Novel Workstation Module and Method for Automatic Blanking of Surgical Forceps

Abstract

1. Introduction

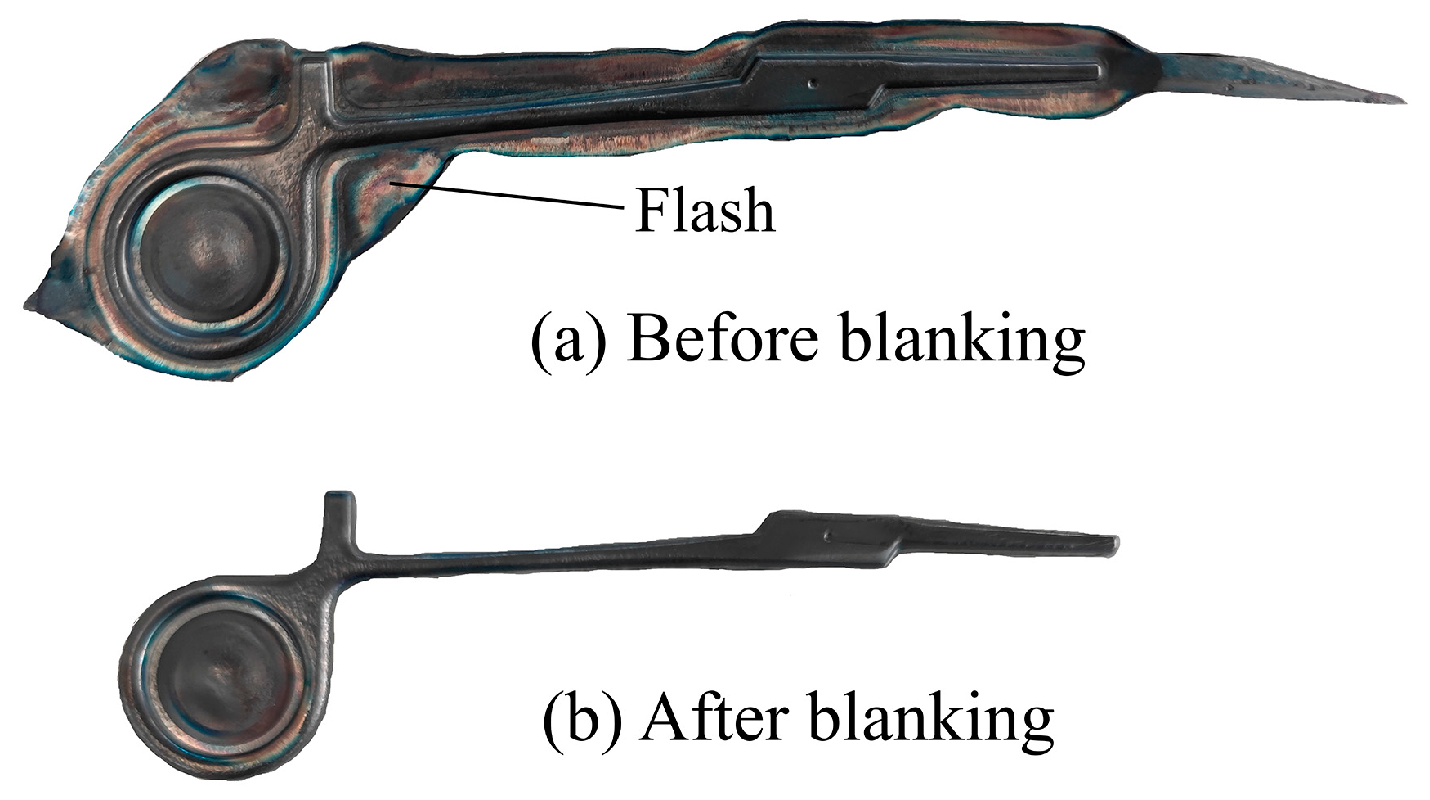

2. Process Analysis

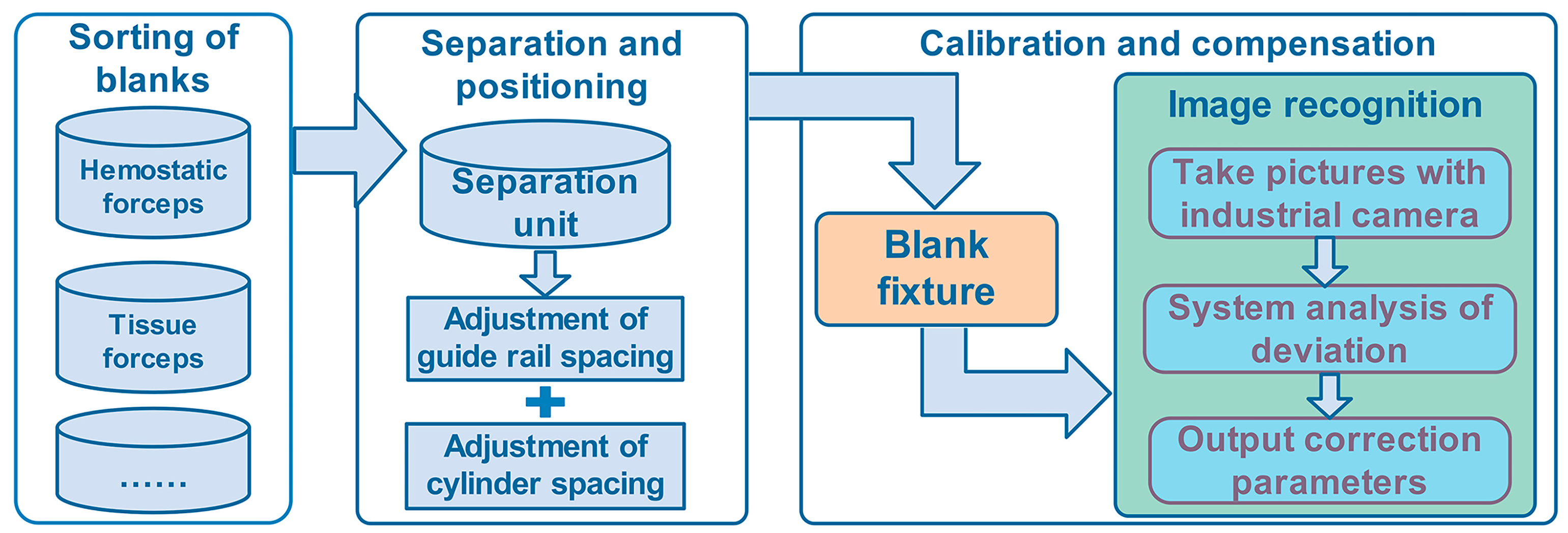

- Due to the messy distribution of blanks in the material box, it is necessary to sort and store the blanks in advance to ensure the continuity of the blanking. Moreover, the blanks must be pre-positioned before they are put into the blanking station.

- The shape of the flash after forging of surgical forceps blank is not exactly consistent, and it belongs to the special-shaped part.

- The automatic transportation of flashes and finished products should be realized after blanking. Due to the small space between the upper and lower molds of the press, the limited operating space greatly increases the difficulty of automatic loading and unloading.

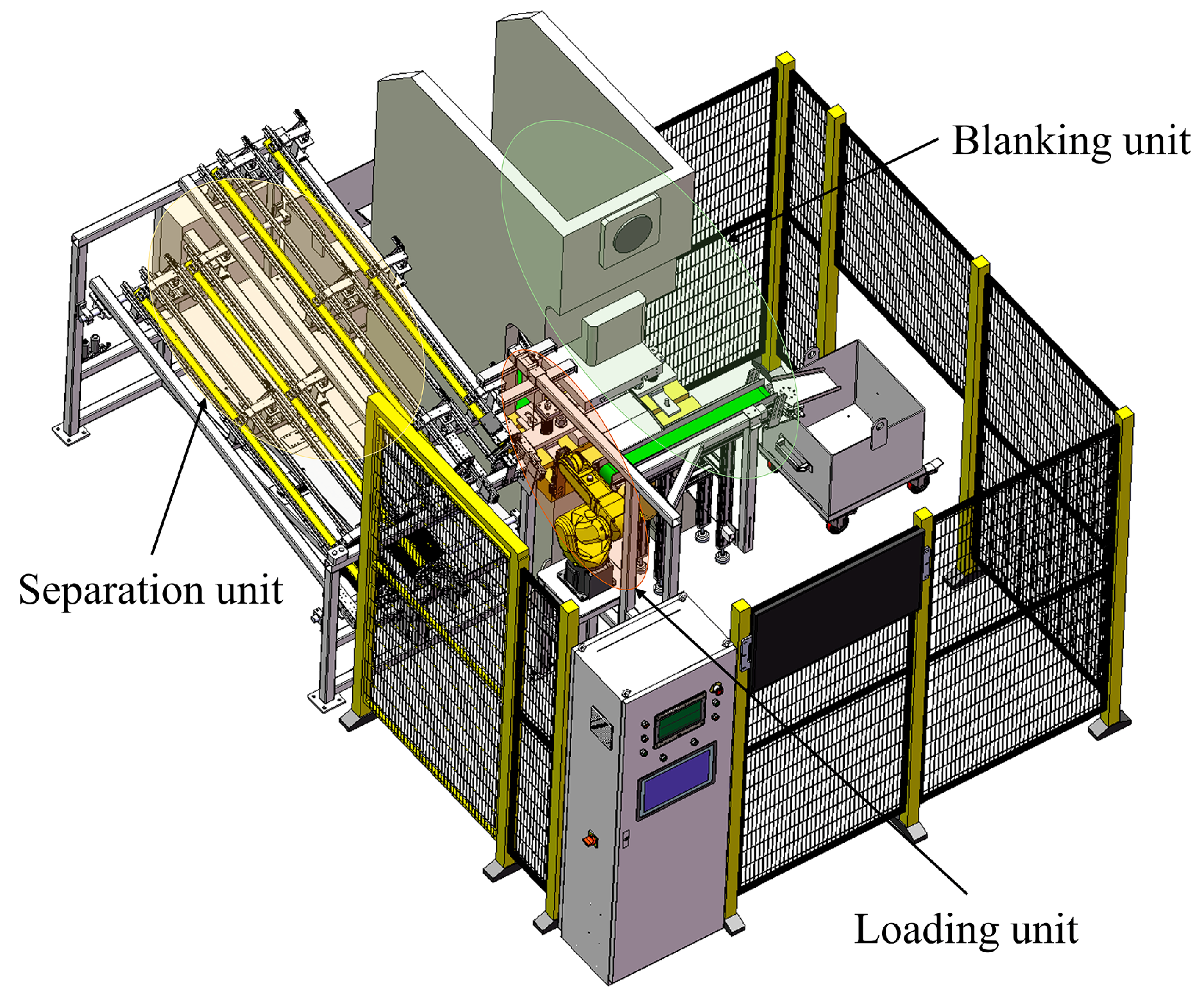

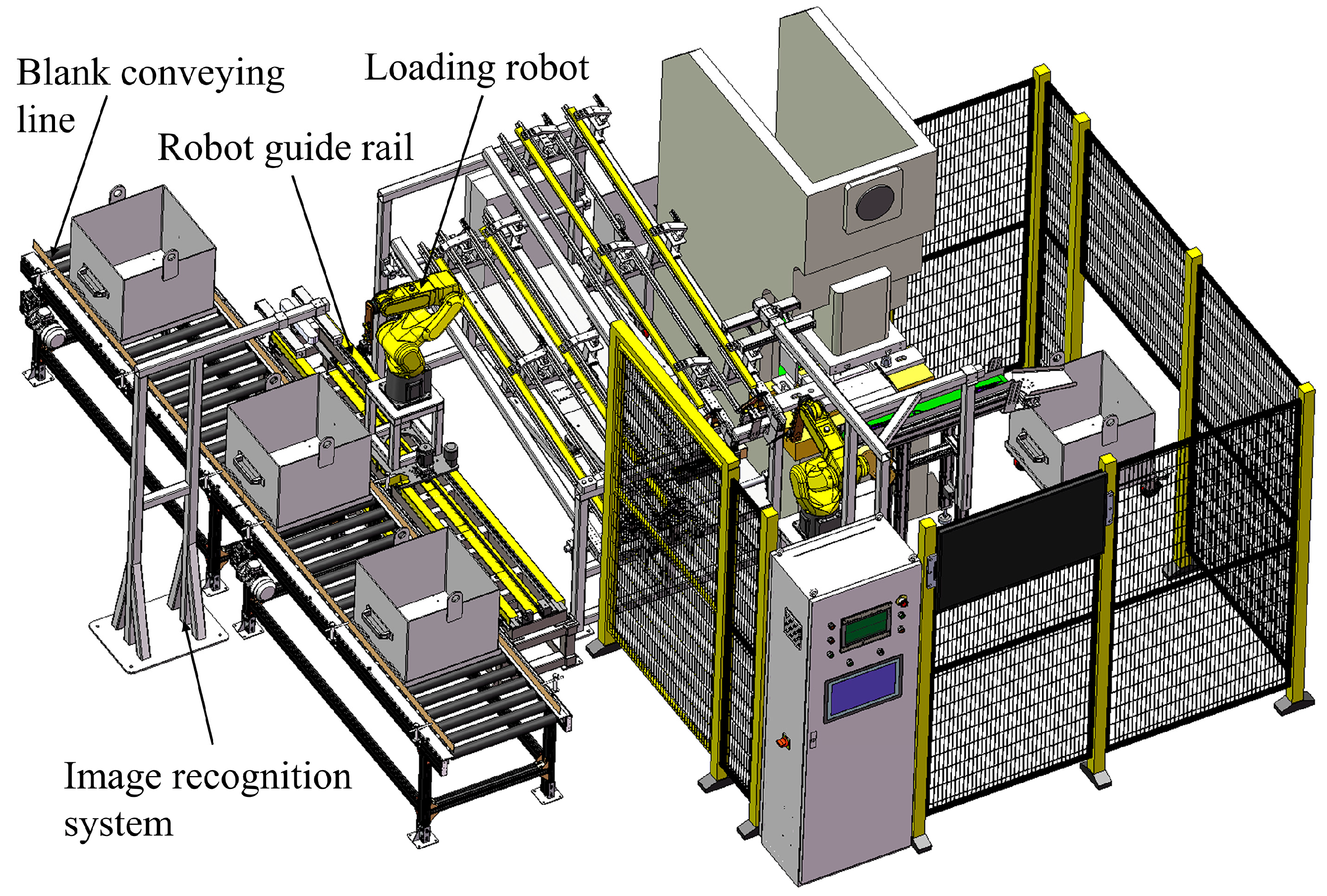

3. Modular Design of Workstation

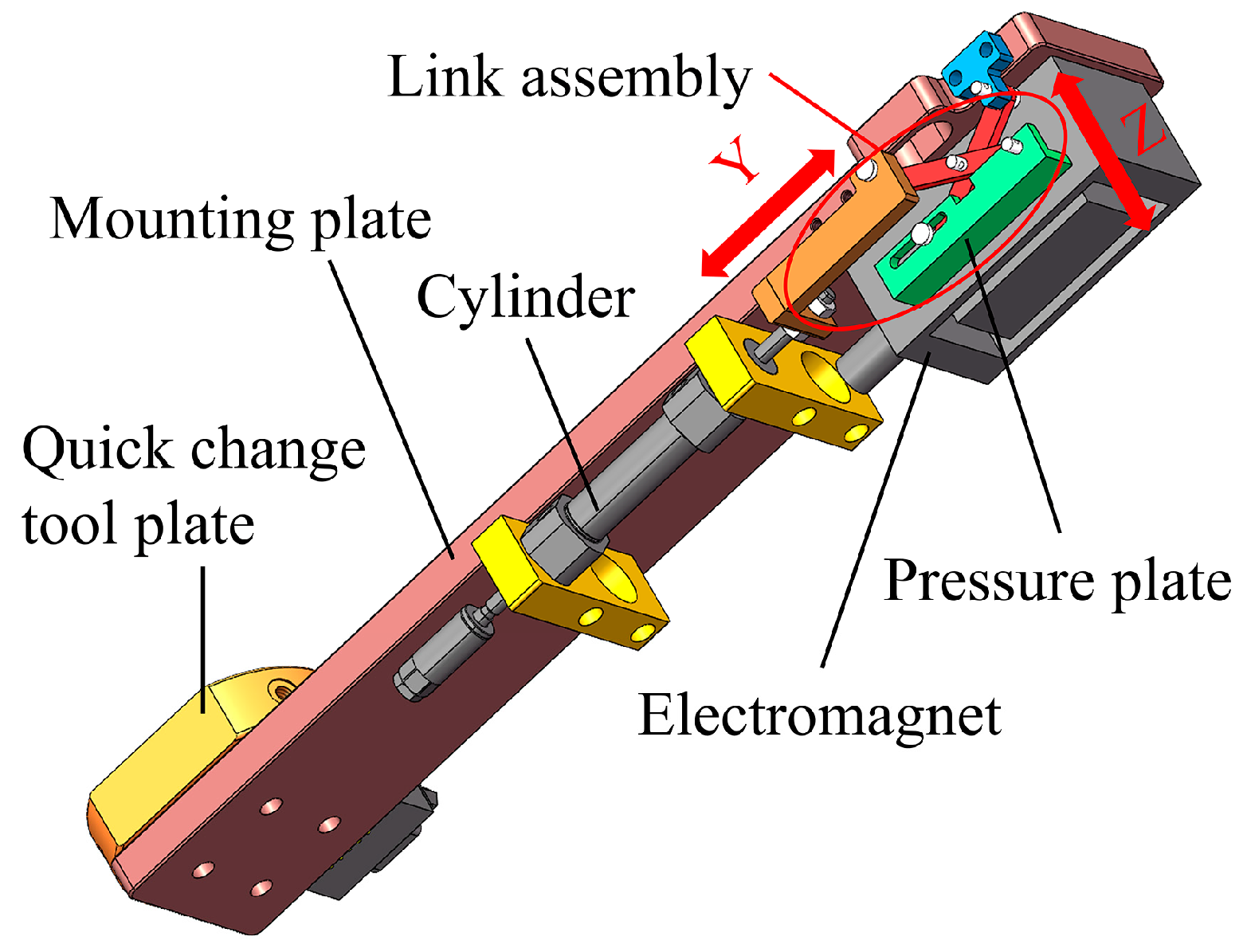

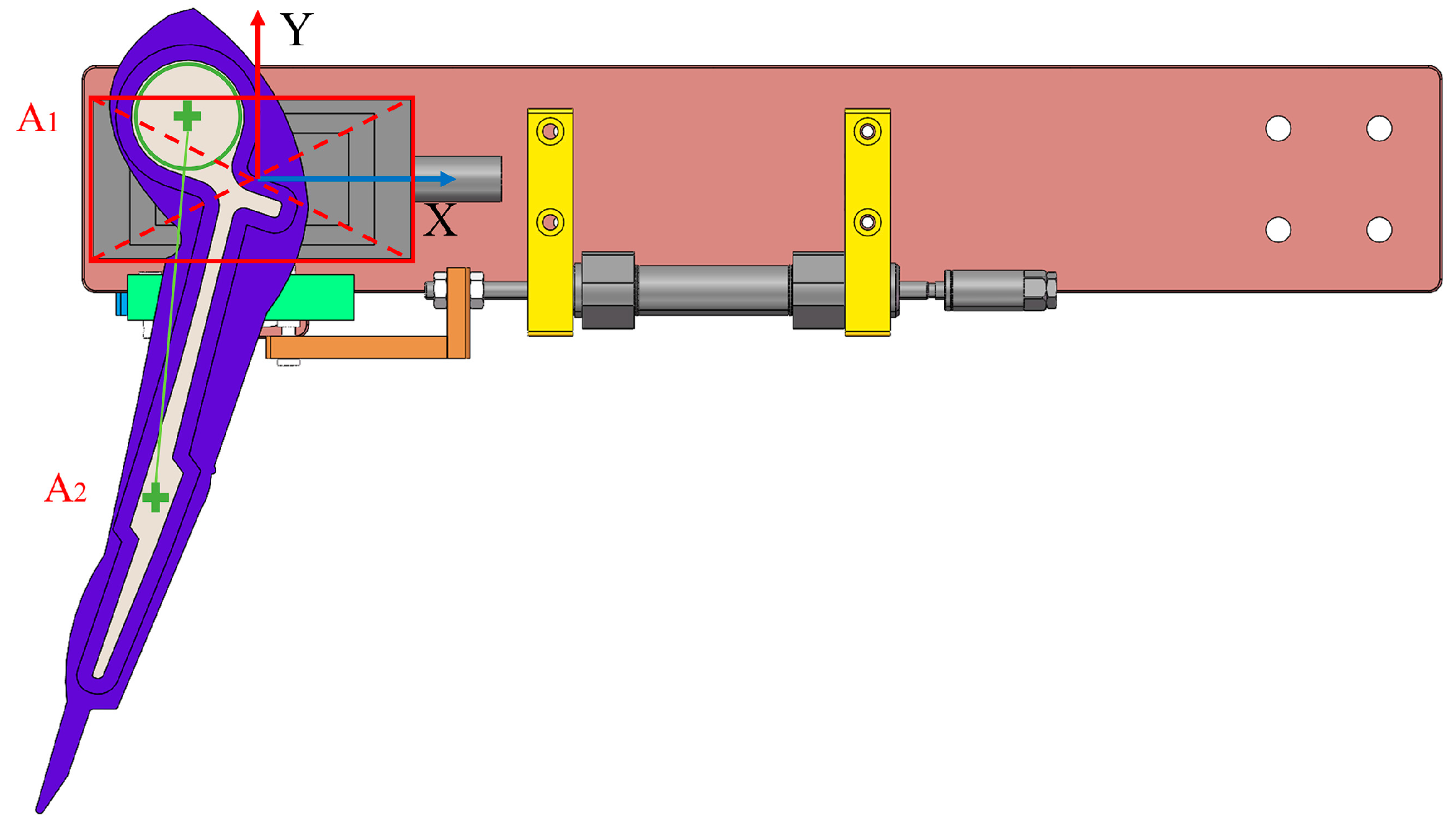

3.1. Design of Blank Fixture

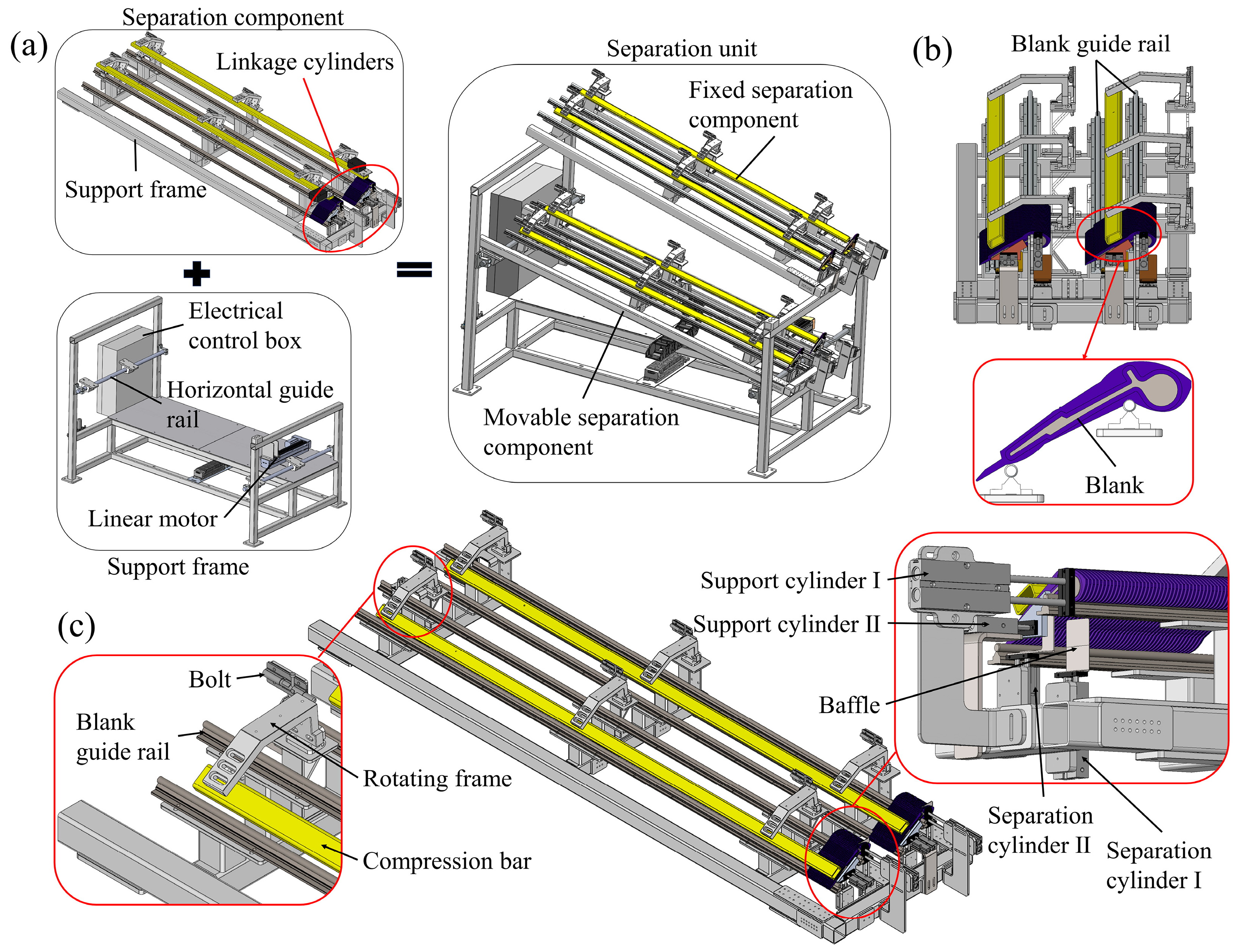

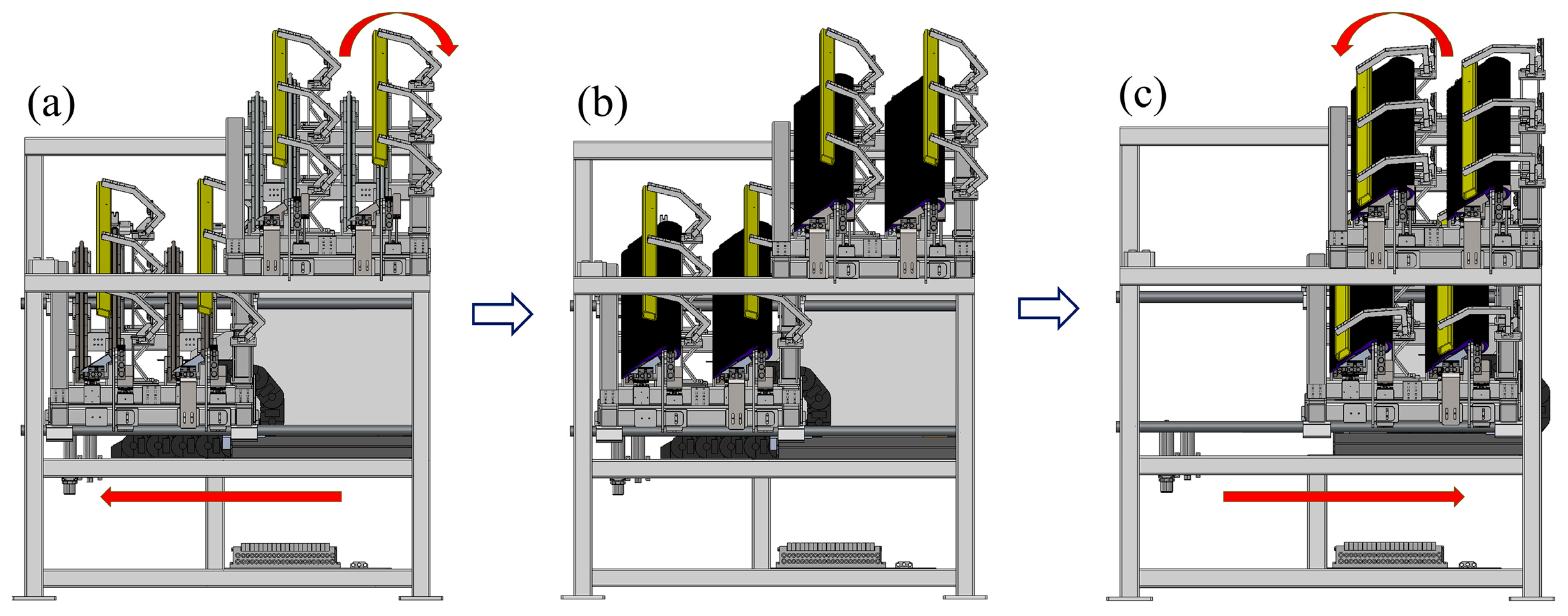

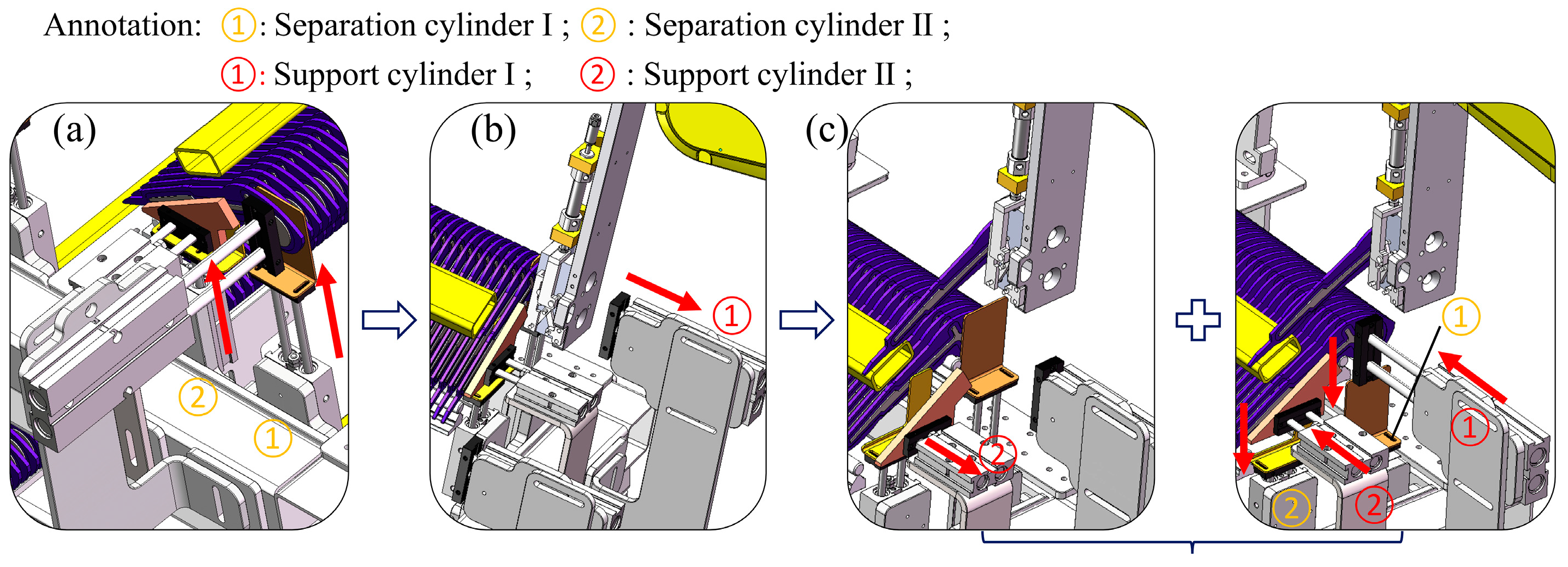

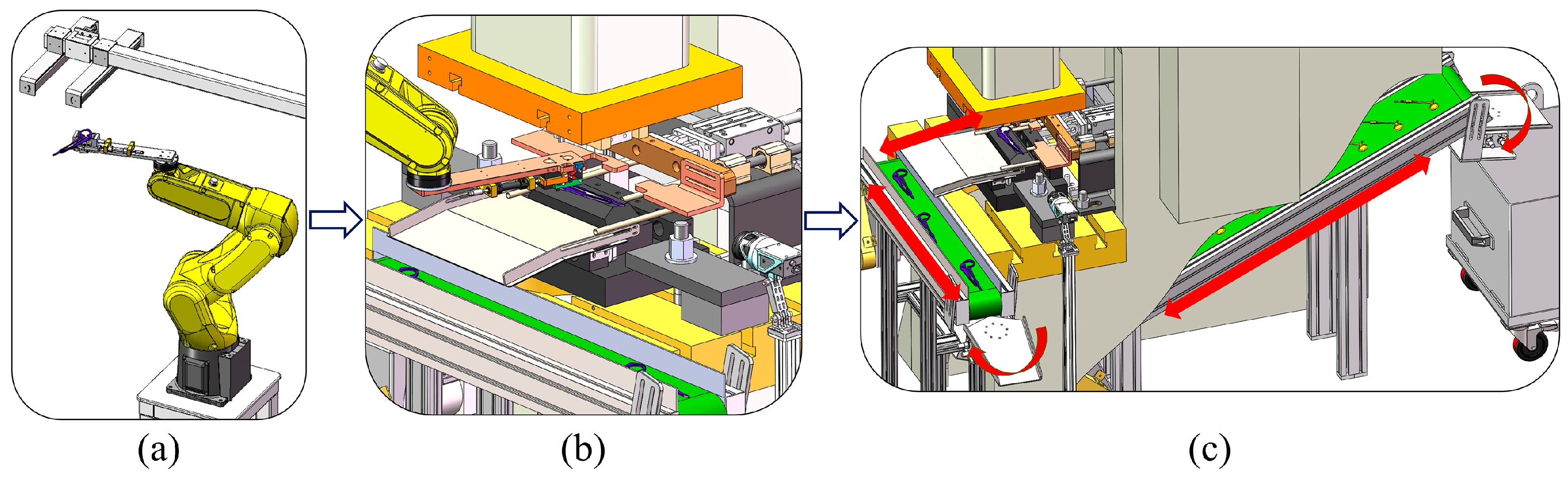

3.2. Design of Separation Unit

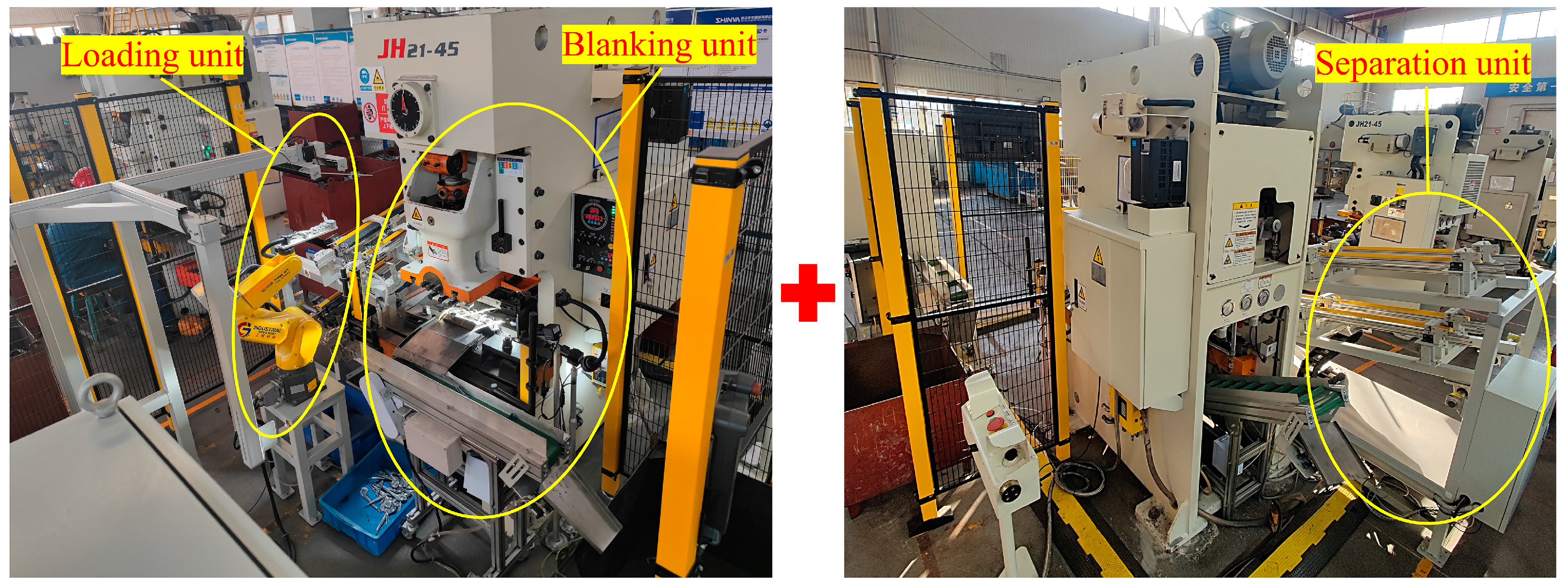

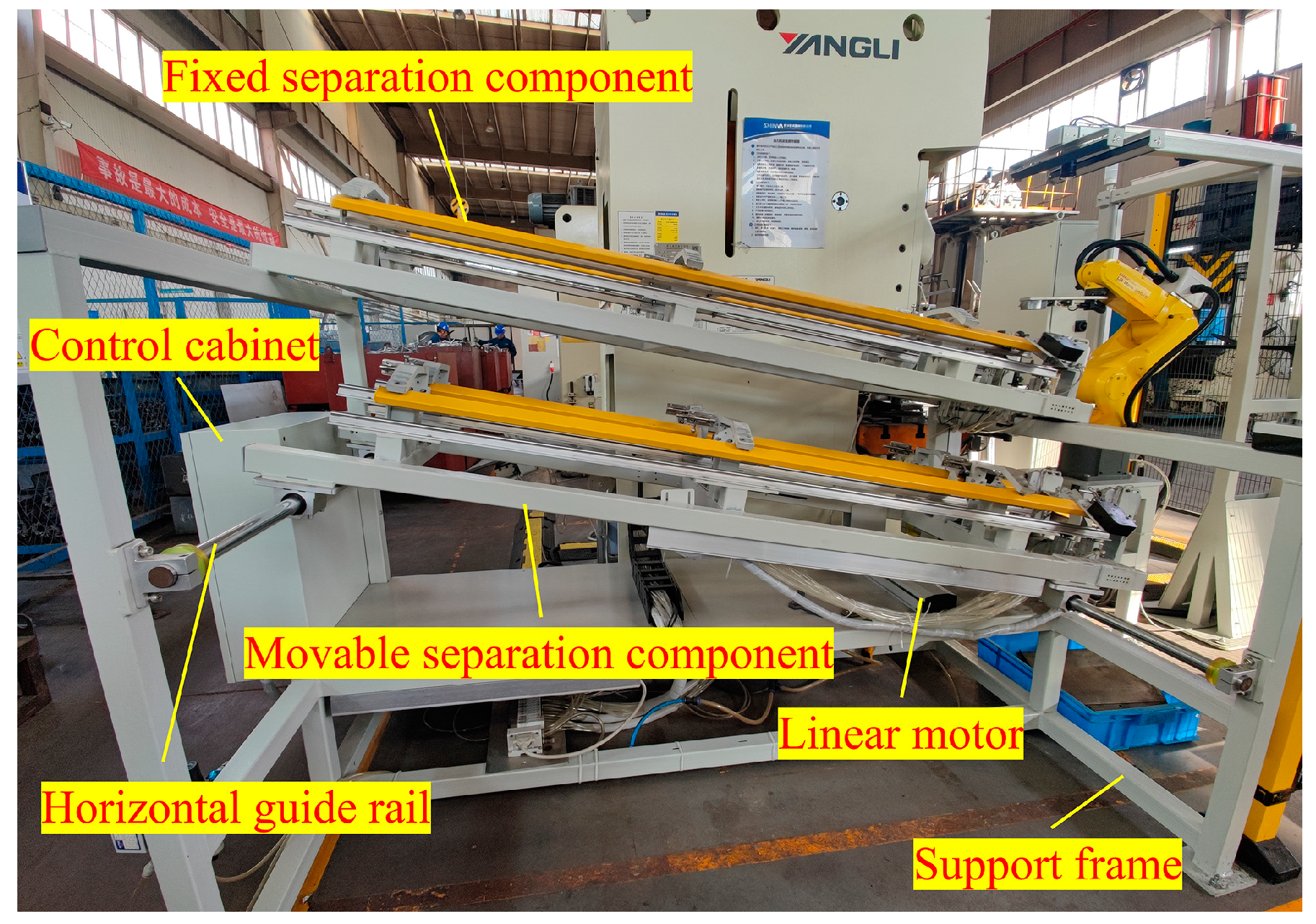

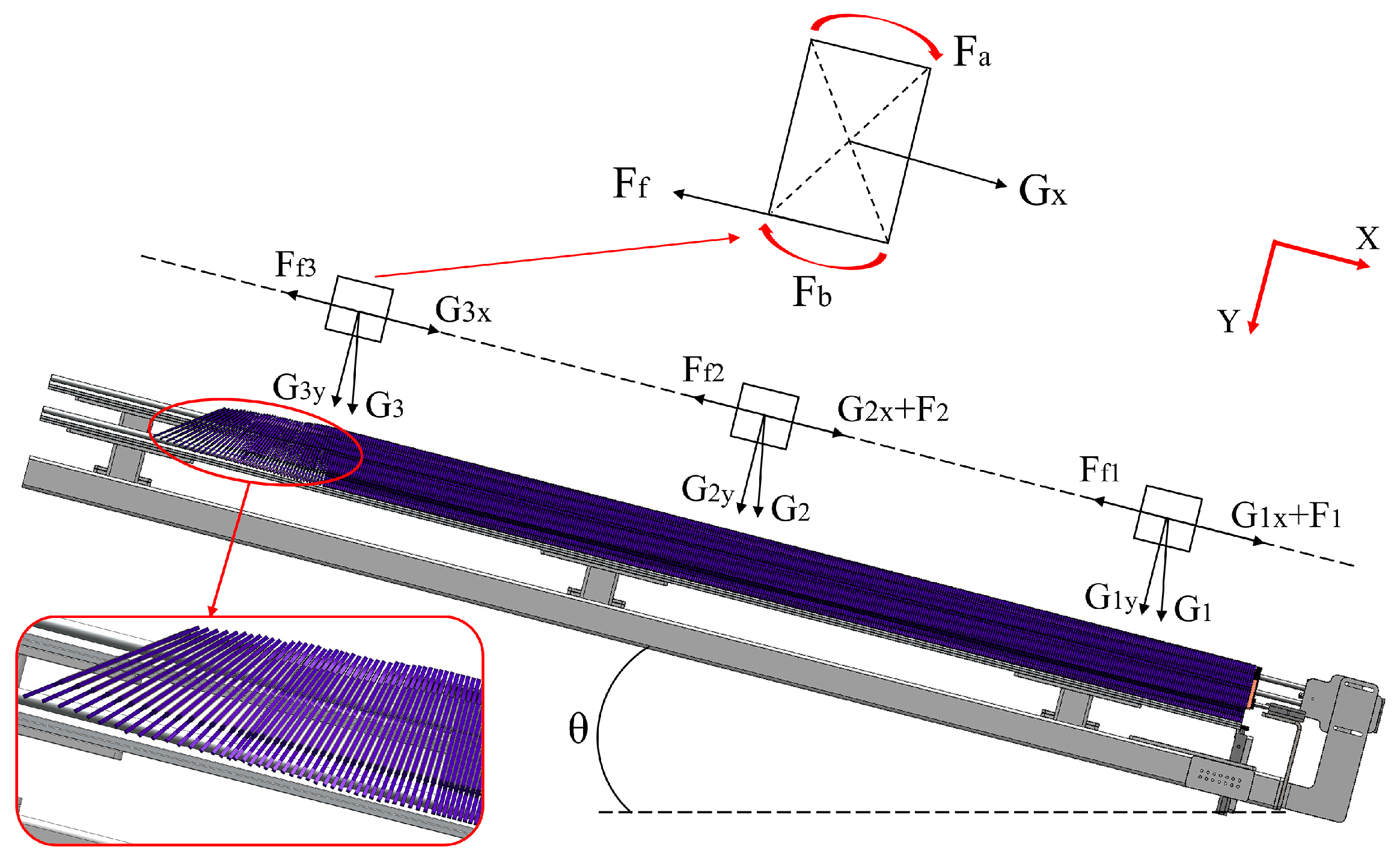

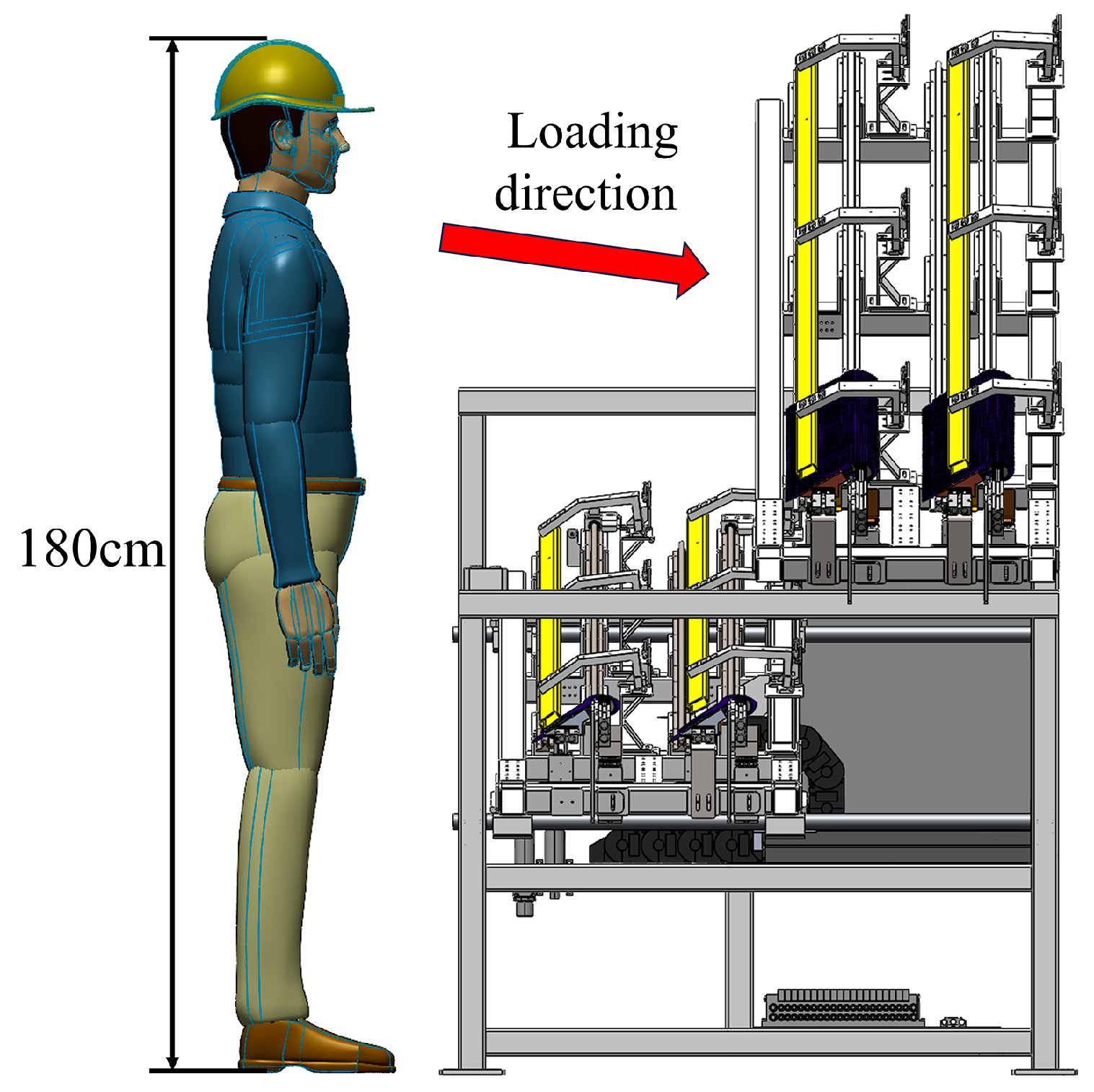

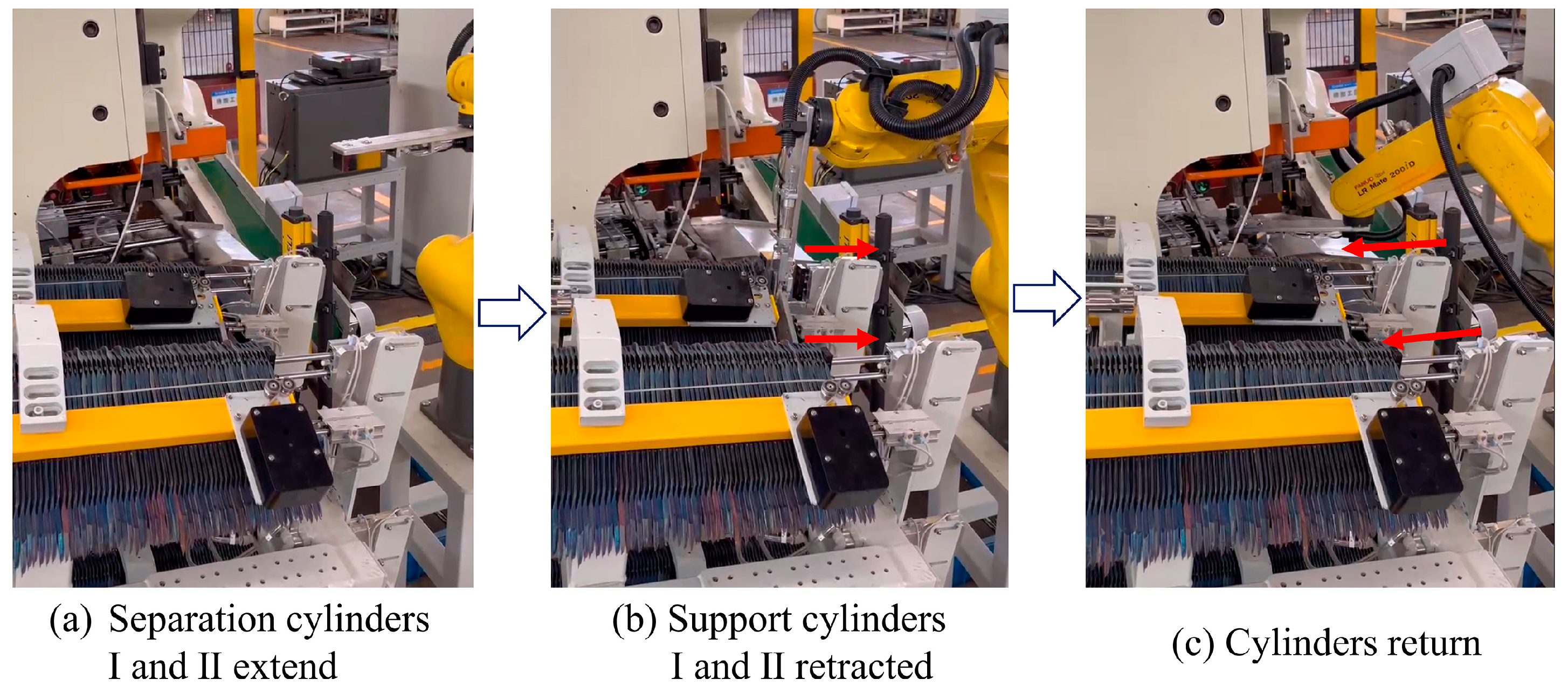

3.3. Design of Loading Unit

3.3.1. Design of General Structure

3.3.2. Design of the Image Recognition System

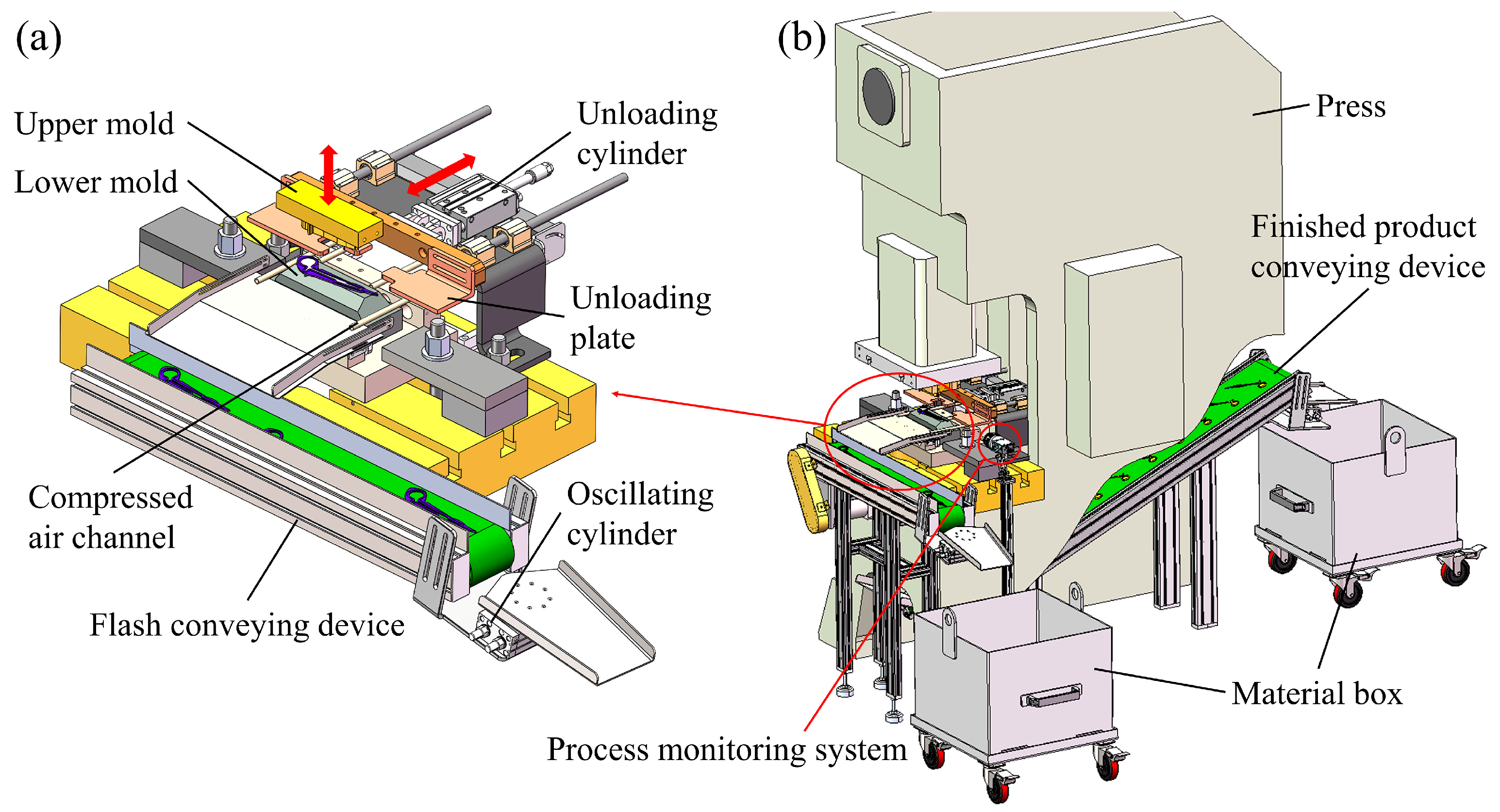

3.4. Design of the Blanking Unit

3.5. System Integration Based on Modular Design

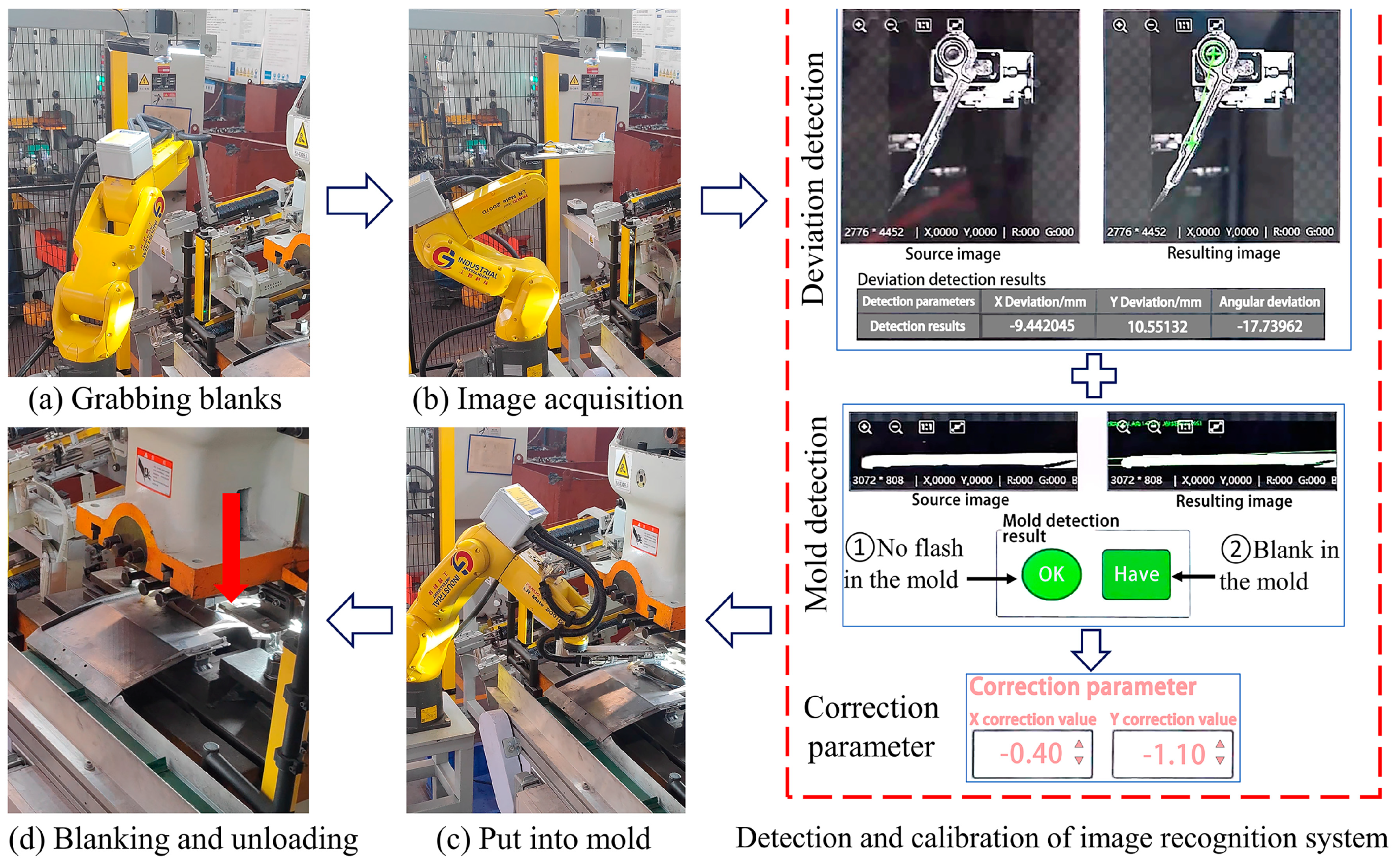

4. Process Method for Workstation

4.1. Overview of Process Method

4.2. Flexibility and Limitations

5. Equipment Selection and Control System Design

6. Experiment and Discussion

6.1. Reliability Analysis of Separation Device

6.2. Analysis of Workstation Efficiency

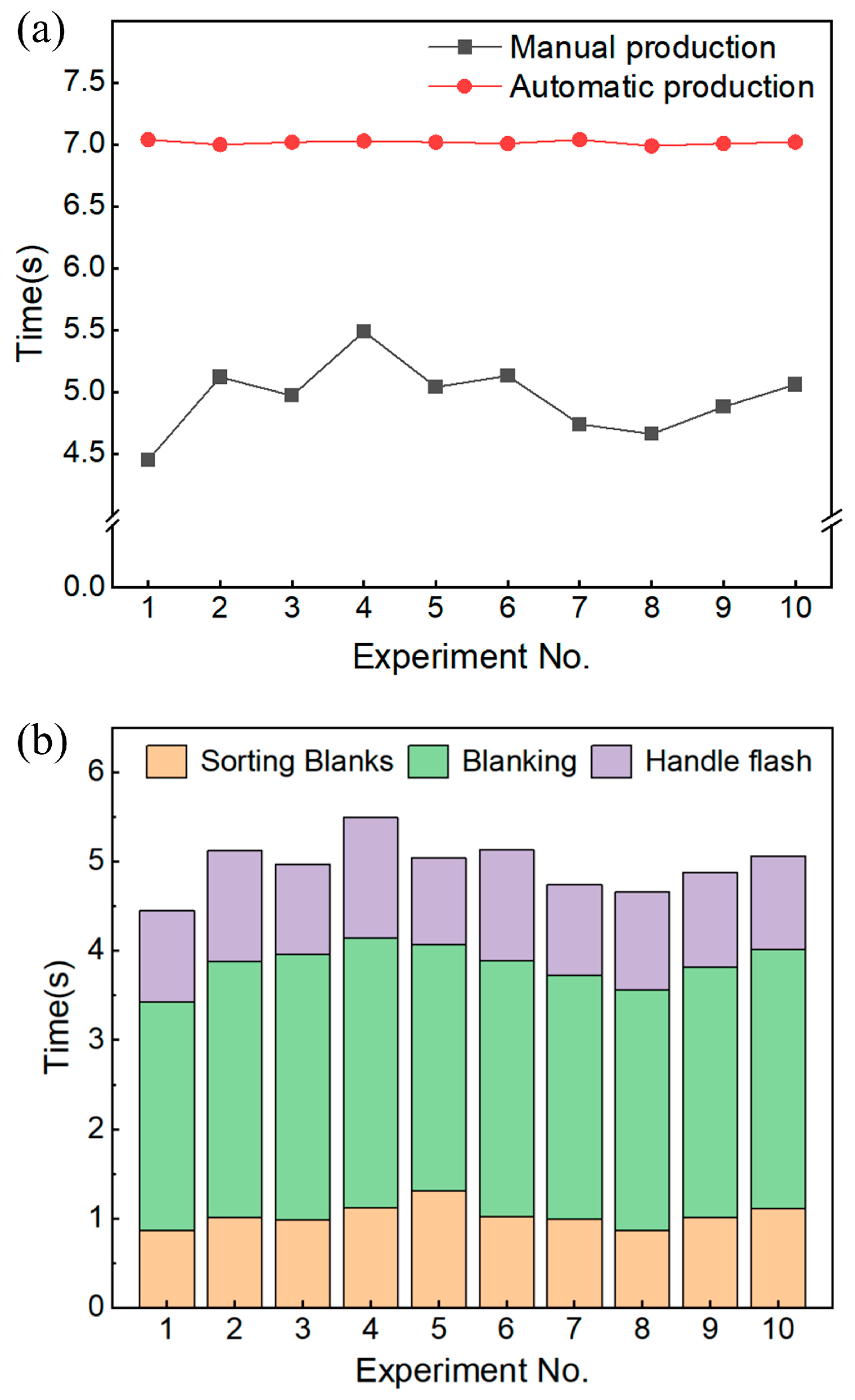

6.3. Stability Analysis of Workstation

6.4. Power Consumption Analysis of the Workstation

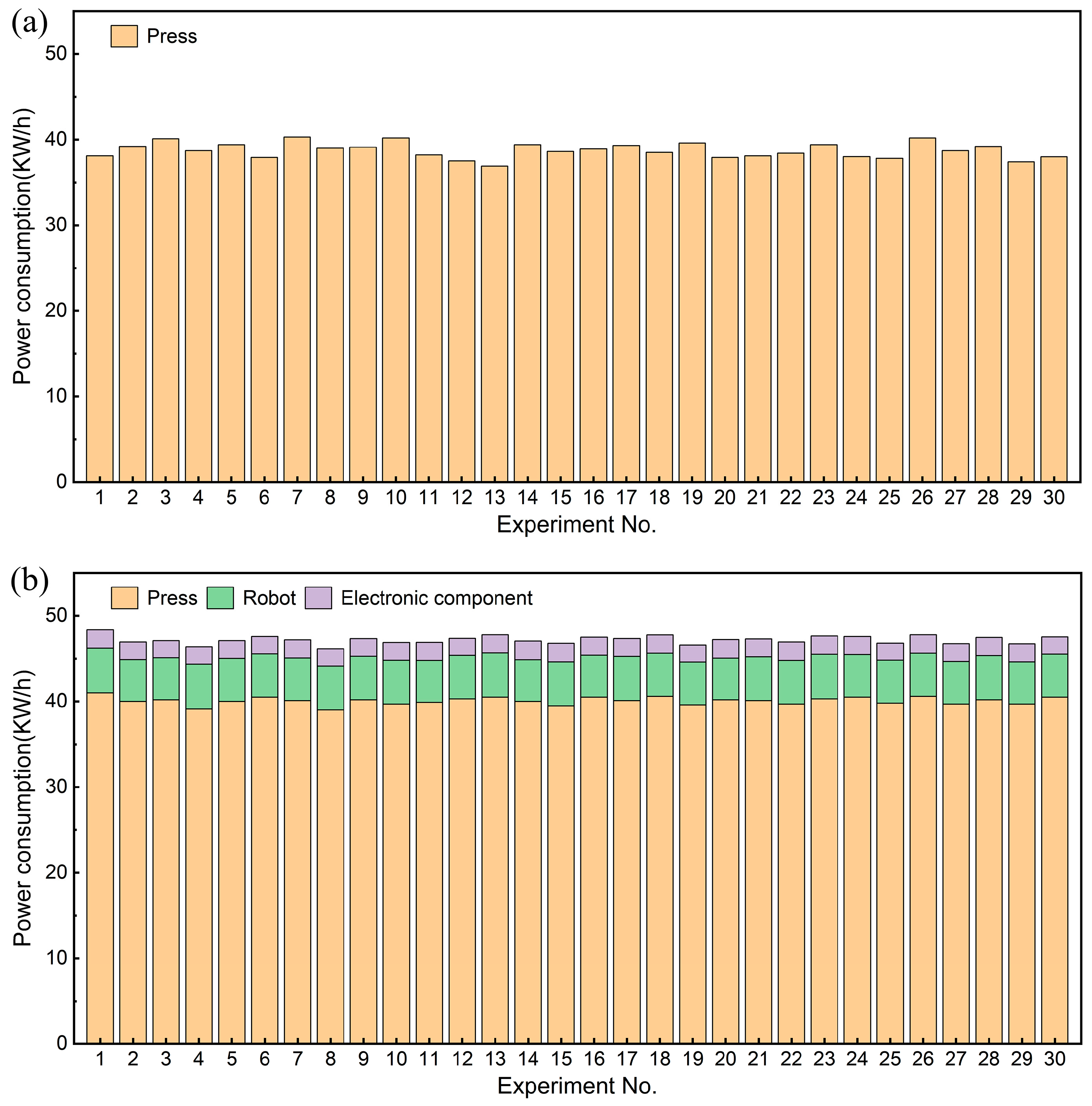

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Aravind, U.; Chakkingal, U.; Venugopal, P. A Review of Fine Blanking: Influence of Die Design and Process Parameters on Edge Quality. J. Mater. Eng. Perform. 2021, 30, 1–32. [Google Scholar] [CrossRef]

- Sahli, M.; Roizard, X.; Assoul, M.; Colas, G.; Giampiccolo, S.; Barbe, J.P. Finite element simulation and experimental investigation of the effect of clearance on the forming quality in the fine blanking process. Microsyst. Technol. 2021, 27, 871–881. [Google Scholar] [CrossRef]

- Zal, V.; Naeini, H.M.; Bahramian, A.R.; Abbaszadeh, B. Experimental evaluation of blanking and piercing of PVC based composite and hybrid laminates. Adv. Manuf. 2016, 4, 248–256. [Google Scholar] [CrossRef]

- Li, G.; Long, X.; Yang, P.; Liang, Z. Advance on friction of stamping forming. Int. J. Adv. Manuf. Technol. 2018, 96, 21–38. [Google Scholar] [CrossRef]

- Liu, Y.; Cheng, T.; Hua, L.; Mao, H. Research on the effect of ultrasonic vibration on the roll-over during the fine blanking process. J. Mech. Sci. Technol. 2017, 31, 835–843. [Google Scholar] [CrossRef]

- Ma, J.; Kremer, G.E.O. A systematic literature review of modular product design (MPD) from the perspective of sustainability. Int. J. Adv. Manuf. Technol. 2016, 86, 1509–1539. [Google Scholar] [CrossRef]

- Zhang, Z.-Y.; Wang, X.-D.; Ren, T.-Q.; Jin, T.-L. Novel gripper module and method for automated assembly of miniature parts. Adv. Manuf. 2023, 11, 295–310. [Google Scholar] [CrossRef]

- Ostrosi, E.; Fougères, A.-J.; Zhang, Z.-F.; Stjepandić, J. Intelligent modular design with holonic fuzzy agents. Adv. Manuf. 2021, 9, 81–103. [Google Scholar] [CrossRef]

- Salvador, F. Toward a Product System Modularity Construct: Literature Review and Reconceptualization. IEEE Trans. Eng. Manag. 2007, 54, 219–240. [Google Scholar] [CrossRef]

- Bonvoisin, J.; Halstenberg, F.; Buchert, T.; Stark, R. A systematic literature review on modular product design. J. Eng. Des. 2016, 27, 488–514. [Google Scholar] [CrossRef]

- Moosavian, A.; Xi, F. Modular design of parallel robots with static redundancy. Mech. Mach. Theory 2016, 96, 26–37. [Google Scholar] [CrossRef]

- Vega-Heredia, M.; Mohan, R.E.; Wen, T.Y.; Aisyah, J.S.; Vengadesh, A.; Ghanta, S.; Vinu, S. Design and modelling of a modular window cleaning robot. Autom. Constr. 2019, 103, 268–278. [Google Scholar] [CrossRef]

- Zhang, B.; Hu, C.; Yang, P.; Liao, Z.; Liao, H. Design and Modularization of Multi-DoF Soft Robotic Actuators. IEEE Robot. Autom. Lett. 2019, 4, 2645–2652. [Google Scholar] [CrossRef]

- Song, Z.; Liu, C.; Chai, F.; Zhao, H. Modular Design of an Efficient Permanent Magnet Vernier Machine. IEEE Trans. Magn. 2020, 56, 7506406. [Google Scholar] [CrossRef]

- Giusti, A.; Althoff, M. On-the-Fly Control Design of Modular Robot Manipulators. IEEE Trans. Control Syst. Technol. 2018, 26, 1484–1491. [Google Scholar] [CrossRef]

- Lu, S.; Ahmad, Z.; Zoppi, M.; Ding, X.; Zlatanov, D.; Molfino, R. Design and Testing of a Highly Reconfigurable Fixture with Lockable Robotic Arms. J. Mech. Des. 2016, 138, 085001. [Google Scholar] [CrossRef]

- Yu, S.; Ye, C.; Tao, G.; Ding, J.; Wang, Y. Design and analysis of a modular rope-climbing robot with the finger-wheeled mechanism. J. Mech. Sci. Technol. 2021, 35, 2197–2207. [Google Scholar] [CrossRef]

- Bai, Y.; Sun, L.; Zhang, M. Design and analysis of multistage adaptive lateral deformation tracked robot. J. Mech. Sci. Technol. 2022, 36, 371–383. [Google Scholar] [CrossRef]

- Ji, W.; Wang, L. Industrial robotic machining: A review. Int. J. Adv. Manuf. Technol. 2019, 103, 1239–1255. [Google Scholar] [CrossRef]

- Kodaira, N. Expected innovation in industrial robots. Adv. Robot. 2016, 30, 1088–1094. [Google Scholar] [CrossRef]

- Li, Z.; Li, S.; Luo, X. An overview of calibration technology of industrial robots. IEEE/CAA J. Autom. Sin. 2021, 8, 23–36. [Google Scholar] [CrossRef]

- Kurka, P.R.G.; Díaz Salazar, A.A. Applications of image processing in robotics and instrumentation. Mech. Syst. Signal Process. 2019, 124, 142–169. [Google Scholar] [CrossRef]

- Ruan, D.; Zhang, W.; Qian, D. Feature-based autonomous target recognition and grasping of industrial robots. Pers. Ubiquitous Comput. 2023, 27, 1355–1367. [Google Scholar] [CrossRef]

- Gao, M.; Li, X.; He, Z.; Yang, Y. An Automatic Assembling System for Sealing Rings Based on Machine Vision. J. Sens. 2017, 2017, 4207432. [Google Scholar] [CrossRef]

- Dhiman, A.; Shah, N.; Adhikari, P.; Kumbhar, S.; Dhanjal, I.S.; Mehendale, N. Firefighting robot with deep learning and machine vision. Neural Comput. Appl. 2022, 34, 2831–2839. [Google Scholar] [CrossRef]

- Ayyad, A.; Halwani, M.; Swart, D.; Muthusamy, R.; Almaskari, F.; Zweiri, Y. Neuromorphic vision based control for the precise positioning of robotic drilling systems. Robot. Comput.-Integr. Manuf. 2023, 79, 102419. [Google Scholar] [CrossRef]

- Banafian, N.; Fesharakifard, R.; Menhaj, M.B. Precise seam tracking in robotic welding by an improved image processing approach. Int. J. Adv. Manuf. Technol. 2021, 114, 251–270. [Google Scholar] [CrossRef]

- Koskinopoulou, M.; Raptopoulos, F.; Papadopoulos, G.; Mavrakis, N.; Maniadakis, M. Robotic Waste Sorting Technology: Toward a Vision-Based Categorization System for the Industrial Robotic Separation of Recyclable Waste. IEEE Robot. Autom. Mag. 2021, 28, 50–60. [Google Scholar] [CrossRef]

- Wang, Z.; Li, P.; Zhang, H.; Zhang, Q.; Ye, C.; Han, W.; Tian, W. A binocular vision method for precise hole recognition in satellite assembly systems. Measurement 2023, 221, 113455. [Google Scholar] [CrossRef]

| Basic Functional Requirements | Module Division |

|---|---|

| Separation and positioning of blanks | Separation unit |

| Deviation detection and robot position calibration of blanks | Loading unit |

| Conveying of finished products and flashes after automatic blanking | Blanking unit |

| Affiliated Unit | Mechanical Component | Subassembly | Model | Specification |

|---|---|---|---|---|

| Separation unit | Support frame | Square tube | — | 50 × 50 × 2.5 mm |

| Linear motor | — | MSX84-MR | Stroke: 400 mm; Power: 100 W | |

| Separation component | Guide rail | SBR support rail | Φ10 × 1900 mm | |

| Supporting cylinder I | TN16X70S_0 | Cylinder diameter: 16 mm; Stroke: 70 mm | ||

| Supporting cylinder II | TN10X10S_0 | Cylinder diameter: 10 mm; Stroke: 10 mm | ||

| Separation cylinder I | TN16X60S_0 | Cylinder diameter: 16 mm; Stroke: 60 mm | ||

| Separation cylinder II | TN16X20S_0 | Cylinder diameter: 16 mm; Stroke: 20 mm | ||

| Tension box | P022 | Line length: 2 m; Tension: 3.5 kg | ||

| Loading unit | Loading robot | — | FANUC LR Mate 200 | Working load:7 kg |

| Image recognition system | Industrial camera | MV-CS060-10GC | F = 16; Sensor: CMOS/IMX178 | |

| Strip light source | MV-LLDS-372 | P = 31.2 W; Color temperature: 6000~7000 K | ||

| Industrial control computer | MV-VC3701P-128G66 | Processor: Intel G5400T 3.1 GHz RAM: 8 GB | ||

| Blank fixture | Electromagnet | HKNAP70 35 30 | P70 × 35 × 30 DC12V | |

| Miniature cylinder | AIRTAC/MIJ | Cylinder diameter: 10 mm; Stroke: 10 mm | ||

| Support frame | Square tube | — | 50 × 50 × 2.5 mm | |

| Blanking unit | Unloading cylinder | — | TCMJ25x80-20 | Cylinder diameter: 20 mm; Stroke: 80 mm |

| Conveying device | Oscillating cylinder | HRQ50A-SBD | Cylinder diameter: 50 mm; Rotation range: 0~190° | |

| Servo motor | MS1H1-20B30CB-T331Z | Power: 200 W; Speed: 3000 rpm | ||

| Aluminum profile | MV-8-4080GL | 40 × 80 mm |

| Serial No. | Inclination Angle (θ)/° | End Height (h)/mm |

|---|---|---|

| 1 | 11 | 1427 |

| 2 | 13 | 1493 |

| 3 | 15 | 1559 |

| 4 | 17 | 1623 |

| 5 | 19 | 1687 |

| 6 | 21 | 1750 |

| 7 | 23 | 1811 |

| 8 | 25 | 1872 |

| Task Name | Average Time/s |

|---|---|

| Separation and pickup of blanks | 1.4 |

| Deviation detection | 0.1 |

| Loading of blanks | 3.8 |

| Blanking and unloading | 1.7 |

| Processing of single blanks | 7.0 |

| Serial No. | Success Rate of Separation Device | Average Daily Output | Defective Rate | Number of Manual Interventions | Reason for Intervention |

|---|---|---|---|---|---|

| 1 | 100% | 4508 | 2.9% | 1 | Vision system II alarm |

| 2 | 100% | 4583 | 2.3% | 0 | — — — |

| 3 | 100% | 4462 | 3.4% | 2 | Vision system II alarm |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Du, X.; Li, J.; Wang, H.; Li, Z.; Li, Y.; Li, Z. Novel Workstation Module and Method for Automatic Blanking of Surgical Forceps. Machines 2024, 12, 556. https://doi.org/10.3390/machines12080556

Du X, Li J, Wang H, Li Z, Li Y, Li Z. Novel Workstation Module and Method for Automatic Blanking of Surgical Forceps. Machines. 2024; 12(8):556. https://doi.org/10.3390/machines12080556

Chicago/Turabian StyleDu, Xianzhen, Jiapeng Li, Haochen Wang, Zhenyu Li, Yusheng Li, and Zhiyuan Li. 2024. "Novel Workstation Module and Method for Automatic Blanking of Surgical Forceps" Machines 12, no. 8: 556. https://doi.org/10.3390/machines12080556

APA StyleDu, X., Li, J., Wang, H., Li, Z., Li, Y., & Li, Z. (2024). Novel Workstation Module and Method for Automatic Blanking of Surgical Forceps. Machines, 12(8), 556. https://doi.org/10.3390/machines12080556