Optimization of Tool Wear and Cutting Parameters in SCCO2-MQL Ultrasonic Vibration Milling of SiCp/Al Composites

Abstract

1. Introduction

2. Experimental Conditions and Procedures

2.1. Experimental Equipment and Tools

2.2. Experimental Plan

3. Experimental Results and Analysis

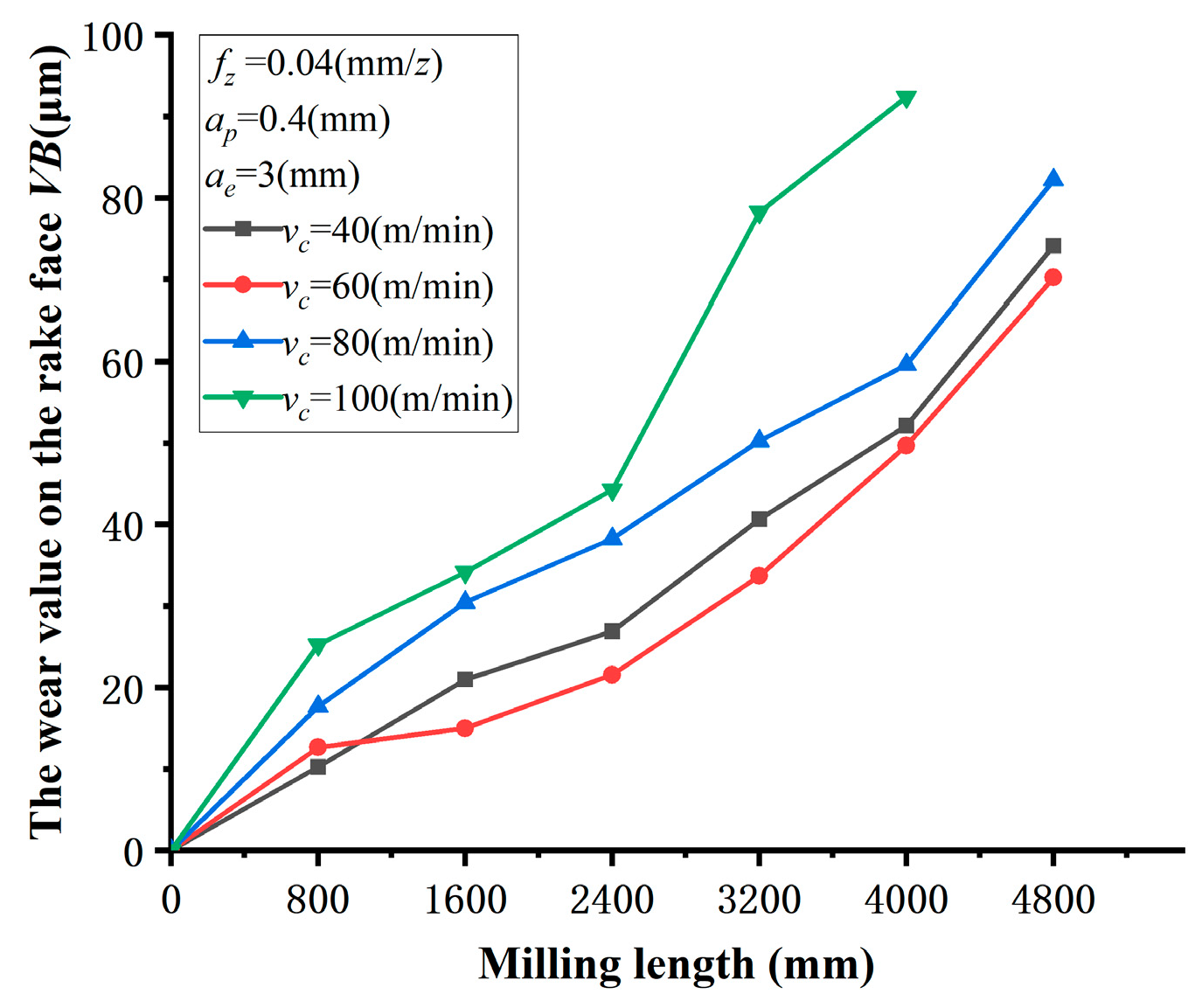

3.1. Impact of Cutting Velocity on Tool Wear

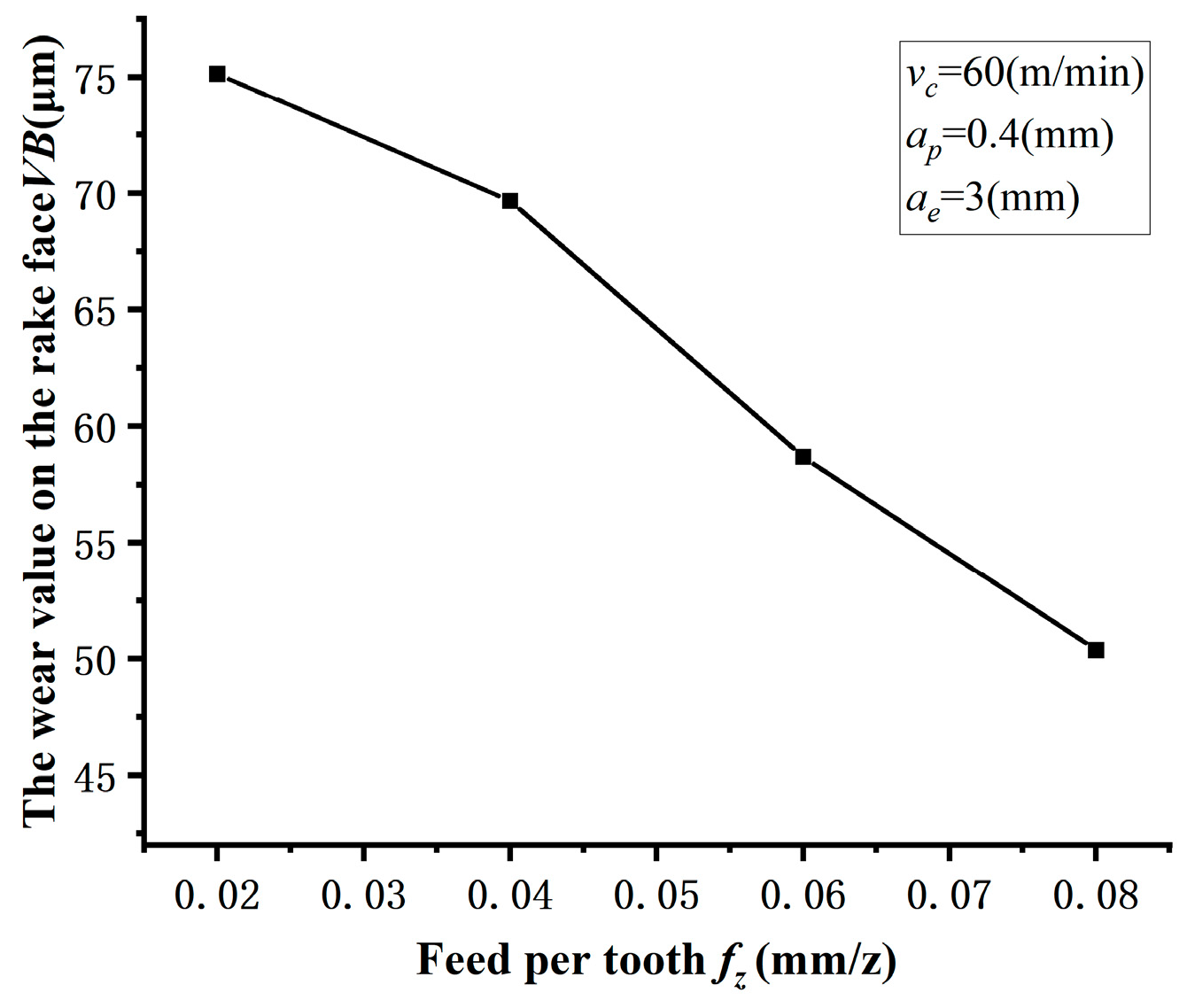

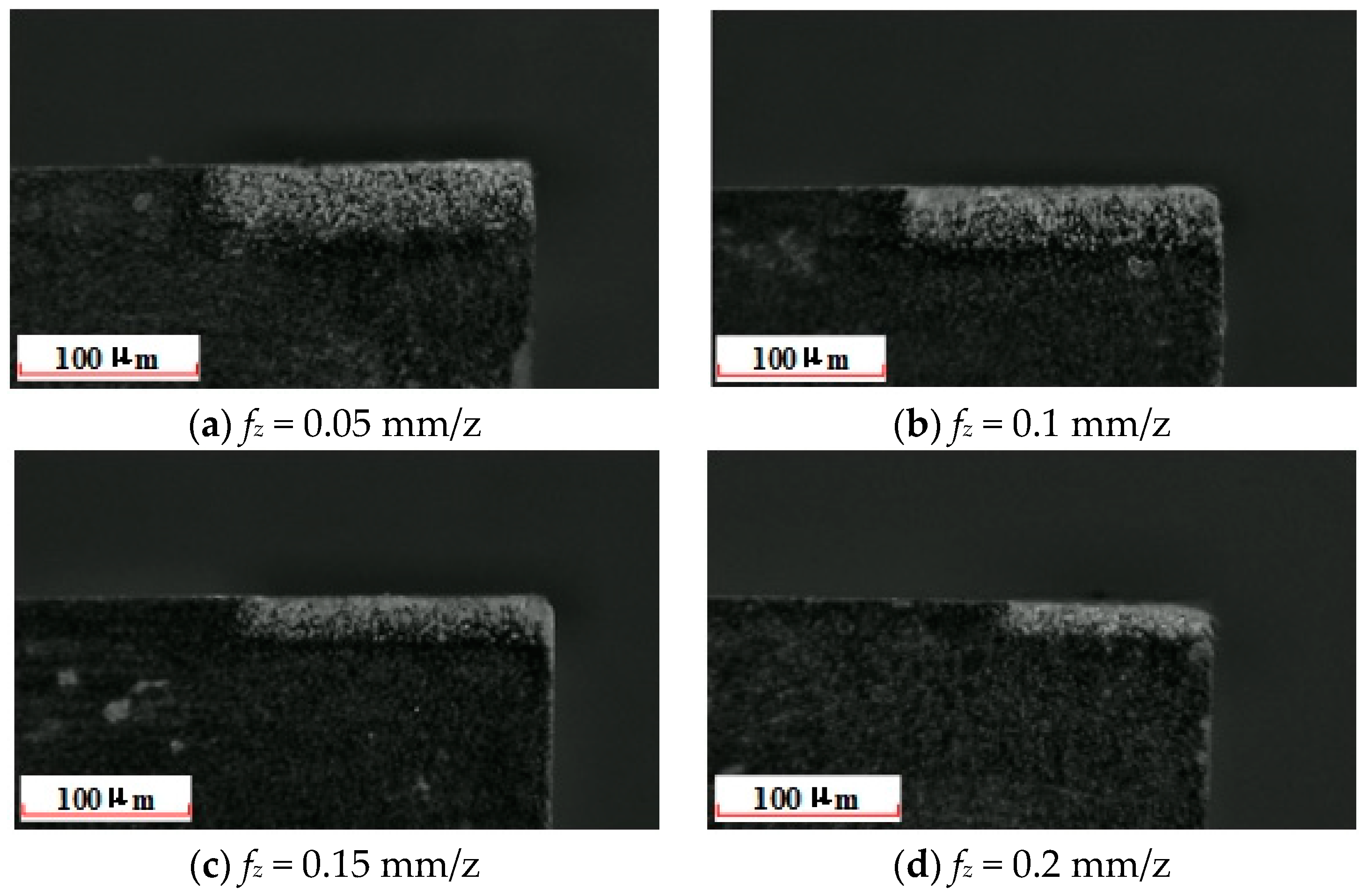

3.2. The Impact of Feed per Tooth on Tool Wear

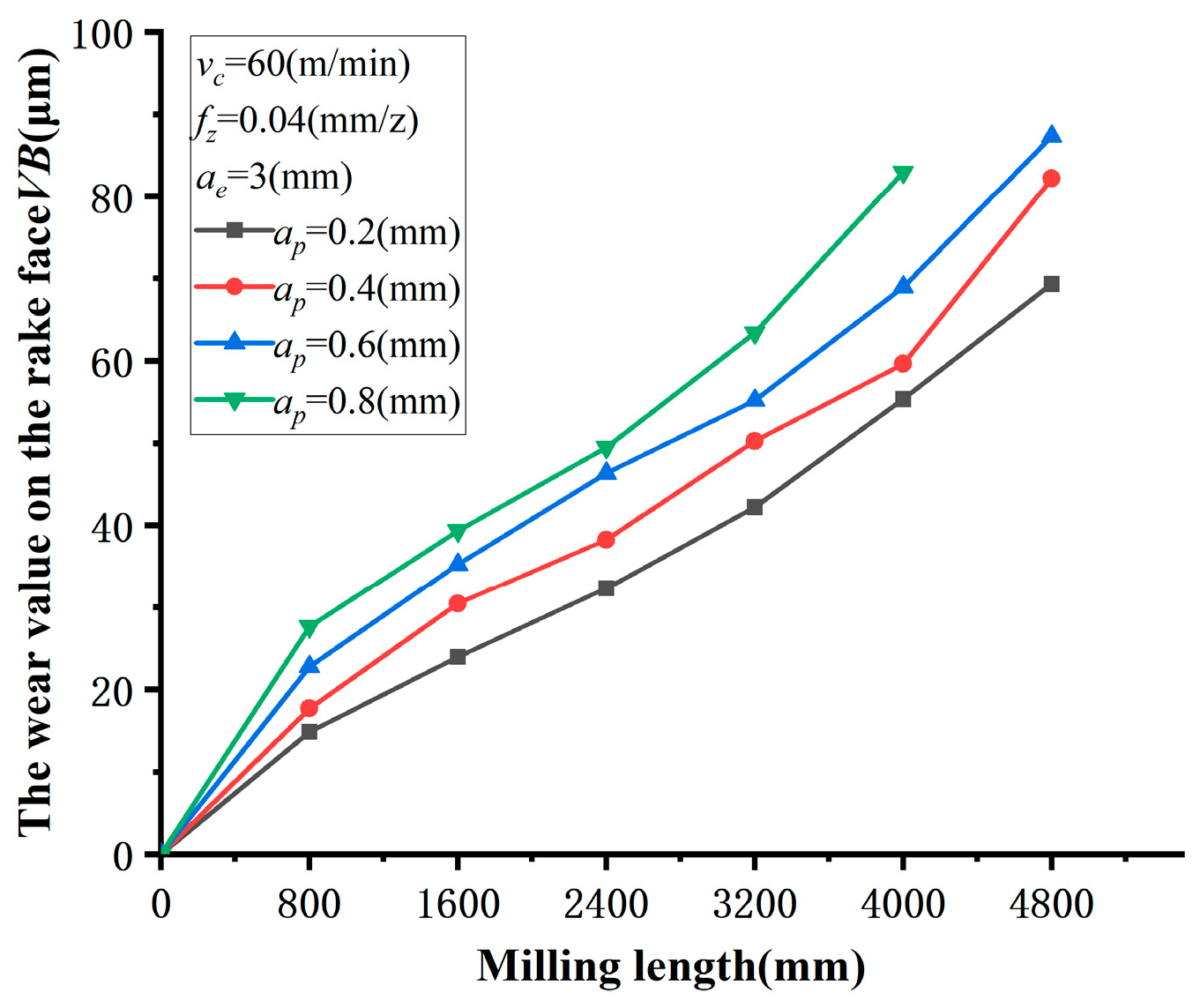

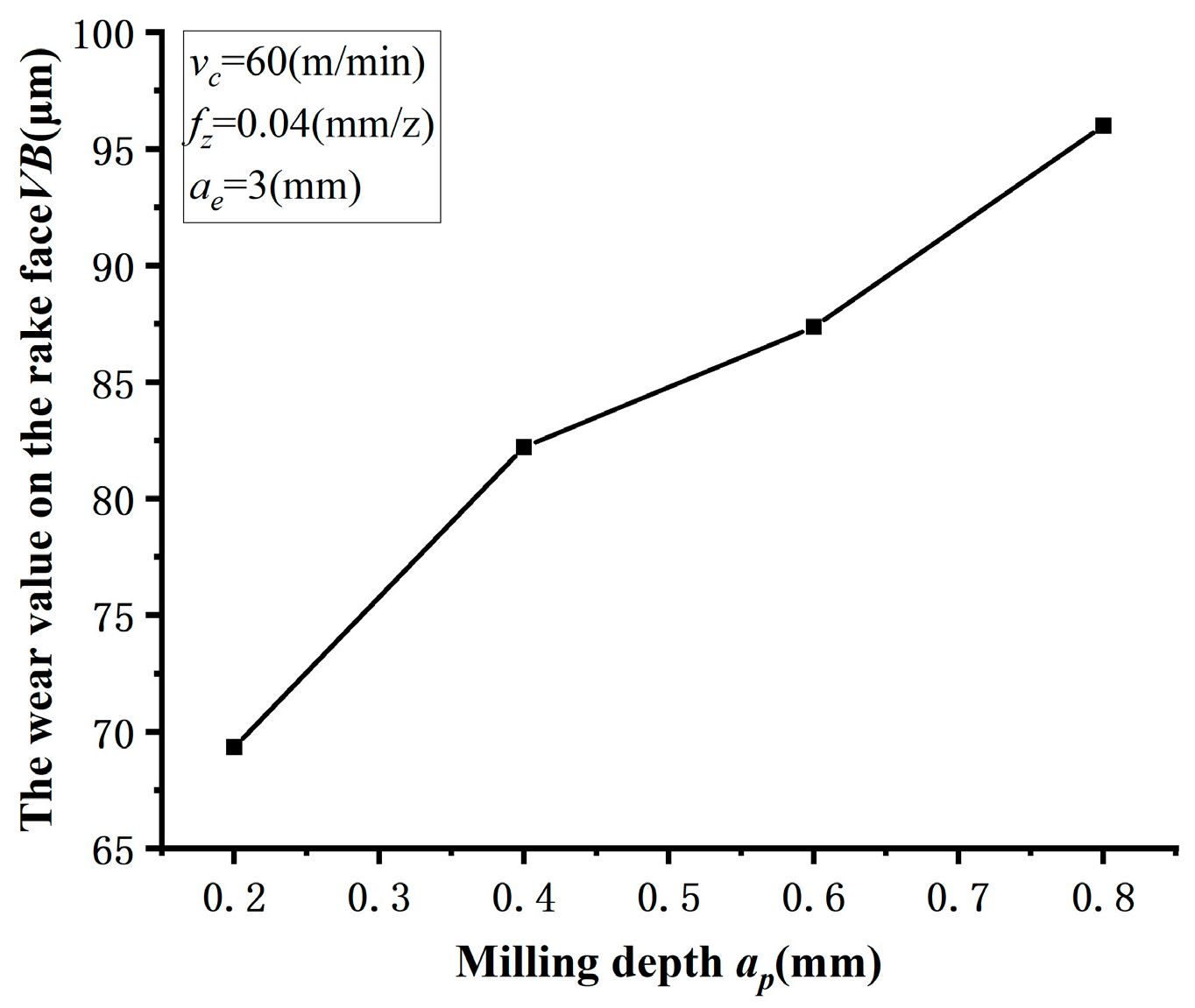

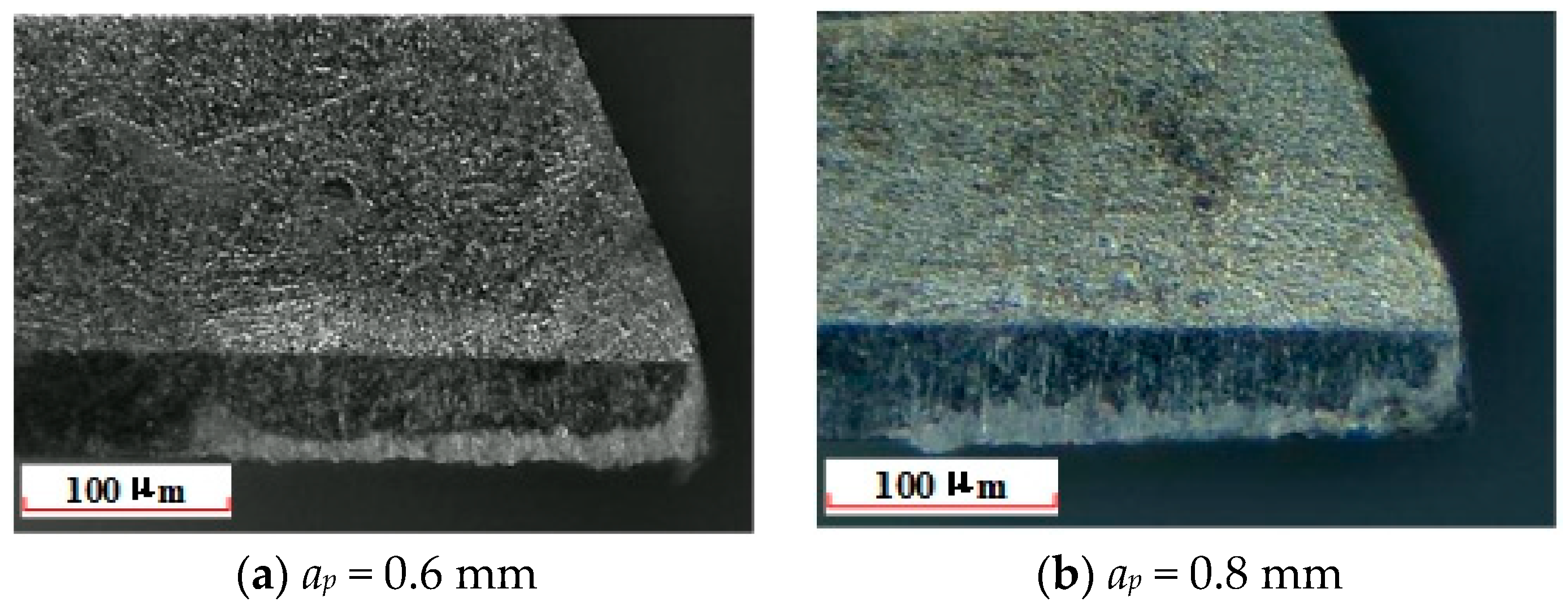

3.3. The Influence of Milling Depth on Tool Wear

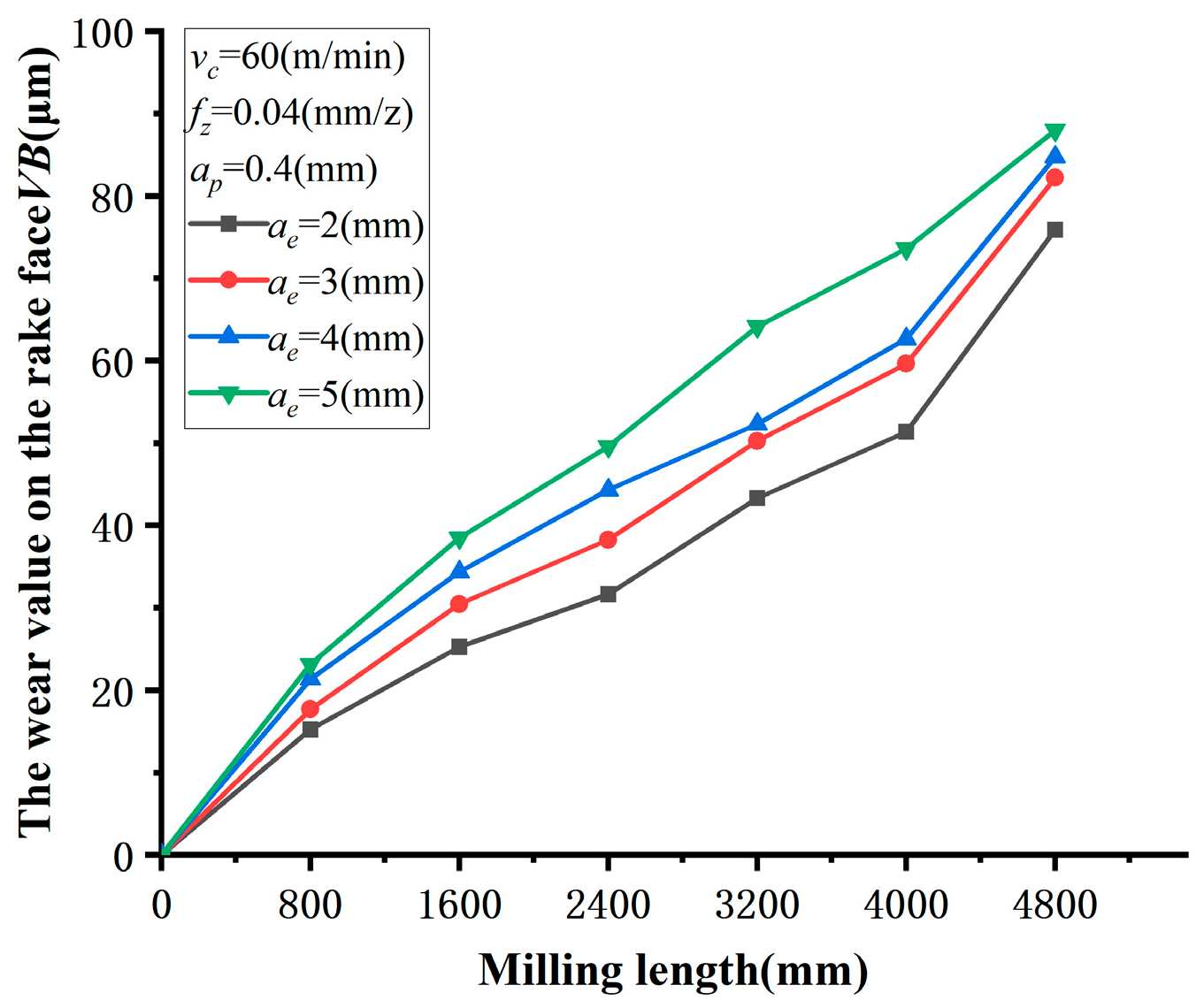

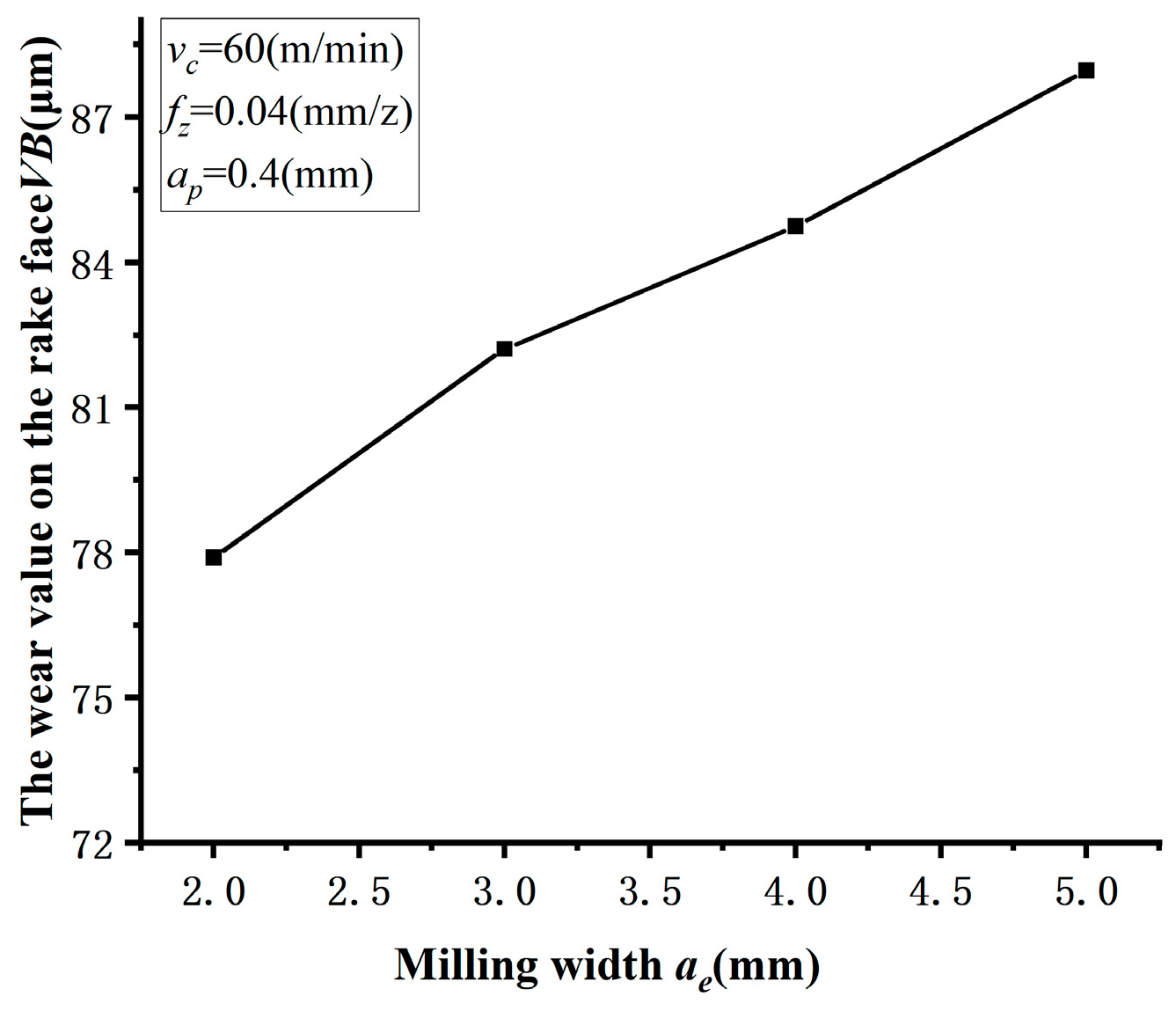

3.4. The Effect of Milling Width on Tool Wear

3.5. Analysis of Tool Wear Mechanism

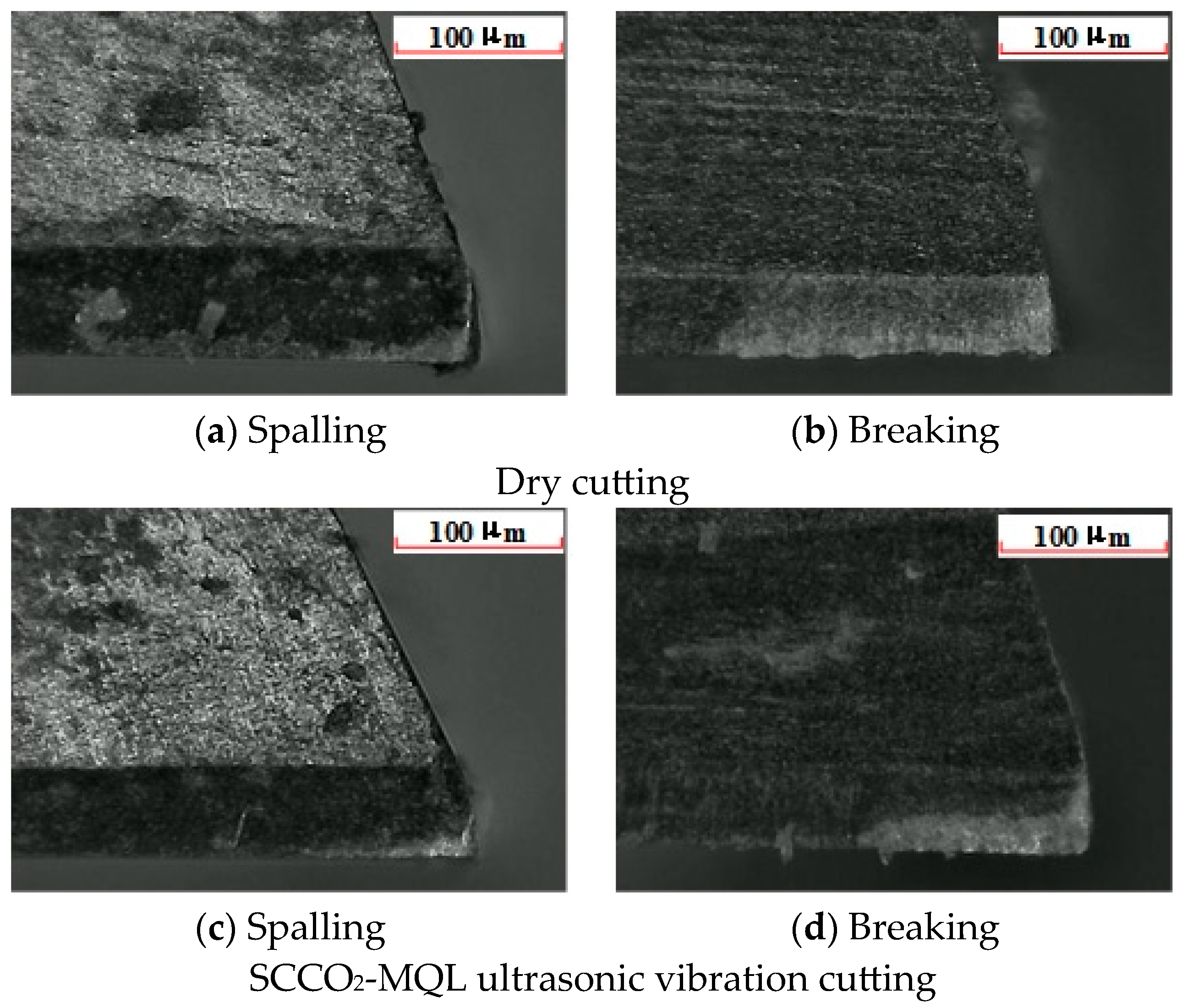

3.5.1. Grain Abrasion

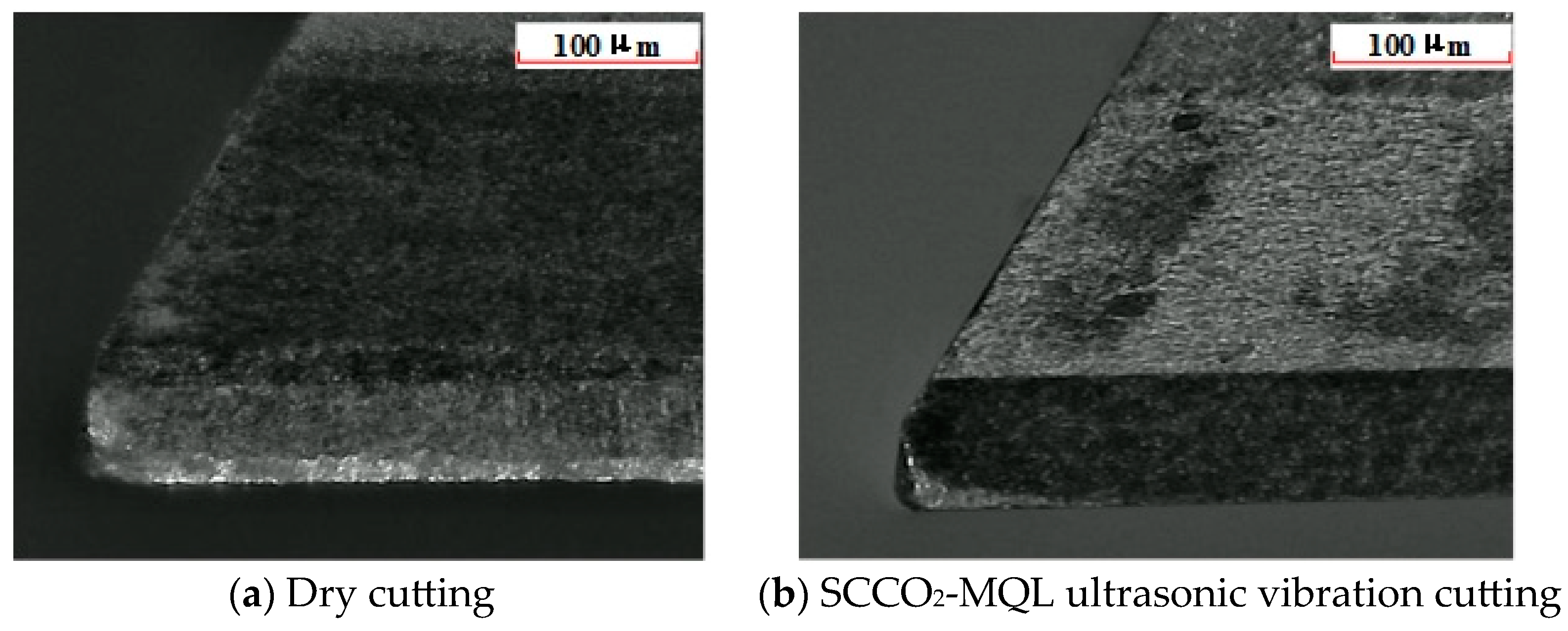

3.5.2. Adhesive Wear

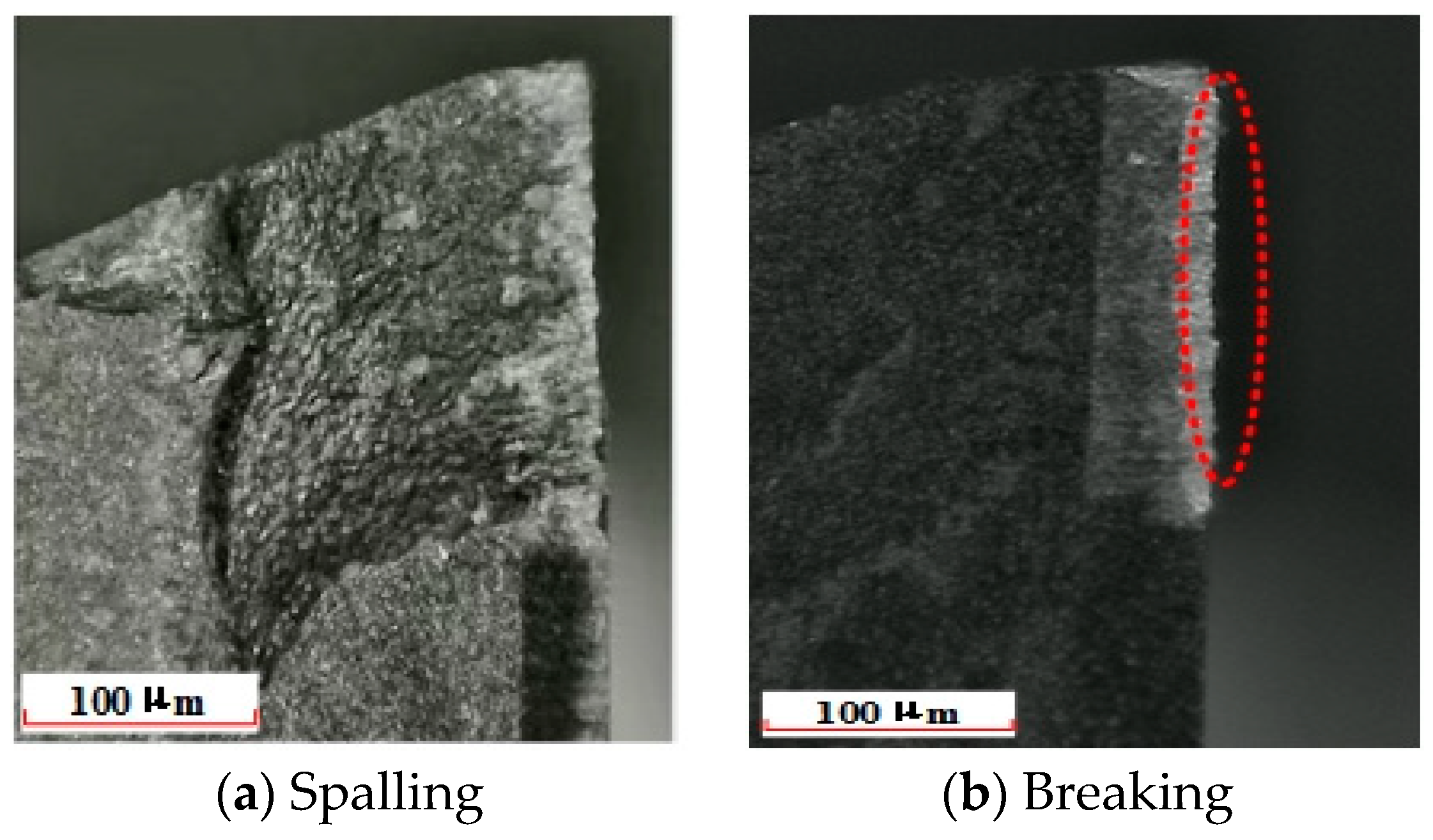

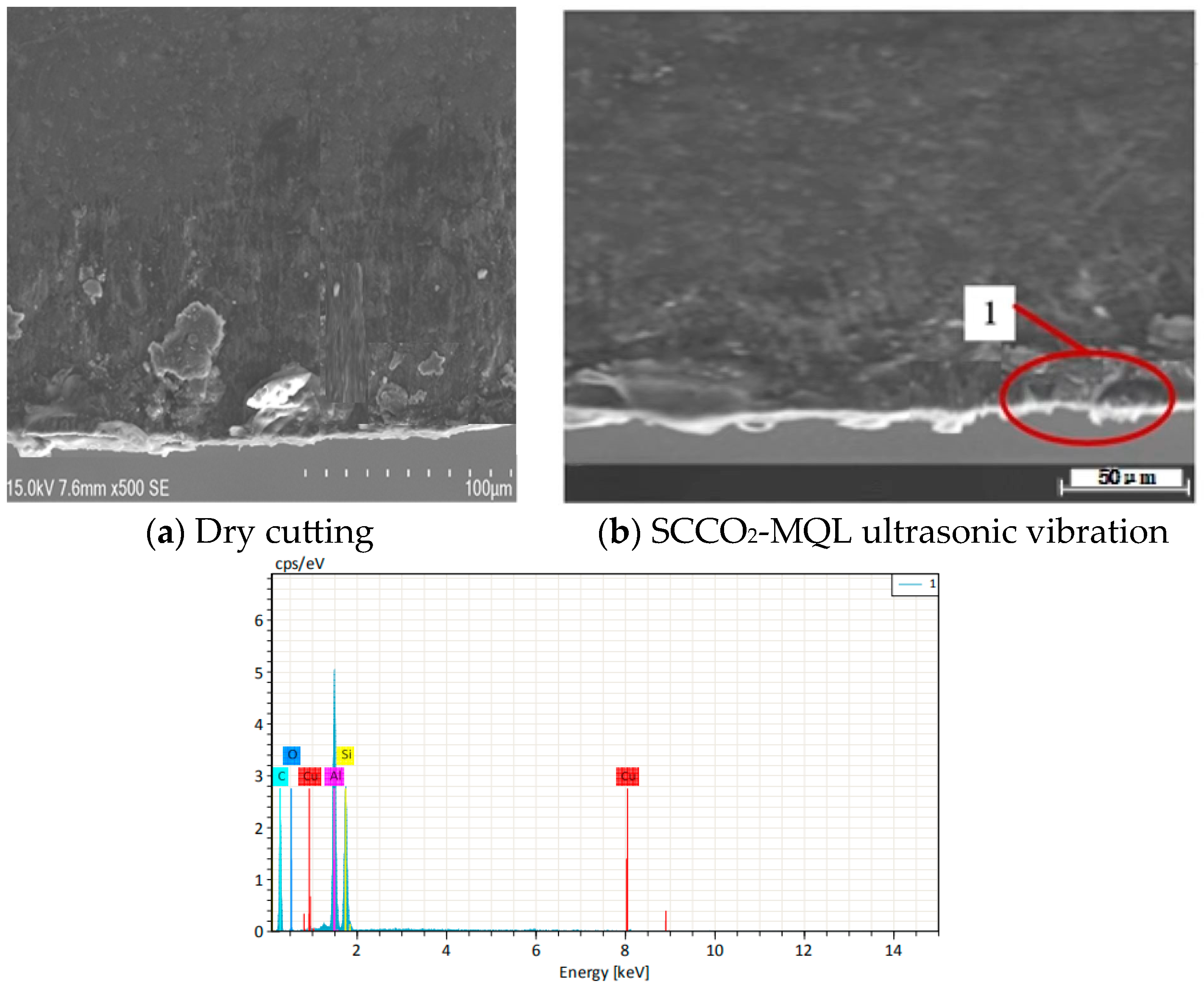

3.5.3. Breaking and Spalling

4. Prediction Model and Parameter Optimization of Tool Wear in SiCp/Al Composite

4.1. Orthogonal Experimental Design and Result Analysis

4.2. Development of Tool Wear Model

4.3. Establishment of Multi-Objective Optimization Function and Optimization of Milling Parameters

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yu, H.; Zhou, X.; Zhang, C. Research Progress of SiC Reflecting Mirror. New Technol. New Process 2006, 5, 26–30. [Google Scholar]

- Liu, J.W.; Cheng, K.; Ding, H. An Investigation of Surface Defect Formation in Micro Milling the 45% SiCp/Al Composite. Procedia CIRP 2016, 45, 211–214. [Google Scholar] [CrossRef]

- Li, M.; Wang, A.; Xie, J. The present research situation and progress of SiC particle-reinforced aluminum matrix composites. Powder Metall. Ind. 2015, 25, 55–60. [Google Scholar] [CrossRef]

- Weinert, K.; König, W. A Consideration of Tool Wear Mechanism When Machining Metal Matrix Composites (MMC). Ann. CIRP 2008, 42, 95–98. [Google Scholar] [CrossRef]

- Wolff, E.G. An Introduction to Metal Matrix Composites. Mater. Res. Bull. 1995, 30, 1585–1587. [Google Scholar] [CrossRef]

- Lv, D. Research on SiCp/Al Composite Machining Technology. Electro-Mech. Eng. 2011, 27, 29–32. [Google Scholar] [CrossRef]

- Zha, H.; Feng, P.; Zhang, J. Wear characteristics of cutting tools in ultrasonic vibration-assisted scratching high volume fraction SiC particle reinforced aluminum matrix composites. J. Jilin Univ. Chang. China 2019, 49, 458–465. [Google Scholar] [CrossRef]

- Ma, G.; Zhang, J.; Yan, F. Finite element analysis of cutting process and surface formation of SiCp/Al composites under conventional and ultrasonic vibration assisted conditions. Manuf. Technol. Mach. Tool. 2024, 4, 51–56. [Google Scholar] [CrossRef]

- Baraya, M.; Yan, J.; Hossam, M. Improving and Predicting the Surface Roughness and the Machining Accuracy in Ultrasonic Vibration-Assisted Milling. J. Vib. Eng. Technol. 2024, 3, 23–27. [Google Scholar] [CrossRef]

- Deswal, N.; Kant, R. Comparative Study of Surface Integrity for AZ31B Magnesium Alloy during the Application of Ultrasonic Vibration and Laser Energies in the Turning Process. J. Mater. Eng. Perform. 2023, 19, 37–41. [Google Scholar] [CrossRef]

- Wu, Y.; Guo, M.; Guo, W. Surface Damage Formation Mechanism of SiCp/Al Composites Based on 2D Cutting. Surf. Technol. 2024, 53, 145–155. [Google Scholar] [CrossRef]

- Kumar, H.; Wadhwa, S.A.; Akhai, S.; Kaushik, A. Parametric optimization of the machining performance of Al-SiCsubp/sub composite using combination of response surface methodology and desirability function. Eng. Res. Express 2024, 6, 025505. [Google Scholar] [CrossRef]

- Davim, J.P.; Baptista, A.M. Relationship between cutting force and PCD cutting tool wear in machining silicon carbide reinforced aluminium. J. Mater. Process. Technol. 2020, 103, 417–423. [Google Scholar] [CrossRef]

- Jiang, Z.; Zhang, W.; Wang, S. Simulation of cutting parameters on tool wear in cutting high-strength steel. Ordnance Mater. Sci. Eng. 2021, 44, 28–32. [Google Scholar] [CrossRef]

- Dhananchezian, M. A Tool Wear Analysis of an Inconel 600 Turned TiAlN Coated Carbide Insert at Various Cutting Speeds. Mater. Today Proc. 2023, 72, 2217–2220. [Google Scholar] [CrossRef]

- Laghari, R.A.; He, N.; Jamil, M.; Gupta, M.K. Tribological and machining characteristics of milling SiCp/Al MMC composites under sustainable cooling conditions. Int. J. Adv. Manuf. Technol. 2023, 128, 2613–2630. [Google Scholar] [CrossRef]

- Swain, P.K.; Mohapatra, K.D.; Swain, P.K. Investigations, Analysis and Performance Comparison of Uncoated CNMG 120408 TTR and Coated 12040822 Carbide Tools during Dry Turning of Al-SiCp Nano Composites. Mater. Today Proc. 2020, 26, 2. [Google Scholar] [CrossRef]

- Bushlya, V.; Lenrick, F.; Gutnichenko, O.; Petrusha, I.; Osipov, O.; Kristiansson, S.; Stahl, J.-E. Performance and Wear Mechanisms of Novel Superhard Diamond and Boron Nitride Based Tools in Machining Al-SiCp Metal Matrix Composite. Wear 2017, 376–377, 152–164. [Google Scholar] [CrossRef]

- Zajac, J.; Duplak, J.; Duplakova, D.; Cizmar, P.; Olexa, I.; Bittner, A. Prediction of Cutting Material Durability by T = f(vc) Dependence for Turning Processes. Processes 2020, 8, 789. [Google Scholar] [CrossRef]

- Zhang, X.; Pan, T.; Ma, A.; Zhao, W. High efficiency orientated milling parameter optimization with tool wear monitoring in roughing operation. Mech. Syst. Signal Process. 2022, 165, 108394. [Google Scholar] [CrossRef]

- Duplák, J.; Hatala, M.; Dupláková, D.; Botko, F. Prediction model of surface roughness parameters of structural steel created by plasma arc cutting via full factor experiment. Mater. Und Werkst. 2019, 50, 1207–1220. [Google Scholar] [CrossRef]

- Ding, P.; Huang, X.; Zhao, C.; Liu, H.; Zhang, X. Online monitoring model of micro-milling force incorporating tool wear prediction process. Expert. Syst. Appl. 2023, 223, 119886. [Google Scholar] [CrossRef]

- Dai, F.; Niu, Q.; Jing, L.; Wang, X.; Liu, L.; Xiao, Y. Multi-objective parameter optimization of longitudinal-torsional ultrasonic vibration assisted milling 60% SiC_p/Al. Aeronaut. Manuf. Technol. 2024, 67, 14–26. [Google Scholar] [CrossRef]

- Niu, Q.; Gao, H.; Zhang, S.; Xiang, D.; Jing, L.; Li, C. Experimental Study on Surface quality and Chip Morphology of SiCp/Al Composites by Ultrasonic vibration assisted milling. Tool. Technol. 2012, 56, 12–17. [Google Scholar]

- Niu, Q.; Tang, L.; Xiang, D. Study on tool wear of cemented carbide coated tool in milling of SiCp/Al composites. J. Henan Polytech. Univ. (Nat. Sci.) Jiaozuo China 2018, 37, 90–93+111. [Google Scholar] [CrossRef]

- Lin, J.; Jia, R.; Zhou, Y. PCD tool wear in cutting SiCp/6005Al composites. Diam. Abras. Eng. 2023, 43, 322–331. [Google Scholar] [CrossRef]

- Sun, W.; Shi, W.; Liu, Y. Study on Tool Wear of Aramid Fiber Reinforced Plastic Composites in Micromilling. Tool. Eng. 2021, 55, 35–40. [Google Scholar] [CrossRef]

- Liu, Z.; Ai, X. Wear Characteristics of Cutting Tools in High Speed Machining. Tribology 2002, 22, 468–471. [Google Scholar] [CrossRef]

- Liang, X.; Cai, C.; An, Q. Cooling and Lubrication Performance of SCCO2 Mixed Oil Film with Water Droplets in TC4 Milling. China Mech. Eng. 2020, 31, 328–335. [Google Scholar] [CrossRef]

- Gao, M.; Tao, C.; Shi, L. Data Analysis and Test of an Uniform Design Experiment Based SAS. J. Ordnance Eng. Coll. 2015, 27, 6–9. [Google Scholar] [CrossRef]

- Yi, Z.J. Mathematical Statistics and Its Engineering Application; Tsinghua University Press: Beijing, China, 2014. [Google Scholar]

| Types of Elements | Weight Percentage (%) | Atomic Percentage (%) |

|---|---|---|

| Carbon | 9.43 | 19.59 |

| Magnesium | 0.51 | 0.47 |

| Aluminum | 43.13 | 34.7 |

| Silicon | 45.13 | 44.34 |

| Copper | 1.80 | 0.9 |

| Number | vc (m/min) | fz (mm/z) | ap (mm) | ae (mm) |

|---|---|---|---|---|

| 1 | 40 | 0.04 | 0.4 | 3 |

| 2 | 60 | 0.04 | 0.4 | 3 |

| 3 | 80 | 0.04 | 0.4 | 3 |

| 4 | 100 | 0.04 | 0.4 | 3 |

| 5 | 60 | 0.02 | 0.4 | 3 |

| 6 | 60 | 0.04 | 0.4 | 3 |

| 7 | 60 | 0.06 | 0.4 | 3 |

| 8 | 60 | 0.08 | 0.4 | 3 |

| 9 | 60 | 0.04 | 0.2 | 3 |

| 10 | 60 | 0.04 | 0.4 | 3 |

| 11 | 60 | 0.04 | 0.6 | 3 |

| 12 | 60 | 0.04 | 0.8 | 3 |

| 13 | 60 | 0.04 | 0.4 | 2 |

| 14 | 60 | 0.04 | 0.4 | 3 |

| 15 | 60 | 0.04 | 0.4 | 4 |

| 16 | 60 | 0.04 | 0.4 | 5 |

| VB (μm) | 800 (mm) | 1600 (mm) | 2400 (mm) | 3200 (mm) | |

|---|---|---|---|---|---|

| Number | |||||

| 1 | 10.24 | 20.69 | 26.89 | 40.65 | |

| 2 | 12.64 | 15.01 | 21.56 | 33.69 | |

| 3 | 17.69 | 30.45 | 38.26 | 50.26 | |

| 4 | 25.23 | 34.16 | 44.25 | 78.23 | |

| 5 | 28.31 | 36.52 | 45.26 | 63.59 | |

| 6 | 30.14 | 35.34 | 43.98 | 56.65 | |

| 7 | 24.31 | 29.35 | 37.65 | 48.36 | |

| 8 | 16.95 | 24.36 | 30.24 | 39.42 | |

| 9 | 14.85 | 23.98 | 32.32 | 42.21 | |

| 10 | 17.69 | 30.45 | 38.26 | 50.26 | |

| 11 | 22.79 | 35.26 | 46.36 | 55.21 | |

| 12 | 27.65 | 39.36 | 49.52 | 63.39 | |

| 13 | 15.21 | 25.25 | 31.64 | 43.32 | |

| 14 | 17.69 | 30.45 | 38.26 | 50.26 | |

| 15 | 21.36 | 34.35 | 44.32 | 52.32 | |

| 16 | 23.14 | 38.49 | 49.58 | 64.16 | |

| Cutting Environment | C (%) | Cu (%) | Mg (%) | Si (%) | O (%) | Al (%) |

|---|---|---|---|---|---|---|

| Dry cutting | 8.35 | 0.02 | 00.68 | 18.36 | 5.96 | 26.67 |

| SCCO2-MQL ultrasonic vibration | 6.01 | 0.04 | 00.21 | 14.23 | 3.99 | 18.14 |

| Factors | vc (m/min) | fz (mm/z) | ap (mm) | ae (mm) | |

|---|---|---|---|---|---|

| Levels | |||||

| 1 | 40 | 0.02 | 0.2 | 2 | |

| 2 | 60 | 0.04 | 0.4 | 3 | |

| 3 | 80 | 0.06 | 0.6 | 4 | |

| 4 | 100 | 0.08 | 0.8 | 5 | |

| Number | vc (m/min) | fz (mm/z) | ap (mm) | ae (mm) | VB (μm) |

|---|---|---|---|---|---|

| 1 | 40 | 0.02 | 0.2 | 2 | 12.69 |

| 2 | 40 | 0.04 | 0.4 | 3 | 10.01 |

| 3 | 40 | 0.06 | 0.6 | 4 | 12.47 |

| 4 | 40 | 0.08 | 0.8 | 5 | 14.01 |

| 5 | 60 | 0.02 | 0.4 | 4 | 11.69 |

| 6 | 60 | 0.04 | 0.2 | 5 | 7.99 |

| 7 | 60 | 0.06 | 0.8 | 2 | 7.21 |

| 8 | 60 | 0.08 | 0.6 | 3 | 6.42 |

| 9 | 80 | 0.02 | 0.6 | 5 | 19.63 |

| 10 | 80 | 0.04 | 0.8 | 4 | 19.01 |

| 11 | 80 | 0.06 | 0.2 | 3 | 13.01 |

| 12 | 80 | 0.08 | 0.4 | 2 | 10.68 |

| 13 | 100 | 0.02 | 0.8 | 3 | 23.16 |

| 14 | 100 | 0.04 | 0.6 | 2 | 20.01 |

| 15 | 100 | 0.06 | 0.4 | 5 | 17.52 |

| 16 | 100 | 0.08 | 0.2 | 4 | 11.69 |

| Parameters | vc (m/min) | fz (mm/z) | ap (mm) | ae (mm) | |

|---|---|---|---|---|---|

| Mean Value | |||||

| 12.295 | 16.7925 | 11.345 | 12.6475 | ||

| 8.3275 | 14.255 | 12.475 | 13.15 | ||

| 15.5825 | 12.5525 | 14.6325 | 13.715 | ||

| 18.095 | 10.7 | 15.8475 | 14.7875 | ||

| R | 9.7675 | 6.0925 | 4.5025 | 2.14 | |

| vc > fz > ap > ae | |||||

| Independent Variables | β1 | β2 | β3 | β4 | Significance of Regression Coefficients |

|---|---|---|---|---|---|

| |vc| | |fz| | |ap| | |ae| | ||

| VB | 3.512 | 2.846 | 2.232 | 0.995 | β1 > β2 > β3 > 2.2010 > β4 |

| Number | vc (m/min) | fz (mm/z) | ap (mm) | ae (mm) | VB | Relative Error (%) | |

|---|---|---|---|---|---|---|---|

| Predicted Value | Actual Value | ||||||

| 1 | 40 | 0.02 | 0.5 | 2 | 11.70 | 10.95 | 6.80 |

| 2 | 40 | 0.05 | 0.8 | 5 | 11.56 | 11.81 | 2.11 |

| 3 | 70 | 0.08 | 0.8 | 4 | 12.57 | 12.65 | 0.63 |

| 4 | 70 | 0.05 | 0.2 | 2 | 11.74 | 11.51 | 1.99 |

| 5 | 100 | 0.02 | 0.5 | 2 | 18.34 | 19.78 | 7.28 |

| 6 | 100 | 0.08 | 0.2 | 4 | 11.57 | 11.90 | 2.77 |

| Average Relative Error of Prediction Model | 3.60 | ||||||

| Number | Milling Length (mm) | VB (μm) | Ra (μm) |

|---|---|---|---|

| 1 | 800 | 19.87 | 0.112 |

| 2 | 1600 | 28.51 | 0.105 |

| 3 | 2400 | 37.28 | 0.097 |

| 4 | 3200 | 45.69 | 0.092 |

| 5 | 4800 | 52.46 | 0.085 |

| Number | Milling Length (mm) | VB (μm) | Ra (μm) |

|---|---|---|---|

| 1 | 800 | 21.65 | 0.158 |

| 2 | 1600 | 42.92 | 0.152 |

| 3 | 2400 | 56.15 | 0.145 |

| 4 | 3200 | 61.32 | 0.138 |

| 5 | 4800 | 70.21 | 0.130 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, H.; Wang, B.; Qu, L.; Wang, X. Optimization of Tool Wear and Cutting Parameters in SCCO2-MQL Ultrasonic Vibration Milling of SiCp/Al Composites. Machines 2024, 12, 646. https://doi.org/10.3390/machines12090646

Zhang H, Wang B, Qu L, Wang X. Optimization of Tool Wear and Cutting Parameters in SCCO2-MQL Ultrasonic Vibration Milling of SiCp/Al Composites. Machines. 2024; 12(9):646. https://doi.org/10.3390/machines12090646

Chicago/Turabian StyleZhang, Huiping, Bowen Wang, Liqiang Qu, and Xinran Wang. 2024. "Optimization of Tool Wear and Cutting Parameters in SCCO2-MQL Ultrasonic Vibration Milling of SiCp/Al Composites" Machines 12, no. 9: 646. https://doi.org/10.3390/machines12090646

APA StyleZhang, H., Wang, B., Qu, L., & Wang, X. (2024). Optimization of Tool Wear and Cutting Parameters in SCCO2-MQL Ultrasonic Vibration Milling of SiCp/Al Composites. Machines, 12(9), 646. https://doi.org/10.3390/machines12090646