1. Introduction

While DC systems offer numerous advantages over their AC counterparts, widespread adoption has historically been hindered by the lack of robust transmission and distribution technologies. However, recent advancements in High Voltage DC (HVDC) have paved the way for long-distance DC power transmission [

1,

2]. Despite this progress, a crucial challenge remains: DC current interruption is inherently difficult due to the absence of natural zero crossings, potentially leading to prolonged arc durations compared to AC systems [

3,

4]. These DC arc faults pose a significant safety hazard, as the sustained high-temperature plasma discharge can trigger catastrophic electrical fires [

5]. Further complicating matters, DC arc faults come in two distinct forms: parallel and series arcs. Parallel arcs, typically caused by short circuits due to insulation breakdowns, follow Paschen’s law, where the minimum breakdown voltage for arc initiation depends on the gas type, pressure, and electrode gap [

5]. In contrast, series arcs arise from loose connections or sudden disconnections between elements such as loads and power sources [

6]. Fortunately, DC arc faults are not silent or invisible. They manifest through a signature combination of acoustic emissions, light bursts, temperature increases, distorted voltages, and high-frequency current signals [

5]. To reliably identify these events, numerous research directions have emerged. One approach focuses on modeling the complex dynamics of DC arc behavior. Scholars have employed diverse techniques, ranging from theoretical analysis to data-driven fitting, to mathematically capture the characteristics of arc phenomena [

7,

8,

9,

10,

11]. Another research paradigm delves into direct arc detection via time–frequency domain analysis. This method relies on extracting key features from the arc’s temporal and spectral signatures [

12,

13]. However, setting appropriate thresholds for distinguishing arc faults from normal operating conditions can be a delicate task, prone to false positives. To address this limitation, researchers have turned to advanced signal processing techniques such as wavelet transforms (WT) and its derivatives. Zhang et al. [

14] leveraged the sum of squared amplitudes of four-level db20 wavelet coefficients as a powerful discriminator between normal and arc-fault states. Wang et al. [

15] combined discrete WT and fast Fourier transform (FFT) to analyze the spectrum of DC series arc currents, demonstrating discrete WT’s superior ability to capture temporal–frequency variations, especially for brief arc events compared to the sampling window limitations of FFT. Beyond analyzing DC-side signals directly, some studies explore the possibility of fault detection through the AC side. This indirect approach analyzes the impact of DC-side faults on the AC side of converter interfaces [

16,

17]. For instance, [

18] proposes comparing estimated and measured power to detect faults in PV modules. Chouder and Silvestre [

19,

20,

21] further refine this concept by developing techniques to categorize various abnormal conditions, including partial-shading errors, alongside normal operation. The process for arc detection, as outlined in [

22], consists of four key steps. Initially, the low-frequency range and high-frequency range components are filtered out, leaving behind the middle-frequency range for subsequent artificial intelligence (AI) analysis. Within this range, eight specific inputs are utilized to identify and detect fault events. A pioneering fault detection approach is introduced, drawing on the mathematical formulation of arc discharge [

23]. This method extracts feature parameters from the time domain, which remain unaffected by fault transition resistance. Moreover, it separately extracts hybrid features from the time–frequency–phase domain, ensuring that the fault-related features extracted possess clear physical significance. The arc signal underwent analysis using discrete wavelet transform and multiresolution analysis to ascertain the optimal frequency band for arc detection [

24].

This study builds upon this rich research landscape by proposing a novel approach for diagnosing DC series arc faults. Our method hinges on a unique concept: utilizing a time signal derived from the power-supply side as a reference input. This strategic reference effectively minimizes system noise influences and facilitates comparison of signal characteristics within smaller, moving intervals. By focusing on subtle changes within these windows, we amplify arc-specific distortions that might otherwise be masked by broader time–frequency domain analysis. These meticulously crafted feature differentials, encapsulating the essence of arcing signatures, are then fed into advanced learning techniques (ALTs). This final stage capitalizes on the pattern recognition prowess of ALTs to achieve superior accuracy and robustness in DC arc-fault detection. The detailed structure of this paper delves deeper into the specifics of our configuration setup, current behavior variations, and the interplay between ALTs and feature differentials. The authors present scientifically rigorous conclusions encompassing diverse current scales and operational rates, culminating in a compelling case for the significance of ALTs in DC arc-fault detection. This exploration paves the way for exciting future developments in DC arc-fault detection systems, ultimately contributing to enhanced safety and reliability in DC power systems.

2. Arc Failure Specifications and Characteristics

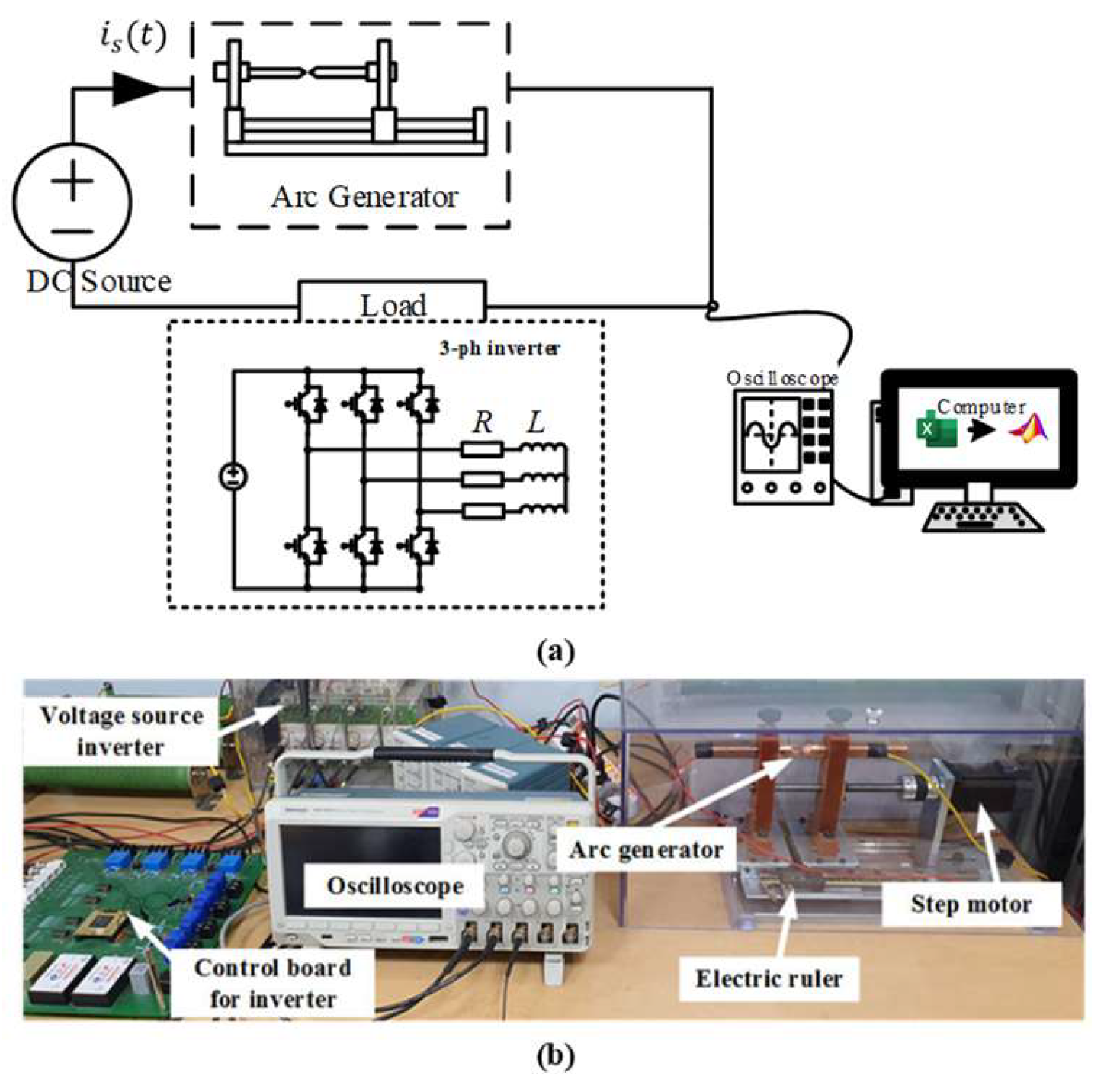

Figure 1 meticulously depicts the intricate dance of data acquisition in our study, emphasizing the rigor and control at the heart of our approach. To ensure scientific robustness, we adhered to the stringent guidelines of UL1699B [

25], meticulously crafting the arc-generation circuitry. This carefully calibrated setup utilized the controlled disjointing of arc rods as the precise trigger for arc initiation, immediately followed by the deployment of a high-fidelity oscilloscope, the Tektronix MSO3054 (Tektronix, Beaverton, OR, USA), a high-accuracy oscilloscope known for its reliability and precision. The decision to utilize this particular model was based on its reputation for providing accurate measurements across a wide range of frequencies and signal types. The Tektronix MSO3054 enabled the authors to capture and analyze the data with confidence, ensuring the integrity of our experimental results. Acquired waveforms were then subjected to rigorous analysis via advanced MATLAB routines, extracting the hidden nuances of arcing behavior. The arc generation setup itself was a symphony of essential components: a stable DC power source, a meticulously designed arc generator, and carefully chosen load elements.

Figure 1 prominently showcases the N8741A DC power supply from Keysight Technologies (Santa Rosa, CA, USA) delivering precisely controlled DC voltage to the load [

26]. An intricate interplay between a high-precision step motor and the customized arc rods ensured their controlled separation, mimicking real-world scenarios with unparalleled precision.

For uncompromising data acquisition, authors employed an oscilloscope boasting a stunning 250 kHz sampling frequency, capturing even the most fleeting of electrical nuances. The sampling rate of 250 kHz was selected based on findings from recent investigations into arc faults in DC networks [

27,

28,

29,

30]. While a higher sampling rate would yield more data points per unit time, it could also increase processing time and computational burden. Given that a key priority in arc diagnosis is prompt fault identification to swiftly isolate errors from the network, it was imperative to strike a balance between efficiency and execution time. Therefore, the sample rate of 250 kHz was deemed sufficiently high to achieve this equilibrium. Further bolstering our data fidelity, the Tektronix TCP312 (Tektronix, Beaverton, OR, USA) current probe meticulously measured arc currents with surgical accuracy. Our investigation, however, did not merely capture data, it unearthed its meaning through comprehensive exploration. We systematically generated DC arcs under a diverse tapestry of experimental conditions, yielding a rich tapestry of datasets. Each parameter was meticulously chosen, ensuring a comprehensive exploration of potential arc behavior. Our chosen source voltage of 300 V provided a realistic baseline, while current amplitudes spanning 5 to 8 A and switching rates ranging from 5 to 20 kHz pushed the boundaries of arc behavior. To further enrich our understanding, authors explored both resistive (10 Ω) and inductive (10 mH) loads, revealing the nuanced impact of circuit characteristics on arcing phenomena.

Figure 1 also unveils the beating heart of our investigation, the three-phase DC–AC converter modules. These inverters, the central load components, played a crucial role in transforming DC signals into their AC counterparts. To ensure precise control, we harnessed the power of space vector modulation (SVPWM) throughout our research. By meticulously manipulating the state of the individual six switching devices within the inverters, authors emulated the sinusoidal waveforms characteristic of the AC network with remarkable fidelity [

31]. This fine-grained control allowed us to adjust both frequency and amplitude parameters with exquisite precision, guaranteeing robust and accurate experimental conditions. It is this meticulous orchestration of data acquisition, arc generation, and control circuitry that truly sets our study apart, laying the foundation for a deep and nuanced understanding of DC arc faults.

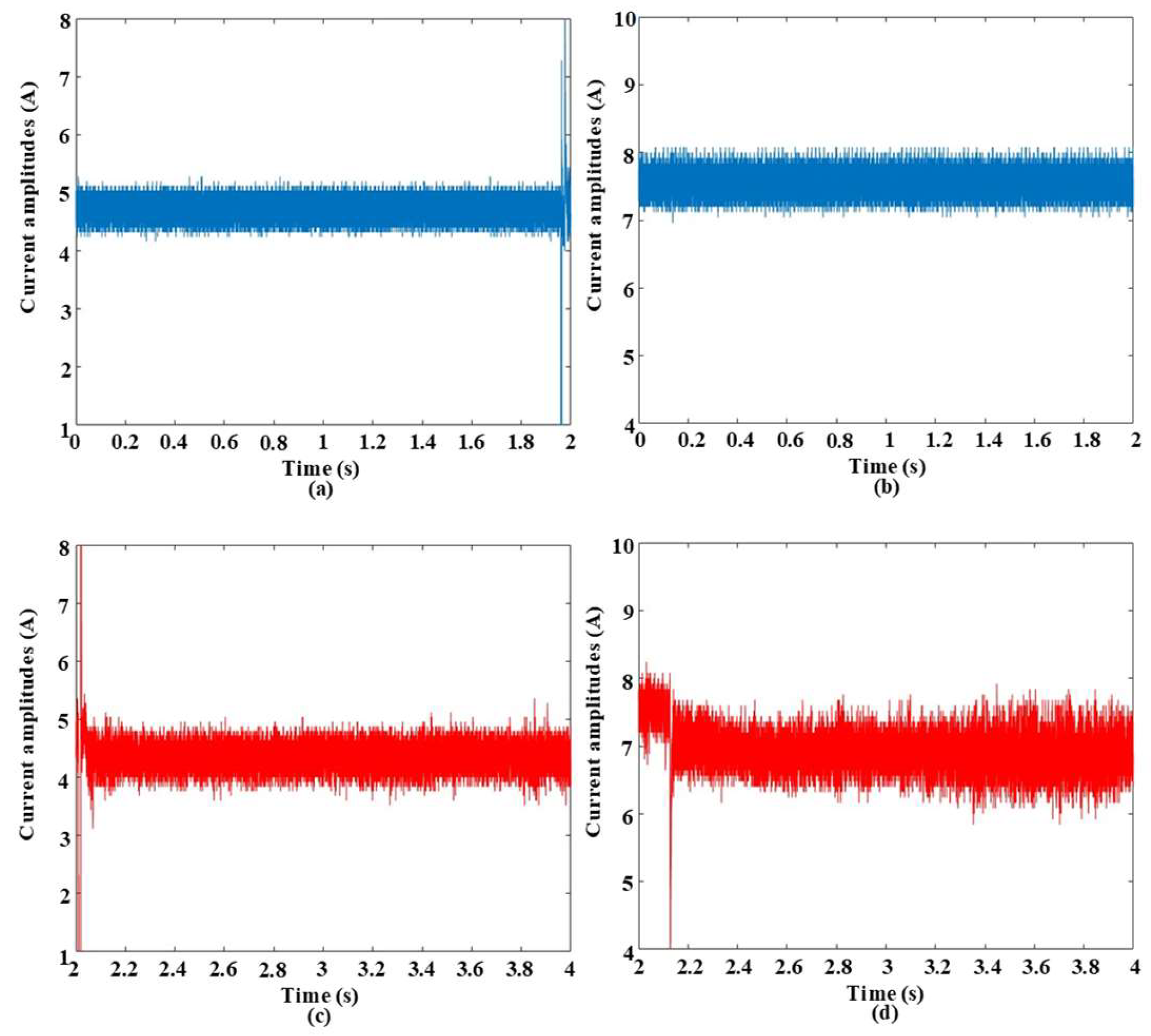

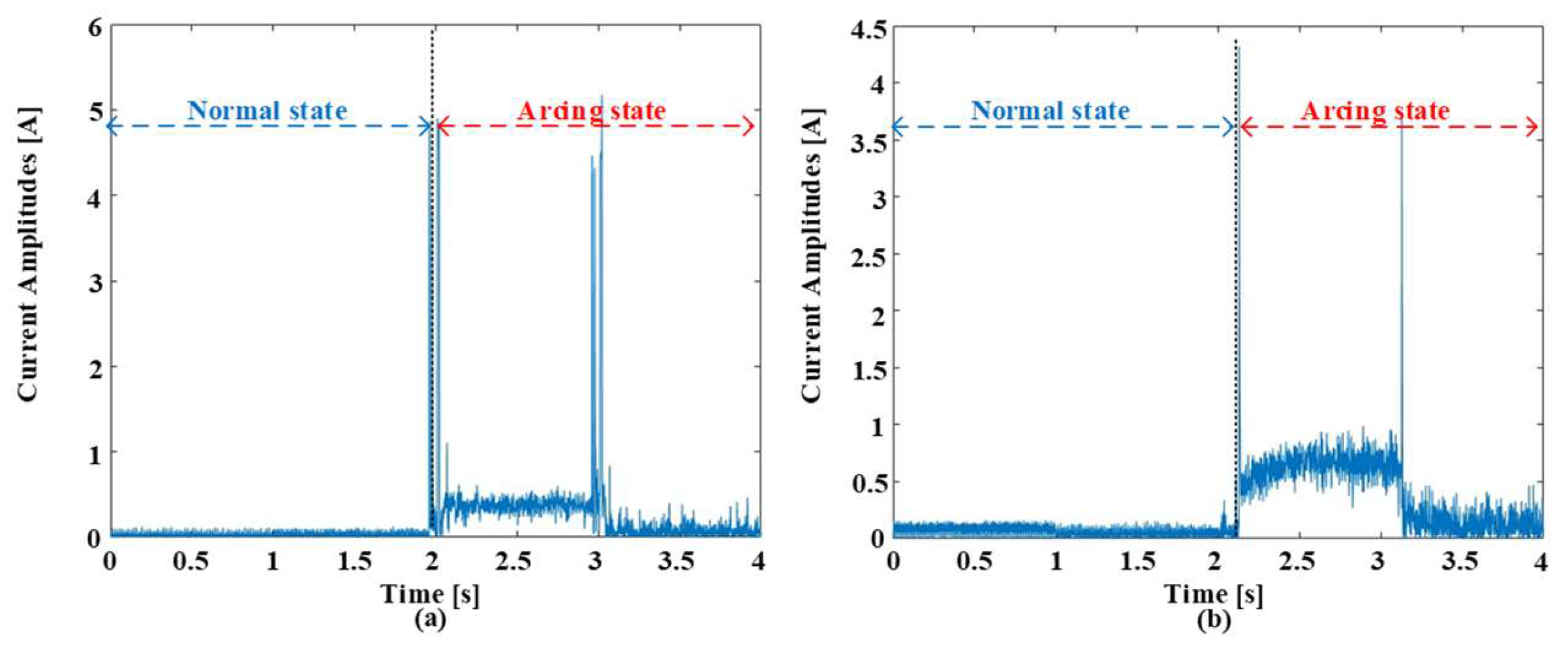

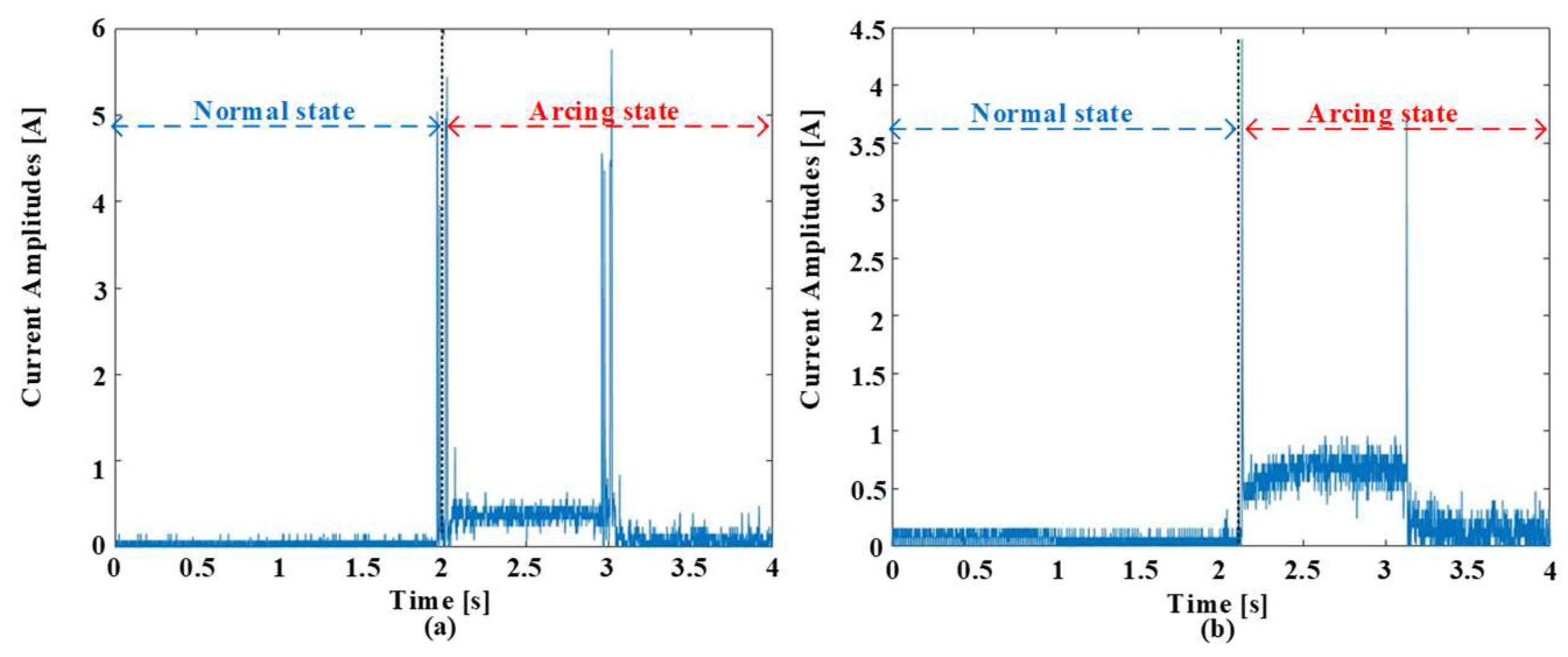

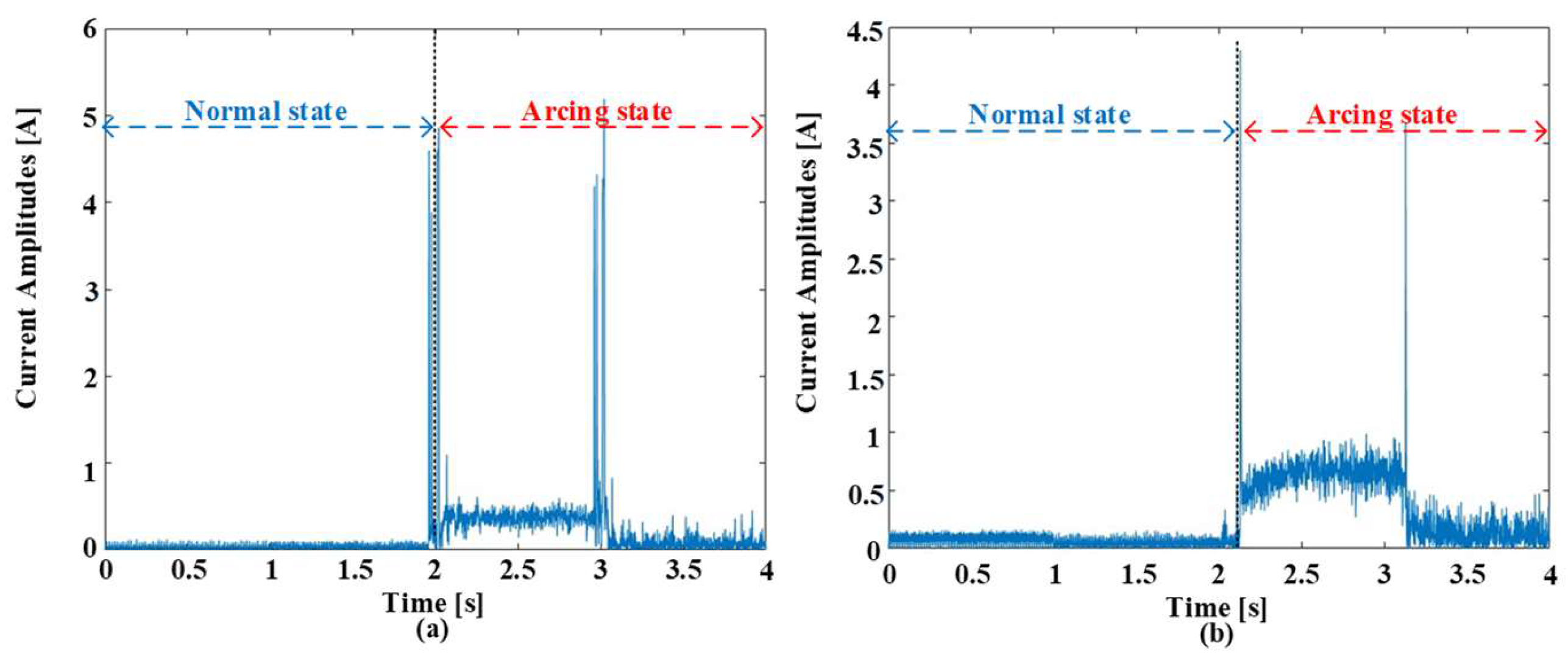

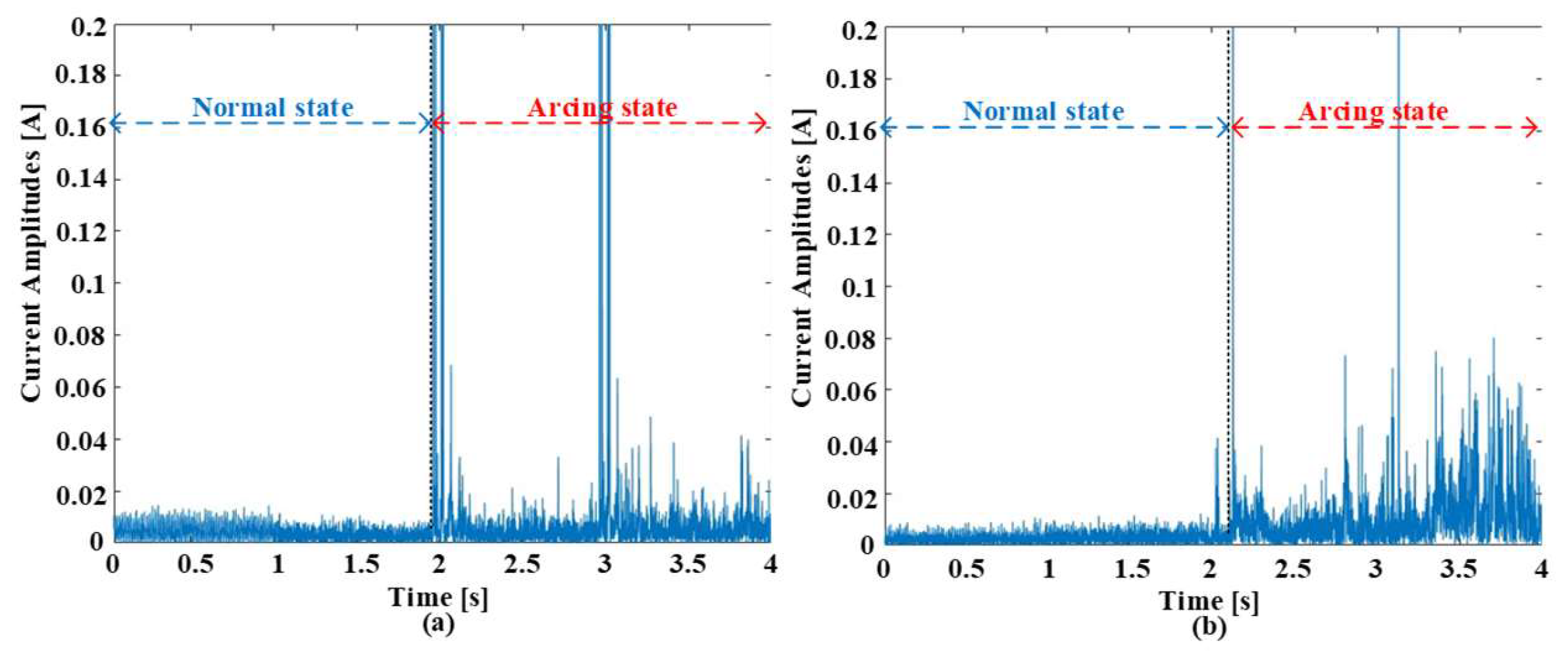

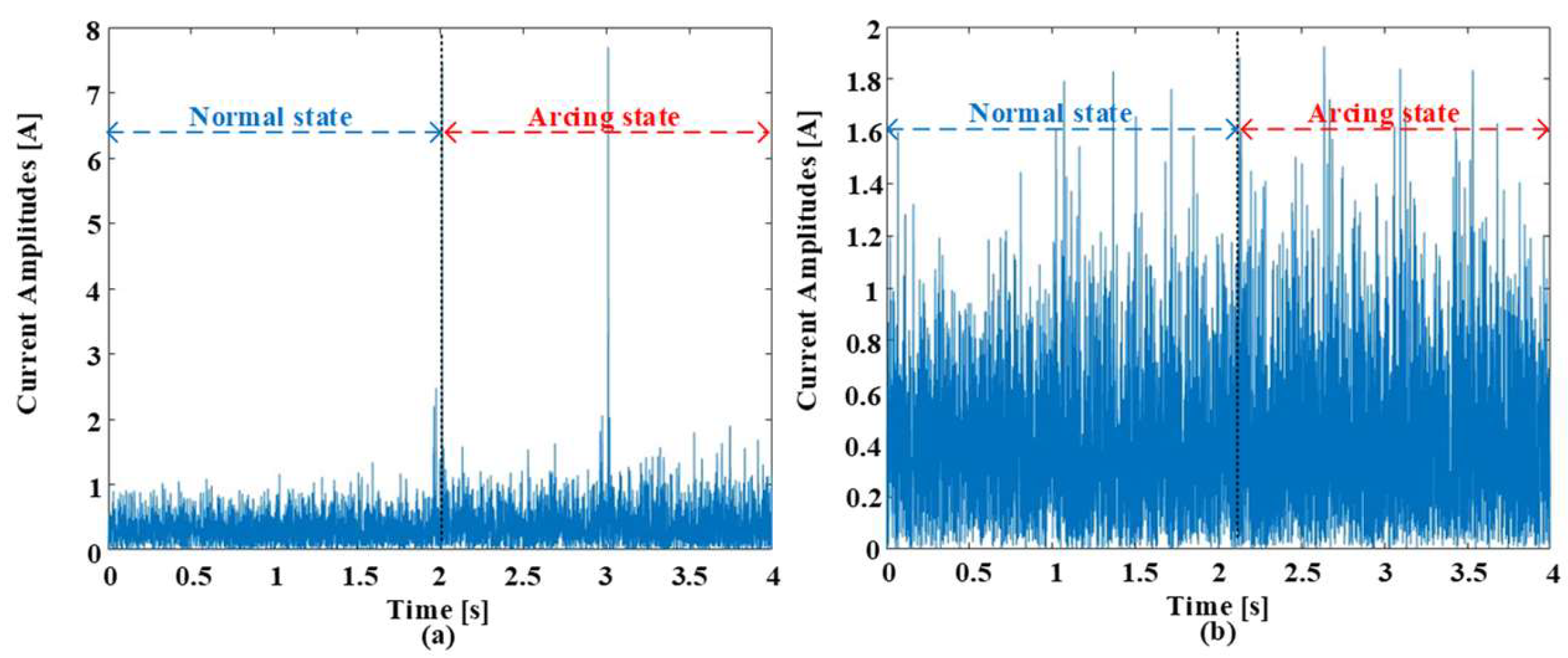

Figure 2 paints a revealing picture of how arc faults dramatically alter the electrical landscape. It showcases waveforms under both normal and arcing conditions at 5 kHz switching frequency and currents of 5 A and 8 A. Although the waveforms follow a similar pattern before the arcing event, the moment an arc forms, the delicate electrical dance erupts into chaos. This chaos manifests in multiple ways. Firstly, harmonic components infiltrate the pure load current, distorting its once smooth rhythm. Imagine ripples spreading across a still pond after a pebble is tossed in. These harmonies, like the ripples, are signatures of the electrical turbulence caused by the arc.

Interestingly, the level of distortion seems to be in increased conversation with the switching frequency, suggesting a hidden relationship between these parameters. Secondly, the current amplitude takes a slight dip upon arcing. This subtle but measurable decrease hints at the energy being diverted to sustain the arc itself. Like a siphon stealing water from a pool, the arc siphons off some of the current’s strength. Most striking, however, are the pronounced spikes in amplitude during the initial phase of the arc. These bursts, like tiny electrical explosions, are the telltale signs of the sparky drama unfolding within the circuit. Notably, the intensity of these sparks appears to waltz with the switching frequency, hinting at a deeper connection between frequency and spark magnitude. These dramatic deviations in waveform behavior are more than just visual curiosities; they hold immense promise for the holy grail of arc fault detection. Their unique dance, shaped by the interplay of arcing and switching frequency, offers a potential treasure trove of discriminative features that could unlock the door to accurate and reliable arc fault identification. It is now up to researchers to decipher the language of these electrical hieroglyphs and translate them into effective detection algorithms. The experimental current being lower than the set reference can be attributed to the fact that the impedance of the experimental setup, including the cables, connectors, and components, can introduce voltage drops along the circuit path. These voltage drops can result in a reduction in the effective voltage across the load, leading to a lower current than expected based on the set reference. The distortion in the arc current tends to be higher with higher current amplitudes due to several reasons. At higher current amplitudes, the arc intensity typically increases. This means that the arc becomes more energetic, producing higher temperatures and greater ionization of the surrounding air. As a result, the arc’s behavior becomes more erratic, leading to larger fluctuations and irregularities in the arc current waveform. Additionally, higher current amplitudes lead to increased heating within the arc, resulting in variations in the arc current waveform. Thermal effects can also induce changes in the arc’s size and shape, further contributing to distortion in the arc current waveform.

4. Diagnosis of DC Arc-Based Feature Difference of Moving Intervals and Advanced Learning Techniques

Figure 9 depicts the proposed framework for accurate arc fault diagnosis, employing a data-driven approach. The initial stage involves high-frequency sampling of continuous current data at 250 kHz. This captured data stream is subsequently segmented into subdatasets of 200 data points each, corresponding to a time interval of 0.8 milliseconds. This segmentation facilitates efficient feature extraction and computational tractability. Within each segment, time–domain features are extracted, capturing relevant characteristics of the electrical signal. Crucially, the differences between these features across consecutive segments are calculated, amplifying subtle variations and potentially revealing the presence of arc faults. There are two data ranges of faulted data being tested; the first range is the range of difference between arc and normal states (from 2 s to 3 s). The second range is the difference between arcing states (from 3 s to 4 s). These data ranges will be denoted as R1 (from 2 s to 3 s) and R2 (from 3 s to 4 s). These processed features, enriched with the temporal dynamics of the data, are then fed into advanced learning models. This provides the models with a comprehensive representation of the electrical state, enabling them to learn complex patterns and accurately classify arc faults.

Notably, the framework incorporates both training and testing phases, ensuring the models’ generalizability across diverse operational scenarios and data conditions. Maintaining a balanced data distribution throughout both phases is paramount, with a 1:1 ratio of normal and arcing state data ensuring unbiased training and promoting fair evaluation. This balanced data diet is crucial for the models’ ability to effectively discriminate between normal and arcing conditions with high accuracy. The primary metric employed to assess the performance of the advanced learning models in this context is accuracy. This metric quantifies the models’ ability to correctly identify and classify the electrical state, serving as a fundamental benchmark for performance evaluation. The accuracy metric is calculated as the ratio of correctly classified datasets to the total number of analyzed datasets.

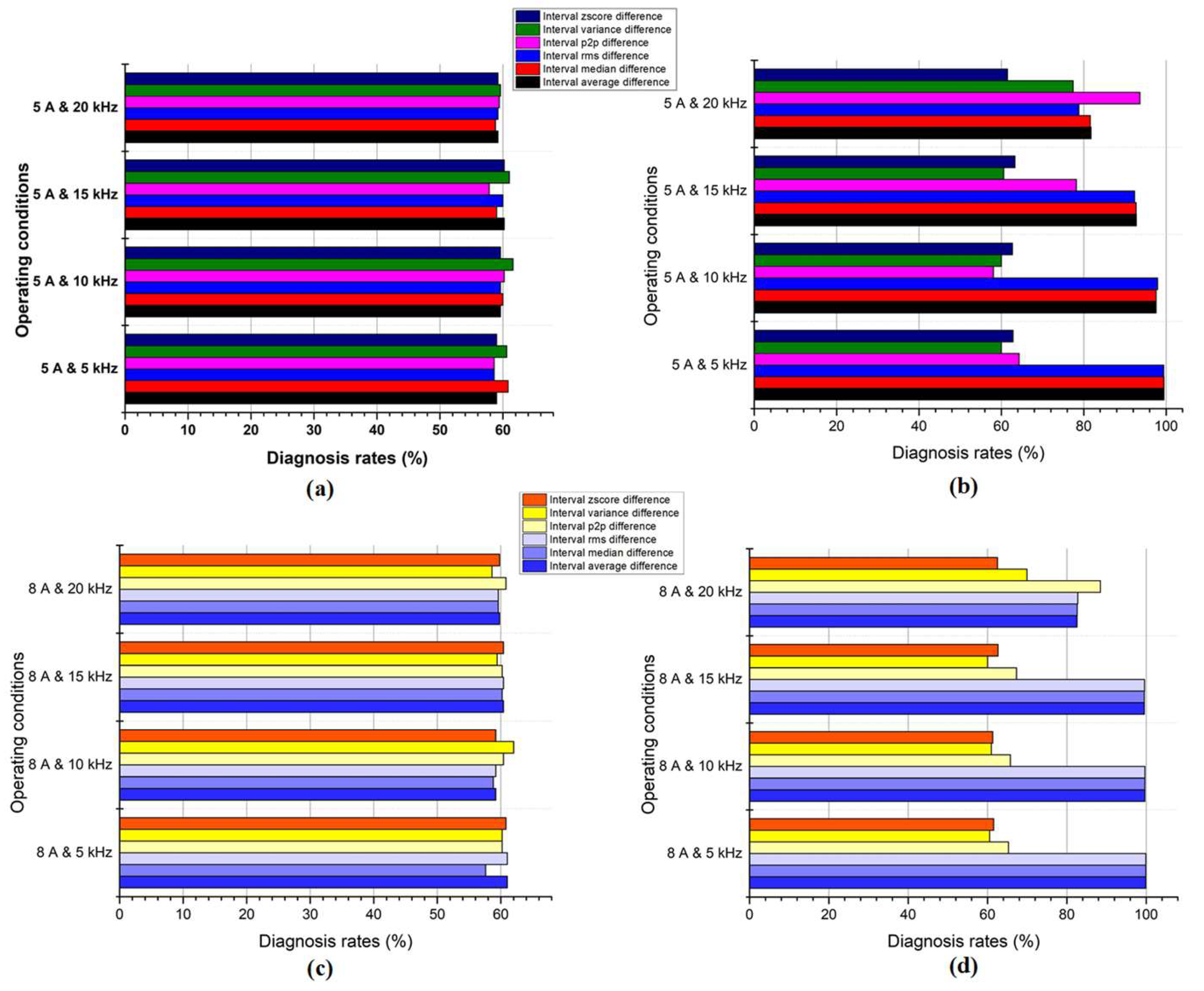

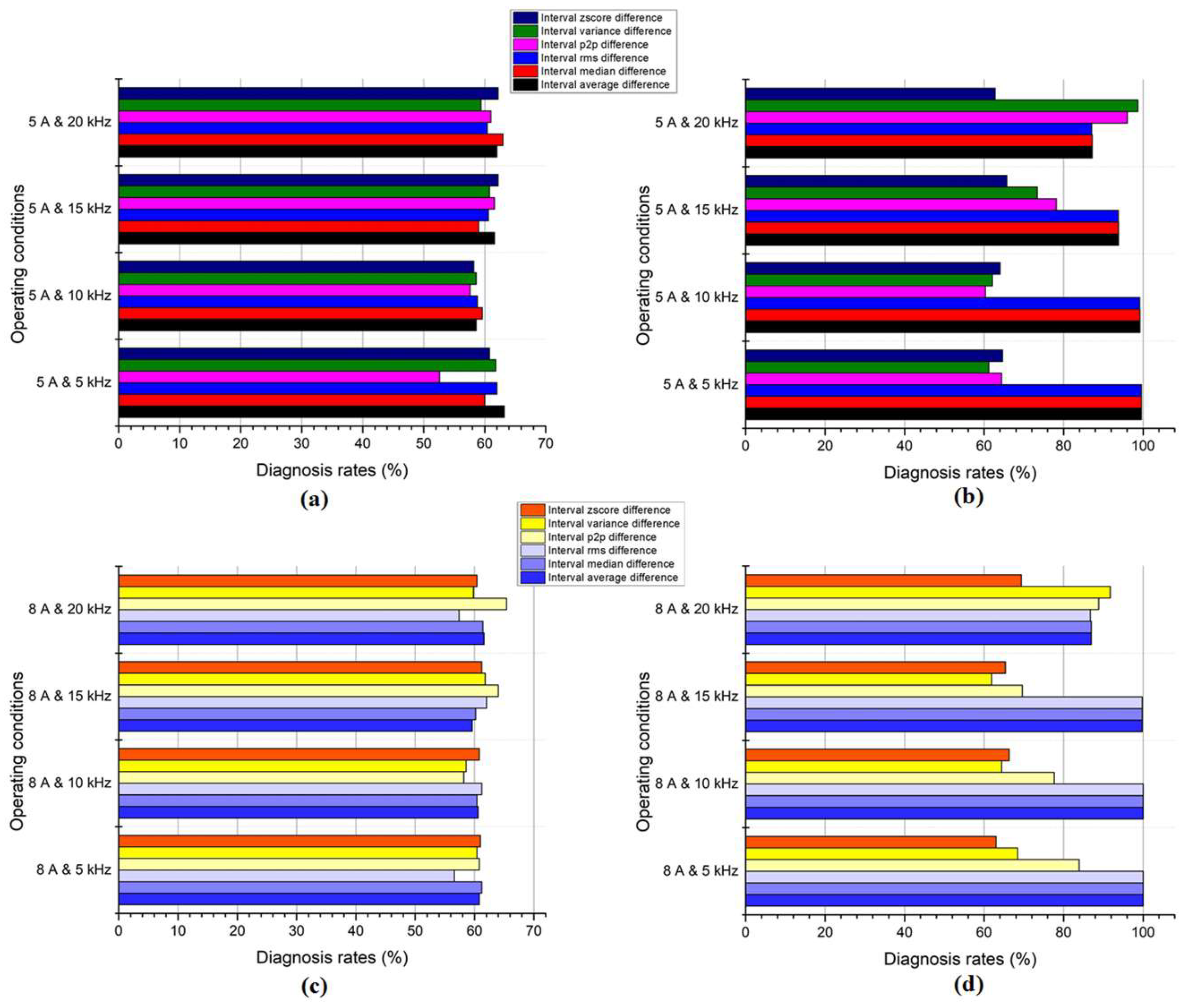

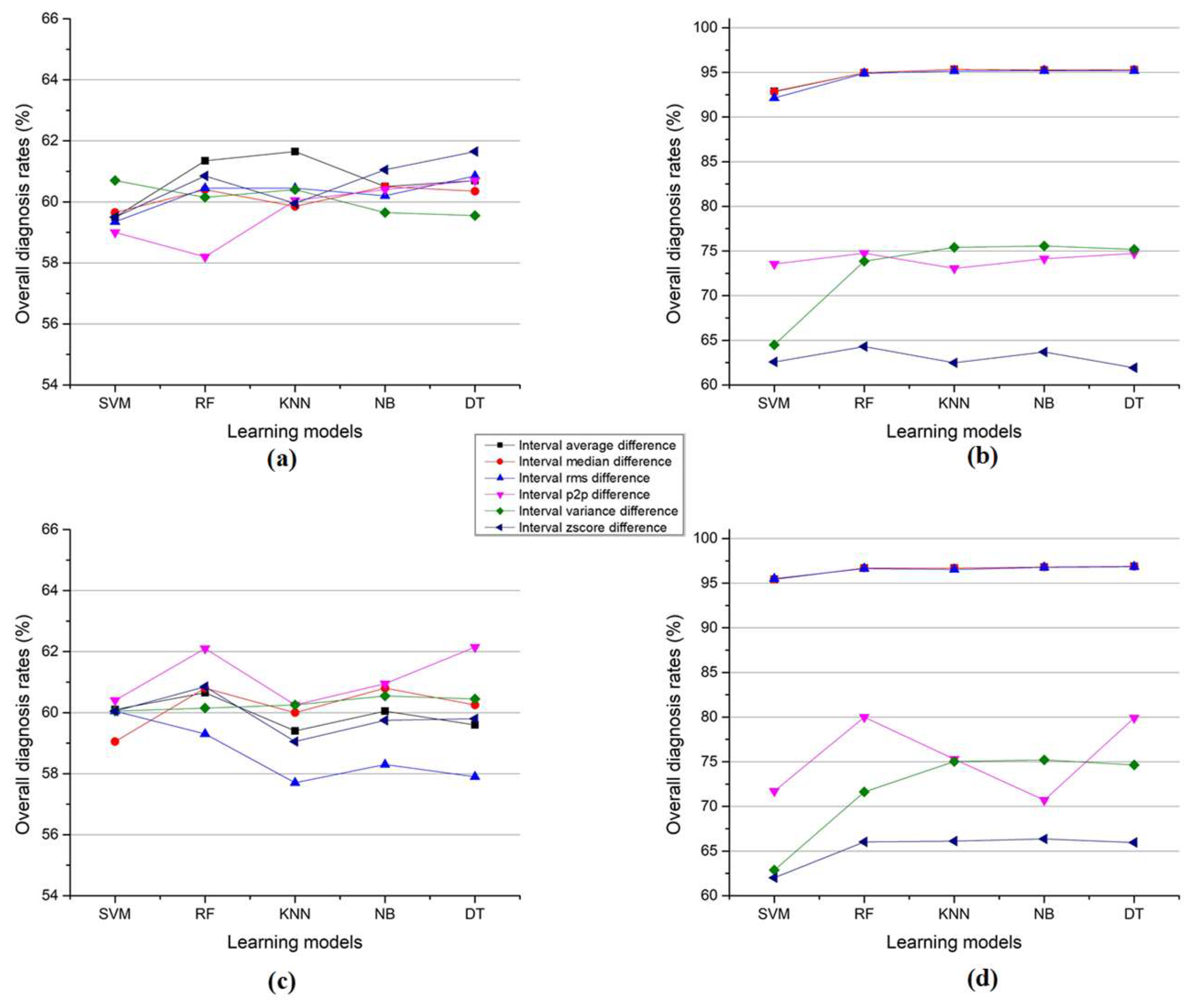

Figure 10 illuminates a compelling debate surrounding the efficacy of various features in diagnosing arc faults within a three-phase inverter. It investigates the interplay between current amplitude (5 A and 8 A), switching frequency, and the subsequent accuracy achieved by difference features between moving intervals and the SVM algorithm. The analysis conducted in

Section 3 regarding the visibility of feature differences finds validation in

Figure 10. The average, median, and RMS values emerge as the frontrunners in terms of accuracy with R1. They operate like seasoned investigators, adept at uncovering subtle clues within the data that betray the presence of an arc fault. However, the plot thickens with the introduction of switching frequency. As it increases, the accuracy of the average, median, and RMS values begins to decline. These features seem overwhelmed by the rapid fluctuations, their focus blurred by the amplified noise. P2P and variance, often less recognized investigative tools, exhibit an inverse relationship, with their accuracy climbing alongside the switching frequency. They shift their focus, honing in on the extreme and rapid changes, finding their own rhythm in the data’s turbulent dance.

The performance at the 8 A current amplitude presents a particularly intriguing scenario. Here, the accuracy curves for all features converge, with P2P and variance even reaching parity with the average, median, and RMS for R1.

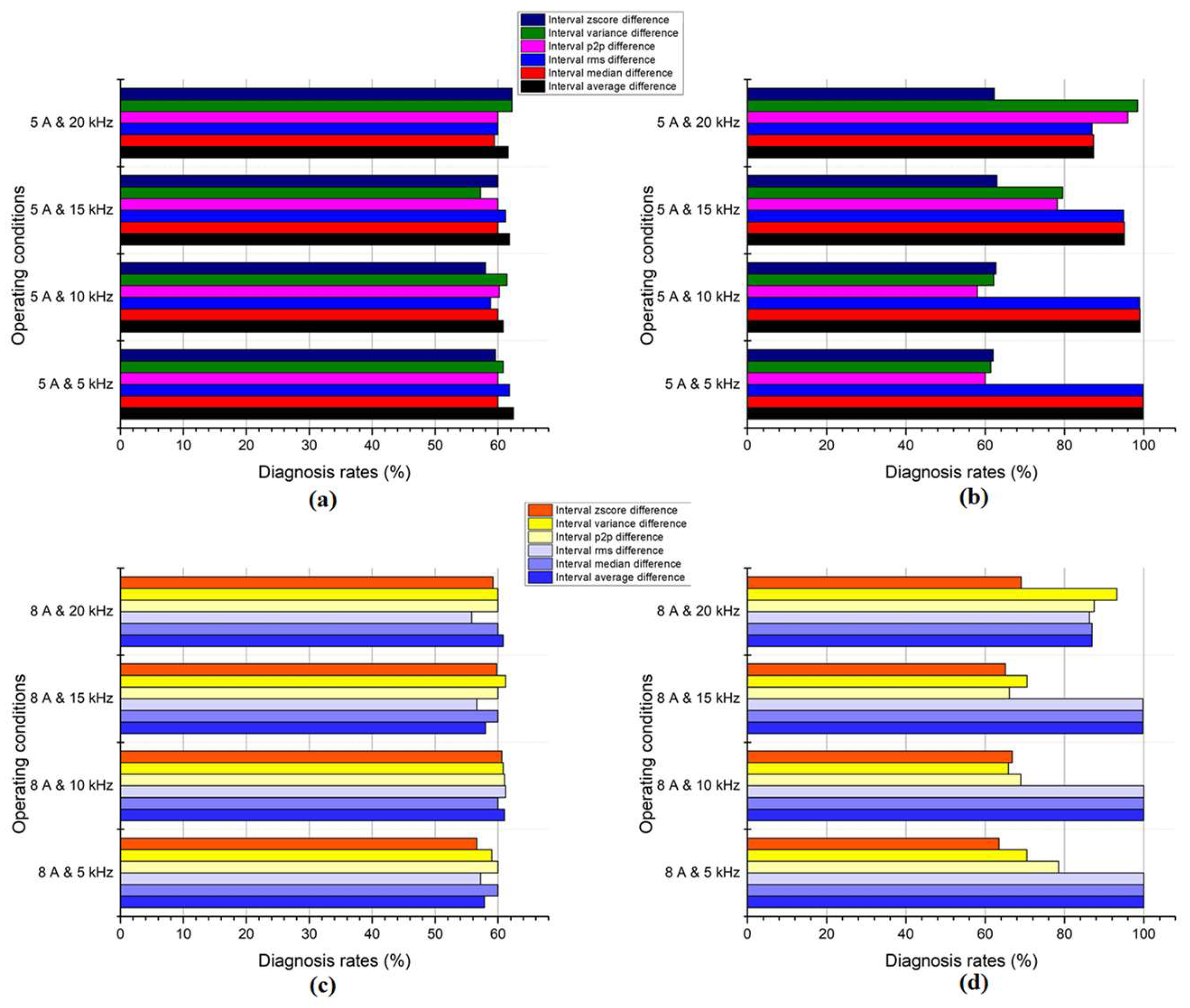

Figure 11 explores how different features perform in diagnosing arc faults in a three-phase inverter. It tests them at two current levels (5 and 8 amps) and three switching speeds. For R1, the average, median, and RMS values are the top performers at low speeds, like skilled detectives finding clues in smooth data. But as the switching increases in speed, their accuracy drops, like struggling to keep up with a chaotic crime scene. P2P and variance, often overlooked tools, shine at higher speeds, focusing on sudden changes and data extremes, like detectives chasing a fast-moving suspect. At 8 amps, all features perform similarly, showing the technique’s adaptability. This detective story reveals that different features work best in different situations, and the technique adjusts to ensure accurate diagnoses regardless. Comparing R1 and R1, R1 shows higher accuracy for all features.

Figure 12 throws open the case file on arc faults in a three-phase inverter, with the KNN algorithm as our trusty forensic tool. Different features in R1, like the average, median, and RMS, act as seasoned investigators, analyzing data clues to identify the culprit. However, the plot thickens with the rising tide of switching frequency. The rapid electrical fluctuations overwhelm our usual suspects, their focus blurred like detectives in a high-speed chase. P2P and variance, often the overlooked duo, step into the spotlight. They are like hawks circling a carcass, thriving on the data’s extremes and sharp changes. Their unique skills actually benefit from the chaos, and their accuracy soars with faster switching. The 8 A current amplitude introduces another twist. Here, all features find their rhythm, with P2P and variance even matching the established trio.

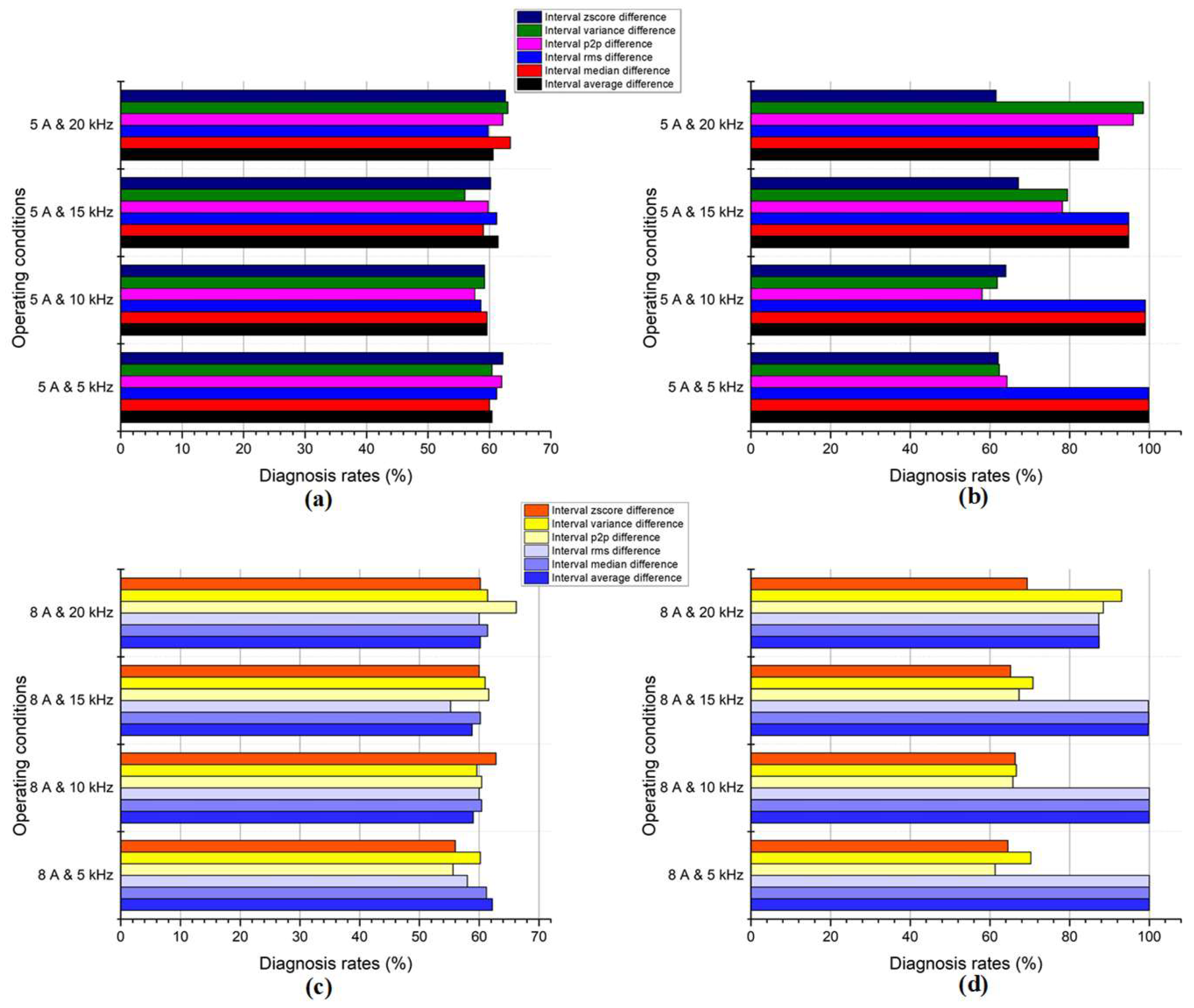

Figure 13 throws shade on the reliability of different tools for spotting arc faults in a three-phase inverter. It tests them at two current levels and three switching speeds, using NB as the detective agency. For R1, the average, median, and RMS are the early stars, like experienced cops good at picking out subtle clues. However, as the switching increases in speed, their accuracy tanks, overwhelmed by the data’s wild swings. P2P and variance, the underdogs, thrive in the chaos, focusing on sudden changes and data extremes, like detectives chasing a fast-moving suspect. For R2, all the features return mediocre performances. At 8 amps, a similar trend as 5 A is observed for both R1 and R2. This shows the outperformance of R1 compared with R2 across various operating conditions.

Figure 14 tackles the mystery of arc faults in a three-phase inverter. It is like a detective thriller, where different features, our sleuths, try to solve the case using clues hidden in the data. The criminal’s tactics change with two variables: the electrical flow (5 or 8 amps) and how fast the system switches (frequency). The usual suspects in R1, the average, median, and RMS, are brilliant at low speeds, picking out subtle patterns in the data. However, as the switching becomes faster, the case becomes tricky. They stumble, overwhelmed by the rapid changes, like detectives in a high-speed chase. P2P and variance are often overlooked; they are like hawk-eyed investigators, thriving on the data’s chaos. They zero in on the extremes and swift changes, their accuracy even rising with higher speeds. It is like they’re dancing to the data’s wild rhythm, while the others struggle to keep up. For R2, the accuracies of all features are lower than that of R1 across various current amplitudes and switching frequencies.

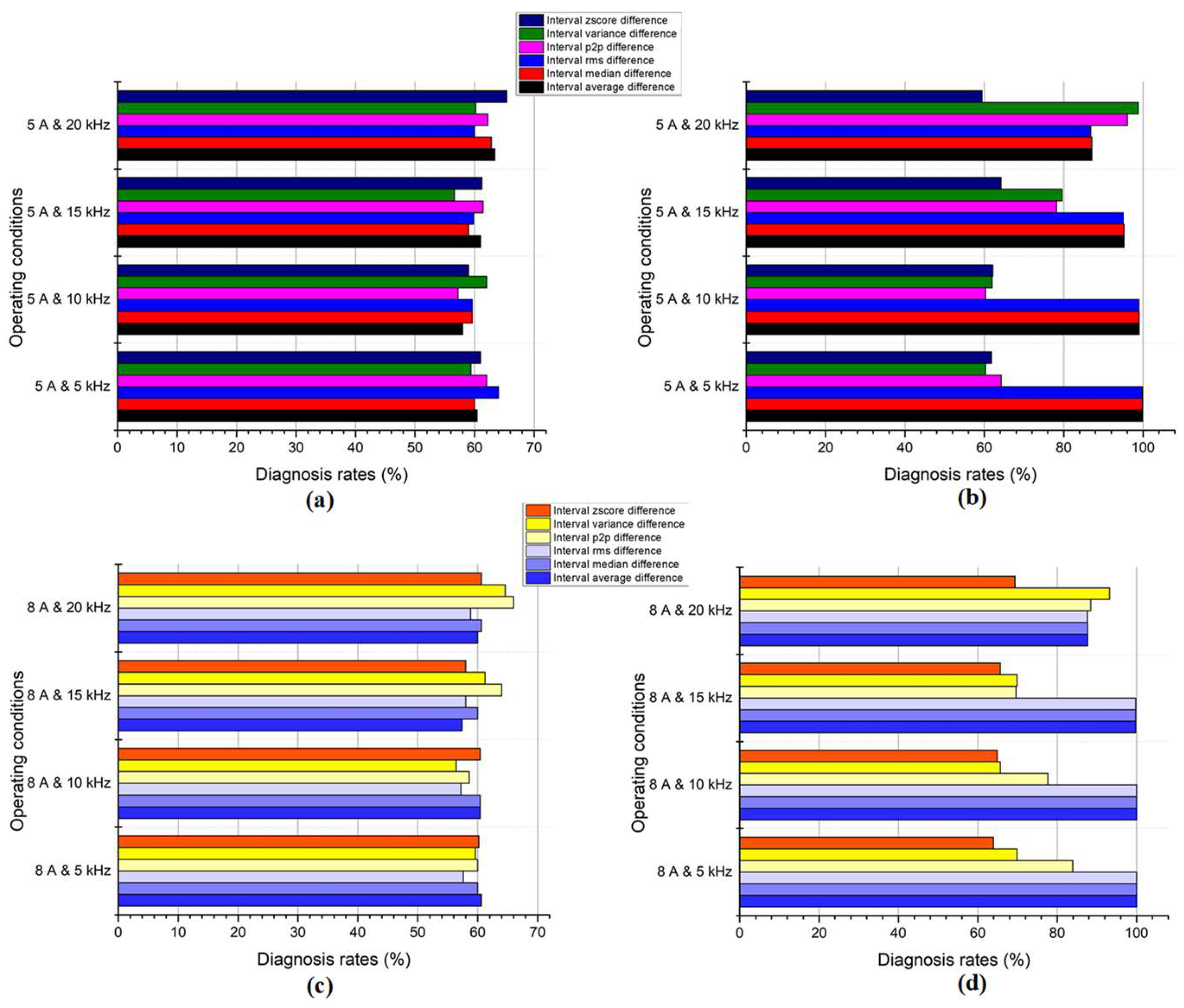

Figure 15, through its comparative analysis of different features, offers invaluable insights for the future refinement and optimization of DC arc-fault detection. It serves as a guide for developing more effective strategies to apprehend DC arc faults, paving the way for enhanced electrical safety measures and reduced risks of catastrophic events. The results displayed in

Figure 10,

Figure 11,

Figure 12,

Figure 13,

Figure 14 and

Figure 15 were derived from experiments conducted with an AC load configuration encompassing both resistive and inductive elements. The experimental setup was crafted to mirror real-world scenarios, where electrical systems often comprise a diverse array of loads representing a mix of resistive and inductive components. While the primary objective of this study revolves around introducing our methodology and showcasing its effectiveness in detecting arc faults under conditions reflective of real-world load diversity, the authors fully acknowledge the significance of exploring how different load types may influence detection performance. Recognizing the complexity of electrical systems and the potential variations in load characteristics across different applications, the author aims to conduct in-depth analyses to delve into the impact of load composition on the performance of the proposed detection approach. By examining results obtained under varying load conditions, the authors aspire to uncover nuanced insights into the interplay between load types and detection algorithm performance. Ultimately, the aim is to advance the understanding of how different load compositions may impact the efficacy and reliability of arc fault detection algorithms, thus contributing to the development of more robust and adaptive diagnostic techniques for electrical systems. The proposed approach relies on analyzing the difference between moving intervals to detect arc faults in DC circuits. When noise influences the current, it induces fluctuations in both normal and arcing states. However, the fluctuations in the arcing state are typically more pronounced than those in the normal state. As a result, when comparing the difference between the moving intervals, the proposed approach can effectively distinguish between normal operation and arc faults.

This is because the significant fluctuations observed during arc faults lead to larger differences between consecutive intervals compared to the relatively smaller differences observed during normal operation. By leveraging this characteristic, the proposed approach can accurately detect arc faults by identifying intervals where the difference exceeds a certain threshold. This analysis demonstrates the robustness of the proposed approach in effectively detecting arc faults in DC circuits, even in the presence of noise-induced fluctuations in the current signal.

Indeed, in more complex DC grids, noise on the DC part can arise from various sources, potentially leading to disturbances in the current signal. While the method described in the paper primarily focuses on detecting arc faults induced by the DC/AC inverter, it is important to acknowledge the potential presence of noise in the DC part from other sources. The assumption of relatively low noise in the DC part simplifies the analysis and facilitates the detection of arc faults primarily caused by the DC/AC inverter. However, in real-world scenarios where noise levels may be higher, additional measures may be necessary to account for and mitigate the effects of noise on the accuracy of arc-fault detection. Future research could explore methods to adapt the proposed approach to handle higher levels of noise in the DC part, ensuring robustness and reliability in detecting arc faults in more complex DC grids. In practical applications, it is not uncommon to encounter inverters with switching frequencies exceeding 20 kHz, highlighting the need to address the potential limitations of the proposed method in such scenarios. While the current method primarily focuses on analyzing signals generated by inverters with relatively low switching frequencies compared to the sampling frequency, it is imperative to recognize the impacts of higher switching frequencies on the dynamics of the current signal. Inverter systems with higher switching frequencies may exhibit distinct signal characteristics and behavior, necessitating additional considerations to ensure the effectiveness of the proposed detection method. To address this concern, future research endeavors will delve deeper into the implications of higher switching frequencies on the performance of the proposed method. This exploration will involve analyses to understand how the signal dynamics vary across different switching frequency ranges. Additionally, the authors will investigate potential modifications or adaptations to the existing detection framework to accommodate a broader spectrum of inverter configurations, including those with higher switching frequencies. These modifications may include refining feature extraction techniques, optimizing algorithm parameters, or developing specialized signal processing algorithms tailored to handle the unique challenges posed by high-frequency switching. While the current study focuses on proposing theoretical frameworks and methodologies for arc-fault detection, the authors acknowledge the necessity of experimental validation to assess the practical effectiveness of these approaches in real-world scenarios. However, it is important to emphasize that experimental validation is a critical component that will be executed in future work. Given the complexity and scope of the experimental setup required for rigorous validation, it was deemed prudent to prioritize the development and presentation of robust theoretical frameworks and methodologies in this initial study. These experiments will involve the implementation of the proposed methods in real-world settings, utilizing appropriate hardware setups and data acquisition systems. By conducting experiments under varying conditions and scenarios, the authors aim to evaluate the performance of the approaches in realistic environments and assess their efficacy in accurately detecting arc faults. Indeed, each PWM technique introduces unique variations in the signal characteristics, particularly in response to the occurrence of an arc fault. These variations stem from the specific modulation strategies and switching patterns employed by each PWM technique. For instance, AZPWM, SPWM, and SVPWM each exhibit distinct voltage and current waveforms, harmonics, and switching patterns. When an arc fault occurs, these characteristics may undergo further alterations, such as amplitude fluctuations, frequency shifts, and waveform distortions, depending on the PWM technique implemented. In future work, the authors plan to investigate how these unique variations in signal characteristics, induced by different PWM techniques, can be leveraged in conjunction with our proposed approach for arc detection. By systematically analyzing the response of each PWM technique to arc faults, the authors aim to identify specific features or patterns that are indicative of fault conditions. These features can then be incorporated into our detection algorithm to enhance its robustness and effectiveness across diverse PWM implementations.