1. Introduction

China is one of the countries with the most severe icing on transmission lines in the world. Since the 1950s, various icing accidents have occurred on transmission and distribution lines in China, causing accidents such as transmission line galloping, wire breakage, and the structural failure of towers, which seriously threaten the safe operation of the power grid [

1,

2,

3,

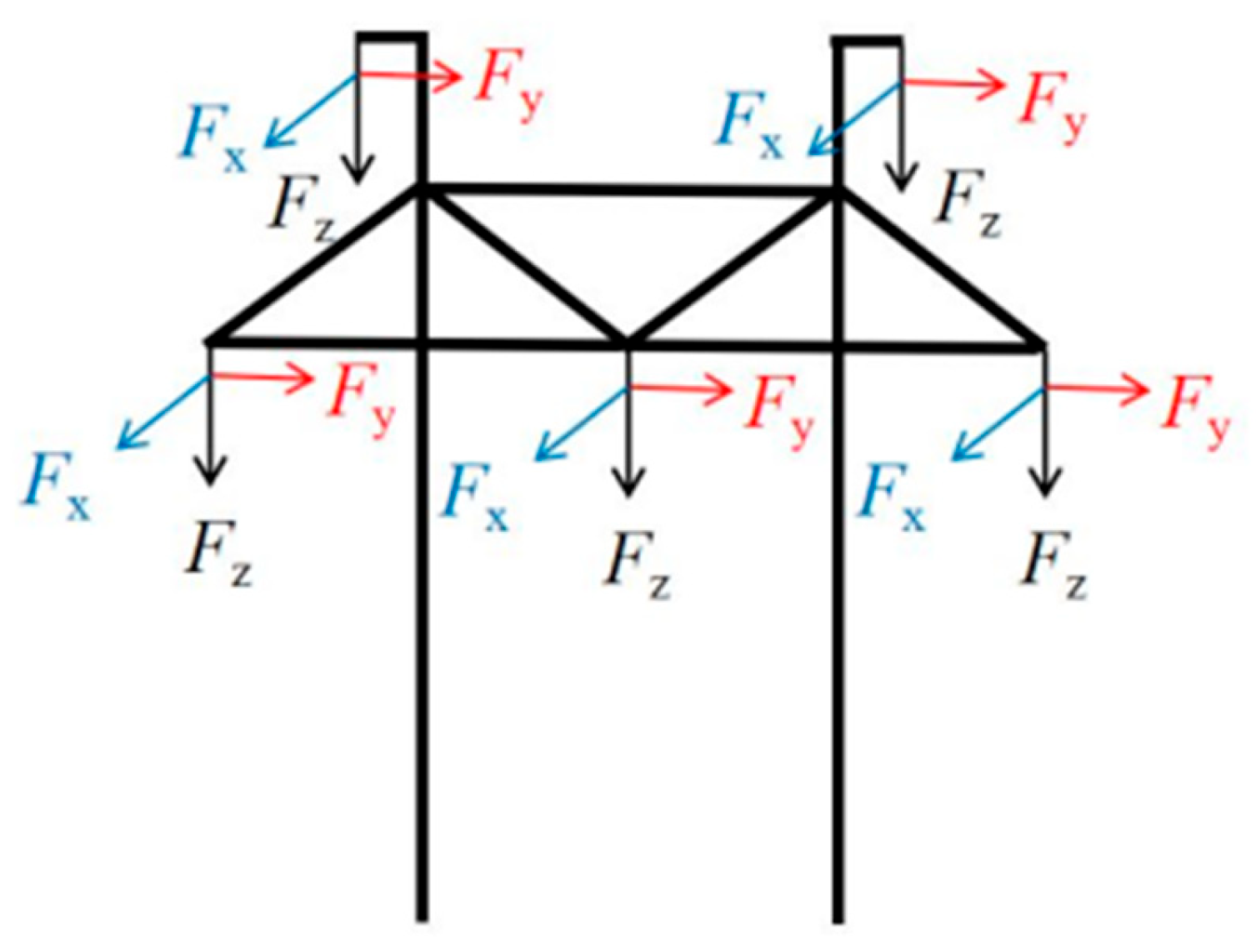

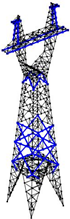

4]. The mechanical characteristic parameters of the weak components reflect the stability and strength of the tower structure, which are key factors in causing the structural failure of the tower. Therefore, it is necessary to research the prediction of the mechanical characteristic parameters of the weak components of the transmission tower.

The transmission tower is composed of a limited number of components. The weak components refer to those that are prone to yielding and failure when the transmission tower is subjected to its own load and external loads. When a component fails, it may affect the stress of adjacent components, which may lead to the structural failure of the tower [

5,

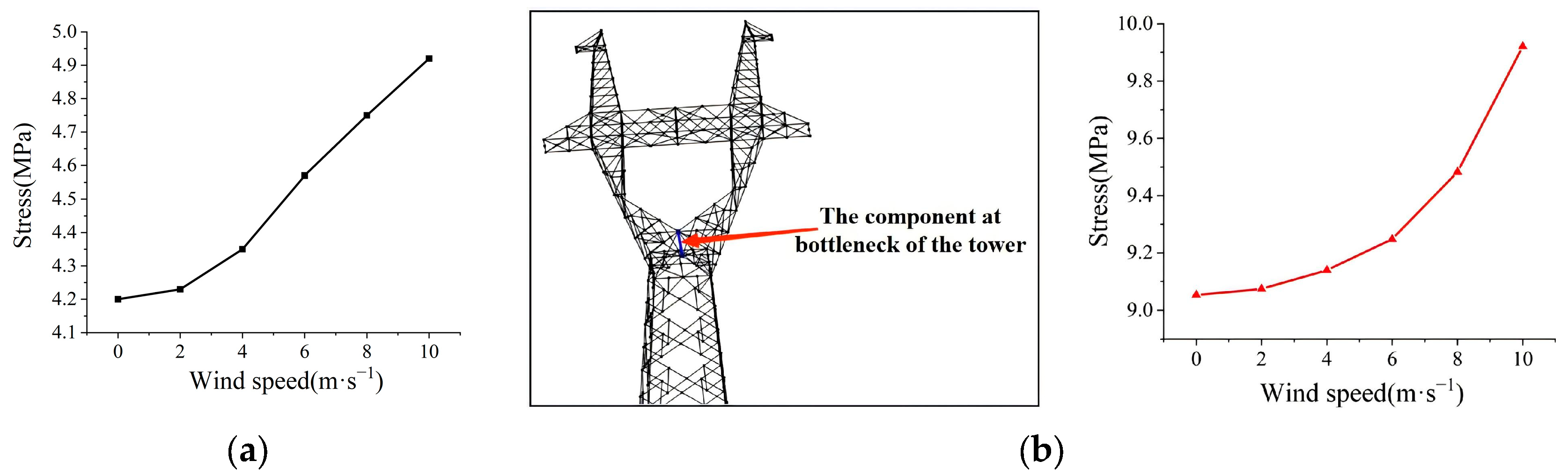

6]. Axial stresses and nodal displacements of transmission towers are important criteria for the structural failure of the tower [

7]. At present, the research on the weak components of transmission towers and their mechanical characteristics mainly focuses on experimental research and finite element simulation research.

In terms of experimental research, Li et al. [

8,

9,

10,

11] carried out real tower tests to analyze and obtain the weak components of the tower under wind and ice loads. However, the experimental research is time-consuming and expensive, and the effective parameters that can be reflected by the experimental results are limited.

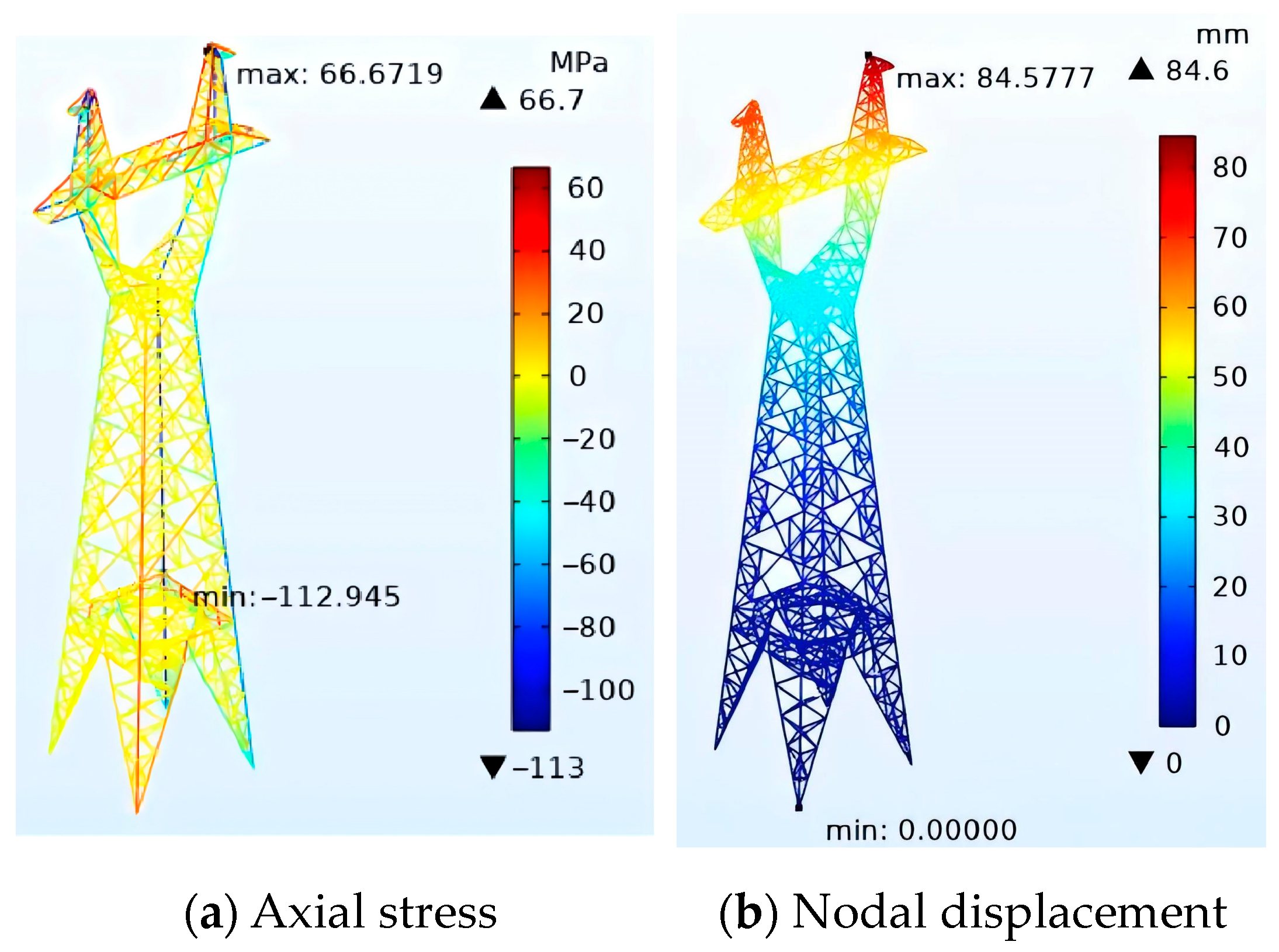

In terms of finite element simulation research, Wen et al. [

12] took a 110 kV transmission tower as an example to establish the finite element simulation model. The axial stresses and nodal displacements of the tower are obtained through simulation, and it is found that axial stresses and nodal displacements are the important factors that lead to the tower collapse. Xie et al. [

13] established the finite element model of a 110 kV transmission tower under wind load and found that a severe wind load may lead to tower collapse. Zhao et al. [

14] established the finite element simulation model of a 220 kV cat-type linear tower to study its mechanical characteristics under different ice-covering conditions. Liu et al. [

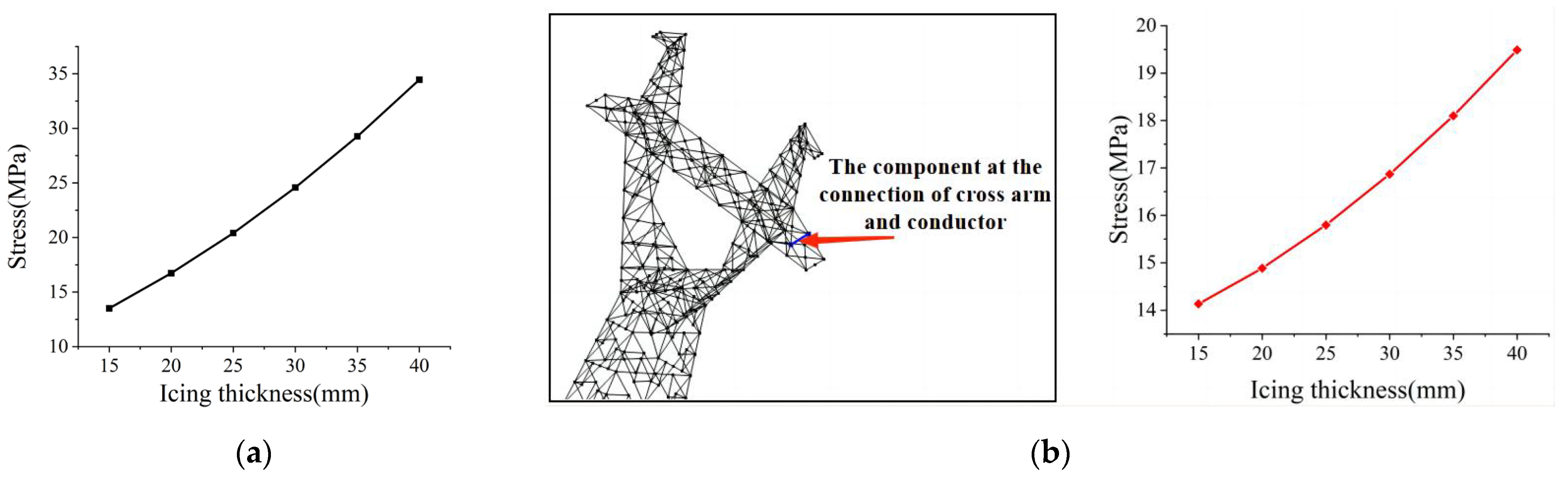

15] established the finite element model of a 500 kV cup-type linear tower under ice and wind loads; the weak components of the transmission tower are obtained by analyzing the maximum axial stress and nodal displacement of the tower. Li et al. [

16] established the simulation model of a 1000 kV ultra-high voltage (UHV) transmission tower-line system and found that the maximum nodal displacement of the tower increased with the increase in ice thickness and wind speed. By establishing the simulation model of the transmission tower, it is convenient to obtain the locations and mechanical characteristic parameters of weak components of the transmission tower. However, the modeling steps of the simulation model are cumbersome and time-consuming.

In recent years, the application of machine learning has become increasingly widespread. Yang et al. [

17] took the isolated-span overhead line as the research object, and the response characteristic parameters of the overhead line after ice-shedding based on a finite element simulation and machine learning were obtained. Wei et al. [

18] used the GA-BP-SVM to predict the galloping amplitude of the transmission line. Xiong et al. [

19] proposed the prediction method for the ice thickness of transmission lines based on BP and SVM algorithms. In predicting the mechanical parameters of transmission towers, Zhang et al. [

20] used a 500 kV transmission tower as the research object, and the law of strain variation in the weak components in the next 6 h was roughly predicted based on an autoregressive integrated moving average model (ARIMA). However, the influence of climate and geographical conditions on the mechanical characteristics of the tower was not considered. Hou et al. [

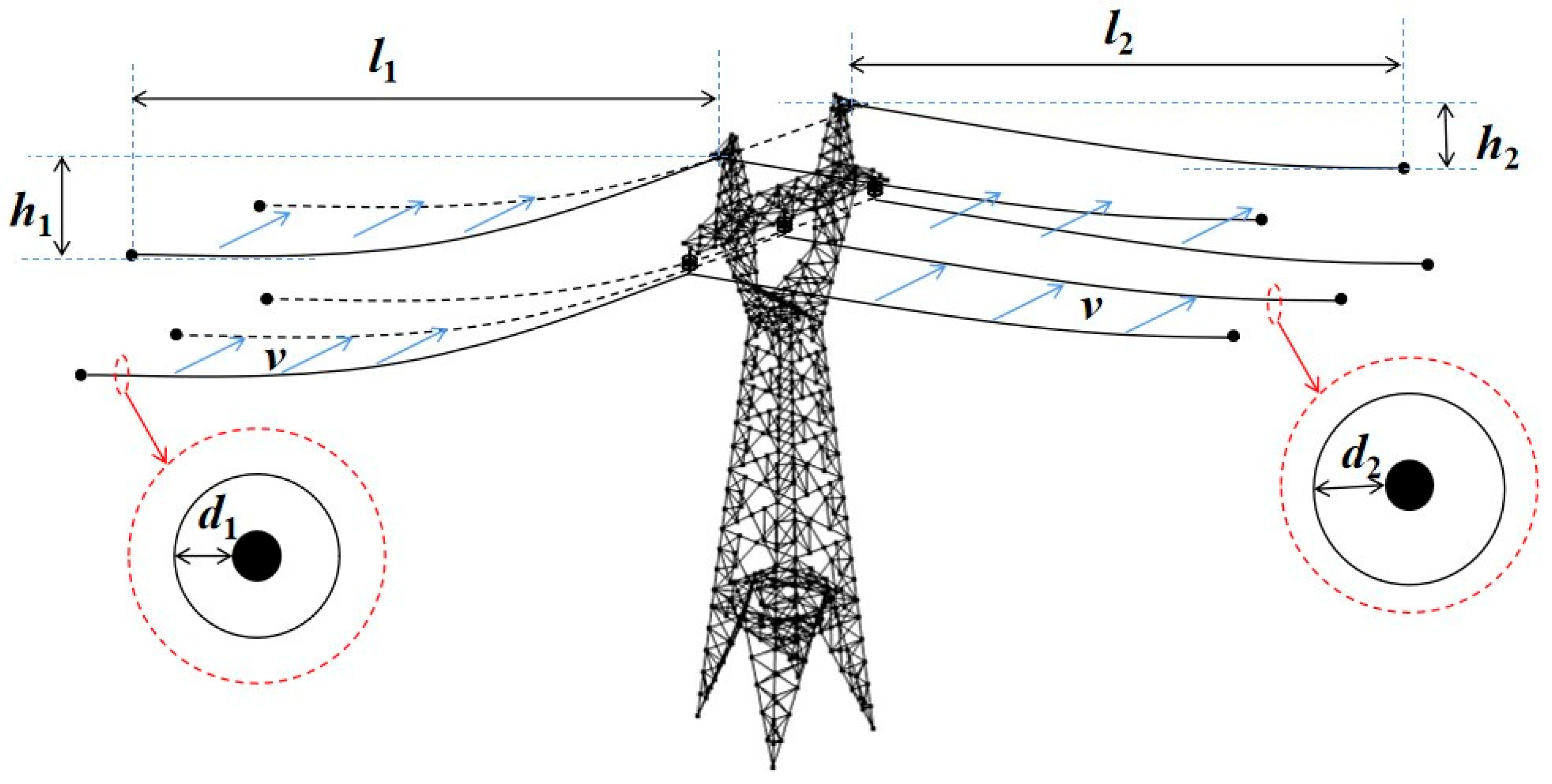

21] used a 10 kV tower of the distribution network as the research object, and the machine learning model was used to predict the tower damage probability by considering the wind speed. However, the icing conditions were not considered, which are important factors affecting the collapse of transmission network towers, as mentioned earlier. At present, the prediction of mechanical characteristic parameters of weak components of transmission towers under ice-covered conditions has not been reported, so it is necessary to carry out the prediction of mechanical characteristic parameters of weak components of transmission towers when transmission lines are covered with ice under different geographical conditions.

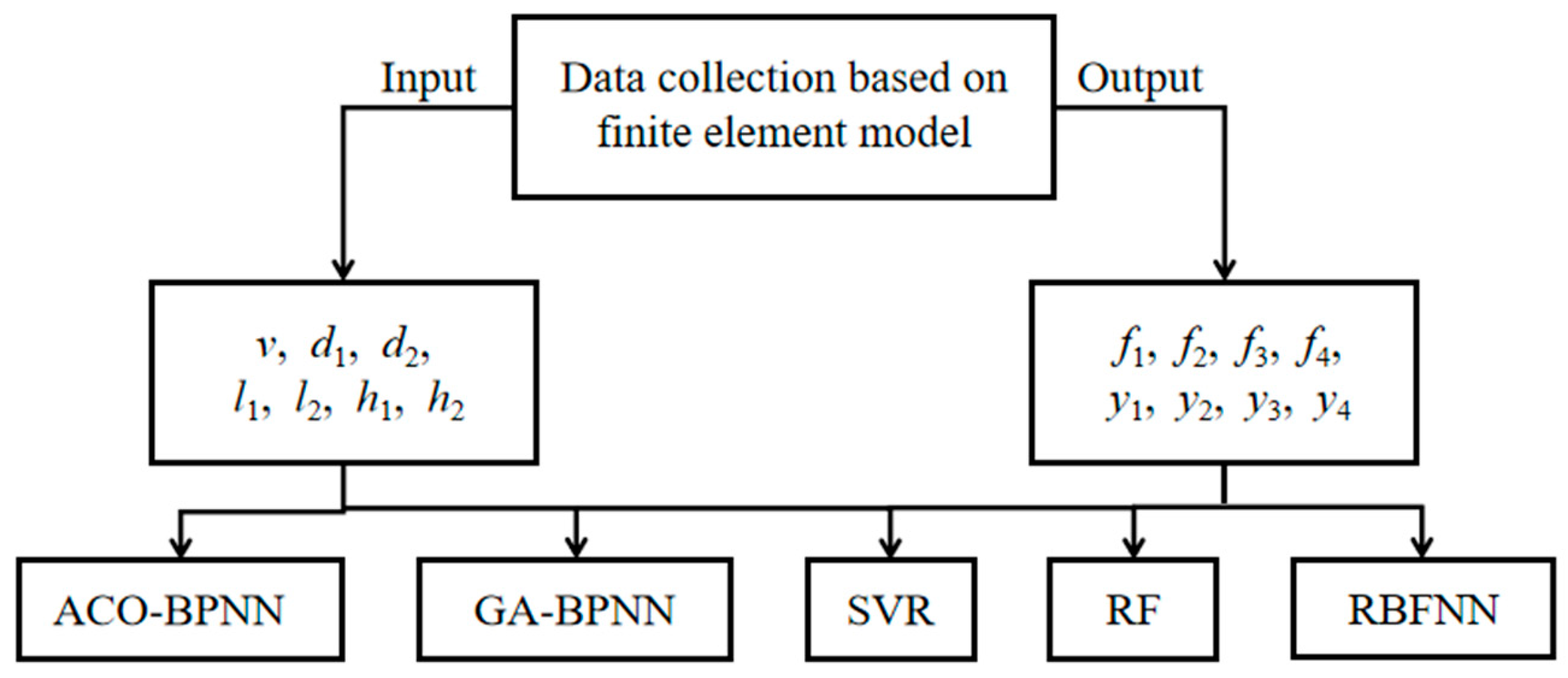

The weak components and mechanical parameters of the transmission tower can be easily obtained by establishing the finite element simulation model of the transmission tower. However, the establishment of the finite element model requires geometric modeling, a material definition, mesh generation, etc., which is cumbersome, time-consuming, and labor-intensive. The analysis and prediction of massive data can be quickly obtained by using a machine learning model. At present, there is a combination of fiber Bragg grating stress sensors and finite element simulations used in the online monitoring research of transmission tower foundation deformation [

22] and the combination of weather station data and machine learning used in the research of tower damage probability [

21]. By combining the advantages of finite element simulation and machine learning, this dual approach is considered to obtain massive data through the finite element simulation and identify data patterns by machine learning so as to quickly predict the mechanical characteristic parameters of the weak components of the transmission tower under ice and wind loads.

To sum up, the 110 kV transmission tower in a heavily iced area is taken as an example. The finite element simulation model is established, and its weak components are obtained. Seven parameters are selected as inputs, which include wind speed, the ice thickness of the long-span side conductor and ground wire, the ice thickness of the short-span side conductor and ground wire, the long-span distance, the short-span distance, and the height difference of the long-span side and short-span side. Eight parameters are selected as outputs, which include the axial stresses and nodal displacements of the four weak components. A total of 1500 sample datasets are constructed. Five types of typical regression prediction models are used to predict and analyze the mechanical characteristic parameters of weak components of transmission towers. The optimal prediction model is obtained. In this paper, the collapse case of a transmission tower is used to verify the accuracy of the prediction model. The research results can provide guidance for the operation and maintenance of transmission towers in heavily iced areas.

4. Regression Prediction Models

4.1. Data Normalization Processing

In order to unify the value ranges of different features into the same interval, eliminate the quantitative differences between different features, prevent feature weight bias, and accelerate the model convergence speed, each regression prediction model should be normalized for both the training and test sets [

54]. The formula is as follows:

where

x is the normalized value,

x0 is the original value,

xmin is the minimum value,

xmax is the maximum value.

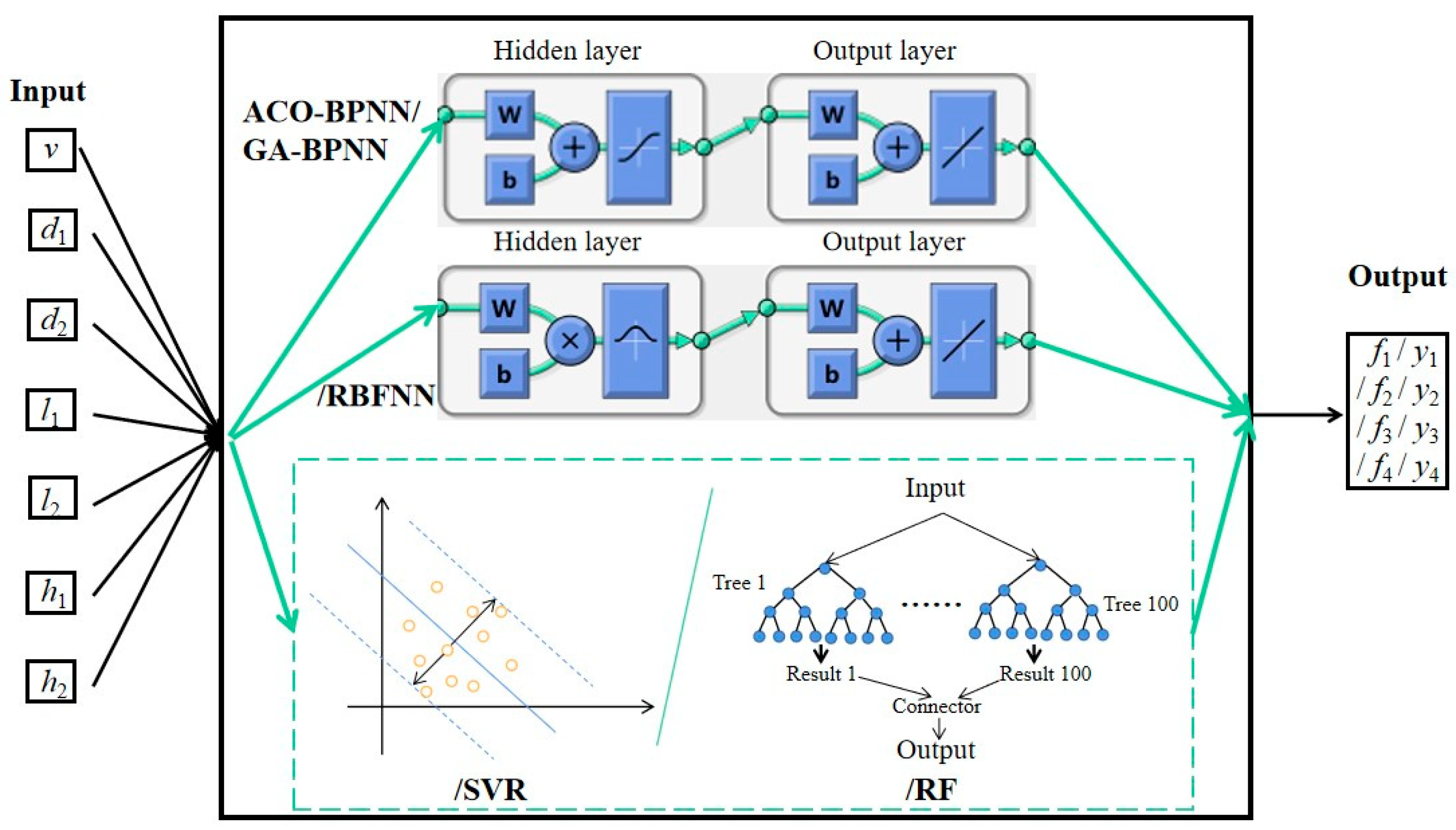

4.2. Regression Prediction Model Establishment

The first step in establishing the model is to set the parameters. According to the research results of Robert Hecht-Nielson [

55], it has been proven that the structure of a three-layer neural network (including one hidden layer) can approximate and fit any continuous function. Based on this conclusion, a BP neural network composed of a three-layer network structure is selected in this paper, including an input layer, a hidden layer, and an output layer. The number of neurons in the hidden layer is determined by the empirical Formula (6) [

56], and the number is set to 12 by manually debugging the algorithm.

where

u is the neurons number of input layer,

w is the neurons number of output layer,

a is a constant ranging from 0 to 10.

By adjusting the algorithm hyper-parameters to optimize the prediction results, the hyper-parameters of ACO-BPNN and GA-BPNN regression prediction models are shown in

Table 7, and the hyper-parameters of SVR, RF, and RBFNN regression prediction models are shown in

Table 8.

4.3. Regression Prediction Model Training

After the hyper-parameters of the five types of regression prediction models are set and the models are constructed, ACO-BPNN, GA-BPNN, SVR, RF, and RBFNN regression prediction models are trained by “train” function, “train” function, “svmtrain” function, “TreeBagger” function, and “newrbe” function, respectively.

The “etime” function is used to obtain the model training time, and the results are shown in

Table 9.

It can be found from

Table 9 that the ACO-BPNN model has the longest training time among the five regression prediction models, with a duration of 1742.8 s. In contrast, the SVR model has the shortest training time of 0.261 s.

Even the ACO-BPNN regression prediction model, which has the longest training time, only takes about half an hour to complete the training process. Compared to building finite simulation models and experimental models, machine learning models require much lower manpower and material costs. It takes more time to build the finite simulation model and set up the test platform, while the time for training the machine learning model is relatively less. Thus, machine learning models show great advantages.

4.4. Analysis of Prediction Results of Regression Prediction Models

After training the five types of regression prediction models, the “sim” function, “sim” function, “svmpredict” function, “predict” function, and “sim” function are used to predict the output of both training and test sets, respectively.

Similarly, the “etime” function is used to calculate the prediction time of different models, and the corresponding outcomes are presented in

Table 10.

To check for overfitting or underfitting, all models predict a total of 1500 sets of data in both the training and test sets. As shown in

Table 10, the GA-BPNN model takes the least time of 0.028 s, while the RF model takes the most time of 0.225 s. In contrast, the finite element simulation model established in this paper takes about 5 s to obtain a set of data results.

The computation time of the machine learning model is much less compared to that of the finite element simulation model, greatly increasing the efficiency of obtaining the mechanical characteristic parameters of the weak components of transmission towers.

- 2.

Prediction results analysis

The prediction effects of five machine learning models are analyzed below.

In this paper,

MSE,

MAE, and

R2 are used as model evaluation indexes for analysis [

17].

MSE is the mean of the sum of the squares of the differences between the predicted and actual values. The smaller the value, the closer the model predictions are to the actual values.

MAE is the mean of the absolute value of the difference between the predicted and actual values, and it is also used to measure the proximity of the predicted value to the actual value. The smaller the value, the more accurate the model’s prediction results are.

R2 reflects the extent to which the independent variable explains the dependent variable and takes values ranging from 0 to 1. The closer

R2 is to one, the better the model fits the observed data. The specific formulas for

R2,

MSE, and

MAE are as follows:

where

zi is the actual simulated value,

zi’ is the model predicted value,

n is the number of samples,

z is the average value of the actual simulated values.

The

R2,

MSE, and

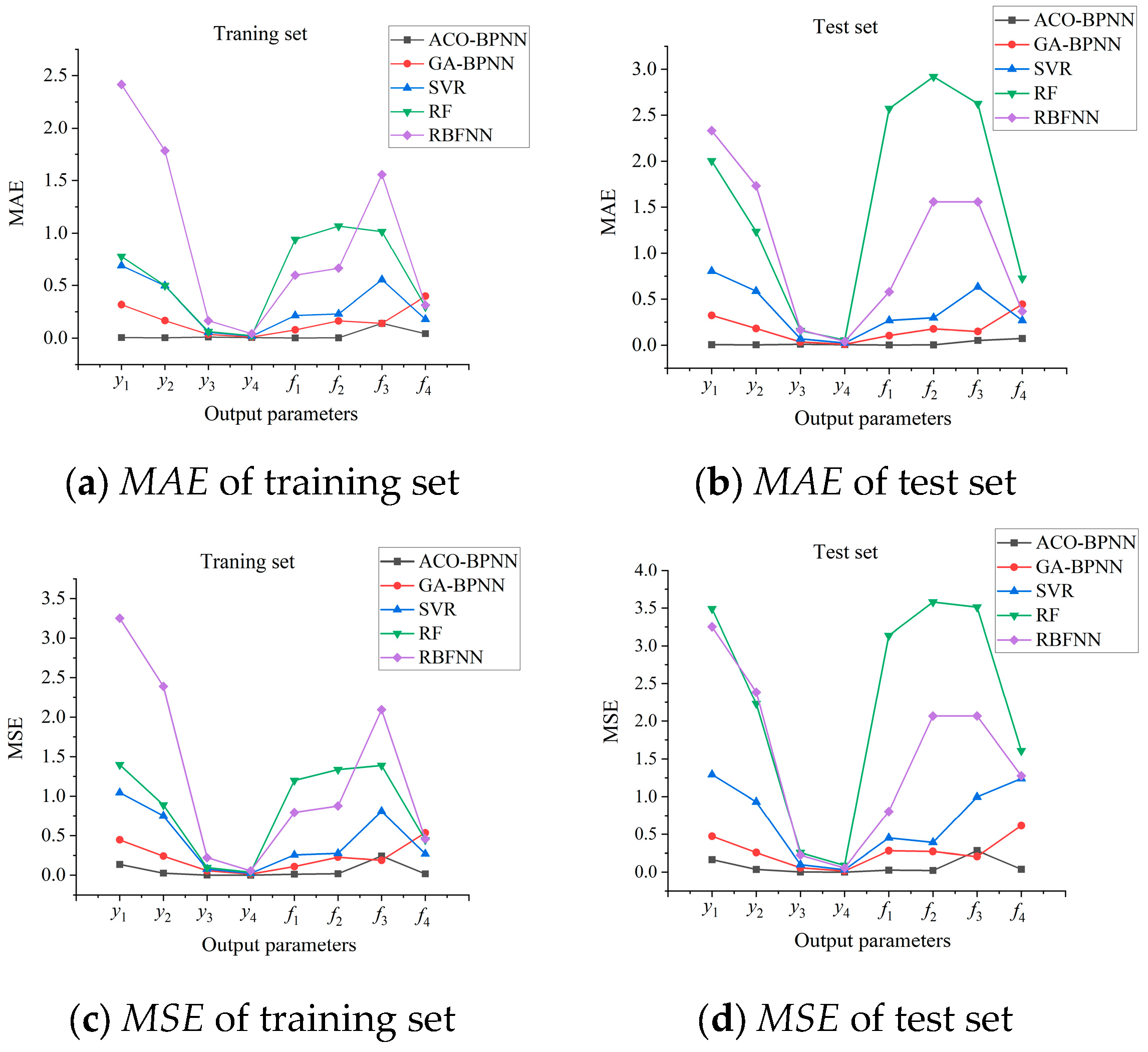

MAE results obtained from the five types of regression prediction models are shown in

Figure 13. It was found that

- (1)

For the prediction of nodal displacements of the four weak components, the MAE of the ACO-BPNN regression prediction model for the training set does not exceed 0.01 mm, 0.15 for MSE, and R2 is not less than 0.999. The MAE of the test set does not exceed 0.01 mm, 0.17 for MSE, and R2 is not less than 0.999.

- (2)

For the prediction of axial stress of the four weak components, the MAE of the ACO-BPNN regression prediction model for the training set of the model does not exceed 0.15 MPa, 0.25 for MSE, and R2 is not less than 0.999, and the MAE of the test set do not exceed 0.06 MPa for MAE, 0.3 for MSE, and R2 is not less than 0.999.

- (3)

The ACO-BPNN regression prediction model has the smallest

MSE and

MAE in both the training and test sets and the largest

R2 among these five regression models, which is approximately equal to one. Furthermore, as shown in

Figure 14, there are minimal differences between

MSE,

MAE, and

R2 for its training and test sets, indicating no under-fitting or over-fitting. Therefore, the ACO-BPNN model predicts the best results and accurately predicts the mechanical characteristic parameters of the weak components of transmission towers.

In summary, the ACO-BPNN regression prediction model is selected for this paper as the prediction model for the mechanical characteristic parameters of the weak components of the transmission tower.

Figure 13.

Evaluation indexes of regression prediction models in this paper.

Figure 13.

Evaluation indexes of regression prediction models in this paper.

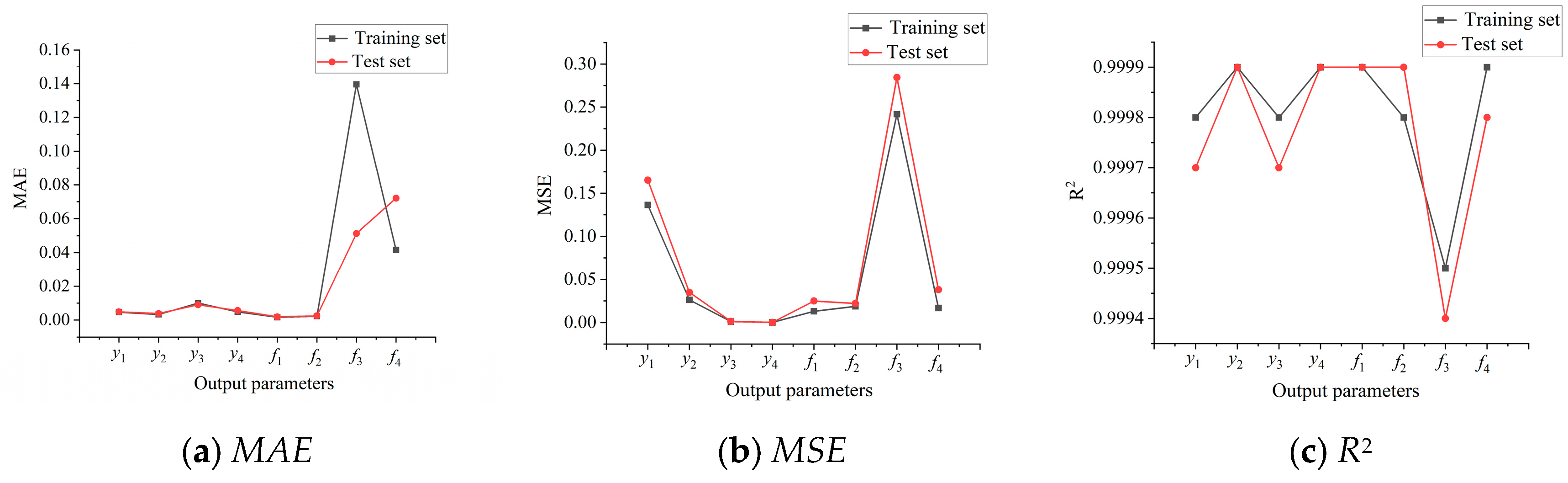

Figure 14.

Comparisons of Evaluation indexes of training set and test set from ACO-BPNN model.

Figure 14.

Comparisons of Evaluation indexes of training set and test set from ACO-BPNN model.

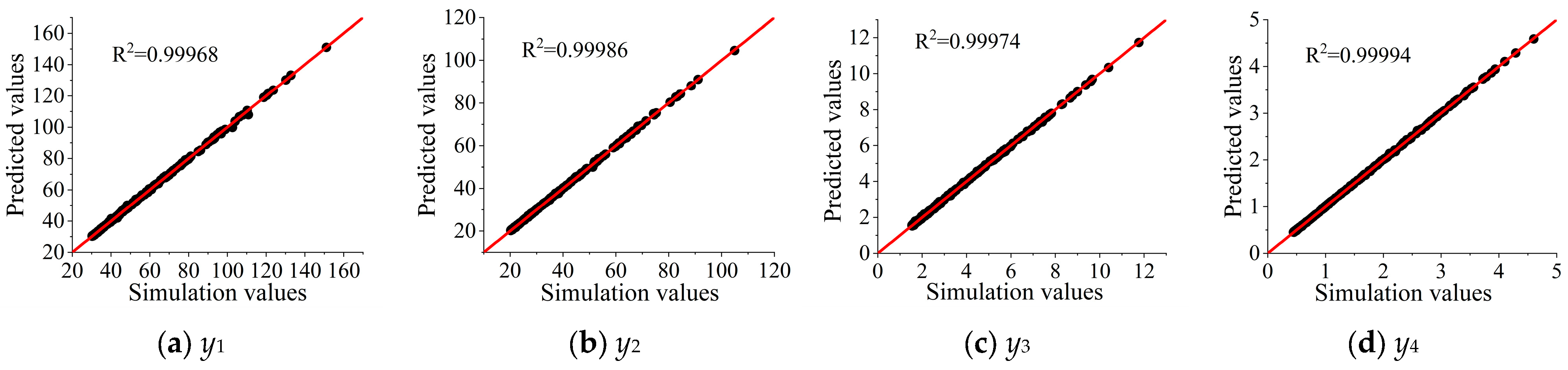

To further illustrate the prediction accuracy of the ACO-BPNN model, the comparison results between the simulation results and the prediction results are given in this paper, as shown in

Figure 15.

As can be seen from

Figure 15, the predicted values of the ACO-BPNN model for the axial stresses and nodal displacements of the four weak components are nearly the same as the simulation values of the finite element simulation model, and the

R2 for each input parameter is more than 0.999, indicating a high degree of fit and accuracy in prediction results. It further illustrates the accuracy and applicability of the prediction model for mechanical characteristic parameters of weak components of a 110 kV transmission tower, based on the simulation model and machine learning established by using the ACO-BPNN regression prediction algorithm.

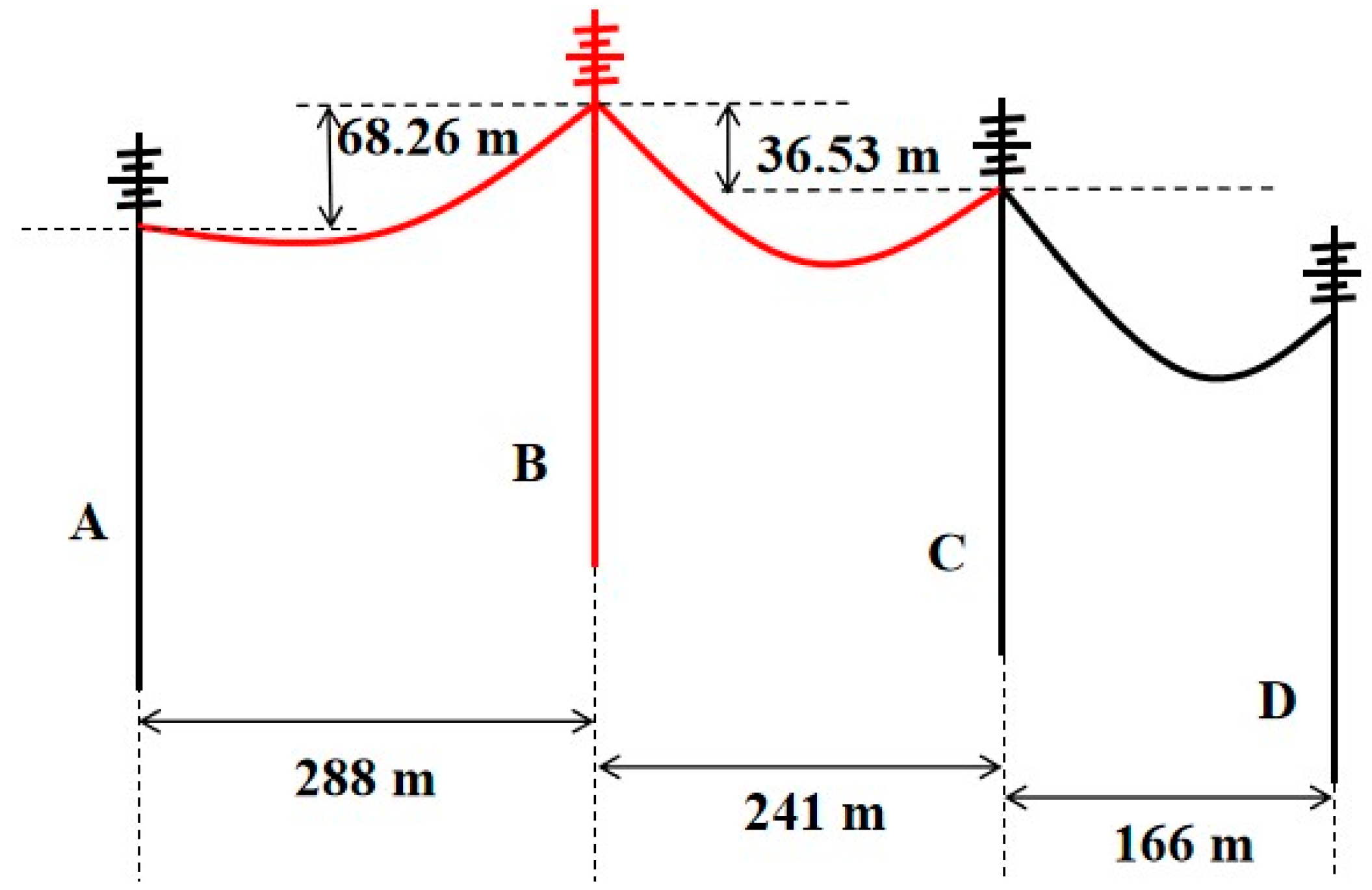

5. Case Analysis of Tower Collapse

The 110 kV transmission tower collapse case is taken as an example to illustrate the application effect of the prediction model proposed in this paper.

The transmission tower and conductors were seriously covered with ice due to extreme weather on 3 May 2017, which led to the tower collapse accident. The tower has a total height of 31 m, a designed wind speed of 27 m·s

−1, and a designed ice thickness of 20 mm. The span distances of the long-span side and short-span side are 411 m and 406 m, respectively. The ice thickness reached 37 mm, and the instantaneous wind speed reached 27 m·s

−1 when the accident occurred [

57].

In order to invert this transmission tower collapse case, the data of relevant parameters are used as a group of input data, and the predictions are carried out using the ACO-BPNN prediction model (the optimal prediction model). The simulated and predicted values of nodal displacement and axial stress of each weak component are obtained, as shown in

Table 11.

As shown in

Table 11, the absolute values of relative errors between the simulated and predicted values of nodal displacements and axial stresses of the weak components are no more than 0.6%, which indicates the prediction model proposed in this paper can accurately predict the mechanical parameters of weak components.

The tower height of the finite element simulation model in this paper is 35.6 m. According to the failure assessment criteria in

Section 2.6, when the nodal displacement of the weak component is greater than 106.8 mm, its operation status is considered Danger Status.

As can be seen from

Table 11, the maximum nodal displacement of the tower is located at the bracket of the ground wire, with the predicted value of 171.87 mm and the simulated value

y1 of 171.89 mm. In addition, the simulated value of the nodal displacement at the connection of the cross arm and conductor

y2 is 120.67 mm, and the predicted value is 120.69 mm. These values are all greater than 106.8 mm. Therefore, it can be clearly found that there is a dangerous risk for tower operation, which is consistent with the accident described in Ref. [

57].