Abstract

Collaboration between humans and machines is the core of the Industry 5.0 paradigm, and collaborative robotics is one the most impactful enabling technologies for small and medium Enterprises (SMEs). In fact, small batch production and high levels of product customization make parts assembly one of the most challenging operations to be automated, and it often still depends on the versatility of human labor. Collaborative robots, for their part, can be easily integrated in this productive paradigm, as they have been specifically developed for coexistence with human beings. This work investigates the performance of collaborative robots in machine parts assembly. Design and research activities were carried out as a case study of industrial relevance at the i-Labs industry laboratory, a pole of innovation that is briefly introduced at the beginning of the paper. A fully-functional prototype of the cobotized station was realized at the end of the project, and several experimental tests were performed to validate the robustness of the assembly process as well as the collaborative nature of the application.

1. Introduction

Robots have been effectively integrated into various industries, including the automotive and pharmaceutical sectors. Their recent proliferation is quickly extending to other fields and workplaces, such as hospitals [1,2,3], construction sites [4,5], public spaces, and offices. Among the surge in robotization in various workplaces, one of the fastest-growing sectors is industrial robots [6]. In particular, collaborative robots, called cobots, have recently made their appearance.

Cobots are a new category of robots designed for direct physical interaction with a human operator, including the ability to manipulate objects in collaboration with a human operator [7,8].

Cobots in manufacturing applications offer flexible layout changes and potential benefits; however, understanding their correct use and characteristics is essential for industry uptake [9,10]. Collaborative human–robot manufacturing cells can reduce human workload, reduce the risk of strain injuries, and are compatible with safety standards [11]. In assembly processes, cobots can lead to more sustainable, high-quality, and efficient manufacturing processes, thereby improving operator working conditions and overall company performance [12]. The integration of robot precision and strength with human dexterity and problem-solving ability has the potential to enhance both the quality of production and the working conditions of employees [13]. Furthermore, cobots can be utilised as an additional hand in the assembly process, offering enhanced precision, the ability to lift heavier components, and a boost in productivity while reducing the risk of injury to workers [14]. In comparison to traditional industrial robots, collaborative robots offer enhanced safety, flexibility, and cost-effectiveness in assembly processes [15].

The integration of collaborative robots in assembly lines has the potential to significantly enhance productivity, particularly when the distribution of workload between workers and robots is optimised [16]. Furthermore, multi-robot multi-operator collaborative assembly systems have the capacity to enhance throughput and flexibility [17]. The need for flexibility is paramount in the modern industry, where a User-Centered Design (UCD) paradigm is even more crucial [18,19]. This paradigm requires custom and/or flexible manufacturing. Several works aiming to satisfy this requirement can be found in the literature [20].

With this in mind, the aim of the present paper is to investigate a collaborative and flexible assembly station designed to handle the tolerated assembly of multiple machine components by using a single gripper and sharing the workspace with human personnel. Here, the presence of the operator is necessary to perform the final testing of the assembled components, which is essential to ensure proper mounting in the associated machine. In other words, while the cobot handles all the heavy and repetitive tasks, the operator adds value to the process by providing experience and insight.

Collaborative robots have been used in previous works for assembly applications. In [21], the authors programmed a dual-arm cobot to assemble the electrical components of a PCB board by using a Time Petri Net to schedule the automated activities, whereas the human–robot interactions were handled by means of a depth camera exploited to acquire the positions of the operator’s hands over time. A similar solution was developed in [22], where a depth sensor capable of recognising body gestures via a skeleton tracker application was integrated into the station to prevent contacts between the operator and the industrial robots. Collaborative machine parts assembly was also investigated in [23], where the authors used a cobot equipped with a custom gripper to attach the bolts of a car wheel. Finally, collaborative robot admittance control was exploited in [11] to obtain the collaborative assembly of homokinetic (Rzeppa) joints. Compared to the aforementioned works, the main novelties of the current paper are:

- Using a collaborative robot to handle tolerated assembly of multiple machine parts without the need for a tool changing system.

- Developing a flexible and reconfigurable station which can be modified or expanded to process different parts.

- Establishing a method to validate safety measures by identifying a proper set of devices.

This work builds upon a previous study in which the first part of this station was developed [24].

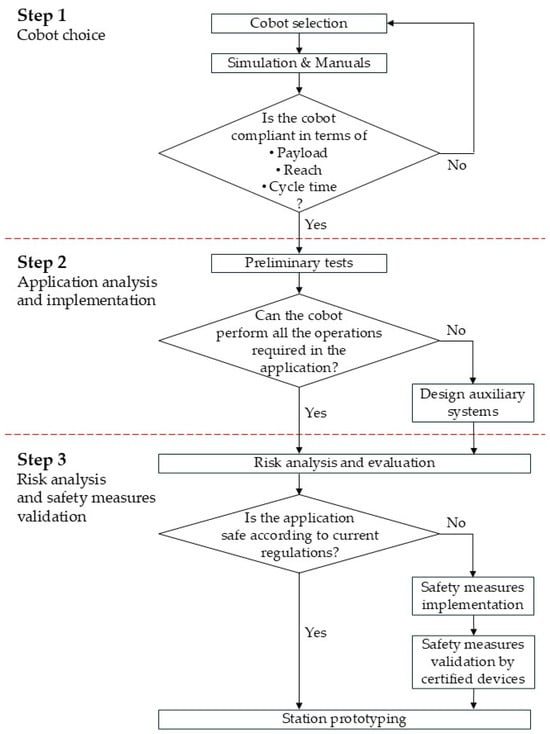

Furthermore, another the purpose of this paper is to present a general methodology that can be used to investigate the possibility of integrating a collaborative robot into industrial processes. The three steps of the proposed method are illustrated in the flowchart shown in Figure 1, and are briefly explained below:

Figure 1.

Flux diagram of the three-step methodology presented in this work.

- Cobot choice: The first step of the procedure is verification of the payload, the reachability of all areas of interest, and the cycle times. This analysis can be conducted by consulting the user manuals and through simulations, providing the most suitable cobot manufacturer and model for the application under study as an output.

- Application analysis and implementation: This intermediate step aims to verify that the collaborative robot can efficiently perform all of the operations required in the application. If the result of this investigation is negative, the integration of auxiliary support systems for the cobot must be considered.

- Risk analysis and safety measures validation: Finally, in the last step, the risks arising from the application, in particular from the auxiliary systems, are analyzed and evaluated. If the presence of the operator in the shared workspace of the robot is one of the project requirements, then appropriate strategies must be adopted in order to mitigate any risks highlighted by the analysis in accordance with current regulations. The chosen safety measures must then be experimentally validated with appropriate and certified tools.

The assembly station presented in this work was designed according to the aforementioned procedure, as detailed in the following sections of the paper. However, as stated before, the workflow and its tools can be generally applied to cobot integration analysis regardless of the application under study. The methods we use in this paper, along with the hardware and software tools, represent a workbench that can be exploited to overcome the challenges associated with using collaborative robots in industrial processes.

The rest of this article is structured as follows. Section 2 defines the scenario under study, including the components to be assembled and the preliminary tests conducted to evaluate the integration of collaborative robots. Subsequently, Section 3 details the actual robotic station, with a focus on the main devices and technological solutions adopted in this study. Section 4 discusses the operation of the station, presenting the collaborative tests conducted to ensure the safety and effectiveness of human–robot interactions. Finally, Section 5 reports the main innovations and results achieved through this study, highlighting its contributions to the field of industrial automation and human–robot collaboration.

2. Scenarios and Preliminary Tests

The customer who commissioned the study is a medium-sized company operating in the local manufacturing industry, specialising in high precision engineering, assembly and production of assembled parts; its innovation needs arise from the adoption of the Industry 4.0 and subsequent Industry 5.0 paradigms. The company intends to innovate its production department, which represents the heart of its business. The company’s need for innovation stems from two main factors: the thrust of the new production paradigms, and a shortage of personnel. In particularly, these production paradigms require:

- Flexibility and customisation, enabling customised mass production to better respond to customer needs.

- Automation and efficiency, as advanced automation reduces human errors while increasing productivity and operational efficiency.

- Competitiveness, as the adoption of advanced technologies enables companies to remain competitive in the ever-changing global marketplace.

- Sustainability, as more advanced technologies can contribute to more sustainable practices and reduce environmental impact.

- Resilience, ensuring business continuity via increased ability to adapt and respond to changes and crises.

At the same time, the company faces increasing difficulties in finding and training personnel for its production and assembly areas. For this reason, it wishes to innovate by automating and robotizing those production and assembly processes that are repetitive, uncomfortable, and provide low added value for the human operator. The renewal process undertaken by the company has a multi-year scope. This work is part of that innovation process, as a continuation of some studies already carried out for the company focused on the automation of their assembly area. In fact, the assemblies described below have already been dealt with in preliminary studies to assess their feasibility.

2.1. Overview of Components and Manual Assembly Processes

This paper investigates automating the assembly of two different machine components. The production volume of these two components is medium to low and the demand is discontinuous, characterized by occasional orders of thousands of parts during the year, making automation of the assembly process optimal. Currently, the assembly process of the two components is performed entirely by human operators.

In the following, the machine components which are the object of this study are referred as component 1 and component 2, whereas the term ‘part’ is generally used to indicate their respective subcomponents such as bearings, Seeger rings, and metal cases.

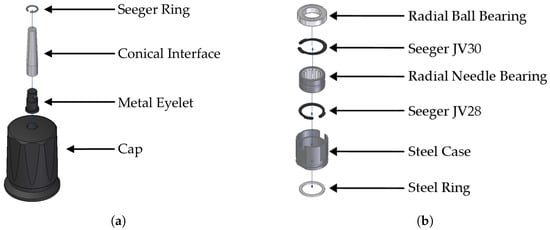

The machine component referred as ‘component 1’ is shown in Figure 2a; it is part of the stock of a rifle, to which a leather strap is attached for transport. Component 1 consists of three parts: a circlip (also known as a Seeger ring) for locking, a metal eyelet into which the leather strap is inserted and on which the seat for the Seeger ring is cut, and a metal cap which is fixed to the rifle and into which the metal eyelet is inserted. The assembly of component 1 involves the use of a conical interface to guide the Seeger ring into its seat on the eyelet. The conical interface is reused for each assembly cycle, and is designed to facilitate the elastic deformation of the ring; the push applied on the Seeger ring when it slides along the conical interface causes the ring to expand and conform to the size of the seat. Upon reaching the seat on the eyelet, the ring attempts to return to its original size, thereby securing the cap to the eyelet through a tightening action. The actual manual assembly process includes the following operations:

Figure 2.

Subfigure (a) shows an exploded view of component 1 with its four labeled parts: the Seeger ring, metal eyelet, cap, and conical interface used for manual assembly, which is displayed in the mounting position. Subfigure (b) displays an exploded view of component 2 with its multiple labeled parts: radial ball bearing, Seeger ring JV30, radial needle bearing, Seeger ring JV28, steel case, and steel ring.

- Pick up and position the eyelet.

- Pick up and position the cap.

- Pick up and position the conical interface.

- Pick up and position the ring on the conical interface.

- Insert the ring into its seat by sliding it along the conical interface by means of a manual press operated by the human operator.

- Remove the conical interface from the workpiece and reposition it in its starting position.

The assembly process of component 1 consists of a sequence of gripping, positioning, and insertion operations. These are all repetitive monotonous actions with low added value for the human operator. According to information provided by the customer, the average time taken by the operator to finish assembling a component is 15 s. This statistic is subject to large oscillations due to several factors that influence the work of the human operator, including:

- Physical and mental fatigue, which can reduce the efficiency and speed of the operator, especially in repetitive and monotonous operations such as those of the component 1 assembly cycle.

- Unplanned interruptions and distractions in the workplace.

Fluctuating production times and the low added value of the performed operations are among the reasons for the customer wanting to conduct this study of production automation.

The second component, referred to in the following as ‘component 2’ and shown in Figure 2b, is a support element for a bandsaw shaft. The assembly consists of seven parts: a steel case, into which the various slots for the rolling and stopping elements are cut; a single-row radial ball bearing; a radial needle roller bearing; two external Seeger rings of different sizes, referred to by their designations (JV28 and JV30); and a steel ring manufactured by the customer. Several of the listed elements must be inserted with interference fit coupling; therefore, a manual press is used by the operator to push the components into the correct position. The assembly process currently performed by the operator consists of the following steps:

- Mounting of Seeger ring JV28 inside the steel case; the Seeger ring is inserted into its seat by means of a ring gripper.

- Insertion of the needle bearing into the housing until it touches Seeger ring JV28; as the case–needle bearing coupling requires interference fitting, the manual press is used to push it into position.

- Again using the manual press, Seeger ring JV30 and the ball bearing are inserted in a single operation.

- Insertion of the steel ring; this element is pushed into the case using the press until its flat surface aligns with the lower edge of the case.

- Installation of the rubber gasket, for which a seat on the gasket is provided for the steel ring previously inserted into the case.

In the final assembly, the two bearings are left free to slide axially. Seeger ring JV28 provides a reference for the position of the radial needle bearing, while Seeger ring JV30 is used as a spacer to prevent contact between the case and the radial ball bearing. After assembly, component 2 is tested by means of a pass/fail test to check whether the process has been carried out correctly. The test involves pushing component 2 against a shaft of tolerated diameter with a determined force equal to 10 N. If the shaft slides freely inside the case, then the assembly is considered correct; however, if the case jams during sliding some components may be misaligned, indicating an incorrect assembly. Similar to component 1, both the assembly process and the verification process of component 2 can be described as a sequence of picking, placing, and inserting components. The cycle time indicated by the customer for completion of the assembly and its verification is 2 min. The same considerations and problems highlighted for the assembly cycle of component 1 apply to component 2 as well; therefore, the customer identified the possibility of innovating the process for both components.

2.2. Preliminary Tests

Following to the flowchart in Figure 1, the development of the station was preceded by a number of preliminary tests. First, functional simulations were carried out in RoboDK to verify that the robot could move quickly enough to perform the two processes within the limits set by the assigned cycle times. In these analyses, the insertion times of the various parts were simulated by including delays in the respective phases. The collaborative robot UR 10e by Universal Robots was chosen as a result of the simulations.

Second, experimental tests were carried out in order to identify the most effective strategies for performing several of the assembly cycle tasks. For component 1, the handling and pushing phases for inserting the Seeger ring into the eyelet housing were analysed. In these tests, two specific plastic fingers were produced by 3D printing (Figure 3). Here, the gripper fingers have two gripping surfaces: a tooth to grasp the Seeger ring, and a groove that reproduces the negative of the conical interface in Figure 2a to push the ring into place.

Figure 3.

Preliminary tests for component 1: Gripping fingers for insertion of the Seeger ring in the conical interface.

In the gripping tests, the Seeger ring was gripped by the tooth on the fingers from among a stack of components and placed on the conical interface. The tests showed that this task could be successfully handled by means of the gripper and collaborative robot solution. However, gripping by means of the gripper was not very repeatable due to the small size of the Seeger ring and inaccuracies in the positioning of the robot. For this reason, an auxiliary system that reduces errors in gripping by the robot was developed in the robot cycle. This system is explained in detail in Section 3.

For the insertion tests of the Seeger ring, the same condition that occurs during the manual assembly cycle was reproduced. Thus, the elements of the assembly were prepositioned on the base for assembly and the conical interface was placed over the metal eyelet by the robot. The Seeger ring inserted into the conical interface was then pushed by the robot along the element by means of the negative groove on the fingers of the gripper until it was inserted into the seat on the eyelet. The tests showed that the force applied by the collaborative robot was sufficient for this operation. Thus, in the final solution, the insertion of the Seeger ring into its seat was performed by the collaborative robot.

The operations that were the subject of the preliminary tests for component 2 involved picking up and handling the two Seeger rings, JV28 and JV30, inserting Seeger ring JV28 into its seat, and pushing the two bearings into the steel case. As the insertion of the bearings inside the case is done by interference, it was necessary to measure the required force with a tensile machine in order to determine whether the robot was able to force the bearings into the case.

In the bearing insertion tests, the metal case was clamped on the plane of the tensile machine, and the part to be pushed was placed on top of it. To make the tests as similar as possible to the real cycle, several parts of the assembly were already inserted; in particular:

- Because Seeger ring JV28 acts as a reference for the position of the needle bearing, this element had already been inserted into its seat.

- The ball bearing was inserted together with Seeger ring JV30, as these two parts are pushed into the case with a single piston stroke during the assembly cycle.

Tests were performed for both the needle bearing and the ball bearing. The values obtained from the tests were on the order of 0.9 kN for the needle bearing and 0.15 kN for the ball bearing. Forces of this magnitude are higher than those that collaborative robots can apply; therefore, an appropriately designed auxiliary system such as a pneumatic cylinder must be included in the robot station to generate the required forces.

Seeger ring insertion tests were performed in order to assess the feasibility of manipulating and inserting the rings using the gripper mounted on the robot flange. For these tests, two plastic fingers with steel tips were produced by 3D printing. A pneumatic gripper was used to provide enough force to deflect the Seeger ring and insert it into its seat. In the tests, the Seeger rings were placed on a base while maintaining the same orientation and the robot was brought into the gripping position. For the JV28 Seeger ring, both the gripping and insertion tasks were tested. For the JV30 Seeger ring only the feasibility of handling with the gripper was assessed, as this ring is not inserted into a seat and instead rests on the inner circumference of the case. Two main problems were found during the tests:

- Insertion of the gripper pins into the holes of the Seeger ring is particularly difficult, as this operation requires high precision in positioning both the robot and the Seeger ring in the gripping position.

- When the JV28 Seeger ring is compressed by the gripper, it tends to rotate out of the plane in a way that is difficult to predict and cannot be repeated.

Therefore, without a complex vision system that adapts the positioning and movements of the robot to the position and configuration assumed by the Seeger ring, gripping and inserting this part is impossible. For this reason, the possibility of manipulating the Seeger rings and inserting the JV28 ring into the case using the robot gripper was discarded and an alternative solution was developed, as described below.

3. Robotic Station Auxiliary Systems

Different technologies and systems are integrated in the assembly station. A number of its components are commercial products, whereas the auxiliary devices was specifically designed for this application. The main component of the station is the UR10e collaborative robot. This cobot has a wrist payload of 10 kg and a reach of 1300 mm, characteristics that make it suitable to support the gripper used to grasp the different parts of both components and to reach all points of the station. In order to prevent risks for the operator and ensure that the application is collaborative, a collaborative tool must be mounted on the wrist of the cobot. For this application, the SCHUNK Co-Act EGP-C 64-N-UREK gripper was used, which is a two-finger parallel gripper certified for collaborative operation.

As stated above, the robotic station needs several crucial auxiliary systems designed to overcome the limits of the chosen collaborative robot and optimize the assembly process of the machine components studied in this work. These auxiliary systems feature several parts manufactured by high-precision stereolithography (SLA). In this work, we used a Formlabs Form 3+ SLA 3D printer, which exploits a laser to polymerise resin. The material used to produce these parts was Grey V4 resin, which has good mechanical properties combining rigidity and strength. The resin also offers high precision, making it perfect for printing complex models drawn for tolerated assembly.

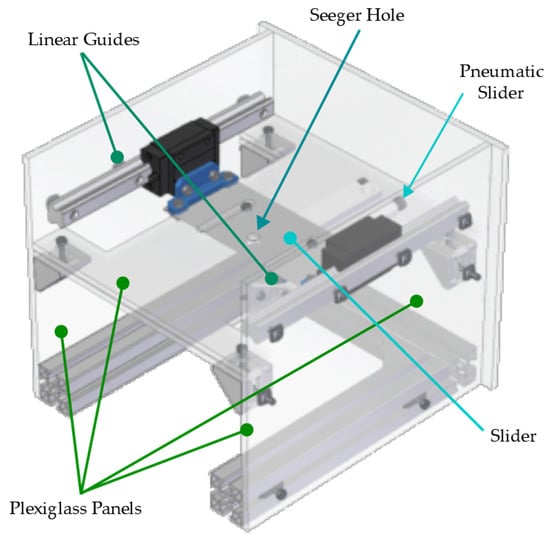

For component 1, an automatic Seeger ring feeding system (Figure 4) and specialized assembly base (Figure 5) were designed to improve the repeatability of Seeger ring handling and enhance alignment of the component parts. The development of an automatic Seeger ring feeding system was necessary to handle gripping of the Seeger rings. In fact, as seen in our preliminary tests, while gripping the Seeger rings using a tooth on the fingers of the gripper is possible, it does not ensure the repeatability of the operation. The automatic feeding system involves insertion of the Seeger ring into the conical interface used for the subsequent pushing and mounting into the eyelet. The cone is grasped by the robot gripper and placed under a hole of the same size as the Seeger ring. The Seeger ring to be inserted is then selected and pushed towards the hole, falling onto the conical interface. The removal and displacement of the Seeger ring from the stack is achieved by means of a ‘sandwich’ structure and the stroke of a pneumatic piston. The ‘sandwich’ structure consists of three plates: the central aluminium plate is moved by the pneumatic piston, while the other two, made of Plexiglas, are fixed. The upper plate has a hole that houses the first element of the Seeger ring stack, while the lower plate contains the hole from which the selected Seeger ring falls onto the conical interface. Thanks to the piston stroke, the hole on the moving plate is brought into alignment with the holes on the fixed plates. When the moving plate hole matches the top plate hole, the first column Seeger ring falls into the moving plate hole and rests on the bottom plate. Subsequently, after the piston is actuated, the moving plate bore matches the bottom plate bore. In this configuration, the Seeger ring falls through the hole of the bottom plate and into the conical interface tightened by the gripper.

Figure 4.

Automatic Seeger ring feeding system mechanism required in order to increase the repeatability of ring insertion over the conical interface for component 1.

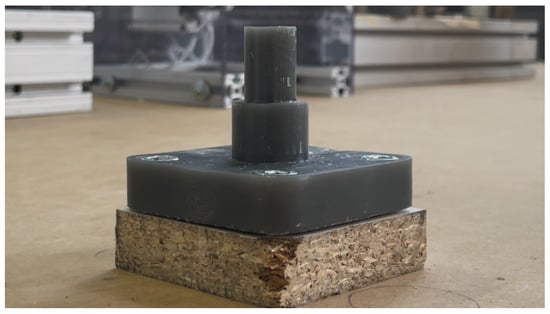

Figure 5.

Assembly base for component 1. This base allows the cap to be assembled, and is designed to accommodate the various part of the component and handle the correct positions.

The assembly base, shown in Figure 5, represents the point of assembly of component 1. Here, the parts of the associated component are placed in sequential order, forming the basis for subsequent assembly. The shape of the assembly base allows for precise and tolerated mounting.

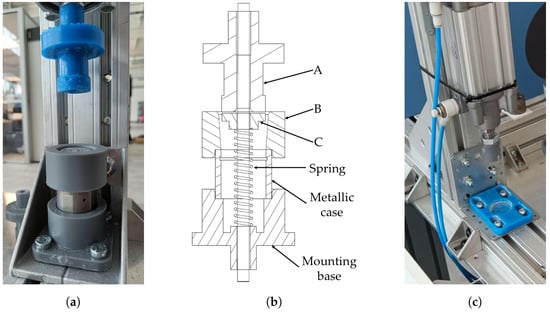

Two pneumatic presses support the precise insertion of the parts of component 2, including the JV28 Seeger ring, which cannot be handled by the cobot alone due to the complexity of its insertion. The first pneumatic press is shown in Figure 6a. This system is also detailed in section view in Figure 6b, where piston A is designed for forcing the Seeger ring into conical guide B. Through the thrust of the piston, the Seeger ring slides inside the conical groove and shrinks. At the end of the conical guide, the Seeger ring reaches maximum compression and is forced into the case. Finally, at the end of the cylinder stroke, the Seeger ring is inserted into its seat. The press also features disc C, which is supported by a compression spring. The Seeger ring is placed on disc C by the robot at the beginning of the insertion process, meaning before the piston stroke. The disc–spring system has a dual function; it prevents the Seeger ring from rotating out of its base plane, thereby preventing jamming, and also allows the system to return to its initial configuration. This solution presents cylindrical symmetry and has the advantage of not depending on the way the Seeger ring is taken up by the robot; thus, it reduces the complexity of the station feeding machines, increases the repeatability of the process, and eliminates the need for a dedicated vision sensor.

Figure 6.

Auxiliary systems designed to assemble component 2. The first press (a,b) inserts the JV28 Seeger ring into a metal case using a pneumatic piston with a 3D-printed cap and conical guide. The second press (c) places bearings and other parts, ensuring correct alignment with a 3D-printed base.

The second pneumatic press, shown in Figure 6c, is used to push the bearings into their positions within the metal case of component 2. This press consists of a pneumatic piston, on which a plastic cap obtained through 3D printing is mounted. A 3D-printed base under the piston aligns the steel case with the cylinder. This design ensures that each inserted part achieves the correct position without the need to adjust the distance traveled by the cap mounted on the piston, as all elements are pushed by the same stroke of the cylinder.

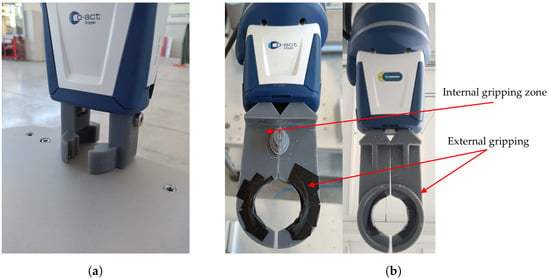

The last custom part developed for this station consists of the fingers of the SCHUNK Co-Act gripper. As stated before, the only positions reached by the Co-Act gripper jaws are ‘fully open’ and ‘fully closed’. Therefore, the fingers of the gripper were designed to grip all the different parts of components 1 and 2 using only these positions. The fingers were obtained by 3D printing, and their design combined several solutions developed in previous works.

For component 1, the fingers of the gripper feature two gripping surfaces: one for gripping the conical interface, and one for gripping the metal eyelet. In addition, the fingers have a conical groove to force the Seeger ring along the conical interface until it is inserted into the seat. Figure 7a shows the prototype of the fingers.

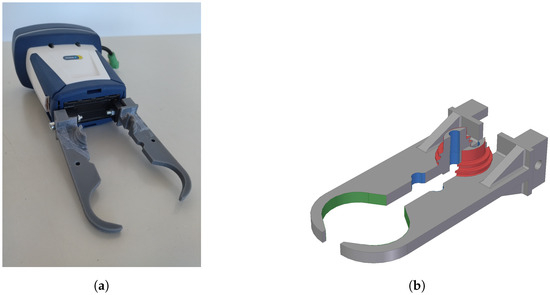

Figure 7.

Custom 3D-printed gripper fingers designed to grip the different parts of the two components using only the ‘fully open’ and ‘fully closed’ positions. Subfigure (a) shows the prototype fingers designed to handle the parts of component 1. Subfigure (b) shows the prototype fingers designed to handle the parts of component 2. Both prototypes were 3D-printed by means of high-precision stereolithography (SLA).

The fingers designed to manipulate component 2 have two gripping zones: one at the end of the fingers, and the other at the base. The decision to include two different zones was due to the need to grip some of the parts from the inside in order to insert them into the steel case. The gripping surfaces at the base of the fingers were designed to grip the two Seeger rings, needle bearing, ball bearing, and steel ring from the inside, whle the surfaces at the end of the fingers allow the other two parts to be gripped from the outside. By rotating the pliers 180°, the surfaces at the tips of the fingers allow the conical guide B in Figure 6b, which is required to insert the JV28 Seeger ring into its seat, to be gripped externally. Finally, the smaller-diameter surface at the end of the fingers allows the metal case to be gripped in both directions of the pliers. This double gripping of the steel case was introduced in order to allow it to be rotated during the assembly cycle. The prototype of the fingers is shown in Figure 7b.

The final gripper fingers solution combines the designs of the fingers developed for components 1 and 2, as shown in Figure 8. In particular, the gripping surfaces for parts with similar diameters, such as the steel ring and Seeger rings JV28 and JV30 for component 2, were joined into a single gripping surface to reduce their number. Finally, the gripping areas were reorganised so as not to interfere with each other.

Figure 8.

Custom 3D-printed gripper fingers designed to grip all the different parts of the two components using only the ‘fully open’ and ‘fully closed’ positions. Subfigure (a) shows the prototype fingers, while subfigure (b) shows the different gripping areas. Green indicates gripping areas shared by the parts of both components, blue indicates gripping areas for component 1 parts, and red indicates gripping areas for component 2 parts.

Table 1 presents a schematic summary of the auxiliary systems designed for the robotic station, illustrating their functionality.

Table 1.

Summary of custom systems in robotic station.

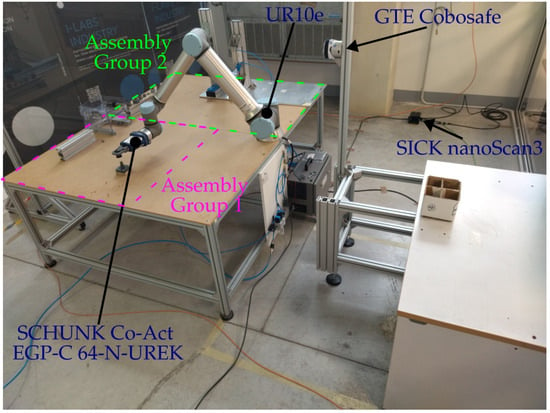

4. Automated Assembly Station

The final assembly station is showed in Figure 9. Here, the UR10e robot is placed on an edge of the work table, whereas the the areas dedicated to component assembly are located on both sides of the cobot. Therefore, the work table is divided into two areas:

Figure 9.

Station layout, arranged according to the client’s requirements. The colored areas on the working table are dedicated to robotized assembly of the components. Areas 1 and 2 can be accessed by the operator to perform final inspection on the products, which are unloaded by the cobot onto the yellow table.

- The first area, intended for component 1, contains the automatic Seeger ring feeder and the assembly base.

- The second area, dedicated to component 2, contains the auxiliary systems necessary for assembly, i.e., the pneumatic presses.

An automated feeding system for the parts of component 2 is beyond the scope of this work. Therefore, after the work cycle of component 2 is completed, the parts required for subsequent assembly must be manually repositioned in their pick-up positions.

According to the customer’s requirements, the storage area for the assembled components is placed behind the UR10e robot approximately 1 m from the work table. This area is also dedicated to the visual inspection, verification, and manual testing of the components performed by the company operators. The developed station layout is flexible and can be modified according to future requirements; for instance, it is possible to change the relative position of the work bench and the finished component unloading area. It is also possible to change the arrangement of the elements on the work bench based on changes in the assembly cycle of a component or the introduction of a new component.

4.1. Station Logic

The station’s logic allows for multiple use cases depending on production requirements. It is possible to choose whether to assemble both components or only one of them. The robotic assembly cycles essentially follow the sequence of operations of the manual cycle with a few variations. For component 1, manual picking of the Seeger rings is replaced by the automated feeding solution. For component 2, the JV28 Seeger ring and bearings are inserted manually using the automated presses described in the previous chapter. As stated before, the pass/fail test is left to the operator. To ensure compliance with cycle times and increase the efficiency of the assembly process, the cobot is programmed to move at the highest speed. The cycle times for assembling the two components are as follows:

- For component 1: 14 s, compared to 15 s for the manual process.

- For component 2: 93 s, compared to 2 min for the manual process.

Following the flux diagram in Figure 1, a risk assessment was performed to prevent injuries to the operator and ensure that the whole application is collaborative. Because the area dedicated to the manual inspections and final tests lies inside the cobot workspace, safety measures must be implemented to mitigate the risks due to unexpected high-speed collisions between the robot and the operator. Furthermore, considering the forces involved in assembling component 2, it is necessary to prevent operators from accidentally placing their hands beneath the presses during operation. Therefore, a SICK NanoScan3 laser scanner was installed on the floor of the station to monitor the entire station. The laser scanner was positioned at the rear of the station, between the work table and the unloading area of the finished components approximately 3 m from the personnel entrance area to the station. The relevant areas which are objects of this monitoring are as follows (Figure 9):

- Area 1 (green): Includes the shared and collaborative workspace.

- Area 2 (red): Behind the pneumatic presses designed for assembly of component 2

In order to prevent injuries to the operator, the station logic integrates the power and force limitation collaborative strategy. Specifically, when the operator moves inside Area 1, the system reduces the robot’s speed below a safety threshold, which is determined as described in the following subsection. Moreover, if the operator reaches Area 2, then the system slows the cobot down, as stated before, and denies consent to the presses through a dedicated safety channel, preventing accidental crushing of the operator’s hands until Area 2 is clear.

4.2. Experimental Collaborative Tests

To assess whether the set safety threshold complies with the limits imposed by current regulations and whether the application is truly collaborative, collision tests were carried out using the GTE Cobosafe CBSF-35 and CBSF-75 contact sensors. The Cobosafe system is a system for measuring force and pressure, and is designed for inspecting transient and quasi-static forces and pressures on collaborative robots (Figure 10). At the heart of the force measurement device is a force sensor with a linear guide measuring mechanism. The CBSF series consists of nine individual force gauges, each with a different spring constant between 10 N/mm and 150 N/mm. Depending on requirements and objectives, the settings can be configured with up to nine force gauges with different spring constants. Combination of the elastic constants with one of the additional damping elements allows the biomechanical properties to be configured in accordance with EN ISO 10218-1 [25], EN ISO 10218-2 [26], or EN ISO/TS 15066 [27].

Figure 10.

GTE Cobosafe CBSF contact sensors, showing the different zones that can be simulated by the sensor, the GTE Cobosafe CBSF contact sensors, and the damping elements.

Using these sensors, we collected data on the pressure and force developed during a simulation of an operator impact. The tests were repeated for different robot speeds in order to identify a safe threshold according to the limits for maximum contact force and pressure specified in ISO/TS 15066:2016 [27]. Specifically, in relation to the robot motion cycle and station layout, two types of tests were performed:

- A simulation of a free collision with the human operator’s shoulder and back; in this test, the UR10e collaborative robot was rotated around its axis 1 until it hit the CBSF-35 sensor.

- A free collision with the operator’s hand, simulating the unloading of a finished component in the inspection area; in this case, the UR10e robot descended along the z-axis until the end effector collided with the CBSF-75 sensor.

Figure 11 shows the station setup for the collision tests performed to assess the safety of the application.

Figure 11.

Robotic station setup during the collision tests, with the GTE Cobosafe sensor positioned between the robot and the unloading area to simulate an impact with the operator’s back.

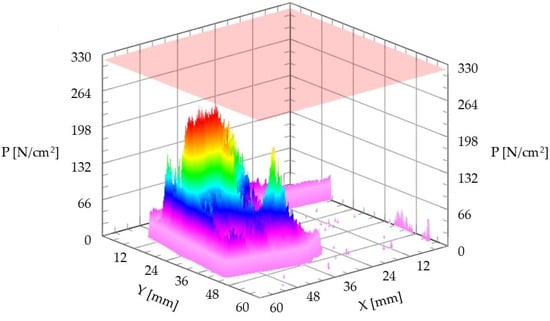

The results of the force and pressure diagrams obtained from the tests is shown in Figure 12 and Figure 13. The force diagram refers to the test simulating a collision with a human operator’s hand, with the speed of the cobot’s end effector being equal to 300 mm/s. In this diagram, the evolution of the force applied to the sensor as a function of time can be observed. In addition, the diagram shows the maximum value provided by the standard. The following figure shows the simulation of an impact with the operator’s shoulder, with a rotation speed along the robot’s first axis of 120°/s. This graph shows the 3D diagram of the pressures applied to the sensor surface using a colour scale to quantify the different pressure values recorded. The maximum value required by the standard is shown in this graph as well.

Figure 12.

Force diagram of the collision test. The graph refers to the test simulating a collision with the human operator’s hand, where the speed of the cobot’s end effector was 300 mm/s.

Figure 13.

A 3D diagram showing the pressures (P) present during the collision test. This graph was obtained for the impact with the operator’s shoulder, with a rotation speed along the robot’s first axis of 120°/s. The colour scale quantifies the different pressure values.

The results of the tests are shown in the Table 2. All of the values reported here are below the limit values indicated by the standard. The joint and linear speeds set during the tests depicted in Figure 12 and Figure 13 and Table 2 were then set as the safety threshold in the station logic according to the power and force limitation collaborative strategy. Therefore, the station’s work cycle complies with the regulations on human–machine collaboration, and the application can be classified as collaborative.

Table 2.

Measurement results of collaborative tests with maximum linear speed equal to 300 mm/s and maximum joint speed equal to 120°/s.

5. Conclusions

This article has describes the development of a fully functional prototype of a cobotized station for the assembly of two different machine components. The resulting station represents an example of integrating different technologies and collaborative systems. Thanks to the layout, which is designed to be adaptable and to integrate safety systems, the station not only fulfills the required criteria of collaboration and precision, it also offers a flexible solution allowing for future modifications according to changing operational requirements. In addition, this work included several experimental tests carried out to validate the robustness of the assembly process and the collaborative nature of the application.

This study provides three main outcomes:

- The developed solution improves the efficiency of the specified manual assembly processes by significantly reducing the cycle time of component 2 while meeting the requirements imposed by the company, including for manual tests and inspections performed by the operator.

- The design methodology introduced in this work and the tools used to verify the compliance of the adopted collaborative strategy could be applied to other projects to certify the collaborative nature of robotic applications, even when non-collaborative robots are involved. This is anticipated to be supported by a forthcoming new version of the regulations which is currently in development.

- The auxiliary device developed to insert the Seeger rings can be industrialized to automate the assembly of machine components.

- The development of this application demonstrates the growing interest and research in implementing collaborative solutions in the manufacturing industry.

From a qualitative perspective, a rigid automation system based on dedicated machines would certainly be capable of performing the same assembly operations with very high performance; however, the components under study are characterized by medium to low and discontinuous production rates; additionally, the company has expressed the need for a flexible and re-configurable assembly station that can be quickly adapted to assemble different components with simple modifications to auxiliary systems and gripping tools, tasks that the company, which is experienced in the production of precision mechanical components, can carry out independently once trained in cobot programming. These reasons underpin the choice to use a collaborative robot instead of rigid machines.

Lastly, the impact of training on new enabling technologies as well as the reskilling of personnel in departments and the development of highly specialized skills offered to designers and R&D technicians should not be underestimated. Among these, collaborative robotics represents a driving force that will enable the company to attract new highly-educated personnel from universities.

The developed station could be the subject of future work and improvements. For instance, an automatic component feeding system for component 2 could be introduced. The current solution assumes manual feeding of the different parts. An automatic feeding system could be realised through one of two different approaches:

- The parts could be placed in the picking area according to an orderly and repeatable pattern, allowing the robot to always pick up the parts from the same places and in the same way.

- The parts could be arranged in the picking station in a random arrangement; in this case, a vision system and component reorientation and separation system would need to be implemented in order to provide the robot with the position and orientation of the components to be picked.

Another potential optimisation would be the integration of a vision system to verify the assembly of the two components. This vision system would have to recognise both the correct assembly of component 1 and the pass/fail test result for component 2. For this purpose, an artificial intelligence could be trained to detect faulty assemblies of components using a camera. In the event of a faulty assembly, the cobot would place the component in a rejection zone.

Author Contributions

Conceptualization, F.E. and A.B.; methodology, F.E.; software, D.P.; validation, F.E., D.P. and C.L.; formal analysis, F.E.; investigation, A.B.; resources, D.C.; data curation, F.E.; writing—original draft preparation, F.E.; writing—review and editing, A.B.; visualization, G.P.; supervision, D.C.; project administration, D.C.; funding acquisition, M.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Acknowledgments

The authors thank the commissioning company for the support and materials provided in carrying out this study.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Dietsch, J. People Meeting Robots in the Workplace [Industrial Activities]. IEEE Robot. Autom. Mag. 2010, 17, 15–16. [Google Scholar] [CrossRef]

- Taylor, A.; Lee, H.R.; Kubota, A.; Riek, L.D. Coordinating Clinical Teams: Using Robots to Empower Nurses to Stop the Line. Proc. ACM Hum. Comput. Interact. 2019, 3, 221. [Google Scholar] [CrossRef]

- Tornbjerg, K.; Kanstrup, A.M.; Skov, M.B.; Rehm, M. Investigating human-robot cooperation in a hospital environment: Scrutinising visions and actual realisation of mobile robots in service work. In Proceedings of the 2021 ACM Designing Interactive Systems Conference, DIS ’21, New York, NY, USA, 28 June–2 July 2021; pp. 381–391. [Google Scholar] [CrossRef]

- Correia Simões, A.; Lucas Soares, A.; Barros, A.C. Factors influencing the intention of managers to adopt collaborative robots (cobots) in manufacturing organizations. J. Eng. Technol. Manag. 2020, 57, 101574. [Google Scholar] [CrossRef]

- Welfare, K.S.; Hallowell, M.R.; Shah, J.A.; Riek, L.D. Consider the Human Work Experience When Integrating Robotics in the Workplace. In Proceedings of the 2019 14th ACM/IEEE International Conference on Human-Robot Interaction (HRI), Daegu, Republic of Korea, 11–14 March 2019; pp. 75–84. [Google Scholar] [CrossRef]

- Foundation, N.S. National Robotics Initiative 2.0: Ubiquitous Collaborative Robots (NRI-2.0). 2019. Available online: https://new.nsf.gov/funding/opportunities/national-robotics-initiative-30-innovations/503641/nsf20-522/solicitation (accessed on 20 June 2024).

- Colgate, J.; Wannasuphoprasit, W.; Peshkin, M. Cobots: Robots for collaboration with human operators. In Proceedings of the 1996 ASME International Mechanical Engineering Congress and Exposition, Atlanta, GA, USA, 17–22 November 1996; pp. 433–439. [Google Scholar]

- Peshkin, M.; Colgate, J.; Wannasuphoprasit, W.; Moore, C.; Gillespie, R.; Akella, P. Cobot architecture. IEEE Trans. Robot. Autom. 2001, 17, 377–390. [Google Scholar] [CrossRef]

- Matheson, E.; Minto, R.; Zampieri, E.G.G.; Faccio, M.; Rosati, G. Human-Robot Collaboration in Manufacturing Applications: A Review. Robotics 2019, 8, 100. [Google Scholar] [CrossRef]

- Vicentini, F. Collaborative Robotics: A Survey. J. Mech. Des. 2021, 143, 040802. [Google Scholar] [CrossRef]

- Cherubini, A.; Passama, R.; Crosnier, A.; Lasnier, A.; Fraisse, P. Collaborative manufacturing with physical human–robot interaction. Robot. Comput. Integr. Manuf. 2016, 40, 1–13. [Google Scholar] [CrossRef]

- Gualtieri, L.; Rauch, E.; Vidoni, R. Human-robot activity allocation algorithm for the redesign of manual assembly systems into human-robot collaborative assembly. Int. J. Comput. Integr. Manuf. 2022, 36, 308–333. [Google Scholar] [CrossRef]

- Makrini, I.E.; Elprama, S.; den Bergh, J.V.; Vanderborght, B.; Knevels, A.J.; Jewell, C.; Stals, F.; Coppel, G.D.; Ravyse, I.; Potargent, J.; et al. Working with Walt: How a Cobot Was Developed and Inserted on an Auto Assembly Line. IEEE Robot. Autom. Mag. 2018, 25, 51–58. [Google Scholar] [CrossRef]

- Safeea, M.; Neto, P.; Béarée, R. The Third Hand, Cobots Assisted Precise Assembly. In Towards Autonomous Robotic Systems, Proceedings of the 20th Annual Conference, TAROS 2019, London, UK, 3–5 July 2019; Proceedings, Part II 20; Springer International Publishing: New York, NY, USA, 2019; pp. 454–457. [Google Scholar] [CrossRef]

- Mohamed Sahan, A.S.; Kathiravan, S.; Lokesh, M.; Raffik, R. Role of Cobots over Industrial Robots in Industry 5.0: A Review. In Proceedings of the 2023 2nd International Conference on Advancements in Electrical, Electronics, Communication, Computing and Automation (ICAECA), Coimbatore, India, 16–17 June 2023; pp. 1–5. [Google Scholar] [CrossRef]

- Weckenborg, C.; Kieckhäfer, K.; Müller, C.; Grunewald, M.; Spengler, T. Balancing of assembly lines with collaborative robots. Bus. Res. 2019, 13, 93–132. [Google Scholar] [CrossRef]

- Boschetti, G.; Bottin, M.; Faccio, M.; Minto, R. Multi-robot multi-operator collaborative assembly systems: A performance evaluation model. J. Intell. Manuf. 2021, 32, 1455–1470. [Google Scholar] [CrossRef]

- Jain, A.; Jain, P.; Chan, F.T.; Singh, S. A review on manufacturing flexibility. Int. J. Prod. Res. 2013, 51, 5946–5970. [Google Scholar] [CrossRef]

- Chammas, A.; Quaresma, M.; Mont’Alvão, C. A Closer Look on the User Centred Design. Procedia Manuf. 2015, 3, 5397–5404. [Google Scholar] [CrossRef]

- Bajrami, A.; Palpacelli, M.C. A Flexible Framework for Robotic Post-Processing of 3D Printed Components. In Proceedings of the Volume 7: 19th IEEE/ASME International Conference on Mechatronic and Embedded Systems and Applications (MESA), Boston, MA, USA, 20–23 August 2023. Paper No. V007T07A006. [Google Scholar] [CrossRef]

- Casalino, A.; Cividini, F.; Zanchettin, A.M.; Piroddi, L.; Rocco, P. Human-robot collaborative assembly: A use-case application. IFAC-PapersOnLine 2018, 51, 194–199. [Google Scholar] [CrossRef]

- Tsarouchi, P.; Matthaiakis, A.S.; Makris, S.; Chryssolouris, G. On a human-robot collaboration in an assembly cell. Int. J. Comput. Integr. Manuf. 2016, 30, 580–589. [Google Scholar] [CrossRef]

- Salunkhe, O.; Stensöta, O.; Åkerman, M.; Berglund, F.; Alveflo, P.A. Assembly 4.0: Wheel Hub Nut Assembly Using a Cobot. IFAC-PapersOnLine 2019, 52, 1632–1637. [Google Scholar] [CrossRef]

- Bajrami, A.; Costa, D.; Palpacelli, M.C.; Emiliani, F. Investigating Collaborative Robotic Assembly: A Case Study of the FANUC CRX-10 iA/L in Industrial Automation at i-Labs. Eng 2024, 5, 532–543. [Google Scholar] [CrossRef]

- EN ISO 10218-1:2011; Robots and Robotic Devices—Safety Requirements for Industrial Robots—Part 1: Robots. International Organization for Standardization: Geneva, Switzerland, 2011.

- EN ISO 10218-2:2011; Robots and Robotic Devices—Safety Requirements for Industrial Robots—Part 2: Robot Systems and Integration. International Organization for Standardization: Geneva, Switzerland, 2011.

- EN ISO/TS 15066:2016; Robots and Robotic Devices—Collaborative Robots. International Organization for Standardization: Geneva, Switzerland, 2016.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).