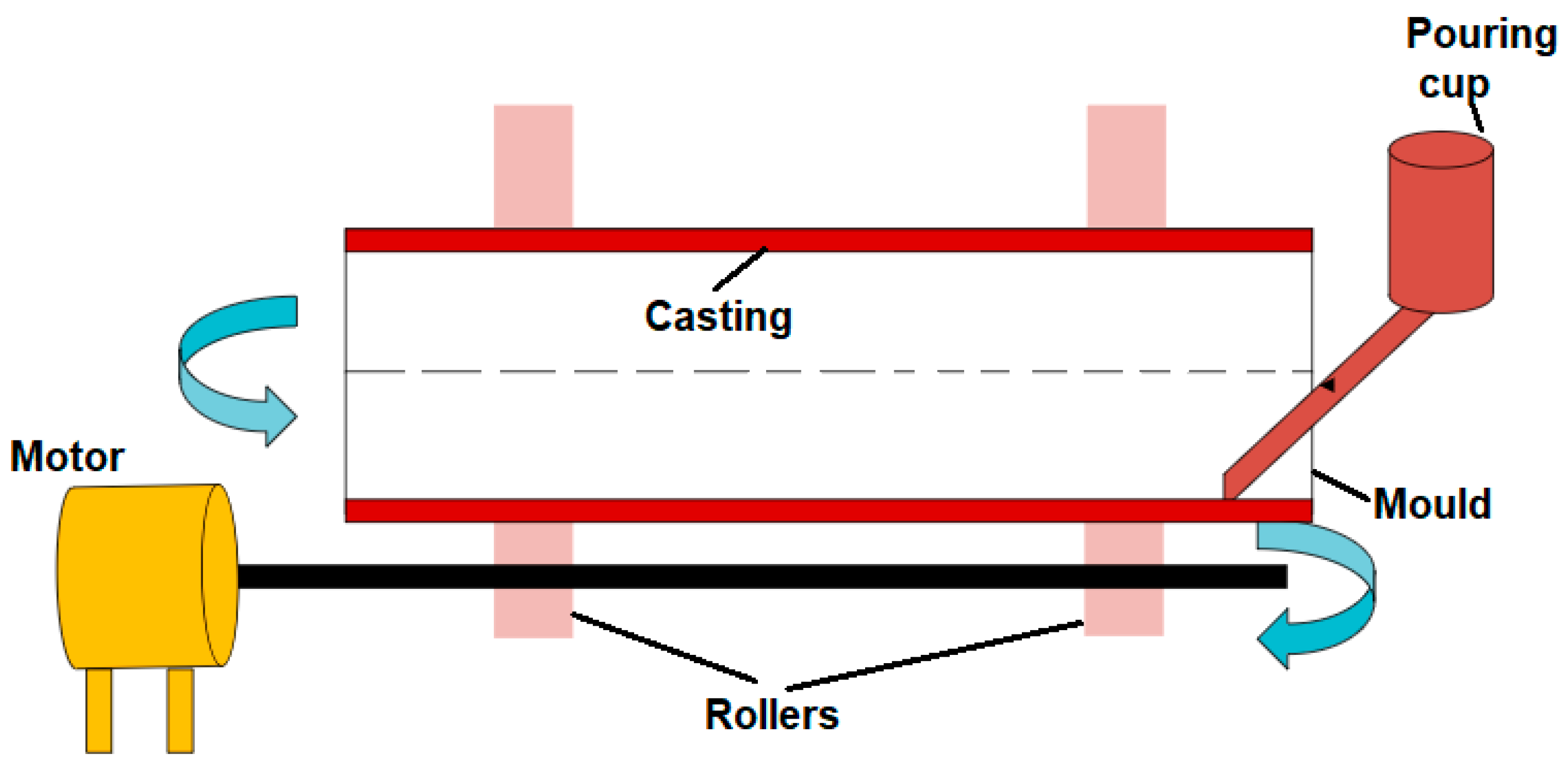

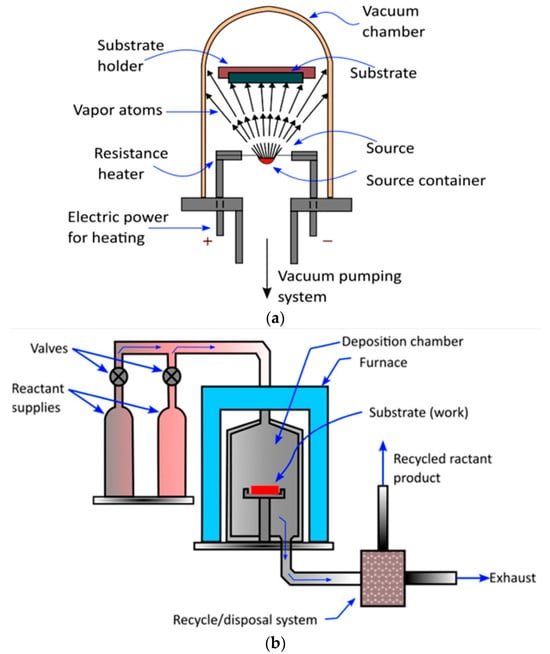

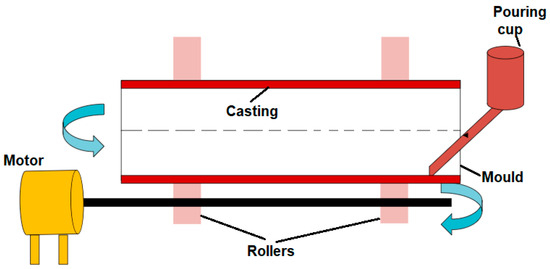

The gas-based methods rely on vapor-phase processing to deposit materials with graded properties. Chemical Vapor Deposition (CVD) and Physical Vapor Deposition (PVD), schematically presented in Figure 4, are common techniques where material layers are formed through chemical reactions or physical processes, respectively [104]. CVD deposits thin films via chemical reactions of precursor gases on a substrate, while PVD transfers material physically, using methods like sputtering or evaporation [24]. In addition, thermal spray techniques involve feedstock material melting in a combustion or plasma flame, flattening on the substrate, solidifying rapidly, and forming a deposit layer by layer [105]. These methods are particularly useful for producing thin films and coatings with precise gradients [106]. In contrast, the liquid-based methods utilize liquid-phase materials or suspensions to fabricate FGMs. Centrifugal casting (Figure 5) leverages centrifugal force to separate materials of varying densities, creating a gradient [21]. Techniques such as electrophoretic deposition (EPD) and sedimentation rely on particle movement in a liquid medium, driven by electric fields or gravity, to form graded layers. Directional solidification, gel-casting, slip-casting, and tape-casting provide additional flexibility for shaping FGMs by controlling solidification patterns or layering. Combustion synthesis, on the other hand, uses self-propagating high-temperature reactions to achieve compositional gradients.

Figure 4.

Illustrative view of: (a) PVD process, (b) CVD process (Reprinted from [24]—open access).

Figure 5.

Centrifugal casting schematic representation.

Finally, the solid-based methods focus on processing solid materials directly. Powder metallurgy, for instance, involves compacting and sintering powders to create a gradient structure, while Spark Plasma Sintering (SPS) uses pulsed electric currents to achieve high-temperature sintering. These techniques are highly effective for producing FGMs with robust mechanical properties and high-temperature stability [84].

Table 1.

Characteristics of the main conventional FGMs fabrication methods.

Table 1.

Characteristics of the main conventional FGMs fabrication methods.

| Method | Material Compatibility | Advantages | Disadvantages |

|---|---|---|---|

| Chemical Vapor Deposition | SiC/C, TiC/SiC, ZnO TiO2/Ti-O-Si etc. [25]. | It facilitates smooth compositional and structural transitions, ensuring seamless material integration in FGMs [24]. | High energy consumption, low efficiency, and high cost [25]. |

| Physical Vapor Deposition | |||

| Thermal spray | Metallic or non-metallic coatings | Versatility in Coating Materials [107,108] Controlled composition gradients [106] Enhanced surface properties [107,108] | Potential for porosity and residual stresses [106,109,110] High initial equipment costs [107,108] |

| Centrifugal casting | Metal-Matrix Composites [60] | Enables excellent mold filling and controlled compositional gradients by utilizing centrifugal force and material density differences [87]. | It is limited to cylindrical FGMs and restricts the types of achievable gradients [87]. |

| Combustion | TiC-Fe-Al2O3, TiC-Ni, TiC-Cu [25] | Efficient, energy-saving, and excellent in recrystallization [25]. | Porosity and structural defects |

| Powder Metallurgy | ZrO2–NiCr [111] B4C/AA7075 [112] Al-Al2O3 metal ceramic mixture [113] | Precise control over microstructure and composition [25]. Low cost, simple operation, low energy consumption, short processing time, and controllable properties [87]. | Challenges in the stacking method including warping, frustum formation, crack propagation, and lamination defects due to uneven particle distribution [84]. |

| Spark plasma sintering | ZrB2–SiC/ZrO2 ZrO2/AISI316L Ti–TiB2–B ZrB2–SiC/ZrO2 Cu/Al2O3/Cu Al2O3-Ti3SiC2 [84] | Achieving melting temperatures for different phases [84]. Ease of operation, precise control of sintering energy, as well as high sintering speed, reproducibility, safety, and reliability [114]. | The challenge lies in ensuring the powders have sufficient electrical conductivity and in achieving a consistent temperature distribution throughout the material [114]. |

2.4. 3D Printing Technology for FGM

The development of FGMs has been greatly advanced by 3D printing technologies. One of the primary benefits is tailored material properties, as AM allows precise control over the material gradient, enabling the creation of parts with varying characteristics like stiffness, thermal conductivity, or wear resistance. Moreover, AM enables the production of complex geometries that would be difficult or impossible to achieve with traditional manufacturing methods. This is particularly advantageous for FGM, as the gradient in material properties often requires intricate internal structures or complex shapes that can be easily fabricated using 3D printing technologies. Another advantage of using AM for FGMs is material efficiency [104]. Unlike subtractive manufacturing processes, which waste material when carving out shapes, AM builds parts layer by layer, using only the necessary amount of material. This minimizes waste, particularly when using expensive or rare materials for the graded components. Additionally, the ability to use a range of materials in a single part further enhances material efficiency and optimizes the performance of FGMs for specific functional requirements.

Furthermore, AM allows for the customization of parts, enabling the creation of FGMs that are tailored to unique applications. This is especially valuable in industries such as healthcare, where medical implants or prosthetics may require specific mechanical or biological properties at different locations within the part to ensure optimal performance and biocompatibility. Examples of FGMs used in biomedical applications include ZrO2 and Al2O3 [16], which have been utilized as framework materials due to their excellent mechanical properties, good aesthetics, and biocompatibility. Additionally, Ti6Al4V is commonly employed in orthopedic and dental implants for its high strength and corrosion resistance [15]. Functionally graded implants composed of titanium (Ti) and hydroxyapatite (HAP) [13] obtained by powder metallurgy can satisfy both mechanical properties and biocompatibilities. Furthermore, Ti-NaCl composite materials have been explored to create porous structures [11].

Finally, the cost-effectiveness of AM for FGMs should not be overlooked. While FGM production using traditional methods may be expensive and time-consuming, AM offers a more cost-effective solution, particularly for low-volume production or when producing prototypes. The flexibility and scalability of AM also contribute to its cost-efficiency, especially when producing small batches or custom parts.

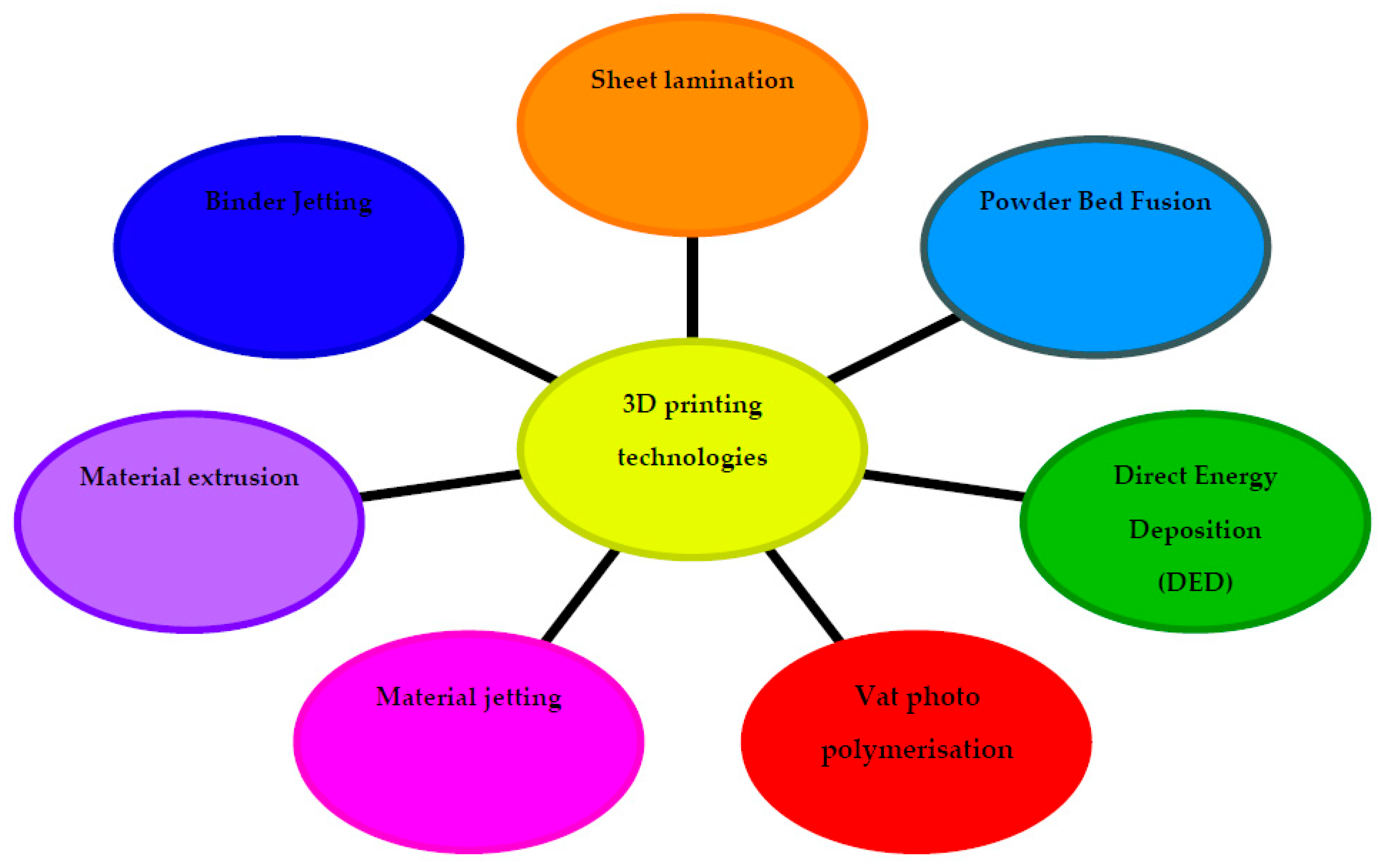

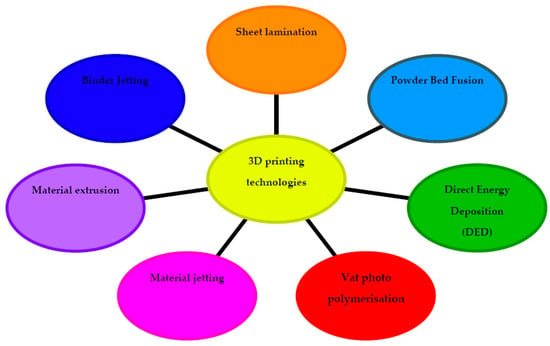

Several 3D printing methods (shown in Figure 6), including binder jetting, powder bed fusion, direct energy deposition (DED), vat photopolymerization, material jetting, material extrusion, and sheet lamination, have been utilized to produce FGMs.

Figure 6.

3D printing technologies used for FGM.

Binder jetting is a widely used method for FGM fabrication, especially used for ceramic or metal-ceramic hybrids [104]. By selectively depositing a binder onto a powder bed, it allows for the combination of different powders to create graded structures. This technique is particularly effective for producing porous FGMs and complex geometries. However, the lack of adhesion between layers and the print resolution, ranging from 20 to 100 microns, present challenges to this technique [115].

Powder bed fusion methods, such as Selective Laser Melting (SLM) or Electron Beam Melting (EBM), offer high precision in producing FGMs. These methods involve the selective melting of powder layers, with the possibility of varying material composition between layers to achieve property gradients. Despite their precision and material versatility, challenges such as high equipment costs and difficulties in managing multiple powder types persist.

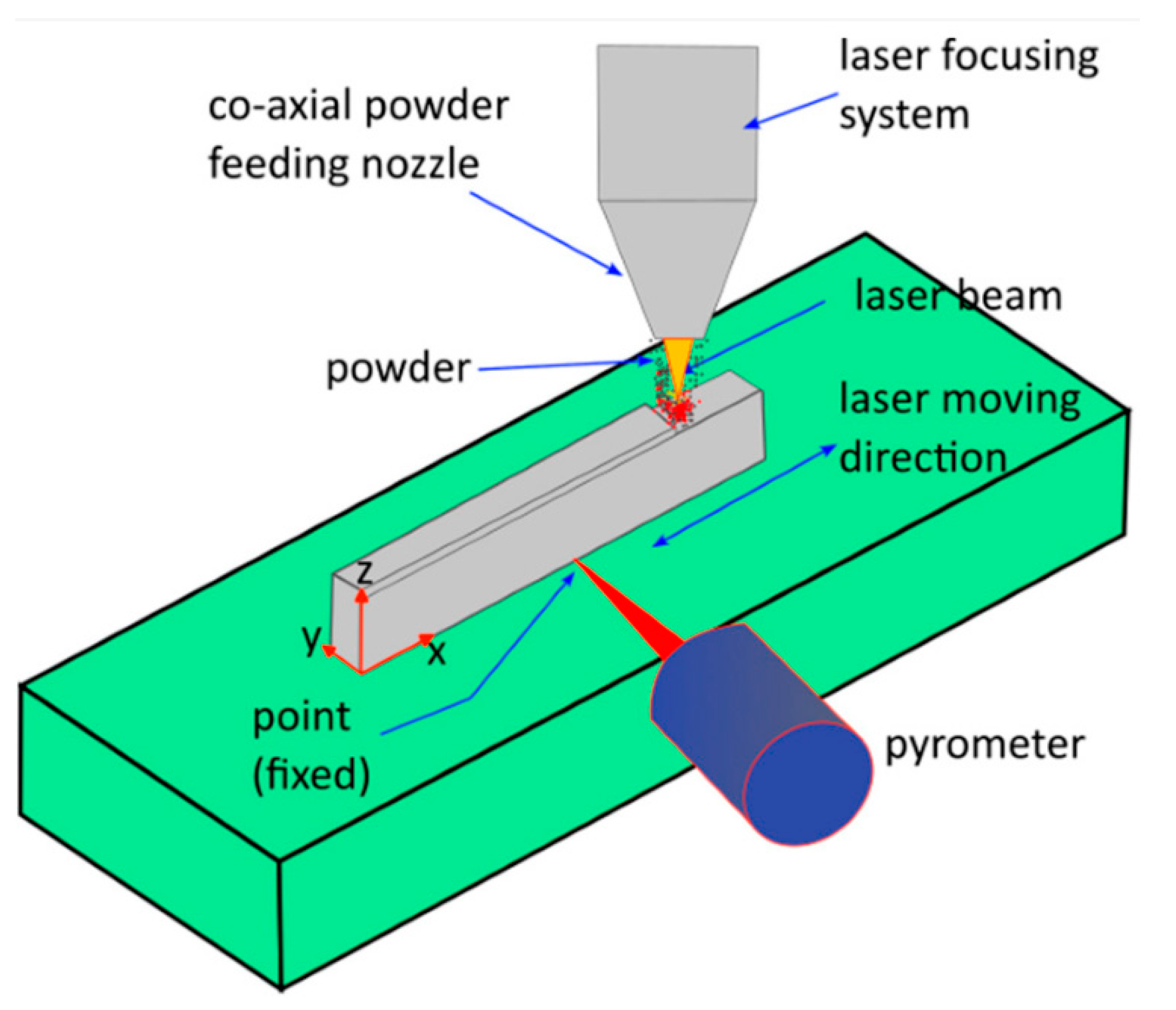

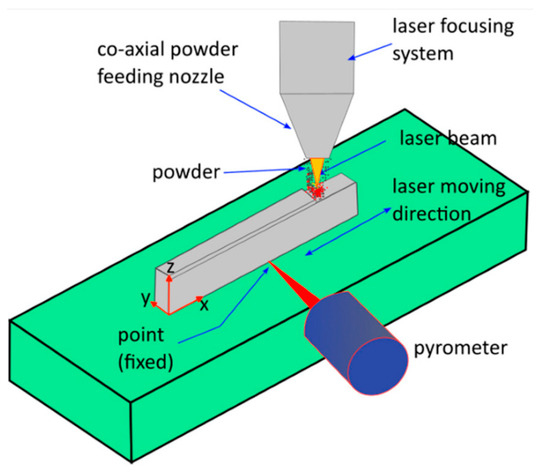

Direct energy deposition (DED), illustrated in Figure 7, is another prominent method for FGM production. Feeding powder or wire into a focused energy source, such as a laser or electron beam, enables real-time control of material composition. This flexibility makes DED highly suitable for producing complex FGM structures [104].

Figure 7.

Schematic view of Laser Metal Deposition (Reprinted from [24]—open access).

Vat photopolymerization involves curing a light-curable resin or slurry in a vat to create a solid preform through polymer chains or crosslinks and it has advantages such as smooth surface finishes, high precision and resolution, ability to produce wall thicknesses from 50 µm to 150 µm, and compatibility with a wide range of commercially available materials [88].

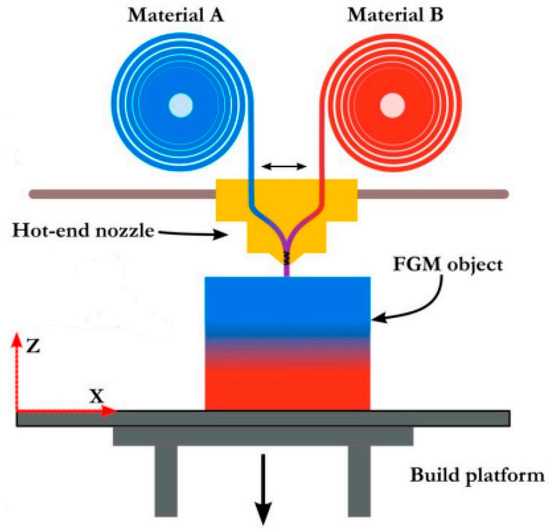

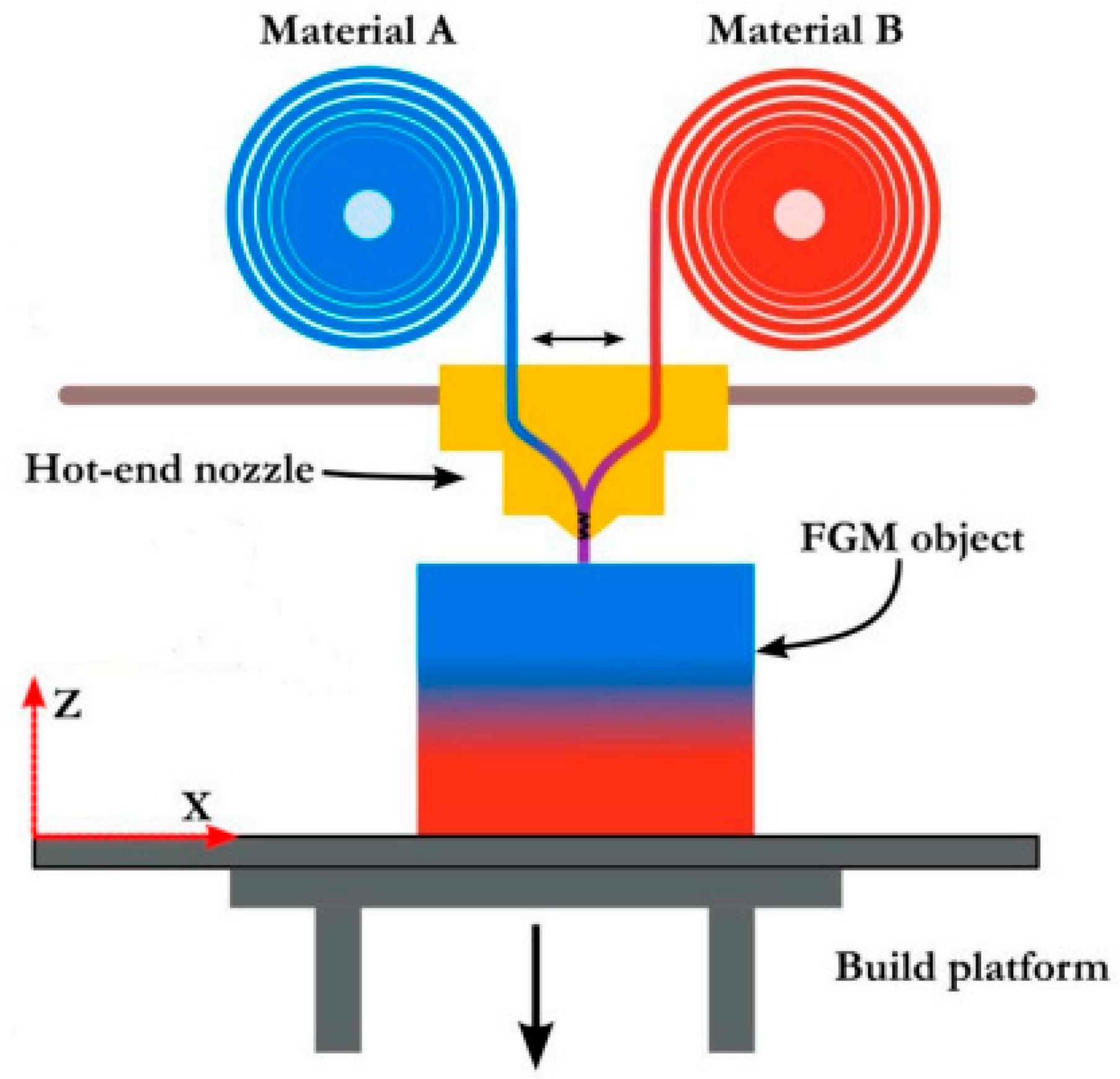

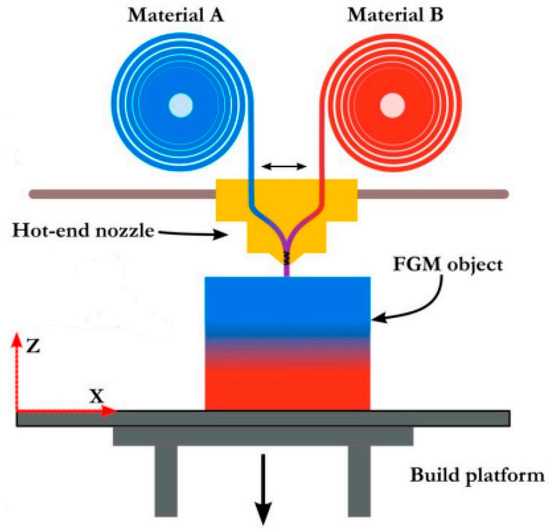

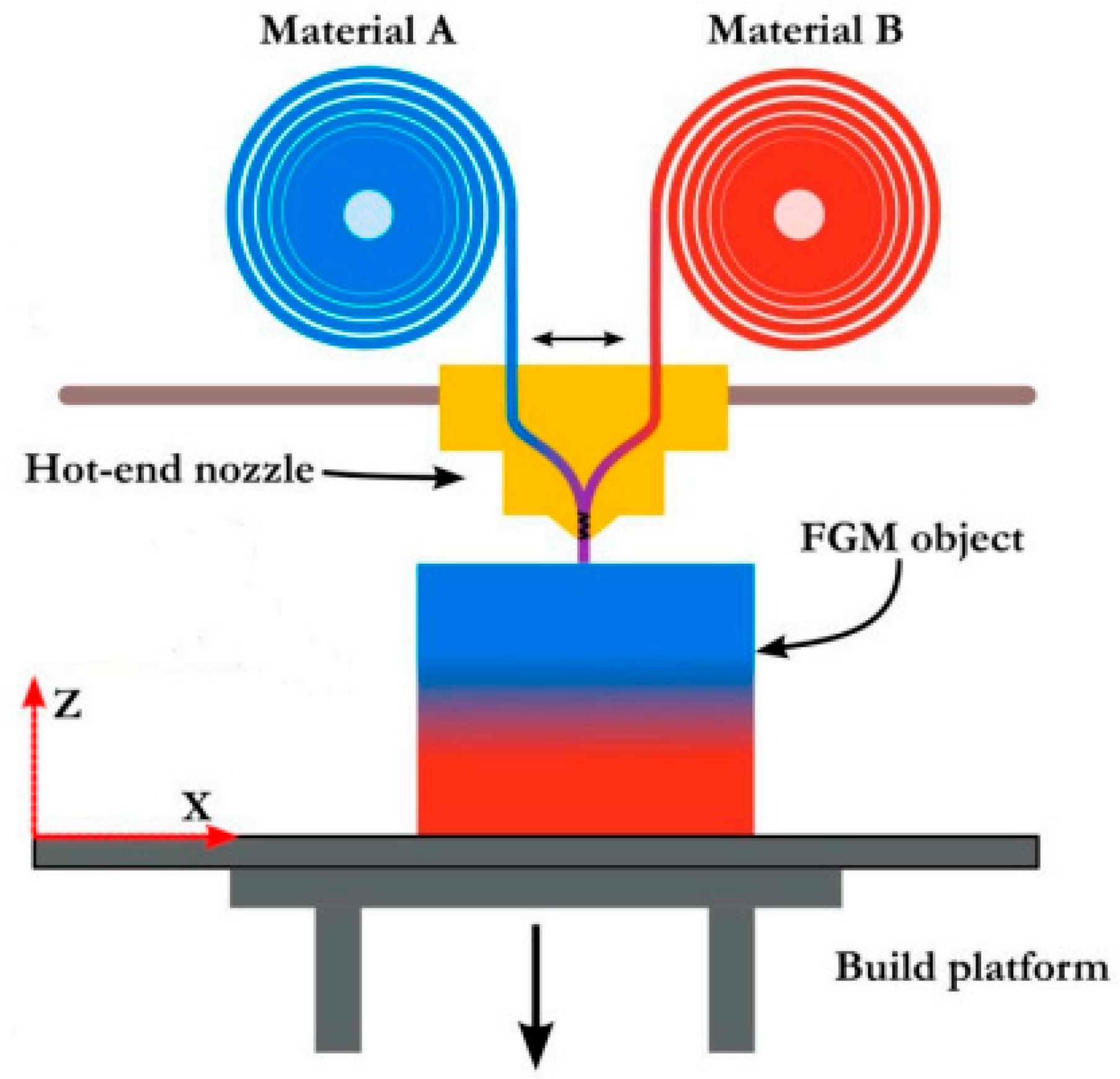

Material jetting and material extrusion are cost-effective and versatile techniques for producing FGMs. Material jetting enables multi-material deposition, making it suitable for creating detailed gradients, but the process is relatively slow. Material extrusion (Figure 8), often used in fused filament fabrication (FFF), can fabricate FGMs by combining different materials in the extrusion process. However, the surface finish and precision may be inferior compared to other methods [88].

Figure 8.

Schematic view of material extrusion FGM parts (Reprinted from [116]—open access).

Figure 8.

Schematic view of material extrusion FGM parts (Reprinted from [116]—open access).

Sheet lamination, though less common, can also be employed for FGMs. By stacking and bonding layers of varying materials, property gradients can be achieved [24].

The application of 3D printing for FGM fabrication offers numerous advantages, such as design flexibility, material efficiency, and the ability to produce complex geometries. However, there are notable limitations, including high equipment costs, challenges in achieving strong material interfaces, and the need for extensive post-processing. There are several structural issues that can affect the performance of the final product. For example, delamination, which is the separation between layers or regions, typically arises from poor bonding or thermal stresses, weakening the material [117,118]. Cracking can occur due to residual stresses or temperature variations [119,120]. Material inhomogeneity [121,122] refers to variations in composition or structure within layers, often due to uneven powder distribution or poor mixing, leading to inconsistencies in material properties. Porosity, often results from incomplete fusion or gas entrapment, reducing the material’s strength [123,124]. Anisotropic behavior refers to variations in material properties along different layers, caused by the layer-by-layer deposition process, which can create inconsistencies in mechanical performance [125]. Another failure mechanism refers to thermal stresses that are caused by strain resulting from temperature gradients and can arise from material mismatch or thermal history, affecting the structural integrity [126,127]. Addressing these issues is essential for improving the reliability and performance of AM-based FGMs. Despite these limitations, 3D printing technologies continue to evolve, holding great promise for the future of FGMs in diverse industries, such as aerospace, biomedical, and automotive engineering.

2.5. Characterization Methods for FGMs

Characterizing FGMs is essential for understanding their unique properties and ensuring their suitability for various applications. This process involves a combination of mechanical testing and microstructural analysis to comprehensively assess the material’s performance.

Mechanical testing is fundamental in evaluating the strength, hardness, and durability of FGMs. For instance, hardness tests, such as the Vickers microhardness test, are employed to measure the material’s resistance to deformation. This method is particularly useful for FGMs, as it allows for the assessment of hardness variations across the gradient regions, providing insights into wear resistance and the effectiveness of the material’s graded design [128]. In addition to hardness testing, tensile and compression tests are conducted to define the stress-strain behavior, yield strength, and elasticity of FGMs [66,129,130,131,132,133].

Microstructural analysis complements mechanical testing by providing a detailed examination of the internal structure of FGMs. Techniques such as scanning electron microscopy (SEM) and optical microscopy (OM) are utilized to observe the material’s morphology and identify any defects or inconsistencies [134,135].

Furthermore, advanced characterization methods like X-ray diffraction (XRD) are employed to identify crystalline phases and assess residual stresses within FGMs. XRD analysis provides valuable information on the material’s crystallographic structure, which is essential for understanding its mechanical properties and potential performance in various applications [136,137,138,139].

2.6. Mechanical Behavior of 3D Printed FGM

The mechanical behavior of 3D-printed FGMs has been extensively studied, as summarized in Table 2, which presents key findings from several experimental investigations.

Table 2.

Summary of studies on mechanical characterization of 3D printed FGM.

2.7. Micromechanical Models for FGMs

Micromechanical models play a very important role in predicting the effective properties of FGMs, where the composition of two materials varies through the thickness of a plate. Different micromechanical approaches help in estimating the effective elastic properties based on the volume fraction of inclusions, which can vary according to power-law (P-FGM), sigmoid (S-FGM), or exponential (E-FGM) distributions [154,155].

The main micromechanical models are:

(a) Voigt and Reuss Models

The Voigt model assumes uniform strain across all phases and determines the macroscopic properties by averaging stresses [156,157,158]. It provides an upper bound on the effective Young’s modulus of the FGM. In contrast, the Reuss model assumes uniform stress and provides a lower bound [159]. These models offer simple analytical expressions for estimating Young’s modulus and Poisson’s ratio of FGMs.

(b) Hashin–Shtrikman Bounds

Hashin and Shtrikman used a variational principle in heterogeneous elasticity to derive upper and lower bounds for effective elastic properties. Notably, the effective material properties obtained from the Hashin–Shtrikman lower bound are equivalent to those predicted by the Mori–Tanaka micromechanical model [157]. Additionally, the upper bound can be derived by swapping the roles of the matrix and inclusion in the Mori–Tanaka formulation [155].

(c) Tamura’s Model

The Tamura model is a micromechanical approach used to estimate the effective elastic properties of two-phase composites, assuming a linear rule of mixture for the effective Poisson’s ratio while introducing an empirical fitting parameter, known as the “stress-to-strain transfer” parameter, in the formulation of the effective Young’s modulus [155,160]. This empirical parameter accounts for the interaction between the matrix and inclusion phases, providing a more refined estimation of the mechanical behavior of FGMs compared to simpler models like Voigt and Reuss. By incorporating this correction, the Tamura model can better capture the stress distribution between the phases, making it particularly useful for materials with graded compositions. Notably, the Tamura formulation simplifies Voigt’s estimation when the empirical parameter qT = ±∞, and Reuss’s estimation when qT = 0 [155].

(d) Local Representative Volume Element (LRVE) Model

The LRVE approach, employed by Gasik and Lilius [161,162], considers a cubic representative volume element to estimate the bulk properties of FGMs. To determine the effective material properties of FGMs, this micromechanical model considers the second phase of a two-phase composite as an inclusion. Utilizing a locally orthotropic representative volume element enables the prediction of the bulk properties of FGMs.

(e) Self-Consistent Method (SCM)

SCM was initially developed for polycrystalline materials but has been extended to FGMs [155]. Unlike other models that distinguish between matrix and inclusions, SCM treats both phases equivalently. Although SCM does not provide explicit formulations like the previous models, it offers a more general framework for estimating effective properties.

The selection of a micromechanical model for FGMs depends on the material distribution and microstructural characteristics. While Voigt and Reuss provide basic estimates, Hashin–Shtrikman bounds and LRVE offer improved accuracy. Tamura’s model introduces empirical corrections, and SCM is suitable for complex microstructures. By combining these methods, researchers can accurately predict the mechanical behavior of FGMs and optimize their design for various engineering applications.

3. Bibliometric Analysis Methodology

This study employs a bibliometric analysis approach to systematically evaluate the research landscape of 3D-printed FGMs. Bibliometric methods provide a quantitative means of assessing research trends, identifying influential studies, and mapping collaborations between researchers and institutions. Given the rapid advancements in additive AM and FGMs, bibliometric analysis offers a structured way to track the evolution of research themes, technological developments, and emerging challenges in the field.

The bibliometric analysis was conducted using the Web of Science (WOS) database due to its extensive coverage of high-impact journals and peer-reviewed publications. This ensures that only credible and relevant sources are included in the dataset.

The search employed the following TS (Topic Search) query:

- TS = (“functionally graded materials”)

- TS = (“3D printed”) OR TS = (“additive manufacturing”)

- #1 AND #2

This query ensured a focused yet comprehensive dataset. The search was restricted to documents in English, including journal articles and reviews, published up to 2024. A total of 945 relevant documents were retrieved through the combined criteria.

The collected publications were analyzed using “VOSviewer” and “CiteSpace” software.

VosViewer software (version 1.6.13, Leiden University, Leiden, The Netherlands) was employed to conduct network mapping of country contributions and thematic research clusters [163,164], while CiteSpace (version 5.7.R2, Drexel University, Philadelphia, PA, USA) was used to identify emerging research trends, citation bursts, and clustering analysis [165]. Together, these tools provided a detailed and multifaceted view of the global research landscape in FGMs 3D printing.

The selection of VOSviewer and CiteSpace for bibliometric analysis was driven by their complementary functionalities in visualizing and interpreting complex research networks. VOSviewer excels in generating network maps with high clarity, particularly for visualizing collaborations between countries, institutions, and authors, as well as co-occurrence patterns of keywords. On the other hand, CiteSpace offers unique capabilities in detecting citation bursts, emerging trends, and co-citation clusters, enabling a deeper understanding of the dynamic evolution of the research field. Together, these tools provide a comprehensive bibliometric perspective by combining detailed network visualization with temporal and thematic analyses, thereby ensuring a robust exploration of the global research landscape on FGMs and additive manufacturing.

Despite its strengths, this bibliometric analysis has certain limitations. First, the study is limited to publications indexed in Web of Science, which, while comprehensive, may exclude relevant studies from other databases such as Scopus, or Google Scholar. Consequently, some significant contributions to FGM research might not be captured in the analysis.

Second, bibliometric methods are inherently dependent on keyword selection. Although we used a well-defined search strategy to ensure a comprehensive dataset, there is always a possibility that some relevant studies were excluded due to variations in terminology used by different authors.

Finally, while VOSviewer and CiteSpace provide robust visualization and clustering capabilities, their outputs are sensitive to parameter settings, such as the minimum citation threshold or the clustering algorithm applied. Small variations in these settings could lead to different interpretations of research trends.

To reduce these limitations, future studies could expand the dataset by incorporating multiple academic databases and refining search queries to capture a broader range of relevant publications. Additionally, a complementary systematic review of selected high-impact papers could provide a more qualitative assessment of key findings, supplementing the quantitative insights gained from bibliometric analysis.

4. Review and Discussion

4.1. Publication Statistics

4.1.1. Annual Publication

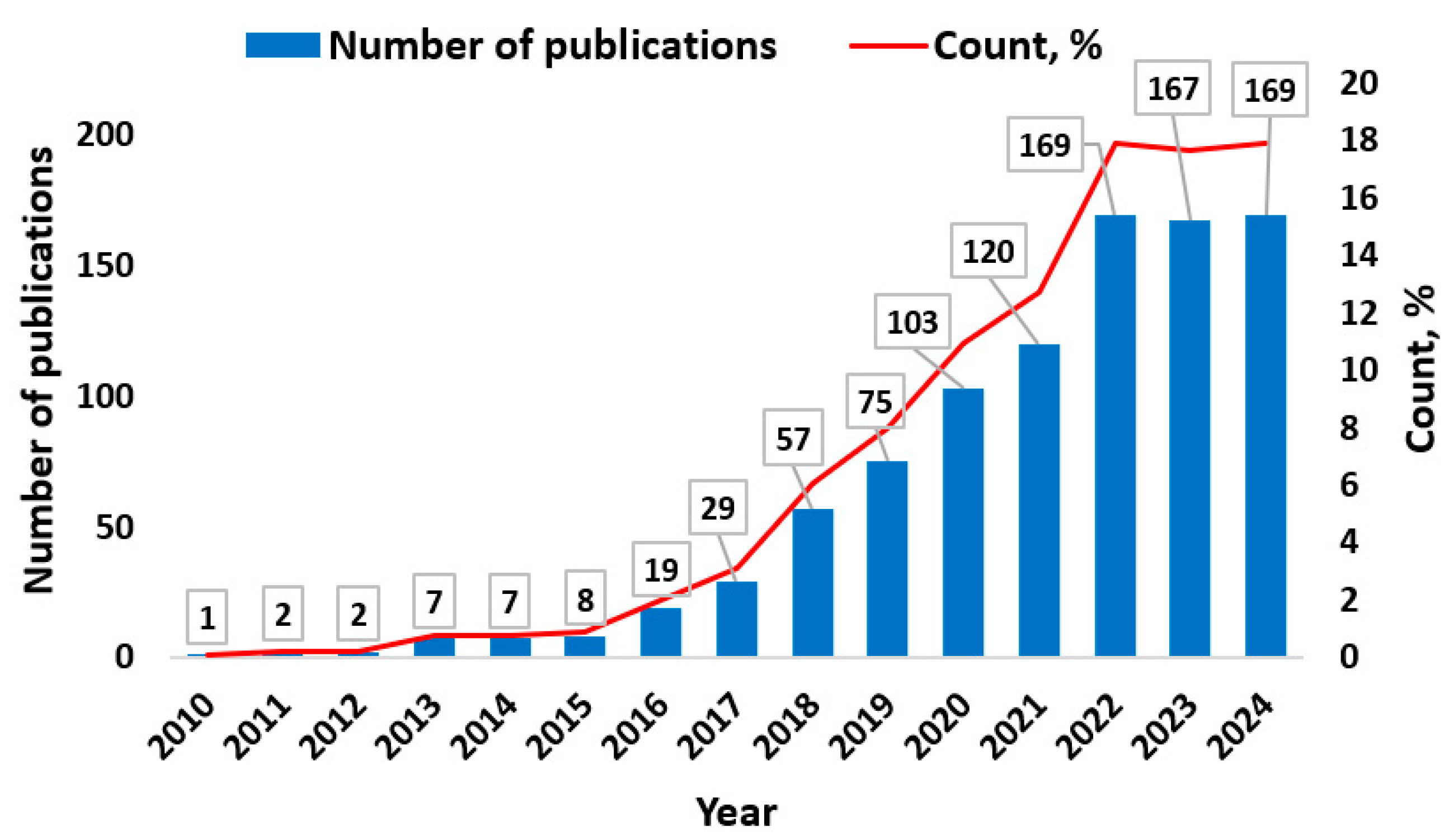

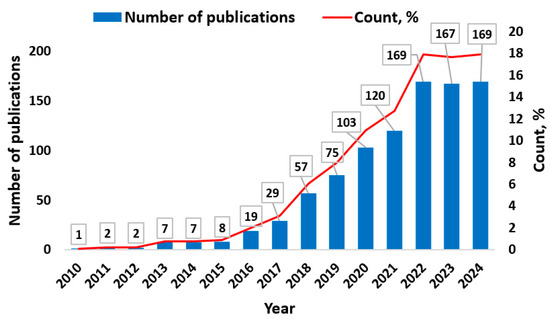

The annual evolution of published papers presented in Figure 9 shows that initially, from 2010 to 2015, the number of publications remains very low, ranging between 1 and 8 annually. During this period, the research activity was minimal, suggesting that the topic was either newly emerging or not widely recognized as significant. However, starting in 2016, there was a noticeable increase in the number of publications, with 19 papers published in that year. This upward trend continues steadily, and by 2017, the number of publications rose to 29. The years following 2017 show accelerated growth, as the numbers jump to 57 in 2018 and further to 75 in 2019. The most significant growth phase occurs from 2020 to 2021, where the number of publications climbs sharply from 120 to 169, representing a peak. This surge could reflect a heightened awareness of the topic’s relevance or its increasing importance in addressing contemporary challenges. Interestingly, after 2021, the number of publications stabilizes at 169, continuing through 2024. This evolution suggests that the field has reached a stage of maturity, with consistent but no longer exponential growth in research output.

Figure 9.

Number of publications by year.

Additionally, Table 3 presents journals with a high number of publications.

Table 3.

Top document sources.

4.1.2. Publication by Country

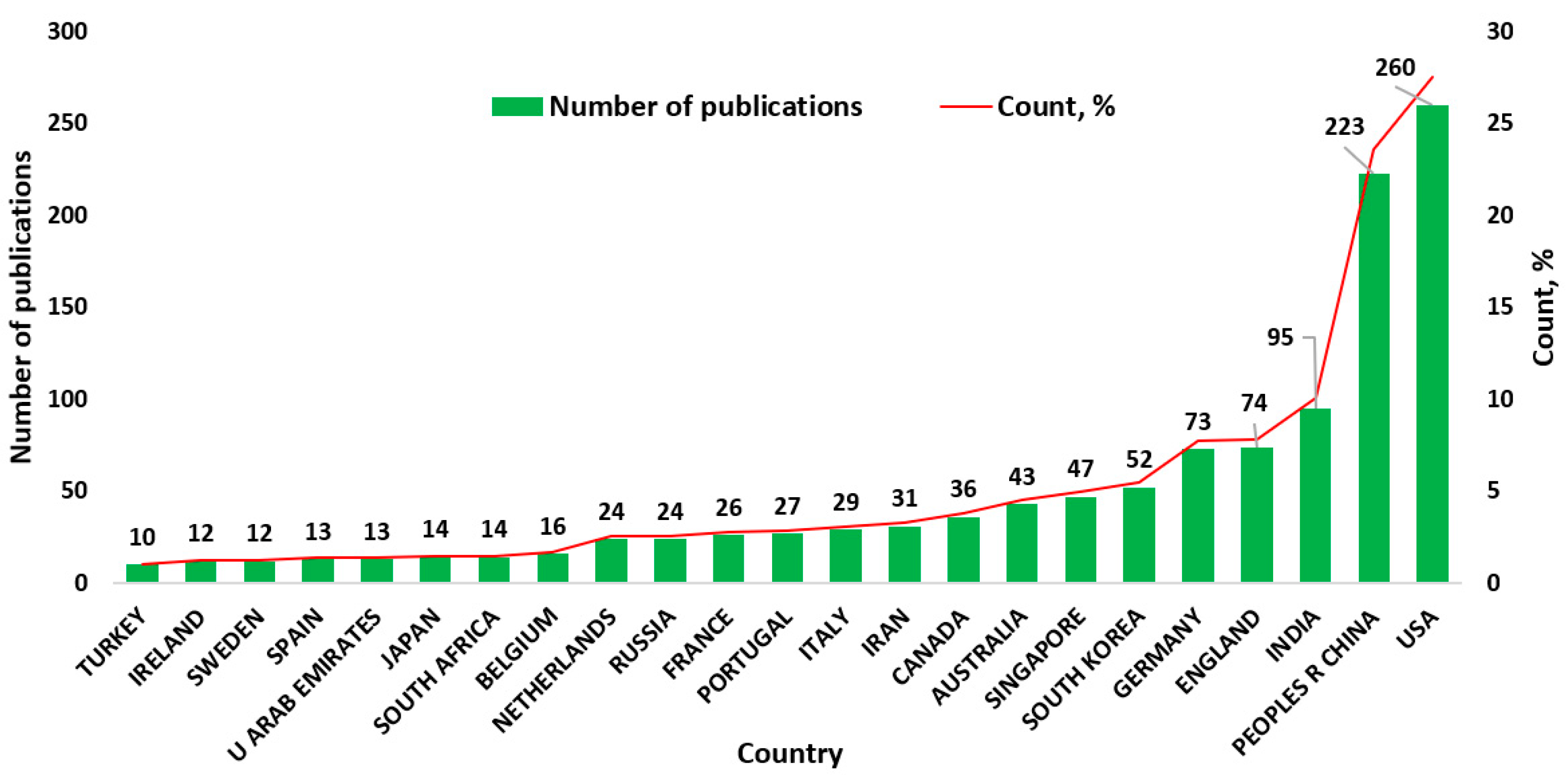

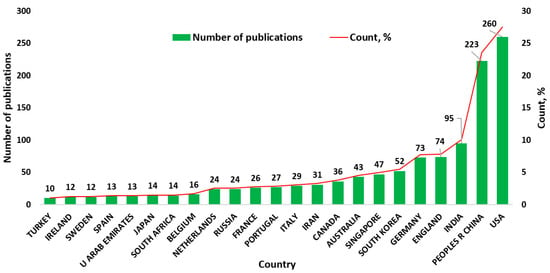

The graph from Figure 10 illustrates the distribution of publications by country and their percentage contributions. The USA leads with the highest number of publications (260) and a significant 27% contribution, followed by China with 223 publications and 23%. Other notable contributors include India (95 publications), England (74), and Germany (73 publications). The contributions from countries like Turkey, Ireland, and Sweden are comparatively lower, with around 10–12 publications each.

Figure 10.

Number of publications by country.

This data highlights the dominance of the USA and China in research output, reflecting their strong focus and resources dedicated to the field, while other countries show moderate to minimal contributions.

4.2. Collaboration Analysis

4.2.1. Institutional Collaboration

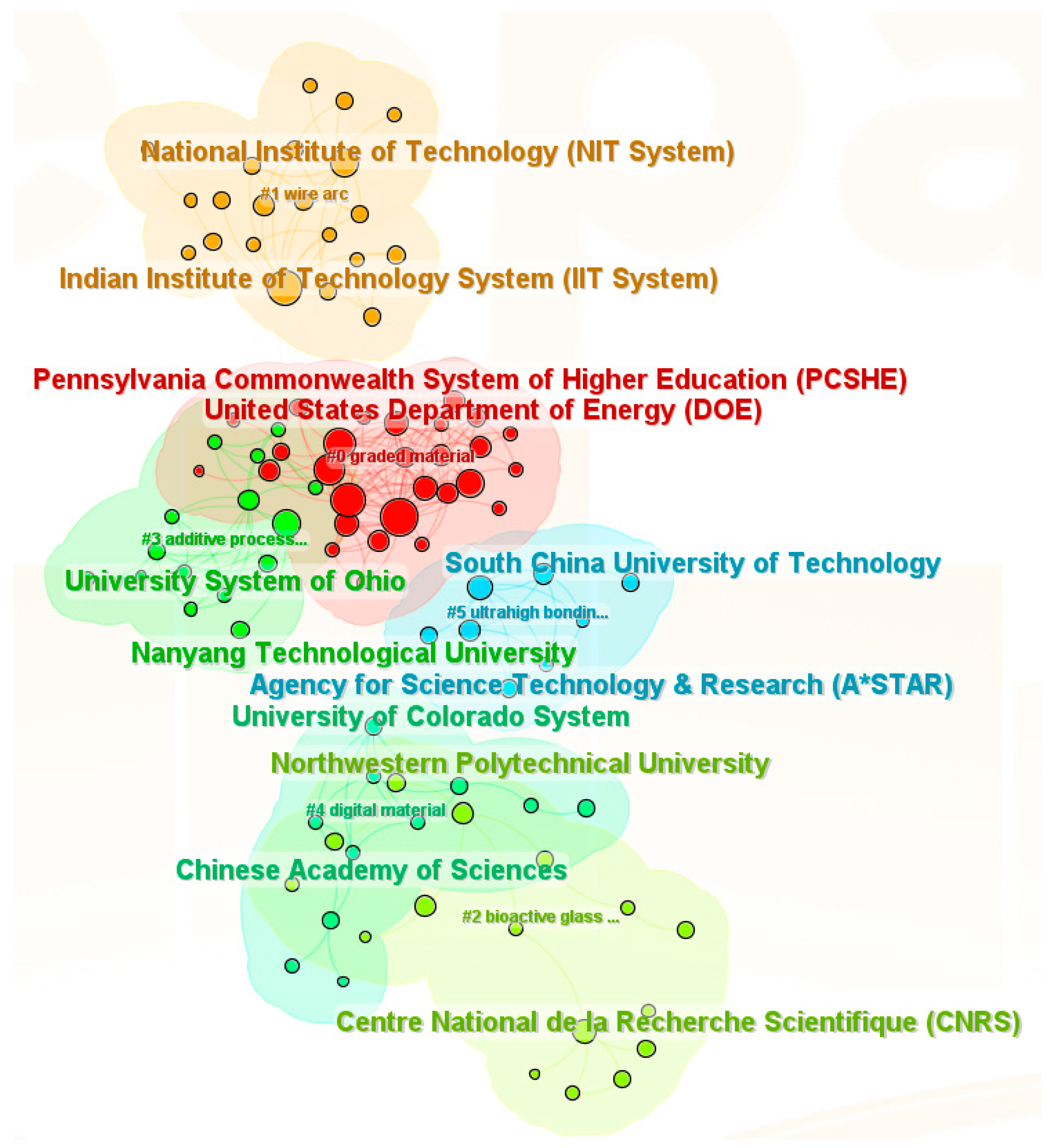

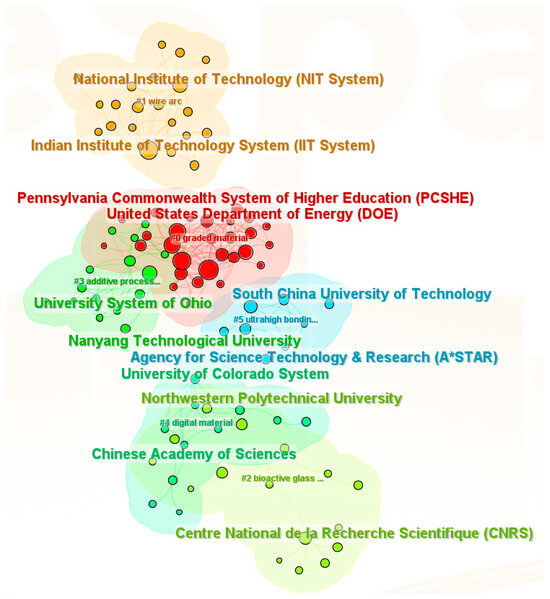

The visualization from Figure 11 generated using CiteSpace highlights the key institutions contributing to research in a particular field. Distinct clusters are formed based on thematic areas and institutional collaborations.

Figure 11.

Institutional collaboration network.

The National Institute of Technology (NIT System) and the Indian Institute of Technology System (IIT System) stand out as significant contributors within their cluster, representing extensive research activity in India. Similarly, the Pennsylvania Commonwealth System of Higher Education (PCSHE) and the United States Department of Energy (DOE) form prominent nodes, indicating their leadership in research activities in the USA. Institutions such as the Chinese Academy of Sciences and the South China University of Technology dominate the research landscape in China, forming large, influential clusters. Other notable contributors include Nanyang Technological University in Singapore and Centre National de la Recherche Scientifique (CNRS) in France, emphasizing international participation in the field. Overall, the visualization underscores the global collaboration among institutions, with notable research hubs in the USA, China, India, and Europe leading advancements.

As shown in Table 4, the United States Department of Energy (DOE) leads with 45 citations, reflecting its important role in driving innovation in additive manufacturing techniques. The Indian Institute of Technology (IIT) System and the Pennsylvania Commonwealth System of Higher Education (PCSHE) follow closely, with 37 and 32 citations, respectively, showcasing their prominent research activities in the field. Other key contributors include Pennsylvania State University and Nanyang Technological University, which have established themselves as influential hubs for collaborative and interdisciplinary research.

Table 4.

Citation counts of institutions.

4.2.2. Countries Collaboration

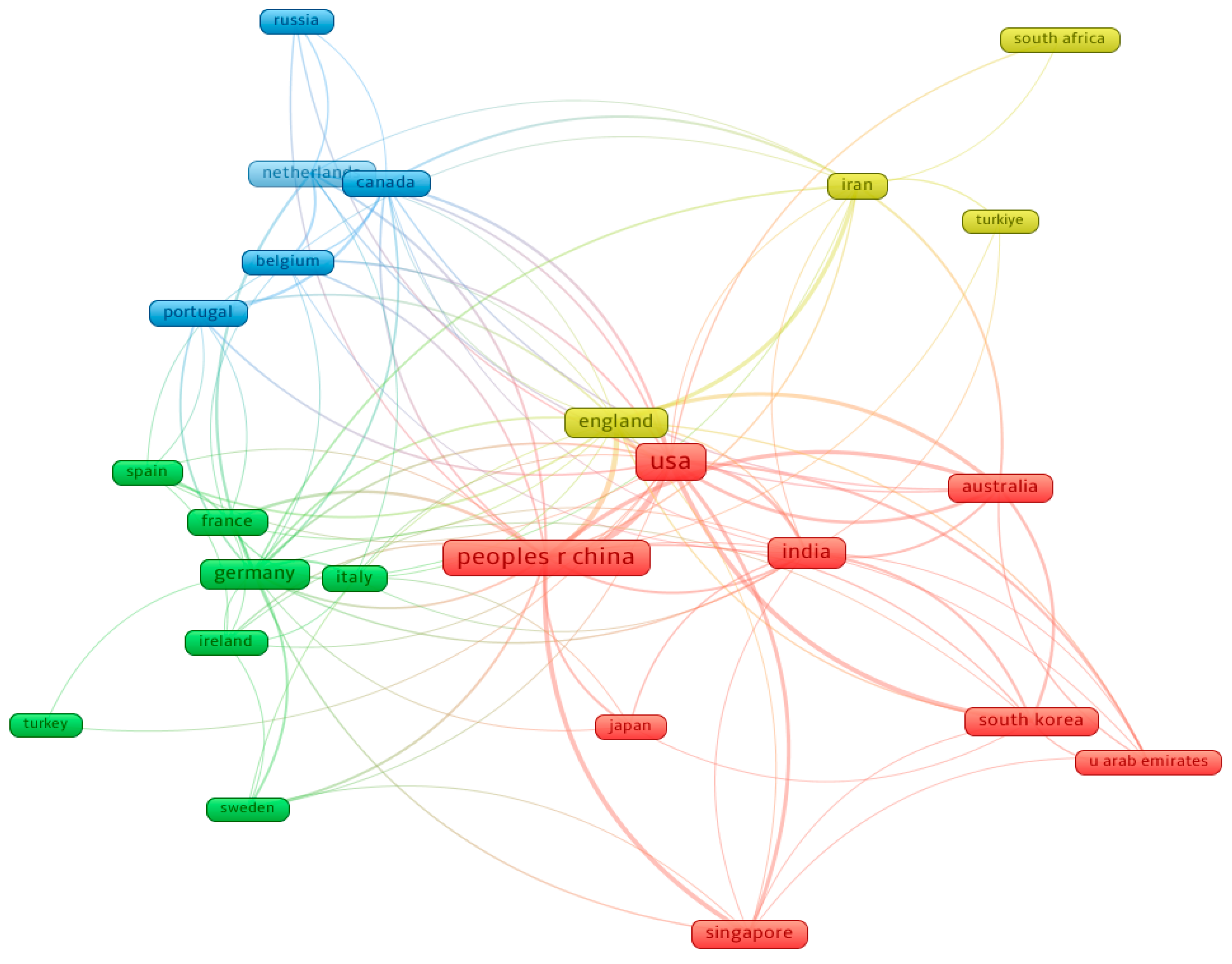

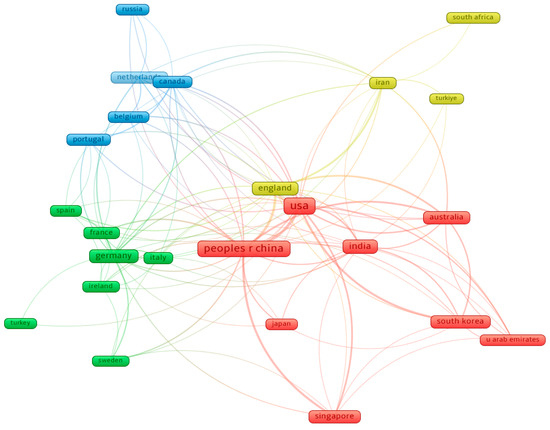

For the countries co-authorship analysis performed in VOSviewer, the minimum number of documents for a country was set to 10, and therefore, from 61 countries, 24 meet the threshold.

The network of countries obtained with VOSviewer is shown in Figure 12.

Figure 12.

Countries network collaboration.

The nodes, representing countries, vary in size, with larger nodes such as “People’s Republic of China”, “USA”, and “India” occupying central positions in the network. These larger nodes suggest a higher degree of connectivity, implying that these countries play significant roles in the overall system.

The red cluster, which includes countries like China, the USA, and India, highlights a group of nations with strong bilateral or multilateral collaborations. This could reflect global partnerships in high-tech industries or shared leadership in cutting-edge research initiatives.

The blue cluster comprises countries like Canada, the Netherlands, and Portugal.

The green cluster, dominated by European countries such as Germany, France, and Italy, reflects robust intra-European collaboration.

The yellow cluster, which includes countries like South Africa, Iran, Turkey, and England highlights emerging contributors to the field. These nations are likely developing their research capacities in FGMs and engaging in collaborations with both regional and global leaders. Their presence in the network suggests increasing interest in additive manufacturing technologies and their application in diverse industries.

4.3. Hot Research Topics

4.3.1. Keyword Co-Occurrence Analysis

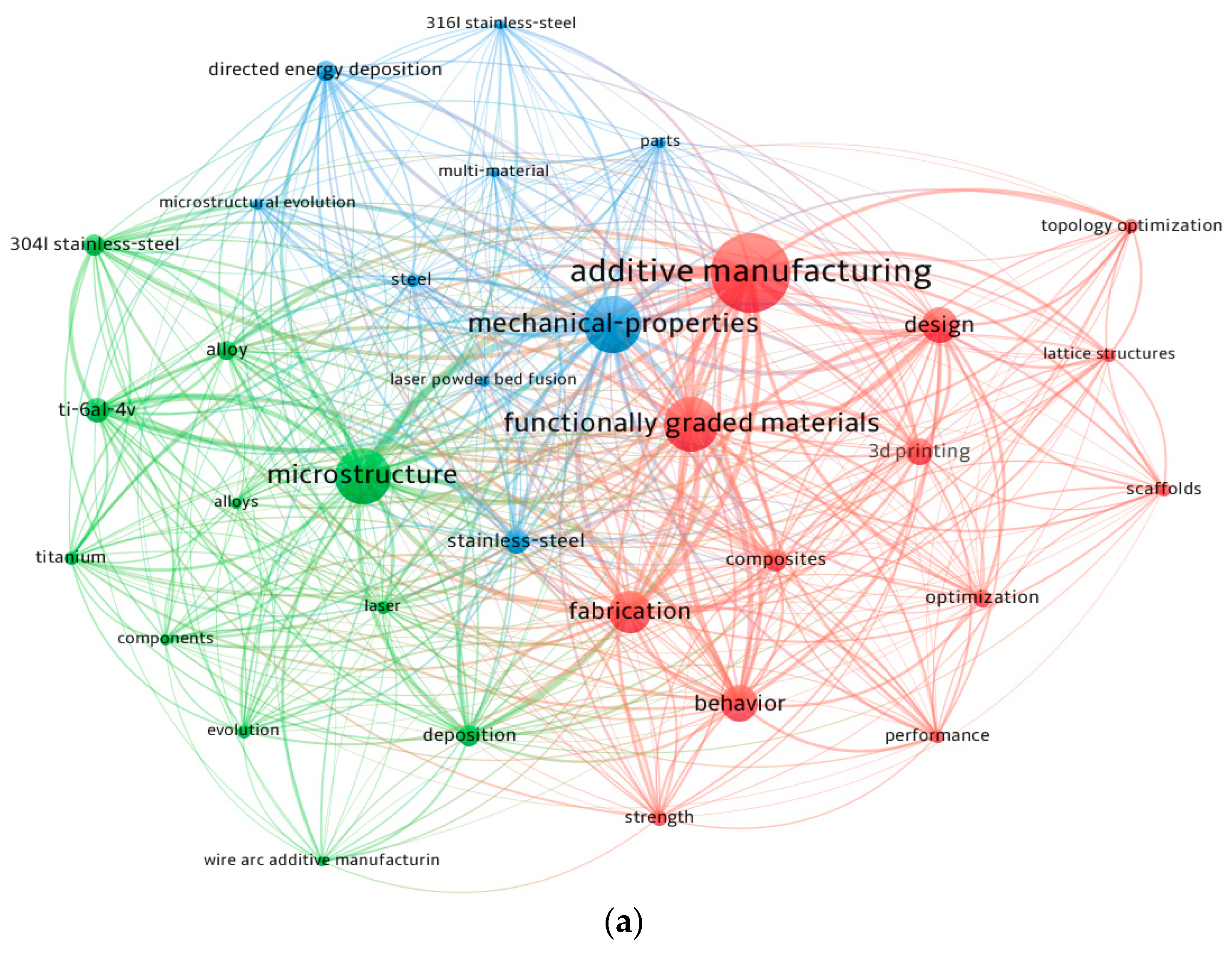

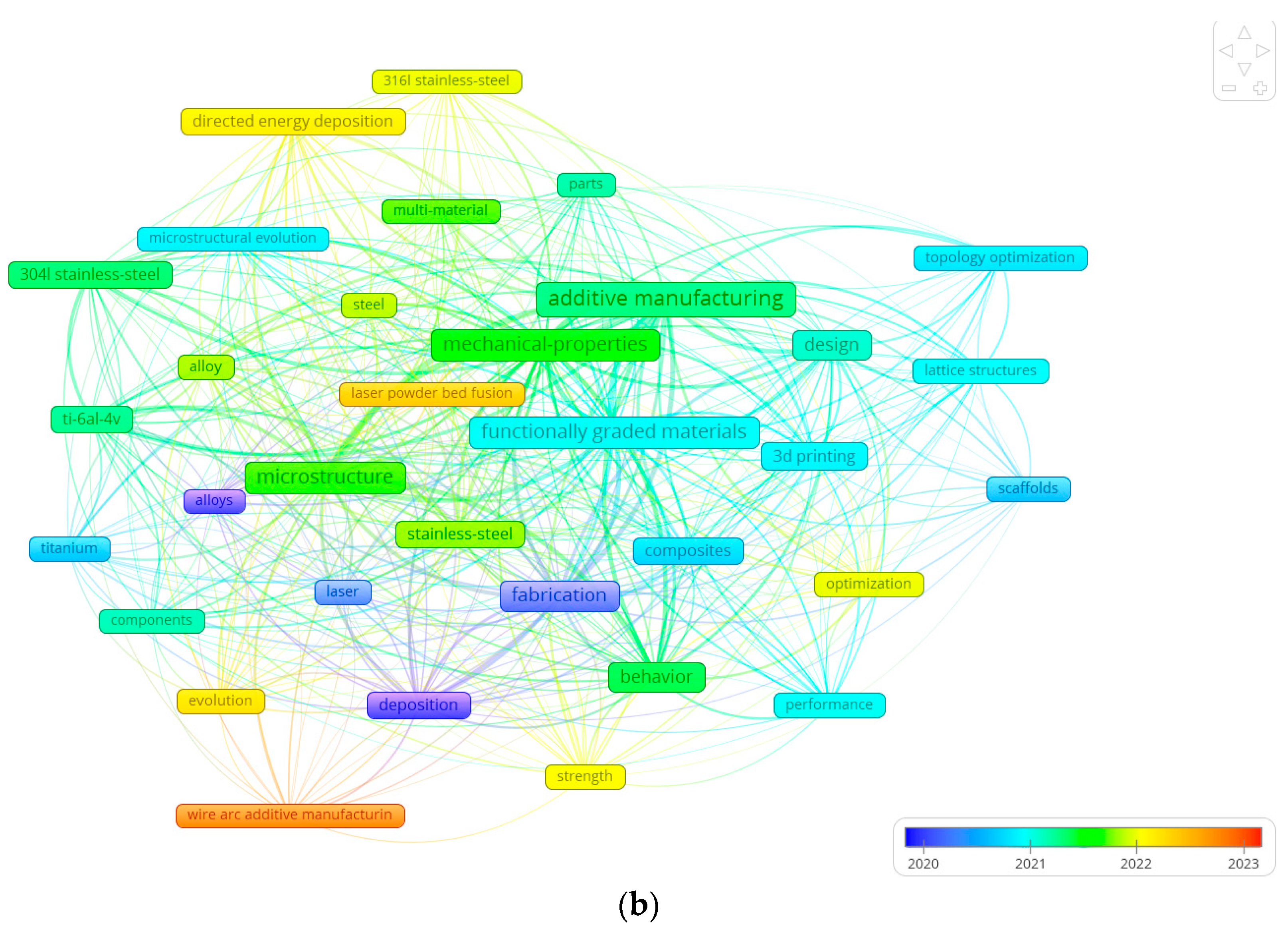

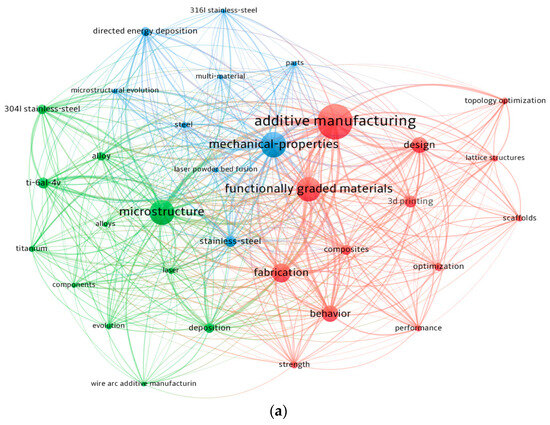

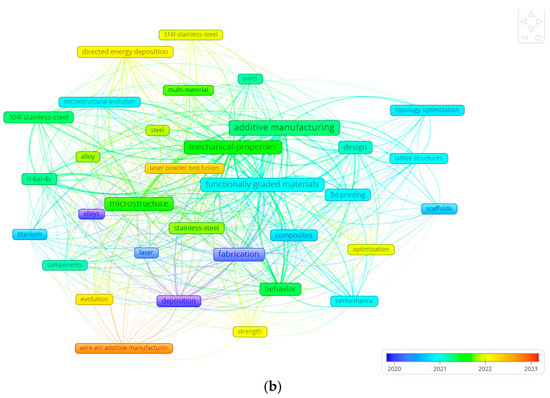

For the keyword co-occurrence analysis performed in VOSviewer, the minimum number of occurrences of a keyword was set to 25, and therefore, of the 3581 keywords, 35 meet the threshold.

In Figure 13a, the network visualization highlights the relationships between frequently co-occurring keywords. Larger nodes, such as “additive manufacturing”, “functionally graded materials”, and “mechanical properties”, indicate central topics in the research landscape. The network is divided into three clusters, For example, the red cluster focuses on design-related aspects, including “topology optimization” and “performance”, while the green cluster is centered around “microstructure” and material-specific terms like “titanium” and “stainless steel.” This visualization underscores the interconnectedness of research themes, demonstrating how concepts like mechanical properties bridge multiple clusters.

Figure 13.

Graphs of author keywords: (a) network visualization; (b) overlay visualization.

Figure 13b, the overlay visualization, adds a temporal dimension to the network analysis by showing the evolution of research trends over time. The map visually captures the evolving nature of this research area, with newer terms like optimization and wire arc additive manufacturing emerging more recently.

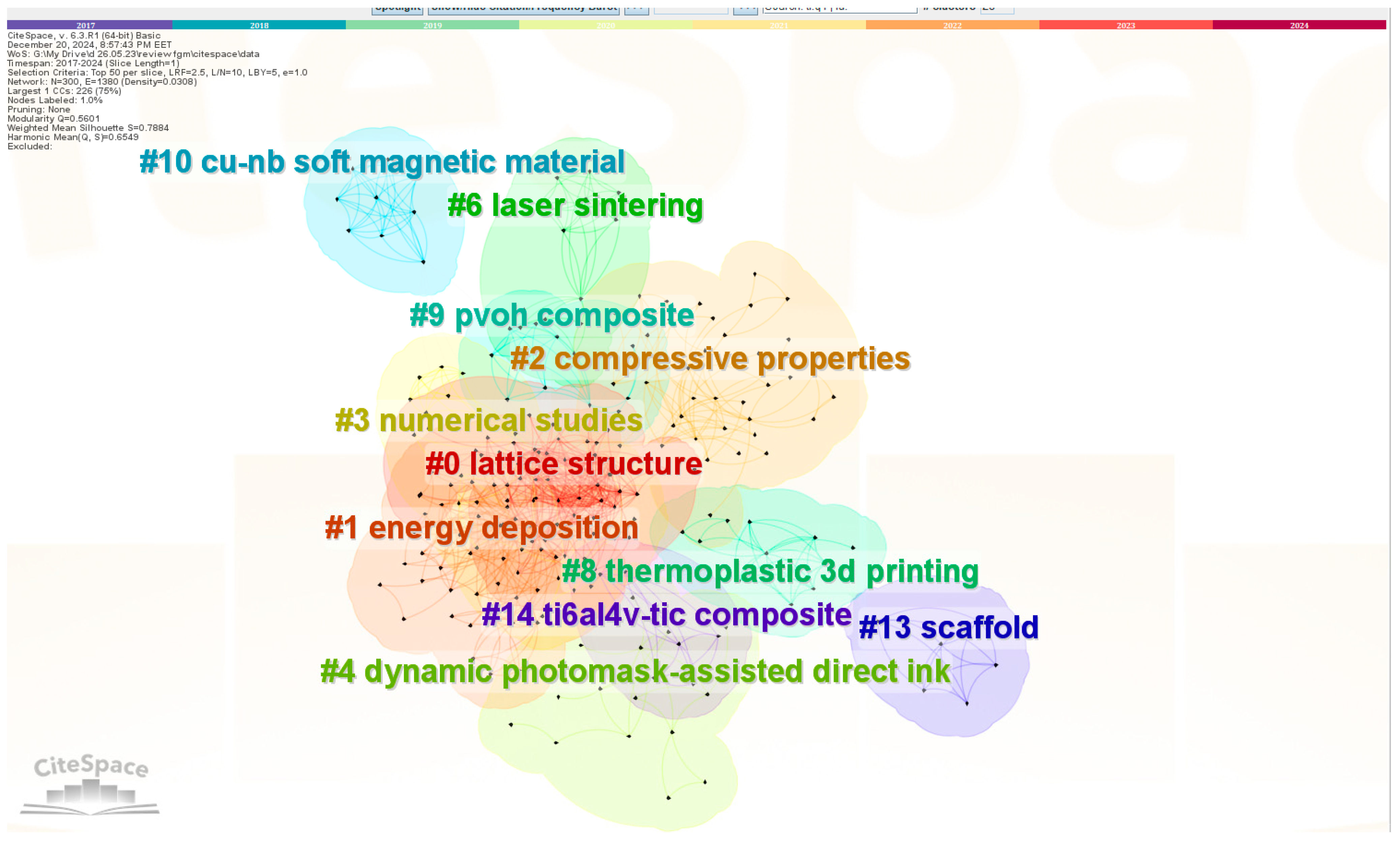

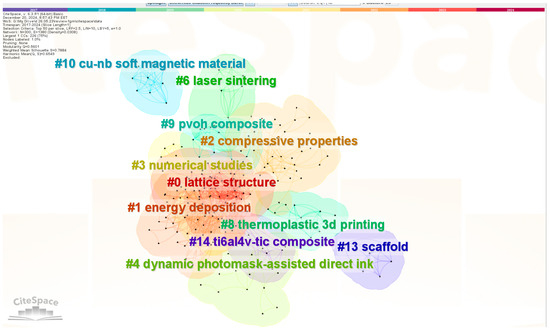

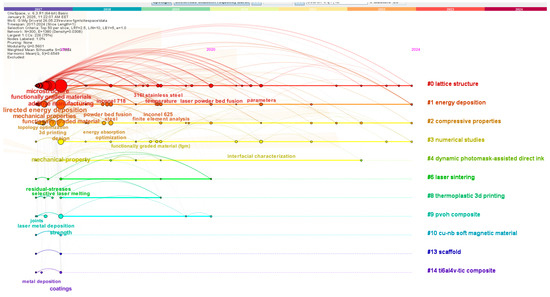

4.3.2. Keyword Clustering Analysis

Keyword Clustering Analysis (Figure 14) performed in CiteSpace groups related keywords based on their co-occurrence patterns, revealing major research themes and trends. By applying clustering algorithms, CiteSpace visualizes these keywords in a network, where each cluster represents a distinct research topic, to identify emerging themes, track their evolution, and understand the structure of the research field over time.

Figure 14.

Clustering visualization generated by CiteSpace.

The network consists of 11 clusters. The largest 11 clusters are summarized as presented in Table 5.

Table 5.

Summary of the largest 11 clusters.

The largest cluster (#0) has 49 members and a silhouette value of 0.666. It is labeled as lattice structure by LLR, additive manufacturing by LSI, and co-v alloy by MI.

The major citing article of the cluster is: Saboori, A (2017.0-JAN) ”An overview of additive manufacturing of titanium components by directed energy deposition: microstructure and mechanical properties”. Applied Sciences-Basel DOI 10.3390/app7090883 [166].

The most cited members in this cluster are additive manufacturing (367), functionally graded materials (226), and microstructure (174).

The second largest cluster (#1) has 47 members and a silhouette value of 0.697. It is labeled as energy deposition by LLR, additive manufacturing by LSI, and co-v alloy by MI.

The major citing article of the cluster is: Rodriguez, J (2019.0-JAN) Functionally graded ss 316l to ni-based structures produced by 3D plasma metal deposition. METALS DOI 10.3390/met9060620 [167].

The most cited members in this cluster are: 201 functionally graded materials, 70 mechanical properties, and 65 directed energy deposition.

The third largest cluster (#2) has 40 members and a silhouette value of 0.759. It is labeled as compressive properties by LLR, additive manufacturing by LSI, and stiffness-tailored interface by MI.

The major citing article of the cluster is: Teimouri, M (2021.0-JAN) ”Mechanical performance of additively manufactured uniform and graded porous structures based on topology-optimized unit cells”. Proceedings of the Institution of Mechanical Engineers Part C-Journal of Mechanical Engineering Science, V235, P26 DOI 10.1177/0954406220947119 [168].

The most cited members in this cluster are: 126 design, 85 3D printing, and 46 optimization.

The 4th largest cluster (#3) has 20 members and a silhouette value of 0.876. It is labeled as numerical studies by LLR, additive manufacturing by LSI, and er70s-6 low carbon steel component by MI.

The major citing article of the cluster is: Bourell, D (2017.0-JAN) ”Materials for additive manufacturing”. CIRP ANNALS-MANUFACTURING TECHNOLOGY, V66, P23 DOI 10.1016/j.cirp.2017.05.009 [169].

The most cited members in this cluster are: 78 mechanical-property, 19 interfacial characterization, and 14 models.

The 5th largest cluster (#4) has 15 members and a silhouette value of 0.88. It is labeled as dynamic photomask-assisted direct ink by LLR, multilevel triboelectric nanogenerator by LSI, and additive manufacturing by MI.

The major citing article of the cluster is: Chen, K (2019.0-JAN) ”Dynamic photomask-assisted direct ink writing multimaterial for multilevel triboelectric nanogenerator”. ADVANCED FUNCTIONAL MATERIALS DOI 10.1002/adfm.201903568 [170].

The most cited members in this cluster are: eight 3D printing, four fused deposition modeling, and three multi-material 3D printing.

The 6th largest cluster (#6) has 13 members and a silhouette value of 0.91. It is labeled as laser sintering by LLR, additive manufacturing by LSI, and additive manufacturing by MI.

The major citing article of the cluster is: Novakov, T (2017.0-JAN) ”Laser sintering of metallic medical materials-a review”. International Journal of Advanced Manufacturing Technology, V93, P30 DOI 10.1007/s00170-017-0705-3 [171].

The most cited members in this cluster are: 11 selective laser melting, 6 residual stresses, and 3 multiple materials.

The 7th largest cluster (#8) has 11 members and a silhouette value of 0.969. It is labeled as thermoplastic 3D printing by LLR, graded material by LSI, and additive manufacturing by MI.

The major citing article of the cluster is: Scheithauer, U (2017.0-JAN) ”Ceramic-based 4d components: additive manufacturing (am) of ceramic-based functionally graded materials (fgm) by thermoplastic 3D printing (t3dp)”. Materials DOI 10.3390/ma10121368 [172].

The most cited members in this cluster are: seven processing parameters, five stereolithography, and three functionally graded materials (FGM).

The 8th largest cluster (#9) has 10 members and a silhouette value of 0.833. It is labeled as pvoh composite by LLR, additive manufacturing by LSI, and additive manufacturing (0.11) by MI.

The major citing article of the cluster is: Li, W (2017.0-JAN) ”Fabrication and characterization of a functionally graded material from ti-6al-4v to ss316 by laser metal deposition”. ADDITIVE MANUFACTURING, V14, P10 DOI 10.1016/j.addma.2016.12.006 [146].

The most cited members in this cluster are: 41 strength, 17 laser metal deposition, and 4 modulus.

4.3.3. Citation Counts

As presented in Table 6, the top-ranked item by citation counts is additive manufacturing in Cluster #0, with citation counts of 367. The second one is functionally graded materials in Cluster #0, with citation counts of 226. The third is functionally graded material in Cluster #1, with citation counts of 201. The fourth is microstructure in Cluster #0, with citation counts of 174. The fifth is a mechanical property in Cluster #0, with citation counts of 173. The sixth is fabrication in Cluster #0, with citation counts of 156. The seventh is behavior in Cluster #0, with citation counts of 139. The eighth is design in Cluster #2, with citation counts of 126. The ninth is 3D printing in Cluster #2, with citation counts of 85. The tenth is a mechanical property in Cluster #3, with citation counts of 78.

Table 6.

Citation counts of keywords.

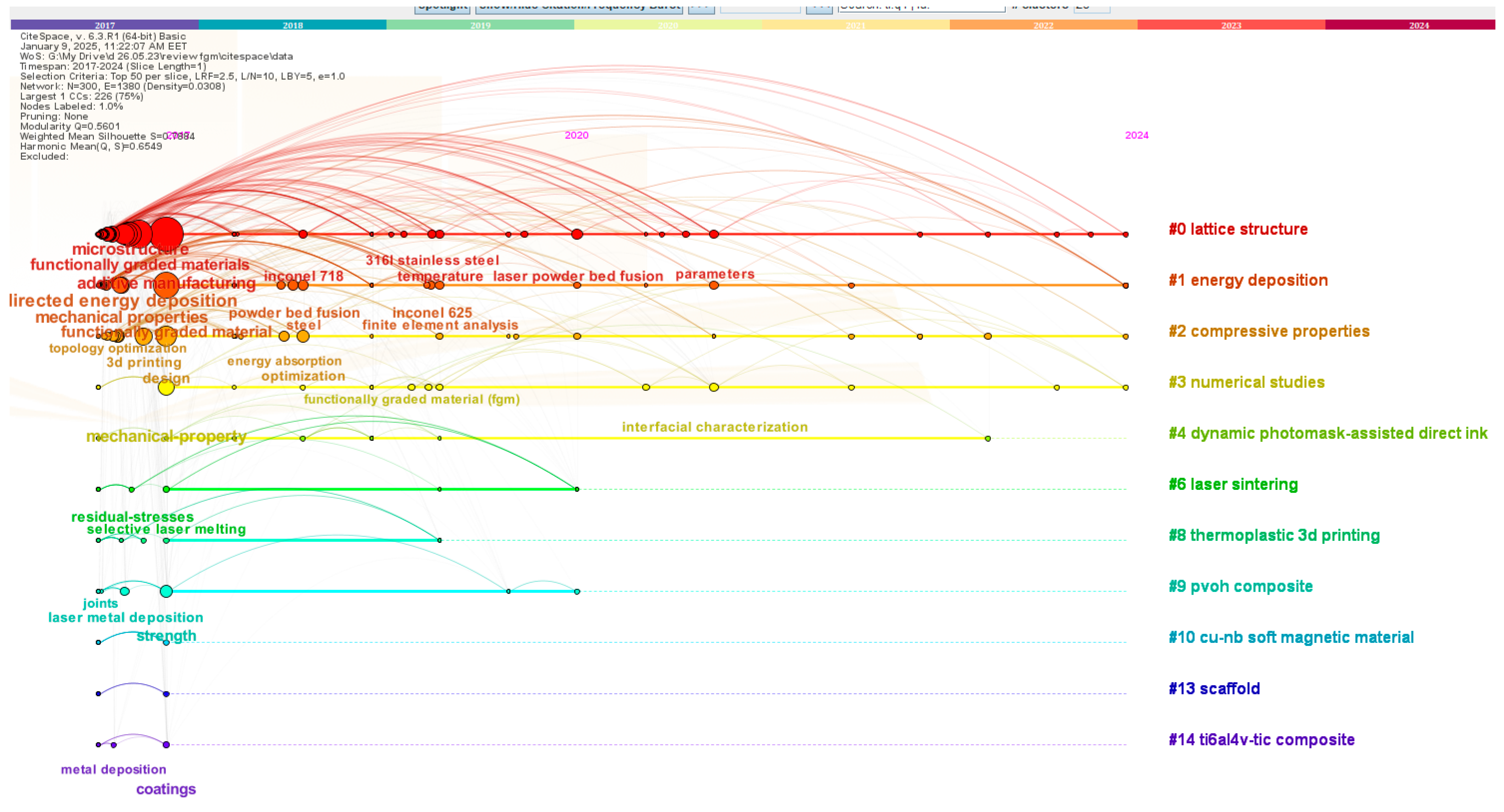

4.3.4. Timeline of Keywords

Figure 15 presents a timeline visualization created from the co-occurrence network of authors’ keywords, generated using CiteSpace.

Figure 15.

The timeline visualization of author keywords, based on CiteSpace (2017–2024).

The timeline visualization indicates initially, the timeline is dominated by foundational topics such as “mechanical property”, “residual stresses”, and “metal deposition”. These early studies laid the groundwork for understanding material behavior and the fundamental processes involved in additive manufacturing. As time progressed, new themes began to emerge, marked by keywords such as “directed energy deposition” and “energy absorption optimization.” These topics indicate a shift toward improving process efficiency and exploring specific functional applications. During this period, the research field started to diversify, focusing not only on the technical aspects of manufacturing but also on optimizing the performance of fabricated structures. Toward the more recent years of the timeline, the focus shifts even further, as evidenced by the appearance of keywords like “lattice structure”, “thermoplastic 3D printing”, and “scaffold.” These terms reflect the cutting-edge advancements in additive manufacturing, including the integration of innovative designs, new materials, and biomedical applications.

The links between the keywords provide additional insights into the interconnectedness of research themes. Early on, the links are fewer and stronger, reflecting isolated studies that focused on core principles. However, as the field expanded, the connections became more complex, bridging diverse topics and promoting interdisciplinary approaches. For example, strong links between clusters such as “#0 lattice structure” and “#1 energy deposition” highlight how advancements in design (e.g., lattice structures) are closely tied to process optimization (e.g., energy deposition techniques).

The size of the nodes further underscores the significance of certain research topics. Larger nodes represent keywords with higher co-occurrence, indicating their importance within the research landscape. For instance, terms such as “additive manufacturing” and “functionally graded materials are essential, as they serve as focal points around which other topics revolve. Over time, these central nodes have grown larger, signifying the increasing attention and relevance of these themes in the literature. In contrast, smaller nodes often represent niche or specialized research areas that, while significant, are more narrowly focused.

4.3.5. Keywords Burst Analysis

Keyword burst analysis was conducted to identify keywords that experience a sudden increase in usage over a specific period, indicating a surge in interest or relevance within a research field. This analysis highlights emerging trends, shifts in focus, or the impact of novel concepts.

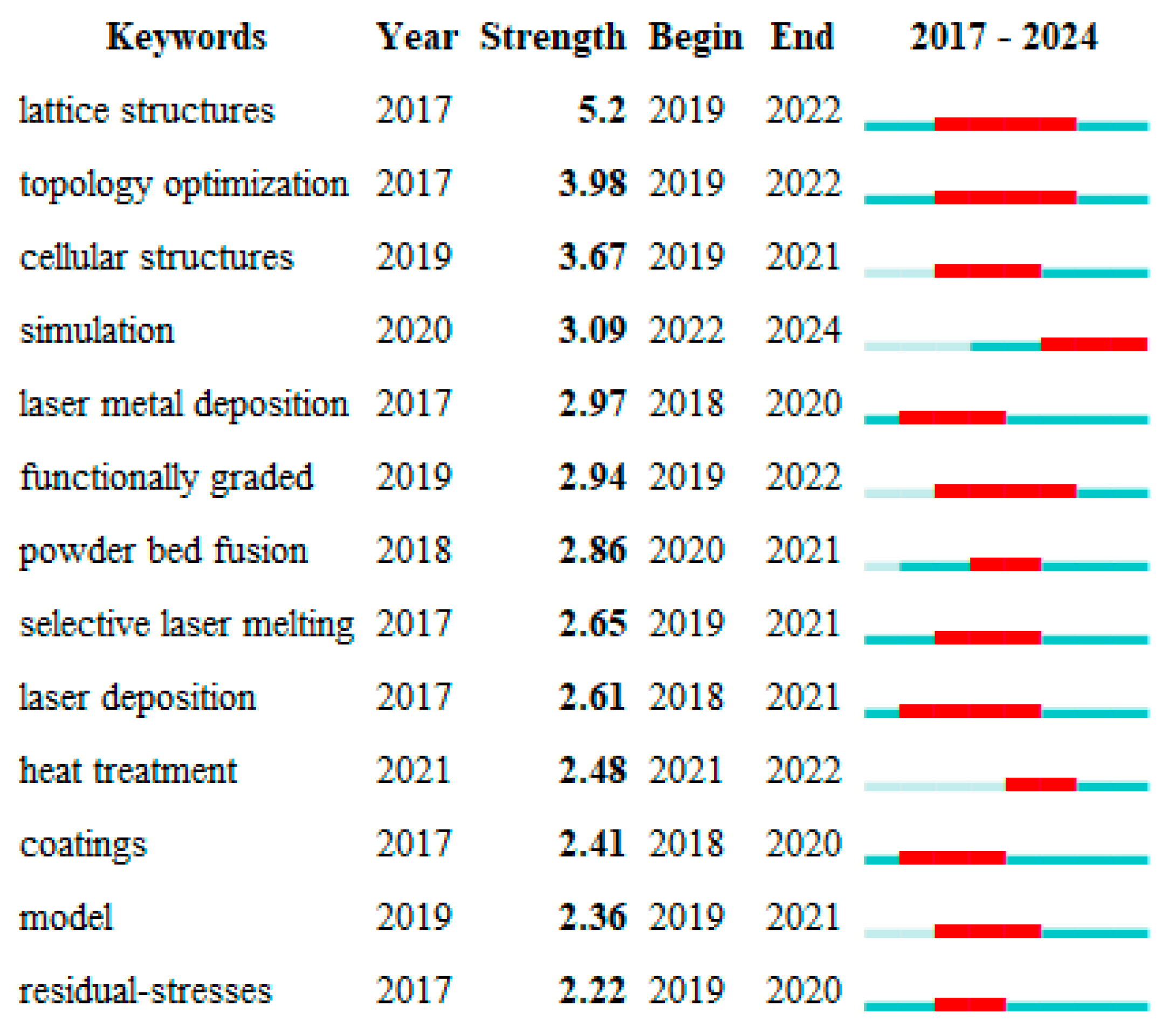

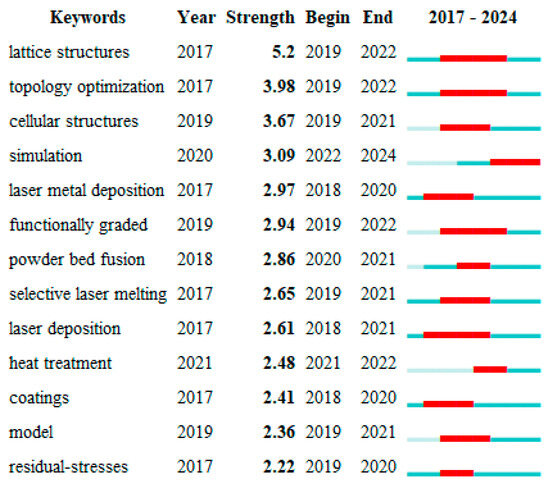

Figure 16 shows the top 13 keywords with the strongest bursts.

Figure 16.

Top 13 keywords with the strongest citation burst.

The top-ranked item by bursts (Table 7) is lattice structures in Cluster #2, with bursts of 5.20. The second one is topology optimization in Cluster #2, with bursts of 3.98. The third is cellular structures in Cluster #2, with bursts of 3.67. The fourth is a simulation in Cluster #1, with bursts of 3.09. The fifth is laser metal deposition in Cluster #9, with bursts of 2.97. The sixth is functionally graded in Cluster #1, with bursts of 2.94. The seventh is powder bed fusion in Cluster #1, with bursts of 2.86. The eighth is selective laser melting in Cluster #6, with bursts of 2.65. The ninth is laser deposition in Cluster #1, with bursts of 2.61. The tenth is a heat treatment in Cluster #0, with bursts of 2.48.

Table 7.

Top-ranked keywords by bursts.

Analyzing Figure 16 it can be noticed that the keyword lattice structures had the strongest citation burst, with a strength of 5.2, beginning in 2019 and continuing until 2022. This indicates a substantial surge of interest and relevance in the research community during this period. Similarly, topology optimization showed a strong citation burst (3.98), also starting in 2019 and lasting through 2022, demonstrating its growing importance in advanced manufacturing and design processes.

Keywords like cellular structures and simulation further underscore the emphasis on innovation in materials and modeling. Cellular structures experienced a burst strength of 3.67 from 2019 to 2021, while simulation emerged with a strength of 3.09, starting in 2020 and projected to remain in focus through 2024.

Research related to laser metal deposition, which has applications in additive manufacturing, saw a consistent burst of interest from 2018 to 2020, with a strength of 2.97. This aligns with the trends observed for functionally graded materials (2019–2022) and powder bed fusion (2020–2021), both of which reflect advancements in additive manufacturing and material design.

Other notable keywords include selective laser melting and laser deposition, which both saw increased attention during overlapping periods (2019–2021 and 2018–2021, respectively), further emphasizing the industry’s focus on precision manufacturing techniques. Additionally, heat treatment and coatings highlight research in material performance and durability, with citation bursts occurring between 2018 and 2021.

Finally, keywords like model (2019–2021) and residual stresses (2019–2020) point to continued interest in theoretical and applied research addressing structural integrity and simulation-based analysis.

4.4. Main Key Findings

To provide a clear and concise overview of the bibliometric analysis, this section summarizes the main findings regarding global research contributions, institutional impact, and emerging research trends. Table 8 presents the most influential countries, institutions, journals, and research topics identified in the analysis.

Table 8.

Summary of Key Bibliometric Findings.

The steady increase in publications since 2016, with a peak in 2021, directly aligns with major breakthroughs in AM processes. Technologies such as selective laser melting (SLM), directed energy deposition (DED), and electron beam melting (EBM) have revolutionized the fabrication of FGMs by enabling precise control over material composition gradients. This has led to significant enhancements in mechanical properties, including improved tensile strength, wear resistance, and elasticity, as well as reduced residual stresses. The bibliometric analysis also highlights the dominant role of the USA and China in advancing FGM research. These countries contribute 27% and 23% of global publications, respectively, underscoring their investment in AM technologies and material innovations. Leading institutions, such as the Chinese Academy of Sciences and the U.S. Department of Energy, are driving research on multi-material integration, computational modeling, and process optimization to further refine FGM properties.

The keyword analysis and clustering results provide further insights into how the research focus has shifted from fundamental studies to application-driven engineering challenges. For instance, terms such as “residual stresses”, “interfacial bonding”, and “mechanical properties” frequently appear, indicating that researchers are actively addressing issues related to structural integrity and long-term performance. Additionally, the increasing prominence of “topology optimization” and “microstructural evolution” suggests a growing emphasis on designing FGMs with optimized material distribution for aerospace, biomedical, and automotive applications. This shift reflects the industry’s need for functionally graded components that balance lightweight structures with enhanced mechanical performance.

From a technical perspective, these research trends have significant implications. The rise in studies focusing on residual stress management and interfacial bonding correlates with the development of post-processing techniques such as heat treatments, laser remelting, and surface coatings to enhance the durability of FGMs.

Beyond material performance, bibliometric findings also highlight key areas requiring further engineering advancements. For example, the rapid growth of research on AM-fabricated FGMs underscores the need for standardized testing protocols and certification frameworks to ensure consistency in mechanical properties across different fabrication methods. Additionally, the increasing occurrence of terms related to sustainability, such as “eco-friendly materials” and “energy efficiency”, suggests a growing emphasis on reducing material waste and energy consumption during FGM production. AM-based FGMs align with these sustainability goals by enabling near-net-shape fabrication, minimizing raw material usage, and improving recyclability.

Another critical insight from the bibliometric data is the increasing integration of computational modeling in FGM research. The frequent co-occurrence of terms such as “finite element analysis” and “multi-material optimization” indicates that numerical simulations are becoming essential for predicting the behavior of FGMs under different loading conditions. This computational approach accelerates the industrial adoption of FGMs by enabling precise control over gradient transitions and mechanical responses, reducing the need for extensive physical testing.

By correlating bibliometric data with engineering advancements, it was demonstrated that the observed research trends reflect not only scientific progress but also industry-driven challenges and priorities. This deeper analysis adds value beyond statistical representation by identifying key areas where further research and technological improvements are needed.

5. Conclusions

This review provides a comprehensive bibliometric and content analysis of FGMs manufactured using AM techniques, with a particular focus on their mechanical properties and industrial applications. The bibliometric analysis highlights a significant increase in research interest since 2016, peaking in 2021, driven by advancements in AM technologies such as SLM and DED. These developments have enabled the precise fabrication of FGMs with tailored mechanical properties, addressing key engineering challenges such as wear resistance, tensile strength optimization, and residual stress management. The dominance of research contributions from the USA and China underscores the global significance of FGMs and their growing role in high-performance applications.

Beyond statistical representation, this review reveals key trends shaping the current and future landscape of FGMs. The transition from fundamental research to application-driven studies indicates a shift toward solving practical challenges in FGM fabrication and implementation. Keyword analysis and clustering results point to emerging themes, including topology optimization, microstructural control, and interfacial bonding enhancement, all of which are important for improving the reliability and performance of graded materials. Moreover, the increasing integration of computational modeling and simulation techniques, such as finite element analysis, highlights the role of digital tools in optimizing gradient design and predicting mechanical behavior under various loading conditions.

From an application perspective, FGMs are being increasingly adopted across diverse industries, with aerospace benefiting from their high-temperature resistance, biomedical engineering leveraging bio-inspired material gradients for implants, and the automotive sector utilizing them for enhanced thermal stability in engine components. However, challenges remain, particularly regarding the standardization of testing methods, the need for cost-effective manufacturing processes, and the environmental impact of FGM production.

To further advance FGM research and applications, future studies should focus on refining AM techniques to improve material homogeneity and interfacial bonding, developing sustainable and recyclable FGM feedstocks to align with global environmental goals, and establishing standardized testing protocols to ensure consistency across different manufacturing methods. Additionally, interdisciplinary collaboration between materials science, mechanical engineering, and computational modeling will be essential for pushing the boundaries of FGM performance and expanding their applicability in next-generation technologies.

By synthesizing bibliometric trends with technical advancements, this review provides a comprehensive understanding of the evolution, challenges, and future prospects of FGMs.

It is important to note that this study primarily analyzes research indexed in Web of Science and considers publications until 2024. Consequently, some studies from other databases or those that do not explicitly use keywords related to FGMs in their titles, abstracts, or keywords may not have been included, potentially introducing bias into the analysis. Another limitation of this study is that the search query did not include the terms ’functionally gradient materials’ and ’functional gradient materials’, which may have resulted in a slightly lower number of retrieved publications. Future studies could incorporate these variations to provide a more comprehensive bibliometric analysis. Nevertheless, this review provides valuable insights into the progress, challenges, and future directions for FGMs, setting the stage for further innovation and adoption of these advanced materials in diverse industries.

Author Contributions

Conceptualization, C.V. and M.T.; methodology, C.V.; software, M.T.; validation, M.T.; formal analysis, M.T.; investigation, C.V. and M.T.; resources, C.V.; data curation, M.T.; writing—original draft preparation, C.V. and M.T.; writing—review and editing, C.V. and M.T.; visualization, M.T.; supervision, C.V.; project administration, M.T.; funding acquisition, C.V. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by George Emil Palade University of Medicine, Pharmacy, Science, and Technology of Targu Mures, research grant number 4175/25.04.2024.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Bhavar, V.; Kattire, P.; Thakare, S.; Patil, S.; Singh, R. A Review on Functionally Gradient Materials (FGMs) and Their Applications. IOP Conf. Ser. Mater. Sci. Eng. 2017, 229, 012021. [Google Scholar] [CrossRef]

- Ali, E.; Althoey, F. Numerical Investigation on Blast Response of Cold-Formed Steel Framing Protected with Functionally Graded Composite Material. Buildings 2022, 12, 118. [Google Scholar] [CrossRef]

- Althoey, F.; Ali, E. A Simplified Stress Analysis of Functionally Graded Beams and Influence of Material Function on Deflection. Appl. Sci. 2021, 11, 11747. [Google Scholar] [CrossRef]

- Zhao, J.; Ai, X.; Deng, J.; Wang, J. Thermal Shock Behaviors of Functionally Graded Ceramic Tool Materials. J. Eur. Ceram. Soc. 2004, 24, 847–854. [Google Scholar] [CrossRef]

- Abubakar, A.A.; Akhtar, S.S.; Alotaibi, A.D.; Al-Athel, K.S.; Hakeem, A.S.; Adesina, A.Y. Development and Analysis of Functionally-Graded SiAlON Composites with Computationally Designed Properties for Cutting Inserts. J. Mater. Res. Technol. 2023, 23, 5861–5879. [Google Scholar] [CrossRef]

- Naik, A.K.; Nazeer, M.; Prasad, D.K.V.D.; Laha, T.; Roy, S. Development of Functionally Graded ZrB2–B4C Composites for Lightweight Ultrahigh-Temperature Aerospace Applications. Ceram. Int. 2022, 48, 33332–33339. [Google Scholar] [CrossRef]

- Williams, J.C.; Boyer, R.R. Opportunities and Issues in the Application of Titanium Alloys for Aerospace Components. Metals 2020, 10, 705. [Google Scholar] [CrossRef]

- Hohe, J.; Hardenacke, V.; Fascio, V.; Girard, Y.; Baumeister, J.; Stöbener, K.; Weise, J.; Lehmhus, D.; Pattofatto, S.; Zeng, H.; et al. Numerical and Experimental Design of Graded Cellular Sandwich Cores for Multi-Functional Aerospace Applications. Mater. Des. 2012, 39, 20–32. [Google Scholar] [CrossRef]

- Basheer, A.A. Advances in the Smart Materials Applications in the Aerospace Industries. Aircr. Eng. Aerosp. Technol. 2020, 92, 1027–1035. [Google Scholar] [CrossRef]

- Rouf, S.; Malik, A.; Raina, A.; Irfan Ul Haq, M.; Naveed, N.; Zolfagharian, A.; Bodaghi, M. Functionally Graded Additive Manufacturing for Orthopedic Applications. J. Orthop. 2022, 33, 70–80. [Google Scholar] [CrossRef]

- Watanabe, Y.; Iwasa, Y.; Sato, H.; Teramoto, A.; Abe, K. Fabrication of Titanium/Biodegradable-Polymer FGM for Medical Application. MSF 2009, 631–632, 199–204. [Google Scholar] [CrossRef]

- Shi, H.; Zhou, P.; Li, J.; Liu, C.; Wang, L. Functional Gradient Metallic Biomaterials: Techniques, Current Scenery, and Future Prospects in the Biomedical Field. Front. Bioeng. Biotechnol. 2021, 8, 616845. [Google Scholar] [CrossRef] [PubMed]

- Watari, F.; Omori, M.; Hirai, T.; Yokoyama, A.; Matsuno, H.; Uo, M.; Miyako, R.; Tamura, Y.; Kawasaki, T. Fabrication and Properties of FGM for Biomedical Application. J. Jpn. Soc. Powder Powder Metall. 2000, 47, 1226–1233. [Google Scholar] [CrossRef]

- Pompe, W.; Worch, H.; Epple, M.; Friess, W.; Gelinsky, M.; Greil, P.; Hempel, U.; Scharnweber, D.; Schulte, K. Functionally Graded Materials for Biomedical Applications. Mater. Sci. Eng. A 2003, 362, 40–60. [Google Scholar] [CrossRef]

- Parthasarathy, J.; Starly, B.; Raman, S. A Design for the Additive Manufacture of Functionally Graded Porous Structures with Tailored Mechanical Properties for Biomedical Applications. J. Manuf. Process. 2011, 13, 160–170. [Google Scholar] [CrossRef]

- Petit, C.; Montanaro, L.; Palmero, P. Functionally Graded Ceramics for Biomedical Application: Concept, Manufacturing, and Properties. Int. J. Appl. Ceram. Technol. 2018, 15, 820–840. [Google Scholar] [CrossRef]

- Ram, S.C.; Chattopadhyay, K.; Chakrabarty, I. High Temperature Tensile Properties of Centrifugally Cast In-Situ Al-Mg2Si Functionally Graded Composites for Automotive Cylinder Block Liners. J. Alloys Compd. 2017, 724, 84–97. [Google Scholar] [CrossRef]

- Jojith, R.; Radhika, N. Fabrication of LM 25/WC Functionally Graded Composite for Automotive Applications and Investigation of Its Mechanical and Wear Properties. J. Braz. Soc. Mech. Sci. Eng. 2018, 40, 292. [Google Scholar] [CrossRef]

- Tošić, G.; Bogdanović, G.; Čukanović, D.; Radaković, A. Functionally Graded Materials in Transport Vehicles—Overview, Fabrication, Application, Modelling. IOP Conf. Ser. Mater. Sci. Eng. 2022, 1271, 012014. [Google Scholar] [CrossRef]

- Saleh, B.I.; Ahmed, M.H. Development of Functionally Graded Tubes Based on Pure Al/Al2O3 Metal Matrix Composites Manufactured by Centrifugal Casting for Automotive Applications. Met. Mater. Int. 2020, 26, 1430–1440. [Google Scholar] [CrossRef]

- Arsha, A.G.; Jayakumar, E.; Rajan, T.P.D.; Antony, V.; Pai, B.C. Design and Fabrication of Functionally Graded In-Situ Aluminium Composites for Automotive Pistons. Mater. Des. 2015, 88, 1201–1209. [Google Scholar] [CrossRef]

- Mallick, A.; Gangi Setti, S.; Sahu, R.K. Centrifugally Cast Functionally Graded Materials: Fabrication and Challenges for Probable Automotive Cylinder Liner Application. Ceram. Int. 2023, 49, 8649–8682. [Google Scholar] [CrossRef]

- Ali, E.; Woldeyes, K.; Urgessa, G. Fire Performance of Functionally-Graded-Material Sheathed Load Bearing Thin-Walled Structural Framing. Fire Saf. J. 2021, 125, 103425. [Google Scholar] [CrossRef]

- Alkunte, S.; Fidan, I.; Naikwadi, V.; Gudavasov, S.; Ali, M.A.; Mahmudov, M.; Hasanov, S.; Cheepu, M. Advancements and Challenges in Additively Manufactured Functionally Graded Materials: A Comprehensive Review. J. Manuf. Mater. Process. 2024, 8, 23. [Google Scholar] [CrossRef]

- Li, Y.; Feng, Z.; Hao, L.; Huang, L.; Xin, C.; Wang, Y.; Bilotti, E.; Essa, K.; Zhang, H.; Li, Z.; et al. A Review on Functionally Graded Materials and Structures via Additive Manufacturing: From Multi-Scale Design to Versatile Functional Properties. Adv. Mater. Technol. 2020, 5, 1900981. [Google Scholar] [CrossRef]

- El-Galy, I.M.; Saleh, B.I.; Ahmed, M.H. Functionally Graded Materials Classifications and Development Trends from Industrial Point of View. SN Appl. Sci. 2019, 1, 1378. [Google Scholar] [CrossRef]

- Mitra, S.; Rahman, M.H.; Motalab, M.; Rakib, T.; Bose, P. Investigation on the Mechanical Properties of Functionally Graded Nickel and Aluminium Alloy by Molecular Dynamics Study. arXiv 2020, arXiv:2004.05651. [Google Scholar]

- Ait Ferhat, Y.; Chorfi, H.; Abacha, I.; Benchikh, L.; Kebaili, M.; Blaoui, M.M.; Boulenouar, A. Evaluation of Stress Intensity Factors in Functionally Graded Plate under Mechanical and Thermal Loadings. Int. J. Interact. Des. Manuf. 2023, 17, 2745–2753. [Google Scholar] [CrossRef]

- Tian, J.; Jing, G.; Han, X.; Hu, G.; Huo, S. Understanding the Thermal Problem of Variable Gradient Functionally Graded Plate Based on Hybrid Numerical Method under Linear Heat Source. Adv. Mech. Eng. 2021, 13, 16878140211017810. [Google Scholar] [CrossRef]

- Han, D.; Fan, H.; Yan, C.; Wang, T.; Yang, Y.; Ali, S.; Wang, G. Heat Conduction and Cracking of Functionally Graded Materials Using an FDEM-Based Thermo-Mechanical Coupling Model. Appl. Sci. 2022, 12, 12279. [Google Scholar] [CrossRef]

- Inala, R. Influence of Hygrothermal Environment and FG Material on Natural Frequency and Parametric Instability of Plates. Mech. Adv. Compos. Struct. 2019, 7, 89–101. [Google Scholar] [CrossRef]

- Zenkour, A.M. Hygro-Thermo-Mechanical Effects on FGM Plates Resting on Elastic Foundations. Compos. Struct. 2010, 93, 234–238. [Google Scholar] [CrossRef]

- Shariyat, M.; Ghafourinam, M. Hygrothermomechanical Creep and Stress Redistribution Analysis of Thick-Walled FGM Spheres with Temperature and Moisture Dependent Material Properties and Inelastic Radius Changes. Int. J. Press. Vessel. Pip. 2019, 169, 94–114. [Google Scholar] [CrossRef]

- Pal, A.; Singh, A.K.; Lakshmi Vara Prasad, M.; Sahu, A. Hygro-Thermal Effect on Dynamic Response of Functionally Graded Plates. In Recent Developments in Structural Engineering, Volume 5; Goel, M.D., Biswas, R., Dhanvijay, S., Eds.; Lecture Notes in Civil Engineering; Springer Nature: Singapore, 2025; Volume 550, pp. 401–409. ISBN 978-981-9770-42-7. [Google Scholar]

- Parihar, R.S.; Setti, S.G.; Sahu, R.K. Recent Advances in the Manufacturing Processes of Functionally Graded Materials: A Review. Sci. Eng. Compos. Mater. 2018, 25, 309–336. [Google Scholar] [CrossRef]

- Kwon, H.; Cho, S.; Leparoux, M.; Kawasaki, A. Dual-Nanoparticulate-Reinforced Aluminum Matrix Composite Materials. Nanotechnology 2012, 23, 225704. [Google Scholar] [CrossRef]

- Kwon, H.; Leparoux, M.; Kawasaki, A. Functionally Graded Dual-Nanoparticulate-Reinforced Aluminium Matrix Bulk Materials Fabricated by Spark Plasma Sintering. J. Mater. Sci. Technol. 2014, 30, 736–742. [Google Scholar] [CrossRef]

- Gantayat, A.K.; Sutar, M.K.; Mohanty, J.R. Dynamic Characteristic of Graphene Reinforced Axial Functionally Graded Beam Using Finite Element Analysis. Mater. Today Proc. 2022, 62, 5923–5927. [Google Scholar] [CrossRef]

- Sasaki, M.; Hirai, T. Thermal Fatigue Resistance of CVD SiC/C Functionally Gradient Material. J. Eur. Ceram. Soc. 1994, 14, 257–260. [Google Scholar] [CrossRef]

- Seifried, S.; Winterer, M.; Hahn, H. Nanocrystalline Gradient Films through Chemical Vapor Synthesis. Scr. Mater. 2001, 44, 2165–2168. [Google Scholar] [CrossRef]

- Dobrzański, L.A.; Żukowska, L.W.; Mikuła, J.; Gołombek, K.; Pakuła, D.; Pancielejko, M. Structure and Mechanical Properties of Gradient PVD Coatings. J. Mater. Process. Technol. 2008, 201, 310–314. [Google Scholar] [CrossRef]

- Wang, X.; Chu, X.; Zhao, H.; Lu, S.; Fang, F.; Li, J.; Fang, X.; Wei, Z.; Wang, X.; Du, P.; et al. Controllable Growth of Functional Gradient ZnO Material Using Chemical Vapor Deposition. Integr. Ferroelectr. 2014, 151, 1–6. [Google Scholar] [CrossRef]

- Khor, K.A.; Gu, Y.W. Effects of Residual Stress on the Performance of Plasma Sprayed Functionally Graded ZrO2/NiCoCrAlY Coatings. Mater. Sci. Eng. A 2000, 277, 64–76. [Google Scholar] [CrossRef]

- Pakseresht, A.H.; Ghasali, E.; Nejati, M.; Shirvanimoghaddam, K.; Javadi, A.H.; Teimouri, R. Development Empirical-Intelligent Relationship between Plasma Spray Parameters and Coating Performance of Yttria-Stabilized Zirconia. Int. J. Adv. Manuf. Technol. 2015, 76, 1031–1045. [Google Scholar] [CrossRef]

- Pakseresht, A.H.; Javadi, A.H.; Nejati, M.; Shirvanimoghaddam, K.; Ghasali, E.; Teimouri, R. Statistical Analysis and Multiobjective Optimization of Process Parameters in Plasma Spraying of Partially Stabilized Zirconia. Int. J. Adv. Manuf. Technol. 2014, 75, 739–753. [Google Scholar] [CrossRef]

- Ivosevic, M.; Knight, R.; Kalidindi, S.R.; Palmese, G.R.; Sutter, J.K. Adhesive/Cohesive Properties of Thermally Sprayed Functionally Graded Coatings for Polymer Matrix Composites. J. Therm. Spray Technol. 2005, 14, 45–51. [Google Scholar] [CrossRef]

- Ma, J.; Tan, G.E.B. Processing and Characterization of Metal–Ceramics Functionally Gradient Materials. J. Mater. Process. Technol. 2001, 113, 446–449. [Google Scholar] [CrossRef]

- Rajasekhar, K.; Suresh Babu, V.; Davidson, M.J. Microstructural and Mechanical Properties of Al-Cu Functionally Graded Materials Fabricated by Powder Metallurgy Method. Mater. Today Proc. 2021, 41, 1156–1159. [Google Scholar] [CrossRef]

- Chouhan, M.; Thakur, L.; Kumar, P. Parametric Optimization and Impact Behaviour of AA7075/SiC FGM Fabricated by Hot Compaction Powder Metallurgy Process. Mater. Today Commun. 2024, 38, 107833. [Google Scholar] [CrossRef]

- Srinivas, P.N.S.; Ravindra, B.P.; Balakrishna, B. Microstructural, Mechanical and Tribological Characterization on the Al Based Functionally Graded Material Fabricated Powder Metallurgy. Mater. Res. Express 2020, 7, 026513. [Google Scholar] [CrossRef]

- Jin, G.; Takeuchi, M.; Honda, S.; Nishikawa, T.; Awaji, H. Properties of Multilayered Mullite/Mo Functionally Graded Materials Fabricated by Powder Metallurgy Processing. Mater. Chem. Phys. 2005, 89, 238–243. [Google Scholar] [CrossRef]

- Tokita, M. Development of Large-Size Ceramic/Metal Bulk FGM Fabricated by Spark Plasma Sintering. Mater. Sci. Forum 1999, 308–311, 83–88. [Google Scholar] [CrossRef]

- Qiao, Z.; Räthel, J.; Berger, L.-M.; Herrmann, M. Investigation of Binderless WC–TiC–Cr3C2 Hard Materials Prepared by Spark Plasma Sintering (SPS). Int. J. Refract. Met. Hard Mater. 2013, 38, 7–14. [Google Scholar] [CrossRef]