Material Extrusion 3D Printing of Micro-Porous Copper-Based Structure for Water Filters

Abstract

1. Introduction

2. Materials and Methods

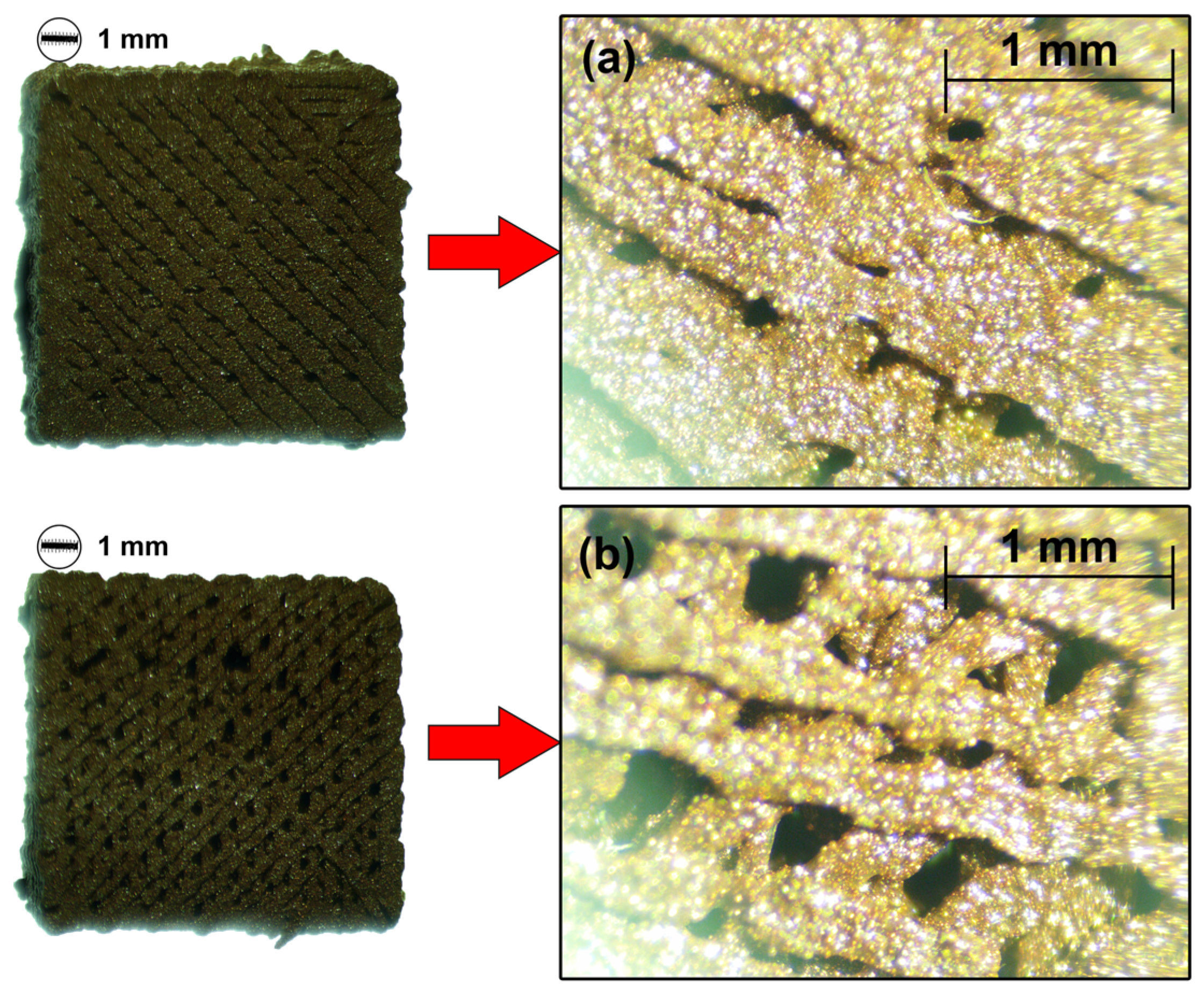

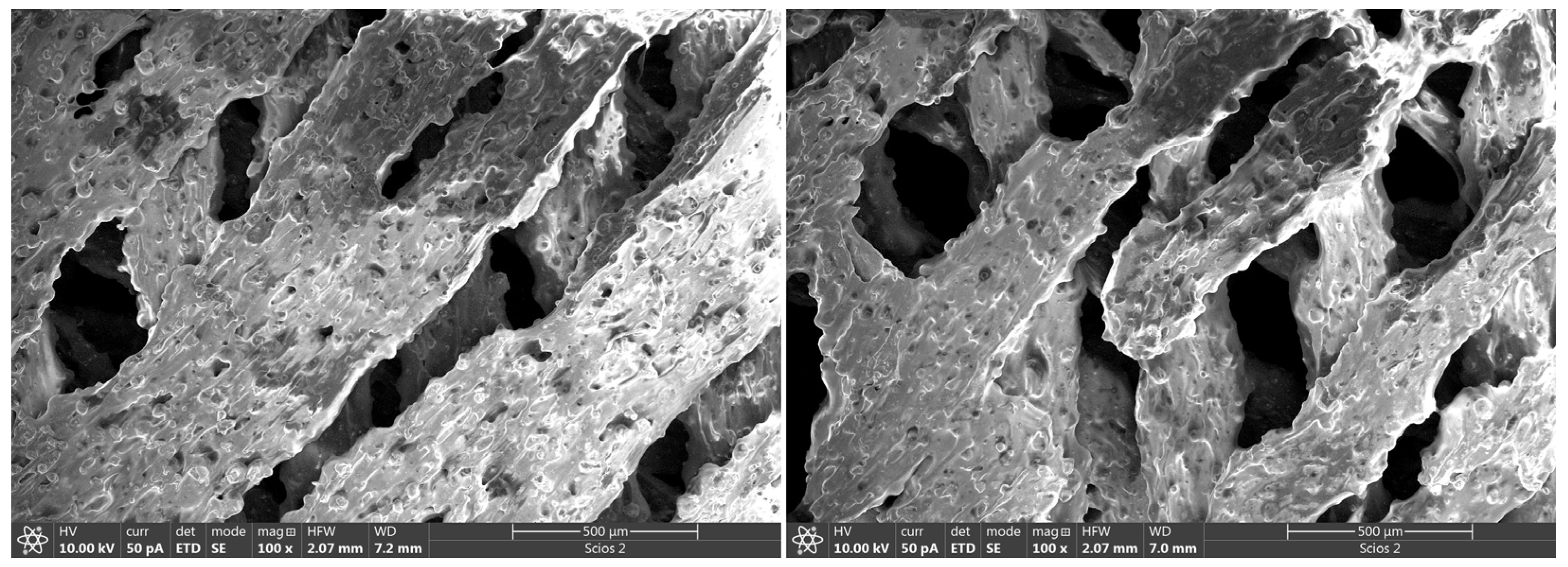

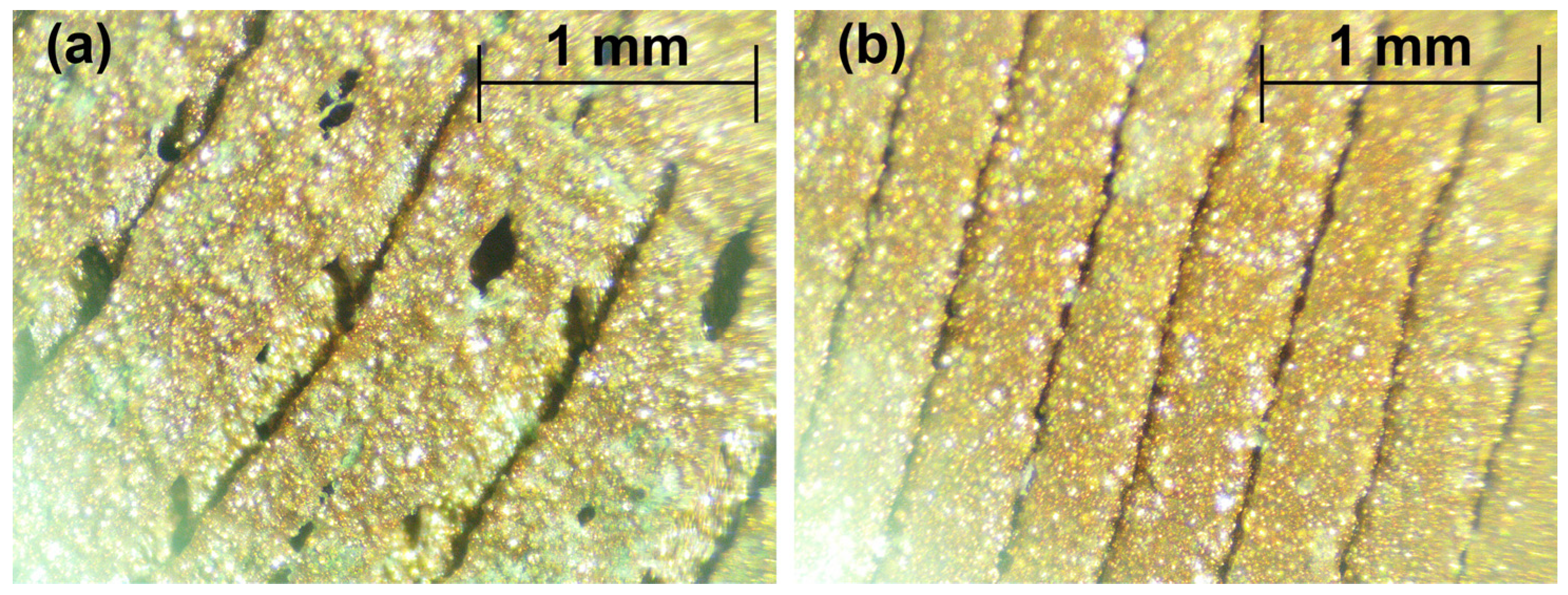

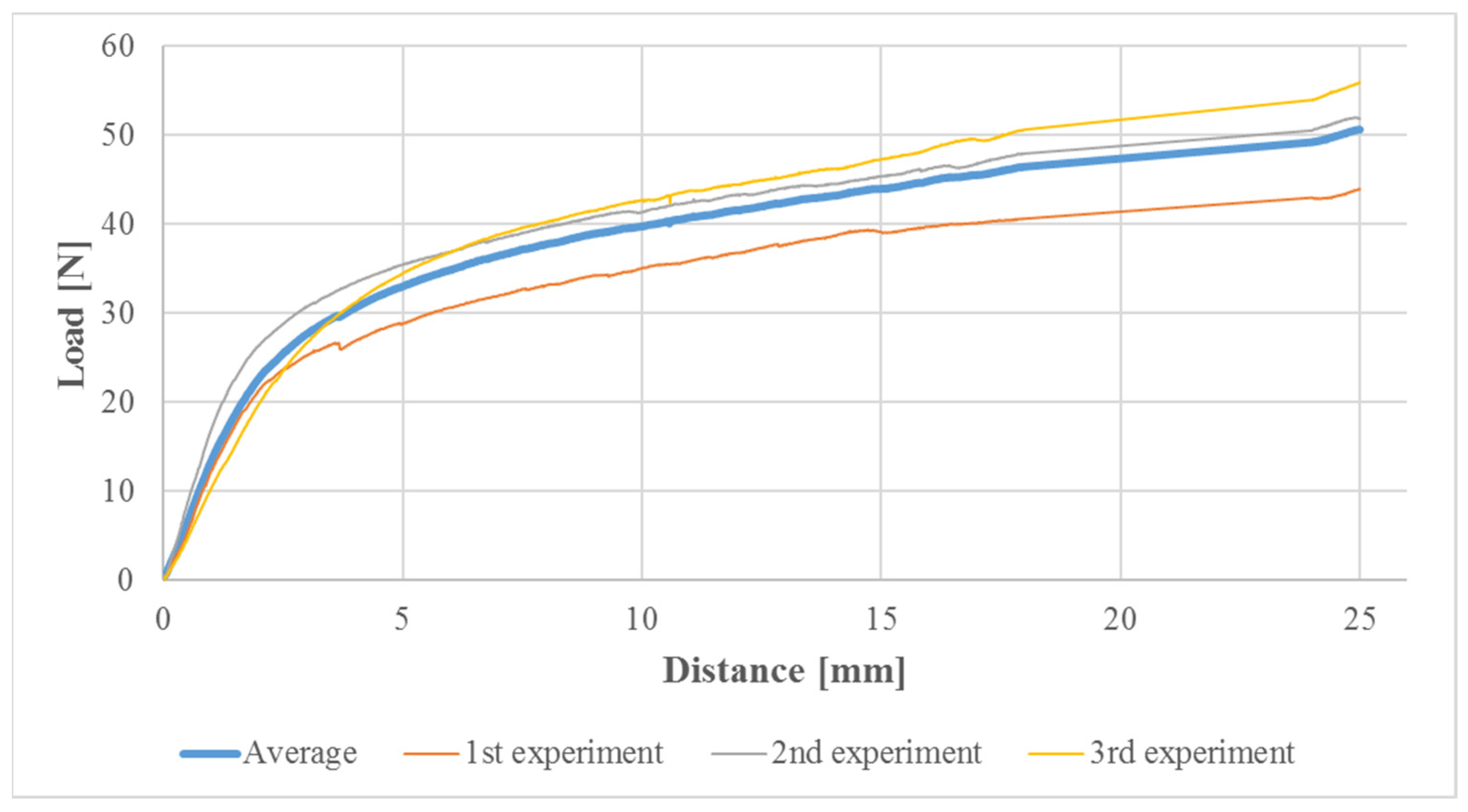

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Alexander, A.E.; Wake, N.; Chepelev, L.; Brantner, P.; Ryan, J.; Wang, K.C. A Guideline for 3D Printing Terminology in Biomedical Research Utilizing ISO/ASTM Standards. 3D Print. Med. 2021, 7, 8. [Google Scholar] [CrossRef]

- Jaisingh Sheoran, A.; Kumar, H. Fused Deposition Modeling Process Parameters Optimization and Effect on Mechanical Properties and Part Quality: Review and Reflection on Present Research. Mater. Today Proc. 2020, 21, 1659–1672. [Google Scholar] [CrossRef]

- Huu, N.H.; Phuoc, D.P.; Huu, T.N.; Thu, H.T.T. Optimization of The FDM Parameters to Improve the Compressive Strength of the PLA-Copper Based Products. IOP Conf. Ser. Mater. Sci. Eng. 2019, 530, 012001. [Google Scholar] [CrossRef]

- Pazhamannil, R.V.; Jishnu Namboodiri, V.N.; Govindan, P.; Edacherian, A. Property Enhancement Approaches of Fused Filament Fabrication Technology: A Review. Polym. Eng. Sci. 2022, 62, 1356–1376. [Google Scholar] [CrossRef]

- Buj-Corral, I.; Sivatte-Adroer, M. An Experimental Investigation about the Dimensional Accuracy and the Porosity of Copper-Filled PLA Fused Filament Fabrication Parts. Metals 2023, 13, 1608. [Google Scholar] [CrossRef]

- Mengesha Medibew, T. A Comprehensive Review on the Optimization of the Fused Deposition Modeling Process Parameter for Better Tensile Strength of PLA-Printed Parts. Adv. Mater. Sci. Eng. 2022, 2022, 1–11. [Google Scholar] [CrossRef]

- Ahmad, M.N.; Ishak, M.R.; Mohammad Taha, M.; Mustapha, F.; Leman, Z. A Review of Natural Fiber-Based Filaments for 3D Printing: Filament Fabrication and Characterization. Materials 2023, 16, 4052. [Google Scholar] [CrossRef]

- Dzindziora, A.; Sulowski, M.; Dzienniak, D. Application of Composite Filament with the Addition of Metallic Powders in 3D Printing. Mater. Sci. Forum 2023, 1081, 109–114. [Google Scholar] [CrossRef]

- Vu, M.C.; Jeong, T.; Kim, J.; Choi, W.K.; Kim, D.H.; Kim, S. 3D Printing of Copper Particles and Poly(Methyl Methacrylate) Beads Containing Poly(Lactic Acid) Composites for Enhancing Thermomechanical Properties. J. Appl. Polym. Sci. 2021, 138, 49776. [Google Scholar] [CrossRef]

- Clark, M.J.; Garg, T.; Rankin, K.E.; Bradshaw, D.; Nightingale, A.M. 3D Printed Filtration and Separation Devices with Integrated Membranes and No Post-Printing Assembly. React. Chem. Eng. 2024, 9, 251–259. [Google Scholar] [CrossRef]

- Fijoł, N.; Mathew, A.P. Accelerated Ageing of 3D Printed Water Purification Filters Based on PLA Reinforced with Green Nanofibers. Polym. Test. 2023, 129, 108270. [Google Scholar] [CrossRef]

- Piekarz, I.; Sorocki, J.; Wincza, K.; Gruszczynski, S.; Papapolymerou, J. Suspended Microstrip Low-Pass Filter Realized Using FDM Type 3D Printing with Conductive Copper-Based Filament. In Proceedings of the 2018 IEEE 68th Electronic Components and Technology Conference (ECTC), San Diego, CA, USA, 29 May–1 June 2018; pp. 2470–2476. [Google Scholar]

- Avşar Aydın, E.; Torun, A.R. 3D Printed PLA/Copper Bowtie Antenna for Biomedical Imaging Applications. Phys. Eng. Sci. Med. 2020, 43, 1183–1193. [Google Scholar] [CrossRef] [PubMed]

- Zárybnická, L.; Machová, D.; Dvořák, K. Effect of Copper or Carbon Fiber Addition to the 3D Printing of Polylactid Samples. Mater. Test. 2020, 62, 727–732. [Google Scholar] [CrossRef]

- Ji, Q.; Wei, J.; Yi, J.; Zhang, L.; Ma, J.; Wang, Z. Study on the Static and Dynamic Mechanical Properties and Constitutive Models of 3D Printed PLA and PLA-Cu Materials. Mater. Today Commun. 2024, 39, 108690. [Google Scholar] [CrossRef]

- Kesavarma, S.; Lee, E.H.; Samykano, M.; Kadirgama, K.; Rahman, M.M.; Sofiah, A.G.N. Flextural Properties of 3D Printed Copper-Filler Polylactic Acid (Cu-PLA). IOP Conf. Ser. Mater. Sci. Eng. 2020, 788, 012051. [Google Scholar] [CrossRef]

- Nishal, M.; Ram Prasad, K.; Salman Dasthageer, M.; Ragunath, A.G. Significance of Additive Manufacturing amidst the Pandemic. Mater. Today Proc. 2023, 72, 2540–2546. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, W.; Al-Marzouqi, A.H.; Nazir, M.H.; Rizvi, T.A.; Zaneldin, E.; Khan, M. Comparative Experimental Investigation of Biodegradable Antimicrobial Polymer-Based Composite Produced by 3D Printing Technology Enriched with Metallic Particles. Int. J. Mol. Sci. 2022, 23, 11235. [Google Scholar] [CrossRef] [PubMed]

- Pavan, M.V.; Balamurugan, K.; Balamurugan, P. Compressive Test Fractured Surface Analysis on PLA-Cu Composite Filament Printed at Different FDM Conditions. IOP Conf. Ser. Mater. Sci. Eng. 2020, 988, 012019. [Google Scholar] [CrossRef]

- Ambruș, S.; Muntean, R.; Kazamer, N.; Codrean, C. Post-processing Technologies of Copper–Polylactic Acid Composites Obtained by 3D Printing Fused Deposition Modeling. Mater. Des. Process. Commun. 2021, 3, e251. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, Y.; Qiu, S.; Wang, C.; Zhang, H.; Guo, J.; Wang, S.; Ma, H. 3D-Printed Filters for Efficient Heavy Metal Removal from Water Using PLA@CS/HAP Composites. Polymers 2023, 15, 4144. [Google Scholar] [CrossRef]

- Fu, F.; Wang, Q. Removal of Heavy Metal Ions from Wastewaters: A Review. J. Environ. Manag. 2011, 92, 407–418. [Google Scholar] [CrossRef]

- Lehnen, A.; Hanke, S.; Schneider, M.; Radelof, C.M.L.; Perestrelo, J.; Reinicke, S.; Reifarth, M.; Taubert, A.; Arndt, K.M.; Hartlieb, M. Modification of 3D-Printed PLA Structures Using Photo-Iniferter Polymerization: Toward On-Demand Antimicrobial Water Filters. Macromol. Rapid Commun. 2023, 44, 2300408. [Google Scholar] [CrossRef]

- Fijoł, N.; Mautner, A.; Grape, E.S.; Bacsik, Z.; Inge, A.K.; Mathew, A.P. MOF@Cell: 3D Printed Biobased Filters Anchored with a Green Metal–Organic Framework for Effluent Treatment. J. Mater. Chem. A 2023, 11, 12384–12394. [Google Scholar] [CrossRef]

- Fijoł, N.; Aguilar-Sánchez, A.; Ruiz-Caldas, M.-X.; Redlinger-Pohn, J.; Mautner, A.; Mathew, A.P. 3D Printed Polylactic Acid (PLA) Filters Reinforced with Polysaccharide Nanofibers for Metal Ions Capture and Microplastics Separation from Water. Chem. Eng. J. 2023, 457, 141153. [Google Scholar] [CrossRef]

- Ballóková, B.; Lázár, M.; Jasminská, N.; Molčanová, Z.; Michalik, Š.; Brestovič, T.; Živčák, J.; Saksl, K. Development and Testing of Copper Filters for Efficient Application in Half-Face Masks. Appl. Sci. 2022, 12, 6824. [Google Scholar] [CrossRef]

- Gupta, S. Design and Model of Facemask to Inactivate the Novel Coronavirus. Int. J. Glob. Environ. Issues 2021, 20, 241. [Google Scholar] [CrossRef]

- Michailidis, N.; Stergioudi, F.; Seventekidis, P.; Tsouknidas, A.; Sagris, D. Production of Porous Copper with High Surface Area for Efficient Water Purification. CIRP J. Manuf. Sci. Technol. 2016, 13, 85–89. [Google Scholar] [CrossRef]

- Dinesh, K.R.; Deva, K.; Dinesh, B.R.; Pavithran, V. Water Purifier with Clogged Copper Filter. In Proceedings of the 2023 Intelligent Computing and Control for Engineering and Business Systems (ICCEBS), Chennai, India, 14 December 2023; IEEE: Chennai, India, 2023; pp. 1–5. [Google Scholar]

- Ayub, H.; Khan, L.A.; McCarthy, E.; Ahad, I.U.; Fleischer, K.; Brabazon, D. Investigating the Morphology, Hardness, and Porosity of Copper Filters Produced via Hydraulic Pressing. J. Mater. Res. Technol. 2022, 19, 208–219. [Google Scholar] [CrossRef]

- Ayub, H.; Khan, L.A.; McCarthy, E.; Ahad, I.U.; Sreenilayam, S.; Fleischer, K.; Brabazon, D. Investigating the Morphology, Hardness, and Porosity of Spherical and Dendritic Copper Powder Filters Produced via Cold Isostatic Pressing. In Characterization of Minerals, Metals, and Materials 2023; Zhang, M., Peng, Z., Li, B., Monteiro, S.N., Soman, R., Hwang, J.-Y., Kalay, Y.E., Escobedo-Diaz, J.P., Carpenter, J.S., Brown, A.D., et al., Eds.; The Minerals, Metals & Materials Series; Springer Nature Switzerland: Cham, Germany, 2023; pp. 207–218. ISBN 978-3-031-22575-8. [Google Scholar]

- Yoo, S.; Yang, I.; Jeong, J.; Chang, J.; Kim, S. Pure Metallic Nanofibrillar Membrane for High-Performance Electrostatic Air Filtration with Antimicrobial and Reusable Characteristics. Environ. Sci. Nano 2023, 10, 2437–2447. [Google Scholar] [CrossRef]

- Sun, X.; Dong, Z.; Cheng, K.; Chu, D.; Kong, D.; Hu, Y.; Duan, J. Fabrication of Oil–Water Separation Copper Filter by Spatial Light Modulated Femtosecond Laser. J. Micromechanics Microengineering 2020, 30, 065007. [Google Scholar] [CrossRef]

- Khew, S.Y.; Tan, C.F.; Yan, H.; Lin, S.; Thian, E.S.; Zhou, R.; Hong, M. Nanosecond Laser Ablation for Enhanced Adhesion of CuO Nanowires on Copper Substrate and Its Application for Oil-Water Separation. Appl. Surf. Sci. 2019, 465, 995–1002. [Google Scholar] [CrossRef]

- Wang, H.; Deng, D.; Zhai, Z.; Yao, Y. Laser-Processed Functional Surface Structures for Multi-Functional Applications-a Review. J. Manuf. Process. 2024, 116, 247–283. [Google Scholar] [CrossRef]

- Popescu, V.; Prodan, D.; Cuc, S.; Saroşi, C.; Furtos, G.; Moldovan, A.; Carpa, R.; Bomboş, D. Antimicrobial Poly (Lactic Acid)/Copper Nanocomposites for Food Packaging Materials. Materials 2023, 16, 1415. [Google Scholar] [CrossRef]

- Lyu, L.; Peng, H.; An, C.; Sun, H.; Yang, X.; Bi, H. An Insight into the Benefits of Substituting Polypropylene with Biodegradable Polylactic Acid Face Masks for Combating Environmental Emissions. Sci. Total Environ. 2023, 905, 167137. [Google Scholar] [CrossRef] [PubMed]

- Pierpaoli, M.; Giosuè, C.; Czerwińska, N.; Rycewicz, M.; Wieloszyńska, A.; Bogdanowicz, R.; Ruello, M.L. Characterization and Filtration Efficiency of Sustainable PLA Fibers Obtained via a Hybrid 3D-Printed/Electrospinning Technique. Materials 2021, 14, 6766. [Google Scholar] [CrossRef]

- Södergård, A.; Stolt, M. Properties of Lactic Acid Based Polymers and Their Correlation with Composition. Prog. Polym. Sci. 2002, 27, 1123–1163. [Google Scholar] [CrossRef]

- ISO 5167-1:2022; Measurement of Fluid Flow by Means of Pressure Differential Devices Inserted in Circular Cross-Section Conduits Running Full—Part 1: General Principles and Requirements. ISO Publications: Geneva, Switzerland, 2022.

- Açıkbaş, G.; Özcan, S.; Çalış Açıkbaş, N. Production and Characterization of a Hybrid Polymer Matrix Composite. Polym. Compos. 2018, 39, 4080–4093. [Google Scholar] [CrossRef]

- Mastalygina, E.E.; Olkhov, A.A.; Vorontsov, N.V.; Kiselev, N.V.; Khaidarov, T.B.; Khaydarov, B.B.; Kolesnikov, E.A.; Burmistrov, I.N. Influence of Copper-Based Fillers on Structural and Mechanical Properties of Polylactic Acid Composites. J. Compos. Sci. 2022, 6, 386. [Google Scholar] [CrossRef]

- Pinto, V.C.; Ramos, T.; Alves, S.; Xavier, J.; Tavares, P.; Moreira, P.M.G.P.; Guedes, R.M. Comparative Failure Analysis of PLA, PLA/GNP and PLA/CNT-COOH Biodegradable Nanocomposites Thin Films. Procedia Eng. 2015, 114, 635–642. [Google Scholar] [CrossRef]

- Li, X.; Wang, Q.; Wei, S.; Lou, W.; Liang, J.; Chen, L.; Xu, L.; Zhou, Y. Microstructure and High-Temperature Mechanical Properties of Cu-W Composite Prepared by Hot Isostatic Pressing. J. Alloys Compd. 2024, 970, 172571. [Google Scholar] [CrossRef]

- Mudakavi, D.; Sreesha, R.B.; Kumar, V.; Adinarayanappa, S.M. A Comprehensive Experimental Investigation on Mechanical Properties and Fracture Morphology of Particulate Composites via Material Extrusion-Based 3D Printing. Results Mater. 2022, 16, 100348. [Google Scholar] [CrossRef]

- Vakharia, V.S.; Kuentz, L.; Salem, A.; Halbig, M.C.; Salem, J.A.; Singh, M. Additive Manufacturing and Characterization of Metal Particulate Reinforced Polylactic Acid (PLA) Polymer Composites. Polymers 2021, 13, 3545. [Google Scholar] [CrossRef]

- Yilmaz, S.; Gul, O.; Eyri, B.; Karsli, N.G.; Yilmaz, T. Analyzing the Influence of Multimaterial 3D Printing and Postprocessing on Mechanical and Tribological Characteristics. Macromol. Mater. Eng. 2024, 309, 2300428. [Google Scholar] [CrossRef]

- Butt, J.; Oxford, P.; Sadeghi-Esfahlani, S.; Ghorabian, M.; Shirvani, H. Hybrid Manufacturing and Mechanical Characterization of Cu/PLA Composites. Arab. J. Sci. Eng. 2020, 45, 9339–9356. [Google Scholar] [CrossRef]

- Mohammadizadeh, M.; Lu, H.; Fidan, I.; Tantawi, K.; Gupta, A.; Hasanov, S.; Zhang, Z.; Alifui-Segbaya, F.; Rennie, A. Mechanical and Thermal Analyses of Metal-PLA Components Fabricated by Metal Material Extrusion. Inventions 2020, 5, 44. [Google Scholar] [CrossRef]

- Török, J.; Törökova, M.; Duplakova, D.; Murcinkova, Z.; Duplak, J.; Kascak, J.; Karkova, M. Advanced Configuration Parameters of Post Processor Influencing Tensile Testing PLA and Add-Mixtures in Polymer Matrix in the Process of FDM Technology. Appl. Sci. 2021, 11, 6212. [Google Scholar] [CrossRef]

- Butt, J.; Bhaskar, R. Investigating the Effects of Annealing on the Mechanical Properties of FFF-Printed Thermoplastics. J. Manuf. Mater. Process. 2020, 4, 38. [Google Scholar] [CrossRef]

- Thumsorn, S.; Prasong, W.; Kurose, T.; Ishigami, A.; Kobayashi, Y.; Ito, H. Rheological Behavior and Dynamic Mechanical Properties for Interpretation of Layer Adhesion in FDM 3D Printing. Polymers 2022, 14, 2721. [Google Scholar] [CrossRef]

- Jabbar Khan, A.; Mateen, A.; Khan, S.; He, L.; Wang, W.; Numan, A.; Peng, K.; Ahmed Malik, I.; Hussain, I.; Zhao, G. 3D Printed Micro-Electrochemical Energy Storage Devices. Batter. Supercaps 2023, 6, e202300190. [Google Scholar] [CrossRef]

- Chen, Y.; Wu, C.; Wei, X.; Meng, X.; Liu, J.; Wang, Q. Morphology Analysis and Process Optimization of Micro-Cylinder Structure in Micro-Nano Additive Manufacturing. J. Mech. Eng. 2023, 59, 286. [Google Scholar] [CrossRef]

- Peng, S.; Sun, S.; Zhu, Y.; Qiu, J.; Yang, H. Colourful 3D Anti-Counterfeiting Label Using Nanoscale Additive Manufacturing. Virtual Phys. Prototyp. 2023, 18, e2179929. [Google Scholar] [CrossRef]

- Jayasinghe, S.N. Electrospray Printing: Unravelling the History of a Support Free Three-Dimensional Additive Manufacturing Technology. Mater. Today 2023, 62, 14–20. [Google Scholar] [CrossRef]

- Menétrey, M.; Koch, L.; Sologubenko, A.; Gerstl, S.; Spolenak, R.; Reiser, A. Targeted Additive Micromodulation of Grain Size in Nanocrystalline Copper Nanostructures by Electrohydrodynamic Redox 3D Printing. Small 2022, 18, 2205302. [Google Scholar] [CrossRef] [PubMed]

- Song, P.; Zhou, C.; Fan, H.; Zhang, B.; Pei, X.; Fan, Y.; Jiang, Q.; Bao, R.; Yang, Q.; Dong, Z.; et al. Novel 3D Porous Biocomposite Scaffolds Fabricated by Fused Deposition Modeling and Gas Foaming Combined Technology. Compos. Part B Eng. 2018, 152, 151–159. [Google Scholar] [CrossRef]

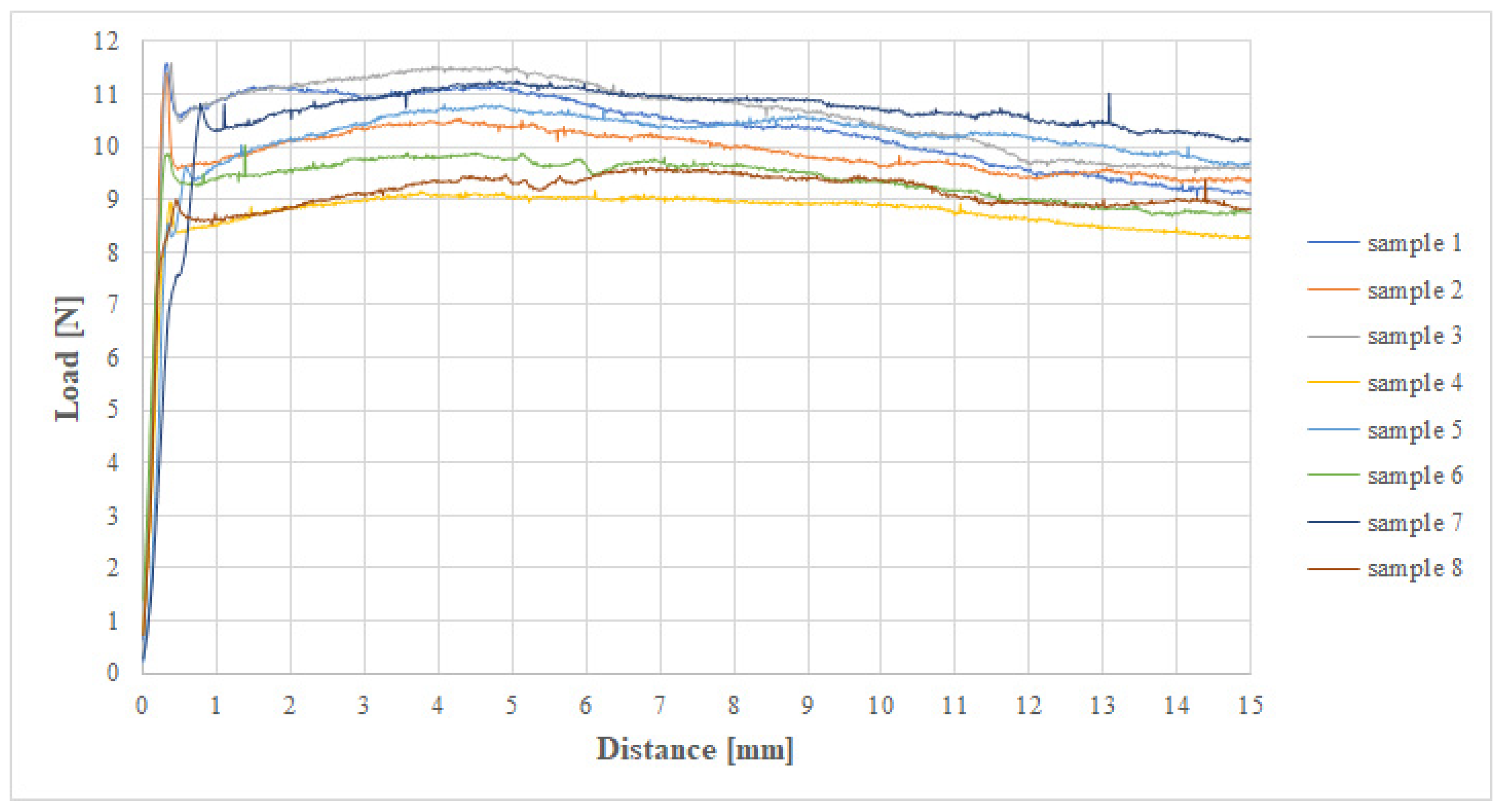

| Sample | Linear Distance [mm] | Nozzle Temperature [°C] | Build Plate Temperature [°C] |

|---|---|---|---|

| 1 | 0.4 | 210 | 60 |

| 2 | 0.4 | 210 | 70 |

| 3 | 0.4 | 220 | 60 |

| 4 | 0.4 | 220 | 70 |

| 5 | 0.5 | 210 | 60 |

| 6 | 0.5 | 210 | 70 |

| 7 | 0.5 | 220 | 60 |

| 8 | 0.5 | 220 | 70 |

| Sample Number | Sample Mass, m [g] | Density of Sample, ρ [g/cm3] | Percentage of Theoretical Density, %T.D. [%] | Percentage of Total Porosity, %T.P. [%] |

|---|---|---|---|---|

| 1 | 0.906 | 1.759 | 48.874 | 51.126 |

| 2 | 0.895 | 1.665 | 46.253 | 53.747 |

| 3 | 0.988 | 1.845 | 51.253 | 48.747 |

| 4 | 0.894 | 1.785 | 49.592 | 50.408 |

| 5 | 0.679 | 1.188 | 32.988 | 67.012 |

| 6 | 0.682 | 1.370 | 38.058 | 61.942 |

| 7 | 0.689 | 1.335 | 37.094 | 62.906 |

| 8 | 0.685 | 1.556 | 43.222 | 56.778 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kotorčević, N.; Milenković, S.; Živić, F.; Jordović, B.; Adamović, D.; Todorović, P.; Grujović, N. Material Extrusion 3D Printing of Micro-Porous Copper-Based Structure for Water Filters. Machines 2024, 12, 470. https://doi.org/10.3390/machines12070470

Kotorčević N, Milenković S, Živić F, Jordović B, Adamović D, Todorović P, Grujović N. Material Extrusion 3D Printing of Micro-Porous Copper-Based Structure for Water Filters. Machines. 2024; 12(7):470. https://doi.org/10.3390/machines12070470

Chicago/Turabian StyleKotorčević, Nikola, Strahinja Milenković, Fatima Živić, Branka Jordović, Dragan Adamović, Petar Todorović, and Nenad Grujović. 2024. "Material Extrusion 3D Printing of Micro-Porous Copper-Based Structure for Water Filters" Machines 12, no. 7: 470. https://doi.org/10.3390/machines12070470

APA StyleKotorčević, N., Milenković, S., Živić, F., Jordović, B., Adamović, D., Todorović, P., & Grujović, N. (2024). Material Extrusion 3D Printing of Micro-Porous Copper-Based Structure for Water Filters. Machines, 12(7), 470. https://doi.org/10.3390/machines12070470