1. Introduction

Suspension systems are significant elements in modern cars [

1]. Suspension systems can be categorized into three groups according to the mold of the dampers [

2]: passive, semi-active, and active suspension systems. Unlike the passive and semi-active forms, there are active actuators that generate active force, which can elevate their properties to a great extent [

3].

With constant technological improvement, on the one hand, a wide variety of sensors are used in suspension systems to monitor the conditions of roads and the movement of vehicles. On the other hand, plentiful control solutions have been applied in control mechanisms. Based on the aforementioned circumstances, a car can maintain optimal balance and control due to active control technology, which lessens shocks and vibrations and enhances ride stability and comfort for the occupants.

Therefore, the control strategy for active suspension has become a hot research topic. Today, active suspension systems are widely used in automobiles. In [

4], an MPC control technology was used in air suspension systems equipped with a multi-mode switching damper. The authors of [

5] presented the

control method under constrained conditions. The authors of [

6] presented a hybrid

and

control algorithm for active suspension. In [

7], a multi-complex model based on predictive control was presented. Ref. [

8] presented a multi-agent approach for active steering and active suspension. For time-varying parameter uncertainty, a robust infinity control method is discussed [

9].

The linear suspension system is the main topic of traditional studies. However, springs and dampers in suspension systems display some nonlinear characteristics, and their precise manifestations are unexpected. As a result, suspension systems are typical nonlinear systems. When the initial nonlinearity of suspension systems is ignored, this can bring about a worse impact on the control effect and significantly reduce the model’s accuracy [

10]. Therefore, nonlinear models serve as the foundation for research with significant practical value.

It is worth noting that the majority of the studies mentioned above were based on the assumption that a suspension system can work at its best; therefore, all of the results stated above are consistent with the premise that every system’s control component is running at its best.

However, vehicle suspension systems are intricate and made up of mechanical, electronic, and other components. As the amount of time spent working rises, certain other unsetting elements can lead to the failure of suspension systems and actuators. In addition, system procedures are highly difficult due to the inherent uncertainties of active suspension systems. Common failures that happen to the actuator consist of gain variation, constant deviation, and seizure failure [

11,

12].

When a common failure of an actuator occurs, traditional controllers cannot perform better. Active suspension systems are sensitive and prone to faults due to their sophisticated design and demanding operating circumstances, which could result in the system performing poorly or failing. To guarantee the control effect when actuator failure occurs, fault-tolerant controllers have been designed. Fault tolerance can ensure the stability of a suspension. Fault-tolerant control techniques that can make up for a failure and keep a closed-loop system operating at a satisfactory rate have been the focus of numerous studies in recent years due to their theoretical and practical significance.

The difficulties rest with reliable fault-tolerant control. Therefore, the design of reliable fault-tolerant controllers has been a topic of extensive study. For example, in [

13], a sliding-mode control method was presented for a linear active suspension with sensor and actuator faults. A reliable fuzzy-based robust feedback strategy was discussed for a vehicle suspension with actuator faults [

14]. The authors of [

15] discussed a robust fault-tolerant controller for active suspension systems with finite frequency constraints. A fuzzy-based fault-tolerant controller was discussed for an electromagnetic system [

16]. In [

17], a feedback-observer-based fault-tolerant controller was presented for active suspension systems.

Sliding-mode control (SMC) is a unique form of nonlinear control that is extremely resilient to uncertain models and disturbances. In addition, SMC is a specific type of nonlinear control method and is extremely resilient to parameter uncertainty and perturbations outside the model [

18]. Numerous studies have used sliding-mode control in active controlling problems. In [

19], a PID-based SMC controller was designed. In [

20], an SMC fault-tolerant controller was used to ensure the suspension performance with actuator failure.

In real systems, sliding-mode control generates high-frequency vibration, and this jittering vibration can affect the accuracy of the system or even destroy it, which affects the control effectiveness of the system. Therefore, scholars have focused their attention on solving the jittering vibration problem of SMC.

However, it is not influenced by changes in control object parameters and the interference of external conditions, and it has very good robustness. Therefore, the jitter vibration problem of sliding-mode control cannot be eliminated but only attenuated. Currently, the commonly used methods are the boundary layer method [

21,

22], the adjustment of the convergence law [

23], and intelligent technology methods.

For example, the authors of [

24] designed a hybrid controller by combining fuzzy control and a sliding-mode approach. For better robustness, global optimality, feasibility, and high efficiency in solving nonlinear problems with high optimization performance, genetic algorithms (GAs) are used in SMC [

25]. Particle swarm optimization (PSO) is also used in SMC to enhance the control effect [

26]. In addition, there are sector characterization approaches, filtering approaches, observer approaches, and so on [

27]. The existing research results show that the use of the fractional-order control strategy is better than the integer-order control strategy [

28]. Based on fractional-order theory, the fractional order is used in SMC to reduce the jitter vibration problem.

In addition, the switching gain in SMC also affects the control effect and can cause a jitter vibration problem.

RBF neural networks have a strong self-learning function and a strong ability to transfer to nonlinear systems. It is possible to approximate the model information of a controlled object and the imposed disturbance using the neural network’s universal approximation property, and with the help of the neural network’s adaptive weight adjustments, it is possible to achieve adaptive neural fully naked sliding-mode control without the use of model information.

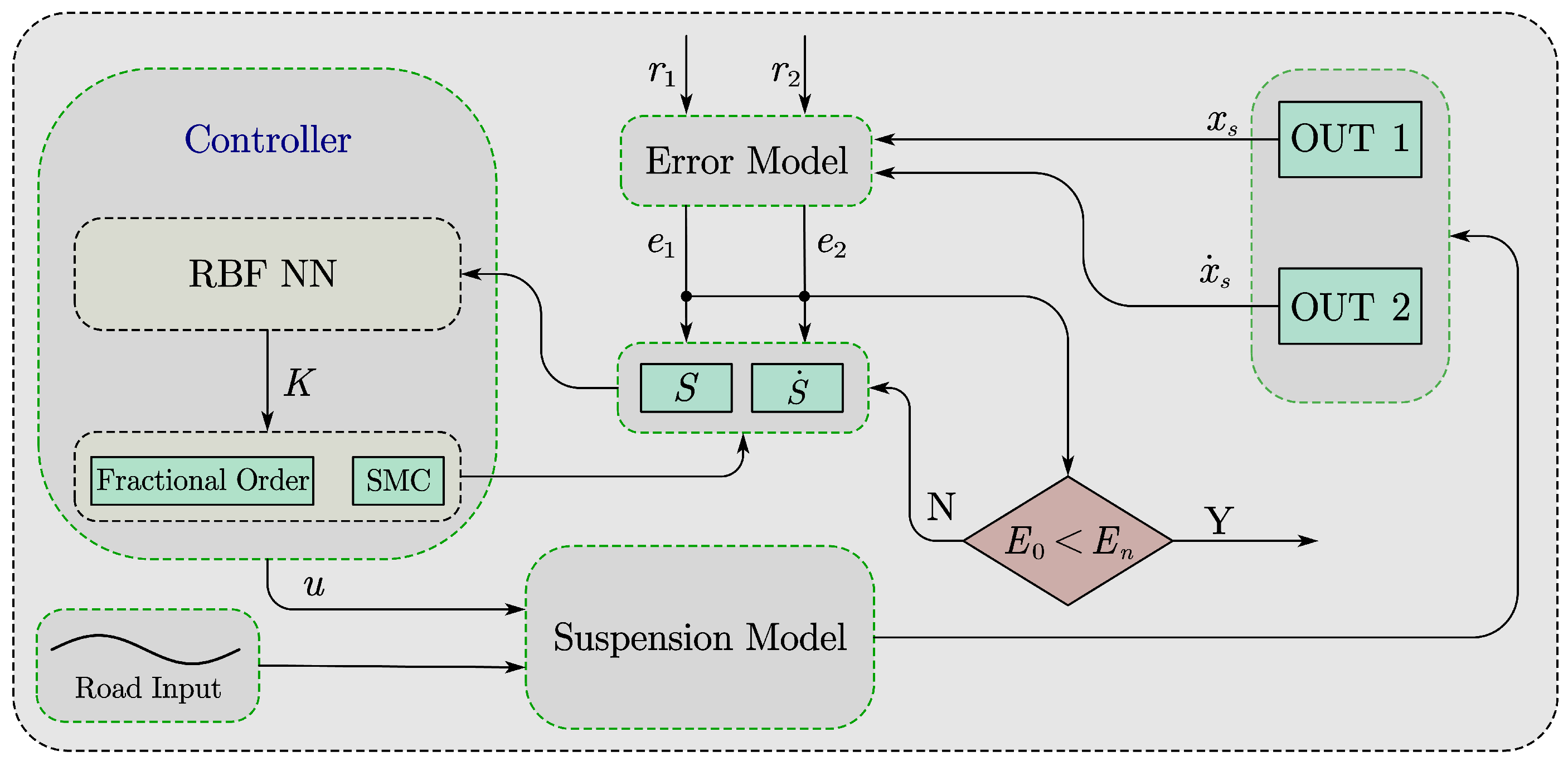

Consequently, in this study, an RBF-based fractional-order SMC fault-tolerant controller was developed to improve ride comfort and handling stability under the partial loss of actuator effectiveness due to a fault. Fractional-order theory and the RBF method are used to reduce the jitter vibration. The RBF neural network is also used to obtain a more appropriate switching gain for SMC.

The main contributions of this study are summarized as follows:

Section 2 gives the road profile model, nonlinear half-car vehicle model, and fault system model. In

Section 3, an RBF-based fractional-order SMC fault-tolerant controller is presented (FRSMC and FRFTC).

Section 4 provides the simulation results. To better illustrate the validity of the methodology proposed in this study, it is compared with the genetic algorithm-based SMC method (GASMC) in the case of no actuator failure. A particle-swarm-optimization-based SMC fault-tolerant controller (PSFTC) is compared with the proposed algorithm in the case of actuator failure.

Section 5 concludes the paper.

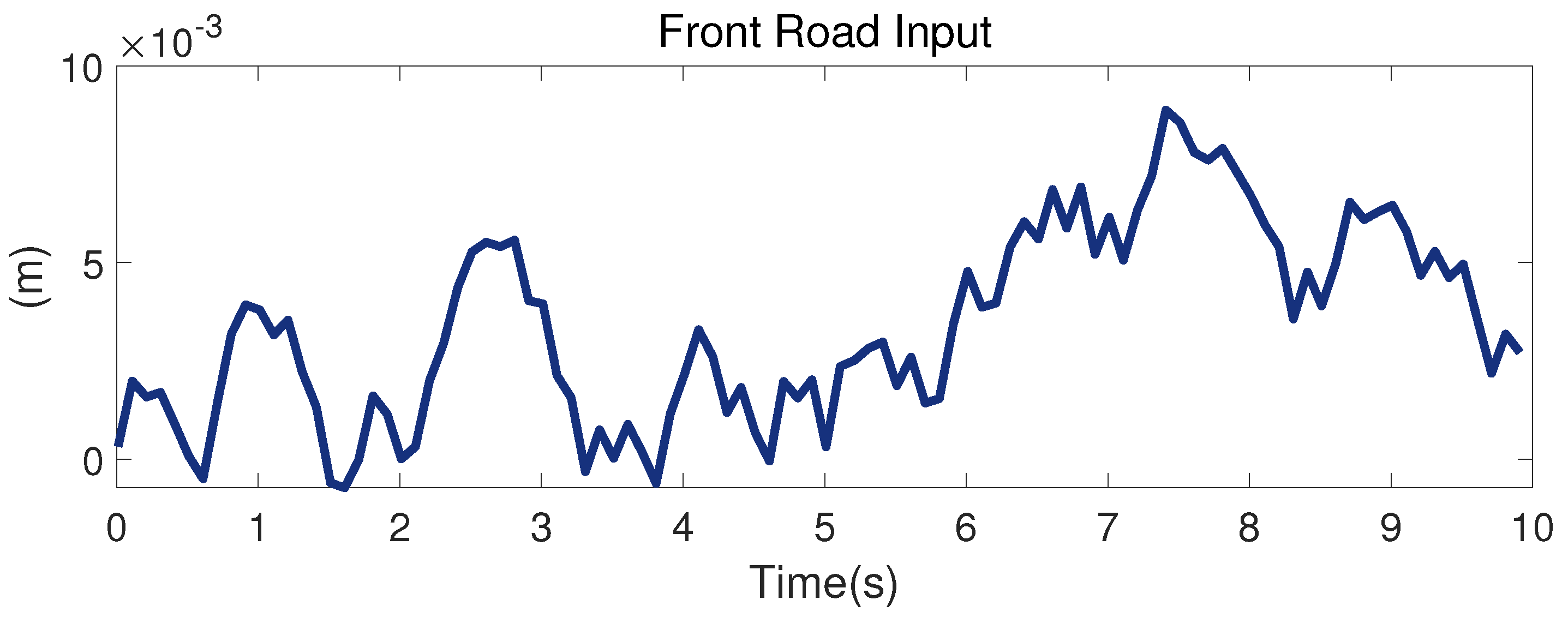

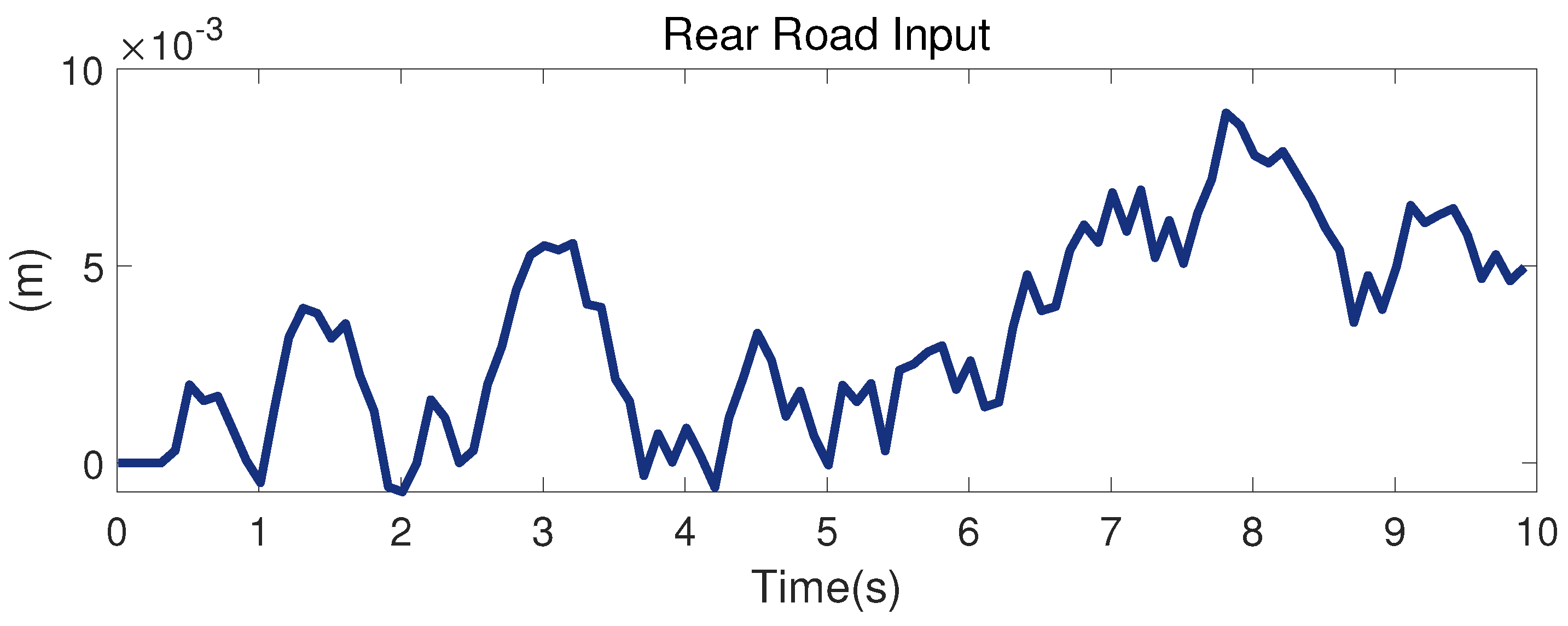

4. Simulation Results and Analysis

This section considers the simulation results, which allowed us to determine the feasibility of the discussed strategy. The parameters of the nonlinear half-suspension model are the design request parameters of a testing half-car model and are displayed in

Table 1.

The relevant mass acceleration, deflection, and dynamic load are chosen as the evaluation metrics to verify the effectiveness of the proposed controller. When evaluating the suspension performance, the car body acceleration and pitch angle acceleration are usually related to the ride comfort, and the suspension deflection and tire dynamic load are usually related to the driving stability.

To better illustrate the validity of the methodology proposed in this study, it is compared with the GASMC in the case of no actuator failure. The PSFTC is compared with the proposed algorithm in the case of actuator failure.

The simulation results are quantified using RMS. The RMS for a collection of

n values

is shown in the following equation:

4.1. The Case of No Actuator Fault

In the case of no actuator fault, which means that all actuators work normally, the matrix is .

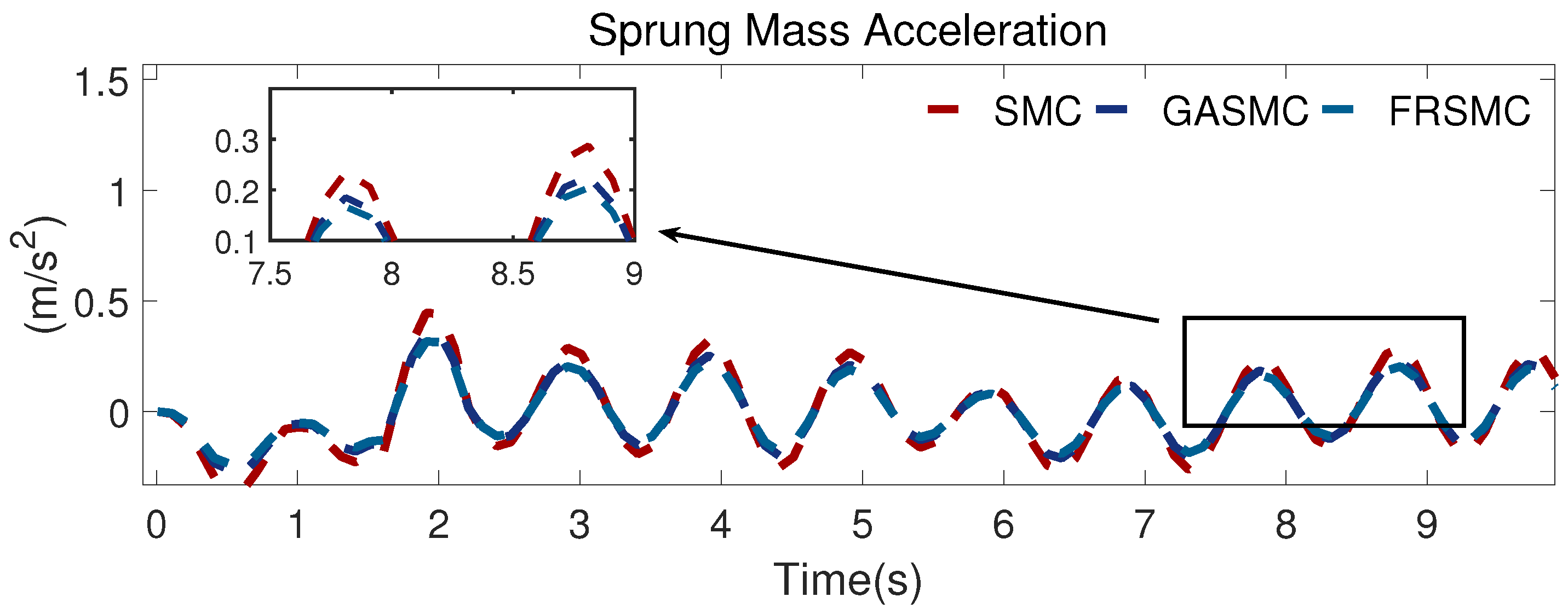

The simulation results are exploited to check the availability of the proposed control method. A comparison with the SMC and GASMC methods for an active suspension is discussed.

The simulation results in the case of no actuator fault are shown in

Figure 6,

Figure 7,

Figure 8,

Figure 9,

Figure 10 and

Figure 11.

Figure 12 presents the degree of improvement compared with the SMC. The RMS values of the evaluation indicators in the case of no actuator failure are shown in

Table 2. In

Figure 6,

Figure 7,

Figure 8,

Figure 9,

Figure 10,

Figure 11 and

Figure 12 and

Table 3, “

” represents the active suspension with the SMC controller, “

” represents the active suspension with the genetic-algorithm-based SMC controller, and “

” represents the RBF-based fractional-order SMC controller.

Figure 6 demonstrates the car body mass acceleration for a nonlinear suspension with the SMC, GASMC, and FRSMC control strategies. We find that the proposed controller leads to a smaller car body acceleration than that of the SMC and GASMC strategies, which means that the vertical motion performance is better for ride comfort with the RBF-based fractional-order SMC controller.

Figure 7 displays the pitch angle acceleration obtained when using the SMC, GASMC, and proposed control strategies. We can see in

Figure 7 that the pitch angle acceleration can be suppressed to a smaller amplitude with the proposed FRSMC method than it can with the other two control methods; thus, it is implied that the performance of the proposed controller in terms of ride comfort is more superior to that of the SMC and GASMC methods for suspension control.

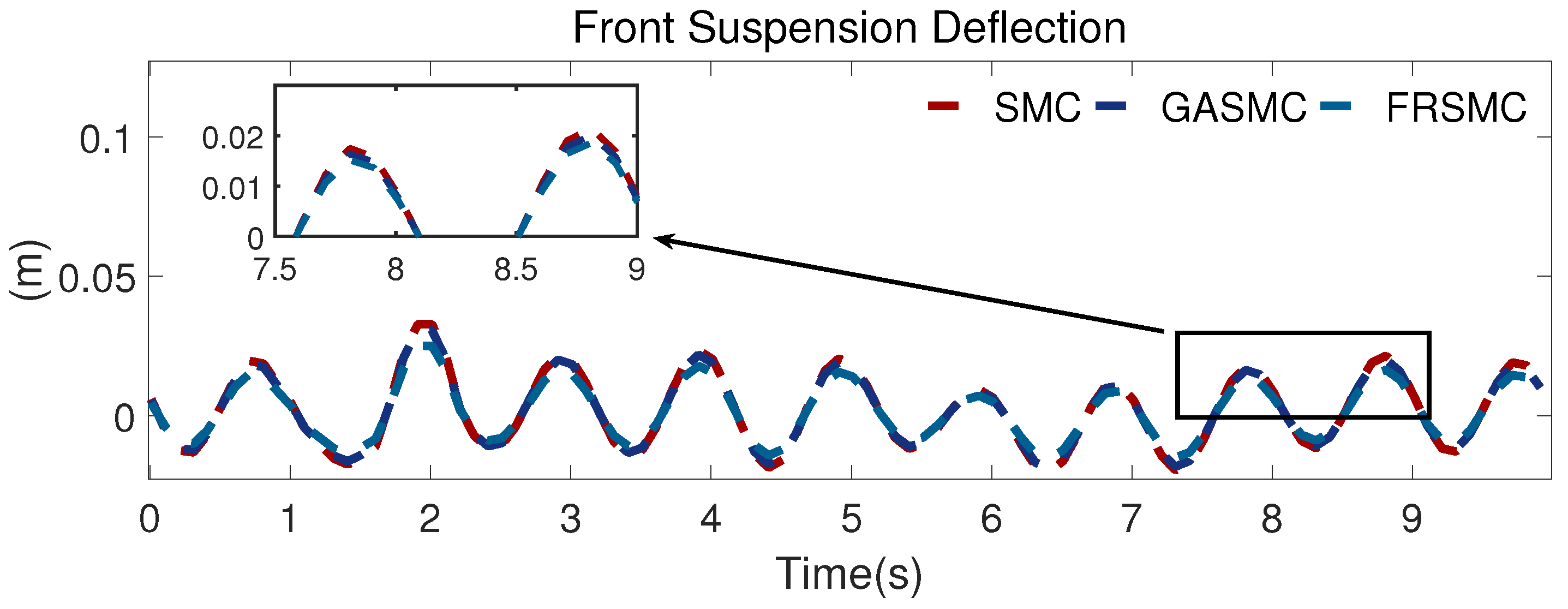

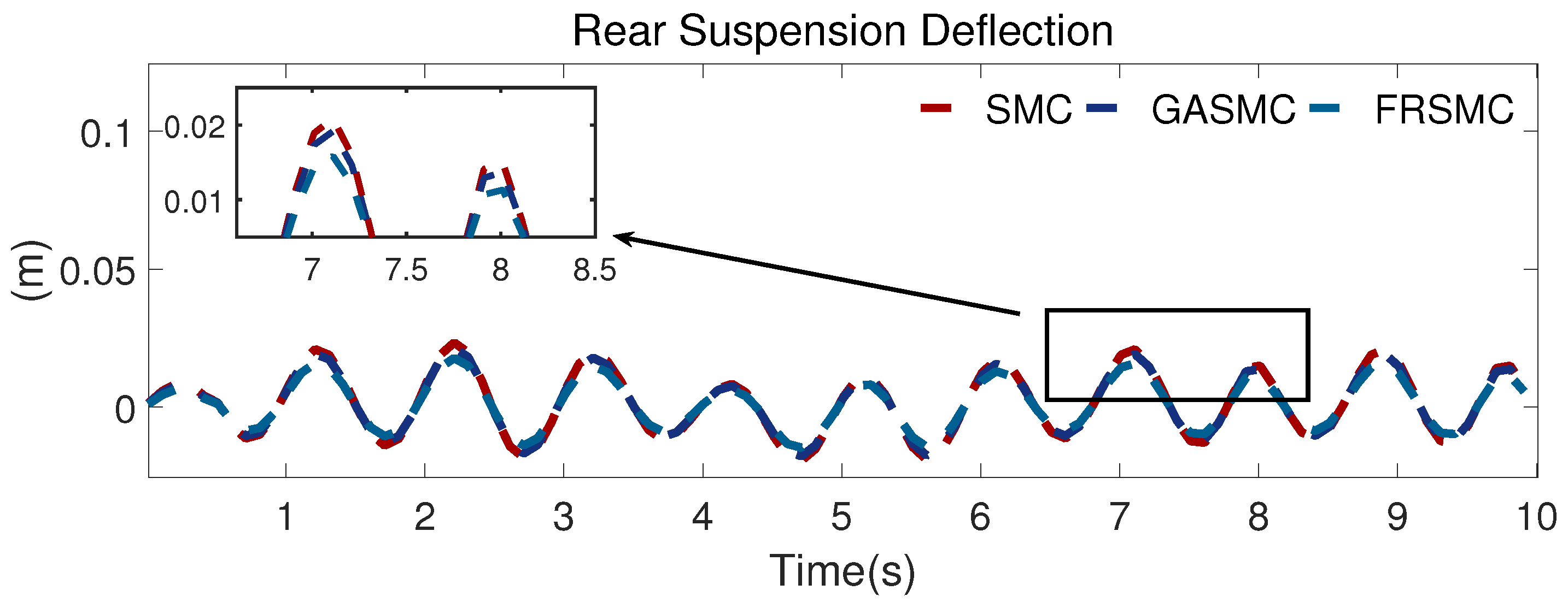

Figure 8 and

Figure 9 show the simulation outcomes for the front and rear suspension deflection. The suspension deflection curves are close to one another in

Figure 8 and

Figure 9. However, we also find that the suspension deflection curves obtained with the FRSMC are smaller than those of the SMC and GASMC methods. These results show that the driving stability performance with the proposed controller is better than that obtained with the others.

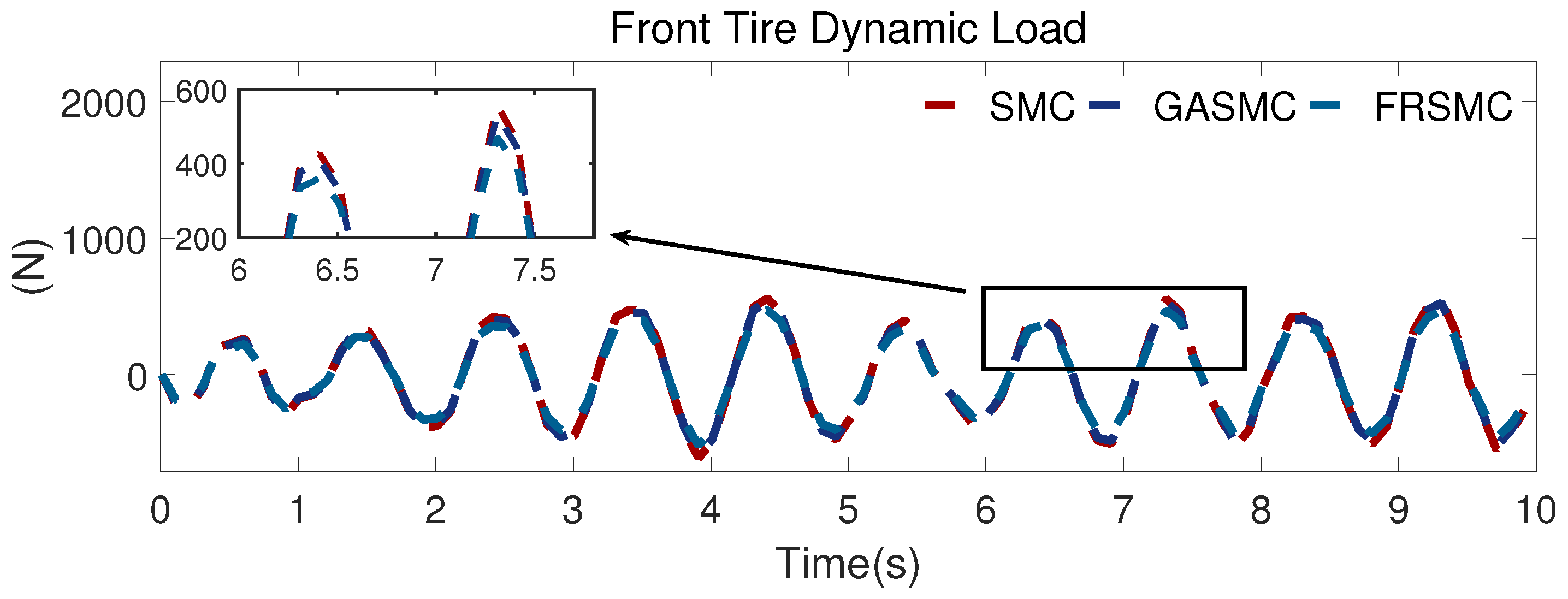

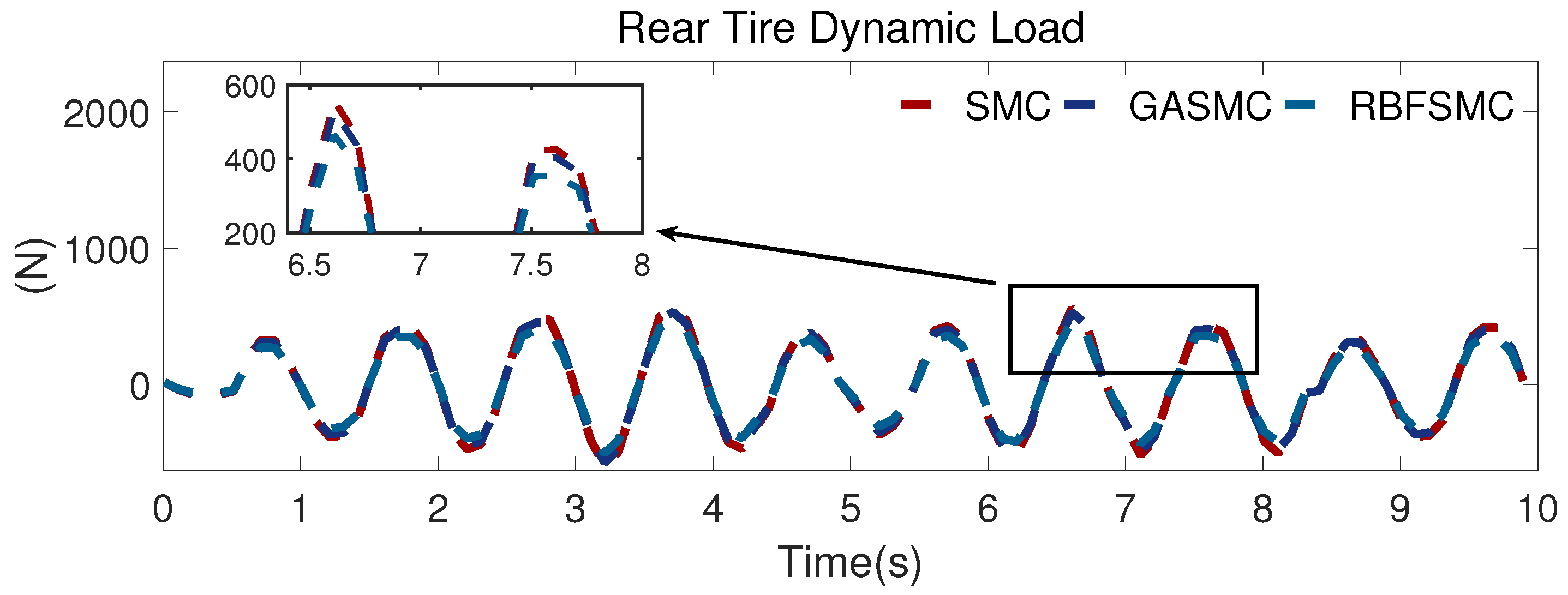

The results for the front- and rear-tire dynamic load are presented in

Figure 10 and

Figure 11. It is clear that, compared with that obtained with SMC and GASMC, the tire dynamic load curve is smoother with FRSMC. These simulation results also provide evidence that the control performance with the proposed controller is more remarkable.

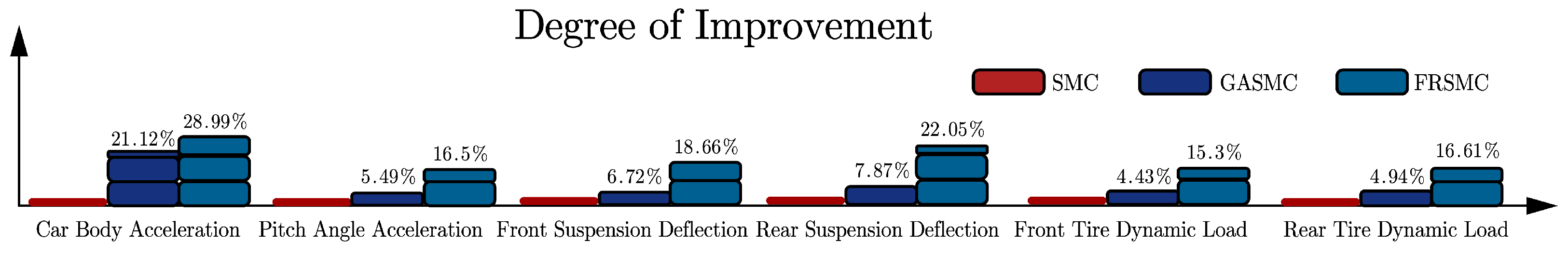

Table 1 shows the simulation results in terms of the RMS values and depicts a comparison among SMC, GASMC, and FRSMC. We also calculated the percentage by which the performance in terms of ride comfort and handling stability increased in comparison with the single sliding-mode control and genetic algorithm control methods.

Figure 12 shows the degree of improvement. As can be seen in

Table 1 and

Figure 12, compared with that of SMC, the RMS value decreased by 21.12% and 28.99% with GASMC and FRSMC. For the pitch angle acceleration, the RMS value decreased by 5.49% and 16.5% with GASMC and FRSMC in comparison with SMC. With the proposed controller, the front and rear suspension deflection improved by 18.66% and 22.05%, respectively, which is better than the control effect obtained with GASMC. For the tire dynamic load, we also find that the RMS value declines by 15.3% and 16.61%, respectively, in comparison with that of the SMC.

According to the RMS values of the performance indicators, the suspension with the proposed FRSMC provides an obvious improvement, which implies that the suspension capabilities are ameliorated to some extent. The above simulation results show that the proposed RBF-based fractional-order SMC controller performs better than the single SMC and GASMC in the case of no actuator fault.

4.2. Case of Actuator Fault

In the case of actuator fault, which means that actuators cannot work normally, the matrix is .

In this section, an extensive simulation is used to demonstrate the effectiveness of the proposed controller. An active suspension with the particle-swarm-optimization-based SMC fault-tolerant control method (PSFTC) and RBF-based fractional-order SMC fault-tolerant control (FRFTC) in the case of actuator fault are used for comparison.

The simulation results in the case of actuator fault are shown in

Figure 13,

Figure 14,

Figure 15,

Figure 16,

Figure 17 and

Figure 18.

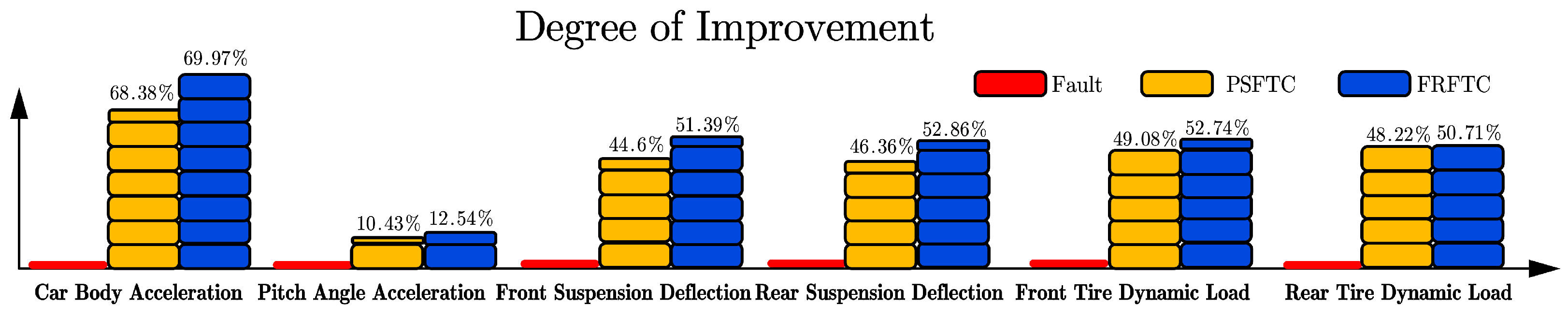

Figure 19 presents the degree of improvement compared with the fault. The RMS values of the evaluation indicators in the case of no actuator fault are shown in

Table 2. In

Figure 13,

Figure 14,

Figure 15,

Figure 16,

Figure 17,

Figure 18 and

Figure 19 and

Table 2, “

” represents the actuator fault in an active suspension, “

” represents the active suspension with the particle-swarm-optimization-based SMC fault-tolerant controller, and “

” represents the active suspension with the proposed fault-tolerant controller; that is, the RBF-based fractional-order SMC fault-tolerant controller.

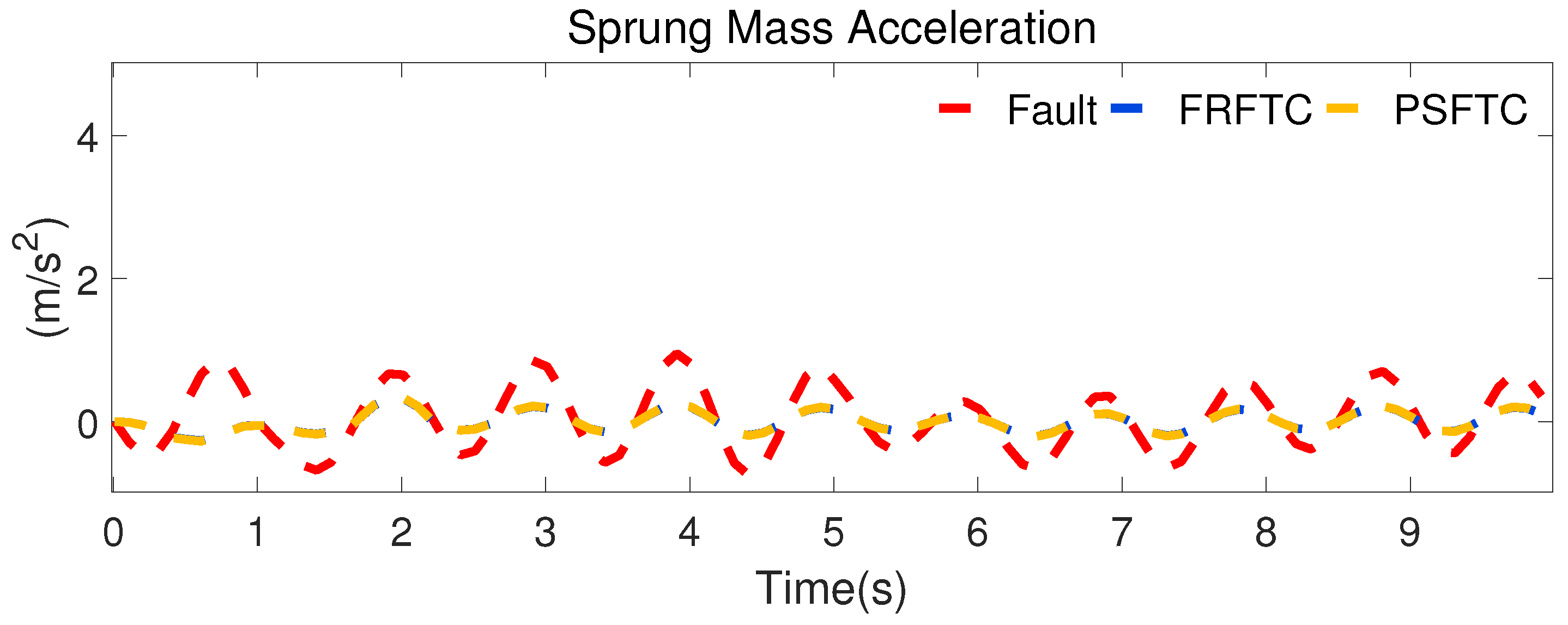

Compared with the actuator fault and fault-tolerant control, it is obvious that the car body acceleration, pitch angle acceleration, suspension deflection, and tire dynamic load fluctuate greatly. It is also obvious that the vibration produced by the road input is much more attenuated when using the fault-tolerant FRFTC.

Figure 13 demonstrates the car body mass acceleration with a nonlinear suspension in the environment of actuator faults with fault-tolerant PSFTC and the designed fault-tolerant controller. It can be seen in

Figure 13 that the proposed FRFTC leads to a smaller car body acceleration than that obtained under the fault conditions and with the PSFTC strategy, which means that the vertical motion of the car body provides better ride comfort when using the fault-tolerant FRFTC.

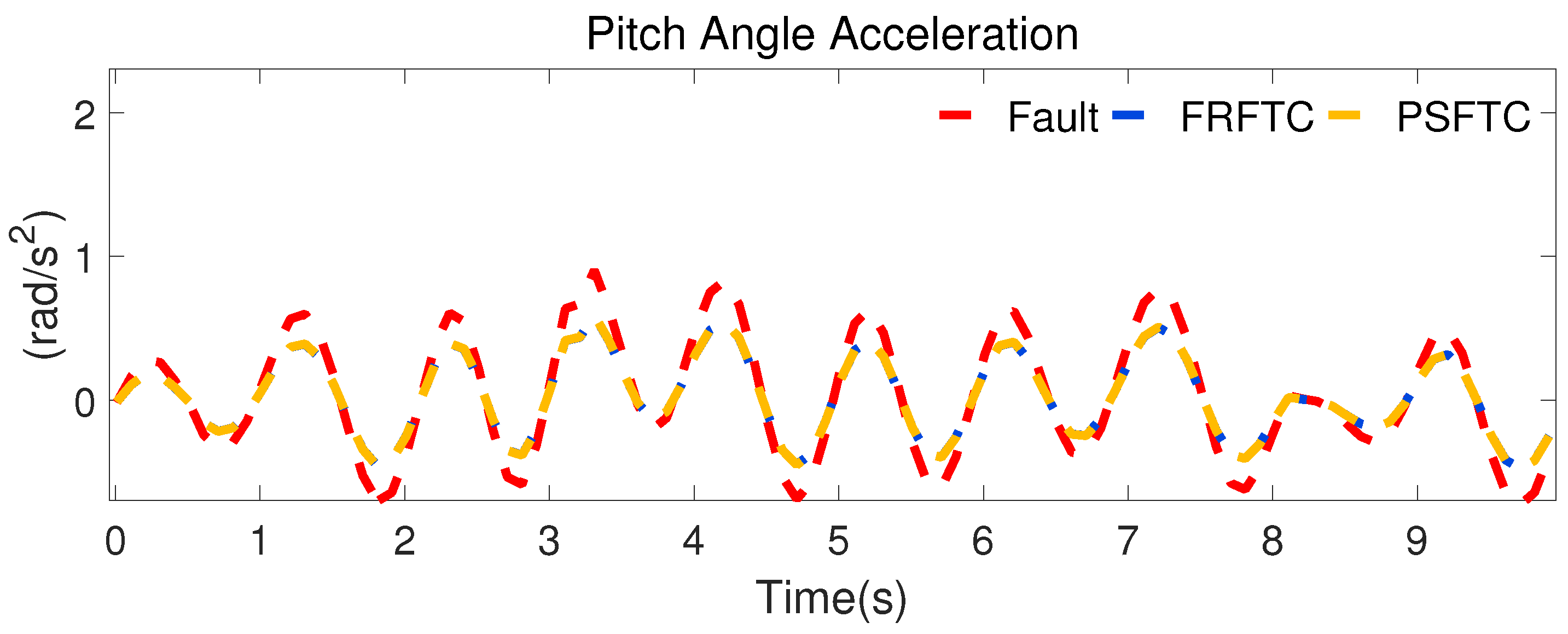

Figure 14 indicates the pitch angle acceleration in the case of actuator fault and with the PSFTC and FRFTC. We can see in

Figure 14 that the pitch angle acceleration can be suppressed to a smaller amplitude with the proposed FRFTC method than with the actuator fault; thus, it is implied that the driving stability of the proposed fault-tolerant controller is superior when maintaining the suspension performance when an actuator failure occurs.

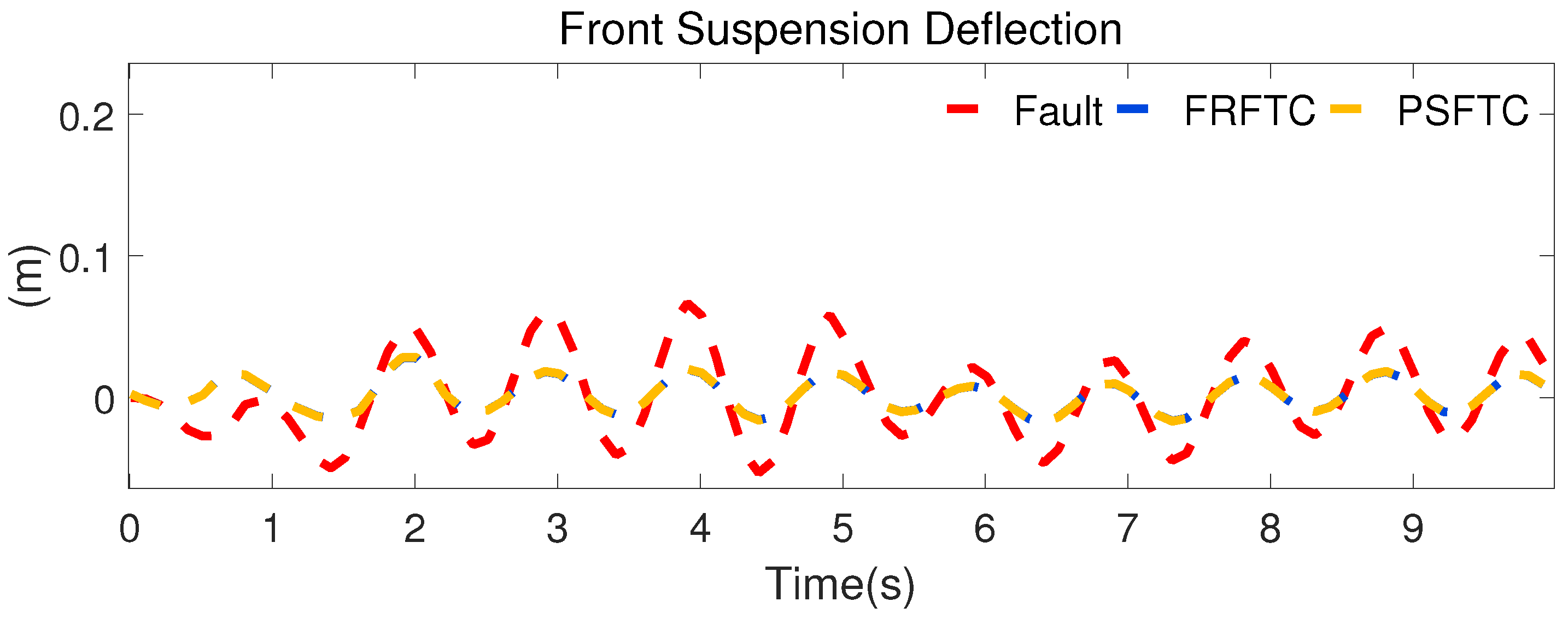

Figure 15 and

Figure 16 show the front and rear suspension deflection in the simulation outcomes. It can be seen in

Figure 15 and

Figure 16 that the suspension deflection curves with the FRFTC are smaller than those in the fault case and the PSFTC method. These results show that the driving stability performance with the proposed controller is better than that with the PSFTC, and the controller is able to bring the fault suspension close to the regular state.

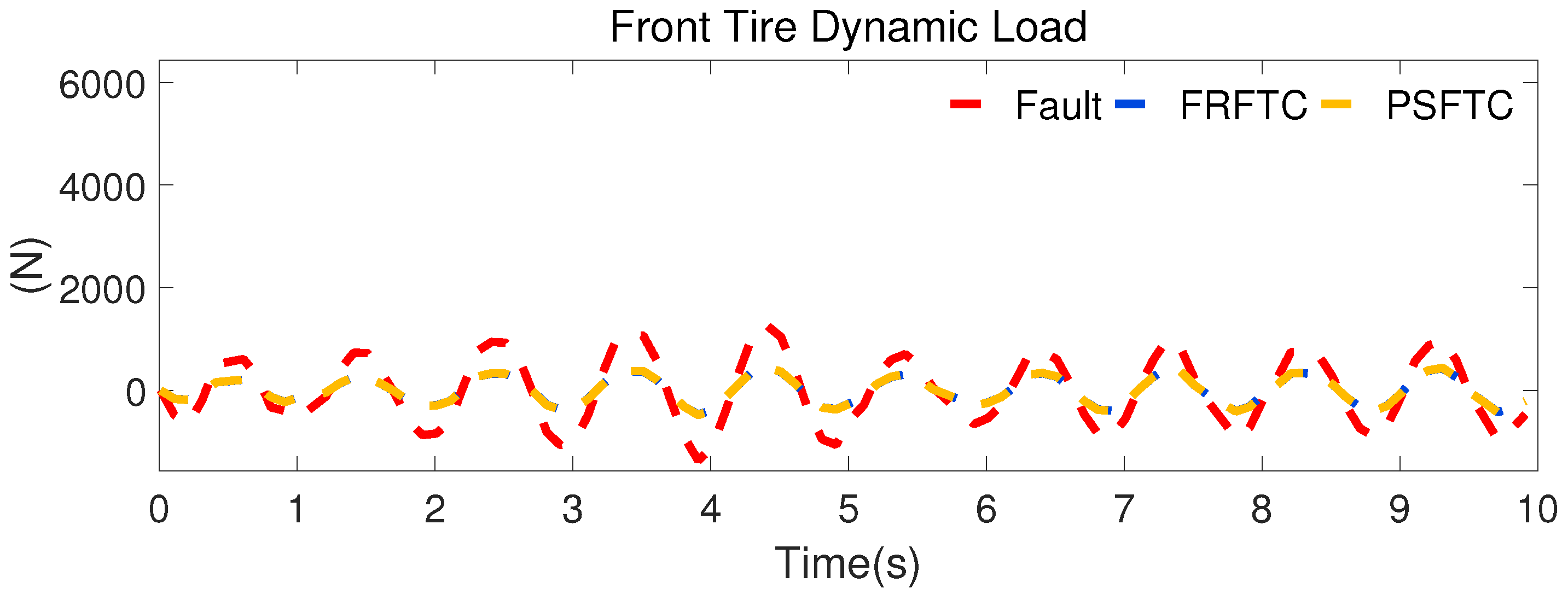

The results of the front- and rear-tire dynamic load are shown in

Figure 17 and

Figure 18. It is clear that, compared with the fault case, both the PSFTC and FRFTC can improve the suspension performance. However, the control effect of the FRFTC is better. These simulation results also provide evidence that the control performance of the proposed fault-tolerant controller is more remarkable.

Table 3 shows the simulation results in terms of the RMS values in a comparison among faults, the PSFTC, and the FRFTC.

Figure 19 shows the degree of improvement. As can be seen in

Table 3 and

Figure 19, it is easily noted that, compared with the actuator fault case, the RMS values decreased by 68.38% and 69.97% with the GASMC and FRSMC. For the pitch angle acceleration, the RMS values decreased by 10.43% and 12.54% with the PSFTC and FRFTC in comparison with the fault case. With the proposed controller, the front and rear suspension deflection improved by 51.39% and 52.86%, respectively, which is better than the control effect with the PSFTC. For the tire dynamic load, we also find that the RMS values declined by 52.74% and 50.71%, respectively, compared with those in the fault case.

5. Discussion and Conclusions

The problem of the fault-tolerant control of actuators was addressed by using a half-car model. An RBF-based fractional-order SMC controller (FRSMC controller) was proposed to enhance vehicles’ dynamic performance in the presence of faults. The proposed hybrid control strategy was exploited to improve the control by accounting for actuator failure. The proposed control law was designed to ensure comfort and stability in suspension system performance on the road.

To overcome the jitter vibration problem in SMC, fractional-order theory and RBF neural networks were used in the proposed controller, and an RBF neural network was also used to obtain the optimal switching gain.

To verify the effectiveness of the proposed control method, two cases consisting of no actuator fault and actuator fault were presented. In the case of no actuator fault, a genetic-algorithm-based sliding-mode controller was compared with the proposed control method. In the case of actuator fault, a particle-swarm-optimization-based sliding-mode control was applied to make a comparison with the proposed method.

According to the simulation results, it was confirmed that the RBF-neural-network-based fractional-order sliding-mode controller had good convergence and control effects. In the case of no actuator fault, the SMC method and genetic-algorithm-based SMC were compared with the proposed control method in healthy cases. Ultimately, addressing these comparisons, it is clear that the controller discussed in this study has better control effects. This confirms the performance of the proposed control algorithm. In the case of actuator fault, the actuator fault problem was considered. A PSO-based SMC fault-tolerant controller and the proposed controller under fault conditions were compared. As shown by the comparison, the fault control method proposed in this study performed better than the other method under the conditions of suspension fault. Therefore, in the case of failure, with the controller proposed in this study, the state of the suspension is essentially the same as that of a healthy suspension. According to the simulation results, this dependable controller can guarantee improved suspension performance in the presence of no actuator faults and the case of such faults.

However, suspension systems are large and complex, and the fault models examined in this study are assumed. This type of failure does not exist in practice. Actual faults come in many forms, and they do not include only gain faults. Faults are also randomized, as is the size of the gain.

Our future research will focus on the following main areas: the suggested control strategy will be implemented in a vehicle system, the nonlinear model will be made more accurate, and a full-automobile dynamic model will be created by using the FRFTC in a real car.