1. Introduction

With the development of modern manufacturing technology, the aviation, aerospace, communications, medical, and bioengineering fields have put forward more stringent requirements for the processing quality of critical components [

1,

2]. For complex and brittle materials such as engineering ceramics, optical glass, single crystal silicon, and composite materials that are difficult to process and whose processing accuracy is difficult to maintain, the most commonly used processing method is to grind them with superabrasive grinding wheels [

3,

4,

5]. The grinding process leverages the micro-cutting effect of numerous grains on the grinding wheel’s working surface to remove material. It shows incomparable advantages in high-precision machining of various difficult-to-machine materials. Furthermore, grinding is essential to ensuring the machining accuracy and surface quality of hard and brittle materials. The grinding wheel surface profile precision directly affects the workpiece material removal rate, surface integrity, ground surface roughness, and so on [

6,

7,

8]. Dressing grinding wheel surface to achieve an ideal wheel surface profile is meaningful for maintaining the material removal efficiency and machining workpiece surface accuracy.

The objective of dressing the grinding wheel is twofold: to achieve a high-precision geometric profile, and to ensure an ample number of sharp grains on its surface. Both are vital for the precision grinding process [

9,

10]. Holesovsky et al. [

11] used diamond dressers to conduct a comparative study on the performance of grinding surface roughness, and the results showed that the dressing speed and dressing depth of the grinding wheel have a significant impact on the surface roughness. Palmer et al. [

12] studied the effect of roller dressing on the surface topography, morphology, and characteristics of alumina grinding wheels with different grain shapes, and the study found that very rough grinding wheels are produced at higher feed rates and speed ratios. As reported by Riemer et al. [

13], the well-dressed electroplated coarse-grained diamond grinding wheel could obtain a ground workpiece surface with surface roughness in the nanometer scale. The truncated diamond abrasive grains with a flat top surface and smaller abrasive protrusion height is meaningful for precision grinding optical glass. A novel dressing method for electroplated coarse-grained diamond grinding wheel using thermochemical reaction between diamond and iron-based materials was introduced in the article. Electroplated coarse-grained diamond grinding wheels were successfully dressed with an iron-based dressing block. Zhang et al. [

14] combined the material water jet system with touch grinding to achieve precise grinding and coarse-grained metal-bonded diamond grinding wheel dressing. Zhao et al. [

15,

16] used electrolytic in-process dressing (ELID) technology combined with metal-based diamond dressing wheels to dress electroplated coarse-grained diamond grinding wheels with grain sizes of D 46

, D 91

, and D 151

, and the low wear rate of the dressed coarse-grained grinding wheel ensures high surface shape accuracy and low machining costs. Due to the extreme hardness of large size diamond abrasive grits and the high bond-grain holding strength, the well dressing of electroplated coarse-grained diamond grinding wheels is still a great challenge. Moreover, the influence of the wheel surface characteristics on the ground workpiece surface quality and the criterion for judging the dressing status of coarse-grained diamond grinding wheels are still unclear. Therefore, it is necessary to improve the understanding of coarse-grained diamond grinding wheel dressing.

It is well known that the grinding wheel surface features, such as the dressing conditions, the average abrasive grain protrusion height, the effective abrasive grain number, and so on, have a tremendous influence on the ground surface quality. Nguyen et al. [

17] studied the influence of grinding wheel surface topography parameters on grinding process, and reported that there is a relationship between the grinding wheel surface topography parameters and surface roughness. Wang et al. [

18] found that the grinding surface morphology characteristics are closely related to the grinding parameters by analyzing and screening the grain trajectories on the workpiece. The surface roughness is improved at small cutting depths as the grinding speed and feed ratio increase. Kacalak et al. [

19] proposed that the machining potential of abrasive tools depends on the grinding wheel structure, the type and performance of grain and bond, the geometric parameters of grain, and active surface morphology. However, it is difficult to measure changes in the surface morphology of the grinding wheel in real-time during actual grinding. To overcome this problem, many researchers have devoted themselves to modeling and simulating the grinding process. Grinding wheel surface topography modeling has gradually become an important method to study the changes in grinding wheel surface topography and its impact on the grinding process. Liu et al. [

20] proposed the basic topographic parameters of grains and two evaluation indices of the grain protrusion degree and the dispersion degree of the grain protrusion area to parametrically evaluate the surface topography of the grinding wheel and a three-dimensional model for the surface topography of the resin-bonded grinding wheel was established. Qiao et al. [

21] proposed a non-Gaussian statistical model to simulate the mill grinding wheel topography, based on the distribution characteristics of grains induced by observing the grinding wheel surface topographies with different grain sizes, and 3D parameters of “Birmingham 14” were introduced to assess the grinding wheel surface quantitatively. Chen et al. [

22] used the moving-average model to reconstruct the surface morphology of the grinding wheel based on the measured data on the grinding wheel surface. Liao et al. [

23,

24] digitized the extracted three-dimensional contour features of the grinding wheel through linear transformation, established a moving average model based on the time series method to generate the surface topography of the grinding wheel, and based on this, a method for generating grinding surfaces with different autocorrelation functions and statistical parameters was established. Salisbury et al. [

25,

26] proposed a grinding wheel surface modeling method based on the measured grinding wheel surface and two-dimensional Fourier transform. Existing research indicates that we can quantitatively assess grinding performance using the morphological characteristics of both the grinding wheel and workpiece surfaces. Therefore, predicting the morphological characteristics and roughness of the workpiece surface is of great significance to improving the grinding quality of the grinding wheel after grinding and dressing.

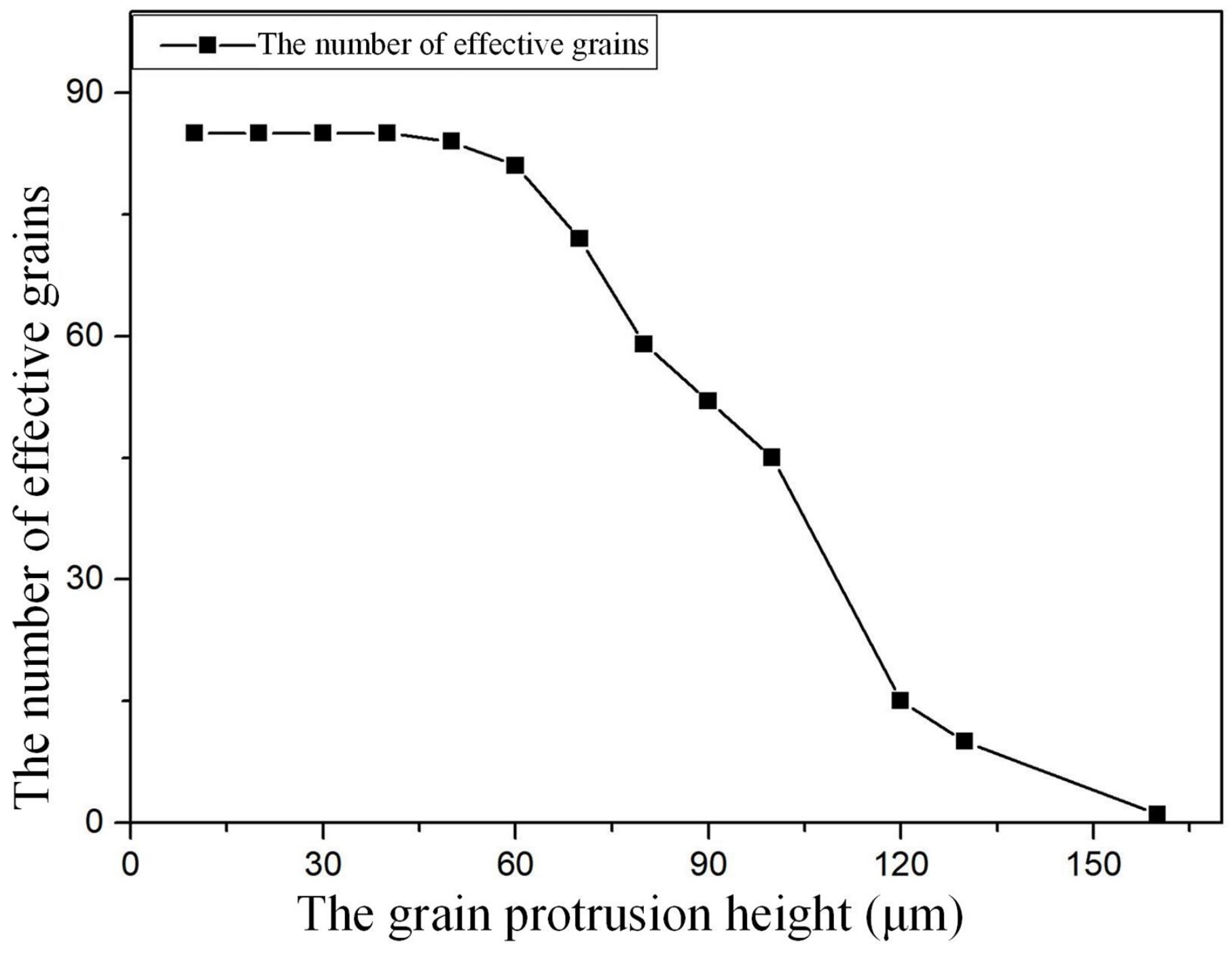

In view of this, this paper aims to establish a morphology evolution model of the coarse-grained diamond grinding wheel surface and workpiece surface based on the dressing characteristics of the grinding wheel to study the evolution of dressing parameters on the morphology characteristics of the grinding wheel surface and workpiece surface. This model fully considers the grinding wheel surface morphology characteristics, such as the number of grains, the geometric shape of the grains, and the cutting-edge height of the grains, and uses numerical modeling to predict the grinding wheel surface and workpiece surface details after dressing. Combined with the dressing and grinding test results of the electroplated coarse-grained diamond grinding wheel, the surface morphology characteristics of the grinding wheel and the changes in the workpiece surface morphology with the protruding height of the grains after dressing were analyzed. Finally, the effectiveness of the model is evaluated by comparing the simulated morphology obtained with the actual morphology observed experimentally.

2. Establishment of Surface Morphology Model

2.1. Shape of the Grain

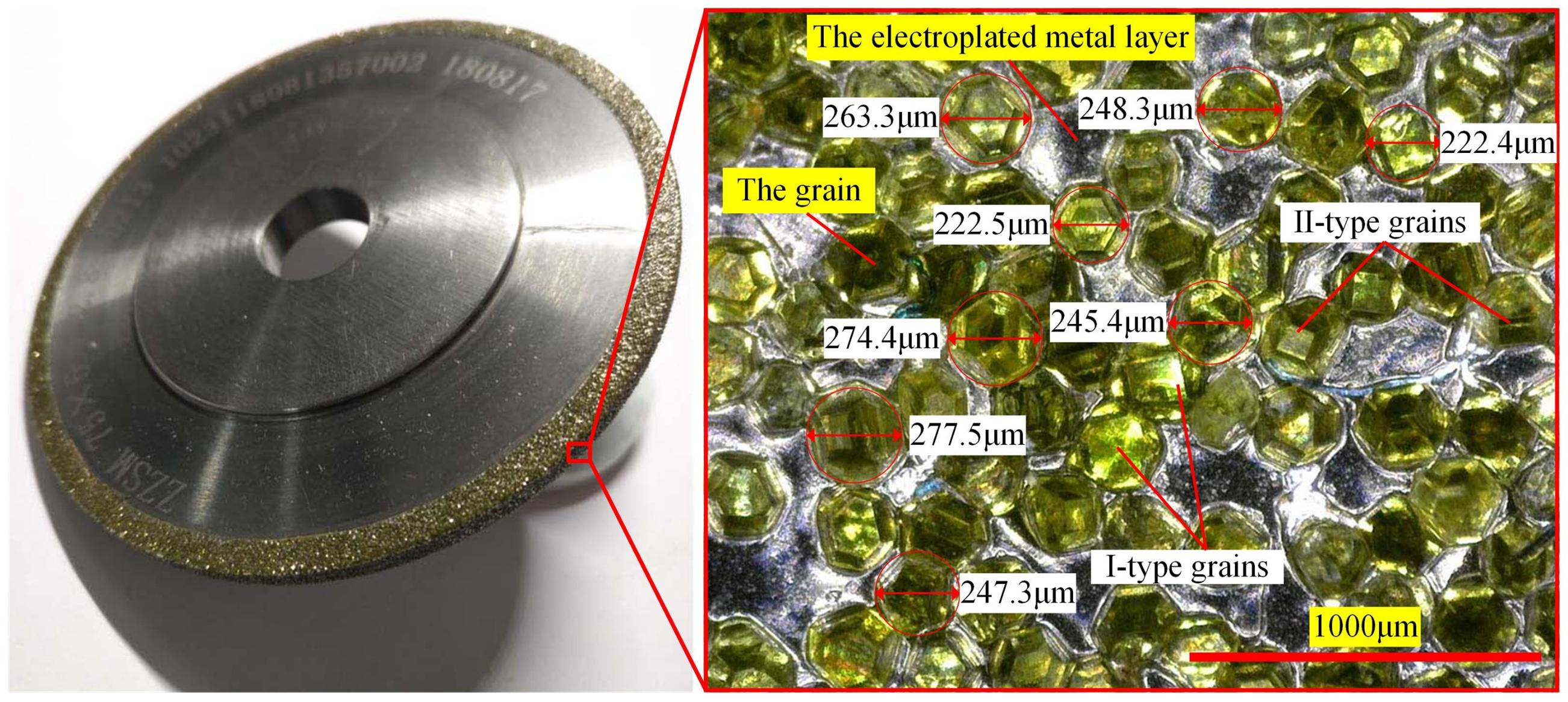

The single-layer electroplated coarse-grained diamond grinding wheel used is shown in

Figure 1. The grains on the grinding wheel are regular in shape, uniform in color, distributed randomly, and exhibit significant protrusion. To thoroughly investigate the impact of the grinding wheel dressing surface on the workpiece’s three-dimensional morphology, our model generates each grain on the surface independently. This generation considers grain parameters, including the grain shape coefficient and grain size. The model also accounts for the randomness of individual grain contours and their distribution on the grinding wheel, enhancing the accuracy of the grinding topography prediction.

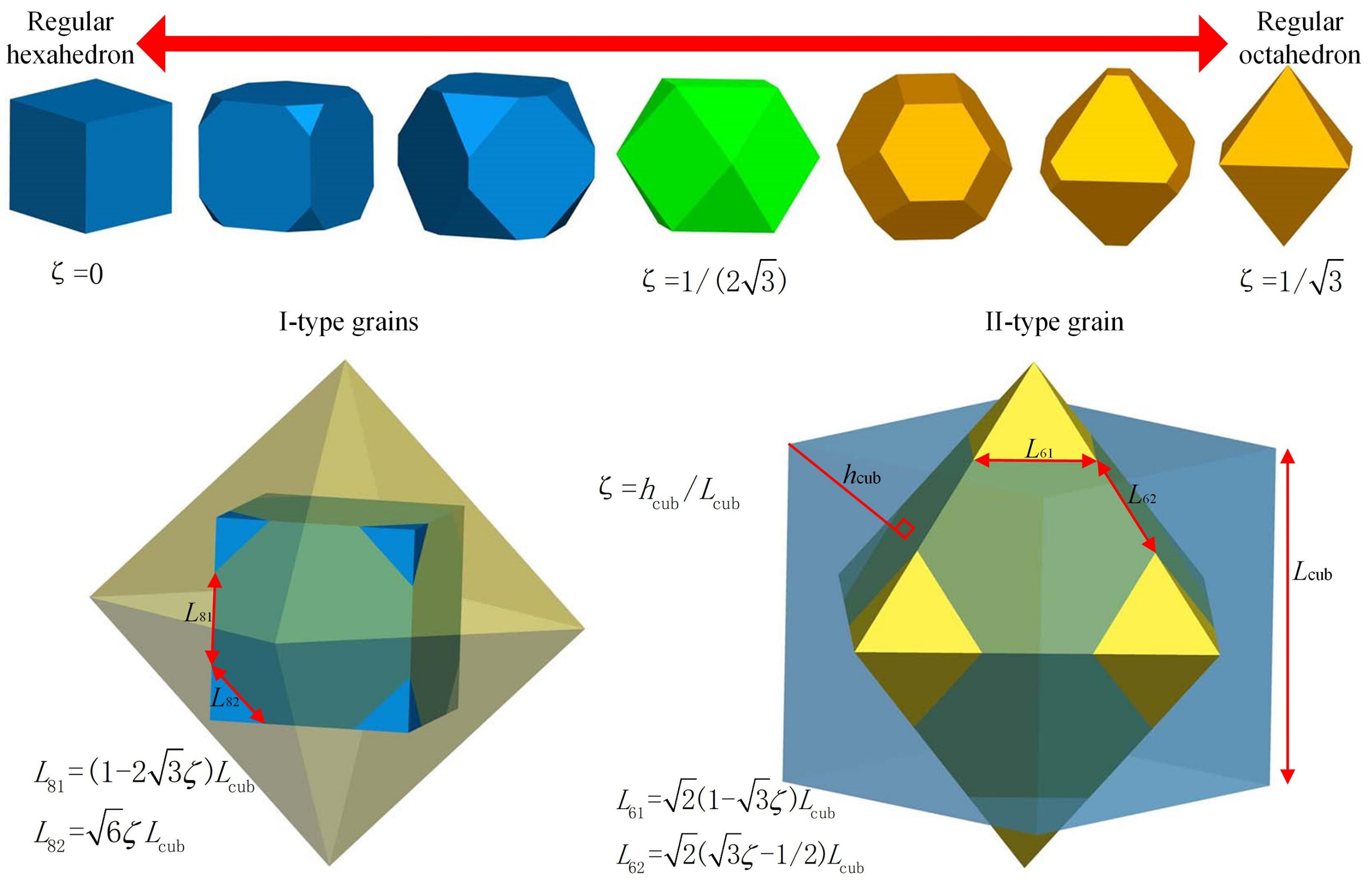

The generation parameters of the grains are independent of each other, so the generated grains are affected by the randomness of the synthesis conditions and have certain differences. The evolution of the crystal shape of grains is shown in

Figure 2. The shape of the grains is formed by truncating regular hexahedrons and regular octahedrons [

27]. The shape of the grains can be described by the shape coefficient

, which is the ratio of the distance

from the vertex of the regular hexahedron to the surface of the regular octahedron and the side length of the regular hexahedron

. If

, the shape of the grain is a regular hexahedron. If

, the grains are I-type grains mainly composed of regular hexahedrons. If

, the grain is a composite shape of a regular hexahedron and a regular octahedron with equal side lengths truncated from each other. If

, the grains are II-type grains dominated by regular octahedrons. If

, the shape of the grain is the regular octahedron.

Based on the evolution of the grain shape, the size of the grains depends on the truncation size of the regular hexahedron and the regular octahedron. Therefore, the maximum diameter

of the grains is shown in Equation (

1):

During the grinding process, the material removal and surface morphology of the workpiece are closely related to the shape/size of the grains. The normal distribution

of the grain shape coefficient and the normal distribution

of the maximum grain size

is applied to the generation of the surface grain; the grain size is calculated using the grain maximum diameter and grain shape coefficient, and thereby generating the specific contour of the grain. The schematic diagram of grain parameters and grain placement orientation used for modeling the surface topography of the grinding wheel is shown in

Figure 3. The grain rotates around the

axis and obeys a uniform distribution of

.

The rotation angles of the grains around the

, and

axes on the surface of the grinding wheel are

, and

, respectively. The coordinates

A of any point on the surface of the grain is

, and the coordinates after rotation are

. It can be expressed as Equation (

2):

In the formula, —the initial position of any point of grain. —the position after adjusting the orientation of any point of the grain. —the rotation angle of grain around the , and axes.

2.2. Spatial Orientation of the Grains

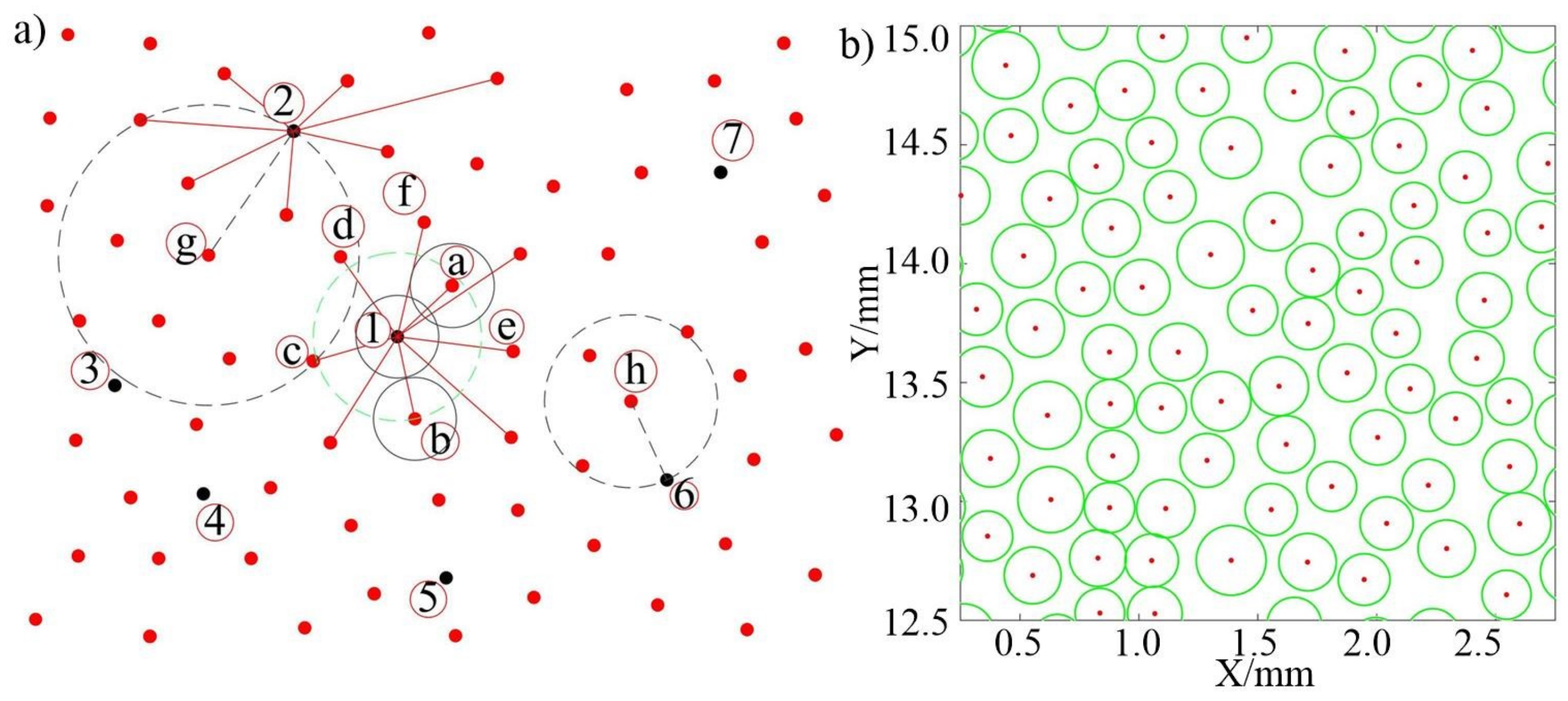

To make the grains evenly distributed on the surface of the grinding wheel, the best-candidate sampling algorithm is used to set the grain density and grain spacing, as shown in

Figure 4, to avoid the interference of multiple grain overlap on the model accuracy [

28]. As shown in

Figure 4a, points 1–6 in the figure are known points, and other red points are candidate points. The spacing between points

a and 1 is the smallest near grain 1. However, the maximum diameter circle of point

a intersects with the maximum diameter circle of point 1, so it is not the best-candidate point. The maximum diameter circle of point 1 is nearly tangent to the maximum diameter circle of point

b, but the spacing between the two points is greater than the sum of the radii of the maximum diameter circle of the grain, so point

b is the best-candidate grain. The grain distribution in some areas of the grinding wheel surface generated by the best-candidate method is shown in

Figure 4b. It can be found that the maximum diameter of the grains changes randomly, and the grains are randomly distributed in the plane area, so it is a relatively ideal grain distribution.

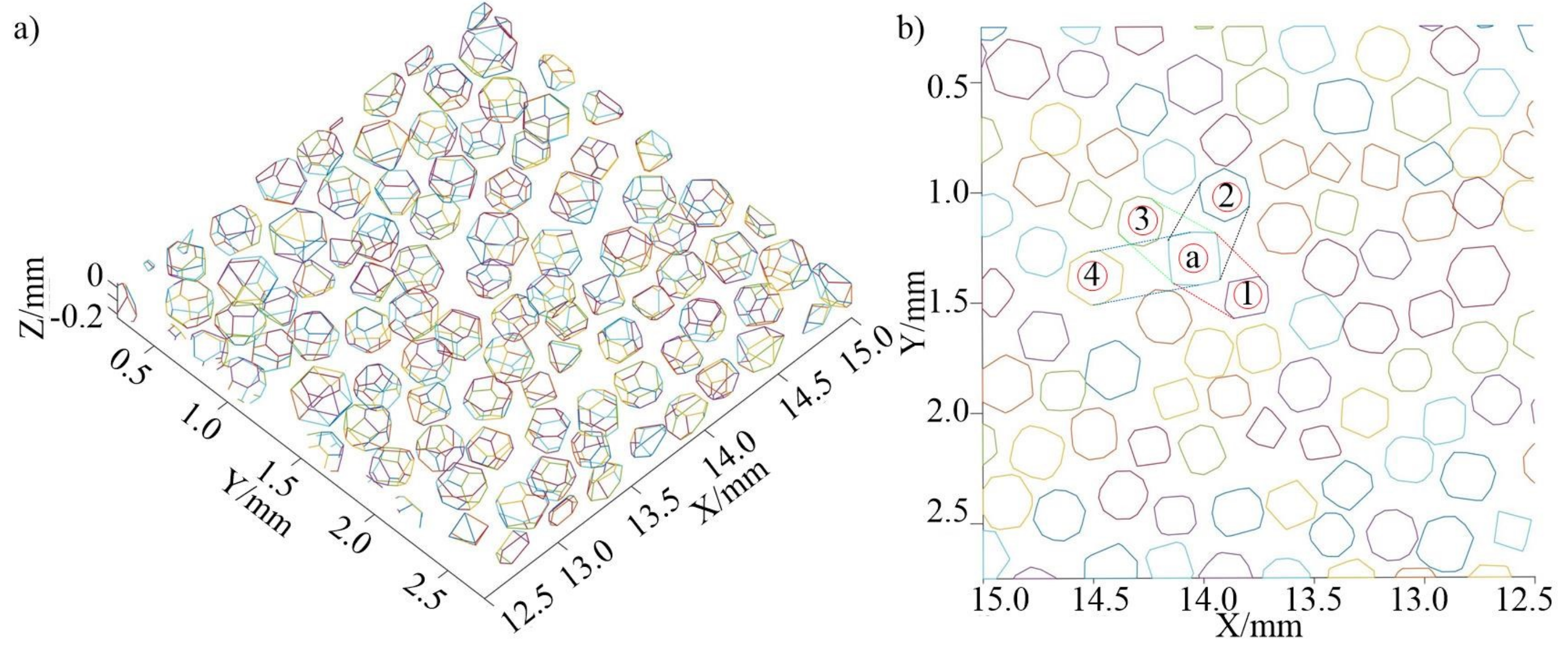

On the basis of generating the center position of the grain, the grain profile of the grinding wheel surface was generated based on the geometric relationship of the grain corner points and the random deflection of the grain on the X/Y/Z axis is shown in

Figure 5a, and the center height of the grain is set to 0

. The shape, spatial orientation, size, and regional position distribution of grains all change randomly. In measuring grain spacing, grains that align closely on a straight line are termed adjacent grains. Controlling grain spacing primarily involves managing the distance between these adjacent grains. To be consistent with the actual measurement of the grain spacing and spacing ratio, the projection of the grain profile in the plane area as shown in

Figure 5b is used to judge adjacent grains. During the evaluation, we calculate the projected area of the two grain profiles. If there are no projection profiles of other grains in the projected area, then the group of grains is adjacent grains. Otherwise, it is not. In the figure, grains 1–4 are located near grain

a, and there are no other projection profiles between grains 1–3 and grain a in the projected area, making them adjacent grains. However, since the projected area between grain 4 and grain a contains the profile of grain 3, they are not considered adjacent.

Further optimization of the protruding height and spatial position of the grains can be carried out using Equation (

3), which compares the statistical data of the grain spacing and protrusion height with the actual measured data. Randomly select any grain spacing within the interval that needs to be adjusted, and randomly generate the corresponding adjustment amounts

, where

i is the grain serial number,

are the initial positions of the grain center,

is the adjusted position of the grain center. If the position of the grain does not interfere with adjacent grains after incremental adjustment and the spacing or height adjustment direction is consistent, the current adjustment is accepted.

In the formula, —the initial position of grain center. —the adjusted position of the grain center. —random adjustment amount of the grain center in the , and z directions.

2.3. Grinding Wheel Surface Topography Model Generation and Dressing

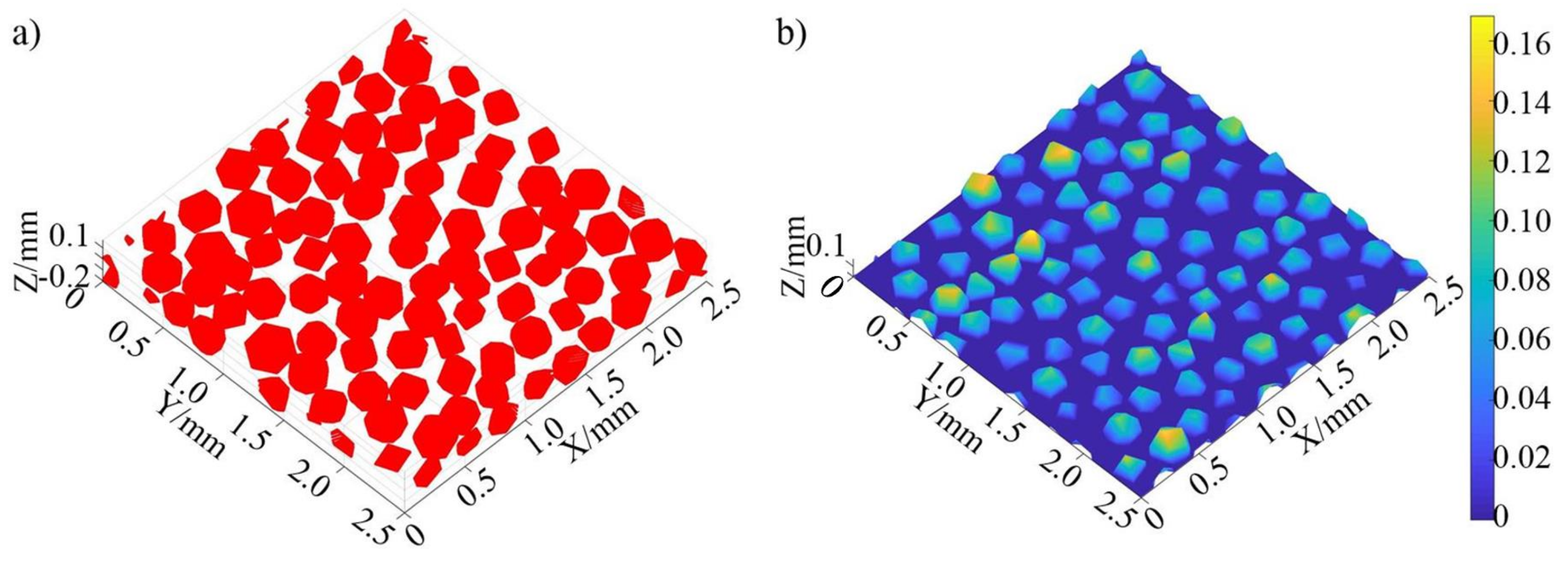

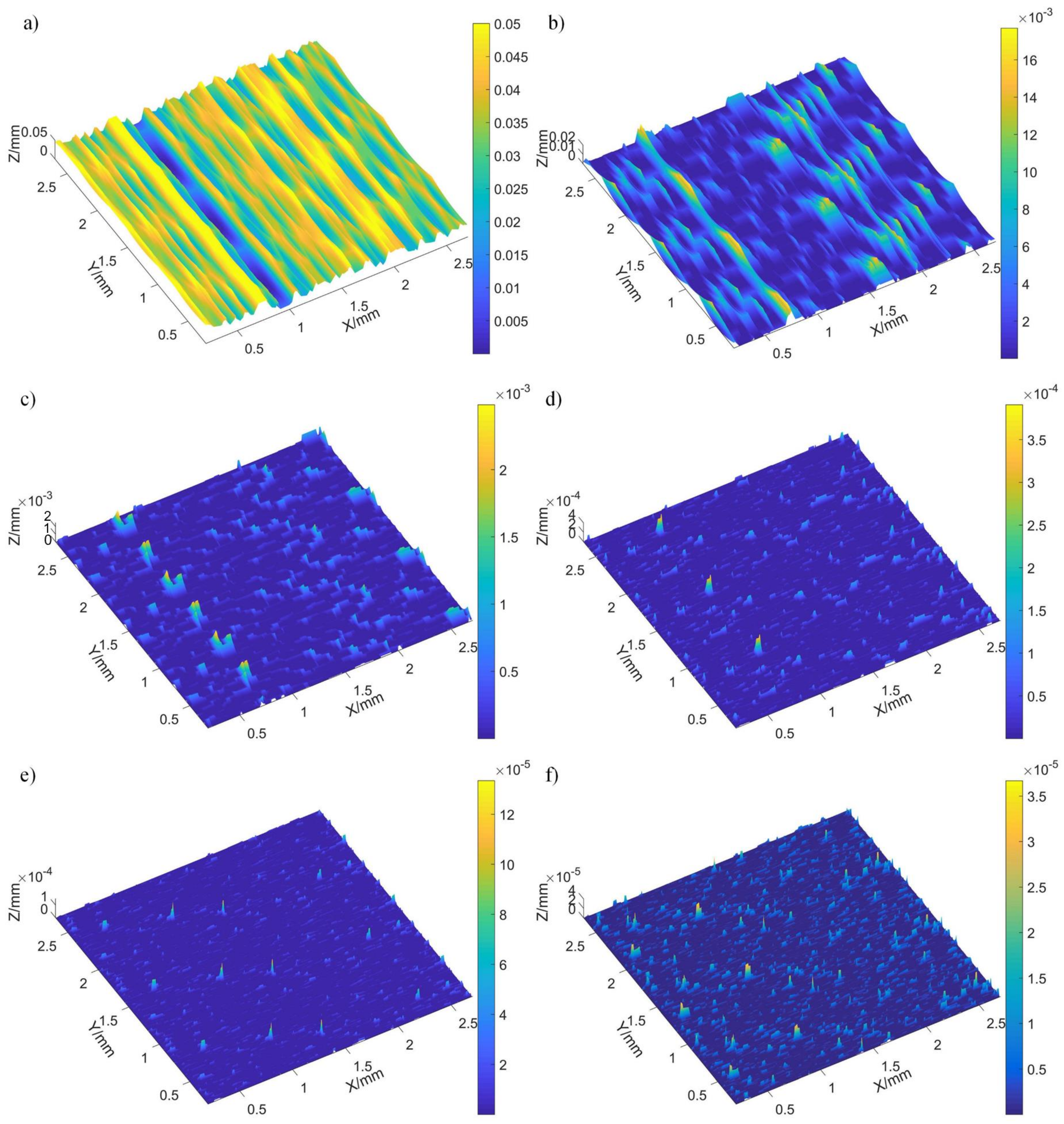

The scatter plot of the grains on the grinding wheel surface obtained by calculating the positions of the grain surface points is shown in

Figure 6a. Since the surface of the electroplated metal layer is far lower than the maximum protruding height of the grains and the top surface of the grains after dressing, the surface height of the electroplated layer is set to the average height, which is 0

. It can be seen from the depth difference between the grains and the surface of the electroplated metal layer in

Figure 6b that the protruding height, size, and orientation of the grains are randomly distributed, and the maximum protruding height of the grains is 170

.

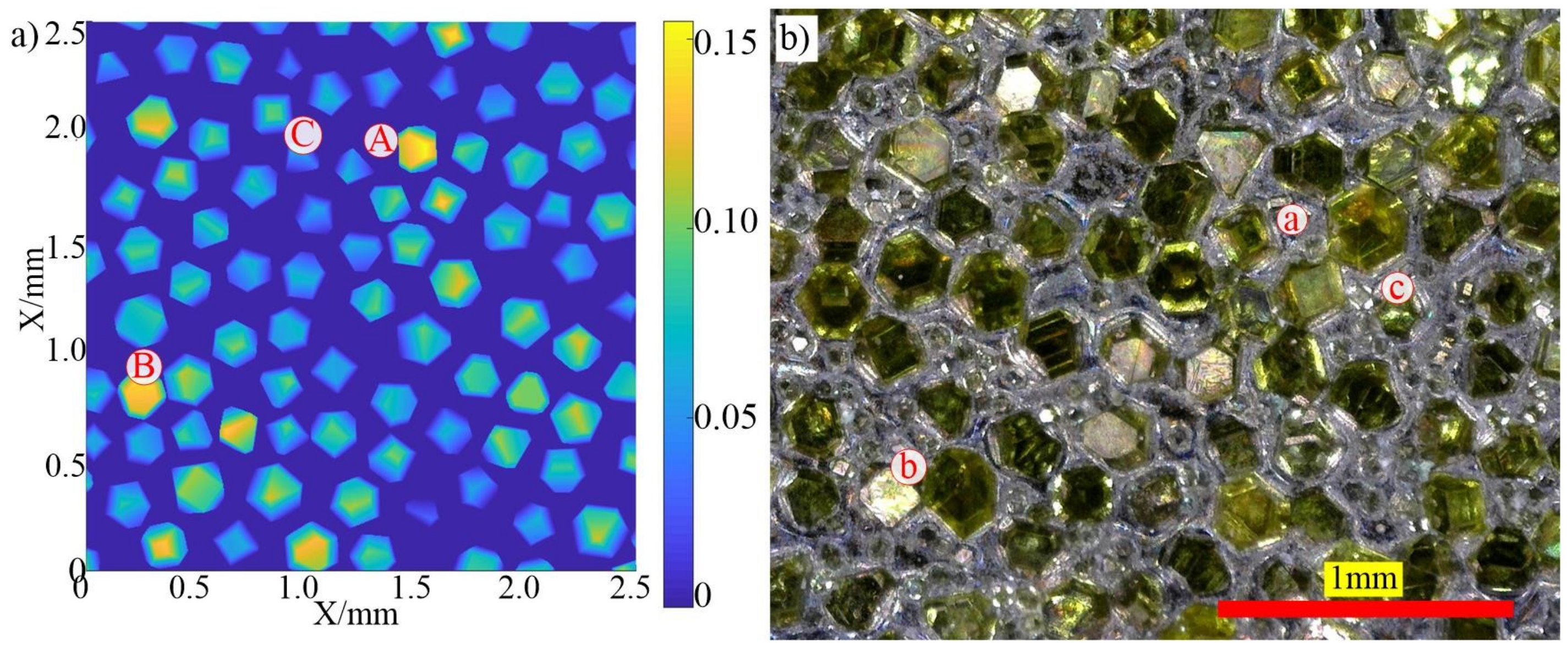

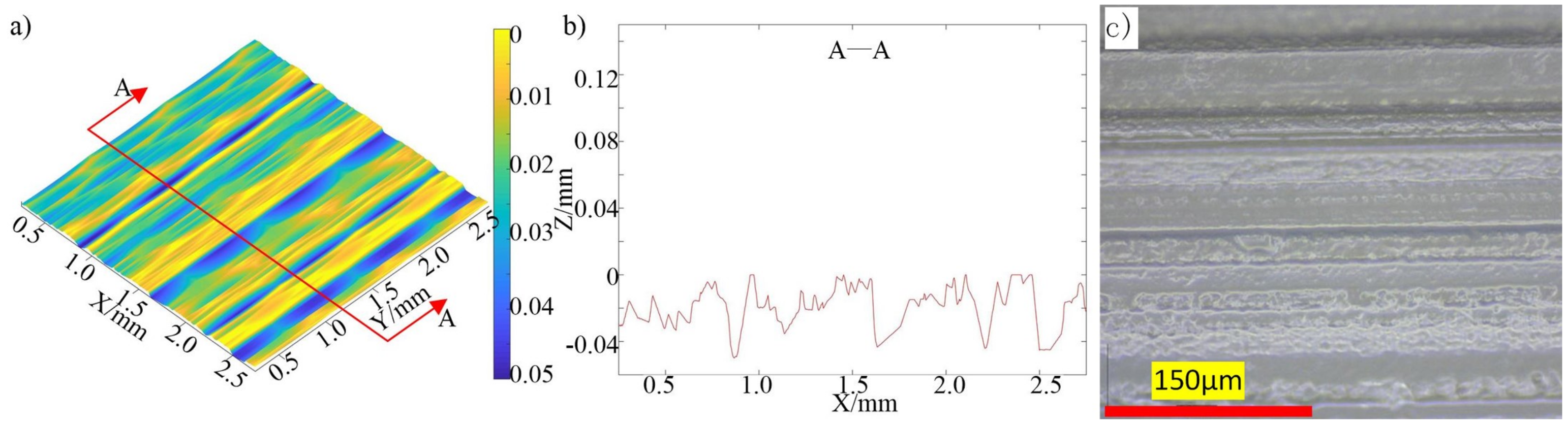

To verify the effectiveness of the grinding wheel surface simulation model, the simulated morphology of the grinding wheel surface was compared with the actual morphology of the grinding wheel surface, and the results are shown in

Figure 7. The density of grains on the surface of the simulated grinding wheel is 12.64 pieces

; the density of grains on the surface of the actual grinding wheel is 12.48 pieces

; and the shape, arrangement, and protrusion height of the grains are relatively similar. In the figure, grains

, and

b are the grains with larger protruding heights, while

C and

c are smaller-sized grains with lower protruding heights.

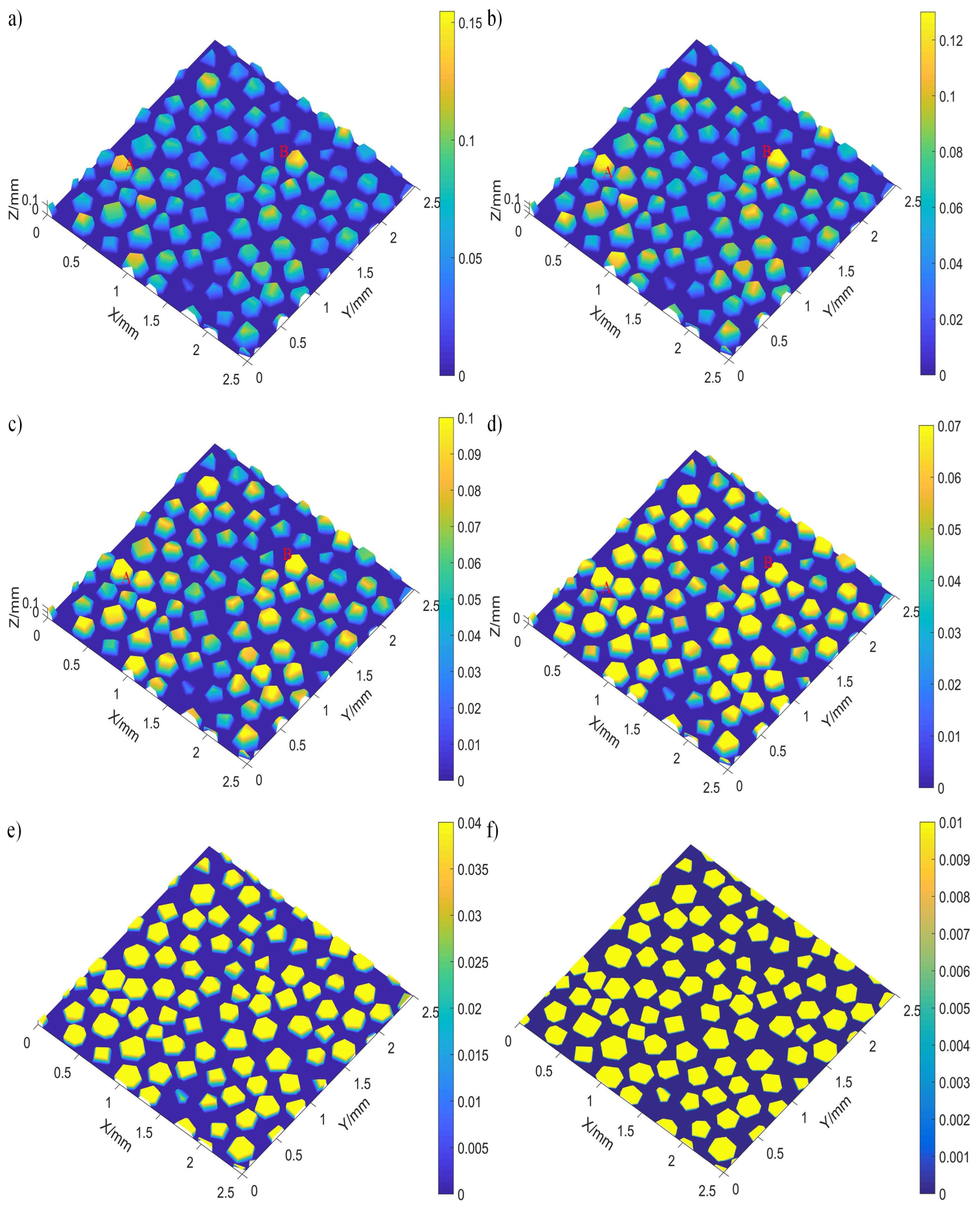

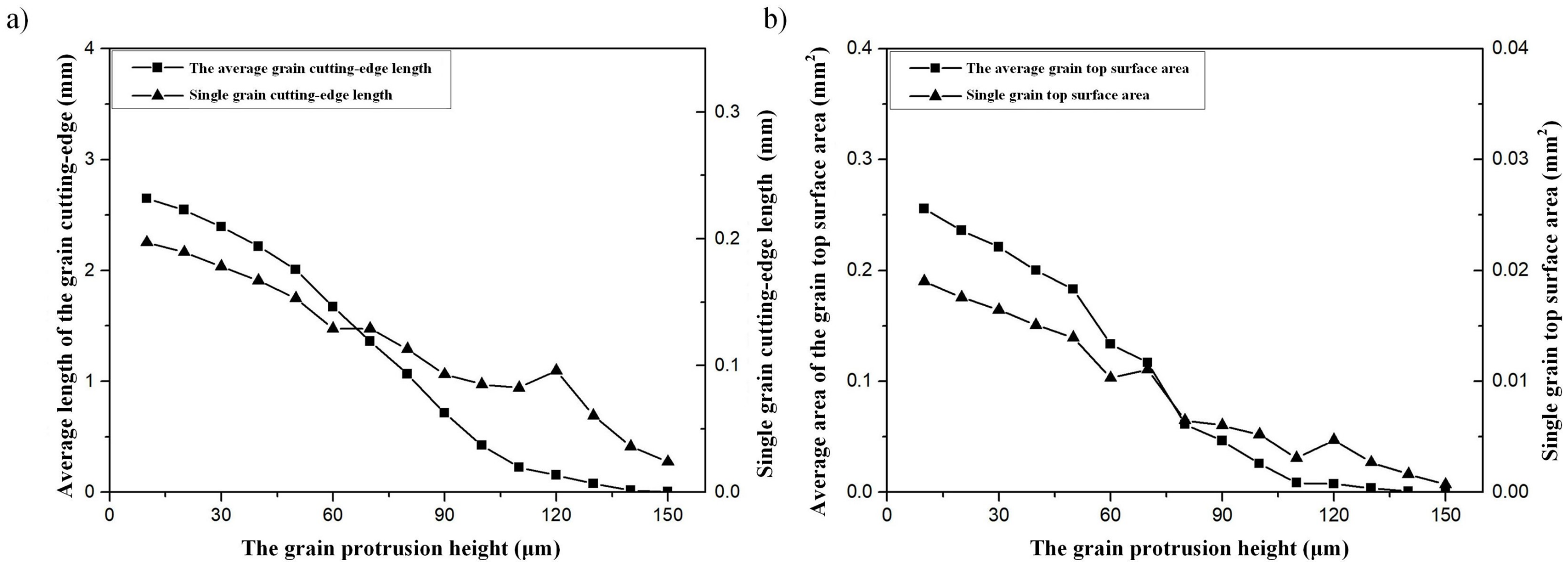

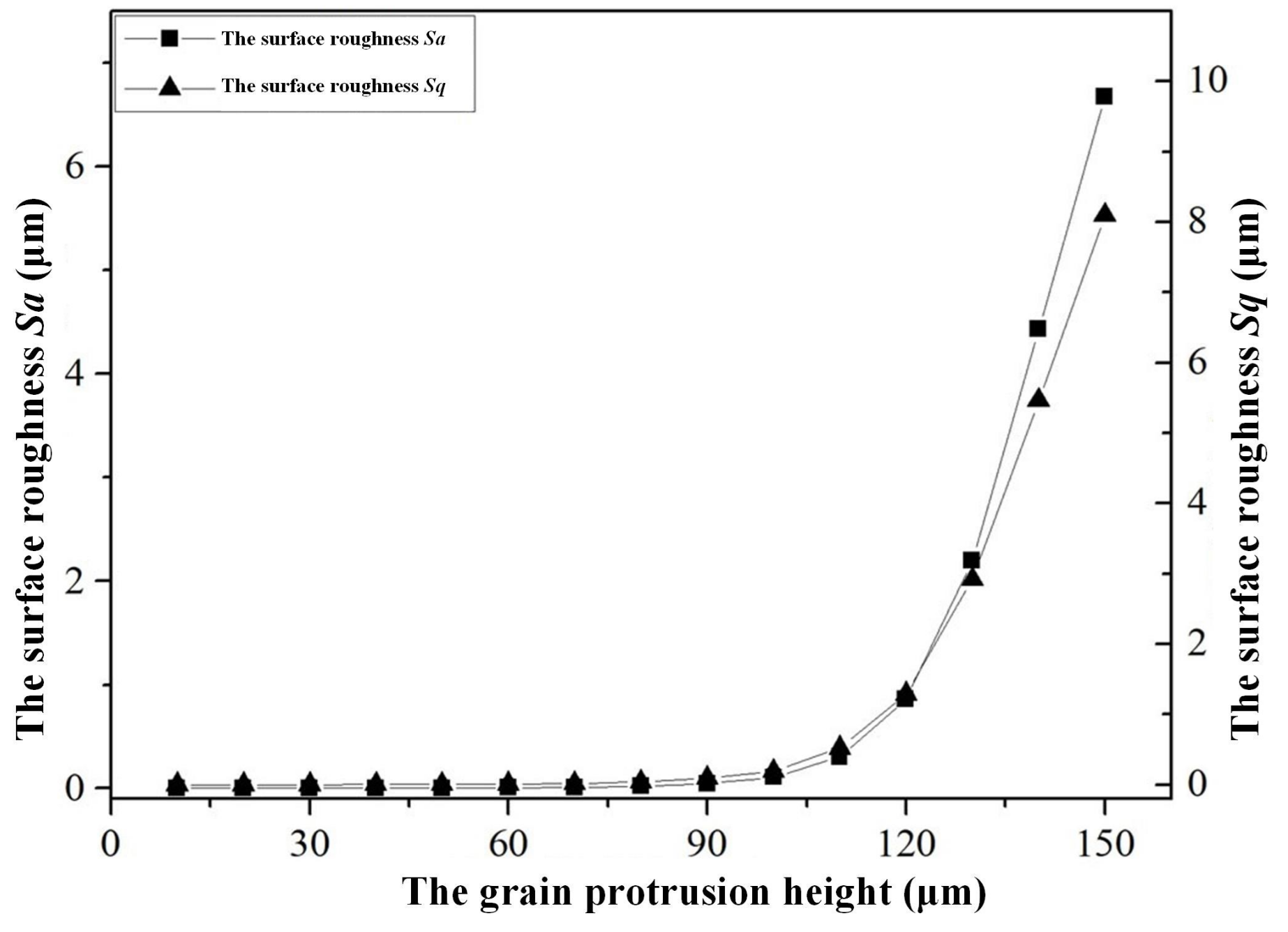

To obtain a consistent protruding height and an ideal grinding wheel profile shape, the surface of the electroplated coarse-grained diamond grinding wheel needs to be dressed before grinding to increase the effective grain density and the width of the single grain cutting-edge. The simulated dressing morphology formed by removing the grain tip is shown in

Figure 8a. The shape of the plane is a polygon formed after the dressing plane intersects with the grain surface. The cutting-edge width of the grain is defined as the projected length of the top surface of the grain in the feed direction after dressing. According to the simulated surface morphology of grinding wheel after dressing, as shown in

Figure 8b, it can be found that although the grains maintain a consistent protrusion height after dressing, the top surface area and profile of the grains are restricted by the size and initial protrusion height of the grains.

2.4. Workpiece Surface Model Generation

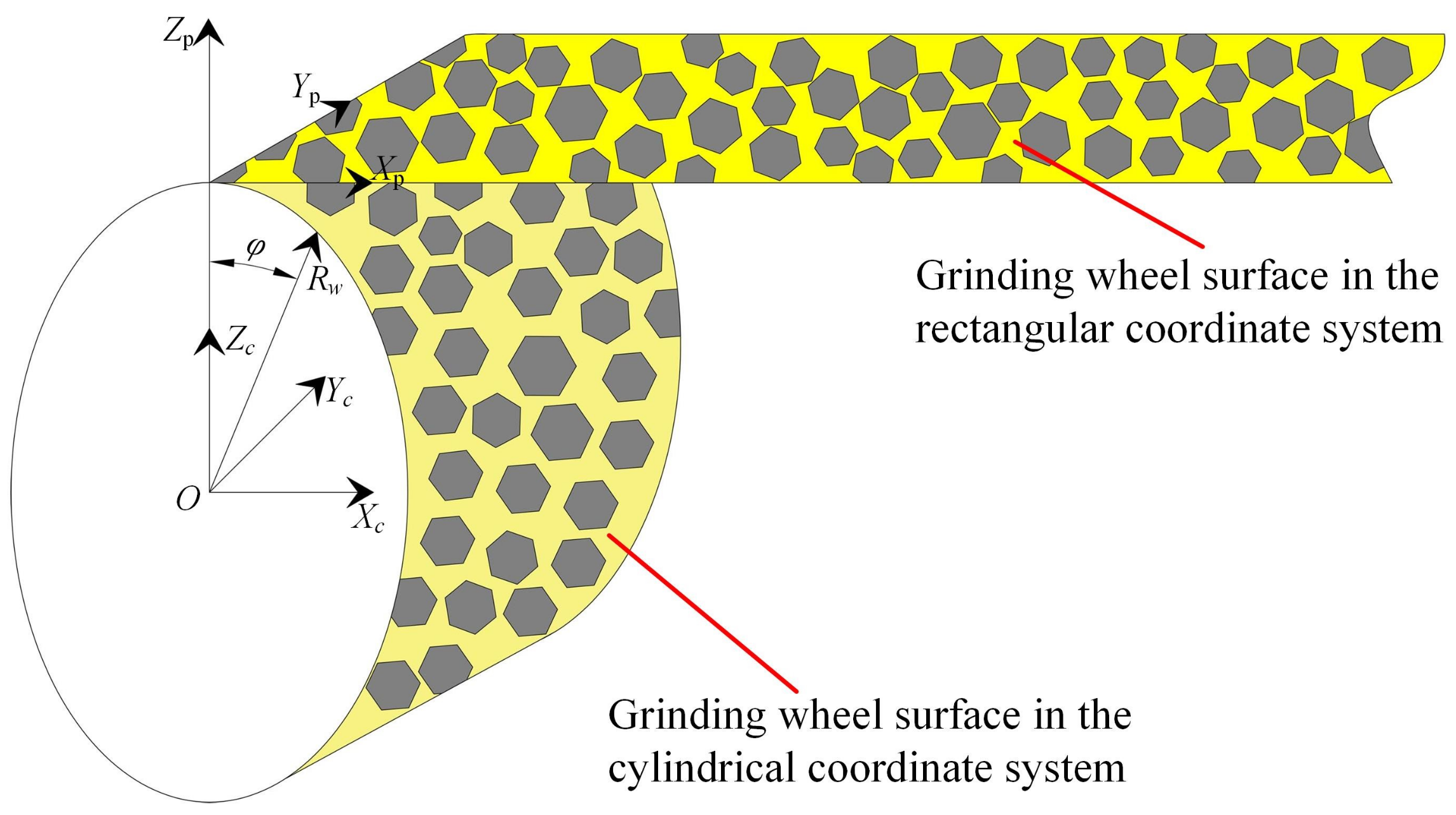

Based on the established grinding wheel surface topography simulation model, a grinding surface morphology model could be established based on the motion relationship between the grinding wheel and the workpiece and be used for in-depth researching the evolution of the ground workpiece surface morphology. To obtain the surface morphology of the workpiece after grinding and to predict the surface roughness, it is necessary to make the ideally designed grinding wheel surface closer to the actual grinding wheel surface. As shown in

Figure 9, the grinding wheel surface modeled in the rectangular coordinate system is converted into the grinding wheel surface in the cylindrical coordinate system, and the grinding processing behavior between the grinding wheel surface and the machined workpiece surface is simulated according to the given grinding process parameters. The grinding wheel surface in the rectangular coordinate system

can be transformed into the grinding wheel surface in the cylindrical coordinate system

,

through Equation (

4):

In the formula, —the coordinates of the plane grinding wheel surface in the Cartesian coordinate system. —the radial coordinates, angle, and axial coordinates on the grinding wheel surface. —grinding wheel surface reference radius.

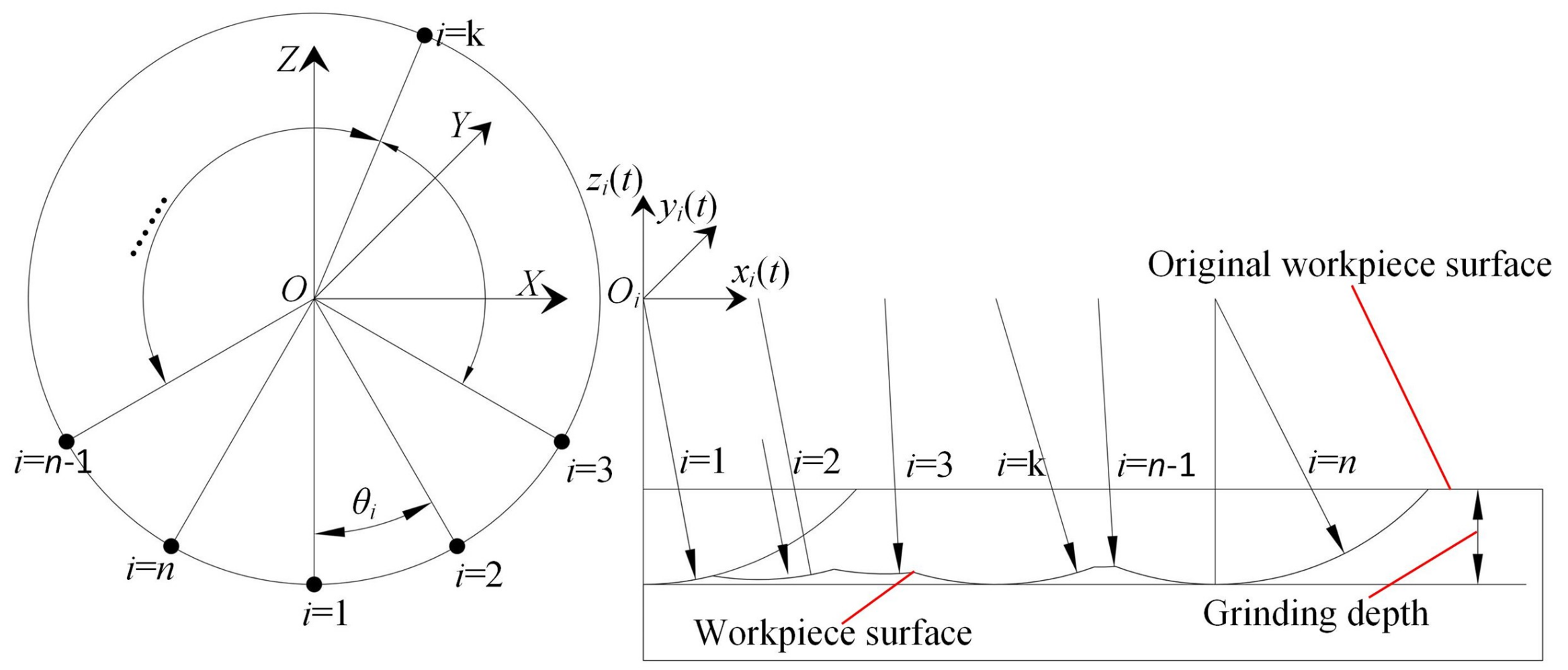

During the grinding process, different grains on the same circumference of the grinding wheel surface pass through the workpiece surface in sequence as time increases. As the grinding time continues, the trajectory formed by the interference of the previous grain on the workpiece may be covered by the trajectory of the subsequent grain; that is, the workpiece surface topography is constantly iterated. The cutting effect of all grains on the same circular trajectory jointly achieves the removal of workpiece material and the formation of the final machined surface. The grinding process is shown in

Figure 10.

The number of grains on the same circular trajectory is

n, and the angle between any point

i on the grinding wheel surface and the starting point of the grinding process is

. The movement trajectory of the grain

i changing with time can be expressed as Equation (

5) [

29]:

In the formula, —the coordinates of any point i on the grinding wheel surface at time —the radial radius of the grinding wheel surface at any point i.

The effective grains on the grinding wheel surface sequentially cut through the workpiece surface as time increases or the grinding wheel rotates. After all the grains on the surface of the grinding wheel pass through the workpiece surface point

, the lowest value of all grains at that point is the surface height of that point. Therefore, any point

on the grinding wheel surface can be expressed as Equation (

6). The height

z of any point on the workpiece surface is obtained by calculating the minimum value of each grain passing through the point through Equation (

6), and taking the minimum value of all values.

In the formula, —the time for any point on the surface of the grinding wheel passing the coordinate point x in the direction of the workpiece surface. —the height of any point i on the surface of the grinding wheel passing the coordinate point x in the direction of the workpiece surface. —the coordinates of any point on the workpiece surface.

For a more accurate prediction of the grinding effect, it is essential to consider not only the kinematic relationship between the grains and the workpiece, but also to integrate the workpiece material removal mechanism into the model. In precision grinding of hard and brittle materials, the workpiece material is mainly removed by a plastic mechanism, so it is assumed that the interaction between the grains and the workpiece surface in the model is plastic removal. After grinding simulation using an undressed grinding wheel with the diameter of

and the width of

at the linear speed of

, the feed speed of

, and the grinding depth of 50

, the workpiece surface morphology and cross-sectional profile with the length and width of

can be obtained as shown in

Figure 11. The data resolution in the X and Y direction of the surfaces presented in

Figure 12 is 10

.The figure indicates that the simulation analysis, through theoretical calculations, can closely match the three-dimensional morphology of the actual workpiece surface. This offers valuable theoretical guidance for optimizing the grinding wheel dressing plan.

3. Experimental Process

The electroplated coarse-grained diamond grinding wheel dressing and grinding processing device are shown in

Figure 13. We investigated how grain protrusion height affects surface morphology and roughness using precision dressing on coarse-grained diamond grinding wheels. Initially, we conducted a dressing experiment on the electroplated coarse-grained diamond grinding wheels. The dressing device is shown in

Figure 13a. A ceramic bonded fine-grained diamond dressing wheel was used on the surface grinding machine tool (MUGK7120 ×) to adjust the protruding height of the grains on the surface of the electroplated coarse-grained diamond grinding wheel. Among them, the protruding height of the grains was the statistical average value of the height difference between grains and the surface of the surrounding electroplated metal layer. Three grinding wheel working surfaces with grain protrusion heights of 50

, 70

, and 100

were dressed. During the dressing process, the dressing wheel speed

was 100–200

, the grinding wheel spindle speed

N was 5000

, the dressing wheel reciprocating feed speed in the

-axis direction was 30–50

, and the single feed depth was 1

. The grain size of ceramic bonded fine-grained diamond dressing wheel was D 76

, the outer diameter of the grinding wheel was

, and the inner diameter was

. The grain size of electroplated coarse-grained diamond grinding wheel was D 213

, the grinding wheel diameter was

, the width was

, the grain burial depth was about

, and the average grain density was

. The single dressing feed depth of the electroplated coarse-grained diamond grinding wheel was 1

. Post-dressing, we utilized a super-depth-of-field three-dimensional microscope (VHX-500F, Keyence Corporation, Osaka, Japan) to inspect the grinding wheels with respective grain protrusion heights of 50

, 70

, and 100

.

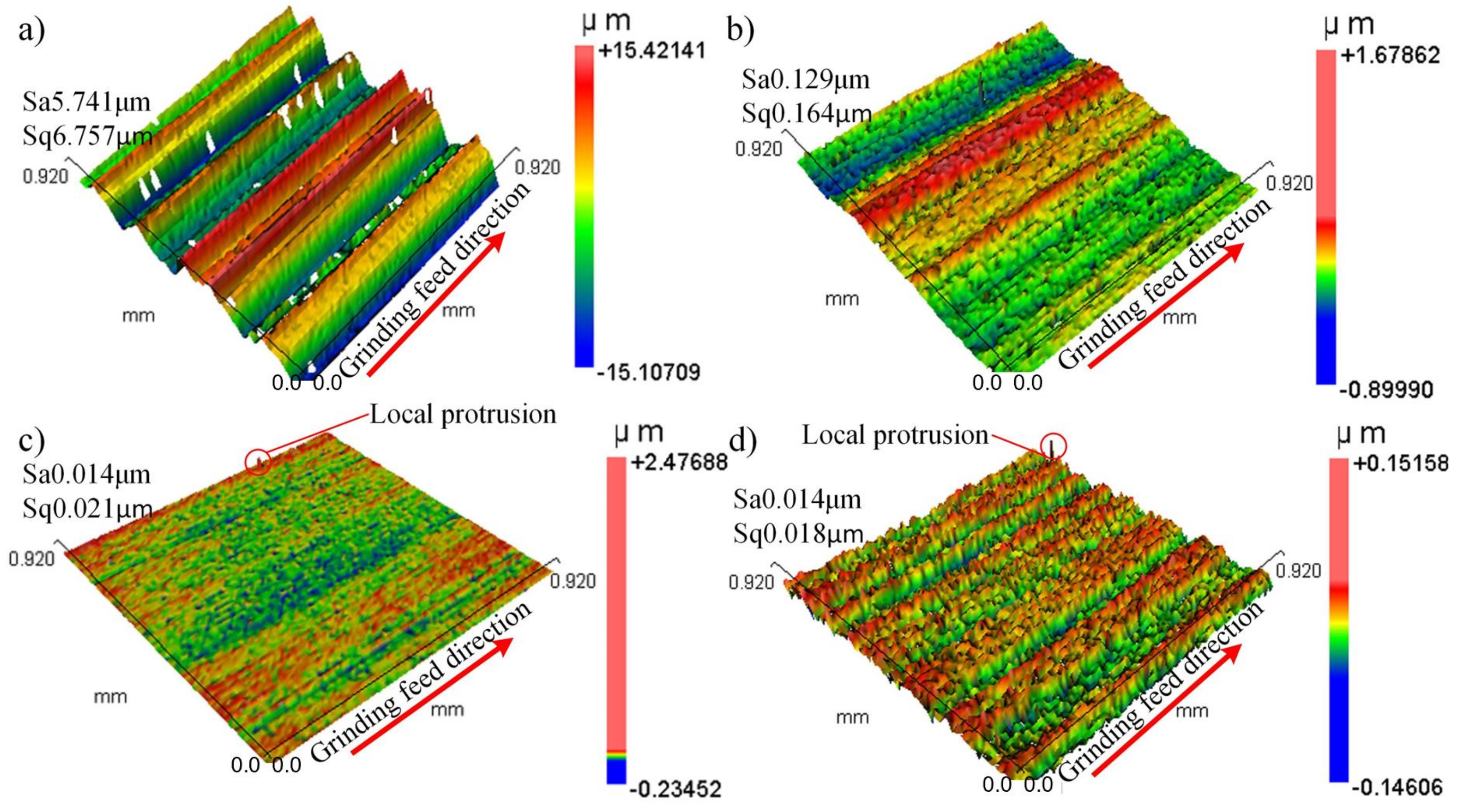

In the second step, the grinding experiments of optical glass BK7 by electroplated coarsegrained diamond grinding wheels with different grain protrusion heights were carried out. The grinding processing experimental device shown in

Figure 13b was used on the surface grinding undressed grinding wheels and dressed grinding wheels with grain protrusion heights of 50

, 70

, and 100

were used to grind the optical glass BK7 workpiece. The BK7 workpiece, characterized by its hard and brittle nature, was crafted from optical glass. The size of the workpiece as shown in

Figure 13c used in the experiment was 30 mm × 20 mm × 15 mm. The original surface was precision lapped and achieved a surface roughness in the level of several microns. The material properties of optical glass BK7 are shown in

Table 1. The grinding process parameters were a grinding wheel speed of

, feed speed of

, and grinding depth of 5

. Post-grinding, we examined the surface texture and roughness of both the grinding wheel and the BK7 optical glass workpiece using instruments like the white light interferometer Zygo NewView 8300 (Zygo Corporation, Middlefield, CT, USA) and the ultra-depth of field three-dimensional microscope VHX-500F (Keyence Corporation, Osaka, Japan).