Abstract

This study explores the comparative evaluation of PLA, carbon fiber-reinforced PLA (PLA-CF), and carbon fiber-reinforced high-temperature polyamide (PAHT-CF) for use in Fused Deposition Modeling (FDM) additive manufacturing. These materials were selected to examine how carbon fiber (CF) reinforcement affects PLA and PAHT, using virgin PLA as the baseline. Mechanical and thermal properties were tested to assess the influence of reinforcement on strength, toughness, and heat transfer. Tensile, impact, and thermal conductivity tests were conducted on all three materials. The results showed that PAHT-CF outperformed both PLA and PLA-CF in all categories, achieving an ultimate tensile strength of 57.5 MPa, an impact strength of 14.30 kJ/m2, and thermal conductivity of 0.182 W/m·K. PLA-CF showed moderate improvements in strength over neat PLA but with increased brittleness and slight improvement in thermal conductivity. Notably, this is the first study to investigate the thermal conductivity and resistivity of PAHT-CF in the literature, offering new insights into its heat dissipation capabilities and suitability for high-temperature applications. These findings highlight the critical role of polymer selection and fiber reinforcement in optimizing material performance. The results offer guidance for material selection in additive manufacturing, especially for lightweight, strong, and thermally efficient parts in various industries.

1. Introduction

Additive Manufacturing (AM), commonly known as 3D printing, is a revolutionary technology that allows for the creation of customized three-dimensional parts directly from digital models [1,2,3]. One of the well-known techniques within AM is Fused Deposition Modeling (FDM). FDM involves layer-by-layer extrusion of thermoplastic materials to build objects, which is particularly valued for its flexibility, cost-effectiveness, and ease of use. FDM allows for rapid prototyping, low-volume production, and the creation of complex geometries that would be difficult or impossible to achieve with traditional manufacturing methods [4,5]. A significant advantage of FDM is the wide range of materials available, allowing manufacturers to fit the properties of the printed part to specific application requirements. The availability of diverse materials is important as it provides solutions for a variety of industries, including aerospace, automotive, medical field, and consumer products, where strength, flexibility, and heat resistance are most important [6,7,8].

Among the many materials used in FDM, Polylactic Acid (PLA) is one of the most popular due to its ease of use and eco-friendly nature [9,10]. It is widely used in prototyping, consumer products, and educational projects due to its low cost and smooth finish when printed [11,12,13]. However, despite its advantages, PLA has several limitations in terms of mechanical and functional performance. In addition to its relatively low tensile strength and limited heat resistance, PLA also suffers from brittleness, low impact strength, poor elongation at break, and slow crystallization rates, which can restrict its dimensional stability. Furthermore, its biodegradability under industrial composting conditions can sometimes translate into limited long-term durability for certain applications. These combined factors restrict its suitability in more demanding environments. Among these limitations, tensile strength and heat resistance are particularly critical, and therefore they form the main focus of the present research [14,15,16,17]. One way to overcome these limitations is through the reinforcement of carbon fiber (CF) into PLA, resulting in a material known as PLA-CF [18,19]. Carbon is a versatile element that occurs in several allotropes, each exhibiting distinct properties. Among its most well-known forms are graphite, which is soft, electrically conductive, and used in lubricants and batteries [20,21], and diamond, which is extremely hard and commonly applied in cutting tools [22,23]. In addition, carbon can be processed into carbon fibers, which combine high strength and low weight, making them excellent polymer reinforcements, although they may also increase brittleness [24,25]. Carbon-based materials enhance strength, thermal conductivity, and wear resistance in various electronics, automotive, and aerospace applications [26,27,28,29]. While thermal conductivity has been studied for several polymer composites, including PLA-CF and PETG-CF systems [30,31], these investigations mainly report modest gains in thermal transport compared to neat polymers. Importantly, such work has not extended to high-temperature polyamide composites.

Carbon Fiber-Reinforced High Temperature Polyamide (PAHT-CF) is another advanced composite material that combines carbon fiber with PAHT. PAHT is a modified version of nylon designed for high-performance applications, known for its superior heat resistance and mechanical properties [32,33]. PAHT-CF is made by reinforcing carbon fibers into PAHT, either as chopped fibers or continuous filaments. The carbon fiber content further enhances its strength-to-weight ratio, resistance to fatigue, and boosts its thermal performance [34]. This makes PAHT-CF an excellent choice for applications exposed to high temperatures, such as in aerospace and automotive [35]. In contrast to PLA-CF, PAHT-CF is specifically engineered to handle environments where high thermal stability, durability, and long-term performance are required [32]. In addition to these advantages, PAHT-CF offers lower moisture absorption than standard polyamides, which contributes to better dimensional stability and reliability under humid conditions. However, its higher material cost, the possibility of warpage if not processed under controlled conditions, and nozzle wear due to the abrasive nature of carbon fibers remain important drawbacks that can restrict its wider use [36,37].

Although recent publications have examined PAHT-CF in terms of mechanical performance, no reports to date have provided quantitative measurements of its thermal conductivity or resistivity. Existing studies on nylon-based or PA6/PA12-CF composites primarily focus on heat deflection temperature or thermal stability under processing conditions rather than direct conductivity testing [38,39]. This absence of data highlights the novelty of our investigation.

This study investigates how CF reinforcement affects PLA and PAHT. By using virgin PLA as a baseline, in this study, the mechanical and thermal properties were compared to examine the effect of CF reinforcement on different polymers. Tensile tests, impact tests, and thermal conductivity tests were conducted to assess each material’s strength, durability, and resistance to heat. This research is the first to compare the mechanical and thermal effects of carbon fiber reinforcement across PLA and PAHT, using virgin PLA as a baseline. Additionally, this is the first research to investigate the thermal conductivity and resistivity of PAHT-CF in the literature, providing a unique contribution to understanding the material’s behavior under different thermal conditions. This will aid engineers and manufacturers in selecting the right material for their specific needs. Future work could explore how print parameters affect the performance of these materials and further investigate their long-term durability in real-world applications.

2. Materials and Methods

2.1. Materials

This study utilized three commercially available filaments: standard PLA, carbon fiber-reinforced PLA (PLA-CF), and carbon fiber-reinforced high-temperature polyamide (PAHT-CF). All filaments had a diameter of 1.75 mm and were obtained from Bambu Lab with manufacturer-verified material profiles. According to the manufacturer’s datasheets, both PLA-CF and PAHT-CF contain approximately 15% chopped carbon fiber by weight. Each filament was dried before printing, following the temperature and duration guidelines provided by the respective material manufacturers. These recommendations typically specify drying conditions such as 4–6 h at 50–60 °C for PLA-based filaments, or 8–12 h at 80–90 °C for high-temperature nylons, including PAHT-CF [40]. They are not set by an official standards body but rather by the manufacturers, who establish them based on the moisture sensitivity and thermal stability of each polymer. Adhering to these instructions helps to minimize moisture-related defects such as poor layer adhesion, surface bubbling, and inconsistent extrusion. PLA served as the baseline due to its common usage and ease of printing, while PLA-CF and PAHT-CF were selected to assess the mechanical and thermal improvements introduced by carbon fiber reinforcement within different polymer matrices. PLA had a green color, PLA-CF had a dark red color and PAHT-CF had a black color. In Table 1, reference mechanical properties from the literature are given for each material in this study.

Table 1.

Reference mechanical properties for each material.

2.2. Printing Process

All specimens were fabricated using a Bambu Lab P1S 3D printer from Bambu Lab, (based in Shenzhen, China) operating on Fused Deposition Modeling (FDM) technology. The printer features a build volume of 256 × 256 × 256 mm. All slicing was performed using Bambu Studio software (version: 2.0.3.54), and 100% infill was used in all prints to eliminate internal voids and ensure maximum material continuity, which is essential for accurate mechanical and thermal testing. Each material was printed using its respective default profile settings provided by Bambu Lab, as given in Table 2. All specimens were fabricated using the same geometry for each material type, ensuring direct comparability of results. A rectilinear raster type with an alternating ±45° infill orientation was applied, as this pattern is commonly used in mechanical testing to provide balanced isotropic properties. The layer height was fixed at 0.2 mm, a value recommended by the printer manufacturer and widely adopted in literature, as it provides a reliable compromise between surface quality, dimensional accuracy, and fabrication time. By keeping these parameters constant, the only variable among the specimens was the filament type. Each print job was performed without changing the slicing parameters, ensuring that the only varying factor among specimens was the filament type. No supports or post-processing was applied before testing.

Table 2.

Default parameters of each filament.

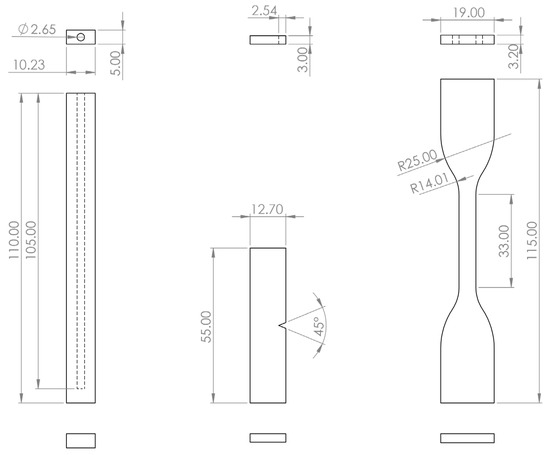

2.3. Specimen Design and Preparation

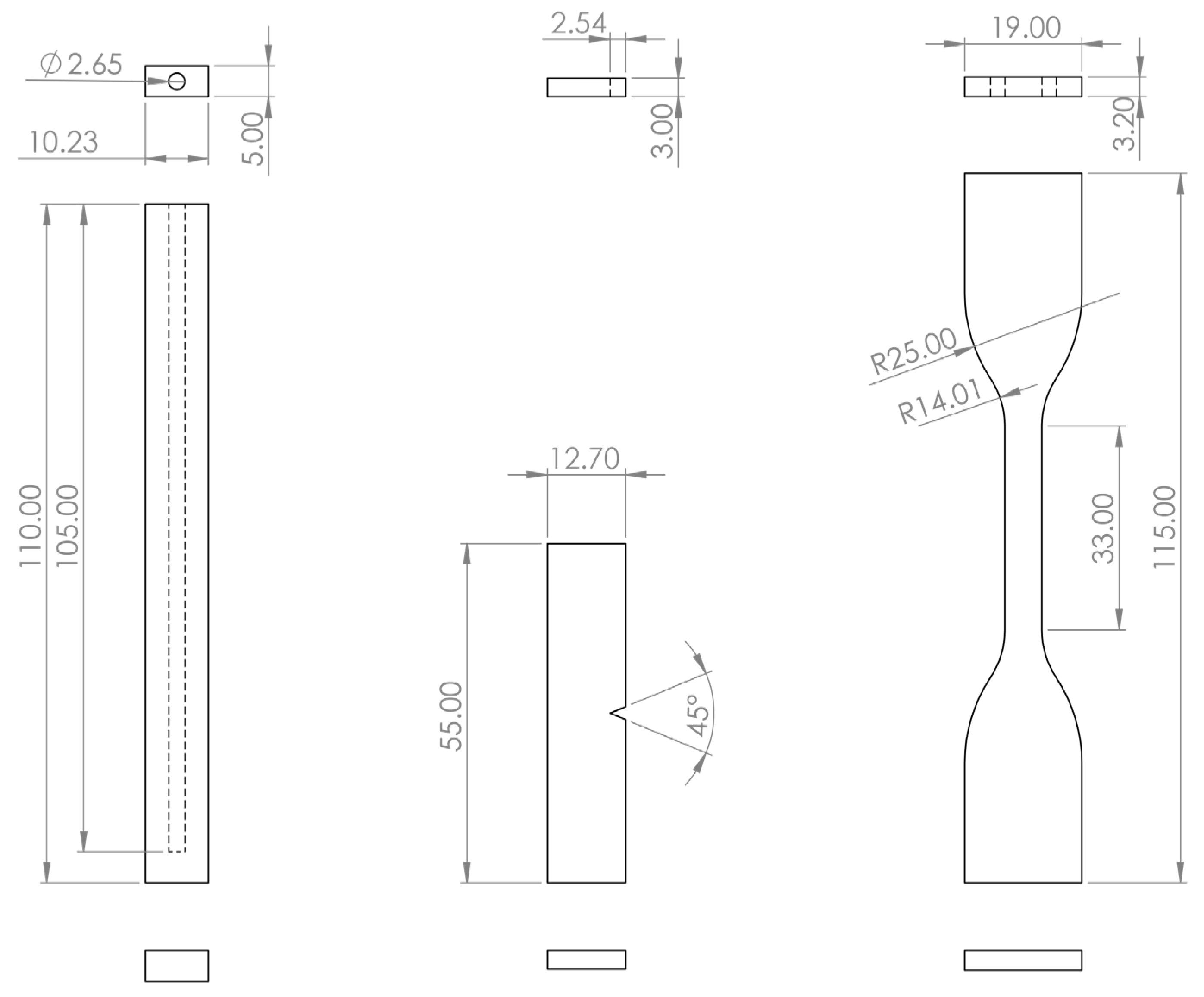

Mechanical and thermal tests were conducted on samples designed in SolidWorks software (2025 version). Two types of geometries were used. Tensile and impact specimens were modeled according to ASTM D638 Type IV [45] and ASTM D256 [46] standards, respectively. For thermal conductivity testing, rectangular bar specimens were created to properly fit the KD2 Pro thermal probe and ensure good thermal contact. The models were sliced using Bambu Studio with the aforementioned fixed parameters and exported as G-code for printing. All samples were printed on the same machine in consecutive batches to minimize environmental variability. In Figure 1, the dimensions of the samples are given.

Figure 1.

Technical drawings of samples (mm).

2.4. Mechanical Testing

Tensile testing was performed using an Instron Universal Testing Machine at a crosshead speed of 5 mm/min, in compliance with ASTM D638. Each material was tested with a minimum of three specimens in order to ensure repeatability and reduce measurement error. Ultimate tensile strength (UTS) and stress–strain behavior were recorded. Impact testing was conducted according to the ASTM D256 notched Izod standard. Energy absorption (in kJ/m2) was calculated to assess each material’s ability to withstand dynamic and sudden loading.

2.5. Thermal Conductivity Testing

Thermal conductivity was measured using a KD2 Pro thermal analyzer (Decagon Devices, Pullman, WA, USA), which operates on the transient line heat source principle. The device was calibrated prior to testing using the manufacturer’s reference standards (e.g., glycerin and agar gel) to ensure accuracy. According to the manufacturer, the system has an accuracy of ±10% (or ±0.01 W/m·K), which was taken as the uncertainty of the measurements. Each specimen was measured three times, and the results are reported as average values with corresponding standard deviations to reflect measurement repeatability.

3. Results and Discussion

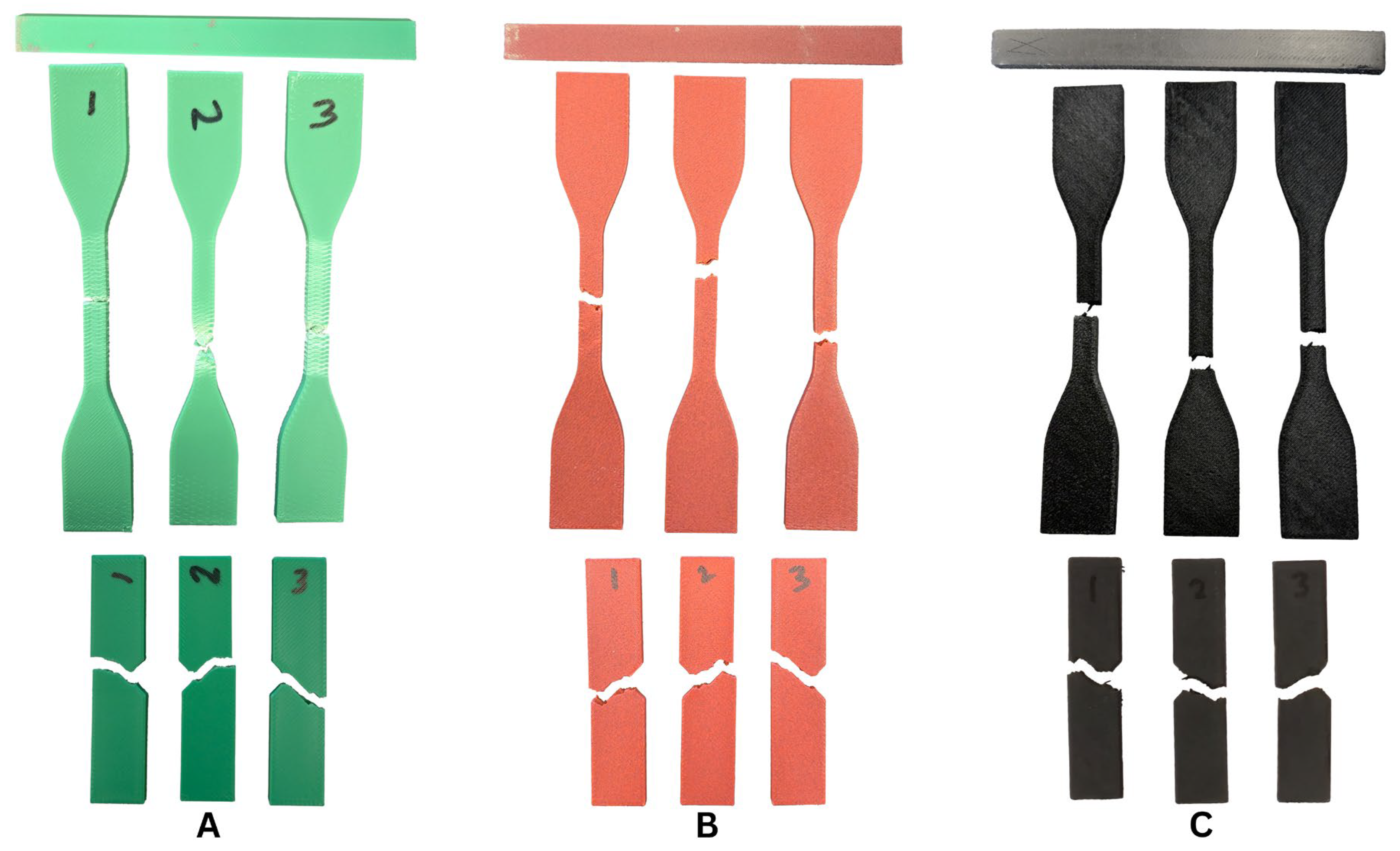

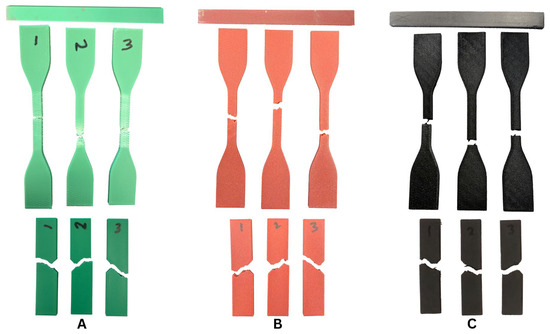

To visually reinforce the mechanical performance trends observed in the quantitative data, Figure 2 displays the fractured tensile and impact specimens of PLA, PLA-CF, and PAHT-CF after testing. The differences in fracture behavior clearly highlight the influence of carbon fiber reinforcement. PLA specimens exhibited relatively ductile failure with more pronounced elongation before breaking. PLA-CF samples showed sharper and more brittle fracture zones, consistent with increased stiffness and strength due to carbon fiber content. The PAHT-CF samples failed abruptly with minimal deformation, reflecting their superior tensile and impact performance but reduced ductility. The impact specimens similarly reveal cleaner, more energy-absorbing fractures in PLA, while the PLA-CF and PAHT-CF samples fractured more abruptly, indicating their higher resistance to crack propagation. Figure 2 shows all the tested samples after the completion of both tensile and impact experiments.

Figure 2.

Images of samples after damage testing: (A) PLA; (B) PLA-CF; (C) PAHT-CF.

To ensure consistency in testing and allow for accurate performance comparisons, the mass of each specimen was measured before testing. Table 3 presents the average mass and standard deviation values for all tensile, impact, and thermal conductivity samples fabricated from PLA, PLA-CF, and PAHT-CF. These measurements highlight the influence of material composition on overall density and material usage.

Table 3.

Weight of samples.

The results presented in the table reveal a clear correlation between material composition, mechanical performance, and weight efficiency. PAHT-CF exhibited the highest mechanical performance, as seen in both the tensile and impact tests, while also being the lightest among the three materials. Its average tensile sample weight was only 5.15 g, yet it achieved the highest ultimate tensile strength, indicating exceptional strength-to-weight efficiency. Similarly, the impact sample weight was the lowest (2.25 g), further supporting PAHT-CF’s suitability for applications requiring both mechanical strength and lightweight properties.

PLA-CF ranked second, showing improved mechanical performance compared to pure PLA, with higher strength and reduced weight. Its average tensile and impact weights were lower than PLA’s (5.69 g vs. 5.95 g for tensile; 2.39 g vs. 2.50 g for impact), suggesting that the addition of carbon fibers not only enhances stiffness and strength but also allows for material reduction without compromising structural integrity. Pure PLA, while still performing adequately, was the heaviest and mechanically weakest among the three, confirming the benefits of reinforcement and polymer modification for weight-critical, high-performance applications.

3.1. Tensile Strength

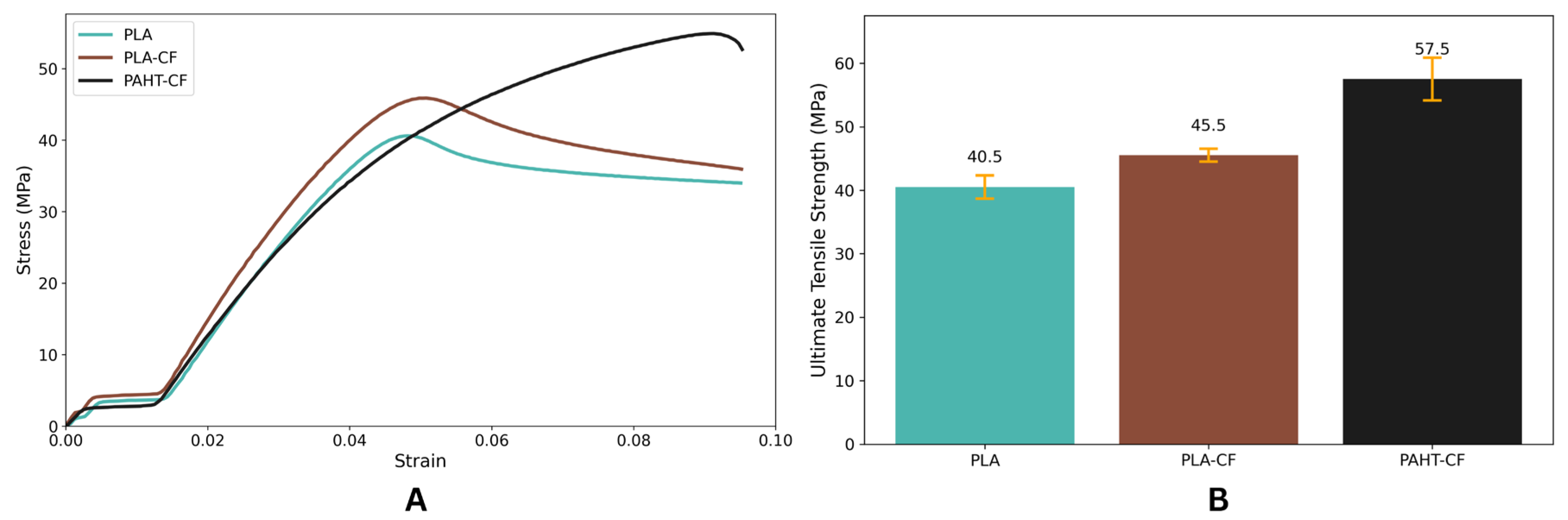

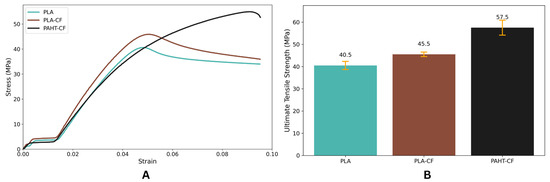

Tensile testing is essential for assessing a material’s mechanical behavior under uniaxial loading, offering key information on properties such as strength, stiffness, and elongation. This data is crucial for understanding how different materials and compositions perform under stress. In Figure 3, the tensile stress–strain curves of the tested samples are shown, illustrating the variation in tensile strength and deformation characteristics among the different formulations.

Figure 3.

Tensile strength measurement results: (A) stress–strain graph; (B) ultimate tensile strength graph.

In Figure 3, part (A) presents the tensile stress–strain behavior of PLA, PLA-CF, and PAHT-CF, while part (B) quantitatively compares their ultimate tensile strength (UTS) values. The curve for PLA in part (A) exhibits a moderate initial stiffness and reaches a peak stress of approximately 40 MPa before gradually softening, indicating limited strain hardening and a tendency toward brittle fracture. The addition of carbon fiber in PLA-CF results in a steeper initial slope, reflecting increased elastic modulus and improved load transfer due to the reinforcing effect of the fibers. PLA-CF reaches a higher peak stress around 45 MPa, but the sharp decline post-yield suggests reduced ductility and limited plastic deformation. PAHT-CF, on the other hand, shows a continuous rise in stress with strain, lacking a distinct yield point, which is characteristic of tougher and more ductile thermoplastics. This indicates that PAHT-CF benefits not only from fiber reinforcement but also from a more ductile and thermally stable polymer matrix, allowing it to achieve both high strength and elongation before failure. These behaviors are consistent with recent literature. For example, Dimitrellou et al. found that PAHT-CF specimens show significantly higher tensile strength and modulus than PLA, and also absorb more energy upon impact, indicating greater ductility and toughness compared to PLA [33]. Likewise, studies of annealed PLA-CF and PAHT-CF composites report that PLA-CF tends to exhibit a steep elastic response followed by a more abrupt drop after peak stress (reflecting limited plastic deformation), whereas PAHT-CF displays more continuous strain-to-failure behavior, supporting its improved matrix ductility and thermal stability. In part (B), this trend is clearly reflected in the UTS values, with PLA reaching 40.5 MPa, PLA-CF increasing to 45.5 MPa, and PAHT-CF achieving a significantly higher strength of 57.5 MPa. This conclusion is supported by the higher ultimate tensile strength of PLA-CF compared to neat PLA, but also by its lower elongation-at-break and the sharper failure in the stress–strain curve, which indicate reduced ductility. The error bars indicate relatively low variability, suggesting consistent performance across tests. These observations confirm that both fiber reinforcement and matrix selection play a critical role in tuning the mechanical properties of polymer composites, with PAHT-CF offering the most favorable combination of strength and toughness among the evaluated materials.

3.2. Impact Strength

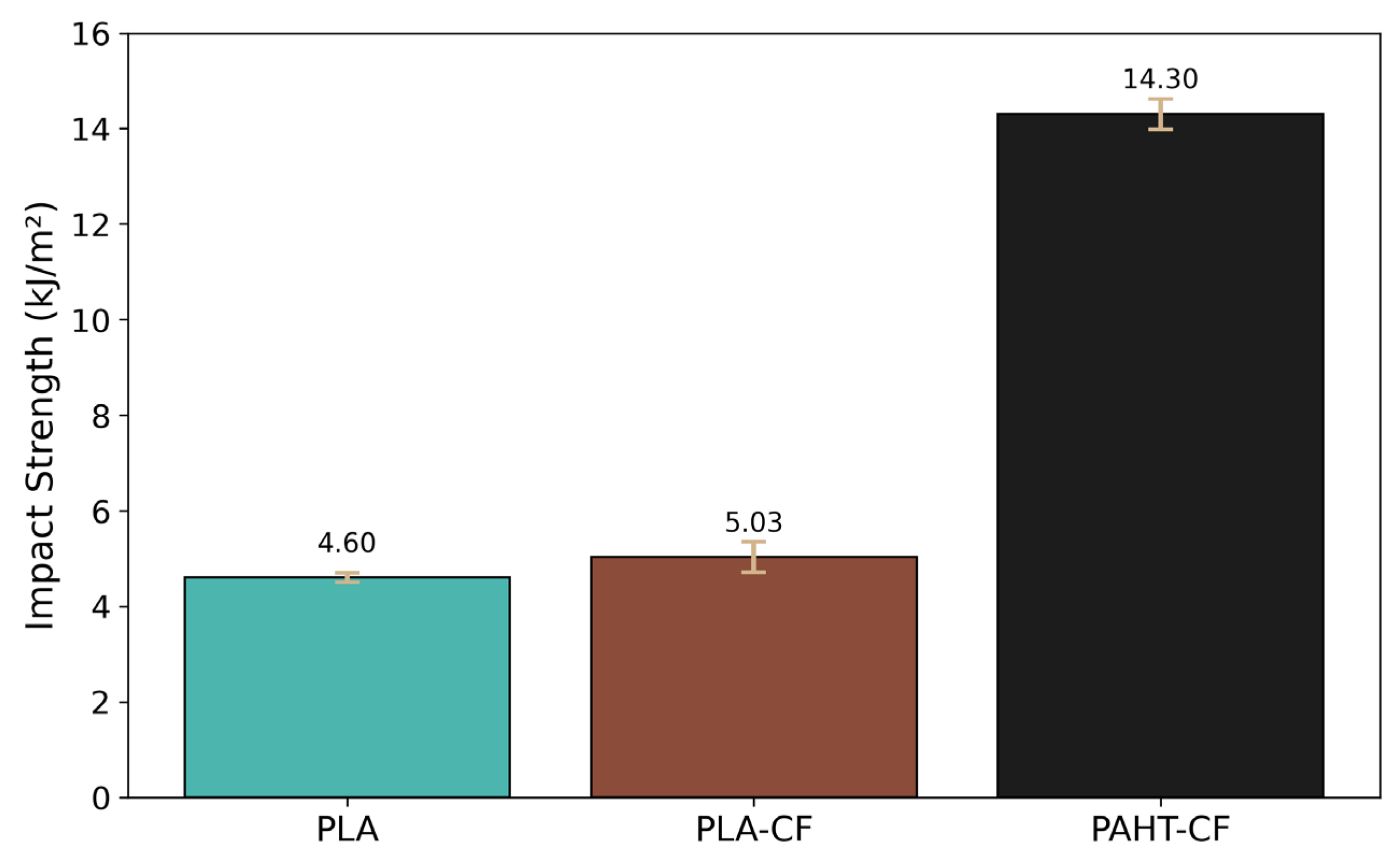

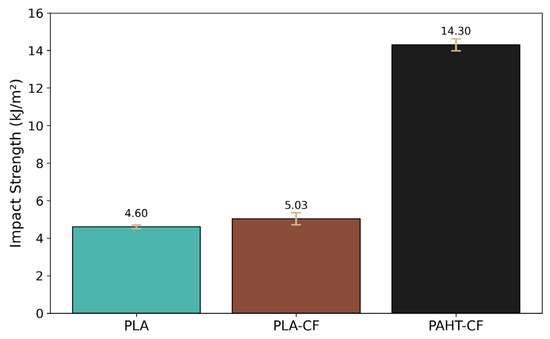

Impact strength is a key mechanical property that reflects a material’s ability to absorb and dissipate energy during sudden or dynamic loading. Unlike tensile testing, which characterizes behavior under gradually applied stress, impact testing simulates real-world scenarios where materials are subjected to abrupt forces or shocks. At high strain rates, polymer chains and reinforcing phases respond differently than under slow loading: the rapid deformation leaves less time for molecular rearrangement, plastic flow, or energy dissipation through viscoelastic mechanisms. As a result, brittle fracture mechanisms are often activated in weaker or less ductile matrices, whereas tougher matrices and well-bonded reinforcements can delay crack initiation and promote energy absorption through mechanisms such as fiber pull-out, crack deflection, or shear yielding. This interplay explains why toughness and fracture resistance may vary strongly with strain rate, making impact testing essential for evaluating polymers and composites in conditions closer to real-life loading. To assess this behavior, impact tests were conducted on all samples, and the resulting energy absorption values were measured. The results are presented in Figure 4, which illustrates and compares the impact strength of PLA, PLA-CF, and PAHT-CF samples.

Figure 4.

Impact strength of samples.

In Figure 4, the impact strength values of PLA, PLA-CF, and PAHT-CF are shown in terms of absorbed energy per unit area (kJ/m2), offering direct insight into each material’s ability to withstand dynamic or sudden loading conditions. The neat PLA sample exhibits the lowest impact strength at 4.60 kJ/m2, consistent with its known brittle behavior and limited energy dissipation capability. The slight increase to 5.03 kJ/m2 observed in PLA-CF indicates that carbon fiber reinforcement provides marginal improvement in resistance to impact-induced failure, likely due to improved stiffness and localized energy absorption around the fiber–matrix interface. However, this enhancement remains relatively limited, as PLA-CF still suffers from low ductility and limited capacity to deform plastically under high strain rates. In contrast, PAHT-CF exhibits a substantial increase in impact strength, reaching 14.30 kJ/m2, more than three times that of neat PLA. This dramatic improvement suggests a synergistic effect between the carbon fibers and the PAHT matrix, where the high-temperature polymer provides superior ductility and crack resistance, allowing for more effective energy dissipation during fracture. The significant gap between PAHT-CF and the other two materials confirms that matrix selection plays a critical role in impact performance, and that the combination of a ductile, thermally stable matrix with high-modulus reinforcements can dramatically enhance a composite’s toughness under dynamic conditions.

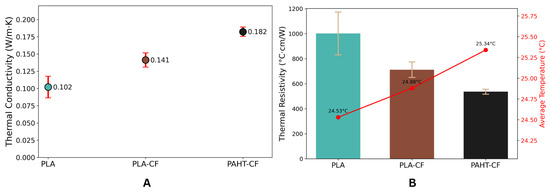

3.3. Thermal Results

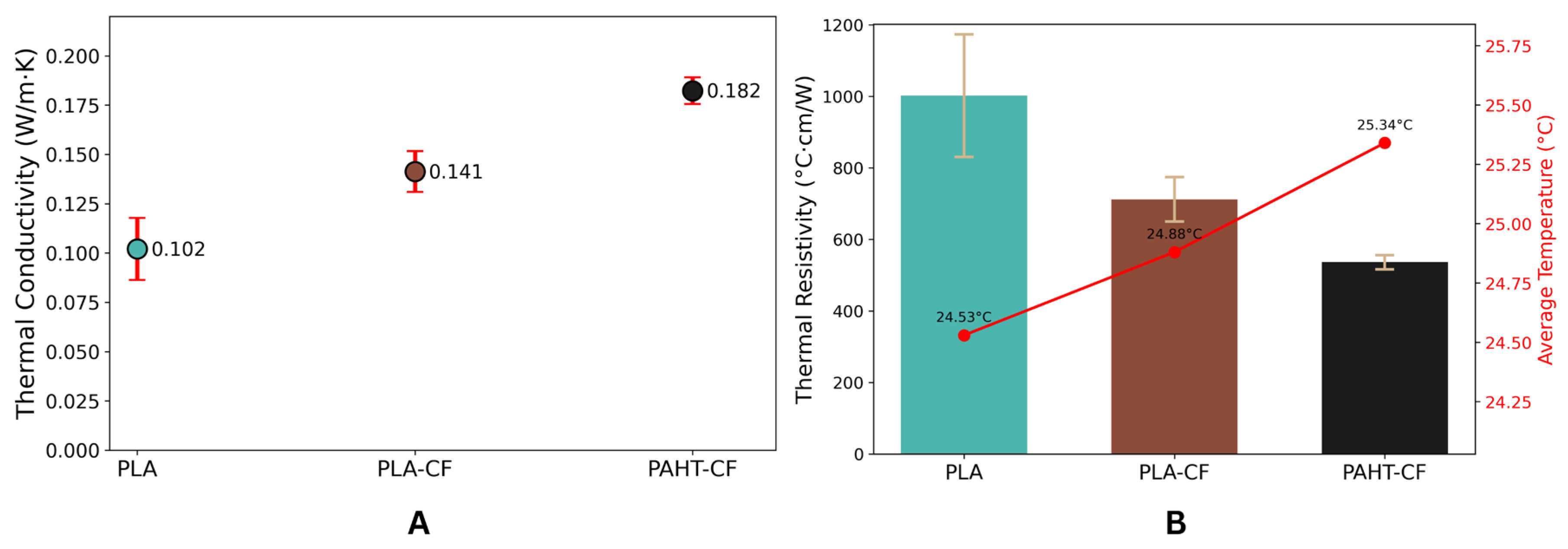

Thermal properties are critical for evaluating the suitability of polymer-based materials in applications involving heat management or thermal insulation. Two key parameters that offer insight into a material’s thermal behavior are thermal conductivity and thermal resistivity. Thermal conductivity measures how efficiently a material conducts heat, while thermal resistivity is its reciprocal and indicates how well a material resists heat flow [47,48]. These properties are particularly important for composite materials where fillers or reinforcements can significantly alter thermal pathways. In this study, thermal conductivity and thermal resistivity were experimentally measured to assess the effect of carbon fiber reinforcement and matrix selection on the thermal transport characteristics of PLA, PLA-CF, and PAHT-CF. The results are presented in Figure 5, enabling direct comparison of both thermal conduction efficiency and insulation capability across the three material systems.

Figure 5.

Thermal performance of samples. (A) is thermal conductivity, and (B) is thermal resistivity.

In Figure 5, part (A) illustrates the measured thermal conductivity values of PLA, PLA-CF, and PAHT-CF, while part (B) presents the corresponding thermal resistivity values along with the average temperatures recorded during testing. These results collectively provide insight into how material composition influences heat transfer behavior in polymer composites.

In part (A), neat PLA shows the lowest thermal conductivity at 0.102 W/m·K, consistent with its nature as a thermoplastic polymer with a disordered molecular structure that inherently limits phonon transport. The incorporation of carbon fiber in PLA-CF results in a noticeable increase in thermal conductivity to 0.141 W/m·K, which can be attributed to the higher thermal conductivity of carbon fibers and the formation of partial conductive pathways within the polymer matrix. PAHT-CF exhibits the highest thermal conductivity at 0.182 W/m·K, suggesting not only a more continuous conductive network due to the reinforcing phase but also an improved matrix-filler interaction that facilitates heat transport. This enhanced conductivity in PAHT-CF also reflects the thermally stable and possibly more crystalline nature of the PAHT matrix, which may reduce phonon scattering and promote better alignment of carbon fibers during processing.

In part (B), the inverse trend is observed in thermal resistivity, which is the reciprocal of thermal conductivity and provides a direct indication of the material’s insulating capacity. PLA demonstrates the highest resistivity at approximately 980 °C·cm/W, aligning with its poor heat conduction. PLA-CF shows reduced resistivity (~710 °C·cm/W), and PAHT-CF achieves the lowest value (~550 °C·cm/W), confirming its superior thermal conduction performance. The red line in part (B) shows the average surface temperature of each sample during testing, which increases slightly with thermal conductivity, from 24.53 °C for PLA to 25.34 °C for PAHT-CF. This correlation further validates the conductivity measurements and suggests that PAHT-CF dissipates heat more efficiently, resulting in higher average temperatures under the same thermal load.

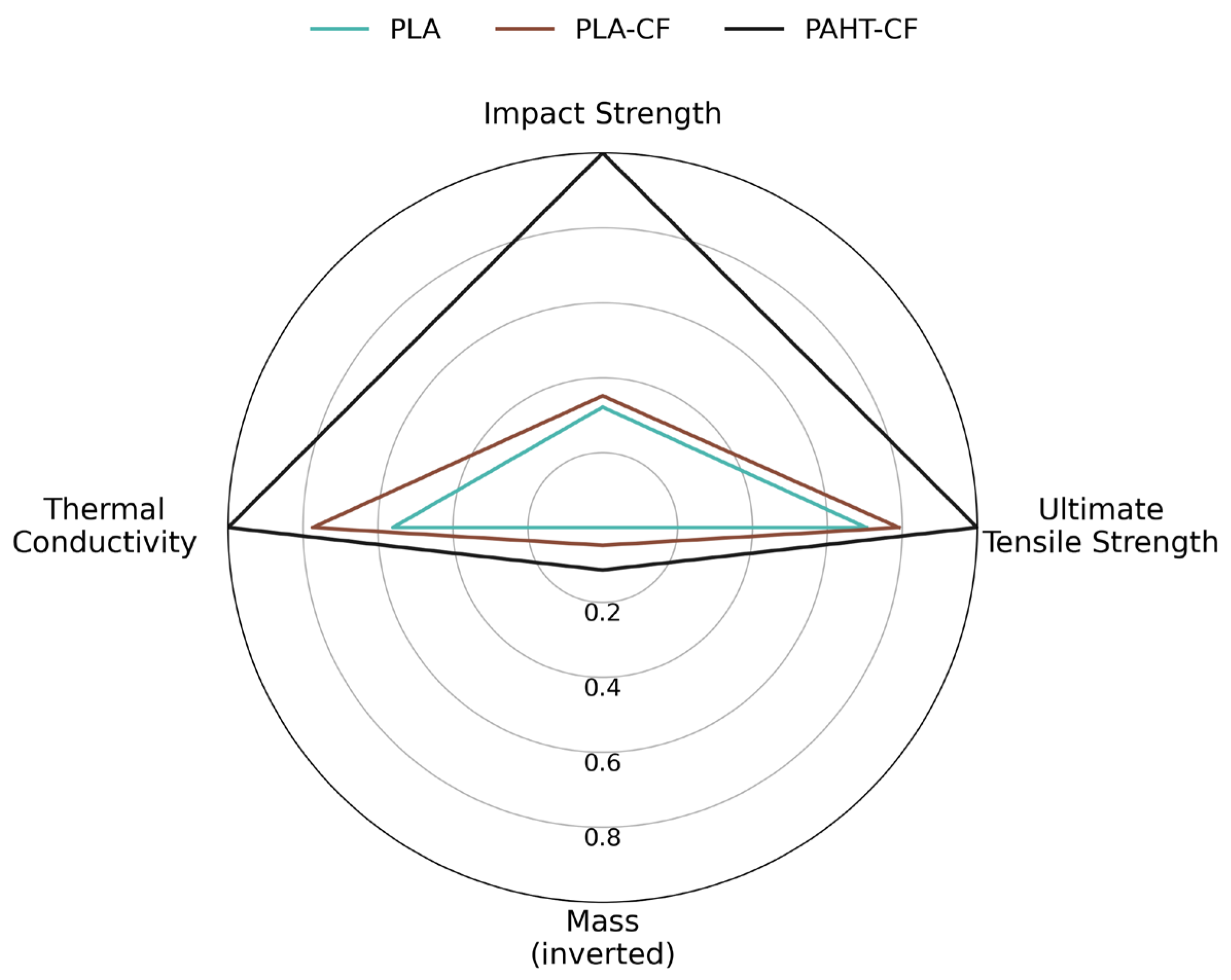

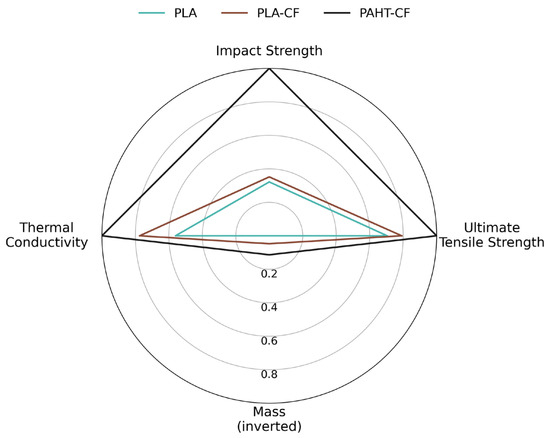

To enable a comprehensive and intuitive comparison of material performance, four key parameters were selected and normalized for each material: ultimate tensile strength, impact strength, thermal conductivity, and mass (inverted). This multi-dimensional assessment allows for a balanced evaluation of mechanical, thermal, and lightweighting characteristics, each of which plays a crucial role in high-performance applications.

First, each parameter was normalized to a 0–1 scale, with the best-performing value in each category scaled to 1. For the mass parameter, an inverse normalization was used, giving higher scores to lighter samples to reflect performance-to-weight efficiency. This normalization ensured fair comparison despite differing units and value ranges.

Subsequently, a radar plot was constructed to visually represent the normalized performance profile of each material. As shown in Figure 6, the radar chart provides an at-a-glance evaluation of the performance trade-offs.

Figure 6.

Overall comparison across different tests.

Among the three materials, PAHT-CF consistently exhibits superior performance, reaching the maximum normalized value in all four axes. This indicates that it provides the highest mechanical strength, impact resistance, and thermal conductivity, while also being the lightest among the samples. PLA-CF follows closely, outperforming neat PLA in every category, particularly in strength and thermal properties. PLA, while the most basic formulation, serves as a baseline reference and demonstrates comparatively lower values across the board. The inclusion of the inverted mass parameter effectively emphasizes the advantage of lighter materials without requiring unit transformation. Overall, the radar chart clearly communicates the comprehensive efficiency of each composite and confirms PAHT-CF as the most effective candidate for applications demanding strength, impact resistance, thermal performance, and weight reduction.

3.4. Printability Observations

The printability of each filament played a significant role in the success and repeatability of the mechanical and thermal tests. Clear differences in processing behavior were observed among PLA, PLA-CF, and PAHT-CF, mainly due to variations in their thermal requirements and rheological characteristics.

PLA was the easiest to print, requiring low nozzle temperatures between 200 and 210 °C and a bed temperature of 60 °C. It adhered well to the build platform and demonstrated stable layer bonding with minimal deformation. Due to its low shrinkage and good flow behavior, PLA prints exhibited high dimensional accuracy, smooth surface finish, and negligible warping. No significant issues such as stringing, over-extrusion, or under-extrusion were encountered under standard FDM settings.

PLA-CF, despite the addition of 15% carbon fiber, printed reliably and smoothly under similar temperature settings (around 210–220 °C). The filament fed consistently through the nozzle, and no major print defects were observed. It retained good bed adhesion and layer fusion, with no warping or delamination. The carbon fiber reinforcement did not noticeably compromise the printing process, and no issues such as stringing or surface defects were recorded during fabrication. This indicates that PLA-CF maintains the user-friendly nature of standard PLA while offering enhanced mechanical properties.

PAHT-CF was the most challenging material to process due to its high-temperature nylon base and carbon fiber reinforcement. It required elevated nozzle temperatures of around 260–270 °C and a bed temperature of at least 90–100 °C. The high thermal demands necessitated a fully enclosed printing environment to prevent rapid cooling and uneven temperature gradients, which otherwise led to significant warping and corner lifting during printing. Furthermore, stringing and over-extrusion were frequently observed, particularly during non-print moves and at layer transitions. These issues are attributed to the higher melt viscosity and slower solidification rate of PAHT-CF, which reduced its responsiveness to conventional retraction settings. In some cases, minor surface irregularities and inconsistent extrusion were also noted, requiring fine-tuning of slicer parameters and travel settings to mitigate defects. In conclusion, PLA and PLA-CF offered excellent printability with minimal adjustments, while PAHT-CF required advanced printer capabilities, higher processing temperatures, and meticulous parameter control to avoid warping and ensure print quality. While the present observations are qualitative, future work should include quantitative measures such as dimensional accuracy, surface roughness, and warpage to provide a fuller evaluation of printability. These findings highlight the balance between material performance and processing complexity, especially when considering carbon fiber-reinforced high-performance polymers.

4. Conclusions

This study presents a comprehensive comparison of PLA, PLA-CF, and PAHT-CF filaments in the context of additive manufacturing using FDM technology. By examining tensile strength, impact resistance, and thermal conductivity, the investigation highlights the significant performance differences introduced by carbon fiber reinforcement and matrix selection.

Among the tested materials, PAHT-CF exhibited superior mechanical and thermal behavior, achieving the highest ultimate tensile strength (57.5 MPa), impact strength (14.30 kJ/m2), and thermal conductivity (0.182 W/m·K). These enhancements are attributed to the synergistic effect of a high-performance polyamide matrix and carbon fiber reinforcement. PLA-CF, while showing improved strength over neat PLA, exhibited increased brittleness and limited improvement in thermal properties. Neat PLA remained the weakest in mechanical and thermal metrics, reinforcing the importance of material selection for engineering applications requiring durability and thermal stability. Additionally, weight analysis showed that improved performance can be achieved with reduced material usage, particularly for PAHT-CF, indicating a high strength-to-weight ratio ideal for lightweight structural applications. The thermal conductivity and resistivity results further confirmed the enhanced heat dissipation behavior of PAHT-CF, making it a promising candidate for high-temperature or heat-sensitive environments.

This study is the first to report on the thermal transport behavior of PAHT-CF in literature, offering new insights into its practical potential. Future work should investigate the effect of printing parameters, hybrid filler systems, and long-term environmental durability to further advance the performance and applicability of composite filaments in additive manufacturing.

Author Contributions

Conceptualization, M.A.; Methodology, M.A.; Investigation, M.E.S., A.A. and S.A.; Data curation, M.A.; Writing—original draft, M.A., M.E.S. and A.A.; Writing—review & editing, M.A., M.E.S., A.A., S.A. and I.D.; Supervision, I.D. All authors have read and agreed to the published version of the manuscript.

Funding

This Research was funded by the natural sciences and engineering research council of Canada (NSERC).

Data Availability Statement

The data that support the findings of this study are available upon reasonable request.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Balletti, C.; Ballarin, M.; Guerra, F. 3D Printing: State of the Art and Future Perspectives. J. Cult. Herit. 2017, 26, 172–182. [Google Scholar] [CrossRef]

- Ali, S.; Deiab, I.; Pervaiz, S. Optimizing the Properties of PHBV/PBAT Blend for Additive Manufacturing. Procedia CIRP 2025, 131, 7–12. [Google Scholar] [CrossRef]

- Alshihabi, M.; Kayacan, M.Y. Effect of Nanosized Carbon Nanotubes, Titanium Nitride and Cubic Boron Nitride Powders on Mechanical and Thermal Properties of SLA 3D Printed Resin Composites. Polym. Compos. 2024, 45, 15561–15573. [Google Scholar] [CrossRef]

- Thumsorn, S.; Prasong, W.; Kurose, T.; Ishigami, A.; Kobayashi, Y.; Ito, H. Rheological Behavior and Dynamic Mechanical Properties for Interpretation of Layer Adhesion in FDM 3D Printing. Polymers 2022, 14, 2721. [Google Scholar] [CrossRef]

- Patel, R.; Desai, C.; Kushwah, S.; Mangrola, M.H. A Review Article on FDM Process Parameters in 3D Printing for Composite Materials. Mater. Today Proc. 2022, 60, 2162–2166. [Google Scholar] [CrossRef]

- Bacciaglia, A.; Ceruti, A.; Liverani, A. Towards Large Parts Manufacturing in Additive Technologies for Aerospace and Automotive Applications. Procedia Comput. Sci. 2022, 200, 1113–1124. [Google Scholar] [CrossRef]

- Trivedi, A.K.; Gupta, M.K.; Singh, H. PLA Based Biocomposites for Sustainable Products: A Review. Adv. Ind. Eng. Polym. Res. 2023, 6, 382–395. [Google Scholar] [CrossRef]

- Alshihabi, M.; Ozkahraman, M.; Kayacan, M.Y. Enhancing the Reliability of a Robotic Arm through Lightweighting and Vibration Control with Modal Analysis and Topology Optimization. Mech. Based Des. Struct. Mach. 2025, 53, 1950–1974. [Google Scholar] [CrossRef]

- Madhavan Nampoothiri, K.; Nair, N.R.; John, R.P. An Overview of the Recent Developments in Polylactide (PLA) Research. Bioresour. Technol. 2010, 101, 8493–8501. [Google Scholar] [CrossRef]

- Ali, S.; Nouzil, I.; Mehra, V.; Eltaggaz, A.; Deiab, I.; Pervaiz, S. Integrated Optimization Scheme for 3D Printing of PLA-APHA Biodegradable Blends. Prog. Addit. Manuf. 2025, 10, 875–886. [Google Scholar] [CrossRef]

- Afrose, M.F.; Masood, S.H.; Iovenitti, P.; Nikzad, M.; Sbarski, I. Effects of Part Build Orientations on Fatigue Behaviour of FDM-Processed PLA Material. Prog. Addit. Manuf. 2016, 1, 21–28. [Google Scholar] [CrossRef]

- Joseph, T.M.; Kallingal, A.; Suresh, A.M.; Mahapatra, D.K.; Hasanin, M.S.; Haponiuk, J.; Thomas, S. 3D Printing of Polylactic Acid: Recent Advances and Opportunities. Int. J. Adv. Manuf. Technol. 2023, 125, 1015–1035. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, Y.; Wu, B.; Cui, C.; Guo, Y.; Yan, C. A Critical Review of Fused Deposition Modeling 3D Printing Technology in Manufacturing Polylactic Acid Parts. Int. J. Adv. Manuf. Technol. 2019, 102, 2877–2889. [Google Scholar] [CrossRef]

- Rajpurohit, S.R.; Dave, H.K. Effect of Process Parameters on Tensile Strength of FDM Printed PLA Part. Rapid Prototyp. J. 2018, 24, 1317–1324. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, L.; Xiong, Z.; Tang, Z.; Zhang, R.; Zhu, J. Research Progress in the Heat Resistance, Toughening and Filling Modification of PLA. Sci. China Chem. 2016, 59, 1355–1368. [Google Scholar] [CrossRef]

- Schyns, Z.O.G.; Shaver, M.P. Mechanical Recycling of Packaging Plastics: A Review. Macromol. Rapid Commun. 2021, 42, 2000415. [Google Scholar] [CrossRef]

- Taib, N.-A.A.B.; Rahman, M.R.; Huda, D.; Kuok, K.K.; Hamdan, S.; Bakri, M.K.B.; Julaihi, M.R.M.B.; Khan, A. A Review on Poly Lactic Acid (PLA) as a Biodegradable Polymer. Polym. Bull. 2023, 80, 1179–1213. [Google Scholar] [CrossRef]

- Pathek, I.A.; da Silva, J.R.F.; Lima, D.D.; Limberger, I.F.; Buenos, A.A.; Scheuer, C.J. Assessment of Carbon Fiber Incorporation Effects on Overall Characteristics and Properties of 3D-Printed PLA. J. Braz. Soc. Mech. Sci. Eng. 2024, 46, 640. [Google Scholar] [CrossRef]

- Li, Y.; Gao, S.; Dong, R.; Ding, X.; Duan, X. Additive Manufacturing of PLA and CF/PLA Binding Layer Specimens via Fused Deposition Modeling. J. Mater. Eng. Perform. 2018, 27, 492–500. [Google Scholar] [CrossRef]

- Wissler, M. Graphite and Carbon Powders for Electrochemical Applications. J. Power Sources 2006, 156, 142–150. [Google Scholar] [CrossRef]

- Nasir, S.; Hussein, M.Z.; Zainal, Z.; Yusof, N.A. Carbon-Based Nanomaterials/Allotropes: A Glimpse of Their Synthesis, Properties and Some Applications. Materials 2018, 11, 295. [Google Scholar] [CrossRef]

- Matthews, A.; Eskildsen, S.S. Engineering Applications for Diamond-like Carbon. Diam. Relat. Mater. 1994, 3, 902–911. [Google Scholar] [CrossRef]

- Falcao, E.H.; Wudl, F. Carbon Allotropes: Beyond Graphite and Diamond. J. Chem. Technol. Biotechnol. 2007, 82, 524–531. [Google Scholar] [CrossRef]

- Yuan, S.; Zhang, C.; Amin, M.; Fan, H.; Liu, M. Development of a Cutting Force Prediction Model Based on Brittle Fracture for Carbon Fiber Reinforced Polymers for Rotary Ultrasonic Drilling. Int. J. Adv. Manuf. Technol. 2015, 81, 1223–1231. [Google Scholar] [CrossRef]

- Kromoser, B.; Preinstorfer, P.; Kollegger, J. Building Lightweight Structures with Carbon-Fiber-Reinforced Polymer-Reinforced Ultra-High-Performance Concrete: Research Approach, Construction Materials, and Conceptual Design of Three Building Components. Struct. Concr. 2019, 20, 730–744. [Google Scholar] [CrossRef]

- Ahmad, H.; Markina, A.A.; Porotnikov, M.V.; Ahmad, F. A Review of Carbon Fiber Materials in Automotive Industry. IOP Conf. Ser. Mater. Sci. Eng. 2020, 971, 032011. [Google Scholar] [CrossRef]

- Tang, S.; Hu, C. Design, Preparation and Properties of Carbon Fiber Reinforced Ultra-High Temperature Ceramic Composites for Aerospace Applications: A Review. J. Mater. Sci. Technol. 2017, 33, 117–130. [Google Scholar] [CrossRef]

- Endo, M.; Hayashi, T.; Kim, Y.A.; Muramatsu, H. Development and Application of Carbon Nanotubes. Jpn. J. Appl. Phys. 2006, 45, 4883. [Google Scholar] [CrossRef]

- Dicks, A.L. The Role of Carbon in Fuel Cells. J. Power Sources 2006, 156, 128–141. [Google Scholar] [CrossRef]

- García, E.; Núñez, P.J.; Caminero, M.A.; Chacón, J.M.; Kamarthi, S. Effects of Carbon Fibre Reinforcement on the Geometric Properties of PETG-Based Filament Using FFF Additive Manufacturing. Compos. Part B Eng. 2022, 235, 109766. [Google Scholar] [CrossRef]

- Cao, M.; Cui, T.; Yue, Y.; Li, C.; Guo, X.; Jia, X.; Wang, B. Preparation and Characterization for the Thermal Stability and Mechanical Property of PLA and PLA/CF Samples Built by FFF Approach. Materials 2023, 16, 5023. [Google Scholar] [CrossRef]

- Zach, T.F.; Dudescu, M.C.; Bere, P. High-Temperature Tensile Performance of Fused Filament Fabricated Discontinuous Carbon Fiber-Reinforced Polyamide. Polymers 2025, 17, 1732. [Google Scholar] [CrossRef]

- Dimitrellou, S.; Iakovidis, I.; Psarianos, D.-R. Mechanical Characterization of Polylactic Acid, Polycarbonate, and Carbon Fiber-Reinforced Polyamide Specimens Fabricated by Fused Deposition Modeling. J. Mater. Eng. Perform. 2024, 33, 3613–3626. [Google Scholar] [CrossRef]

- Sadaghian, H.; Khalilzadehtabrizi, S.; Farzam, M.; Dehghan, S. Behavior of 3D-Printed Polymers under Monotonic Torsion—A Database of 15 Different Materials. Addit. Manuf. 2022, 60, 103251. [Google Scholar] [CrossRef]

- Condruz, M.-R.; Paraschiv, A.; Badea, T.-A.; Useriu, D.; Frigioescu, T.-F.; Badea, G.; Cican, G. A Study on Mechanical Properties of Low-Cost Thermoplastic-Based Materials for Material Extrusion Additive Manufacturing. Polymers 2023, 15, 2981. [Google Scholar] [CrossRef]

- Zaharia, S.-M.; Pascariu, I.S.; Chicos, L.-A.; Buican, G.R.; Pop, M.A.; Lancea, C.; Stamate, V.M. Material Extrusion Additive Manufacturing of the Composite UAV Used for Search-and-Rescue Missions. Drones 2023, 7, 602. [Google Scholar] [CrossRef]

- Belei, C.; Joeressen, J.; Amancio-Filho, S.T. Fused-Filament Fabrication of Short Carbon Fiber-Reinforced Polyamide: Parameter Optimization for Improved Performance under Uniaxial Tensile Loading. Polymers 2022, 14, 1292. [Google Scholar] [CrossRef] [PubMed]

- Li, Q.; Rao, R.; Hong, X.; Hu, H.; Li, Y.; Gong, Z.; Zheng, Y. Thermal Conductive Nylon 6 Composites Using Hybrid Fillers to Construct a Three-Dimensional Thermal Conductive Network. Polym. Compos. 2024, 45, 6169–6183. [Google Scholar] [CrossRef]

- Seki, Y.; Kizilkan, E.; İşbilir, A.; Sarikanat, M.; Altay, L. Enhanced In-Plane and through-Plane Thermal Conductivity and Mechanical Properties of Polyamide 4.6 Composites Loaded with Hybrid Carbon Fiber, Synthetic Graphite and Graphene. Polym. Compos. 2021, 42, 4630–4642. [Google Scholar] [CrossRef]

- Limpadapun, K.; Sukmanee, J. A Study of an Effect on Moisture from 3D Printer Filament Drying Processes. Key Eng. Mater. 2021, 902, 101–106. [Google Scholar] [CrossRef]

- Mu, W.; Chen, X.; Li, S.; Sun, Y.; Wang, Q.; Na, J. Mechanical Performances Analysis and Prediction of Short Plant Fiber-Reinforced PLA Composites. Polymers 2023, 15, 3222. [Google Scholar] [CrossRef] [PubMed]

- Cao, M.; Cui, T.; Yue, Y.; Li, C.; Guo, X.; Jia, X.; Wang, B. Investigation of Carbon Fiber on the Tensile Property of FDM-Produced PLA Specimen. Polymers 2022, 14, 5230. [Google Scholar] [CrossRef] [PubMed]

- Travieso-Rodriguez, J.A.; Jerez-Mesa, R.; Llumà, J.; Traver-Ramos, O.; Gomez-Gras, G.; Roa Rovira, J.J. Mechanical Properties of 3D-Printing Polylactic Acid Parts Subjected to Bending Stress and Fatigue Testing. Materials 2019, 12, 3859. [Google Scholar] [CrossRef]

- Kumar, K.R.; Mohanavel, V.; Kiran, K. Mechanical Properties and Characterization of Polylactic Acid/Carbon Fiber Composite Fabricated by Fused Deposition Modeling. J. Mater. Eng. Perform. 2022, 31, 4877–4886. [Google Scholar] [CrossRef]

- ASTM D638; Standard Test Method for Tensile Properties of Plastics. ASTM International: West Conshohocken, PA, USA, 2014.

- ASTM D256; Standard Test Methods for Determining the Izod Pendulum Impact Resistance of Plastics. ASTM International: West Conshohocken, PA, USA, 2018.

- Mukherji, D. Thermal Conductivity of Polymers: A Simple Matter Where Complexity Matters. Macromol. Rapid Commun. 2024, 45, 2400517. [Google Scholar] [CrossRef]

- Huang, C.; Qian, X.; Yang, R. Thermal Conductivity of Polymers and Polymer Nanocomposites. Mater. Sci. Eng. R Rep. 2018, 132, 1–22. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).