Exploring the Impact of Cooling Environments on the Machinability of AM-AlSi10Mg: Optimizing Cooling Techniques and Predictive Modelling

Abstract

1. Introduction

2. Materials and Methods

2.1. Cooling Conditions

2.2. Measurement

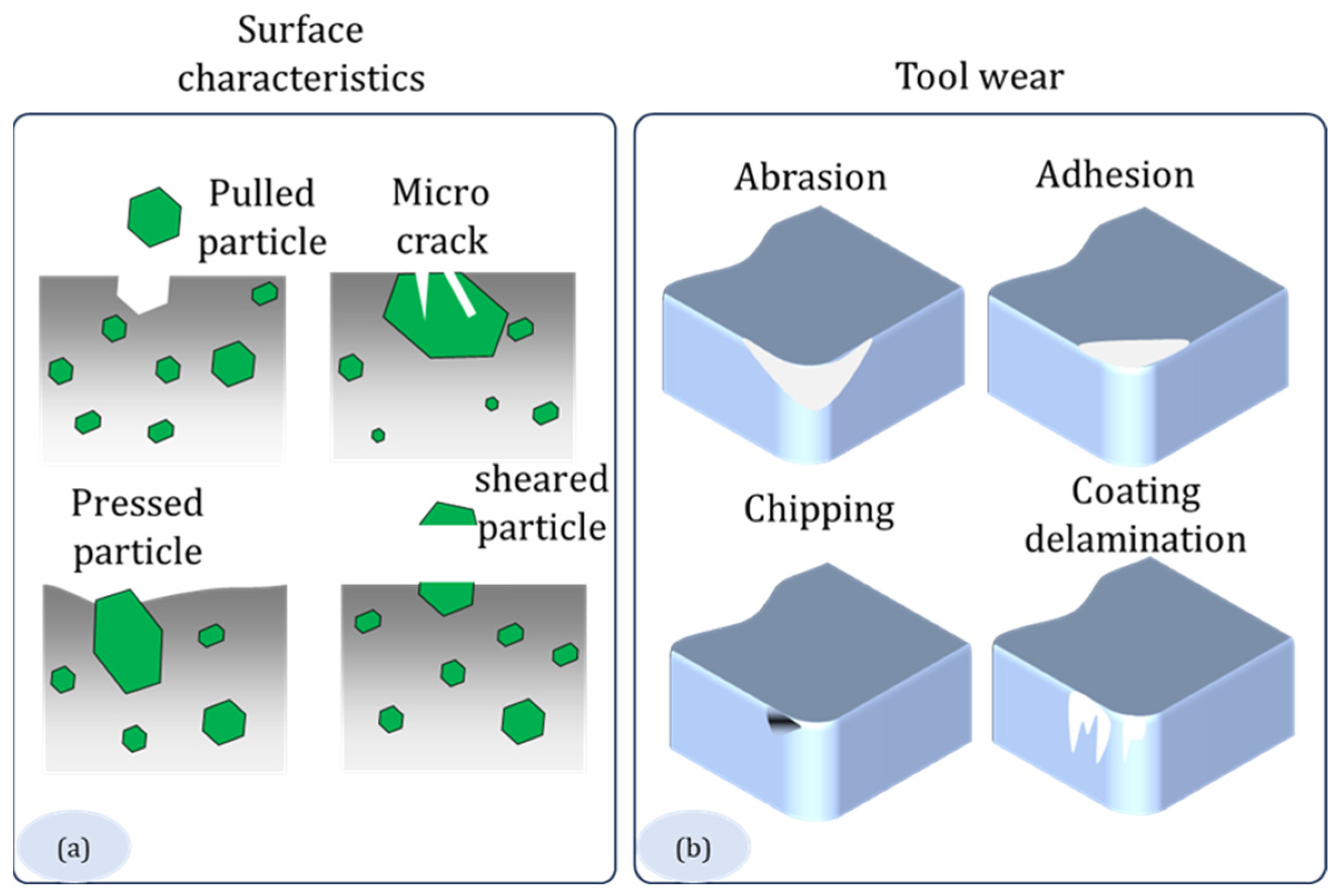

3. Material Removal and Tool Wear Mechanisms

4. Results and Discussions

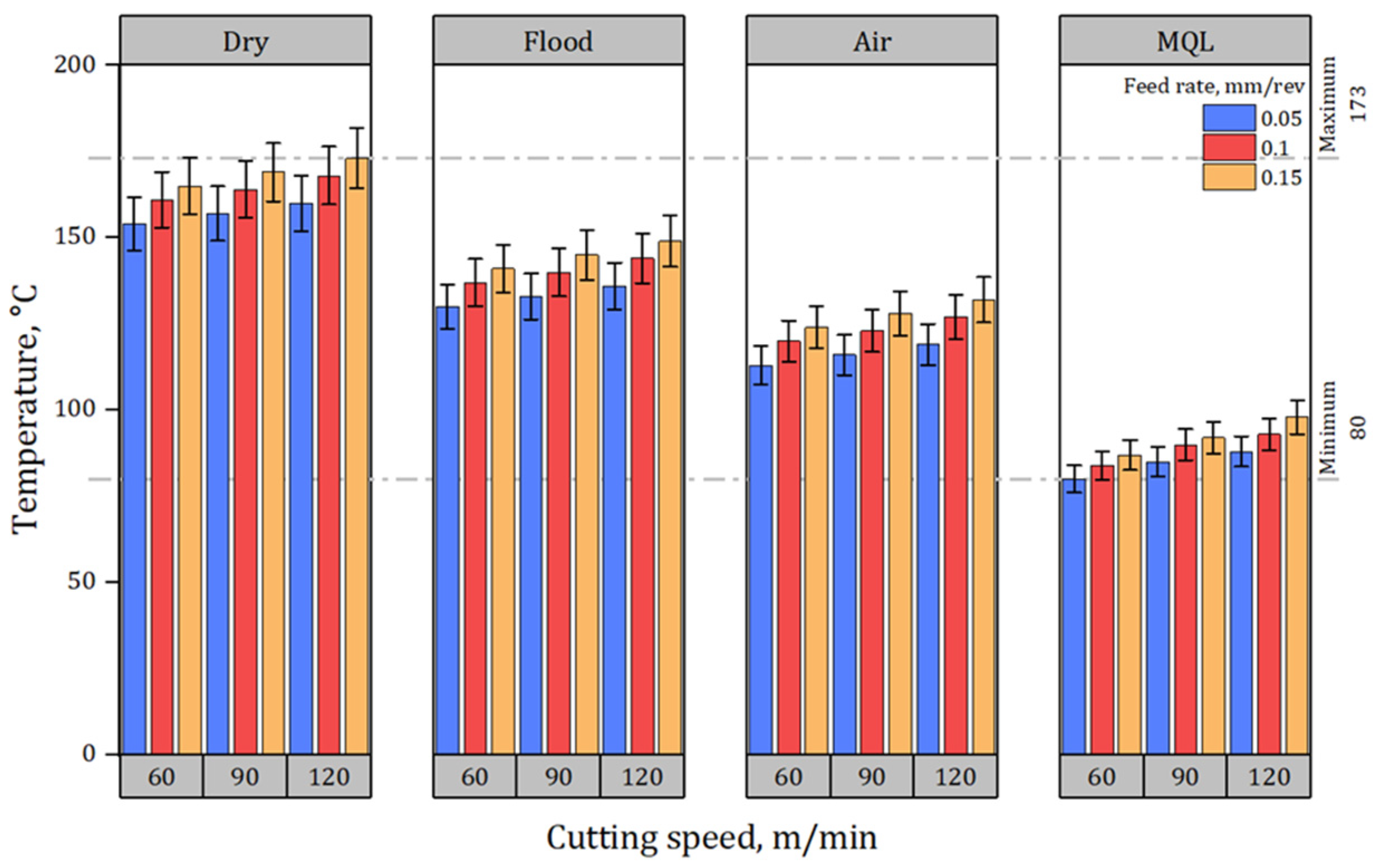

4.1. Effect of Temperature

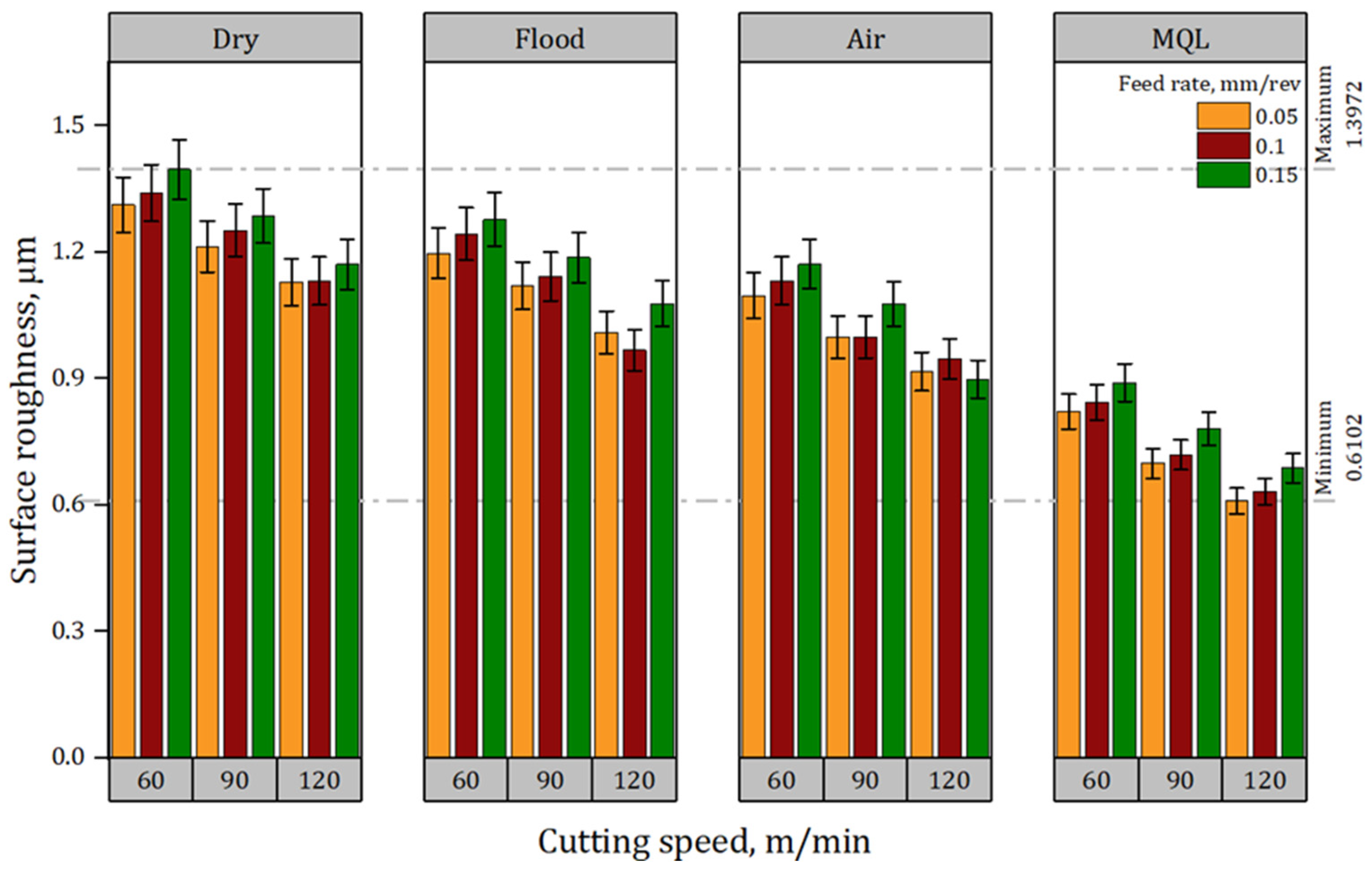

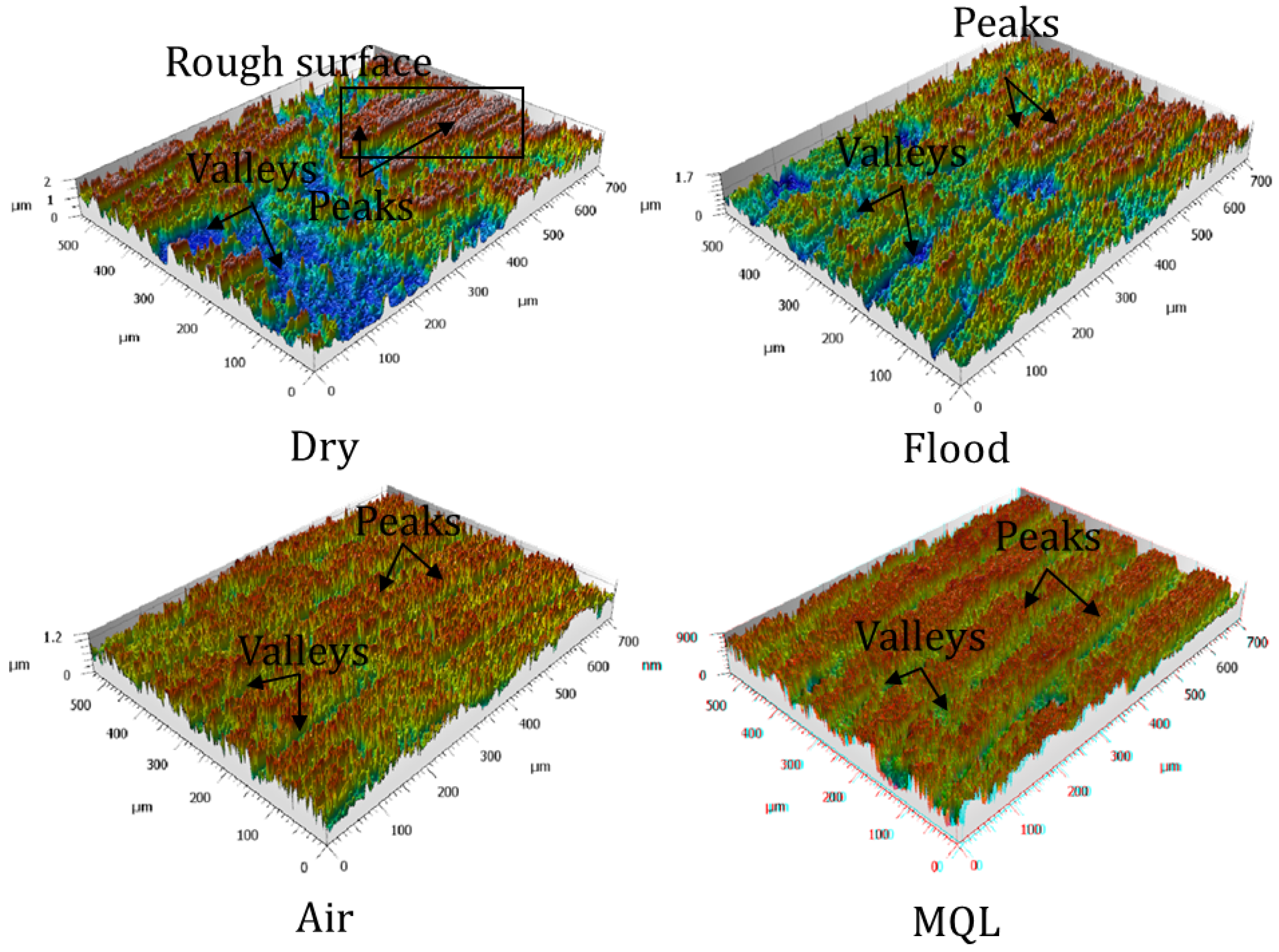

4.2. Effect of Surface Roughness

4.3. Effect of Flank Wear

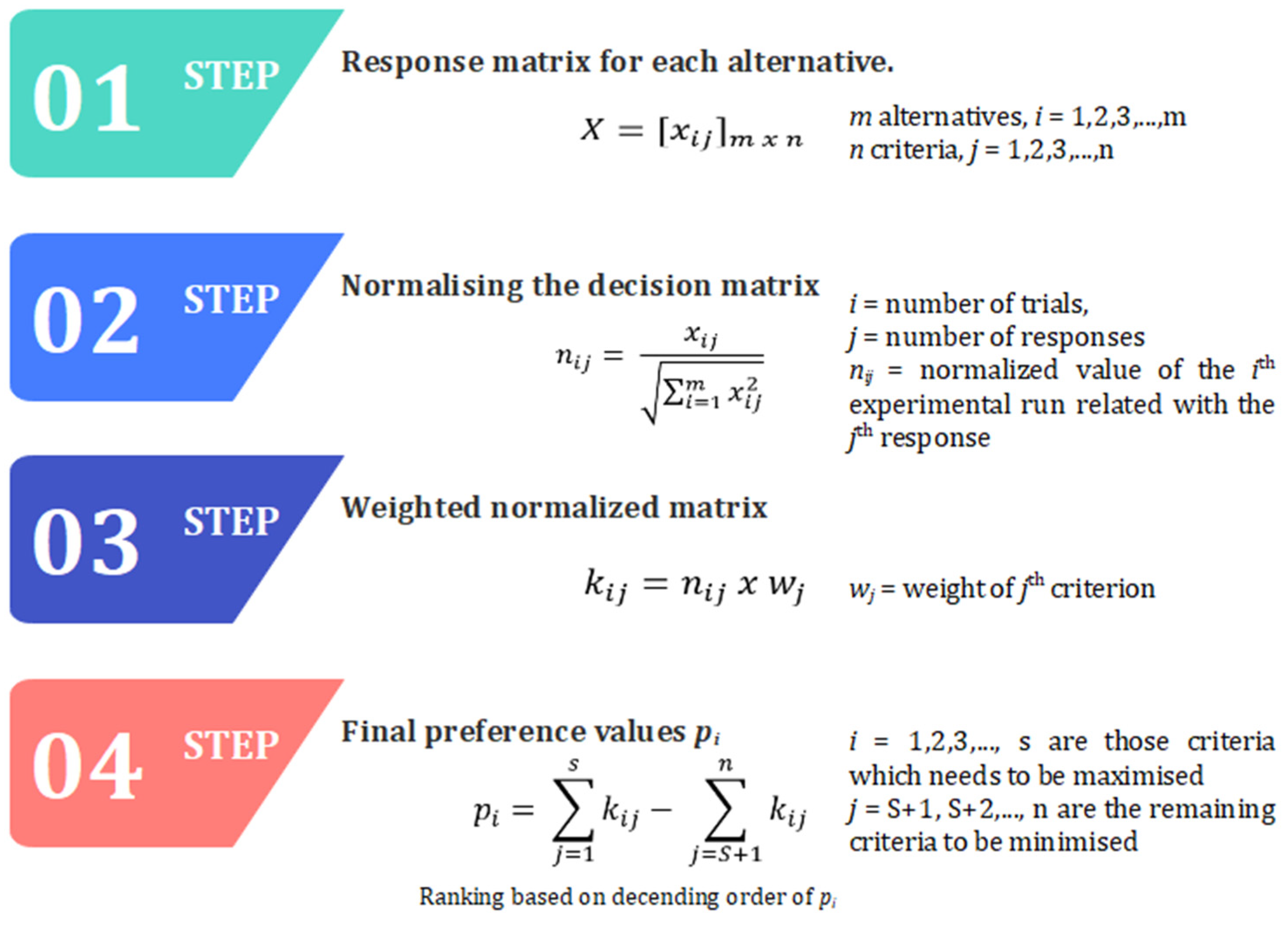

5. Optimizations with MOORA

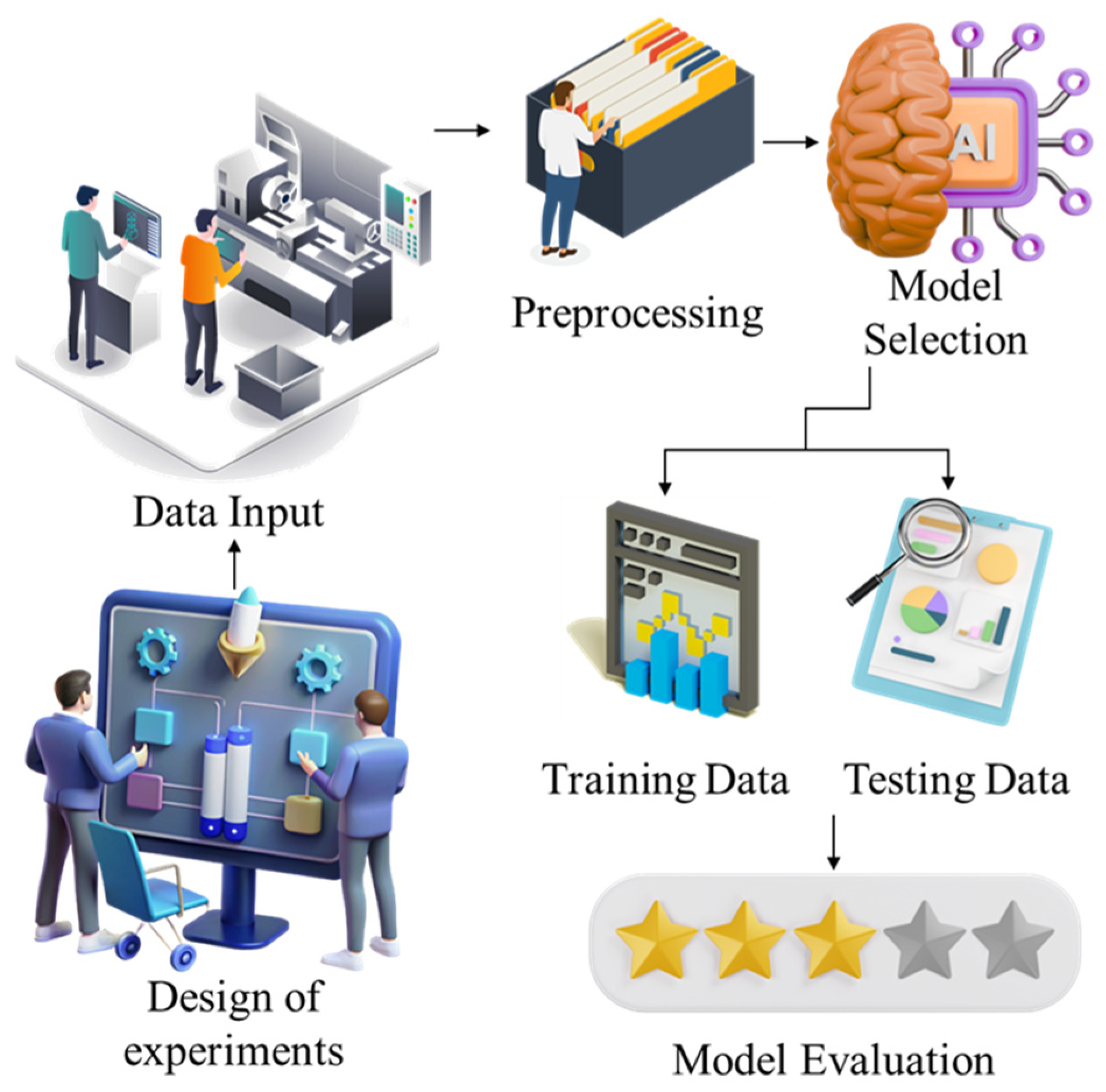

6. Machine Learning

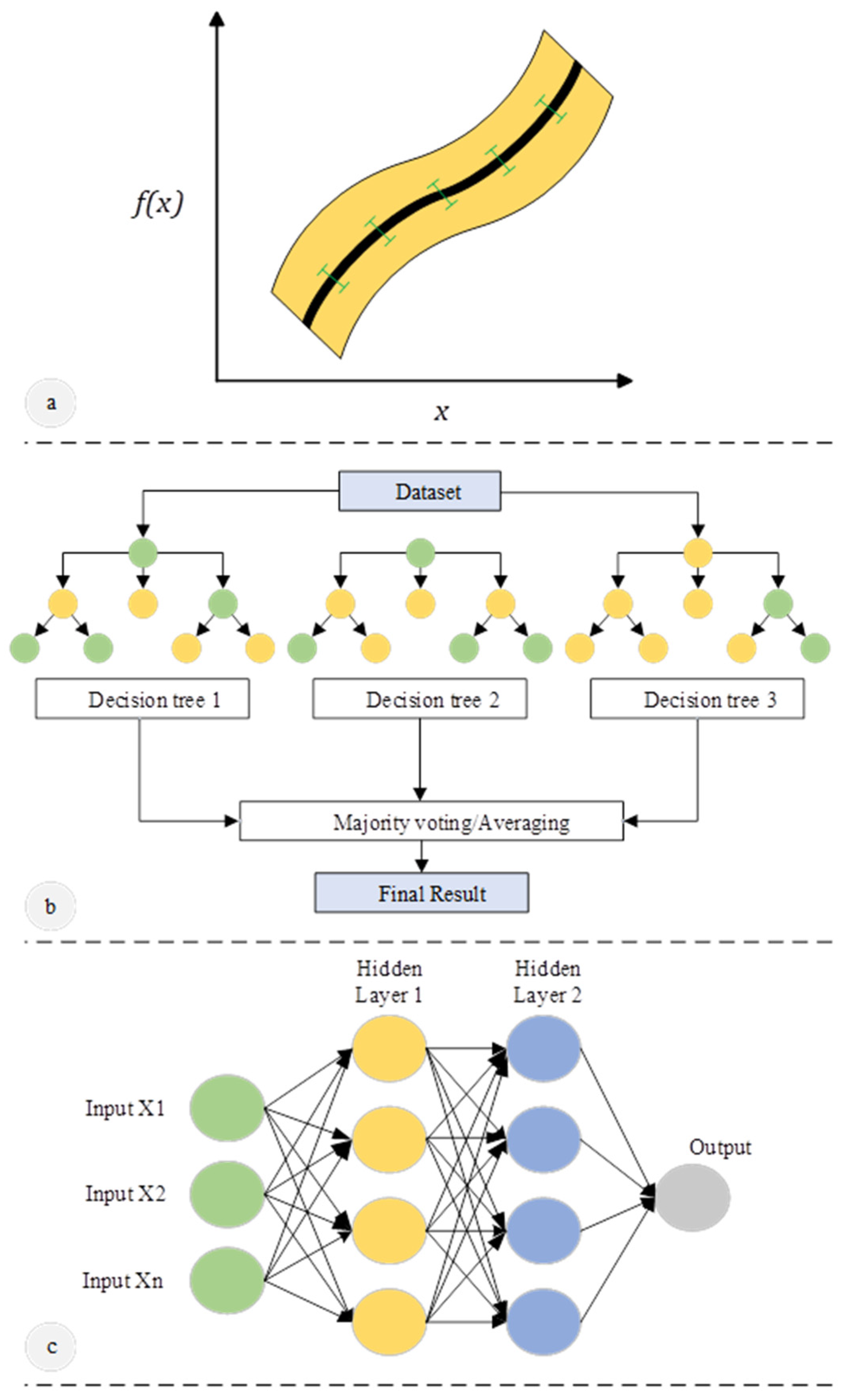

- Gaussian Process Regression

- Random Forest

- Multi-Layer Perceptron

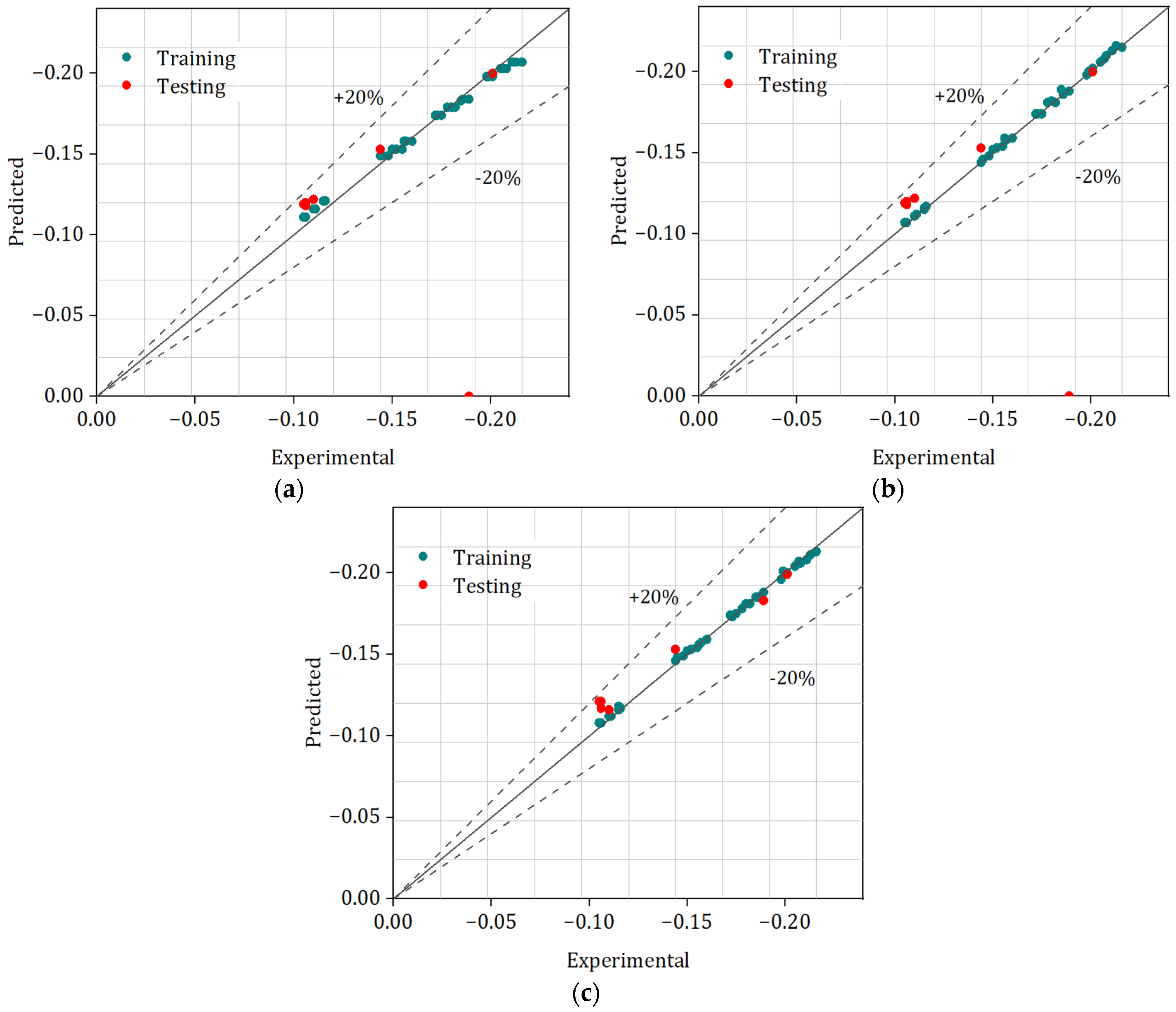

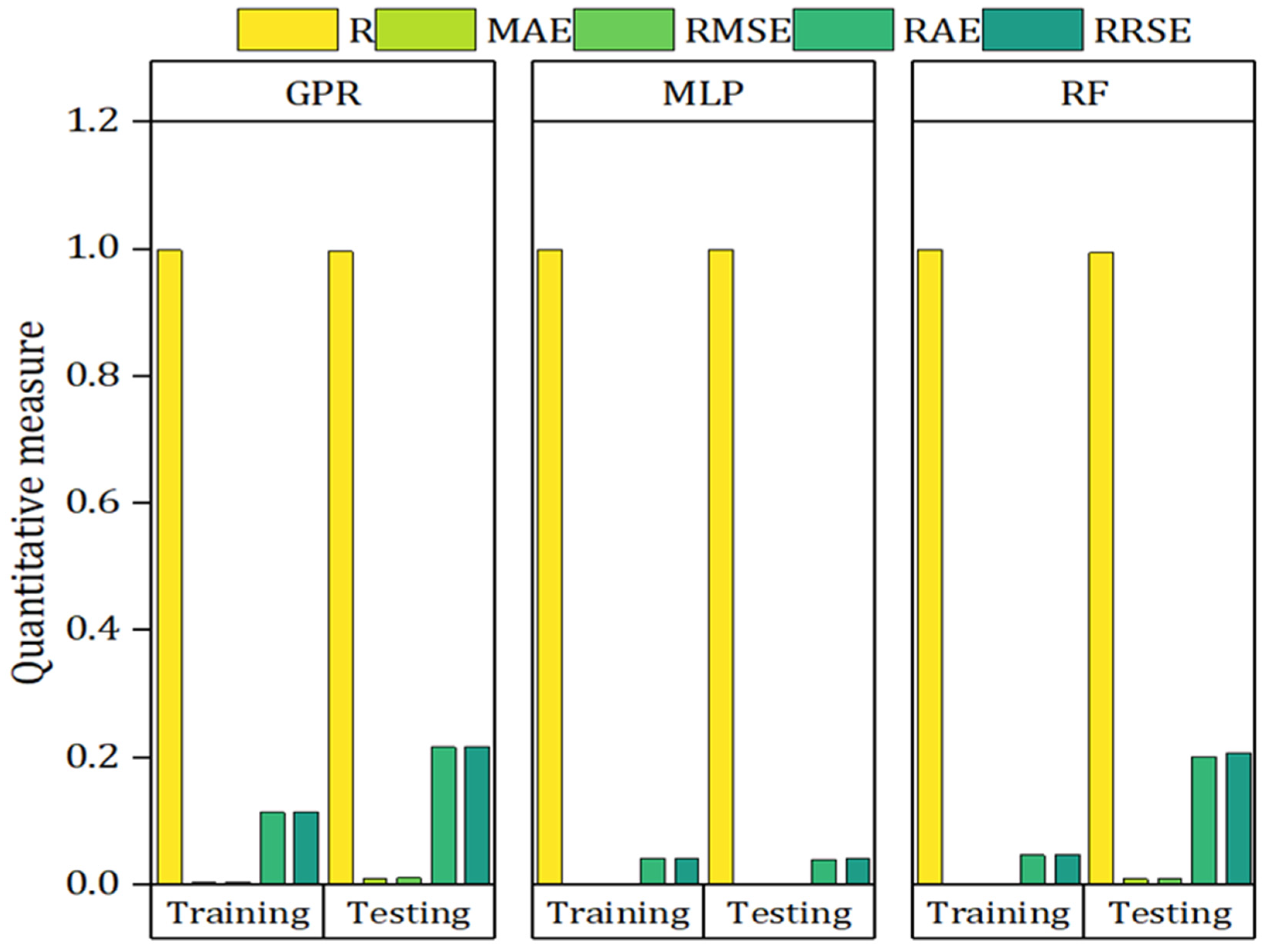

6.1. Prediction

6.2. Evaluation Metrics

7. Conclusions

- The machining environment has a major impact on the cutting temperature; dry cutting yields the highest temperature, 173 °C, at 120 m/min and 0.15 mm/rev. The greatest shift is made with MQL employing Cao, which reduces heat generation (80–98 °C) because of its excellent lubricating and film-forming qualities.

- Due to higher friction and vibration, dry cutting produces the highest Ra values at 60 m/min and 0.15 mm/rev, and the peak Ra is 1.3972 µm. By minimizing friction and tool wear, MQL produces the best results, lowering Ra to 0.6102 µm at 120 m/min and 0.05 mm/rev. With the lowest Ra values across all the conditions, the air and oil combination turns out to be the most efficient.

- MQL effectively lowers Vb, making it the most successful C/L method. It prolongs tool life, reduces friction, and stops excessive heat buildup with its thin oil spray. MQL ensures stable cutting performance by reducing severe adhesion and coating peel-off, in contrast to other conditions. By lowering wear and metal transfer, the enhanced lubrication maintains superior surface quality.

- The ideal machining parameters, which ensure effective performance, were determined by the MOORA method to be MQL, with a Vc of 90 m/min, and fr of 0.05 mm/rev. This combination reduced tool wear (Vb = 0.078 mm), maintained an ideal temperature of 85 °C, and produced a fine Ra of 0.6999 µm. The outcomes verify enhanced surface quality, longer tool life, and lower operating expenses, making it perfect for precision machining.

- With R values of 0.9993 in testing and 0.9995 in training, MLP demonstrated the highest correlation between predicted and measured values, surpassing GPR and RF in terms of predictive accuracy. Furthermore, MLP had the lowest error rates in both the training and testing stages and showed higher accuracy across all assessment metrics (MAE, RMSE, RAE, and RRSE).

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| AM | Additively Manufactured |

| LPBF | Laser powder bed fusion |

| EBM | Electron Beam Melting |

| MQL | Minimal Quantity Lubrication |

| MOORA | Multi-Objective Optimization by Ratio Analysis |

| ML | Machine Learning |

| MLP | Multi-Layer Perceptron |

| GPR | Gaussian Process Regression |

| RF | Random Forest |

| SLM | Selective Laser Melting |

| LT | Layer thickness |

| SM | Subtractive Manufacturing |

| GP | Genetic Programming |

| BUE | Built-up Edge |

| MAE | Mean Absolute Error |

| RMSE | Root Mean Squared Error |

| RAE | Relative Absolute Error |

| RRSE | Relative Squared Error |

References

- Lee, H.; Lim, C.H.J.; Low, M.J.; Tham, N.; Murukeshan, V.M.; Kim, Y.J. Lasers in additive manufacturing: A review. Int. J. Precis. Eng. Manuf.-Green Technol. 2017, 4, 307–322. [Google Scholar] [CrossRef]

- Boretti, A. Metal additive manufacturing for internal combustion enginecomponents: A narrative review of applications, materials, processes, challenges, and future directions. Int. J. Adv. Manuf. Technol. 2025, 139, 6355–6397. [Google Scholar] [CrossRef]

- Pardeep, P.D. Exploring the Role of 3D Printing in Aerospace Engineering: Innovations in Lightweight Structural Components. Shodh Prakashan J. Eng. Sci. Res. 2025, 1, 77–98. [Google Scholar]

- Obeidi, M.A. Metal additive manufacturing by laser-powder bed fusion: Guidelines for process optimisation. Results Eng. 2022, 15, 100473. [Google Scholar] [CrossRef]

- Aboulkhair, N.T.; Simonelli, M.; Parry, L.; Ashcroft, I.; Tuck, C.; Hague, R. 3D printing of Aluminium alloys: Additive Manufacturing of Aluminium alloys using selective laser melting. Prog. Mater. Sci. 2019, 106, 100578. [Google Scholar] [CrossRef]

- Taghian, M.; Mosallanejad, M.H.; Lannunziata, E.; Del Greco, G.; Iuliano, L.; Saboori, A. Laser powder bed fusion of metallic components: Latest progress in productivity, quality, and cost perspectives. J. Mater. Res. Technol. 2023, 27, 6484–6500. [Google Scholar] [CrossRef]

- Poncelet, O.; Marteleur, M.; van der Rest, C.; Rigo, O.; Adrien, J.; Dancette, S.; Dancette, S.; Simar, A. Critical assessment of the impact of process parameters on vertical roughness and hardness of thin walls of AlSi10Mg processed by laser powder bed fusion. Addit. Manuf. 2021, 38, 101801. [Google Scholar] [CrossRef]

- Soe, A.N.; Sombatmai, A.; Promoppatum, P.; Srimaneepong, V.; Trachoo, V.; Pandee, P. Effect of post-processing treatments on surface roughness and mechanical properties of laser powder bed fusion of Ti–6Al–4V. J. Mater. Res. Technol. 2024, 32, 3788–3803. [Google Scholar] [CrossRef]

- Ross, N.S.; Srinivasan, N.; Ananth, M.B.J.; AlFaify, A.Y.; Anwar, S.; Gupta, M.K. Performance assessment of different cooling conditions in improving the machining and tribological characteristics of additively manufactured AlSi10Mg alloy. Tribol. Int. 2023, 186, 108631. [Google Scholar] [CrossRef]

- Schneider, S.A.; Hermsen, S.; Kirchmann, S.; Ganser, P.; Bergs, T.; Schleifenbaum, J.H. Machinability Analysis for Milling of Additively Manufactured Inconel 718 with Specifically Induced Porosity; Gottfried Wilhelm Leibniz Universität Hannover, Institut für Fertigungstechnik und Werkzeugmaschinen: Hannover, Germany, 2022; pp. 51–58. [Google Scholar]

- Bandyopadhyay, A.; Traxel, K.D.; Lang, M.; Juhasz, M.; Eliaz, N.; Bose, S. Alloy design via additive manufacturing: Advantages, challenges, applications and perspectives. Mater. Today 2022, 52, 207–224. [Google Scholar] [CrossRef]

- Zimmermann, M.; Müller, D.; Kirsch, B.; Greco, S.; Aurich, J.C. Analysis of the machinability when milling AlSi10Mg additively manufactured via laser-based powder bed fusion. Int. J. Adv. Manuf. Technol. 2021, 112, 989–1005. [Google Scholar] [CrossRef]

- Ross, N.S.; Rai, R.; Ananth, M.B.J.; Srinivasan, D.; Ganesh, M.; Gupta, M.K.; Korkmaz, M.E.; Krolczyk, G.M. Carbon emissions and overall sustainability assessment in eco-friendly machining of Monel-400 alloy. Sustain. Mater. Technol. 2023, 37, e00675. [Google Scholar] [CrossRef]

- Wood, P.; Díaz-Álvarez, J.; Rusinek, A.; Gunputh, U.; Bahi, S.; Díaz-Álvarez, A.; Miguélez, M.H.; Lu, Y.L.; Platek, P.; Sienkiewicz, J. Microstructure effects on the machinability of AM-produced superalloys. Crystals 2023, 13, 1190. [Google Scholar] [CrossRef]

- Lubis, M.I.J.; Ginting, A. A Review: Development of MQL systems applied for metal cutting. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Medan, Indonesia, 3–4 September 2020; IOP Publishing: Bristol, UK, 2020. [Google Scholar]

- Ramoni, M.; Shanmugam, R.; Ross, N.S.; Gupta, M.K. An experimental investigation of hybrid manufactured SLM based Al-Si10-Mg alloy under mist cooling conditions. J. Manuf. Process. 2021, 70, 225–235. [Google Scholar] [CrossRef]

- Radhika, N.; Babudeva Senapathi, S.; Subramaniam, R.; Subramany, R.; Vishnu, K.N. Pattern recognition based surface roughness prediction in turning hybrid metal matrix composite using random forest algorithm. Ind. Lubr. Tribol. 2013, 65, 311–319. [Google Scholar] [CrossRef]

- Babu, T.R.; Samuel, G.L. Prediction of Machining Quality and Tool Wear in Micro-Turning Machine Using Machine Learning Models. In Advances in Micro and Nano Manufacturing and Surface Engineering: Proceedings of AIMTDR 2021; Springer Nature: Singapore, 2022; pp. 1–12. [Google Scholar]

- Bustillo, A.; Pimenov, D.Y.; Mia, M.; Kapłonek, W. Machine-learning for automatic prediction of flatness deviation considering the wear of the face mill teeth. J. Intell. Manuf. 2021, 32, 895–912. [Google Scholar] [CrossRef]

- Laghari, R.A.; Pourmostaghimi, V.; Laghari, A.A.; Qazani, M.R.C.; Sarhan, A.A. Genetic modeling for enhancing machining performance of high-volume fraction 45% SiCp/Al particle reinforcement metal matrix composite. Arab. J. Sci. Eng. 2025, 50, 9043–9059. [Google Scholar] [CrossRef]

- Al Ansari, M.S.; Kaliappan, S.; Mrudula, G.; Dehankar, P.B.; Maranan, R.; Teja, P.V.S. Optimizing Milling Parameters for Al7075/nano SiC/TiC Hybrid Metal Matrix Composites using Taguchi Analysis and ANN Prediction. E3S Web Conf. 2024, 556, 01021. [Google Scholar]

- Hong, Y.; Guo, K.; Sun, J.; Yang, B.; Zhang, C. Investigation on vibration properties of 3D printed lattice structures filled with tin–bismuth alloy. J. Appl. Phys. 2022, 131, 065105. [Google Scholar] [CrossRef]

- Sun, Q.; Sun, J.; Guo, K.; Liu, J. Investigation on mechanical properties and energy absorption capabilities of AlSi10Mg triply periodic minimal surface sheet structures fabricated via selective laser melting. J. Mater. Eng. Perform. 2022, 31, 9110–9121. [Google Scholar] [CrossRef]

- Jia, D.; Li, C.; Zhang, Y.; Yang, M.; Wang, Y.; Guo, S.; Cao, H. Specific energy and surface roughness of minimum quantity lubrication grinding Ni-based alloy with mixed vegetable oil-based nanofluids. Precis. Eng. 2017, 50, 248–262. [Google Scholar] [CrossRef]

- Korkmaz, M.E.; Gupta, M.K.; Ross, N.S.; Sivalingam, V. Implementation of green cooling/lubrication strategies in metal cutting industries: A state of the art towards sustainable future and challenges. Sustain. Mater. Technol. 2023, 36, e00641. [Google Scholar] [CrossRef]

- Ross, N.S.; Mashinini, P.M.; Mishra, P.; Ananth, M.B.J.; Mustafa, S.M.; Gupta, M.K.; Korkmaz, M.E.; Nag, A. Enhancing surface quality and tool life in SLM-machined components with Dual-MQL approach. J. Mater. Res. Technol. 2024, 31, 1837–1852. [Google Scholar] [CrossRef]

- Ramanan, K.V.; Ramesh Babu, S.; Jebaraj, M.; Nimel Sworna Ross, K. Face turning of Incoloy 800 under MQL and nano-MQL environments. Mater. Manuf. Process. 2021, 36, 1769–1780. [Google Scholar] [CrossRef]

- Ross, N.S.; Sheeba, P.T.; Shibi, C.S.; Gupta, M.K.; Korkmaz, M.E.; Sharma, V.S. A novel approach of tool condition monitoring in sustainable machining of Ni alloy with transfer learning models. J. Intell. Manuf. 2024, 35, 757–775. [Google Scholar] [CrossRef]

- Gupta, M.K.; Mia, M.; Jamil, M.; Singh, R.; Singla, A.K.; Song, Q.; Liu, Z.Q.; Khan, A.M.; Sarikaya, M. Machinability investigations of hardened steel with biodegradable oil-based MQL spray system. Int. J. Adv. Manuf. Technol. 2020, 108, 735–748. [Google Scholar] [CrossRef]

- Karabacak, Y.E. Intelligent milling tool wear estimation based on machine learning algorithms. J. Mech. Sci. Technol. 2024, 38, 835–850. [Google Scholar] [CrossRef]

- Sivalingam, V.; Zhou, Q.; Ross, N.S.; Tiwari, S.; Selvam, B.; Sun, J.; Gupta, M.K. Identification of tool wear and surface morphology measurements in sustainable milling of Al 6082 hybrid metal matrix composite. J. Mater. Res. Technol. 2023, 27, 7570–7581. [Google Scholar] [CrossRef]

- Prashanth, G.S.; Sekar, P.; Bontha, S.; Balan, A.S.S. Grinding parameters prediction under different cooling environments using machine learning techniques. Mater. Manuf. Process. 2023, 38, 235–244. [Google Scholar] [CrossRef]

- Sankaranarayanan, R.; Hynes, N.R.J.; Kumar, J.S.; Sujana, J.A.J. Random decision forest based sustainable green machining using Citrullus lanatus extract as bio-cutting fluid. J. Manuf. Process. 2021, 68, 1814–1823. [Google Scholar] [CrossRef]

- Danish, M.; Gupta, M.K.; Irfan, S.A.; Ghazali, S.M.; Rathore, M.F.; Krolczyk, G.M.; Alsaady, A. Machine learning models for prediction and classification of tool wear in sustainable milling of additively manufactured 316 stainless steel. Results Eng. 2024, 22, 102015. [Google Scholar] [CrossRef]

| Milling machine | Feeler FV 1000 |

| Workpiece | AlSi10Mg |

| Dimension (cm) | 10 × 5 × 1 |

| Insert (tool) coating | WC-TiAlN |

| Insert Model | APMT |

| Length of cut (cm) | 5 (2 passes) |

| Speed (m/min) | 45–60 |

| Feed (mm/rev) | 0.1–0.20 |

| Radial DOC (mm) | 12 |

| Axial DOC (mm) | 2 |

| Environment | Cutting Speed | Feed Rate | Normalized (nij) | Weighted (kij) | Pi | Rank | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| Dry | 60 | 0.05 | 0.1953 | 0.2065 | 0.1917 | 0.0651 | 0.0688 | 0.0639 | −0.1978 | 28 |

| Dry | 60 | 0.1 | 0.2041 | 0.2109 | 0.1993 | 0.0680 | 0.0703 | 0.0664 | −0.2048 | 31 |

| Dry | 60 | 0.15 | 0.2092 | 0.2197 | 0.2043 | 0.0697 | 0.0732 | 0.0681 | −0.2111 | 34 |

| Dry | 90 | 0.05 | 0.1991 | 0.1909 | 0.2068 | 0.0664 | 0.0636 | 0.0689 | −0.1989 | 29 |

| Dry | 90 | 0.1 | 0.2079 | 0.1970 | 0.2168 | 0.0693 | 0.0657 | 0.0723 | −0.2072 | 32 |

| Dry | 90 | 0.15 | 0.2143 | 0.2024 | 0.2318 | 0.0714 | 0.0675 | 0.0773 | −0.2162 | 36 |

| Dry | 120 | 0.05 | 0.2029 | 0.1777 | 0.2231 | 0.0676 | 0.0592 | 0.0744 | −0.2012 | 30 |

| Dry | 120 | 0.1 | 0.2130 | 0.1781 | 0.2331 | 0.0710 | 0.0594 | 0.0777 | −0.2081 | 33 |

| Dry | 120 | 0.15 | 0.2193 | 0.1842 | 0.2356 | 0.0731 | 0.0614 | 0.0785 | −0.2130 | 35 |

| Flood | 60 | 0.05 | 0.1648 | 0.1884 | 0.1642 | 0.0549 | 0.0628 | 0.0547 | −0.1725 | 19 |

| Flood | 60 | 0.1 | 0.1737 | 0.1956 | 0.1717 | 0.0579 | 0.0652 | 0.0572 | −0.1803 | 23 |

| Flood | 60 | 0.15 | 0.1788 | 0.2010 | 0.1767 | 0.0596 | 0.0670 | 0.0589 | −0.1855 | 25 |

| Flood | 90 | 0.05 | 0.1686 | 0.1763 | 0.1792 | 0.0562 | 0.0588 | 0.0597 | −0.1747 | 21 |

| Flood | 90 | 0.1 | 0.1775 | 0.1797 | 0.1892 | 0.0592 | 0.0599 | 0.0631 | −0.1822 | 24 |

| Flood | 90 | 0.15 | 0.1838 | 0.1868 | 0.1967 | 0.0613 | 0.0623 | 0.0656 | −0.1891 | 27 |

| Flood | 120 | 0.05 | 0.1724 | 0.1588 | 0.1880 | 0.0575 | 0.0529 | 0.0627 | −0.1731 | 20 |

| Flood | 120 | 0.1 | 0.1826 | 0.1523 | 0.1980 | 0.0609 | 0.0508 | 0.0660 | −0.1776 | 22 |

| Flood | 120 | 0.15 | 0.1889 | 0.1696 | 0.2005 | 0.0630 | 0.0565 | 0.0668 | −0.1864 | 26 |

| Air | 60 | 0.05 | 0.1433 | 0.1727 | 0.1165 | 0.0478 | 0.0576 | 0.0388 | −0.1442 | 10 |

| Air | 60 | 0.1 | 0.1521 | 0.1781 | 0.1203 | 0.0507 | 0.0594 | 0.0401 | −0.1502 | 13 |

| Air | 60 | 0.15 | 0.1572 | 0.1844 | 0.1291 | 0.0524 | 0.0615 | 0.0430 | −0.1569 | 17 |

| Air | 90 | 0.05 | 0.1471 | 0.1571 | 0.1316 | 0.0490 | 0.0524 | 0.0439 | −0.1453 | 11 |

| Air | 90 | 0.1 | 0.1560 | 0.1573 | 0.1416 | 0.0520 | 0.0524 | 0.0472 | −0.1516 | 14 |

| Air | 90 | 0.15 | 0.1623 | 0.1695 | 0.1491 | 0.0541 | 0.0565 | 0.0497 | −0.1603 | 18 |

| Air | 120 | 0.05 | 0.1509 | 0.1442 | 0.1479 | 0.0503 | 0.0481 | 0.0493 | −0.1477 | 12 |

| Air | 120 | 0.1 | 0.1610 | 0.1492 | 0.1541 | 0.0537 | 0.0497 | 0.0514 | −0.1548 | 15 |

| Air | 120 | 0.15 | 0.1674 | 0.1414 | 0.1592 | 0.0558 | 0.0471 | 0.0531 | −0.1560 | 16 |

| MQL | 60 | 0.05 | 0.1014 | 0.1293 | 0.0865 | 0.0338 | 0.0431 | 0.0288 | −0.1057 | 2 |

| MQL | 60 | 0.1 | 0.1065 | 0.1327 | 0.0902 | 0.0355 | 0.0442 | 0.0301 | −0.1098 | 5 |

| MQL | 60 | 0.15 | 0.1103 | 0.1401 | 0.0940 | 0.0368 | 0.0467 | 0.0313 | −0.1148 | 7 |

| MQL | 90 | 0.05 | 0.1078 | 0.1100 | 0.0977 | 0.0359 | 0.0367 | 0.0326 | −0.1052 | 1 |

| MQL | 90 | 0.1 | 0.1141 | 0.1132 | 0.1015 | 0.0380 | 0.0377 | 0.0338 | −0.1096 | 4 |

| MQL | 90 | 0.15 | 0.1166 | 0.1230 | 0.1053 | 0.0389 | 0.0410 | 0.0351 | −0.1150 | 8 |

| MQL | 120 | 0.05 | 0.1116 | 0.0959 | 0.1115 | 0.0372 | 0.0320 | 0.0372 | −0.1064 | 3 |

| MQL | 120 | 0.1 | 0.1179 | 0.0996 | 0.1140 | 0.0393 | 0.0332 | 0.0380 | −0.1105 | 6 |

| MQL | 120 | 0.15 | 0.1243 | 0.1082 | 0.1165 | 0.0414 | 0.0361 | 0.0388 | −0.1163 | 9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dou, Z.; Guo, K.; Sun, J.; Huang, X. Exploring the Impact of Cooling Environments on the Machinability of AM-AlSi10Mg: Optimizing Cooling Techniques and Predictive Modelling. Machines 2025, 13, 984. https://doi.org/10.3390/machines13110984

Dou Z, Guo K, Sun J, Huang X. Exploring the Impact of Cooling Environments on the Machinability of AM-AlSi10Mg: Optimizing Cooling Techniques and Predictive Modelling. Machines. 2025; 13(11):984. https://doi.org/10.3390/machines13110984

Chicago/Turabian StyleDou, Zhenhua, Kai Guo, Jie Sun, and Xiaoming Huang. 2025. "Exploring the Impact of Cooling Environments on the Machinability of AM-AlSi10Mg: Optimizing Cooling Techniques and Predictive Modelling" Machines 13, no. 11: 984. https://doi.org/10.3390/machines13110984

APA StyleDou, Z., Guo, K., Sun, J., & Huang, X. (2025). Exploring the Impact of Cooling Environments on the Machinability of AM-AlSi10Mg: Optimizing Cooling Techniques and Predictive Modelling. Machines, 13(11), 984. https://doi.org/10.3390/machines13110984