Physical Ergonomics Monitoring in Human–Robot Collaboration: A Standard-Based Approach for Hand-Guiding Applications

Abstract

1. Introduction

- REBA (rapid entire body assessment): Initially proposed in [24], it is based on scoring (i) the postures of different groups of body parts, (ii) the load, (iii) the coupling factors and (iv) the activity. The scores are then combined to obtain the degree of risk by consulting a decision table. The approaches relying on this methodology may lead to modifications of robot pose and action sequence [25], may indicate the more appropriate body configuration [26] or may support task allocation [27].

- RULA (rapid upper limb assessment): introduced in [28], it consists of evaluating body posture, force and repetition, considering neck, trunk and upper extremities. Approaches based on this methodology rely on the adjustments of robot motions to comply with human poses [29,30] or can be used to predict the physical risk.

- The WISHA (Washington Industrial Safety and Health Act) index, which is, in turn, derived from the NIOSH (National Institute for Occupational Safety and Health) equations [31]. An approach building on this methodology enables the adaption of online robot motion planning to cope with human ergonomics [32].

2. Material and Methods

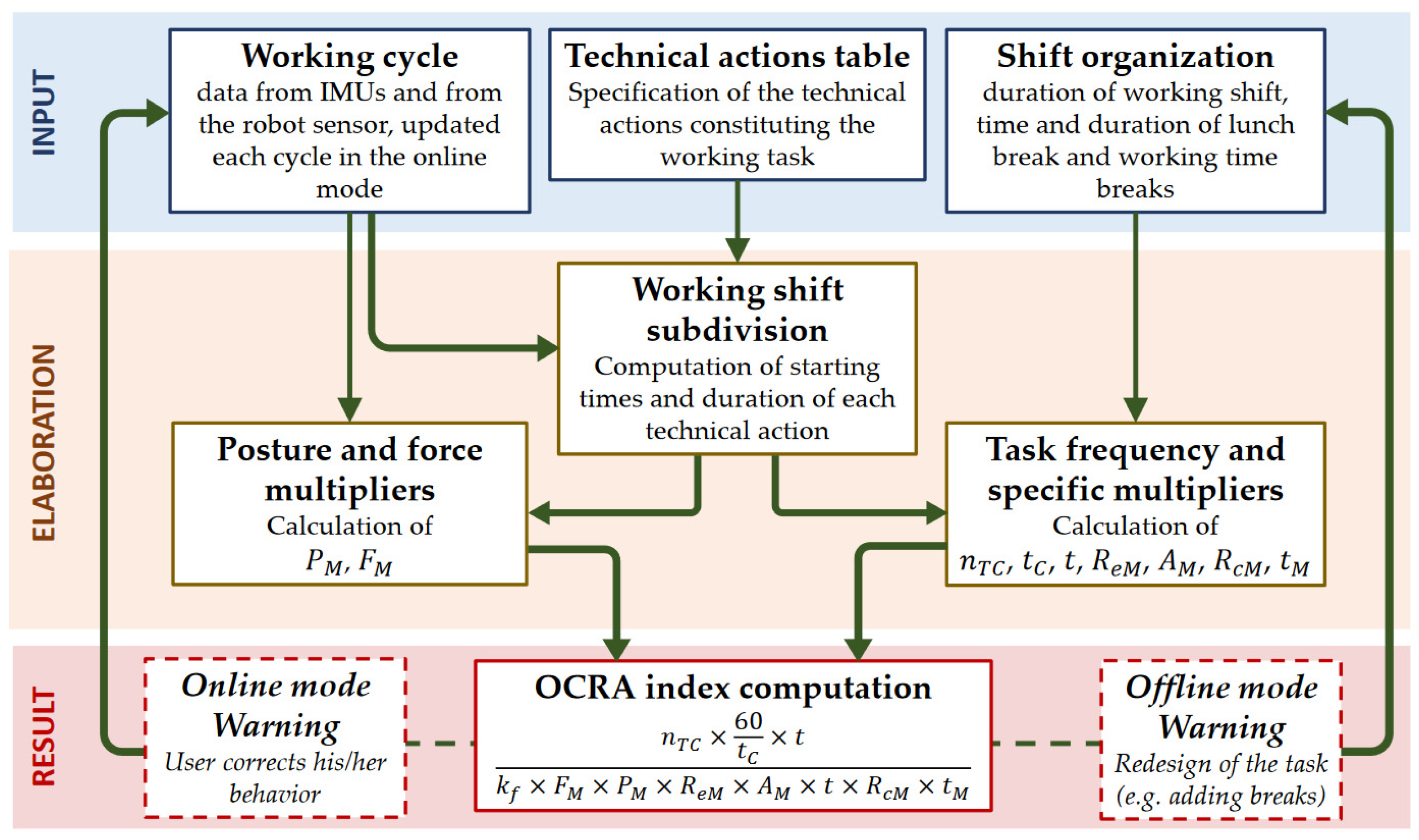

2.1. Ergonomics Assessment

- Force information : According to [21], it can be estimated in three different ways: (a) through an EMG sensor by the percentage of muscle activation compared to the maximum contraction, (b) by the percentage of a basis force provided for relevant poses in the standard EN 1005-3 [40] or (c) more qualitatively, based on the amount of effort perceived by operators during a testing campaign.

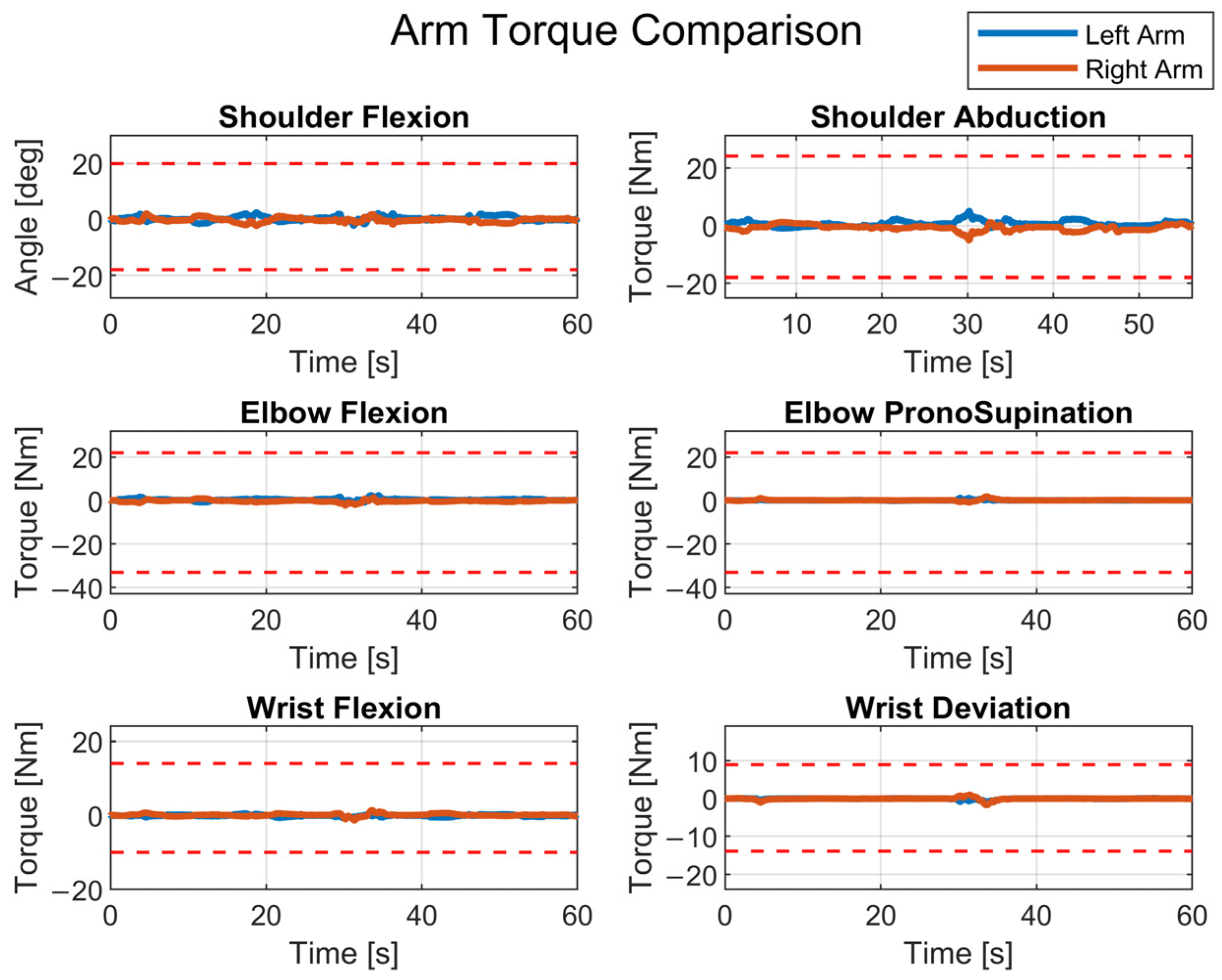

- Posture information : This is determined based on the percentage of time on which shoulder, elbow and wrist joint angles exceed specific angle limits, as defined in [21].

- Task frequency and characteristic information , , , , , , : These parameters enable the consideration of factors which make the shift more fatiguing for the worker.

- No risk (green zone), with values lower than 2.2.

- Very low risk (yellow zone), with values in the range 2.2–3.5.

- Risk (red zone), with values higher than 3.5.

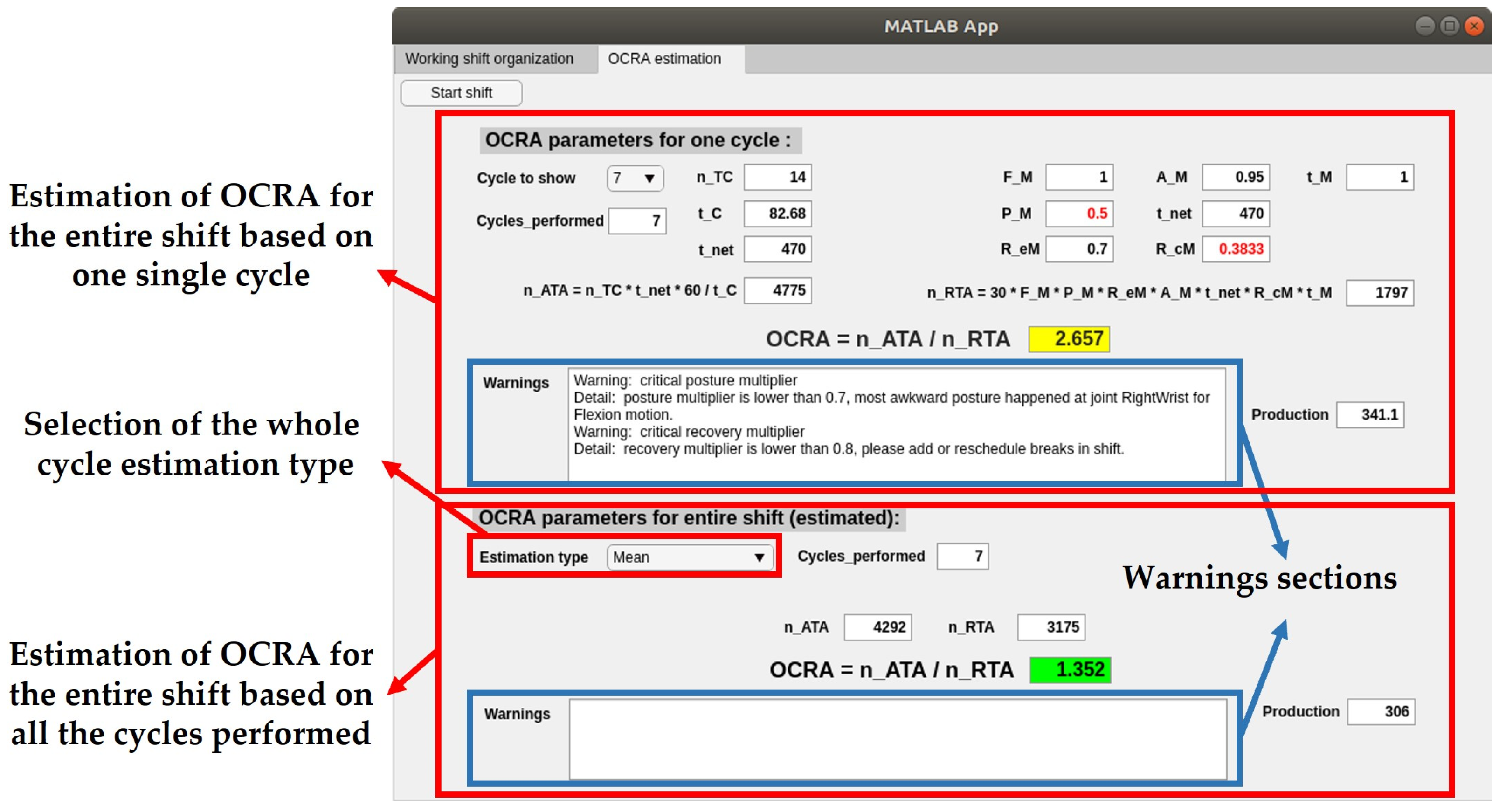

2.2. The SaRAH App

3. Tests and Results

3.1. Task and Workcell Description

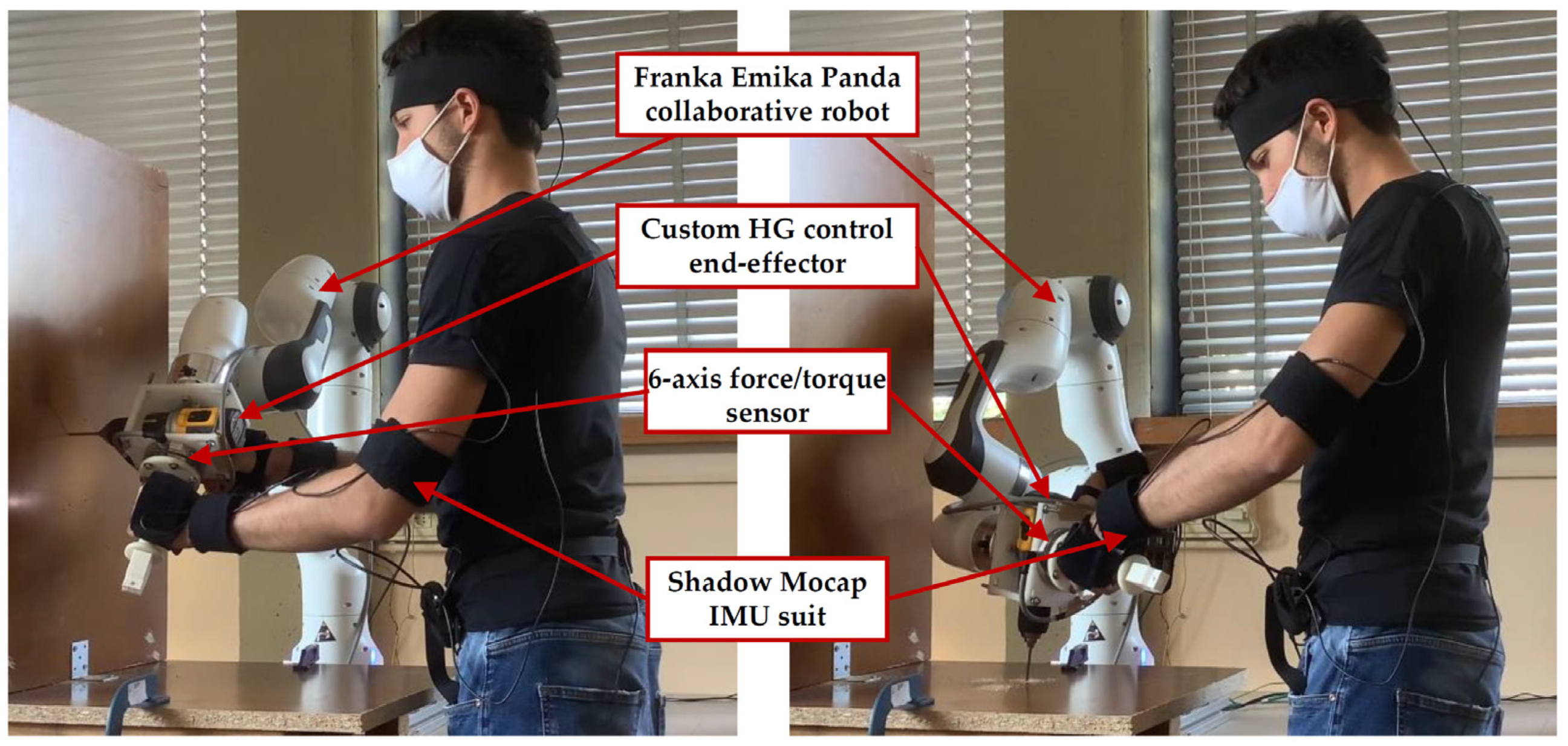

- Franka Emika Panda robot: a seven-degree-of-freedom collaborative robot, having a cycle time of 1000 Hz and equipped with torque sensors in all the joints to measure end-effector loads and detect impacts with obstacles in the workspace. In case of an impact, the robot stops and enters into error status, thus preventing harmful interactions with humans within the workspace.

- An electric drill, mounted as the end-effector of the robot with a custom mechanical interface, made of 3D-printed flanges. The custom fixture is also provided with an additional handle so that the operator can grab the end-effector, which incorporates the drill, with his/her right hand on the drill grip and with their left hand on the additional handle. The handle also includes a button that enables switching between two different robot control modes (as detailed below).

- Schunk Axia80 sensor: a six-axis force/torque sensor sending data at a frequency of 1000 Hz and mounted in between the mechanical interface and a 3D-printed additional handle, in order to measure, together with the robot joint torque sensors, the forces and torques exerted by the human operator on the robot.

- Shadow MoCap suit: a system of 17 IMU sensors placed in several points of the human body (on the arms, legs, back, chest and head), sending data at a frequency of 400 Hz. The IMUs are used to track the position of the human body, which is needed to evaluate the effort of the operator. It is worth observing that the drifting issue typical of this type of sensor is mitigated in the considered set-up by the given information of hands position, which is obtained by robot encoders considering that the handle and the drill are constantly held.

- Manual guidance mode: the operator moves the robot to the desired position to drill the hole. In this phase, the robot is controlled in torque, mainly providing compensation for the gravity force and a support action—driven by the force information acquired by the six-axis force sensor—necessary to compensate for the internal friction of joint gearsets.

- Drilling mode: in this phase, the robot is controlled in velocity and is activated when the force measured by the six-axis force sensor is higher than a pre-defined threshold in the direction of the tip of the drill. The robot is programmed to move forward (or backwards, depending on the direction of the force), minimizing the effort exerted by the operator and ensuring drilling direction. Weight compensation is also provided in this mode.

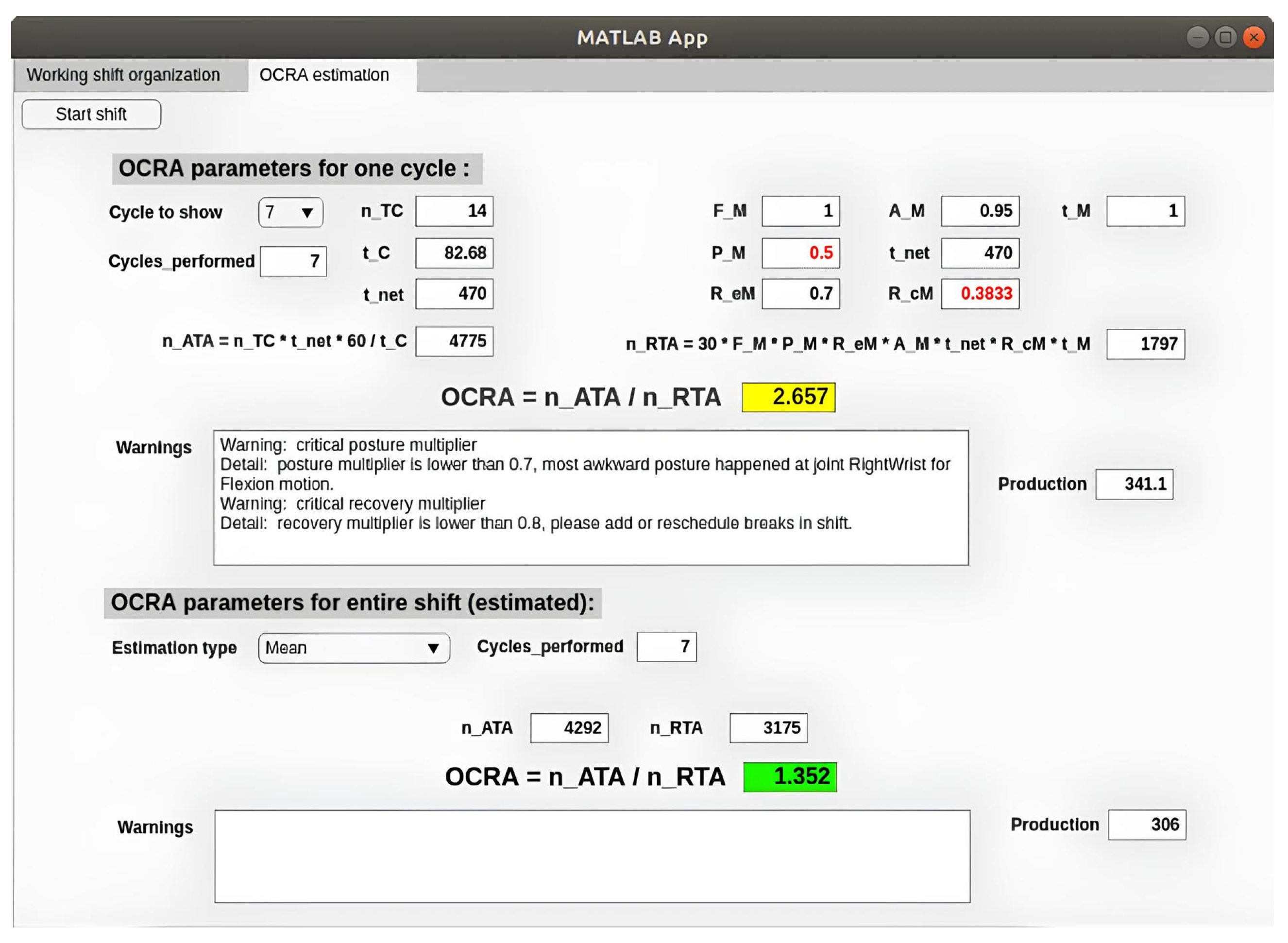

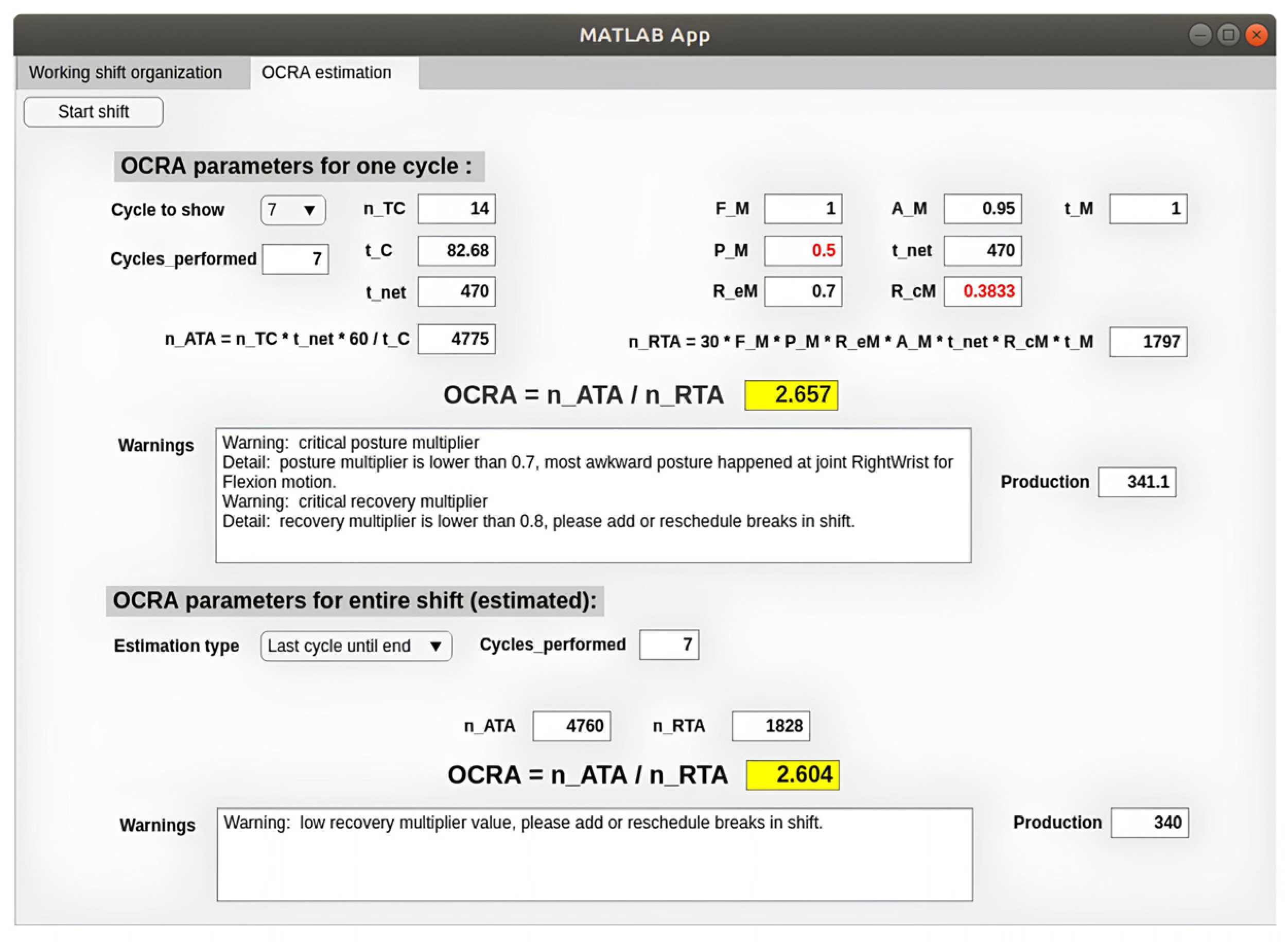

3.2. Evaluation with OCRA App

- Position the end-effector (manual guidance control mode)

- Start bit rotation by pressing the drill trigger

- Push to drill (drilling control mode)

- Move away (drilling control mode)

3.2.1. Offline Mode

3.2.2. Online Mode

4. Discussion

4.1. Offline Task Planning

4.2. Online Ergonomics Improvement

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Bauer, A.; Wollherr, D.; Buss, M. Human-robot collaboration: A survey. Int. J. Humanoid Robot. 2008, 5, 47–66. [Google Scholar] [CrossRef]

- Ajoudani, A.; Zanchettin, A.M.; Ivaldi, S.; Albu-Schäffer, A.; Kosuge, K.; Khatib, O. Progress and prospects of the human-robot collaboration. Auton. Robot. 2018, 42, 957–975. [Google Scholar] [CrossRef]

- Villani, V.; Pini, F.; Leali, F.; Secchi, C. Survey on human–robot collaboration in industrial settings: Safety, intuitive interfaces and applications. Mechatronics 2018, 55, 248–266. [Google Scholar] [CrossRef]

- Sherwani, F.; Asad, M.M.; Ibrahim, B.S.K.K. Collaborative Robots and Industrial Revolution 4.0 (IR 4.0). In Proceedings of the International Conference on Emerging Trends in Smart Technologies (ICETST), Karachi, Pakistan, 26–27 March 2020; pp. 1–5. [Google Scholar]

- Salunkhe, O.; Stensöta, O.; Åkerman, M.; Berglund, A.F.; Alveflo, P. Assembly 4.0: Wheel Hub Nut Assembly Using a Cobot. IFAC-Pap. 2019, 52, 1632–1637. [Google Scholar] [CrossRef]

- International Federation of Robotics. World Robotics 2022, Presentation. Available online: https://ifr.org/downloads/press2018/2022_WR_extended_version.pdf (accessed on 23 March 2023).

- Alves, J.; Lima, T.M.; Gaspar, P.D. Is Industry 5.0 a Human-Centred Approach? A Systematic Review. Processes 2023, 11, 193. [Google Scholar] [CrossRef]

- Maurtua, I.; Ibarguren, A.; Kidal, J.; Susperregi, L.; Sierra, B. Human-robot collaboration in industrial applications: Safety, interaction and trust. Int. J. Adv. Robot. Syst. 2017, 14, 1729881417716010. [Google Scholar] [CrossRef]

- Zacharaki, A.; Kostavelis, I.; Gasteratos, A.; Dokas, I. Safety bounds in human-robot interaction: A survey. Saf. Sci. 2020, 127, 104667. [Google Scholar] [CrossRef]

- Saenz, J.; Behrens, R.; Schulenburg, E.; Petersen, H.; GIbaru, O.; Neto, P.; Elkmann, N. Methods for considering safety in design of robotics application featuring human-robot collaboration. Int. J. Adv. Manuf. Tech. 2020, 107, 2313–2331. [Google Scholar] [CrossRef]

- ISO/TS 15066:2016; Robots and Robotic Devices—Collaborative Robots. International Organization for Standardization: Geneva, Switzerland, 2016.

- Valori, M.; Scibilia, A.; Fassi, I.; Saenz, J.; Behrens, R.; Herbster, S.; Bidard, C.; Lucet, E.; Magisson, A.; Schaake, L.; et al. Validating Safety in Human-Robot Collaboration: Standards and New Perspectives. Robotics 2021, 10, 65. [Google Scholar] [CrossRef]

- Gualtieri, L.; Rauch, E.; Vidoni, R. Emerging research fields in safety and ergonomics in industrial collaborative robotics: A systematic literature review. Robot. Comput. Manuf. 2021, 67, 101998. [Google Scholar] [CrossRef]

- Arents, J.; Abolins, V.; Judvaitis, J.; Vismanis, O.; Oraby, A.; Ozols, K. Human–Robot Collaboration Trends and Safety Aspects: A Systematic Review. Sens. Actuator Netw. 2021, 10, 48. [Google Scholar] [CrossRef]

- Scibilia, A.; Valori, M.; Pedrocchi, N.; Fassi, I.; Herbster, S.; Behrens, R.; Saenz, J.; Magisson, A.; Bidard, C.; Kühnrich, M.; et al. Analysis of Interlaboratory Safety Related Tests in Power and Force Limited Collaborative Robots. IEEE Access 2021, 9, 80873–80882. [Google Scholar] [CrossRef]

- de Kok, J.; Vroonhof, P.; Snijders, J.; Roullis, G.; Clarke, M.; Peereboom, K.; van Dorst, P.; Isusi, I. Work-Related Musculoskeletal Disorders: Prevalence, Costs and Demographics in the EU. European Agency for Safety and Health at Work. 2020. Available online: https://data.europa.eu/doi/10.2802/66947 (accessed on 23 March 2023).

- Kolus, A.; Wells, R.; Neumann, P. Production quality and human factors engineering: A systematic review and theoretical framework. Appl. Ergon. 2018, 73, 55–89. [Google Scholar] [CrossRef]

- Rodrick, D.; Karwowski, W.; Sherehiy, B. Human Factors and Ergonomics Standards. In Handbook of Human Factors and Ergonomics, 4th ed.; Salvendy, G., Ed.; John Wiley & Sons: Hoboken, NJ, USA, 2012. [Google Scholar]

- ISO 11228-1:2021; Ergonomics—Manual Handling—Part 1: Lifting, Lowering and Carrying. International Organization for Standardization: Geneva, Switzerland, 2021.

- ISO 11228-2:2021; Ergonomics—Manual Handling—Part 2: Pushing and Pulling. International Organization for Standardization: Geneva, Switzerland, 2007.

- ISO 11228-3:2021; Ergonomics—Manual Handling—Part 3: Handling of Low Load at High Frequency. International Organization for Standardization: Geneva, Switzerland, 2007.

- Occhipinti, E.; Colombini, D. The OCRA Method: Assessment of Exposure to Occupational Repetitive Actions of the Upper Limbs. In International Encyclopedia of Ergonomics and Human Factors; Krawowski, W., Ed.; Taylor & Francis: London, UK; New York, NY, USA, 2001; Volume 1, pp. 1875–1879. [Google Scholar]

- Lorenzini, M.; Lagomarsino, M.; Fortini, L.; Gholami, S.; Ajoudani, A. Ergonomic human-robot collaboration in industry: A review. Front. Robot. AI 2023, 9, 813907. [Google Scholar] [CrossRef]

- Hignett, S.; McAtamney, L. Rapid entire body assessment (REBA). Appl. Ergon. 2000, 31, 201–205. [Google Scholar] [CrossRef]

- Busch, B.; Toussaint, M.; Lopes, M. Planning ergonomic sequences of actions in human-robot interaction. In Proceedings of the International Conference on Robotics and Automation (ICRA), Brisbane, QLD, Australia, 21–25 May 2018; pp. 1916–1923. [Google Scholar]

- Zanchettin, A.M.; Lotano, E.; Rocco, P. Collaborative robot assistant for the ergonomic manipulation of cumbersome objects. In Proceedings of the International Conference on Intelligent Robots and Systems (IROS), Macau, China, 3–8 November 2019; pp. 6729–6734. [Google Scholar]

- El Makrini, I.; Merckaert, K.; De Winter, J.; Lefeber, D.; Vanderborght, B. Task allocation for improved ergonomics in human-robot collaborative assembly. Interact. Stud. 2019, 20, 102–133. [Google Scholar] [CrossRef]

- McAtamney, L.; Corlett, E.N. RULA: A survey method for the investigation of work-related upper limb disorders. Appl. Ergon. 1993, 24, 91–99. [Google Scholar] [CrossRef]

- Ferraguti, F.; Villa, R.; Landi, C.T.; Zanchettin, A.M.; Rocco, P.; Secchi, C. A unified architecture for physical and ergonomic human–robot collaboration. Robotica 2020, 38, 669–683. [Google Scholar] [CrossRef]

- Shafti, A.; Ataka, A.; Lazpita, B.U.; Shiva, A.; Wurdemann, H.A.; Althoefer, K. Real-time robot-assisted ergonomics. In Proceedings of the International Conference on Robotics and Automation (ICRA), Montreal, QC, Canada, 20–24 May 2019; pp. 1975–1981. [Google Scholar]

- Waters, T.R.; Putz-Anderson, V.; Garg, A.; Fine, L.J. Revised niosh equation for the design and evaluation of manual lifting tasks. Ergonomics 1993, 36, 749–776. [Google Scholar] [CrossRef]

- Fusaro, F.; Lamon, E.; De Momi, E.; Ajoudani, A. A human-aware method to plan complex cooperative and autonomous tasks using behavior trees. In Proceedings of the International Conference on Humanoid Robots (Humanoids), Munich, Germany, 19–21 July 2021; pp. 522–529. [Google Scholar]

- Stradioto, J.P.; Michaloski, A.O.; de Paula Xavier, A.A.; Colombini, D. Comparison of RULA and Checklist OCRA Ergonomic Risk Methods for Civil Construction. Ind. Eng. Manag. Syst. 2020, 19, 790–802. [Google Scholar] [CrossRef]

- Colombini, D. Scientific basis of the OCRA method for risk assessment of biomechanical overload of upper limb, as preferred method in ISO standards on biomechanical risk factors. Scand. J. Work Environ. Health 2018, 44, 46–438. [Google Scholar] [CrossRef]

- Triviño-Tonato, E.; Masood, J.; Cibeira, R.P.; Dacal-Nieto, A. CO-GUIDING: Ergonomic Analysis of a Hand Guidance System for Car Door Assembly. Wearable Robotics: Challenges and Trends. WeRob 2020. Biosyst. Biorobot. 2020, 202, 27. [Google Scholar]

- Gopinath, V.; Johansen, K.; Ölvander, J. Risk assessment for collaborative operation: A case study on hand-guided industrial robots. In Risk Assessment; Svalova, V., Ed.; Intech Open: Rijeka, Croatia, 2018; pp. 167–189. [Google Scholar]

- Saenz, J.; Bessler, J.; Valori, M.; Prange, G.; Fassi, I.; Bidard, C.; Bach Lassen, A.; Paniti, I.; Toth, A.; Stuke, T.; et al. An Online Toolkit for Applications Featuring Collaborative Robots Across Different Domains. IEEE Trans. Hum. Mach. Syst. 2022, 53, 657–667. [Google Scholar] [CrossRef]

- Stefana, E.; Marciano, F.; Rossi, D.; Cocca, P.; Tomasoni, G. Wearable Devices for Ergonomics: A Systematic Literature Review. Sensors 2021, 21, 777. [Google Scholar] [CrossRef]

- Lenzi, S.E.; Standoli, C.E.; Andreoni, G.; Perego, P.; Lopomo, N.F. Comparison Among Standard Method, Dedicated Toolbox and Kinematic-Based Approach in Assessing Risk of Developing Upper Limb Musculoskeletal Disorders. In Advances in Human Factors in Wearable Technologies and Game Design; Ahram, T.Z., di Cham, A.C., Eds.; Springer International Publishing: Berlin/Heidelberg, Germany, 2019; Volume 795, pp. 135–145. [Google Scholar] [CrossRef]

- EN 1005-3 2002+A1:2008; Safety of Machinery—Human Physical Performance—Part 3: Recommended Force Limits for Machinery Operation. European Committee for Standardization: Bruxelles, Belgium, 2008.

- Avallone, G.; Monari, E.; Chen, Y.; Agostini, L.; Sancisi, N.; Vertechy, R. A COBOT-IMU Hand-Guiding System with Online Collision Avoidance in Null Space. In ROMANSY 24-Robot Design, Dynamics and Control: Proceedings of the 24th CISM IFToMM Symposium; Springer International Publishing: Cham, Switzerland, 2022; pp. 151–159. [Google Scholar]

- Contini, R.; Drillis, R.J.; Bluestein, E.M. Determination of Body Segment Parameters. Hum. Factors 1963, 5, 493–504. [Google Scholar] [CrossRef]

- Latella, C.; Kuppuswamy, N.; Romano, F.; Traversaro, S.; Nori, F. Whole-body human inverse dynamics with distributed micro-accelerometers, gyros and force sensing. Sensors 2016, 16, 727. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Monari, E.; Avallone, G.; Valori, M.; Agostini, L.; Chen, Y.; Palazzi, E.; Vertechy, R. Physical Ergonomics Monitoring in Human–Robot Collaboration: A Standard-Based Approach for Hand-Guiding Applications. Machines 2024, 12, 231. https://doi.org/10.3390/machines12040231

Monari E, Avallone G, Valori M, Agostini L, Chen Y, Palazzi E, Vertechy R. Physical Ergonomics Monitoring in Human–Robot Collaboration: A Standard-Based Approach for Hand-Guiding Applications. Machines. 2024; 12(4):231. https://doi.org/10.3390/machines12040231

Chicago/Turabian StyleMonari, Eugenio, Giulia Avallone, Marcello Valori, Lorenzo Agostini, Yi Chen, Emanuele Palazzi, and Rocco Vertechy. 2024. "Physical Ergonomics Monitoring in Human–Robot Collaboration: A Standard-Based Approach for Hand-Guiding Applications" Machines 12, no. 4: 231. https://doi.org/10.3390/machines12040231

APA StyleMonari, E., Avallone, G., Valori, M., Agostini, L., Chen, Y., Palazzi, E., & Vertechy, R. (2024). Physical Ergonomics Monitoring in Human–Robot Collaboration: A Standard-Based Approach for Hand-Guiding Applications. Machines, 12(4), 231. https://doi.org/10.3390/machines12040231