Design and Performance Analysis of a High-Temperature Forging Deformation Simulation Device for Dual Manipulators

Abstract

1. Introduction

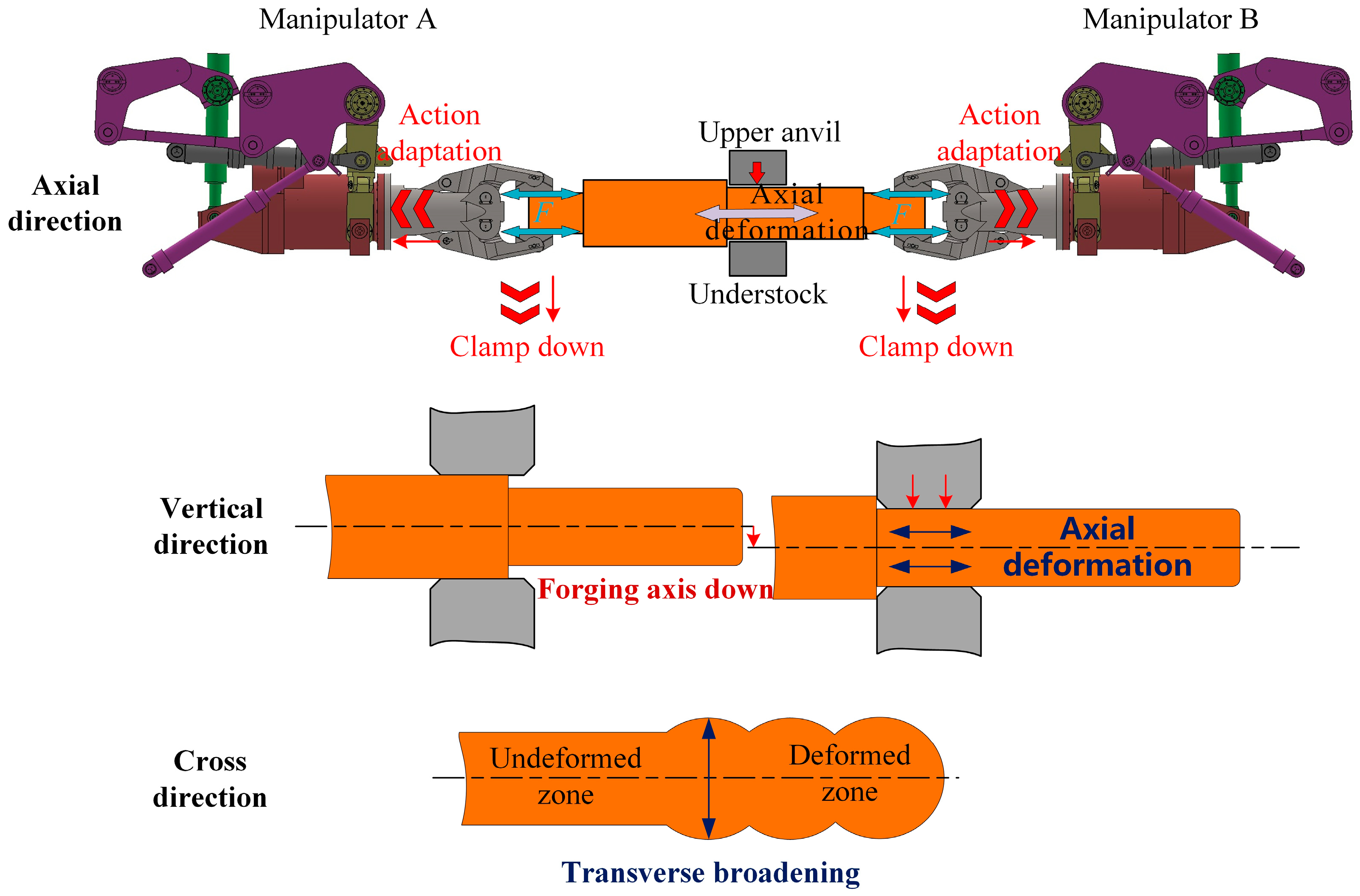

2. Analysis of Boundary Conditions in HTFDSD Design

2.1. Functional Requirements Analysis of HTFDSD

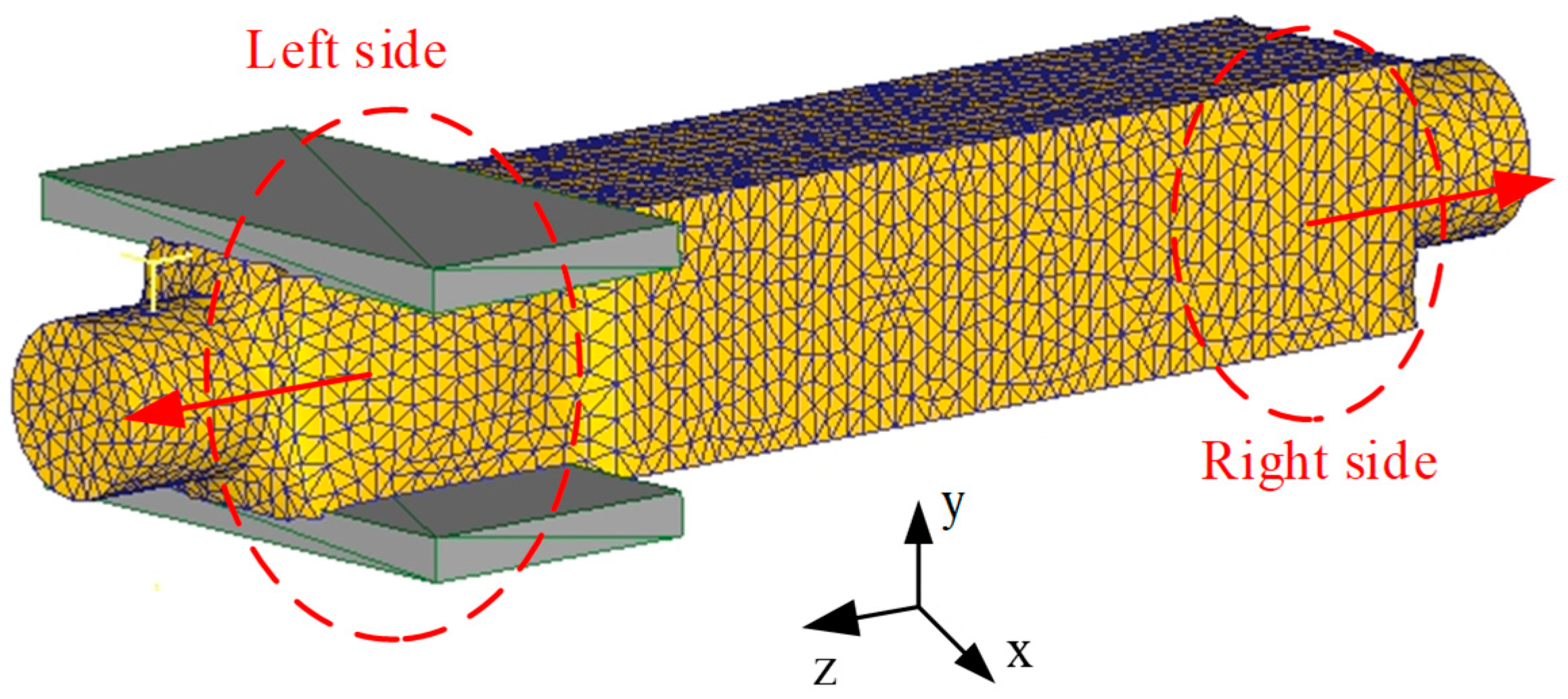

2.2. Influence of Various Factors on the Axial Deformation Behavior of Forgings

| Initial Forging Temperature | Blank Width Ratio | Forging Speed | Friction Factor | Reduction Ratio |

|---|---|---|---|---|

| 850 °C | 0.6 | 40 mm/s | 0.6 | 20% |

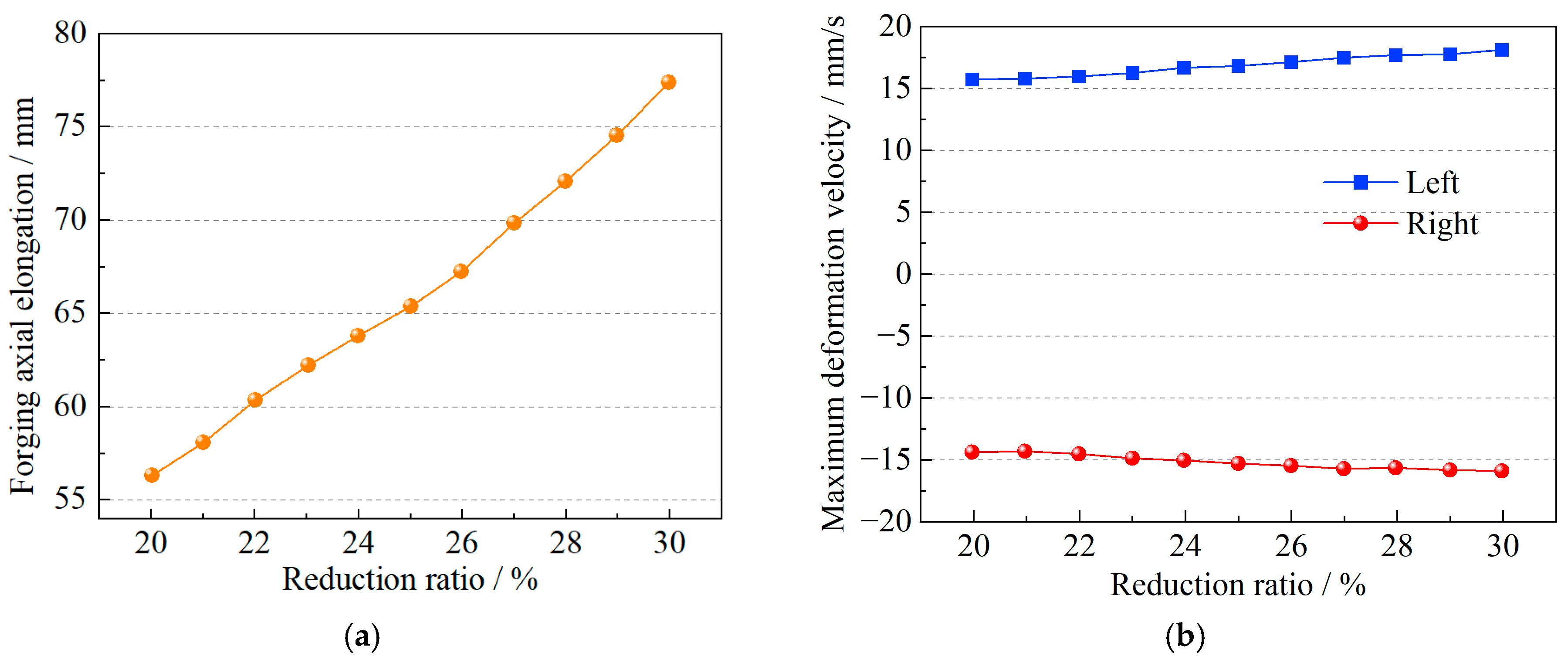

2.2.1. Effect of Reduction Ratio on the Axial Deformation of Forgings

2.2.2. Effect of Blank Width Ratio on the Axial Deformation of Forgings

2.2.3. Effect of Initial Forging Temperature on the Axial Deformation of Forgings

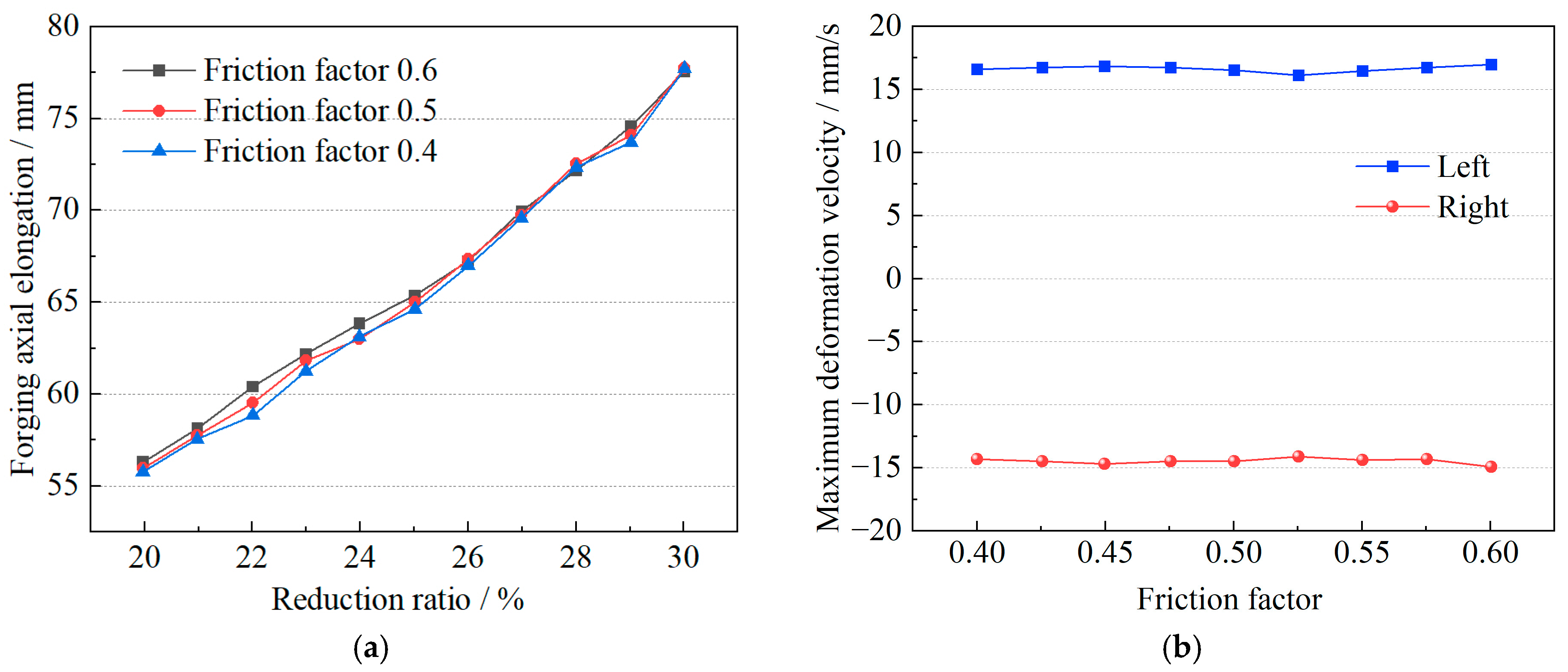

2.2.4. Effect of Friction Factor on the Axial Deformation of Forgings

2.2.5. Effect of Forging Speed on the Axial Deformation of Forgings

- The device must be capable of simulating deformation in both the axial and vertical directions of the forging.

- The deformation magnitude and velocity on both sides of the forging are similar, indicating symmetric deformation. Therefore, during axial deformation simulation, the device should ensure synchronized and symmetric motion on both sides.

- The device must incorporate force feedback functionality to support coordinated control of dual manipulators in future applications.

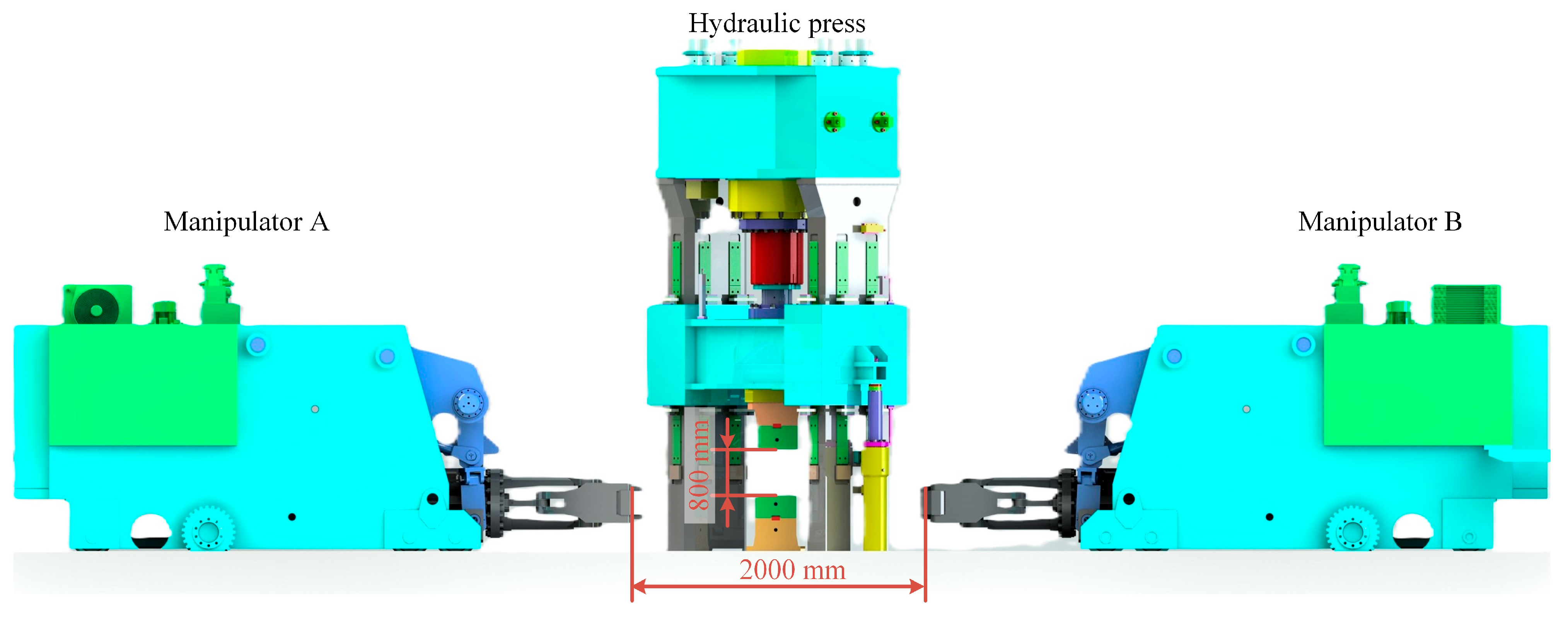

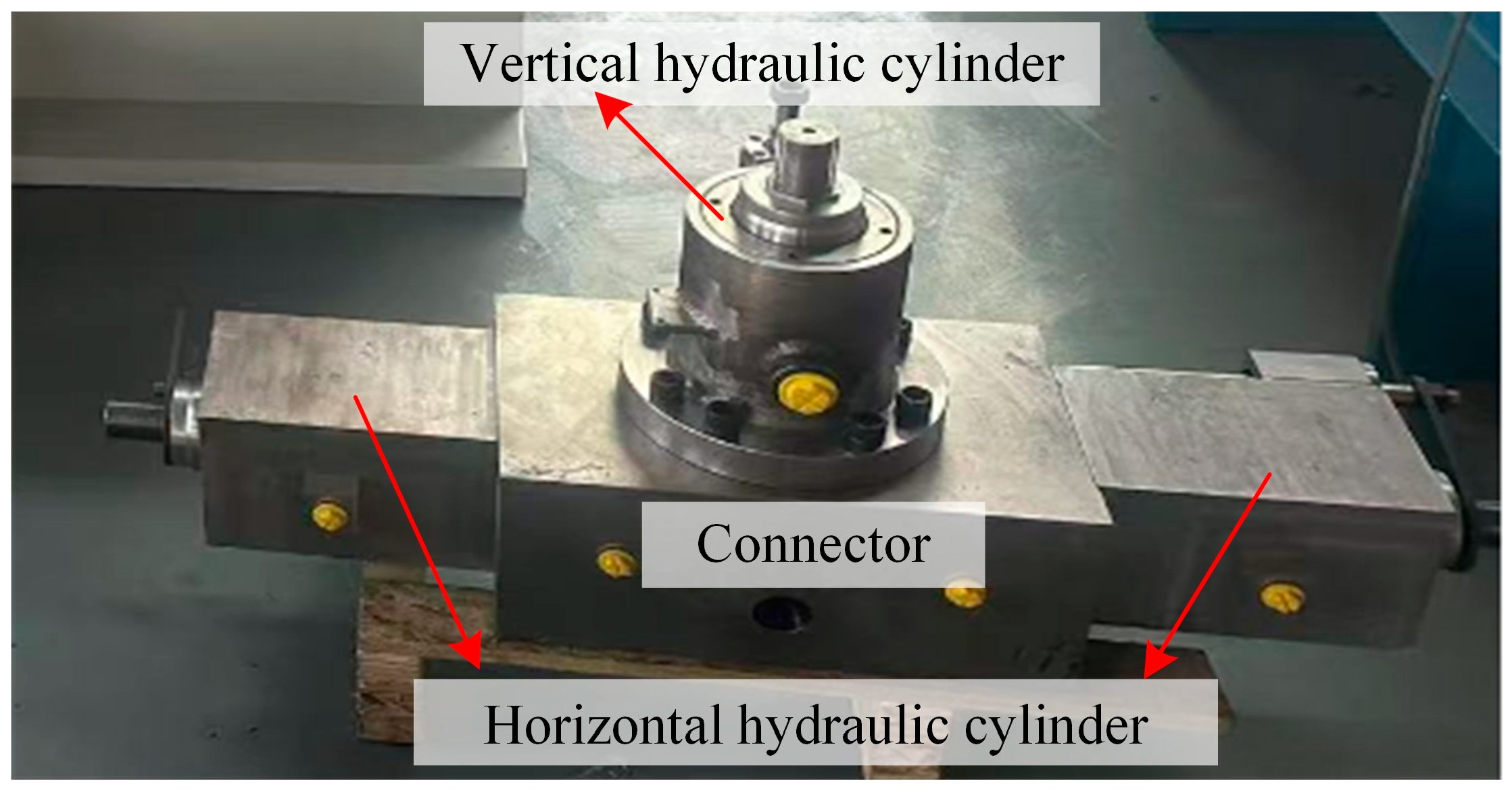

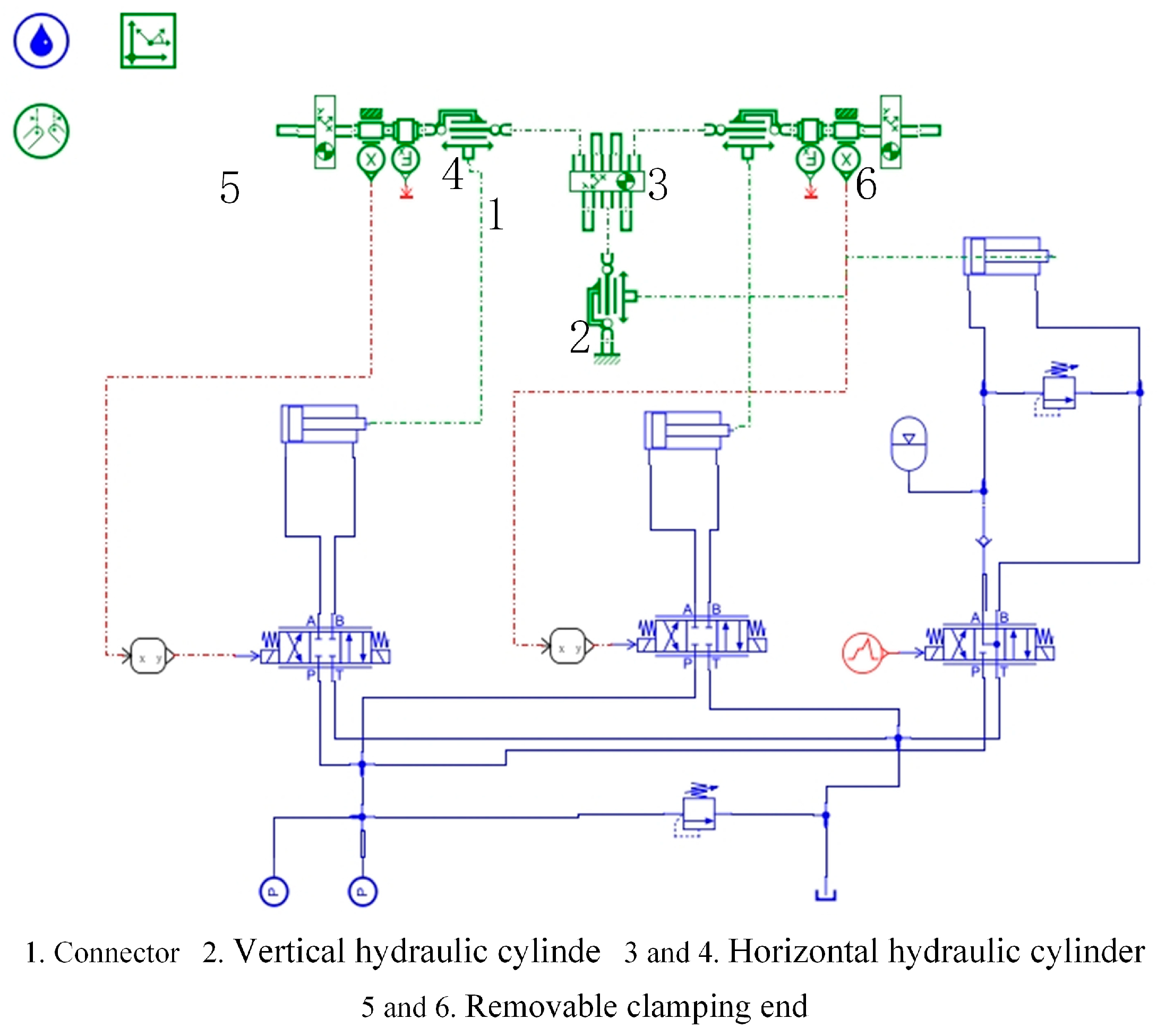

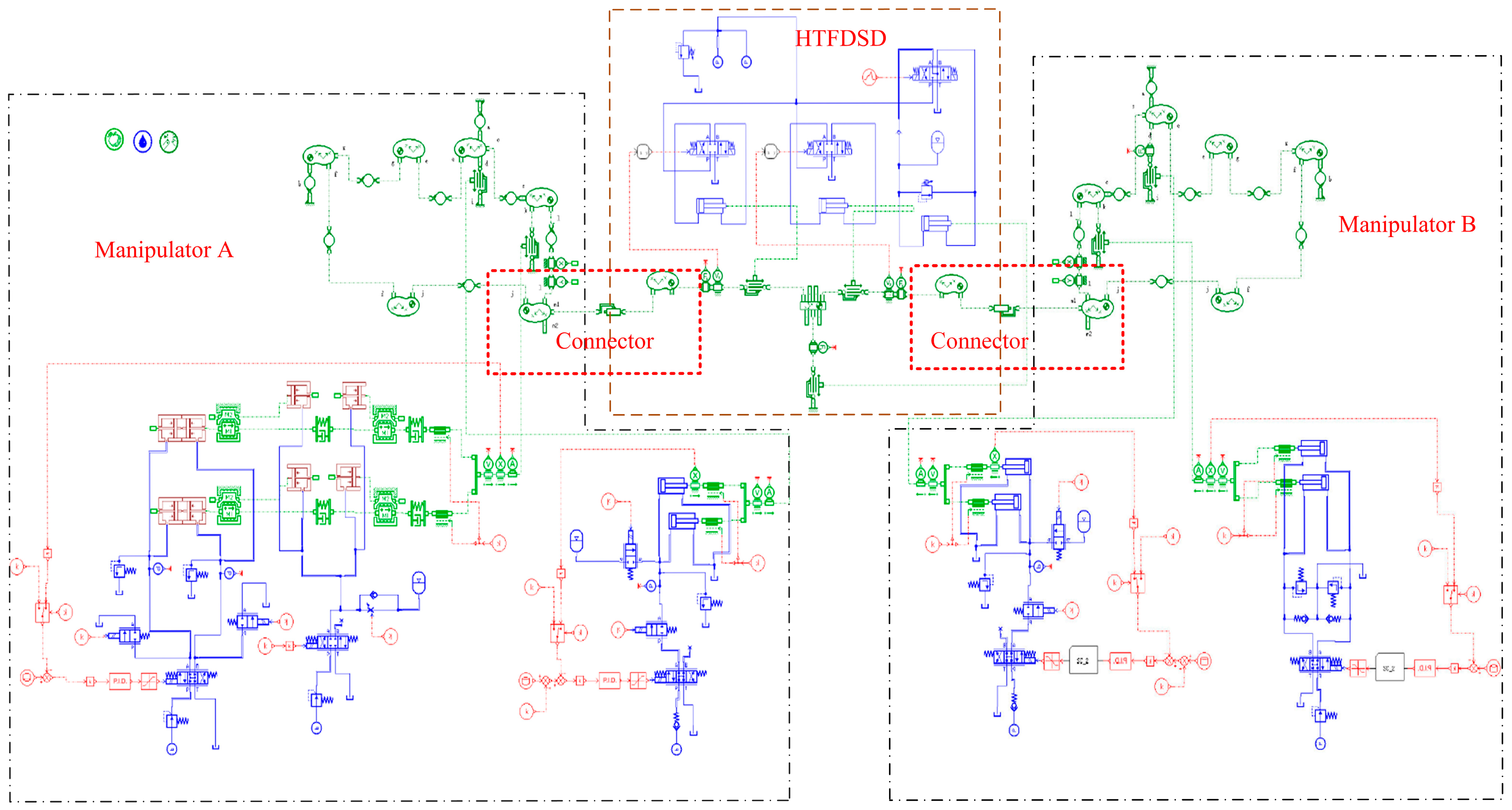

3. Structure Design of HTFDSD

3.1. Structural Design of HTFDSD

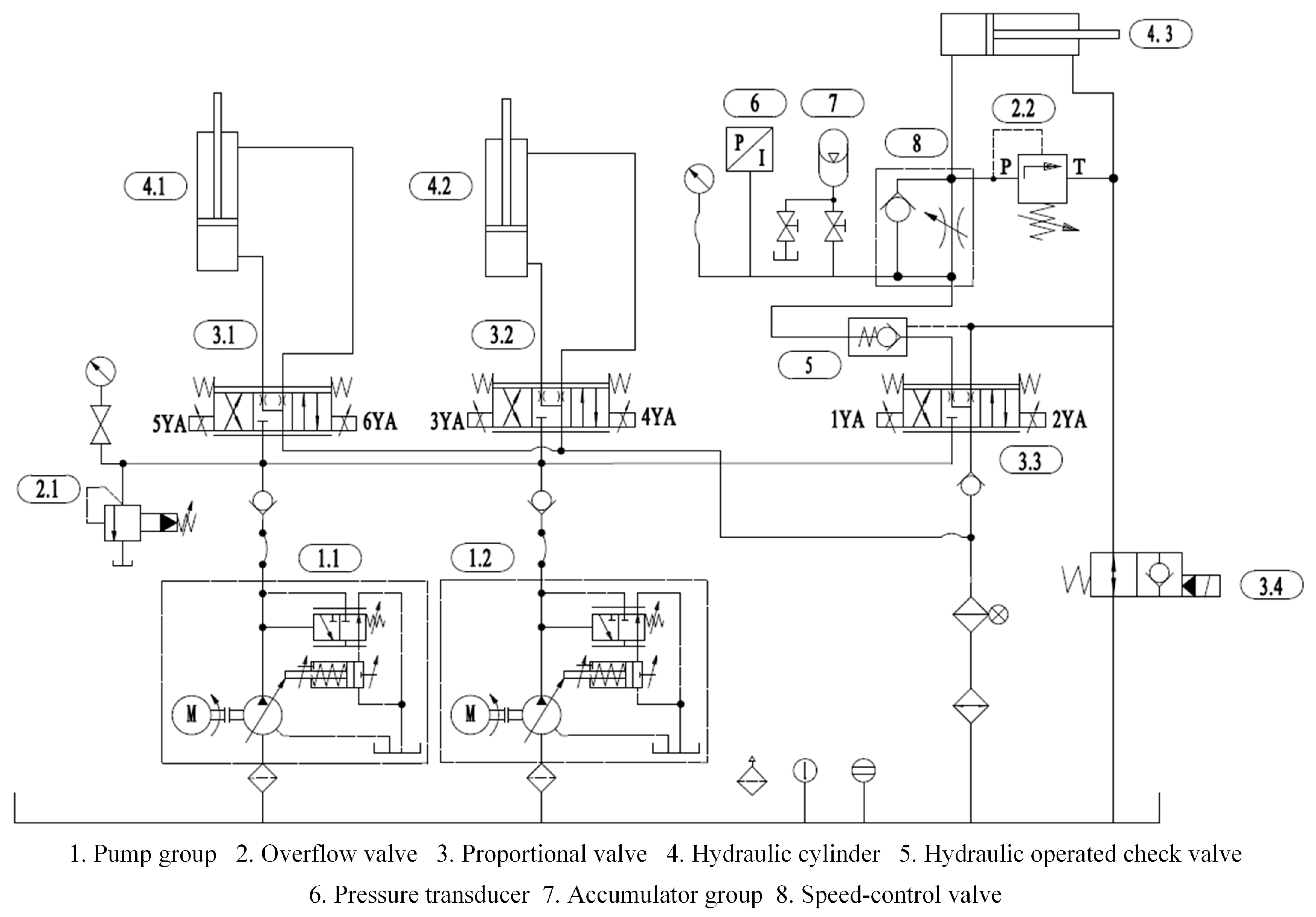

3.2. Design of the Hydraulic System for HTFDSD

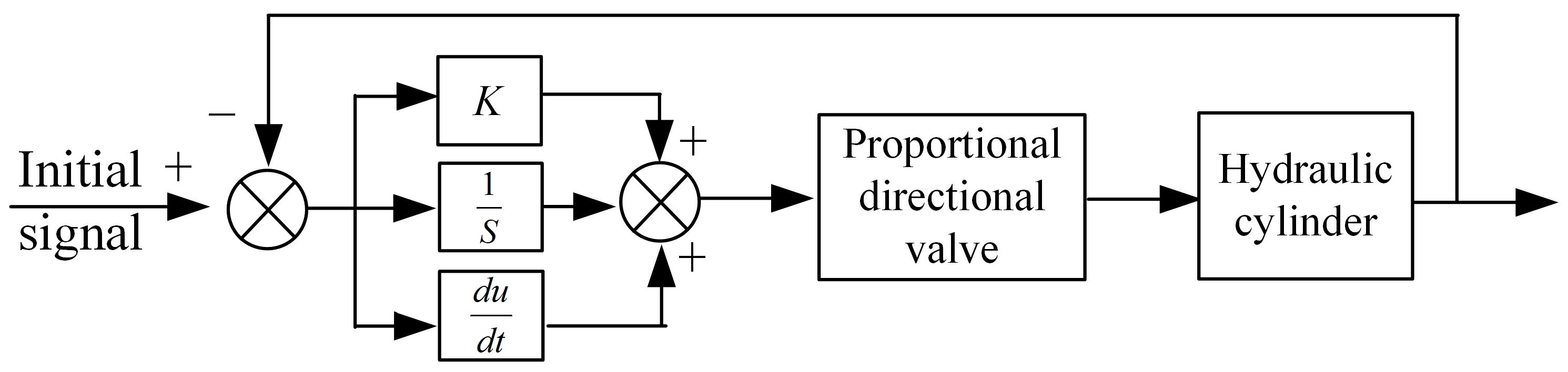

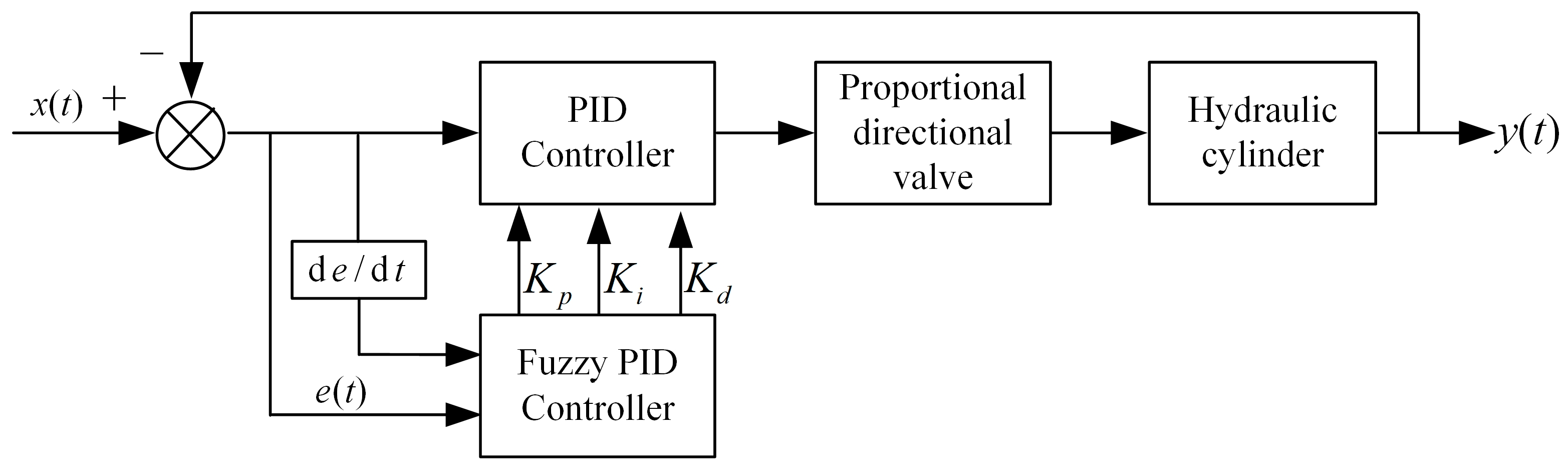

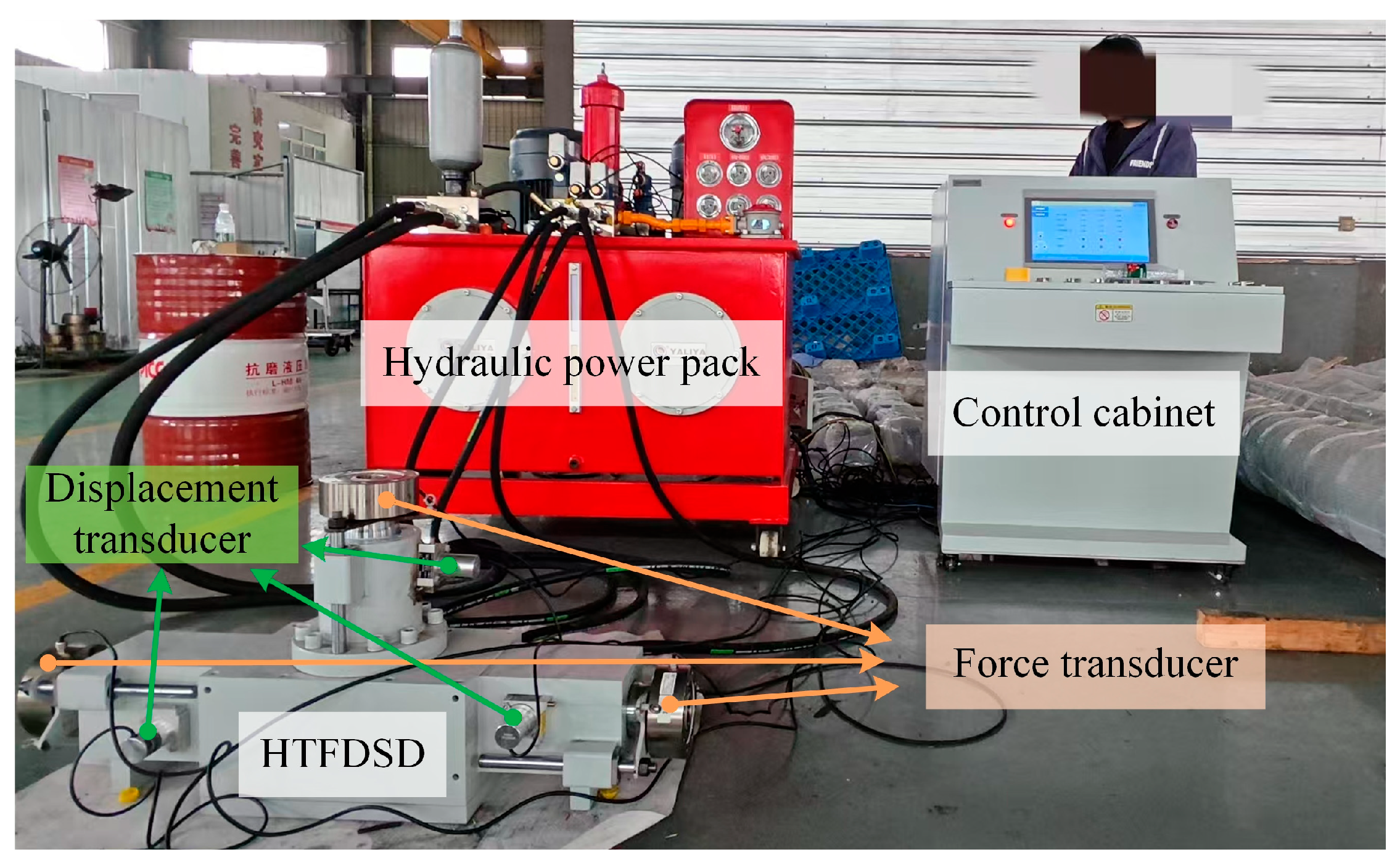

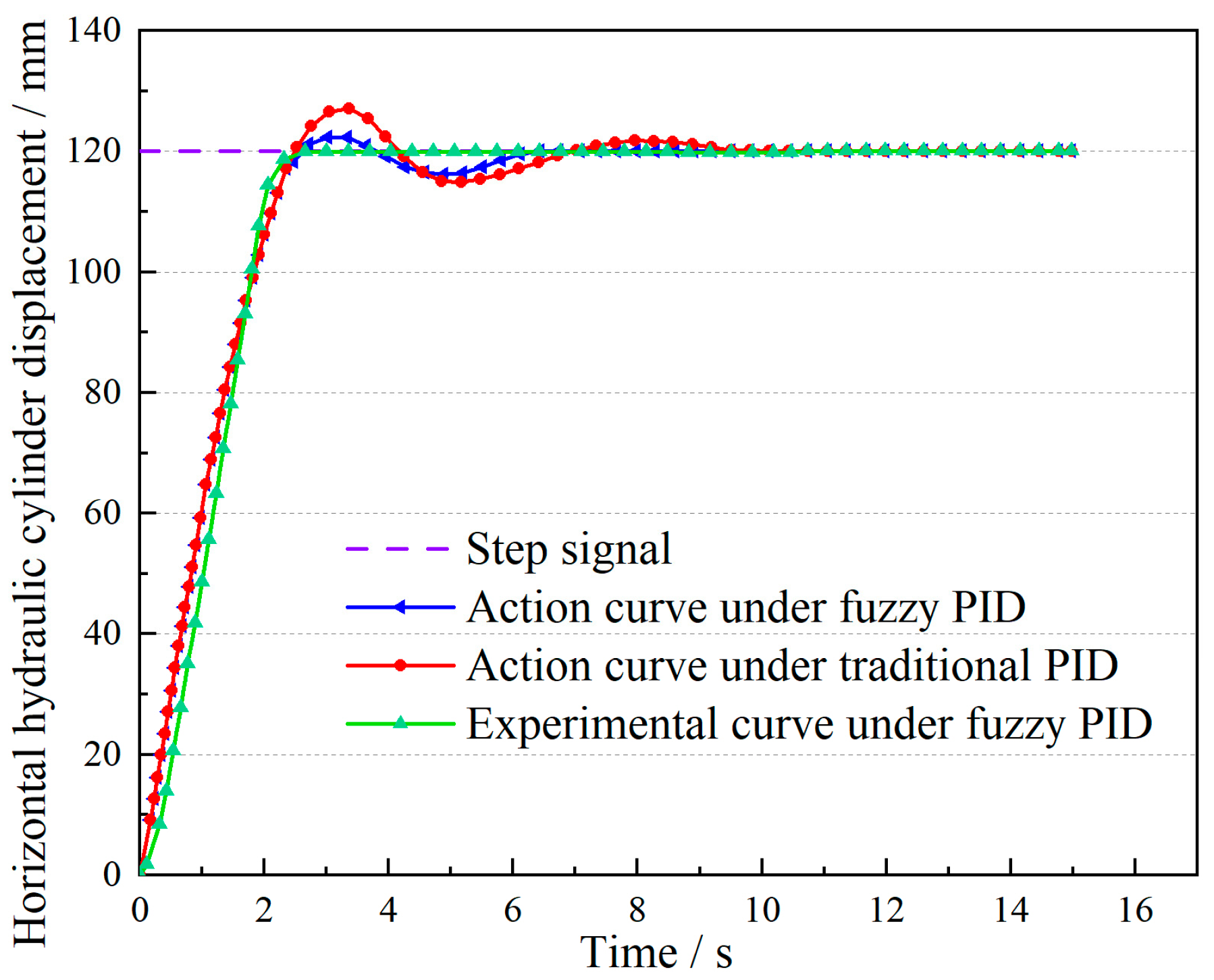

3.3. Control Performance Analysis of HTFDSD

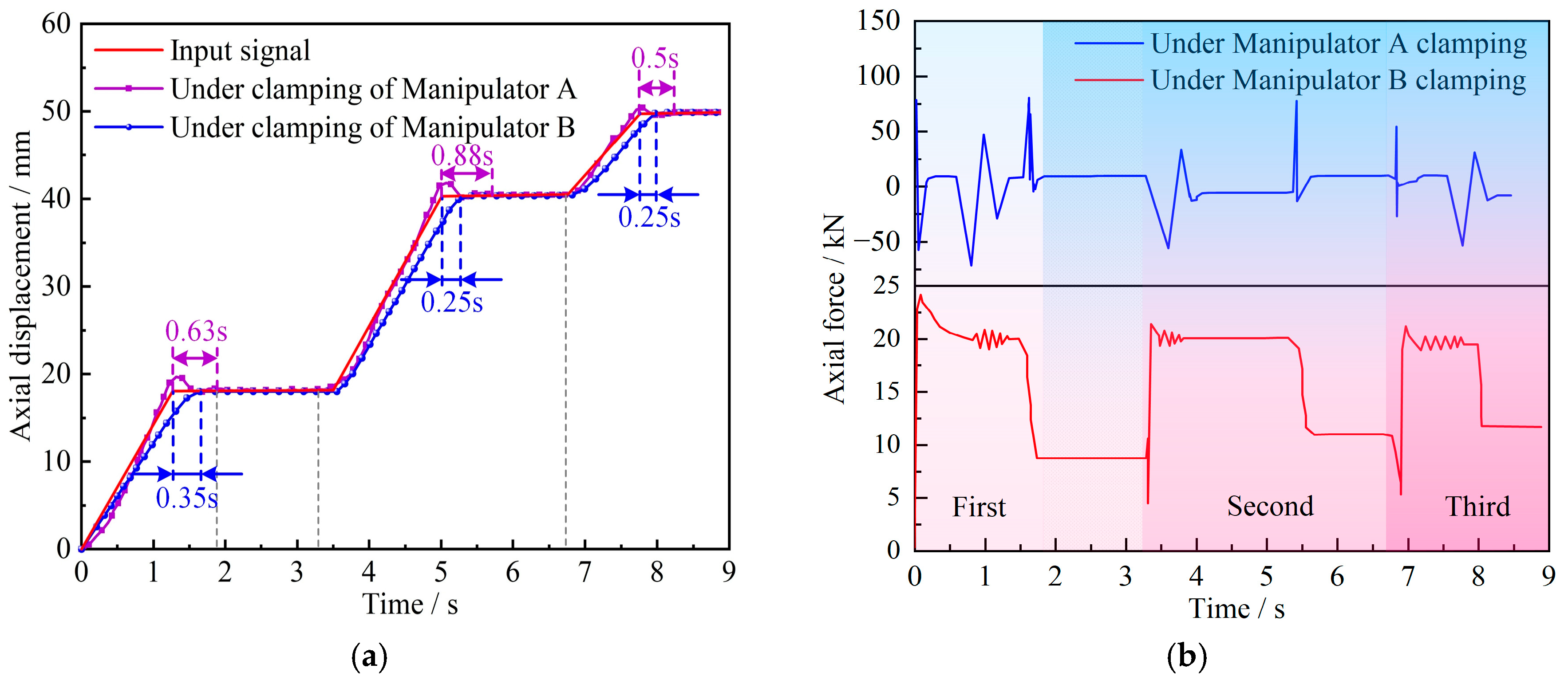

4. Co-Simulation Analysis of HTFDSD and Dual Forging Manipulators

5. Expanded Discussion on Error Sources and Limitations

- Hydraulic System Non-Idealities: Time delays in servo valve response, nonlinear friction in hydraulic cylinders (especially from seal assemblies), and environmental fluctuations affecting hydraulic oil viscosity (e.g., temperature changes) can introduce hysteresis and force ripples, impacting control accuracy and dynamic tracking performance.

- Signal Noise: Measurement noise from sensors (e.g., force and displacement sensors) can affect the feedback signal quality, potentially leading to oscillations in the control system.

- Simulation Simplifications: In the joint simulation model, simplifications were inevitably made. These include mesh deformation in dynamic simulations, which may not perfectly capture localized stress concentrations, and the material modeling of the simulated workpiece, which might not account for all complex high-temperature rheological behaviors. These factors could contribute to discrepancies between simulated and actual physical responses.

6. Conclusions

- Numerical analysis of the deformation behavior of high-temperature forgings during the elongation process was conducted using DEFORM software. The ranges of axial deformation, maximum deformation velocity, and deformation force were determined, establishing the operational specifications and functional requirements of HTFDSD.

- The mechanical structure and hydraulic system of HTFDSD were designed according to engineering requirements. The dynamic response characteristics of the HTFDSD under conventional PID and fuzzy PID control were compared through simulations, and the feasibility of the fuzzy PID control strategy was experimentally validated.

- A joint simulation model combining HTFDSD and the dual forging manipulator clamping system was developed. The dynamic response of the simulated workpiece under typical cooperative operating conditions was analyzed. Results indicate that the dynamic characteristics of HTFDSD are strongly influenced by buffering load: the more severe the load variation, the more pronounced the displacement oscillations; and the larger the load, the more evident the following lag phenomenon.

7. Patents

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| HTFDSD | High-Temperature Forging Deformation Simulation Device |

References

- Ma, H.; Huang, X.; Cui, X.; Wang, P.; Chen, Y.; Hu, Z.; Hua, L. Management Control and Integration Technology of Intelligent Production Line for Multi-Variety and Complex Aerospace Ring Forgings: A Review. Metals 2022, 12, 1079. [Google Scholar] [CrossRef]

- Liu, X.; Qiao, M.; Meng, B. Research on key technology of intelligent production line of aircraft structural parts based on intelligent manufacturing. IOP Conf. Series. Earth Environ. Sci. 2020, 440, 022004. [Google Scholar] [CrossRef]

- Ding, H.; Feng, Z.; Yang, W.; Kecskeméthy, A. Structure synthesis of 6-DOF forging manipulators. Mech. Mach. Theory 2017, 111, 135–151. [Google Scholar] [CrossRef]

- Hou, J.; Zhang, Z.; Zhou, H.; Ning, D.; Gong, Y. Hydraulic systems control based on the characteristics of major-motion mechanism for an open-die forging manipulator. Adv. Mech. Eng. 2017, 9, 81–99. [Google Scholar] [CrossRef]

- Xing, Y.; Zhai, F.; He, Z.; Wang, X.; Zhao, R. Enhanced Force Sensing Method Using BP Neural Network and Sensitive Point Analysis for Forging Manipulator Clamping Mechanism in Operational Conditions. Machines 2025, 13, 226. [Google Scholar] [CrossRef]

- Wang, X.; Zhai, F.; Zhao, R.; Xing, Y.; He, Z. Synchronous control method for the walking system of the dual forging manipulators based on triangular velocity planning. Mech. Based Des. Struct. Mach. 2024, 53, 1228–1248. [Google Scholar] [CrossRef]

- Ding, W.; Deng, H.; Zhang, Y.; Ren, Y. Optimum Design of the Jaw Clamping Mechanism of Forging Manipulators Based on Force Transmissibility. Appl. Mech. Mater. 2012, 157–158, 737–742. [Google Scholar] [CrossRef]

- He, Z.; Zhai, F.; Xing, Y.; Wang, X.; Zhao, R.; Chang, R. Research on the perception capability and characteristics based on the full-attitude indirect sensing model of forging force. Mech. Based Des. Struct. Mach. 2025, 53, 5513–5533. [Google Scholar] [CrossRef]

- Kukuryk, M. Analysis of deformation and microstructural evolution in the hot forging of the Ti-6Al-4V alloy. Arch. Metall. Mater. 2015, 60, 597–604. [Google Scholar] [CrossRef]

- Liu, Y.; Baker, T.N. Deformation characteristics of IMI685 titanium alloy under β isothermal forging solutions. Mater. Sci. Eng. A 1995, 197, 125–131. [Google Scholar] [CrossRef]

- Alimov, A.; Zabelyan, D.; Burlakov, I.; Korotkov, I.; Gladkov, Y. Simulation of deformation behavior and microstructure evolution during hot forging of TC11 titanium alloy. Defect Diffus. Forum. 2018, 385, 449–454. [Google Scholar] [CrossRef]

- Wu, R.H.; Pang, K.C. Computer simulation on formation of precision forgings of titanium alloy and superalloy. Mater. Sci. Forum 2007, 539, 3130–3135. [Google Scholar] [CrossRef]

- Fang, X.; Shao, Y.; Lu, J.; Liu, L. Influence of forging process parameters on residual stress of TC4 titanium alloy forgings. Forg. Stamp. Technol. 2021, 46, 1–8. [Google Scholar] [CrossRef]

- Chen, Y.; Min, X.; Zhang, H.; Dai, J.; Zhou, Y. Effect of strain rate on mechanical properties of tc17 and tc4 alloy forgings. J. Aeronaut. Mater. 2023, 43, 49–59. [Google Scholar] [CrossRef]

- Kim, B.T.; Eom, J.; Choi, I.; Lee, M.C.; Park, S.; Joun, M.S. Computer simulation of complex hot forging processes by a forging simulator based on finite volume method. Trans. Mater. Process. 2007, 16, 187–192. [Google Scholar] [CrossRef][Green Version]

- Zhang, P.; Yao, Z.; Du, Z. Analysis of Forging Compliance Process and Design of the Forging Simulator. J. Shanghai Jiaotong Univ. 2010, 43, 674–677+682. [Google Scholar] [CrossRef]

- Im, C.S.; Suh, S.R.; Lee, M.C.; Kim, J.H.; Joun, M.S. Computer aided process design in cold-former forging using a forging simulator and a commercial cad software. J. Mater. Process. Technol. 1999, 95, 155–163. [Google Scholar] [CrossRef]

| Serial Number | Project | Unit | Numerical Value |

|---|---|---|---|

| 1 | Total width limit (extended state) | mm | 2000 |

| 2 | Total height limit (extended state) | mm | 700 |

| 3 | Hydraulic cylinder load | t | 30 |

| 4 | Horizontal hydraulic cylinder stroke | mm | 120 |

| 5 | Vertical hydraulic cylinder stroke | mm | 100 |

| 6 | Hydraulic cylinder piston rod action speed | mm/s | 0–50 |

| 7 | Removable clamping end diameter | mm | 150 |

| 8 | Removable clamping end length | mm | 300 |

| 9 | Pressure sensor range | t | 7.5–30 |

| 10 | Connector width | mm | 350 |

| 11 | Radius of ball hinge ball head | mm | 261 |

| 12 | Maximum swing angle of spherical hinge structure | ° | 10 |

| Serial Number | Project | Unit | Numerical Value |

|---|---|---|---|

| 1 | System pressure | MPa | 25 |

| 2 | Hydraulic cylinder inner diameter | mm | 120 |

| 3 | Hydraulic cylinder piston rod diameter | mm | 85 |

| 4 | Maximum flow of hydraulic cylinder | L/min | 31 |

| Serial Number | Project | Quantity | Parameters Required | Model |

|---|---|---|---|---|

| 1 | Constant pressure variable piston pump | 2 | Displacement 25 mL/r Pressure 25 MPa | A10VS028DR/31R-PPA12N00 |

| 2 | Electrical machine | 2 | 380 v; 50 Hz; 18.5 kW | YE4-180M-4P-18.5KW-B5 |

| 3 | Horizontal cylinder circuit proportional directional valve | 2 | Rated flow rate 31 L/min Diameter 6 mm | 4WREE6E32-2X/G24K31/F1 |

| 4 | Vertical cylinder circuit proportional directional valve | 1 | Rated flow rate 31 L/min Diameter 6 mm | 4WREE6W32-2X/G24K31/F1 |

| 5 | Electromagnetic relief valve | 1 | Opening pressure 25 MPa | DBW10-1-50B/315BG24NZ5L |

| 6 | Accumulator | 1 | Total volume 16 L Initial pressure 14.1 MPa | HAB20-330-6X/0G09G-2F111-C |

| 7 | Orifice check valve | 1 | Maximum flow rate 50 L/min Maximum pressure 31.5 MPa | MK10G1X/V |

| 8 | Vertical circuit safety valve | 1 | Opening pressure 31.5 MPa | DBW10B-1-50B/315BG24NZ5L |

| 9 | Force transducer | 3 | Measuring range 0–30 t Precision: 0.05%F·S | JLBU-1 |

| 10 | Displacement transducer | 3 | Maximum displacement 300 mm Precision: ±0.15% | MPS-S-300-A |

| 11 | PLC controller | 1 | / | SIEMENS S7-1200PLC |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Zhai, F.; Wang, Z.; Yang, Z.; Zhao, R.; Gu, Z. Design and Performance Analysis of a High-Temperature Forging Deformation Simulation Device for Dual Manipulators. Machines 2025, 13, 999. https://doi.org/10.3390/machines13110999

Wang X, Zhai F, Wang Z, Yang Z, Zhao R, Gu Z. Design and Performance Analysis of a High-Temperature Forging Deformation Simulation Device for Dual Manipulators. Machines. 2025; 13(11):999. https://doi.org/10.3390/machines13110999

Chicago/Turabian StyleWang, Xiaonan, Fugang Zhai, Ziyuan Wang, Zhuofan Yang, Runyuan Zhao, and Zunzheng Gu. 2025. "Design and Performance Analysis of a High-Temperature Forging Deformation Simulation Device for Dual Manipulators" Machines 13, no. 11: 999. https://doi.org/10.3390/machines13110999

APA StyleWang, X., Zhai, F., Wang, Z., Yang, Z., Zhao, R., & Gu, Z. (2025). Design and Performance Analysis of a High-Temperature Forging Deformation Simulation Device for Dual Manipulators. Machines, 13(11), 999. https://doi.org/10.3390/machines13110999