Electrical and Thermal Anisotropy in Additively Manufactured AlSi10Mg and Fe-Si Samples †

Abstract

1. Introduction

2. Methodology

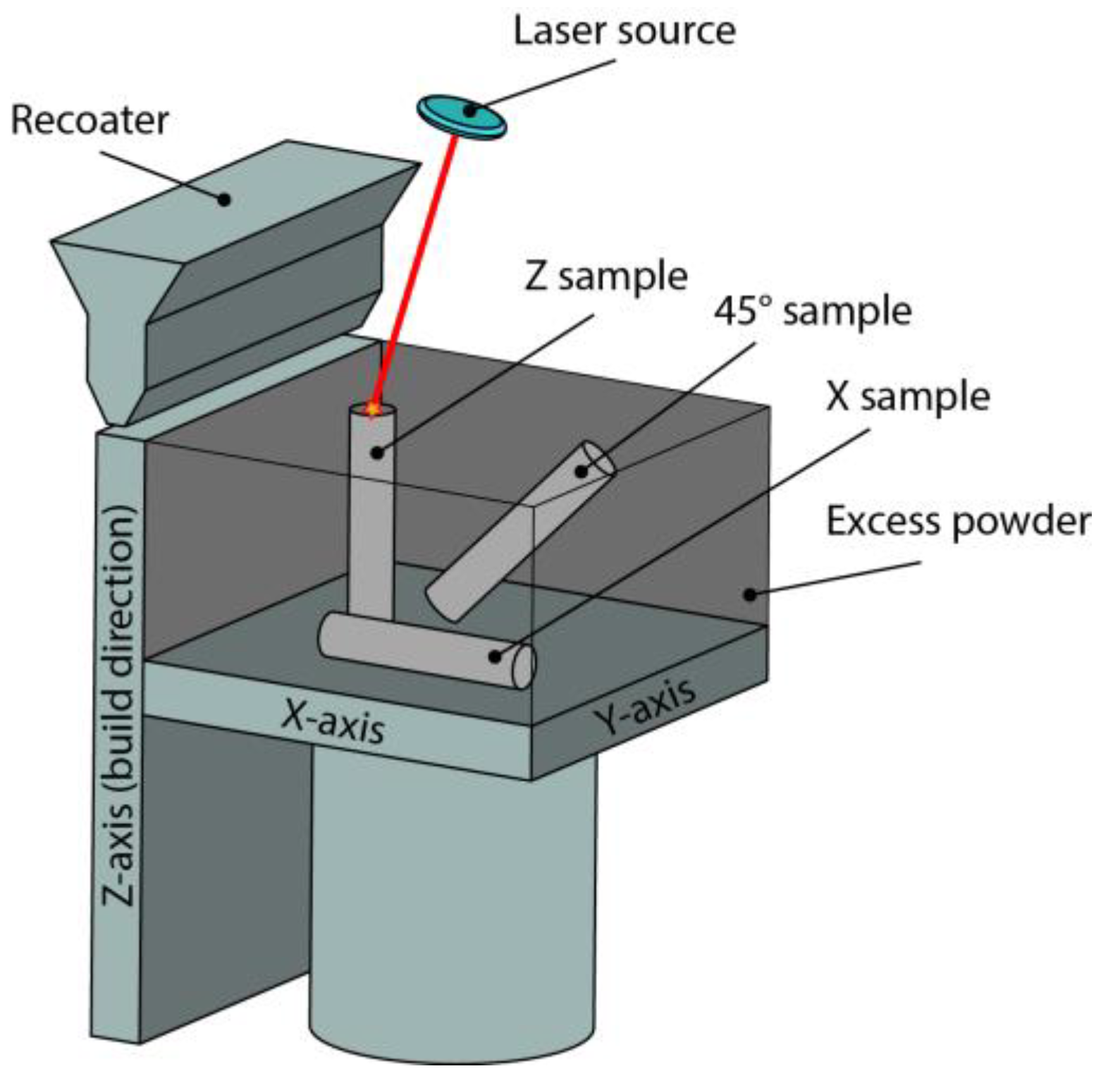

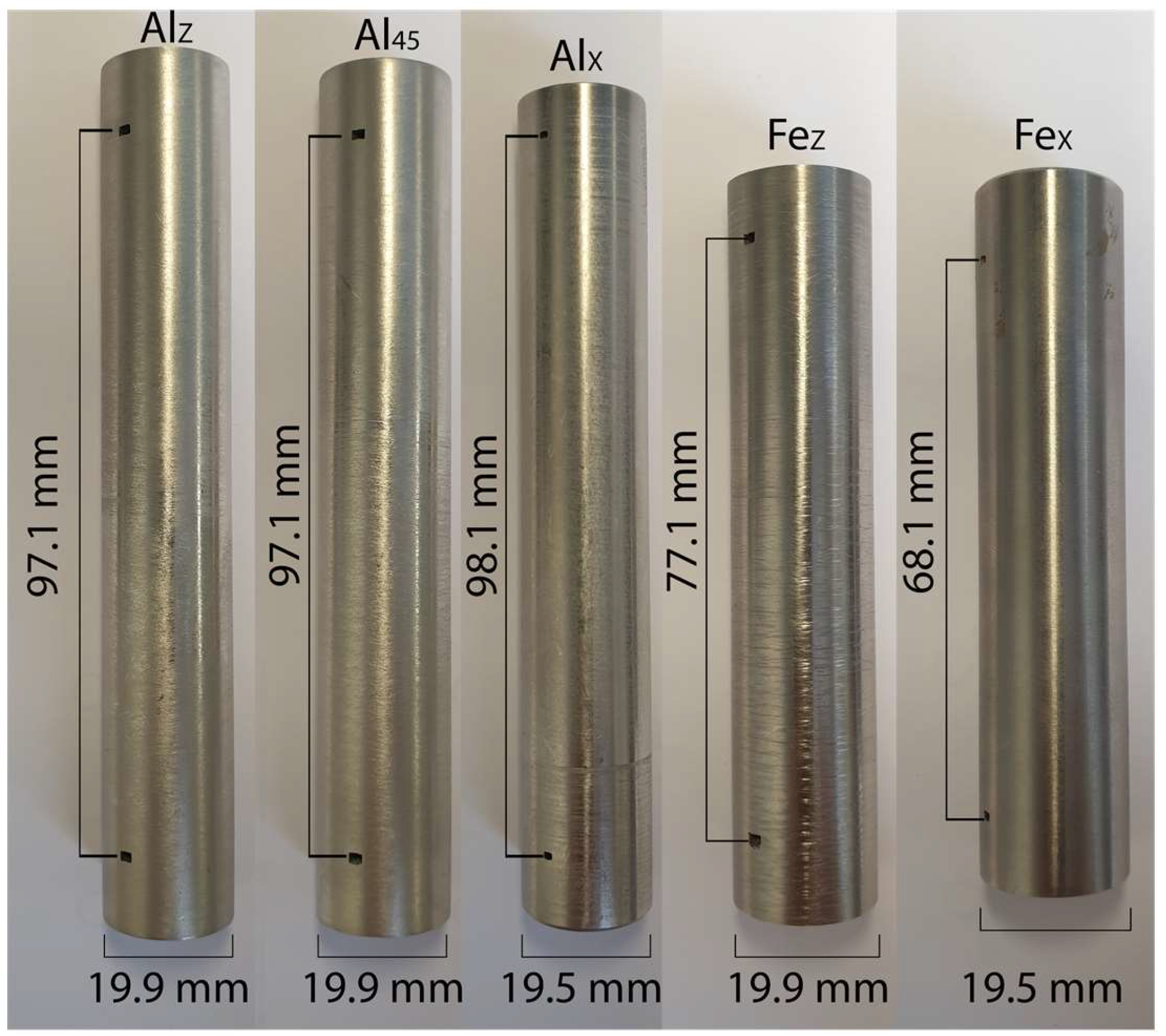

2.1. Sample Preparation

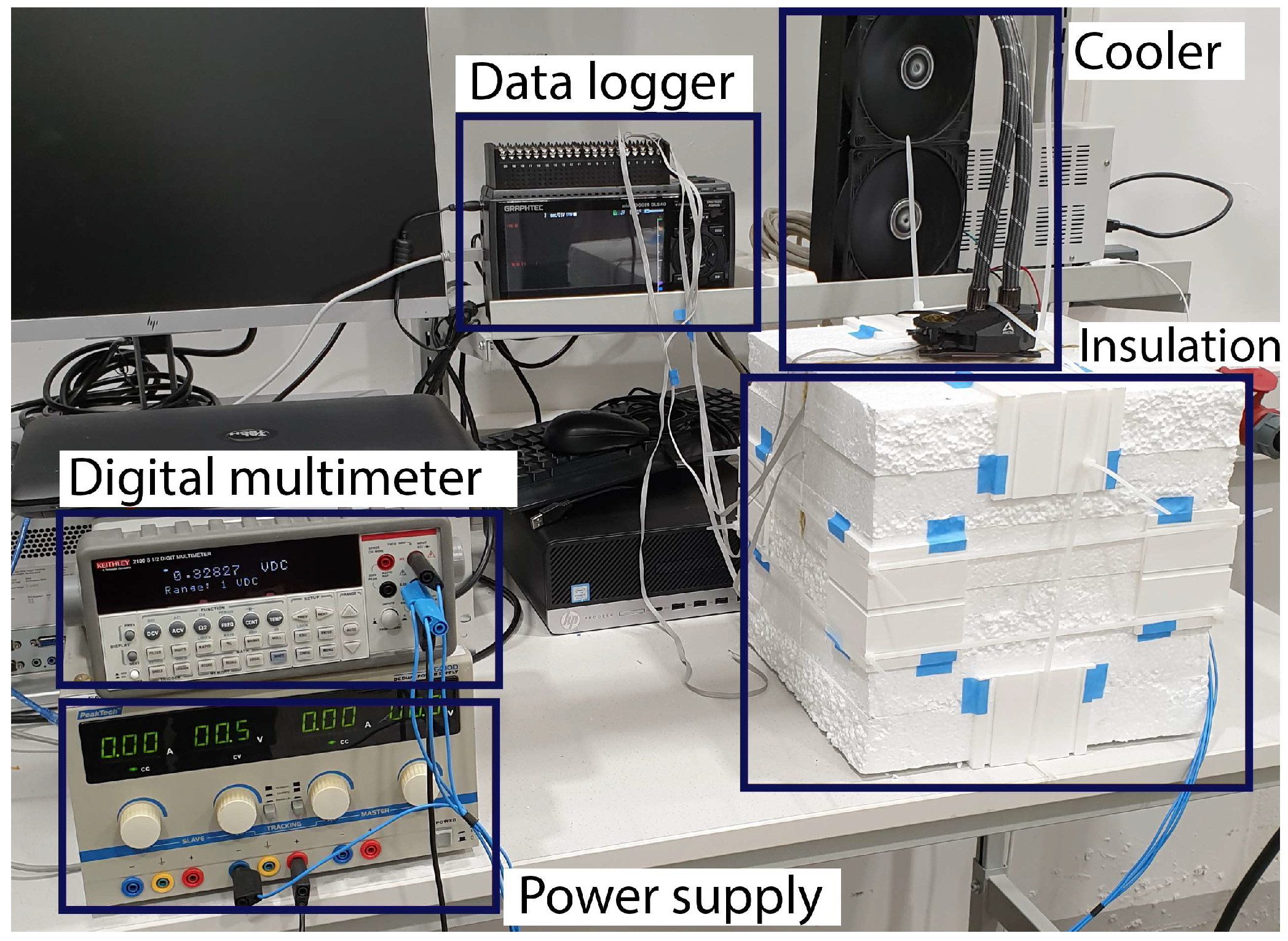

2.2. Measuring Thermal Conductivity

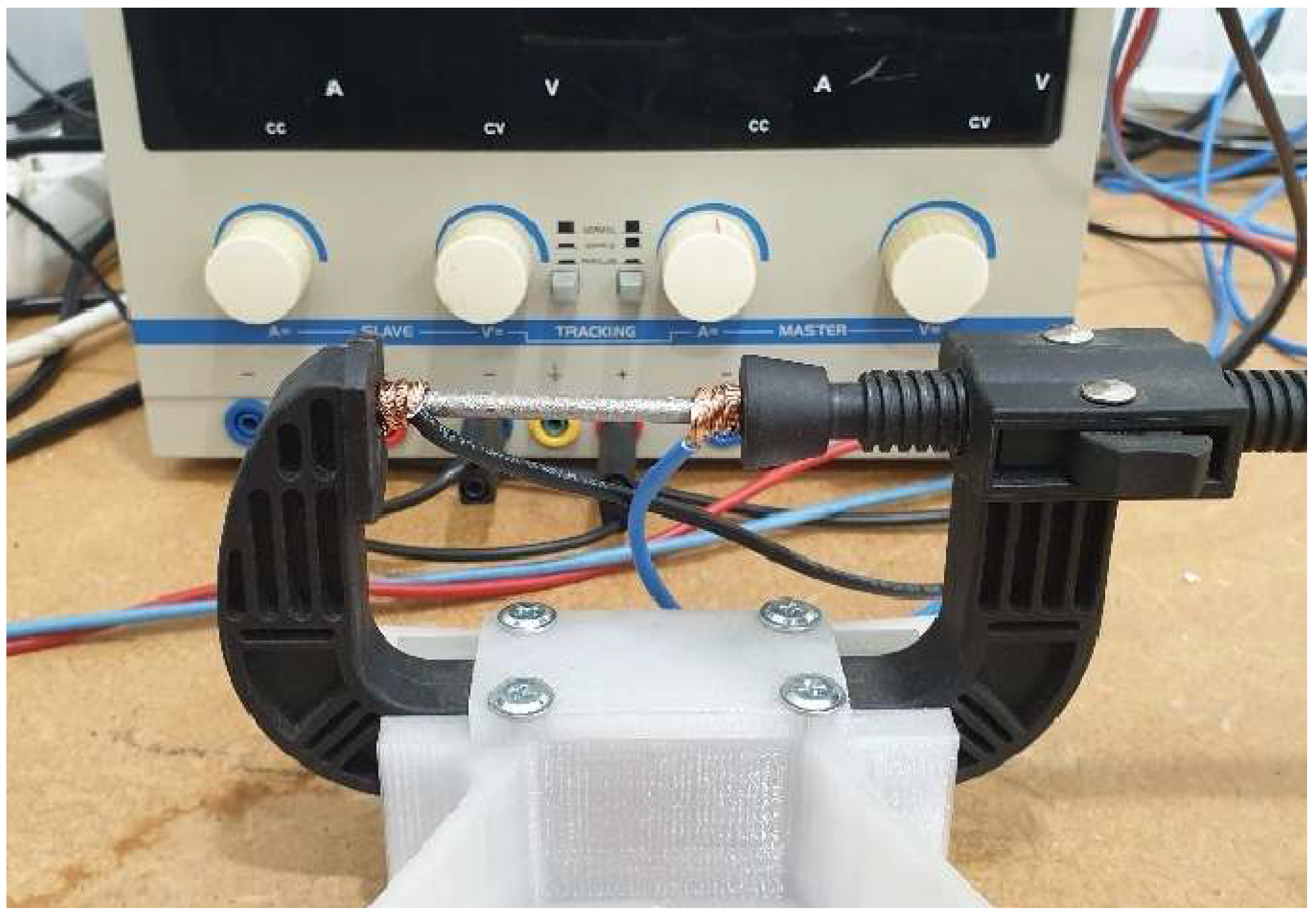

2.3. Measuring Electrical Conductivity

2.4. Microstructure Imaging

3. Results and Discussion

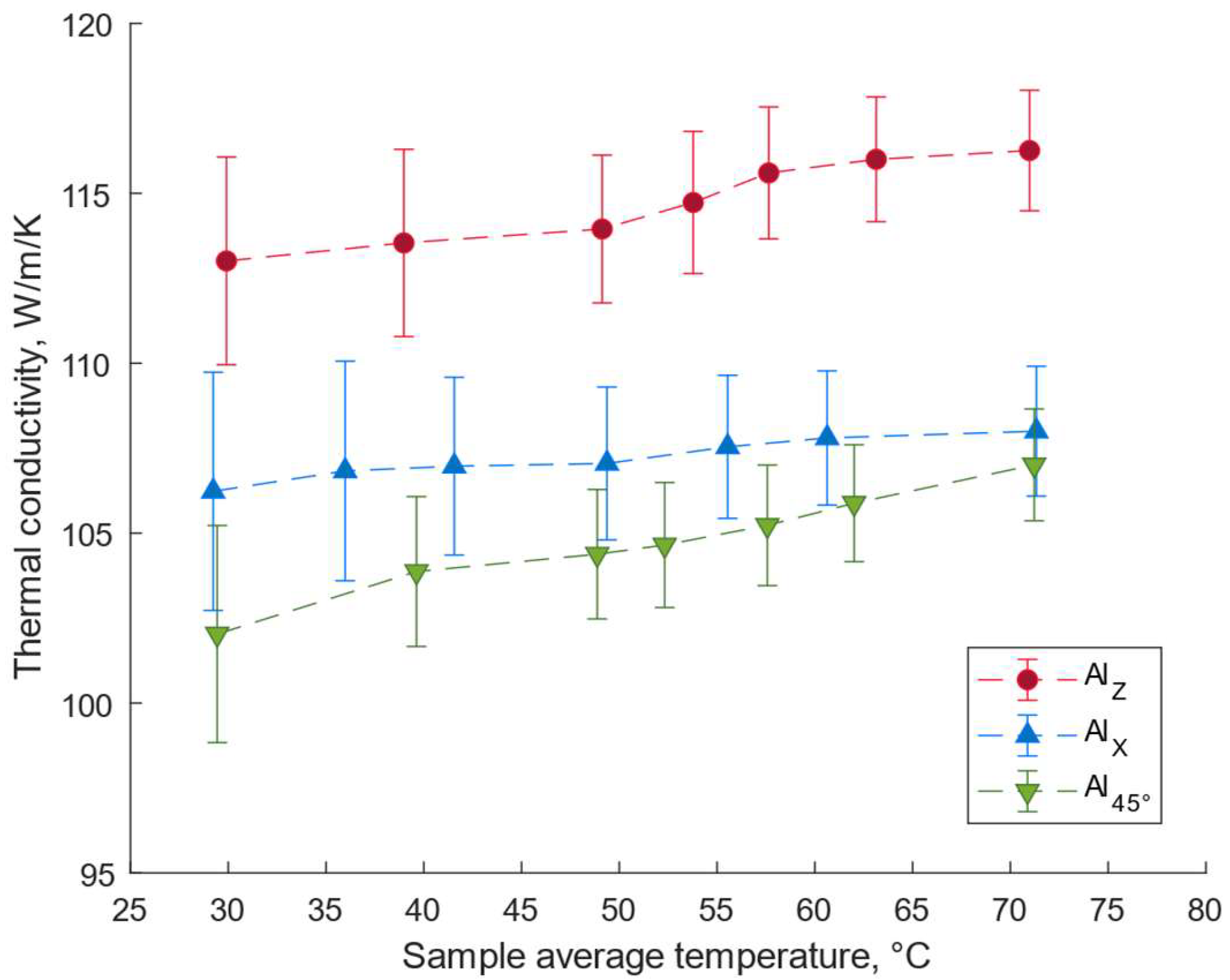

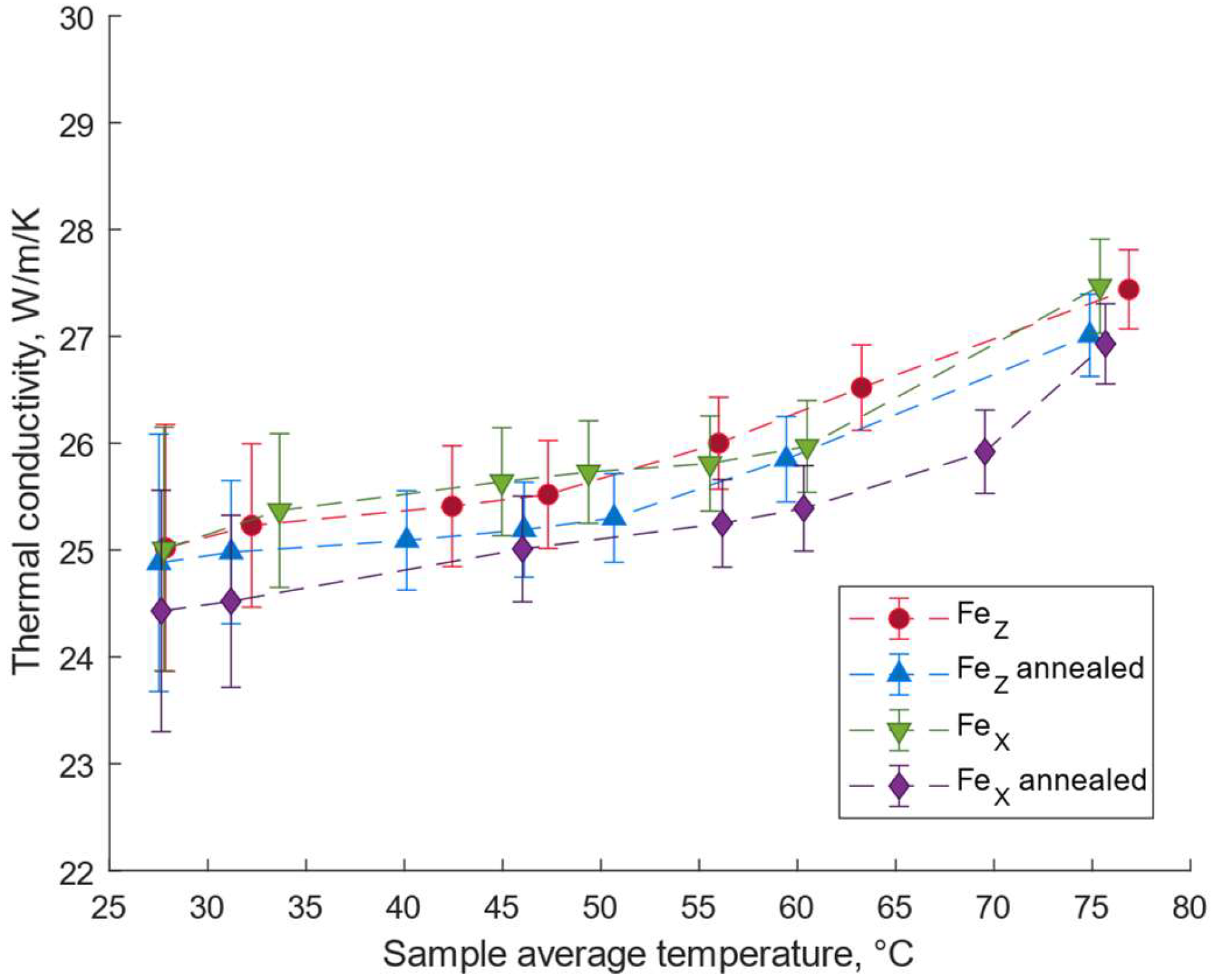

3.1. Thermal Conductivity Results

3.2. Electrical Conductivity Results

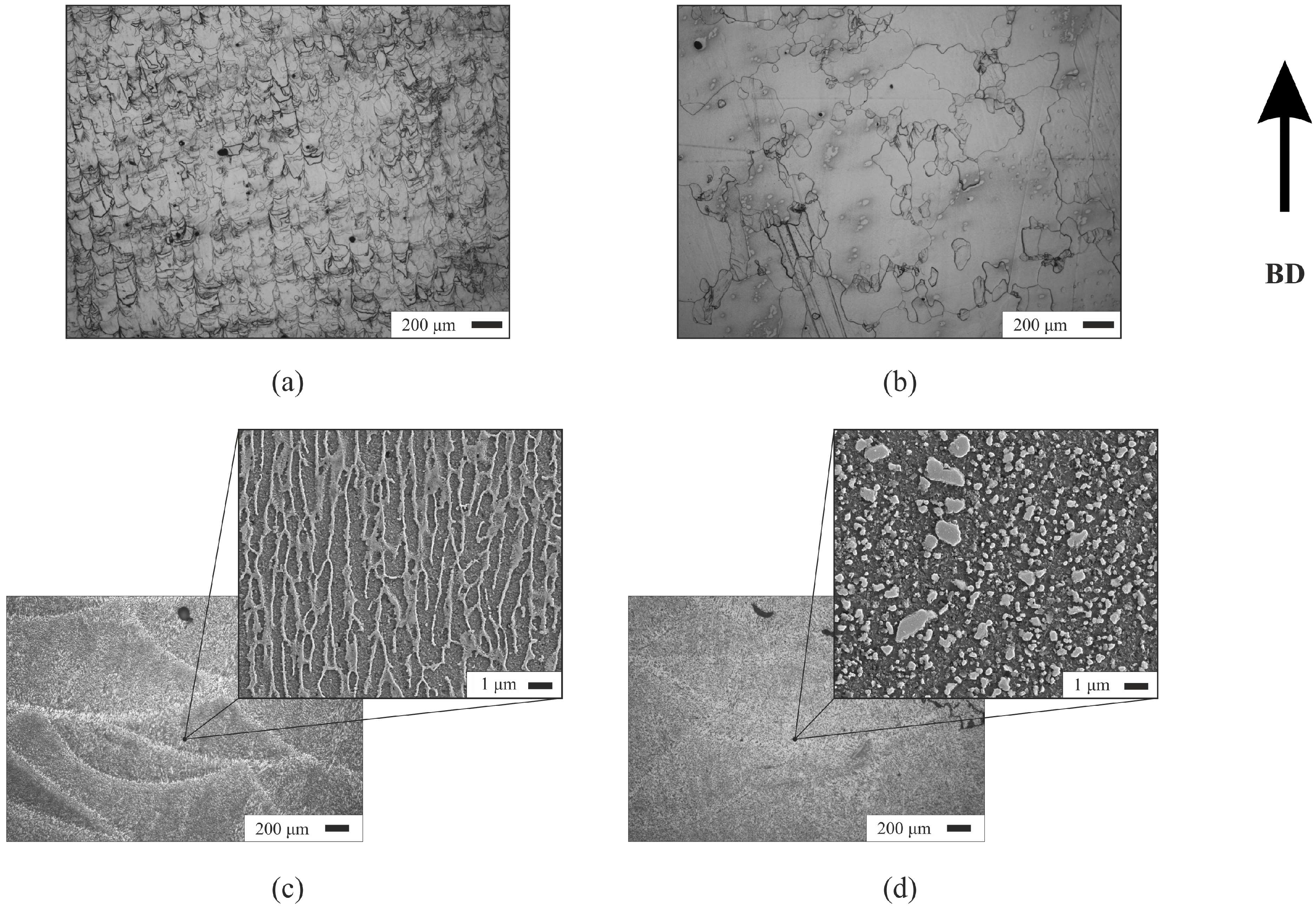

3.3. Microstructure Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sarap, M.; Kallaste, A.; Ghahfarokhi, P.S.; Tiismus, H.; Vaimann, T. The Effect of Build Direction on the Thermal Conductivity of Additively Manufactured AlSi10Mg and Silicon-steel Samples. In Proceedings of the 2022 International Conference on Electrical Machines (ICEM), Valencia, Spain, 5–8 September 2022; pp. 538–543. [Google Scholar] [CrossRef]

- Wang, D.; Wei, Y.; Wei, X.; Khanlari, K.; Wang, Z.; Feng, Y.; Yang, X. Selective Laser Melting of Pure Ag and 925Ag Alloy and Their Thermal Conductivity. Crystals 2022, 12, 480. [Google Scholar] [CrossRef]

- Kim, M.S. Effects of Processing Parameters of Selective Laser Melting Process on Thermal Conductivity of AlSi10Mg Alloy. Materials 2021, 14, 2410. [Google Scholar] [CrossRef] [PubMed]

- Attar, H.; Calin, M.; Zhang, L.C.; Scudino, S.; Eckert, J. Manufacture by selective laser melting and mechanical behavior of commercially pure titanium. Mater. Sci. Eng. A 2014, 593, 170–177. [Google Scholar] [CrossRef]

- Barba, D.; Alabort, C.; Tang, Y.T.; Viscasillas, M.J.; Reed, R.C.; Alabort, E. On the size and orientation effect in additive manufactured Ti-6Al-4V. Mater. Des. 2020, 186, 108235. [Google Scholar] [CrossRef]

- Rosenthal, I.; Stern, A.; Frage, N. Microstructure and Mechanical Properties of AlSi10Mg Parts Produced by the Laser Beam Additive Manufacturing (AM) Technology. Metallogr. Microstruct. Anal. 2014, 3, 448–453. [Google Scholar] [CrossRef]

- Tiismus, H.; Kallaste, A.; Vaimann, T.; Lind, L.; Virro, I.; Rassõlkin, A.; Dedova, T. Laser Additively Manufactured Magnetic Core Design and Process for Electrical Machine Applications. Energies 2022, 15, 3665. [Google Scholar] [CrossRef]

- Wohlers, C.; Juris, P.; Kabelac, S.; Ponick, B. Design and direct liquid cooling of tooth-coil windings. Electr. Eng. 2018, 100, 2299–2308. [Google Scholar] [CrossRef]

- Garibaldi, M.; Ashcroft, I.; Simonelli, M.; Hague, R. Metallurgy of high-silicon steel parts produced using Selective Laser Melting. Acta Mater. 2016, 110, 207–216. [Google Scholar] [CrossRef]

- Kang, N.; El Mansori, M.; Guittonneau, F.; Liao, H.; Fu, Y.; Aubry, E. Controllable mesostructure, magnetic properties of soft magnetic Fe-Ni-Si by using selective laser melting from nickel coated high silicon steel powder. Appl. Surf. Sci. 2018, 455, 736–741. [Google Scholar] [CrossRef]

- Mfusi, B.J.; Tshabalala, L.C.; Popoola, A.P.I.; Mathe, N.R. The effect of selective laser melting build orientation on the mechanical properties of AlSi10Mg parts. IOP Conf. Ser. Mater. Sci. Eng. 2018, 430, 012028. [Google Scholar] [CrossRef]

- Strumza, E.; Yeheskel, O.; Hayun, S. The effect of texture on the anisotropy of thermophysical properties of additively manufactured AlSi10Mg. Addit. Manuf. 2019, 29, 100762. [Google Scholar] [CrossRef]

- Yang, P.; Deibler, L.A.; Bradley, D.R.; Stefan, D.K.; Carroll, J.D. Microstructure evolution and thermal properties of an additively manufactured, solution treatable AlSi10Mg part. J. Mater. Res. 2018, 33, 4040–4052. [Google Scholar] [CrossRef]

- Kim, W.R.; Bang, G.B.; Kwon, O.; Jung, K.H.; Park, H.K.; Kim, G.H.; Jeong, H.T.; Kim, H.G. Fabrication of porous pure titanium via selective laser melting under low-energy-density process conditions. Mater. Des. 2020, 195, 109035. [Google Scholar] [CrossRef]

- Peng, T.; Chen, C. Influence of energy density on energy demand and porosity of 316L stainless steel fabricated by selective laser melting. Int. J. Precis. Eng. Manuf.—Green Technol. 2018, 5, 55–62. [Google Scholar] [CrossRef]

- Greco, S.; Gutzeit, K.; Hotz, H.; Kirsch, B.; Aurich, J.C. Selective laser melting (SLM) of AISI 316L—Impact of laser power, layer thickness, and hatch spacing on roughness, density, and microhardness at constant input energy density. Int. J. Adv. Manuf. Technol. 2020, 108, 1551–1562. [Google Scholar] [CrossRef]

- Thijs, L.; Kempen, K.; Kruth, J.P.; van Humbeeck, J. Fine-structured aluminium products with controllable texture by selective laser melting of pre-alloyed AlSi10Mg powder. Acta Mater. 2013, 61, 1809–1819. [Google Scholar] [CrossRef]

- ASTM E1461; Standard Test Method for Thermal Diffusivity by the Flash Method. ASTM: West Conshohocken, PA, USA, 2013.

- SLM Solutions, Material Data Sheet Al-Alloy AlSi10Mg/EN AC-4300/EN AC-AlSi10Mg. Available online: https://www.slm-solutions.com/fileadmin/Content/Powder/MDS/nw/2024/MDS_AlSi10Mg_2024-04.1_EN.pdf (accessed on 23 December 2024).

- EOS Aluminium AlSi10Mg Material Data Sheet Metal Solutions. Available online: https://www.eos.info/var/assets/03_system-related-assets/material-related-contents/metal-materials-and-examples/metal-material-datasheet/aluminium/material_datasheet_eos_aluminium-alsi10mg_en_web.pdf (accessed on 23 December 2024).

- Tiismus, H.; Kallaste, A.; Belahcen, A.; Tarraste, M.; Vaimann, T.; Rassõlkin, A.; Asad, B.; Shams Ghahfarokhi, P. AC Magnetic Loss Reduction of SLM Processed Fe-Si for Additive Manufacturing of Electrical Machines. Energies 2021, 14, 1241. [Google Scholar] [CrossRef]

- Si 3 and, A. 0 4%, Chemical Composition, Typical Electrical Steel, Thin Non-Oriented Grades Coating SURALAC® 7000. Available online: https://www.polarislaserlaminations.com/Cogent.pdf (accessed on 23 December 2024).

- Silbernagel, C.; Ashcroft, I.; Dickens, P.; Galea, M. Electrical resistivity of additively manufactured AlSi10Mg for use in electric motors. Addit. Manuf. 2018, 21, 395–403. [Google Scholar] [CrossRef]

- Kimura, T.; Nakamoto, T.; Mizuno, M.; Araki, H. Effect of silicon content on densification, mechanical and thermal properties of Al-xSi binary alloys fabricated using selective laser melting. Mater. Sci. Eng. A 2017, 682, 593–602. [Google Scholar] [CrossRef]

- Xing, Y.; Wang, W.; Al-azzani, H. Assessment of thermal properties of various types of high-strength steels at elevated temperatures. Fire Saf. J. 2021, 122, 103348. [Google Scholar] [CrossRef]

- Garibaldi, M.; Ashcroft, I.; Lemke, J.N.; Simonelli, M.; Hague, R. Effect of annealing on the microstructure and magnetic properties of soft magnetic Fe-Si produced via laser additive manufacturing. Scr. Mater. 2018, 142, 121–125. [Google Scholar] [CrossRef]

- Takata, N.; Kodaira, H.; Sekizawa, K.; Suzuki, A.; Kobashi, M. Change in microstructure of selectively laser melted AlSi10Mg alloy with heat treatments. Mater. Sci. Eng. A 2017, 704, 218–228. [Google Scholar] [CrossRef]

| Measured Property | Material | Manufacturing Orientation | No. of Samples Created |

|---|---|---|---|

| Thermal conductivity | AlSi10Mg | Z | 1 |

| 45° | 1 | ||

| X | 1 | ||

| FeSi (3.7%wt. Si) | Z | 1 | |

| X | 1 | ||

| Electrical conductivity | AlSi10Mg | Z | 2 |

| X | 2 | ||

| FeSi (3.7%wt. Si) | Z | 2 | |

| X | 2 |

| Parameter | Value (Aluminum) | Value (Steel) |

|---|---|---|

| Layer thickness | 50 µm | 50 µm |

| Hatch distance | 170 µm | 120 µm |

| Laser power | 350 W | 250 W |

| Scanning velocity | 1.15 m/s | 0.5 m/s |

| Scan strategy | Stripes | Stripes |

| Environment | Nitrogen | Nitrogen |

| Oxygen content | ~0.1% | ~0.1% |

| Sample | Thermal Conductivity at 35 °C (W/m/K) | Thermal Conductivity at 70 °C (W/m/K) |

|---|---|---|

| as-built | 113.3 ± 3.1 | 116.2 ± 1.8 |

| annealed | 148.2 ± 3.5 | 149.5 ± 2.3 |

| as-built | 103.0 ± 3.2 | 106.9 ± 1.7 |

| annealed | 148.5 ± 3.7 | 149.9 ± 2.4 |

| as-built | 106.7 ± 3.5 | 108.0 ± 2.0 |

| annealed | 148.2 ± 3.8 | 149.8 ± 2.3 |

| as-built | 25.3 ± 0.8 | 27.0 ± 0.4 |

| annealed | 25.0 ± 0.7 | 26.6 ± 0.4 |

| as-built | 25.4 ± 0.7 | 26.9 ± 0.4 |

| annealed | 24.6 ± 0.8 | 26.0 ± 0.4 |

| Sample | Electrical Conductivity at 20 °C (MS/m) |

|---|---|

| as-built | 14.70 ± 0.27 |

| /annealed | 23.88 ± 0.50 |

| as-built | 13.08 ± 0.36 |

| /annealed | 24.72 ± 0.86 |

| as-built | 1.76 ± 0.03 |

| /annealed | 1.78 ± 0.03 |

| as-built | 1.76 ± 0.03 |

| /annealed | 1.77 ± 0.03 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sarap, M.; Tiismus, H.; Kallaste, A.; Saarna, M.; Kolnes, M.; Shams Ghahfarokhi, P.; Vaimann, T. Electrical and Thermal Anisotropy in Additively Manufactured AlSi10Mg and Fe-Si Samples. Machines 2025, 13, 1. https://doi.org/10.3390/machines13010001

Sarap M, Tiismus H, Kallaste A, Saarna M, Kolnes M, Shams Ghahfarokhi P, Vaimann T. Electrical and Thermal Anisotropy in Additively Manufactured AlSi10Mg and Fe-Si Samples. Machines. 2025; 13(1):1. https://doi.org/10.3390/machines13010001

Chicago/Turabian StyleSarap, Martin, Hans Tiismus, Ants Kallaste, Mart Saarna, Märt Kolnes, Payam Shams Ghahfarokhi, and Toomas Vaimann. 2025. "Electrical and Thermal Anisotropy in Additively Manufactured AlSi10Mg and Fe-Si Samples" Machines 13, no. 1: 1. https://doi.org/10.3390/machines13010001

APA StyleSarap, M., Tiismus, H., Kallaste, A., Saarna, M., Kolnes, M., Shams Ghahfarokhi, P., & Vaimann, T. (2025). Electrical and Thermal Anisotropy in Additively Manufactured AlSi10Mg and Fe-Si Samples. Machines, 13(1), 1. https://doi.org/10.3390/machines13010001