Geometric Modeling and Error Propagation Analysis of an Over-Constrained Spindle Head with Kinematic Interactions

Abstract

1. Introduction

2. Geometric Error Modeling and Comparison of Individual Limbs

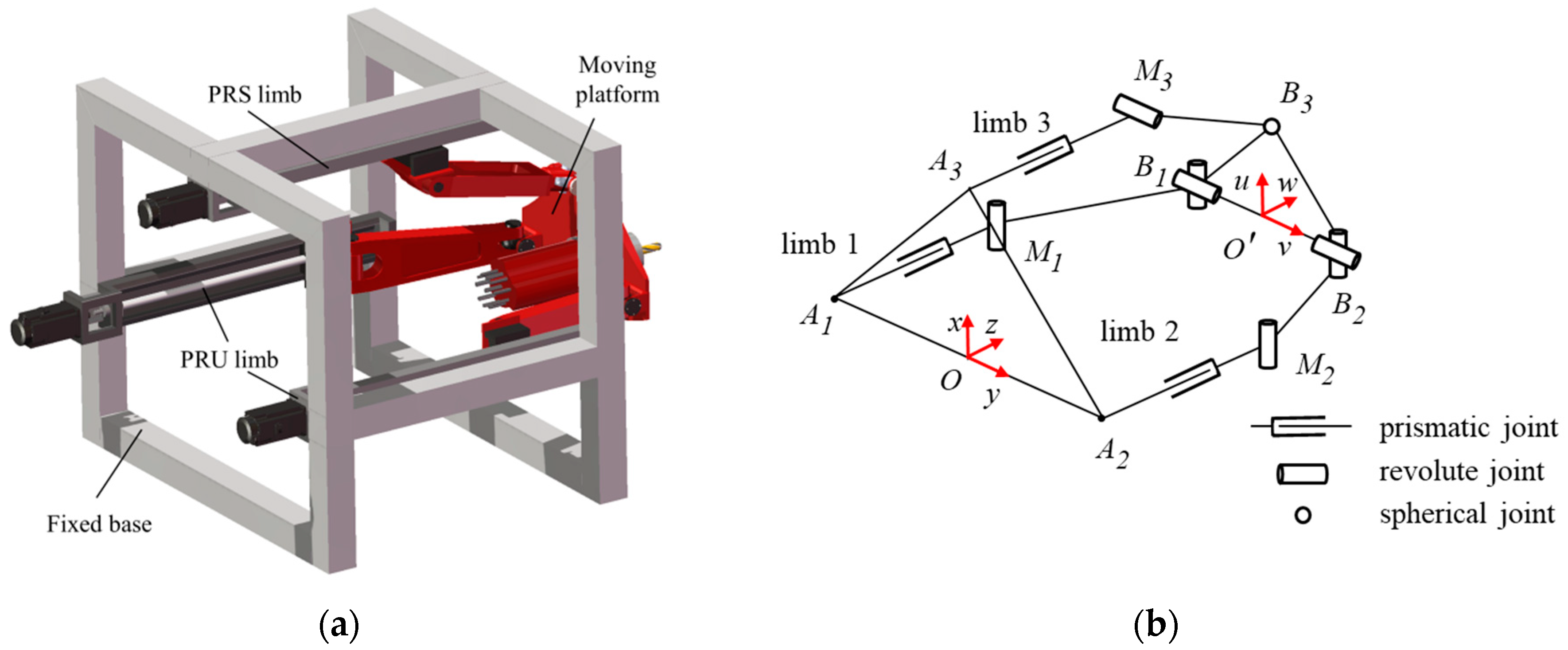

2.1. Structure Description and Coordinates Settings

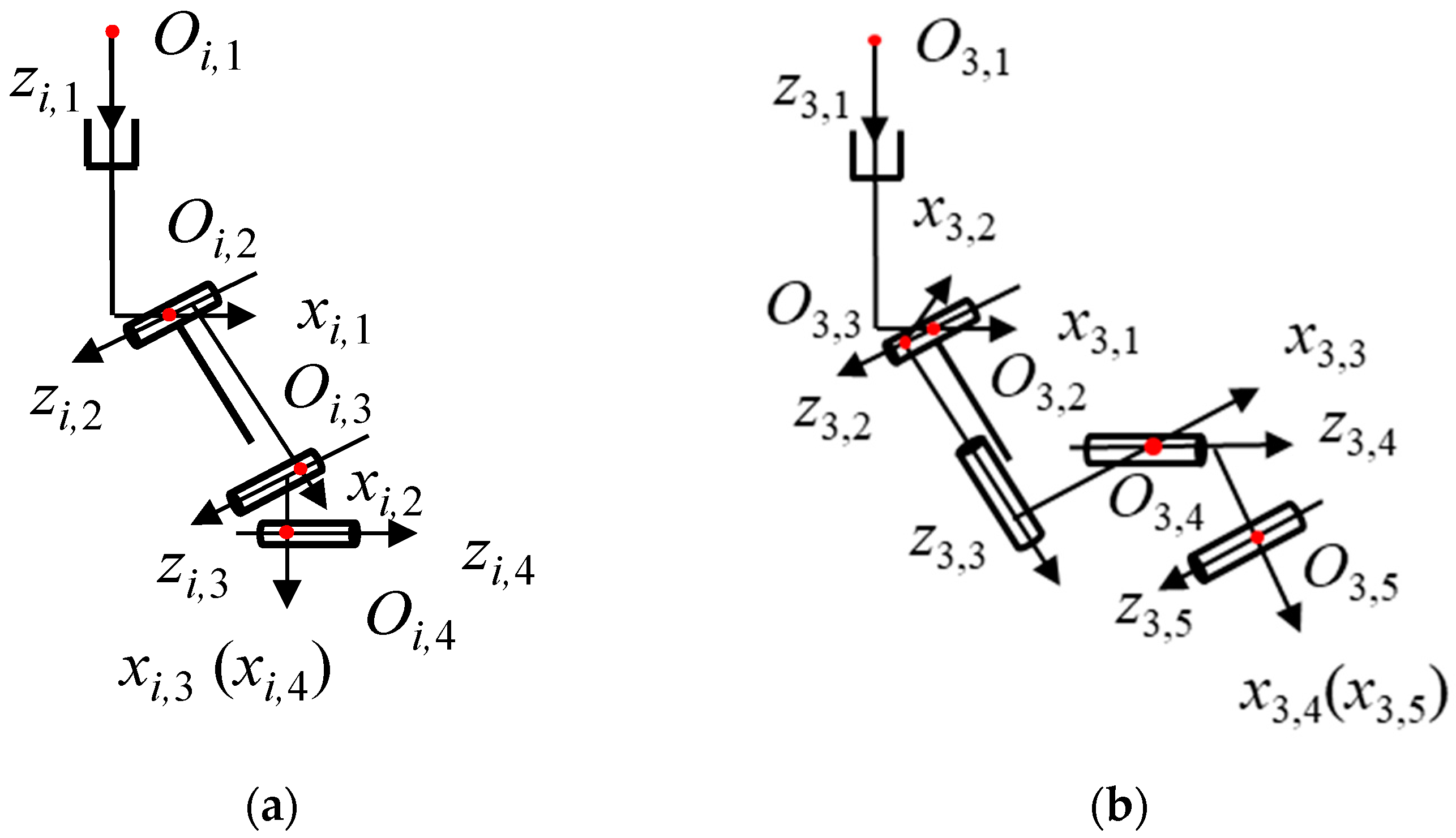

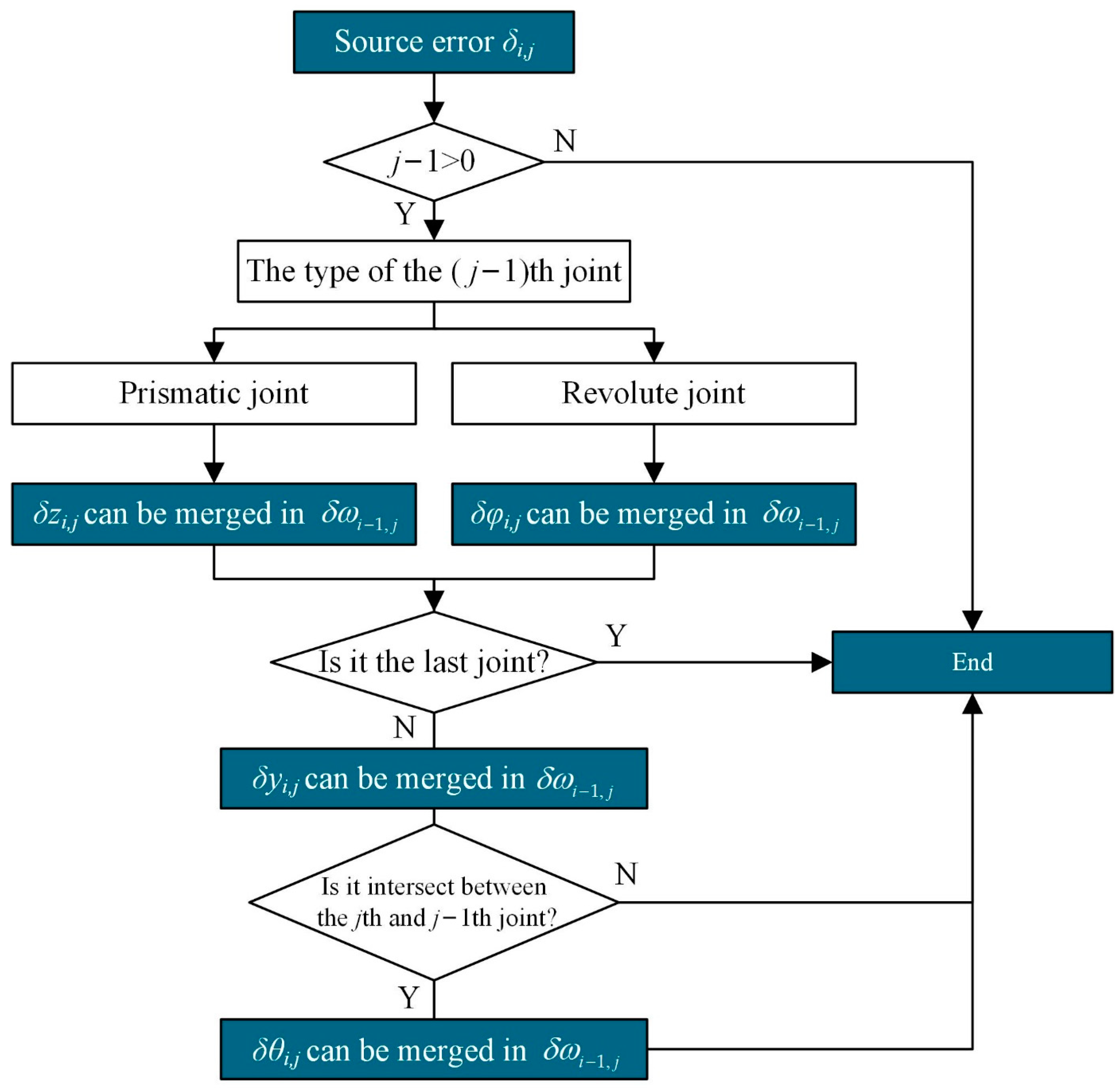

2.2. Error Modeling of Individual Limbs

2.3. Error Modeling of the Spindle Head

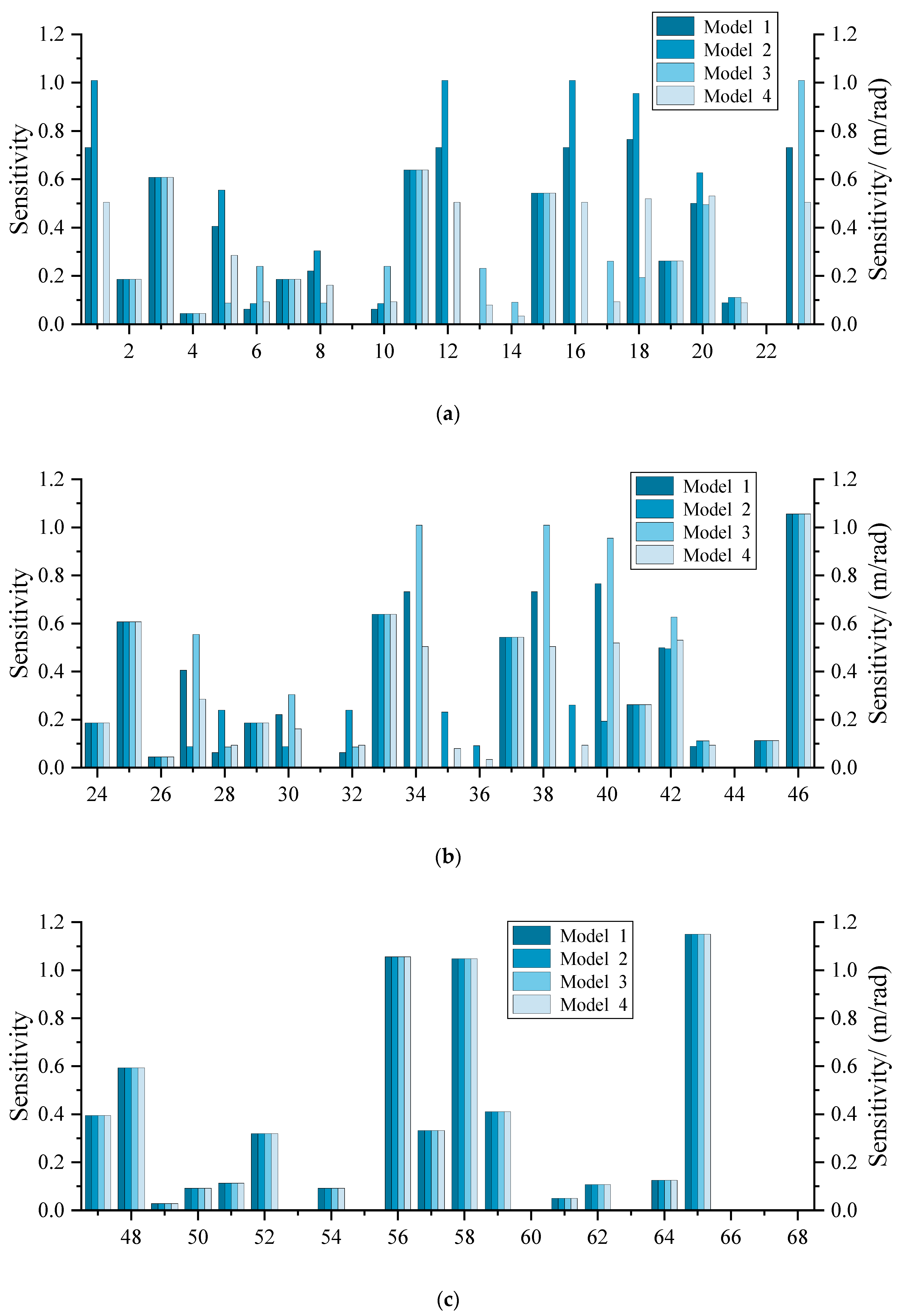

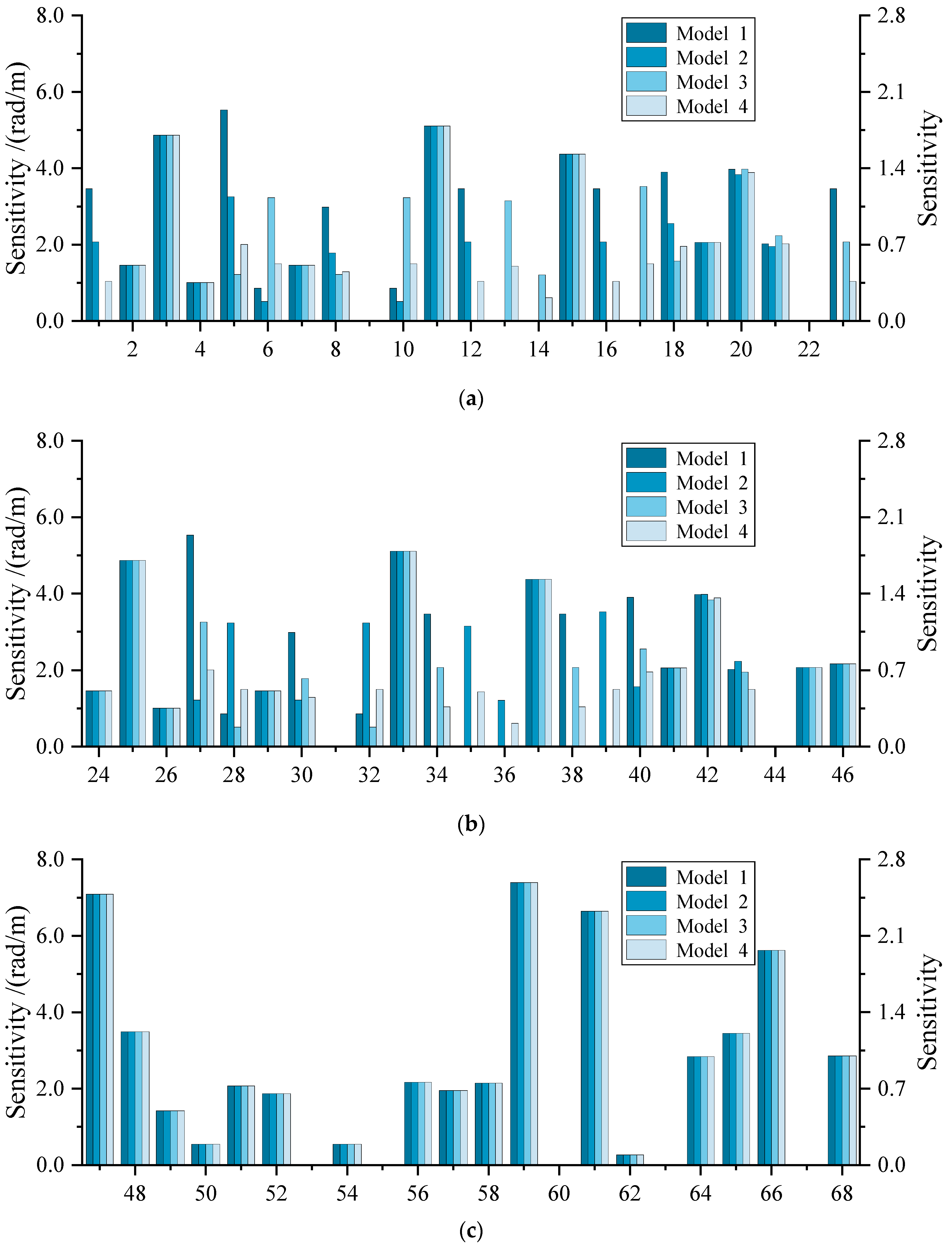

2.4. Comparative Sensitivity Analysis

3. Error Propagation Analysis with Kinematic Interactions

3.1. Error Propagation Index

3.2. Error Propagation Analysis for Individual Limb

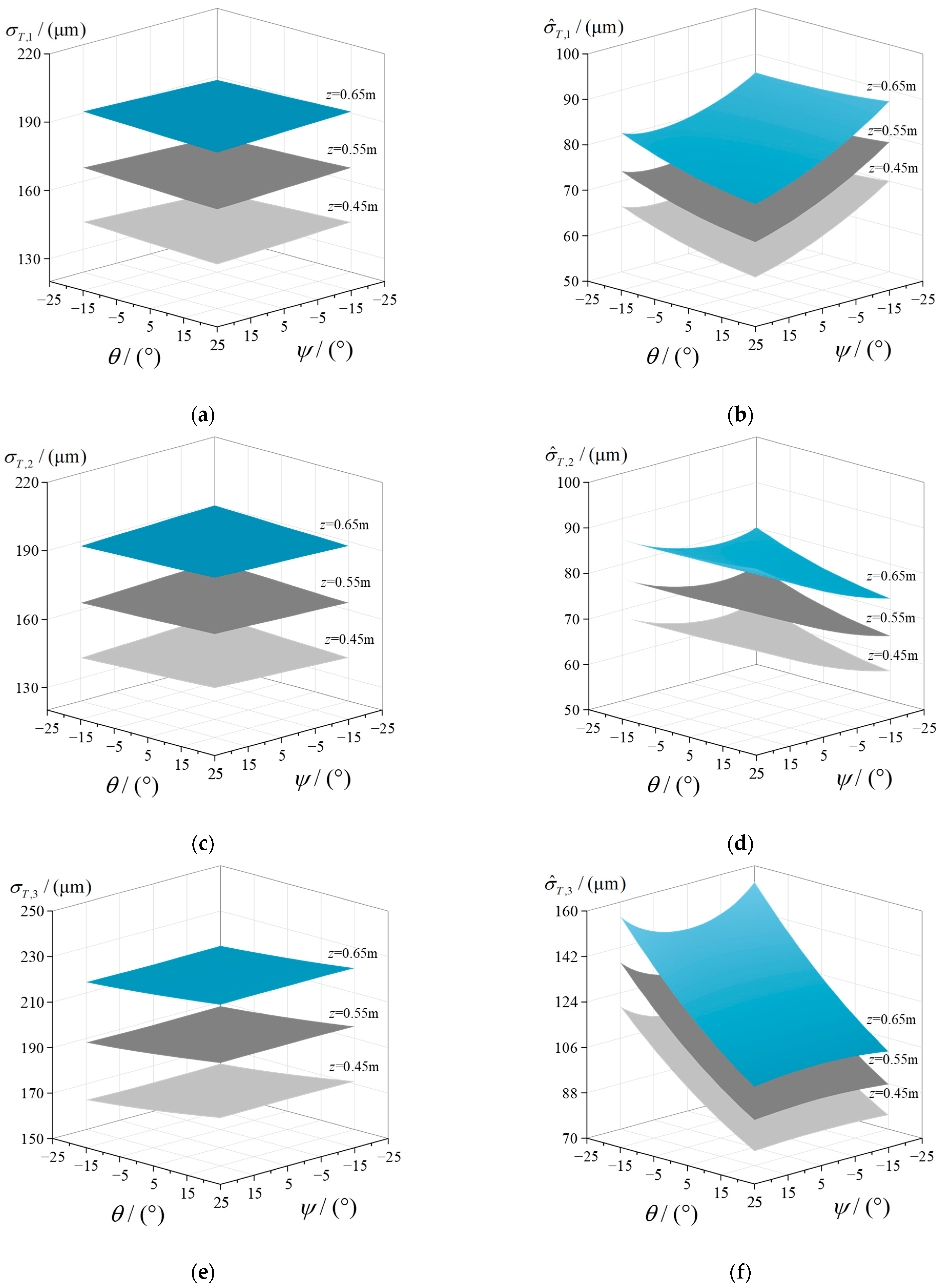

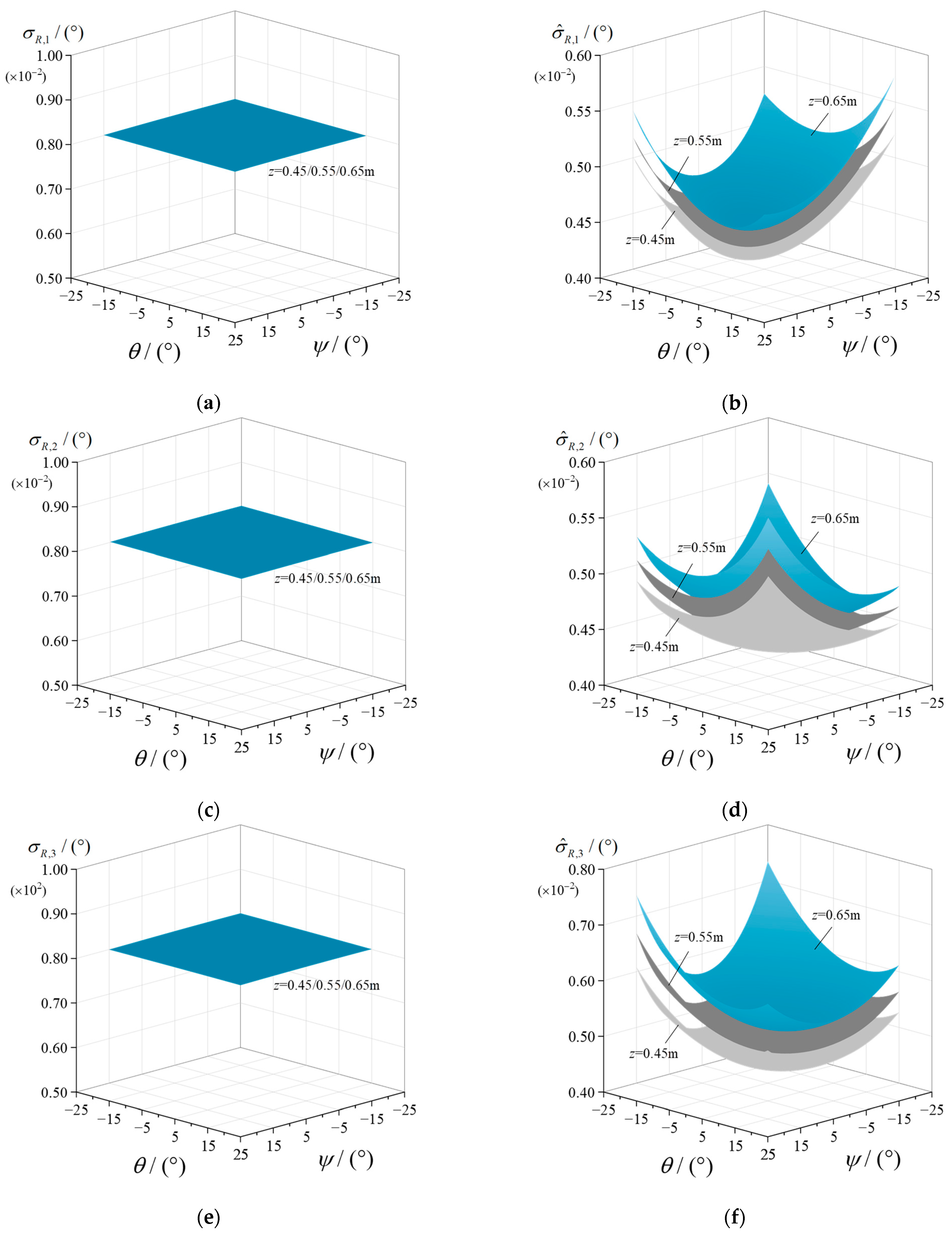

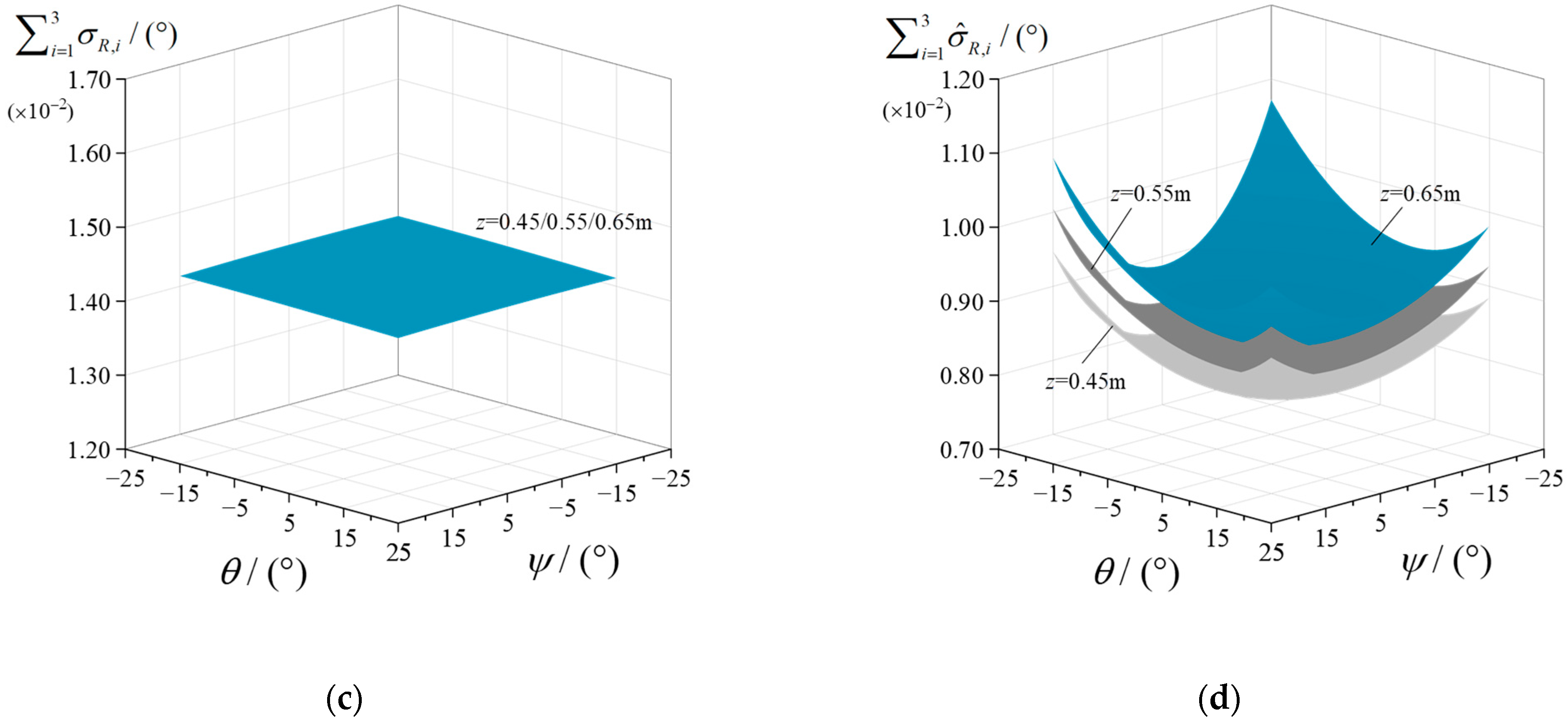

3.3. Error Propagation Analysis for Terminal Platform

4. Conclusions

- (1)

- Four geometric error models considering different combinations of constraint wrenches are established for the over-constrained spindle head. A set of sensitivity indices is formulated to evaluate the effectiveness of these models. Comparative sensitivity analysis suggests that among the three error models considered without all constraints, there are six source errors that cannot be identified. A model incorporating all constraint wrenches can effectively reflect the influence of all geometric source errors on the terminal position/orientation error of the spindle head and is suitable for error propagation intensity analysis of such an over-constrained mechanical system.

- (2)

- The proposed error propagation indices quantitatively describe how much the perturbation of geometric errors affect the kinematic accuracy of the individual limb structure. The coupled error propagation indices quantitatively describe the perturbation to the terminal accuracy of the spindle head caused by the geometric errors of an individual limb structure. These two kinds of performance indices can be adopted to analyze the error propagation at the limb structural level and the mechanical system level of the spindle head, respectively.

- (3)

- Further error propagation analysis results show that the error propagation indices for the three limbs are pose-dependent, and the kinematic errors of a limb structure are subject to varying degrees of compensation from the other limbs. The average of linear error indices of limb 1 and limb 2 are reduced by 56.6%; the average of linear error indices of limb 3 are reduced by 43.2%. Moreover, there is a mutual compensation relationship between the geometric errors of the limbs in such an over-constrained spindle head. By taking the mixing mechanism as an example, the results show that the average linear error is reduced by 47.7%. Such interactive compensation significantly reduces the moving platform’s linear error, enhancing the terminal accuracy of the spindle head.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Rong, Y.; Zhang, X.; Dou, T.; Wang, H. Type synthesis of non-overconstrained and overconstrained two rotation and three translation (2R3T) parallel mechanisms with three branched chains. Mech. Sci. 2023, 14, 567–577. [Google Scholar] [CrossRef]

- Righettini, P.; Strada, R.; Cortinovis, F.; Tabaldi, F.; Santinelli, J.; Ginammi, A. An Experimental Investigation of the Dynamic Performances of a High Speed 4-DOF 5R Parallel Robot Using Inverse Dynamics Control. Robotics 2024, 13, 54. [Google Scholar] [CrossRef]

- Görgülü, I.; Dede, M.I.C.; Kiper, G. Stiffness modeling of a 2-DoF over-constrained planar parallel mechanism. Mech. Mach. Theory 2023, 185, 105343. [Google Scholar] [CrossRef]

- Chen, M.; Zhang, Q.; Ge, Y.; Qin, X.; Sun, Y. Dynamic analysis of an over-constrained parallel mechanism with the principle of virtual work. Math. Comput. Model. Dyn. Syst. 2021, 27, 347–372. [Google Scholar] [CrossRef]

- Wang, Y.; Belzile, B.; Angles, J.; Li, Q. Kinematic analysis and optimum design of a novel 2PUR-2RPU parallel robot. Mech. Mach. Theory 2019, 139, 407–423. [Google Scholar] [CrossRef]

- Shen, X.; Xu, L.; Li, Q. Motion/Force constraint indices of redundantly actuated parallel manipulators with over constraints. Mech. Mach. Theory 2021, 165, 104427. [Google Scholar] [CrossRef]

- López-Custodio, P.C.; Dai, J.; Fu, R. Kinematics and constraints of the Exechon robot accounting offsets due to errors in the base joint axes. J. Mech. Robot. 2020, 12, 21109. [Google Scholar] [CrossRef]

- Zhang, J.; Zhao, Y.; Jin, Y. Kinetostatic-model-based stiffness analysis of Exechon PKM. Robot. Comput. Integr. Manuf. 2016, 37, 208–220. [Google Scholar] [CrossRef]

- Zoppi, M.; Zlatanov, D.; Molfino, R. Kinematics analysis of the Exechon tripod. In Proceedings of the ASME 2010 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Montreal, QC, Canada, 15–18 August 2010. [Google Scholar] [CrossRef]

- Jin, Y.; Bi, Z.M.; Liu, H.T.; Higgins, C.; Price, M.; Chen, W.H.; Huang, T. Kinematic analysis and dimensional synthesis of Exechon parallel kinematic machine for large volume machining. J. Mech. Robot. 2015, 7, 041004. [Google Scholar] [CrossRef]

- Yuan, Y.; Sun, W. An integrated kinematic calibration and dynamic identification method with only static measurements for serial robot. IEEE/ASME Trans. Mechatron. 2023, 28, 2762–2773. [Google Scholar] [CrossRef]

- Shukla, G.; Whitney, D.E. The path method for analyzing mobility and constraint of mechanisms and assemblies. IEEE Trans. Autom. Sci. Eng. 2005, 2, 184–192. [Google Scholar] [CrossRef]

- Raksiri, C.; Pa-im, K.; Rodkwan, S. An Analysis of Joint Assembly Geometric Errors Affecting End-Effector for Six-Axis Robots. Robotics 2020, 9, 27. [Google Scholar] [CrossRef]

- Kong, L.Y.; Chen, G.L.; Wang, H.; Huang, G.; Zhang, D. Kinematic calibration of a 3-PRRU parallel manipulator based on the complete, minimal and continuous error model. Robot. Comput. Integr. Manuf. 2021, 71, 102158. [Google Scholar] [CrossRef]

- Fu, Z.; Dai, J.; Yang, K.; Chen, X.; López-Custodio, P. Analysis of unified error model and simulated parameters calibration for robotic machining based on lie theory. Comput. Integr. Manuf. 2020, 61, 101855. [Google Scholar] [CrossRef]

- Sun, T.; Liu, C.; Lian, B.; Wang, P.; Song, Y. Calibration for precision kinematic control of an articulated serial robot. IEEE Trans. Ind. Electron. 2021, 68, 6000–6009. [Google Scholar] [CrossRef]

- Sun, T.; Lian, B.; Yang, S.; Song, Y. Kinematic calibration of serial and parallel robots based on finite and instantaneous screw theory. IEEE Trans. Robot. 2020, 36, 816–834. [Google Scholar] [CrossRef]

- Zhao, A.; Toudeshki, A.; Ehsani, R.; Sun, J.-Q. Data-Driven Inverse Kinematics Approximation of a Delta Robot with Stepper Motors. Robotics 2023, 12, 135. [Google Scholar] [CrossRef]

- Ni, Y.; Cui, Y.; Jia, S.; Lu, C.; Lu, W. Error identification and compensation of 1T2R parallel power head based on trajectory optimization and principal component analysis. IEEE Trans. Robot. 2020, 36, 816–834. [Google Scholar] [CrossRef]

- Luo, X.; Xie, F.; Liu, X.; Xie, Z. Kinematic calibration of a 5-axis parallel machining robot based on dimensionless error mapping matrix. Robot. Comput. Integr. Manuf. 2021, 70, 102115. [Google Scholar] [CrossRef]

- Mei, B.; Xie, F.; Liu, X.; Yang, C. Elasto-geometrical error modeling and compensation of a five-axis parallel machining robot. Precis. Eng. 2021, 69, 48–61. [Google Scholar] [CrossRef]

- Chen, G.; Kong, L.; Li, Q.; Wang, H.; Lin, Z. Complete, minimal and continuous error models for the kinematic calibration of parallel manipulators based on POE formula. Mech. Mach. Theory 2018, 121, 844–856. [Google Scholar] [CrossRef]

- Ye, H.; Wu, J.; Wang, D. A general approach for geometric error modeling of over-constrained hybrid robot. Mech. Mach. Theory 2022, 176, 104998. [Google Scholar] [CrossRef]

- Jiang, S.; Chi, C.; Fang, H.; Tang, T.; Zhang, J. A minimal-error-model based two-step kinematic calibration methodology for redundantly actuated parallel manipulators: An application to a 3-DOF spindle head. Mech. Mach. Theory 2022, 167, 104532. [Google Scholar] [CrossRef]

- Luo, X.; Xie, F.; Liu, X. Kinematic calibration of the 3-degree-of-freedom redundantly actuated spatial parallel module of a five-axis hybrid machine. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2020, 234, 1185–1197. [Google Scholar] [CrossRef]

- Shen, Y.; Chen, M.; Skelton, R.E. A Markov data-based approach to system identification and output error covariance analysis for tensegrity structures. Nonlinear Dyn. 2024, 112, 7215–7231. [Google Scholar] [CrossRef]

- Ye, C.; Yang, J.; Zhao, H.; Ding, H. Task-dependent workpiece placement optimization for minimizing contour errors induced by the low posture-dependent stiffness of robotic milling. Int. J. Mech. Sci. 2021, 205, 106601. [Google Scholar] [CrossRef]

- Chen, C.; Peng, F.; Yan, R.; Li, Y.; Wei, D.; Fan, Z. Stiffness performance index based posture and feed orientation optimization in robotic milling process. Robot. Comput. Integr. Manuf. 2019, 55, 29–40. [Google Scholar] [CrossRef]

- Wang, L.; Li, M.; Yu, G. A Novel Error Sensitivity Analysis Method for a Parallel Spindle Head. Robotics 2023, 12, 129. [Google Scholar] [CrossRef]

- Luo, X.; Xie, F.; Liu, X. Error modeling and sensitivity analysis of a novel 5-degree of freedom parallel kinematic machine tool. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2019, 233, 1637–1652. [Google Scholar] [CrossRef]

- Wu, M.; Yue, X.; Chen, W.; Nie, Q.; Zhang, Y. Accuracy analysis and synthesis of asymmetric parallel mechanism based on Sobol-QMC. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2020, 234, 4200–4214. [Google Scholar] [CrossRef]

- Li, G.; Qu, H.; Guo, S. Sensitivity analysis of a planar parallel manipulator with kinematic redundancy. J. Mech. Eng. 2020, 56, 45–57. [Google Scholar] [CrossRef]

- Shi, K.; Wang, Z.; Yan, C.; Wang, Z. Design and performance analysis of the 4UPS-RRR parallel ankle rehabilitation mechanism. Mech. Sci. 2024, 15, 417–430. [Google Scholar] [CrossRef]

- Wang, J.; Lau, H.Y.K. Dexterity Analysis Based on Jacobian and Performance Optimization for Multi-Segment Continuum Robots. ASME J. Mech. Robot. 2021, 13, 061012. [Google Scholar] [CrossRef]

- Nabavi, S.N.; Shariatee, M.; Enferadi, J.; Akbarzadeh, A. Parametric design and multi-objective optimization of a general 6-PUS parallel manipulator. Mech. Mach. Theory 2020, 152, 103913. [Google Scholar] [CrossRef]

| Parameters | Value | Parameters | Value |

|---|---|---|---|

| ra | 0.250 m | qf | 0–0.5 m |

| a | 0.315 m | Rf | 0–60° |

| rb | 0.178 m | Uf | 65–145° |

| Sf | 65–145° |

| Order (nth) | Source Error | Order (nth) | Source Error | Order (nth) | Source Error | Order (nth) | Source Error | Order (nth) | Source Error |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 15 | 29 | 43 | 57 | |||||

| 2 | 16 | 30 | 44 | 58 | |||||

| 3 | 17 | 31 | 45 | 59 | |||||

| 4 | 18 | 32 | 46 | 60 | |||||

| 5 | 19 | 33 | 47 | 61 | |||||

| 6 | 20 | 34 | 48 | 62 | |||||

| 7 | 21 | 35 | 49 | 63 | |||||

| 8 | 22 | 36 | 50 | 64 | |||||

| 9 | 23 | 37 | 51 | 65 | |||||

| 10 | 24 | 38 | 52 | 66 | |||||

| 11 | 25 | 39 | 53 | 67 | |||||

| 12 | 26 | 40 | 54 | 68 | |||||

| 13 | 27 | 41 | 55 | ||||||

| 14 | 28 | 42 | 56 |

| Error Models | ||

|---|---|---|

| Model 1 | ||

| Model 2 | ||

| Model 3 | ||

| Model 4 |

| Source Errors | Model 1 | Model 2 | Model 3 | Model 4 | Source Errors | Model 1 | Model 2 | Model 3 | Model 4 |

|---|---|---|---|---|---|---|---|---|---|

| √ | √ | × | √ | √ | × | √ | √ | ||

| √ | √ | √ | √ | √ | √ | √ | √ | ||

| √ | √ | √ | √ | √ | √ | √ | √ | ||

| √ | √ | √ | √ | √ | √ | √ | √ | ||

| √ | √ | √ | √ | √ | √ | √ | √ | ||

| √ | √ | × | √ | √ | × | √ | √ | ||

| × | × | √ | √ | × | √ | × | √ | ||

| × | × | √ | √ | × | √ | × | √ | ||

| √ | √ | × | √ | √ | × | √ | √ | ||

| × | × | √ | √ | × | √ | × | √ | ||

| √ | √ | √ | √ | √ | √ | √ | √ | ||

| √ | √ | √ | √ | √ | √ | √ | √ | ||

| √ | √ | √ | √ | √ | √ | √ | √ |

| Error | Tolerance | Error | Tolerance | Error | Tolerance | Error | Tolerance |

|---|---|---|---|---|---|---|---|

| 130 μm | 62 μm | 0.056° | 114 μm | ||||

| 87 μm | 0.014° | 0.056° | 43 μm | ||||

| 36 μm | 0.014° | 0.025° | 27 μm | ||||

| 0.064° | 0.010° | 48 μm | 0.034° | ||||

| 0.085° | 14 μm | 28 μm | 0.006° | ||||

| 0.032° | 74 μm | 0.0138° | 0.080° |

| Error | Tolerance | Error | Tolerance | Error | Tolerance | Error | Tolerance |

|---|---|---|---|---|---|---|---|

| 142 μm | 0.014° | 46 μm | 27 μm | ||||

| 93 μm | 0.014° | 0.016° | 0.031° | ||||

| 41 μm | 0.010° | 65 μm | 0.005° | ||||

| 0.075° | 63 μm | 36 μm | 0.037° | ||||

| 0.091° | 14 μm | 0.014° | |||||

| 0.037° | 0.068° | 63 μm | |||||

| 62 μm | 32 μm | 25 μm |

| Error | Tolerance | Error | Tolerance | Error | Tolerance | Error | Tolerance |

|---|---|---|---|---|---|---|---|

| 67 μm | 67 μm | 69 μm | 0.039° | ||||

| 0.036° | 0.036° | 0.036° | |||||

| 0.041° | 0.041° | 0.046° | |||||

| 0.035° | 0.035° | 0.037° |

| Index | Limb 1 | Limb 2 | Limb 3 | ||||

|---|---|---|---|---|---|---|---|

| Average | Maximum | Average | Maximum | Average | Maximum | ||

| Linear error indices | (μm) | 169.0 | 194.7 | 168.5 | 194.1 | 195.8 | 225.0 |

| (μm) | 73.4 | 89.6 | 73.1 | 89.0 | 111.2 | 157.8 | |

| 56.6% | 54.0% | 56.6% | 54.1% | 43.2% | 29.9% | ||

| Linear error indices | (°) | 8.21 × 10−3 | 8.23 × 10−3 | 8.21 × 10−3 | 8.22 × 10−3 | 8.34 × 10−3 | 8.35 × 10−3 |

| (°) | 4.66 × 10−3 | 5.83 × 10−3 | 4.66 × 10−3 | 5.82 × 10−3 | 5.32 × 10−3 | 7.54 × 10−3 | |

| 43.2% | 29.2% | 43.2% | 29.2% | 36.2% | 9.7% | ||

| End Index | Average | Maximum | |

|---|---|---|---|

| Linear error indices | (μm) | 313.6 | 359.2 |

| (μm) | 163.9 | 213.0 | |

| 47.7% | 40.7% | ||

| Angular error indices | (°) | 1.43 × 10−2 | 1.44 × 10−2 |

| (°) | 8.68 × 10−3 | 1.09 × 10−2 | |

| 39.3% | 24.3% | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shen, Y.; Tang, T.; Fang, H. Geometric Modeling and Error Propagation Analysis of an Over-Constrained Spindle Head with Kinematic Interactions. Machines 2024, 12, 651. https://doi.org/10.3390/machines12090651

Shen Y, Tang T, Fang H. Geometric Modeling and Error Propagation Analysis of an Over-Constrained Spindle Head with Kinematic Interactions. Machines. 2024; 12(9):651. https://doi.org/10.3390/machines12090651

Chicago/Turabian StyleShen, Yifeng, Tengfei Tang, and Hanliang Fang. 2024. "Geometric Modeling and Error Propagation Analysis of an Over-Constrained Spindle Head with Kinematic Interactions" Machines 12, no. 9: 651. https://doi.org/10.3390/machines12090651

APA StyleShen, Y., Tang, T., & Fang, H. (2024). Geometric Modeling and Error Propagation Analysis of an Over-Constrained Spindle Head with Kinematic Interactions. Machines, 12(9), 651. https://doi.org/10.3390/machines12090651