Abstract

In certain mining areas, bauxite ore exhibits high and uneven hardness, causing frequent overloads in the cutting heads of bauxite mining equipment and challenging the dynamic performance and reliability of its gear transmission system. To investigate the influence of macro-geometric parameters, a dynamic model was built using MASTA software (version 13.0.1). This study systematically analyzed the effects of pressure angle, face width, and bottom clearance coefficient on gear meshing characteristics, service life, and vibration noise under various loads. A preferred set of parameters was determined and validated through vibration and noise tests. The results show that increasing the pressure angle and face width improves gear meshing and fatigue life, while the bottom clearance coefficient has an optimal value of 0.4. Increasing the bottom clearance coefficient exacerbates vibration and noise, with other parameters causing fluctuations under different conditions. The optimal parameters of 23° pressure angle, 75 mm face width, and 0.4 bottom clearance coefficient effectively reduce vibration and noise, providing a theoretical and practical basis for improving the cutting transmission system.

1. Introduction

With the gradual depletion of surface bauxite resources in China, underground bauxite mining has become an inevitable trend. In this context, drawing on the experience of fully mechanized longwall mining in the coal mining industry, there is an urgent industry need to develop drum-type underground bauxite mining equipment for underground bauxite extraction. As the core power transmission component of this equipment, the cutting section transmission system consistently operates under harsh conditions involving heavy loads and strong impacts, with frequent overload occurrences. Its dynamic characteristics and reliability directly determine the operational performance and service life of the entire machine.

As the core elements in gear design, gear geometric parameters play a critical role in regulating the meshing process and directly influence the dynamic performance and reliability of gear transmission systems. Consequently, extensive research has been conducted worldwide to enhance gear performance through parameter optimization. From the perspective of improving gear meshing performance, adjusting geometric parameters effectively reduces contact stress during engagement. Wang et al. [1] demonstrated that appropriate increases in deflection angle and addendum coefficient through tooth flank modification lead to reductions in both bending and contact stresses. Namboothiri and Marimuthu [2] analyzed the effects of macro design parameters—such as contact ratio, rim thickness, number of teeth, and addendum coefficient—on gear fracture resistance, providing valuable theoretical support for high-contact-ratio (HCR) gear design. Wang et al. [3] investigated the influence of modified profile parameters on load sharing factor and tooth contact pressure using a numerical contact model for profile-modified gears. Transmission error (TE), defined as the deviation between the actual position of the driven gear and its theoretically ideal position [4], is a key metric for assessing transmission smoothness [5,6]. Gear modification represents one of the most effective strategies for minimizing transmission error [7,8,9]. Optimizing geometric parameters significantly mitigates meshing impact, vibration, and noise. Litvin et al. [10] applied mathematical methods to develop a parabolic modification theory, thereby reducing meshing impact. Zhou et al. [11] proposed a two-stage profile modification curve; the modified gear model showed improved transmission error characteristics and reduced vibration and noise levels. Bozca [12] optimized gearbox geometric design parameters based on a transmission error model, achieving a gear structure with enhanced bending and contact strength, and confirmed that lower transmission error correlates with reduced vibration and noise. İrsel [13], using the specialized gear design software Romax and a full factorial algorithm, examined three helical gear modification factors—crown, lead slope, and tip relief—and derived an optimized tooth profile that reduced noise response by approximately 10%. Yang et al. [14] proposed an optimal modification design method aimed at minimizing peak-to-peak transmission error (PPTE) in helical gear pairs; vehicle road tests with optimized prototypes validated the method’s effectiveness in reducing both PPTE and drive axle vibration. Cianciotta et al. [15] introduced a gear design optimization approach to reduce noise emissions in automotive e-axles, experimentally verifying its feasibility. Guilbault et al. [16,17,18,19,20,21] developed methods for predicting gear fatigue life and provided frameworks for gear reliability assessment. Wang [22] demonstrated through gear fatigue tests that profile modification can extend tooth bending fatigue life. Overall, optimizing gear geometric parameters contributes to enhanced dynamic performance [23,24,25,26] and improved reliability [27,28,29] of gear transmission systems.

However, a comprehensive review of existing literature reveals two prominent research gaps. First, most studies focus on micro-geometric parameters such as gear modifications, with relatively few addressing the influence of macro-geometric parameters like pressure angle and face width. Second, the load characteristics (shock loads, fluctuations, heavy loads) and transmission methods of mining equipment drive systems are distinctly different from those commonly found in wind power or automotive gear transmission systems. Whether the principles established in general applications still hold true under such extreme and unique working conditions, and how to appropriately apply and balance these principles, are precisely what this study aims to investigate and address. Finally, as research on bauxite mining equipment remains in its early stages with limited relevant studies, the existing literature has largely overlooked the overload issues in gear transmission systems caused by variations in bauxite hardness and cementation, revealing a distinct research gap.

Based on this foundation, the present study focuses on the motor shaft gear that has the highest failure rate in the cutting section transmission system of bauxite mining equipment as the research subject. With the number of gear teeth and module kept constant, the investigation centers on three key macro-geometric parameters—pressure angle, face width, and tip clearance coefficient—and systematically evaluates their influence on the dynamic performance and reliability of the transmission system. The paper is organized as follows: Section 2 outlines the theoretical basis and establishes a dynamic model of the transmission system using the nodal finite element method within MASTA 13.0.1 software. Section 3 conducts a systematic analysis of variations in gear contact stress, misalignment, transmission error, and fatigue life under different parameter settings, and further explores their effects on the system’s vibration and noise characteristics. Section 4 proposes a preferred design scheme for the gear geometric parameters, which is subsequently validated through testing on a gear loading test rig. Finally, Section 5 presents the conclusions.

2. Establishment of the Cutting Transmission System Model for Bauxite Mining Equipment

2.1. Dynamic Model of the Cutting Transmission System

The cutting section transmission system of bauxite mining equipment, functioning as a multi-stage gearbox with multiple excitation sources and a complex transmission path, has dynamic characteristics that directly influence the operational performance and reliability of the equipment. Based on the lumped parameter finite element method, this study comprehensively accounts for the motion and force coupling effects among key components—including gears, shafts, bearings, and the housing—and establishes a dynamic model of the gear transmission system.

The global dynamic equation of the gear transmission system is given by Equation (1):

where , and are the global acceleration, velocity, and displacement column vectors of the system, respectively; , , are the mass, damping, and stiffness matrices assembled from all components; and is the total external force vector acting on the system.

For the drive shaft, in the context of the nodal finite element method, it is discretized into Timoshenko beam elements, each possessing six degrees of freedom—three translational (in the x, y, and z directions) and three rotational (about the x, y, and z axes). The dynamic equation governing the Timoshenko beam element between node and node is given in Equation (2):

where , and are the acceleration, velocity, and displacement column vectors, respectively, between node and node in the geodetic coordinate system; , , and denote the mass matrix, damping matrix, and stiffness matrix of the beam element, respectively.

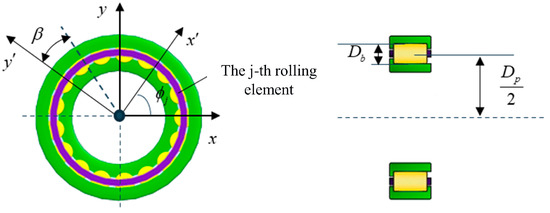

Based on Hertz contact theory and integrated with the Heaviside function, the bearing is modeled as a nonlinear spring–damping element, as illustrated in Figure 1. The complete dynamic response of the bearing comprises both nonlinear contact forces and damping forces. The damping effects are computed by the MASTA software at the system level and integrated into the global damping matrix of the overall dynamic equations.

Figure 1.

Theoretical model of bearing joint element dynamics.

Under complex loading conditions, the displacements of n rollers after compressive contact within the raceway are and . The matrix of the nonlinear contact force is in the form shown in Equation (3):

in the above equation, is the Hertzian contact stiffness; is the total compressive contact deformation of the rolling elements, and are the displacement components in the and directions, respectively, and is the angular position of the -th rolling element.

In the nodal finite element method, gear pairs are modeled as time-varying spring-dampers, accounting for time-varying mesh stiffness and transmission error excitation. Taking the first-stage gear as an example, the dynamic equations for parallel-axis spur gears are given by Equation (4):

here, and denote the mass, moment of inertia, and base circle radius of Gear 1, respectively. The variables and represent the angular displacement, angular velocity, and angular acceleration of Gear 1, respectively. Translational motion of the gear center in the x-direction is described by and , which correspond to displacement, velocity, and acceleration, respectively. Similarly, , and represent the translational displacement, velocity, and acceleration in the y-direction. The meshing stiffness of the gear pair is denoted by , while represent the support stiffnesses in the x- and y-directions, respectively. The torsional stiffness of the shaft is given by . The relative displacement of the gear pair along the line of action is expressed as , is the pressure angle, denotes the torsional displacement of the gear, and refers to the static displacement.

2.2. Model of the Cutting Transmission System

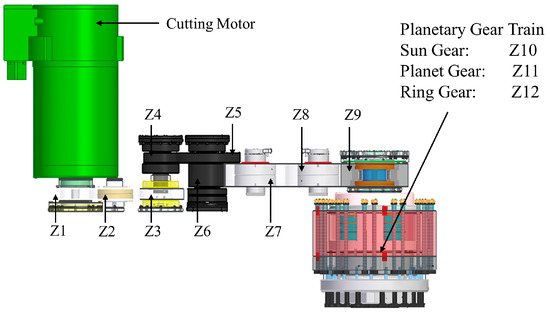

Based on the transmission system model of a conventional drum shearer’s cutting unit and incorporating the operational characteristics specific to bauxite mining, a three-dimensional gear transmission model for the cutting unit of bauxite mining equipment was developed, as illustrated in Figure 2. The cutting unit is powered by an 8-pole, 300 kW electric motor. Key geometric parameters of the gears are summarized in Table 1. The gears are fabricated from CrNi-series low-carbon alloy steel and machined to a precision grade of 7.

Figure 2.

Cutting gear transmission system of the bauxite mining machine.

Table 1.

Transmission distribution table at all levels.

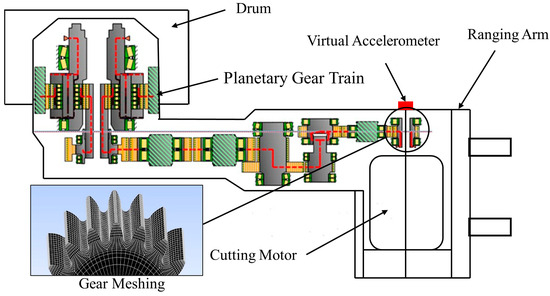

Given that dynamic performance and reliability testing of gear transmission systems often involve lengthy cycles and high costs, a substantial body of related research has been conducted using commercial software [1,2,13,14,15,18,19,20,21,24,25,26]. Accordingly, this study is also based on MASTA (version 13.0.1; Smart Manufacturing Technology Ltd., Nottingham, UK), a specialized software for gear transmission analysis. In MASTA, components such as bearings, shafts, and splines were incorporated. The gear contact fatigue limit stress was set to 1400 MPa, and the bending fatigue limit stress to 600 MPa based on the gear material. A “.cdb” mesh file of the complete finite element shell for the cutting section was generated using ANSYS 2022R1 and imported into MASTA 13.0.1, establishing the dynamic model of the cutting transmission system for bauxite mining equipment, as shown in Figure 3. During the simulation, the gear mesh stiffness is modeled as a time-varying stiffness model that fully accounts for factors such as pressure angle, face width, and bottom clearance coefficient. The motor was set to a rated speed of 739 r/min, and a constant torque of 125,175.43 N·m was applied at the drum to simulate normal operation under rated load. Given the high hardness of certain bauxite deposits and the frequent overloads during cutting, the cutting motor typically incorporates a 10–20% safety margin. Accordingly, overload conditions were simulated by applying 110% and 125% of the rated load. Since the motor shaft gear operates at high rotational speeds and meshing frequencies, it is the most prone to failure in the cutting transmission system and is highly sensitive to factors such as tooth profile errors. Therefore, it was selected as the research subject to investigate the influence of gear geometric parameters on meshing characteristics, vibration, and noise under overload conditions.

Figure 3.

Transmission system of the cutting section of the bauxite mining machine based on MASTA.

3. Results and Discussion

3.1. Influence of Pressure Angle on Gear Meshing Characteristics and Fatigue Life

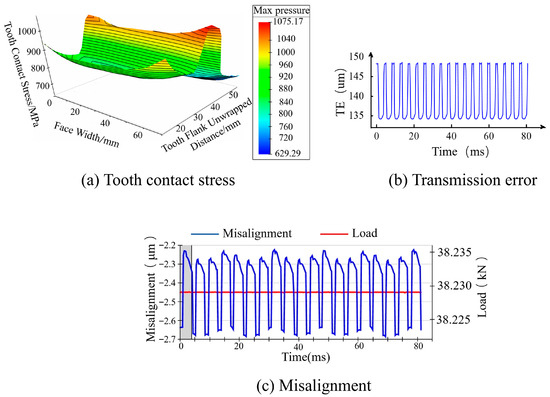

The meshing behavior of gears with pressure angles ranging from 20° to 25° was simulated under various load conditions to evaluate their effects on tooth contact stress, misalignment, transmission error, and fatigue life. Figure 4 shows the corresponding curves for the motor pinion under the rated load.

Figure 4.

Response curves of tooth contact stress, transmission error, and misalignment for the motor pinion under rated load conditions.

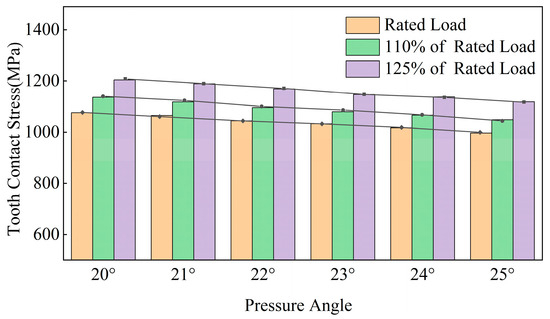

Figure 5 presents the tooth contact stress under different loads and pressure angles. The peak contact stress decreases approximately linearly with increasing pressure angle across all load cases. A comparison between the 20° and 25° pressure angles (Table 2) quantifies this reduction in both absolute and percentage terms.

Figure 5.

Tooth contact stress under different working conditions and different pressure angles.

Table 2.

Comparison of stress amplitude at 20° and 25° of motor gear.

The peak stress reduction ranges from 7.11% to 7.77% under different loads, demonstrating the beneficial effect of a larger pressure angle on contact performance. This improvement stems from the reduced tangential force component at the pitch circle, which lowers the shear load on the tooth flank.

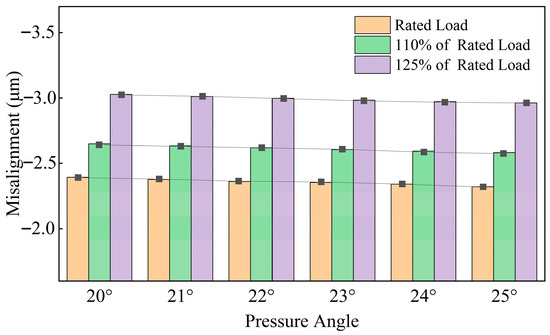

Figure 6 illustrates the average misalignment under different working conditions and pressure angles. As a key negative indicator of dynamic performance, the average misalignment decreases linearly with increasing pressure angle. Under the given conditions, each 1° increase reduces misalignment by approximately 0.015 μm, indicating smoother meshing. At a constant pressure angle, more severe drum loading produces greater misalignment.

Figure 6.

Misalignment under different working conditions and different pressure angles.

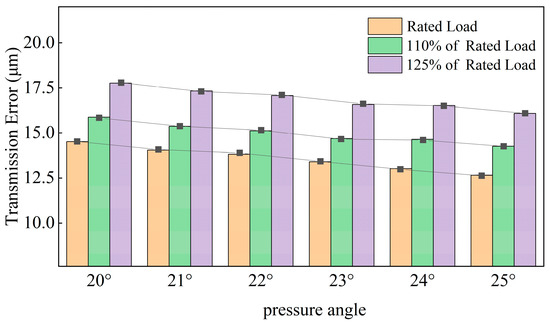

Figure 7 depicts the peak-to-peak transmission error (PPTE) under multiple load conditions. Excessive PPTE compromises transmission stability. The simulation results reveal that PPTE decreases significantly with increasing pressure angle, confirming that a larger pressure angle promotes smoother operation. Furthermore, PPTE increases with applied load.

Figure 7.

Peak-to-peak transmission error under different working conditions and different pressure angles.

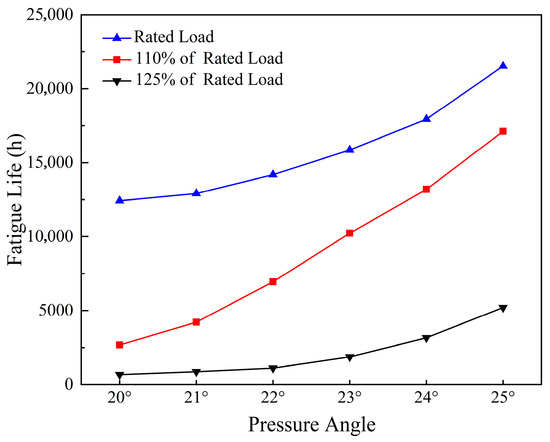

Following the ISO 6336 standard [30], the fatigue life of the motor pinion was predicted through simulation; the results under various conditions are presented in Figure 8.

Figure 8.

Fatigue life under different working conditions and different pressure angles.

As shown in Figure 8, the fatigue life improves with an increase in pressure angle, though the growth trends vary under different load conditions. Figure 5, Figure 6 and Figure 7 demonstrate that increasing the pressure angle enhances gear meshing performance by reducing both misalignment and transmission error. Under rated load conditions, the system inherently maintains favorable meshing alignment with minimal misalignment. Thus, while increasing the pressure angle improves fatigue life under such conditions, the extent and potential for improvement remain relatively limited. Under 125% rated load, severe system deformation and misalignment significantly constrain the beneficial effect of pressure angle increases on meshing performance, leading to diminished effectiveness of this improvement. In contrast, under 110% load, where increased load exacerbates system deformation and degrades meshing performance, raising the pressure angle proves most effective in optimizing load distribution, mitigating stress concentration, and consequently enhancing fatigue life.

3.2. Influence of Face Width on Gear Meshing Characteristics and Fatigue Life

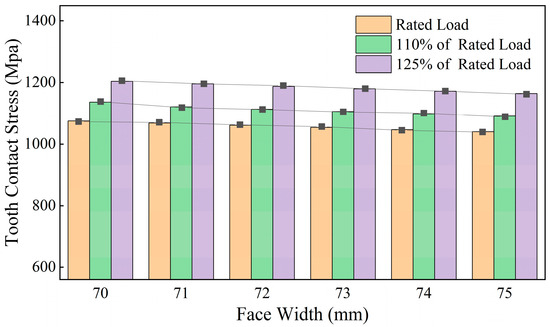

The face width was varied within the range of 70–75 mm to investigate its influence on tooth contact stress, misalignment, transmission error, and fatigue life. Figure 9 shows the tooth contact stress of the motor pinion under different working conditions and face widths.

Figure 9.

Tooth contact stress under different working conditions and different face widths.

As shown in Figure 9, increasing the face width results in an approximately linear reduction in peak tooth contact stress. According to Hertzian contact theory, under constant load torque, a larger face width increases the effective gear contact area, enabling more uniform load distribution and thereby reducing contact stress. This effect helps mitigate the risk of tooth flank pitting and tooth root fracture.

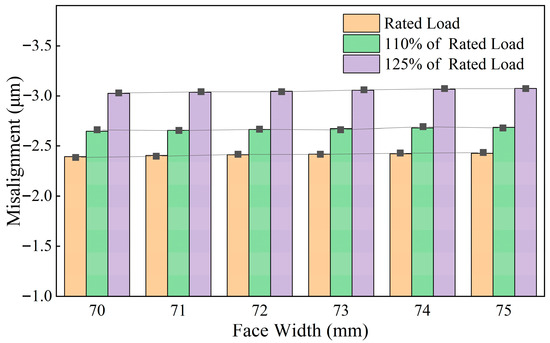

Figure 10 illustrates the misalignment of the high-speed stage gear across different face widths. Misalignment refers to the deviation between the actual meshing position of a gear pair under load and its ideal theoretical meshing position, resulting from elastic deformations of the shaft, bearings, and housing. It is primarily influenced by factors such as axial installation accuracy, bearing axial float, bearing deformation, and housing deformation, rather than geometric parameters like face width. The main role of face width is to enhance the load-carrying capacity and axial contact ratio of gears, without directly altering the misalignment values caused by installation or bearing-related factors. Therefore, changes in face width do not lead to significant variations in the average misalignment.

Figure 10.

Misalignment under different working conditions and different face widths.

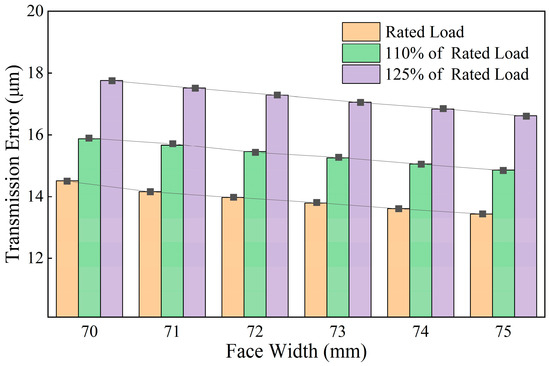

Figure 11 presents the peak-to-peak transmission error (PPTE) of the high-speed stage gear under various working conditions and face widths. For a given operating condition, PPTE decreases significantly with increasing face width, demonstrating that a larger face width enhances transmission smoothness and stability.

Figure 11.

Peak-to-peak transmission error under different working conditions and different face widths.

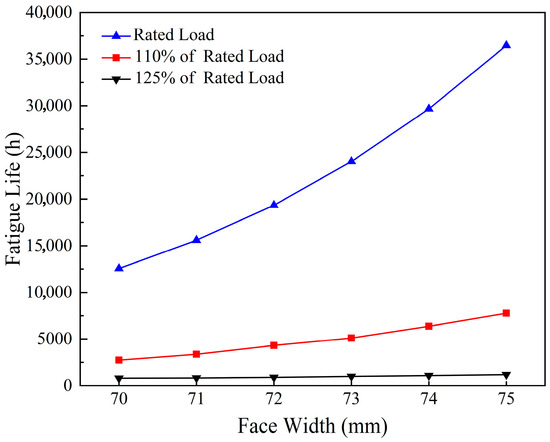

Figure 12 displays the predicted service life of the gear under different working conditions and face widths. As evident from the figure, fatigue life improves with increasing face width. The most rapid increase in fatigue life occurs under nominal (100%) load, followed by the 110% overload condition, while the improvement becomes progressively smaller under 125% overload. This trend highlights the detrimental effect of excessive drum loading on gear durability.

Figure 12.

Fatigue life under different working conditions and different face widths.

3.3. Influence of Bottom Clearance Coefficient on Gear Meshing Characteristics and Fatigue Life

The meshing characteristics under different working conditions were investigated for bottom clearance coefficients of 0.2, 0.25, 0.3, 0.35, and 0.4, with particular attention to their effects on tooth contact stress, misalignment, transmission error, and fatigue life.

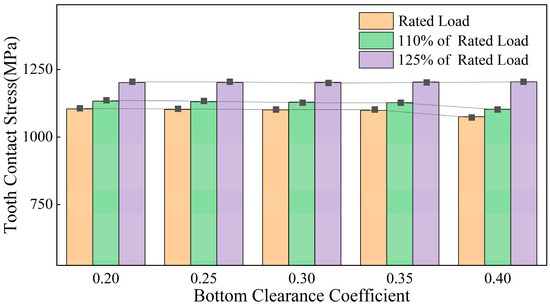

Figure 13 shows the tooth contact stress of the high-speed stage gear under various working conditions and bottom clearance coefficients. Under both 100% and 110% load conditions, increasing the bottom clearance coefficient up to 0.35 results in no significant change in contact stress. However, when the coefficient increases from 0.35 to 0.4, a marked reduction in contact stress is observed. This phenomenon occurs because when the bottom clearance coefficient increases from 0.35 to 0.4, the further raised addendum height significantly reduces the portion of the tooth tip participating in meshing. The contact point distribution shifts from a mixed pattern involving both the tooth flank and tip to one predominantly concentrated in the middle-lower region of the tooth flank. This specific area features a larger radius of curvature of the tooth profile. According to the Hertzian contact stress formula, contact stress is inversely proportional to the square root of the radius of curvature. Consequently, the contact stress undergoes a rapid, step-like decline rather than a gradual nonlinear change. However, under the 125% rated load condition, the substantial increase in load itself far outweighs the stress concentration improvement brought by variations in the bottom clearance coefficient. Moreover, under high loads, the tooth flank contact area becomes fully engaged due to elastic deformation, and increasing the bottom clearance coefficient can no longer alter this state of complete load-bearing contact. Therefore, the contact stress no longer exhibits significant fluctuations with changes in the bottom clearance coefficient.

Figure 13.

Tooth contact stress under different working conditions and different bottom clearance coefficients.

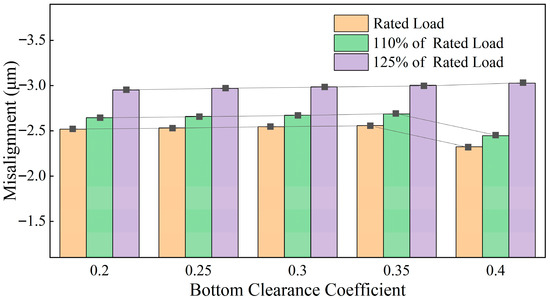

Figure 14 illustrates the misalignment of the motor pinion under different working conditions and bottom clearance coefficients. At 100% and 110% load levels, increasing the coefficient below 0.4 leads to a slight upward trend in misalignment. However, a substantial decrease occurs when the coefficient reaches 0.4. Under the 125% overload condition, misalignment increases linearly with the bottom clearance coefficient, albeit at a moderate rate.

Figure 14.

Misalignment under different working conditions and different bottom clearance coefficients.

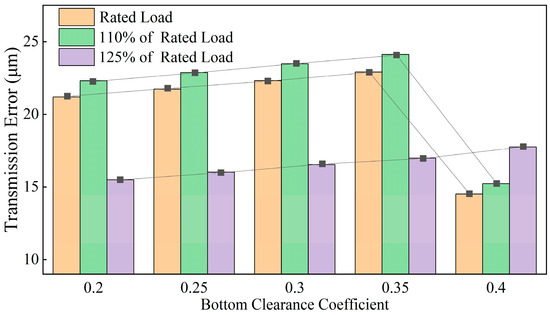

Figure 15 presents the peak-to-peak transmission error (PPTE) of the high-speed stage gear under various conditions and bottom clearance coefficients. At 100% and 110% loads, PPTE increases gradually as the coefficient rises from 0.2 to 0.35, but a sharp drop is observed when the coefficient increases from 0.35 to 0.4. Under 125% load, PPTE increases steadily with the coefficient. It is noteworthy that significant differences are observed in both the meshing misalignment and peak-to-peak transmission error between the 110% and 125% rated load conditions. This phenomenon can be attributed to the fact that under 110% load, the system behavior likely remains within the “linear region,” where the adverse effects of overload remain controllable and have not triggered qualitative changes. However, when the load increases to 125%, the system may transition into the “nonlinear region,” potentially activating mechanisms such as exacerbated shaft deformation, which drastically amplifies both meshing misalignment and transmission error, thereby manifesting as the pronounced discrepancies shown in the data.

Figure 15.

Peak-to-peak transmission error under different working conditions and different bottom clearance coefficients.

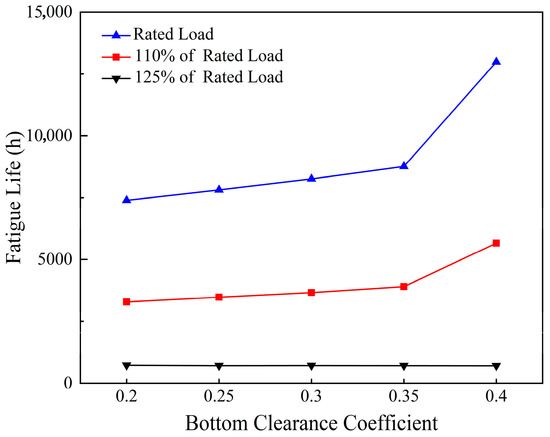

Figure 16 shows the service life of the motor pinion under different working conditions and bottom clearance coefficients. At 100% and 110% load levels, fatigue life increases with the bottom clearance coefficient. Under severe overload (125%), however, service life exhibits a gradual decline as the coefficient increases. As can be seen from Figure 14 and Figure 15, under the severe overload condition of 125%, both the meshing misalignment and transmission error of the transmission system increase with the rising bottom clearance coefficient, indicating a degradation in gear meshing performance under this operating condition as the coefficient grows. Furthermore, an increase in the bottom clearance coefficient leads to a reduction in the tooth root fillet radius, resulting in stress concentration at the gear root. Consequently, under severe overload conditions, the gear fatigue life exhibits a gradual declining trend. Only under nominal (100%) load and with a bottom clearance coefficient of 0.4 does the gear achieve the required design life.

Figure 16.

Fatigue life under different working conditions and different bottom clearance coefficients.

3.4. Influence of Gear Geometric Parameters on Vibration and Noise in the Cutting Transmission System

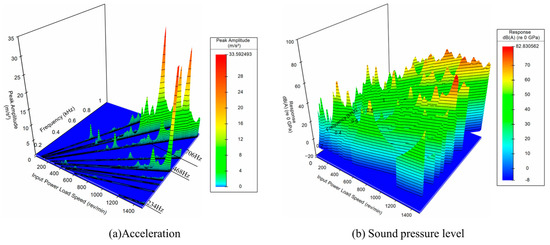

The vibration and noise characteristics of the motor pinion were numerically simulated using MASTA, a nodal finite element-based gear transmission simulation software, to investigate the variation trends of vibration and noise levels with respect to different structural parameters under various operating conditions. Figure 17 presents the acceleration amplitude and sound pressure level responses at a measurement point on the first shaft under 110% load, with a pressure angle of 20°, a face width of 70 mm, and a bottom clearance coefficient of 0.4.

Figure 17.

Acceleration and sound pressure levels of the motor gear under 110% load.

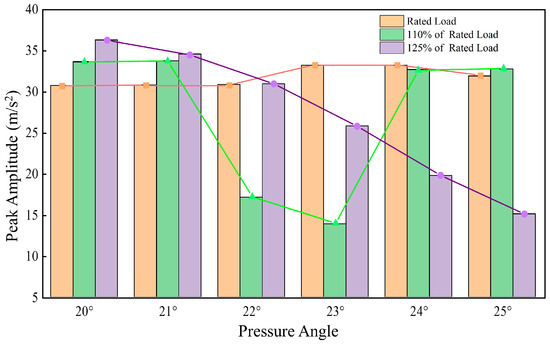

3.4.1. Influence of Pressure Angle on Vibration and Noise in the Gear Transmission System

The acceleration amplitude reflects the vibration level of the motor pinion in the cutting transmission system. Figure 18 shows the acceleration response amplitudes under different operating conditions and pressure angles. At 100% load, the acceleration amplitude remains nearly constant as the pressure angle increases from 20° to 22°, exhibits a slight increase at 23°, and then experiences a minor reduction at 25°. Under 110% load, a significant decrease in the peak acceleration amplitude is observed at pressure angles of 22° and 23°, which can be attributed to the complex interaction between the system’s dynamic excitation and its inherent structural properties induced by the change in pressure angle. The vibrational response of the gear transmission system results from the combined superposition of multiple excitation components, including its fundamental frequency, higher-order harmonics, and sidebands generated by shaft frequency modulation. When the pressure angle changes, the gear mesh stiffness, as well as the amplitude and waveform of the transmission error, also vary, thereby affecting the phase and energy distribution of these dynamic excitations. Within the specific parameter range of 22° and 23°, it is inferred that the adjustment of the pressure angle induces favorable changes in the phase relationships of certain dominant excitation orders. Combined with the reduction in peak-to-peak transmission error (PPTE) and the mitigation of meshing impacts resulting from the increased pressure angle, these effects collectively lead to the cancellation or attenuation of the total vibrational energy near the system’s resonant frequencies or along key transmission paths. Ultimately, this manifests macroscopically as a sharp decline in the peak acceleration amplitude under this operating condition. Under 125% load, the acceleration amplitude exhibits an overall decreasing trend with increasing pressure angle.

Figure 18.

Acceleration response amplitude under different working conditions and different pressure angles.

A semi-free sound field with a radius of 10 m was configured in MASTA, and A-weighting was applied to the data. Figure 19 displays the maximum sound pressure level responses under different operating conditions and pressure angles. At 100% load, the sound pressure level shows an overall increasing trend with the pressure angle, not exceeding 84 dB. Under 110% and 125% loads, the sound pressure level first decreases and then increases as the pressure angle rises.

Figure 19.

Sound pressure level response amplitude under different working conditions and different pressure angles.

An integrated analysis of the acceleration and sound pressure level responses across all investigated conditions indicates that pressure angles of 22° and 23° result in a substantial reduction in both vibration and noise levels, confirming superior dynamic performance for the transmission system at these specific configurations.

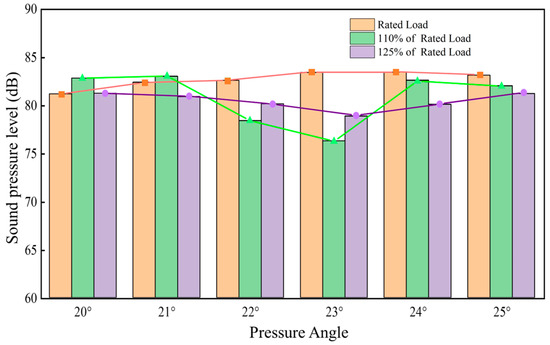

3.4.2. Influence of Face Width on Vibration and Noise in the Gear Transmission System

Figure 20 shows the acceleration amplitude response under different face widths. With the exception of the 75 mm face width, the peak acceleration increases with higher drum load torque. Under 100% load, the acceleration amplitude decreases gradually as the face width increases. At 110% load, the amplitude initially decreases when the face width increases from 70 mm to 71 mm; beyond this point, it remains nearly constant, exhibiting only a minor increase (not exceeding 1 m/s2) at 74 mm. Under 125% load, the overall trend shows a clear decreasing pattern, except for a notable spike in acceleration amplitude at 74 mm.

Figure 20.

Acceleration response amplitude under different working conditions and different face widths.

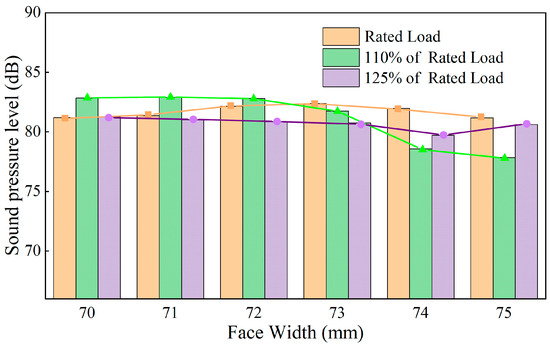

Figure 21 illustrates the maximum sound pressure level response under varying face widths. Under both 100% and 110% load conditions, the sound pressure level first increases and then decreases with increasing face width, indicating that face width adjustment significantly influences the noise characteristics of the cutting transmission system. Under 125% load, the sound pressure level decreases between 70 mm and 74 mm, followed by a slight rise at 75 mm; however, all measured values remain within the factory noise standards for bauxite mining equipment.

Figure 21.

Sound pressure level response amplitude under different working conditions and different face widths.

Considering both vibration and noise performance, face widths of 73 mm and 75 mm exhibit favorable reductions in acceleration amplitude. Meanwhile, face widths of 70 mm, 74 mm, and 75 mm each demonstrate distinct advantages in minimizing sound pressure levels across different operating conditions, suggesting that optimal noise control may require condition-specific design choices.

3.4.3. Influence of Bottom Clearance Coefficient on Vibration and Noise in the Gear Transmission System

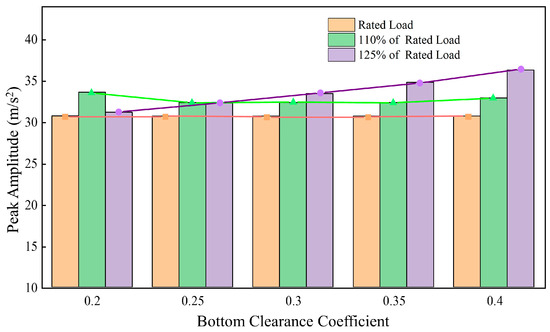

Figure 22 presents the acceleration amplitude under different bottom clearance coefficients. Under 100% load, the acceleration amplitude remains largely unchanged across all coefficient values, with fluctuations limited to within 0.04 m/s2. At 110% load, a noticeably higher acceleration amplitude occurs only at a coefficient of 0.2, while variations at other values are negligible. Under 125% load, the acceleration amplitude increases significantly as the bottom clearance coefficient increases, indicating deteriorating dynamic stability.

Figure 22.

Acceleration response amplitude under different working conditions and different bottom clearance coefficients.

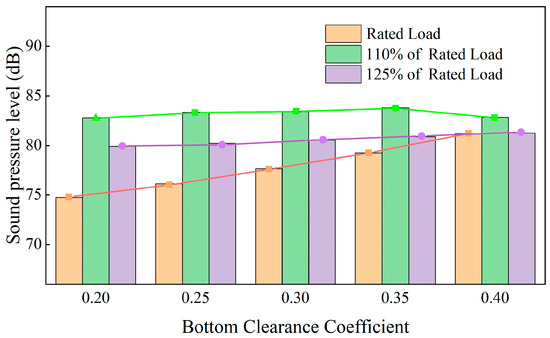

Figure 23 displays the sound pressure level response amplitude under different bottom clearance coefficients. At 100% load, the sound pressure level rises linearly from 74.74 dB to 81.19 dB as the coefficient increases. Under 110% load, the level first increases and then decreases, peaking at a coefficient of 0.35. Under 125% load, the sound pressure level exhibits a gradual upward trend with increasing coefficient.

Figure 23.

Sound pressure level response amplitude under different working conditions and different bottom clearance coefficients.

A comprehensive evaluation of both acceleration and sound pressure level responses across operating conditions reveals that, compared to a bottom clearance coefficient of 0.4, a coefficient of 0.2 leads to modest improvements in vibration and noise reduction. However, this benefit is offset by a significant deterioration in transmission smoothness and gear service life, as previously demonstrated in meshing performance and fatigue analyses.

4. Test Validation

4.1. Test Equipment

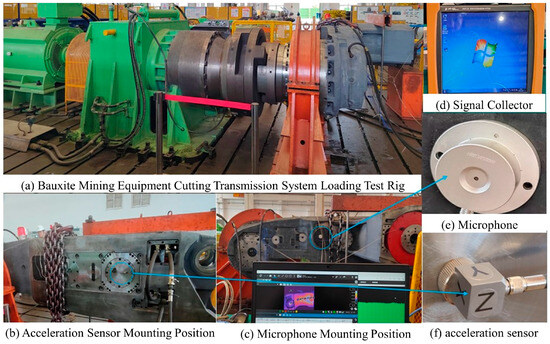

To validate the effectiveness of the reliability analysis and improvement methods for the motor pinion in the cutting transmission system of bauxite mining equipment, meshing performance tests were conducted before and after gear improvement using a dedicated loading test rig (China Coal Technology & Engineering Group Shanghai Co., Ltd., Shanghai, China). As illustrated in Figure 24, the test rig comprises a drive motor, a test cutting unit, a companion speed-increasing gearbox, a load motor, an electrical feedback system, a control system, and a measurement system. The drive motor is a flame-proof mining three-phase asynchronous AC motor with a rated power of 300 kW and a rated input speed of 739 r/min. During testing, vibration acceleration and acoustic data are acquired using acceleration sensors and a microphone, respectively. The vibration signals are processed through a DH5925N dynamic signal acquisition and analysis system (Donghua Testing Technology Co., Ltd., Taizhou, China).

Figure 24.

Cutting drive system vibration and noise characteristics test.

A comprehensive evaluation of gear meshing characteristics, service life, and vibration/noise performance informed the structural optimization of the gear transmission system’s geometric parameters. The specific improvements are detailed in Table 3, while the planetary reduction mechanism and idler gears remained unmodified. Experimental measurements of vibration acceleration signals were conducted at 50%, 75%, 100%, and 110% of the rated load, comparing performance before and after gear improvement. Additionally, acoustic signals were captured under the 110% load condition.

Table 3.

Gear structure parameters before and after improvement.

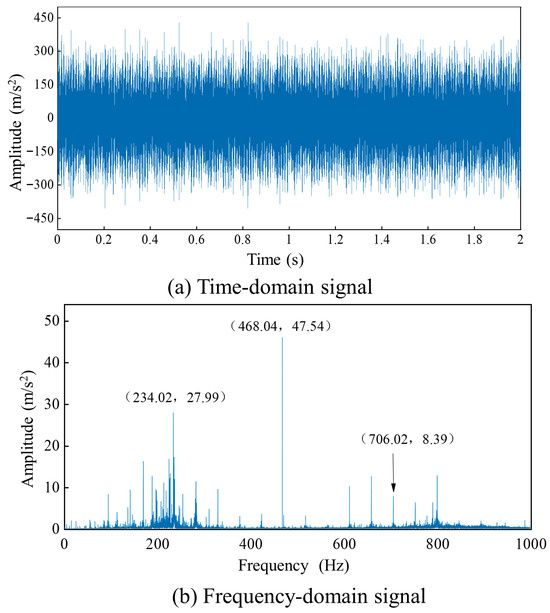

4.2. Validation Results and Analysis

Once the test rig’s ranging arm reached steady-state operation, data were acquired using the DH5925N acquisition instrument equipped with acceleration sensors. A 2 s segment of the vibration acceleration signal was captured and processed via Fourier transform to obtain the acceleration response under 110% load before the improvement, as illustrated in Figure 25. Figure 25a presents the time-domain waveform of the acceleration signal, while Figure 25b displays the corresponding frequency spectrum. The three dominant peaks in the spectrum correspond to the first, second, and third harmonics of the meshing frequency of the high-speed gear pair. The frequency with the highest amplitude is 468.04 Hz, which aligns precisely with the second harmonic of the first-stage gear pair meshing frequency. This observation shows excellent agreement with the simulation results presented in Figure 17a, thereby confirming the accuracy of the simulation model.

Figure 25.

Acceleration signal under 110% of the rated load vibration test.

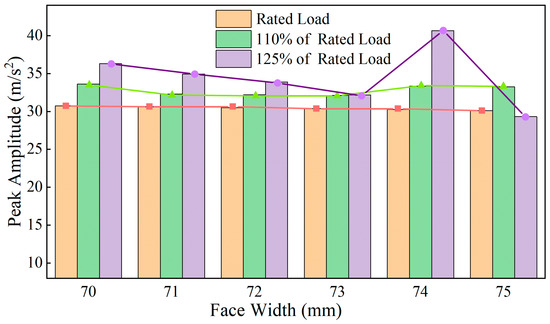

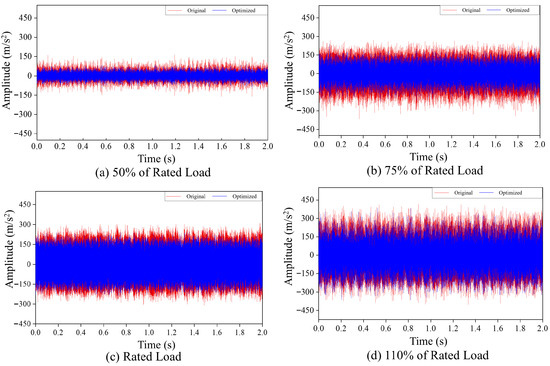

Figure 26 compares vibration signals before and after gear improvement across various load conditions. The consistently lower vibration amplitudes following the improvement indicate enhanced gear performance and substantiate the effectiveness and reliability of the simulation approach.

Figure 26.

Vibration signals before and after gear optimization under different loading conditions.

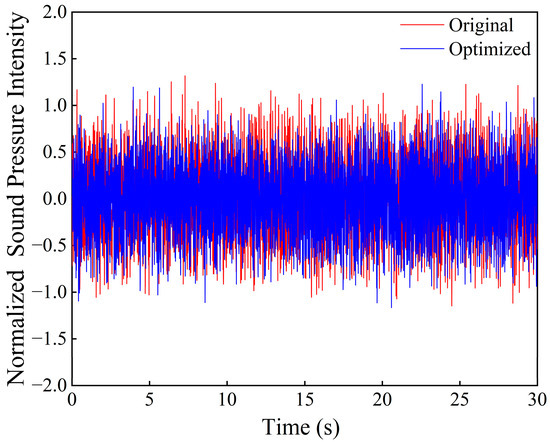

Using MATLAB R2022a, the first 30 s segment of the audio signal was downsampled, filtered, and normalized. The resulting time-domain waveforms of the gear transmission system noise under 110% load, before and after the improvement, are presented in Figure 27. The vertical axis represents the normalized sound pressure level, which reflects the noise intensity in the gear transmission system. As shown in the figure, the noise amplitude is significantly reduced after the improvement, further validating the accuracy of the simulation results and confirming the feasibility of the improved design for the gear transmission system in bauxite mining equipment.

Figure 27.

Comparison of noise characteristics in the cutting transmission system before and after optimization.

4.3. Limitations

While this study has systematically analyzed the effects of pressure angle, face width, and bottom clearance coefficient on the dynamic performance and fatigue life of the gear transmission system via simulations in MASTA software and has experimentally validated the feasibility of the preferred selection of gear geometric parameters, the following limitations persist:

- The research method relied primarily on simulation analysis. Due to constraints in experimental cost and availability, optimal gear parameters were determined via MASTA simulations. The loading conditions applied in the simulations may not fully represent real-world operational scenarios, and factors such as temperature and gear manufacturing errors were not incorporated into the modeling process.

- Experimental validation was limited by testing capabilities. Only vibration and noise measurements were conducted on the improved gears. Comprehensive fatigue life testing under full-range operating conditions was not carried out, and the long-term reliability of the system under sustained overload conditions remains unverified.

- The scope of parameter selection was constrained. This study focused exclusively on three macro-geometric parameters: pressure angle, face width, and bottom clearance coefficient. It did not account for micro-level design factors—such as gear modifications and material heat treatment processes—or their potential synergistic effects on overall system performance.

5. Conclusions

This study investigates the motor gear with the highest failure rate in the cutting transmission system of bauxite mining equipment. Simulations were performed using MASTA software to analyze the system’s dynamic characteristics, including vibration and noise, and to assess its reliability. The simulation results were then validated experimentally on a gear transmission system loading test rig, leading to the following conclusions:

- Increasing the pressure angle significantly enhances gear meshing performance, resulting in reduced tooth contact stress, misalignment, and peak-to-peak transmission error (PPTE) across all operating conditions, along with an improvement in gear fatigue life. Similarly, increasing the face width reduces contact stress and transmission error, thereby extending service life, although it has a negligible influence on misalignment. An optimal bottom clearance coefficient of 0.4 was identified, which effectively lowers contact stress, misalignment, and PPTE under both rated and 110% load conditions, thus improving meshing quality and fatigue life.

- Adjusting gear geometric parameters enables effective control over vibration and noise during meshing. Pressure angles of 22° and 23° yield significant reductions in vibration acceleration and sound pressure level. Face widths of 73 mm and 75 mm demonstrate superior performance in minimizing acceleration amplitude, while 70 mm, 74 mm, and 75 mm exhibit distinct advantages in sound pressure level reduction under different operating conditions. While increasing the bottom clearance coefficient generally elevates noise levels, at 0.4, the noise remains within acceptable limits, concurrently ensuring transmission smoothness and system reliability.

- Loading tests performed on the selected parameter set—comprising a 23° pressure angle, 75 mm face width, and 0.4 bottom clearance coefficient—confirmed that this configuration effectively suppresses vibration and noise in the cutting transmission system. These experimental results validate the feasibility and effectiveness of enhancing dynamic performance by selecting key gear geometric parameters.

Author Contributions

Conceptualization, Q.H., W.X., K.G. and X.Z.; methodology, Q.H.; software, Q.H.; validation, Q.H., Z.M., N.J. and Y.B.; formal analysis, Q.H.; investigation, Q.H.; resources, W.X.; data curation, Q.H.; writing—original draft preparation, Y.B.; writing—review and editing, Q.H., W.X. and K.G.; visualization, Z.M., N.J. and Y.B.; supervision, X.Z.; project administration, Q.H.; funding acquisition, Q.H., W.X. and K.G. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Independent Research Project of State Key Laboratory of Intelligent Coal Mining and Strata Control (Shanghai; Grant No. 02052804824J).

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

Authors Qiulai Huang, Weipeng Xu, Ziyao Ma and Ning Jiang were employed by the company China Coal Technology & Engineering Group Shanghai Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| TE | Transmission Error |

| PPTE | Peak-to-Peak Transmission Error |

| ISO | International Organization for Standardization |

| HCR | High-Contact Ratio |

References

- Wang, Y.; Liu, P.; Dou, D. Investigation of Load Capacity of High-Contact-Ratio Internal Spur Gear Drive with Arc Path of Contact. Appl. Sci. 2022, 12, 3345. [Google Scholar] [CrossRef]

- Namboothiri, N.V.; Marimuthu, P. Fracture Characteristics of Asymmetric High Contact Ratio Spur Gear Based on Strain Energy Release Rate. Eng. Fail. Anal. 2022, 134, 106038. [Google Scholar] [CrossRef]

- Wang, H.; Yan, C.; Zhou, C.; Hu, B.; Dong, J.; Yin, L. A Loaded Tooth Contact Analysis (LTCA) Model of Profile Modified Gears. Meccanica 2025, 60, 17–37. [Google Scholar] [CrossRef]

- Nevzat Özgüven, H.; Houser, D.R. Mathematical Models Used in Gear Dynamics—A Review. J. Sound Vib. 1988, 121, 383–411. [Google Scholar] [CrossRef]

- Dong, C.; Pei, W.; Liu, Y.; Wei, Y.; Li, D.; Guo, R.; Ren, Z. Experimental Research on Transmission Characteristics of Elliptic Gear Transmission Systems. Stroj. Vestn.-J. Mech. Eng. 2022, 68, 702–712. [Google Scholar] [CrossRef]

- Benatar, M.; Handschuh, M.; Kahraman, A.; Talbot, D. Static and Dynamic Transmission Error Measurements of Helical Gear Pairs With Various Tooth Modifications. J. Mech. Des. 2019, 141, 103301. [Google Scholar] [CrossRef]

- Autiero, M.; Paoli, G.; Cirelli, M.; Valentini, P.P. The Effect of Different Profile Modifications on the Static and Dynamic Transmission Error of Spur Gears. Mech. Mach. Theory 2024, 201, 105752. [Google Scholar] [CrossRef]

- Sánchez, M.B.; Pleguezuelos, M.; Pedrero, J.I. Influence of Profile Modification on the Transmission Error of Spur Gears under Surface Wear. Mech. Mach. Theory 2024, 191, 105473. [Google Scholar] [CrossRef]

- Kim, S.; Moon, S.; Sohn, J.; Park, Y.; Choi, C.; Lee, G. Macro Geometry Optimization of a Helical Gear Pair for Mass, Efficiency, and Transmission Error. Mech. Mach. Theory 2020, 144, 103634. [Google Scholar] [CrossRef]

- Litvin, F.L.; Gonzalez-Perez, I.; Fuentes, A.; Hayasaka, K.; Yukishima, K. Topology of Modified Surfaces of Involute Helical Gears with Line Contact Developed for Improvement of Bearing Contact, Reduction of Transmission Errors, and Stress Analysis. Math. Comput. Model. 2005, 42, 1063–1078. [Google Scholar] [CrossRef]

- Zhou, D.; Guo, Y.; Yang, J.; Zhang, Y. Study on the Parameter Influences of Gear Tooth Profile Modification and Transmission Error Analysis. Machines 2024, 12, 316. [Google Scholar] [CrossRef]

- Bozca, M. Transmission Error Model-Based Optimisation of the Geometric Design Parameters of an Automotive Transmission Gearbox to Reduce Gear-Rattle Noise. Appl. Acoust. 2018, 130, 247–259. [Google Scholar] [CrossRef]

- İrsel, G. Effects of Modification on the Strength–Weight Ratio of Standard Bevel Gears. Mech. Based Des. Struct. Mach. 2022, 50, 1456–1480. [Google Scholar] [CrossRef]

- Yang, J.; Chen, Z.; Shi, W.; Yuan, R.; Liu, J.; Zhao, Y. Vibration Control of Commercial Vehicle Drive Axles Based on Modification of Helical Gears. Mech. Syst. Signal Process. 2023, 193, 110252. [Google Scholar] [CrossRef]

- Cianciotta, L.; Cirelli, M.; Valentini, P.P. Multi-Objective Optimization of Gear Design of E-Axles to Improve Noise Emission and Load Distribution. Machines 2025, 13, 330. [Google Scholar] [CrossRef]

- Guilbault, R.; Gosselin, C.; Cloutier, L. Express Model for Load Sharing and Stress Analysis in Helical Gears. J. Mech. Des. 2004, 127, 1161–1172. [Google Scholar] [CrossRef]

- Nagamura, K.; Terauchi, Y.; Martowibowo, S.Y. Study on Gear Bending Fatigue Strength Design Based on Reliability Engineering: Prediction of Crack Propagation and Fatigue Life of MAC14 Supercarburized Steel Gear. JSME Int. J. Ser. C Dyn. Control Robot. Des. Manuf. 1994, 37, 795–803. [Google Scholar] [CrossRef][Green Version]

- Nejad, A.R.; Gao, Z.; Moan, T. On Long-Term Fatigue Damage and Reliability Analysis of Gears under Wind Loads in Offshore Wind Turbine Drivetrains. Int. J. Fatigue 2014, 61, 116–128. [Google Scholar] [CrossRef]

- Lee, K.; Oh, J.; Song, M. Enhanced Fatigue SN Curve Generation for Gear Bending Fatigue Life Prediction Using Multi-Objective Optimization Algorithms. Eng. Fail. Anal. 2025, 167, 108960. [Google Scholar] [CrossRef]

- Li, Y.-H.; Zhang, C.; Yin, H.; Cao, Y.; Bai, X. Modification Optimization-Based Fatigue Life Analysis and Improvement of EMU Gear. Int. J. Struct. Integr. 2021, 12, 760–772. [Google Scholar] [CrossRef]

- Rajesh, S.; Marimuthu, P.; Dinesh Babu, P.; Venkatraman, R. Contact Fatigue Life Estimation for Asymmetric Helical Gear Drives. Int. J. Fatigue 2022, 164, 107155. [Google Scholar] [CrossRef]

- Wang, C. A Study into the Impact of Tooth Root Transition Curve Morphology on the Bending Fatigue Life of Gears. Int. J. Fatigue 2025, 190, 108643. [Google Scholar] [CrossRef]

- Anuradha, G.; Sagi, R.P.; Shakya, P.; Sekhar, A.S. Influence of Geometric Parameters on the Dynamic Performance of Spiral Bevel Gear. J. Vib. Eng. Technol. 2024, 12, 9097–9111. [Google Scholar] [CrossRef]

- Hao, L.; Li, W.; Zhang, X. Impact of Gear Modification on Gear Dynamic Characteristics. J. Fail. Anal. Prev. 2023, 23, 853–864. [Google Scholar] [CrossRef]

- Chu, X.; Chen, F. Geometric Design and Basic Feature Analysis of Double Helical Face Gears. Machines 2025, 13, 912. [Google Scholar] [CrossRef]

- Hu, Z.; Tang, J.; Zhong, J.; Chen, S.; Yan, H. Effects of Tooth Profile Modification on Dynamic Responses of a High Speed Gear-Rotor-Bearing System. Mech. Syst. Signal Process. 2016, 76–77, 294–318. [Google Scholar] [CrossRef]

- Rao, S.S.; Das, G. Reliability Based Optimum Design of Gear Trains. J. Mech. Transm. Autom. Des. 1984, 106, 17–22. [Google Scholar] [CrossRef]

- Al-Shareedah, E.M.; Alawi, H. Reliability Analysis of Bevel Gears with and without Back Support. Mech. Mach. Theory 1987, 22, 13–20. [Google Scholar] [CrossRef]

- Fonseca, D.J.; Shishoo, S.; Lim, T.C.; Chen, D.S. A Genetic Algorithm Approach to Minimize Transmission Error of Automotive Spur Gear Sets. Appl. Artif. Intell. 2005, 19, 153–179. [Google Scholar] [CrossRef]

- ISO6336; Calculation of Load Capacity of Spur and Helical Gears. The International Organization for Standardization: Geneva, Switzerland, 2019.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).