Analysis of Energy Efficiency in Spur Gear Transmissions: Cycloidal Versus Involute Profiles

Abstract

1. Introduction

- It produces fewer vibrations and maintains constant loads on axles because the normal force at the contact point has an invariant direction and is nearly constant in magnitude.

- It has low sensitivity to slight variations in gear center distance.

- It allows for the use of cutter tools (racks) with straight flanks.

- By displacing the cutter tool, the bending strength at the tooth root is increased (bigger root thickness) and the center distance can be adjusted. However, it has the drawbacks of the tip thickness being weakened and the contact ratio being decreased.

- Higher tooth strength because the tooth has a wider root and is therefore easier to manufacture with casting techniques or when small gears are required.

- Lower Hertzian contact stresses because the contact surfaces are a pair of convex–concave surfaces (epicycloid–hypocycloid), while the involute has convex–convex surfaces.

- No possibility of tooth undercutting, allowing for a lower number of teeth than involute and, hence, higher gear ratios.

- If the generating diameters are half of the pitch diameter, which is normal for cycloidal teeth, the hypocycloid becomes a straight line following the radial direction, making it easier to manufacture.

- The cutting tools (rack) for manufacturing the flanks are not as simple as in the involute profile (straight flanks).

- It is more sensitive to the distance between gear centers, which implies higher costs to achieve manufacturing tolerances. An incorrect distance produces a non-constant gear ratio and, therefore, induced vibrations.

- The analytical development of the cycloidal profile in terms of energy and torque transmission, as well as its sensitivity to variations in the auxiliary centrode diameters.

- A comparison of the energy efficiency of the involute and the cycloidal profiles with respect to gear ratio and gear size (module).

2. Materials and Methods

2.1. Coefficient of Friction Analytical Models Including Elastohydrodynamic Formulation

2.1.1. Elastohydrodynamic Lubrication (EHL) Model

2.1.2. Mixed Elastohydrodynamic Lubrication (MEHL) Model

2.1.3. Coefficient of Friction Versus the Slip-to-Roll Ratio

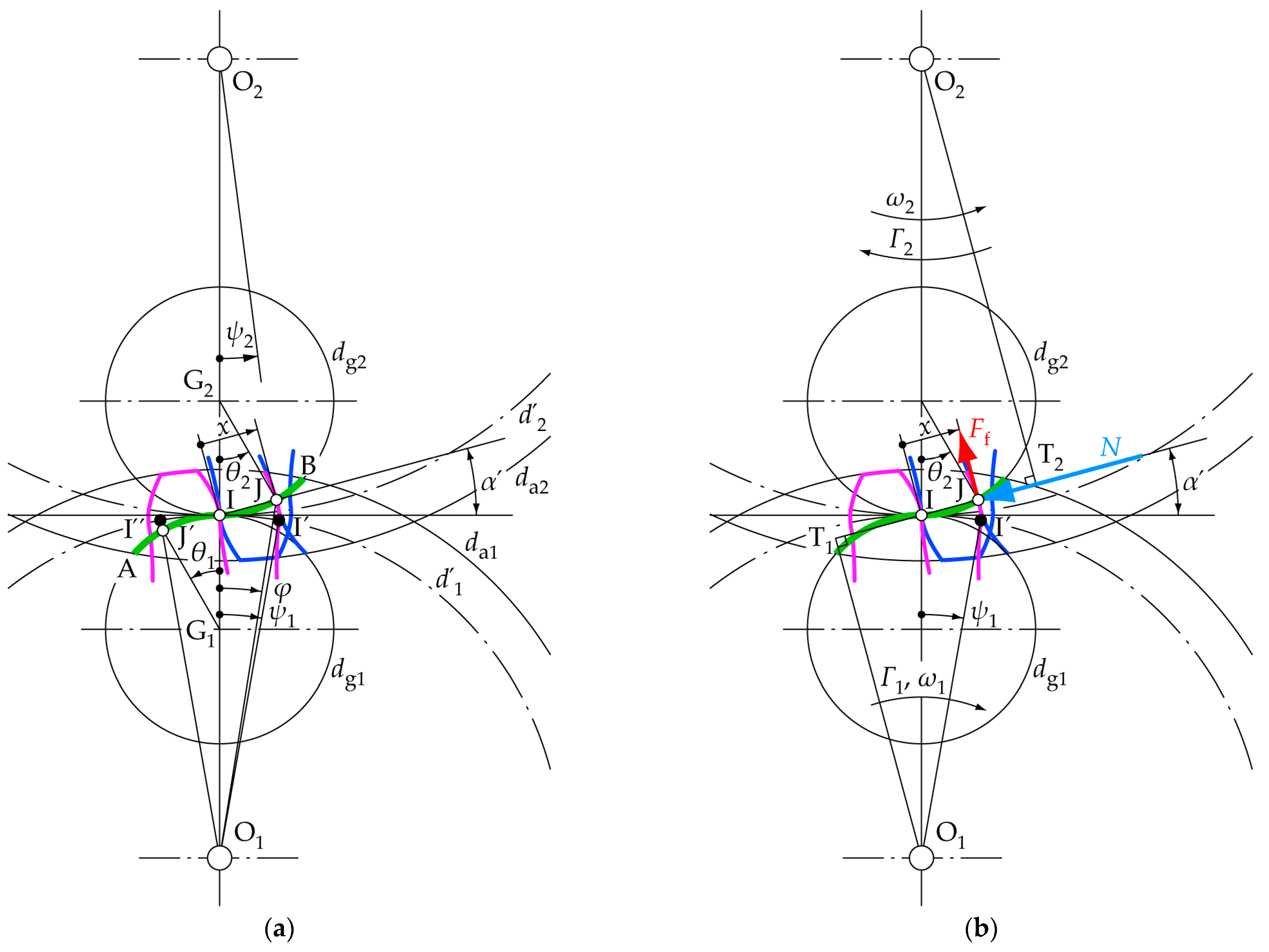

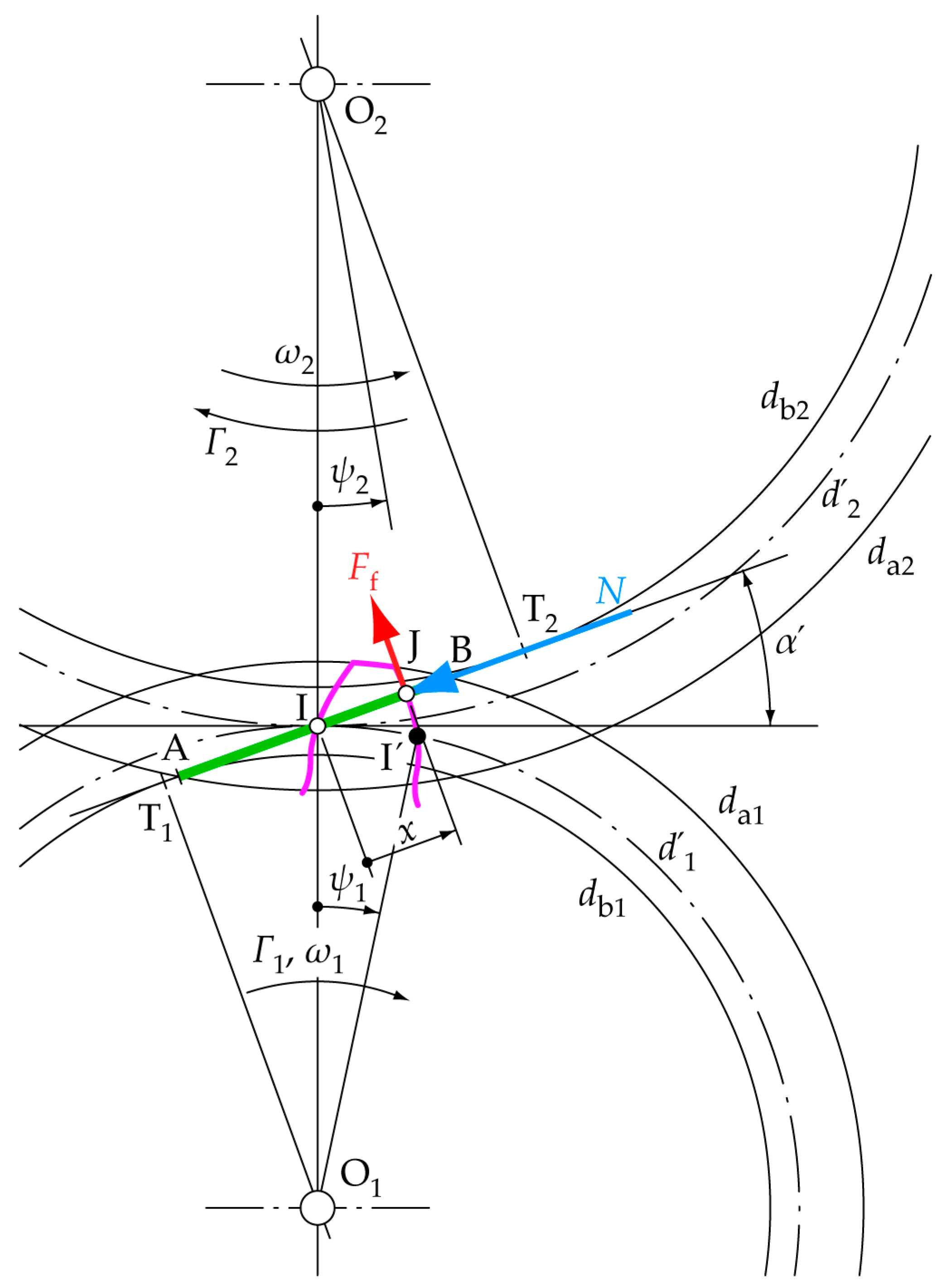

2.2. Cycloidal Output/Input Torque Ratio

2.2.1. Pinion

2.2.2. Wheel

2.3. Involute Profile Output/Input Torque Ratio

2.3.1. Pinion

2.3.2. Wheel

2.4. Energy Efficiency

3. Results

3.1. Iterative Process to Determine the Coefficient of Friction and the Torque Ratio

- Step 1: Calculate the geometric and the kinematic parameters Ve, Vs, SRR, and R.

- Step 2: Determine the torque ratio Γ2/Γ1 and the normal force N by applying the LMT and AMT; an initial value for μ and a maximum target error εmax are required.

- Step 3: Calculate the maximum Hertzian pressure pH, the average pressure p, as well as the normal load per unit width W′.

- Step 4: Recalculate the coefficient of friction using the formulation of the selected friction model.

3.2. Cycloidal Profile: Efficiency with Respect to the Auxiliary Centrode Diameters and Their Limits

- The pressure angle α′ increases at both ends of the path of contact as dg1,2 decrease. Consequently, the normal force N at the contact point becomes larger for a given input torque, leading to increased fatigue damage on gear tooth surfaces and higher loads on the shafts. Additionally, with a higher pressure angle, the center distance tolerance between the pinon and the wheel has a greater influence on the dimensional errors of the ideal contact point between the meshing teeth.

- The tooth height increases as dg1,2 diminishes to maintain a constant contact ratio, resulting in a larger tooth bending moment.

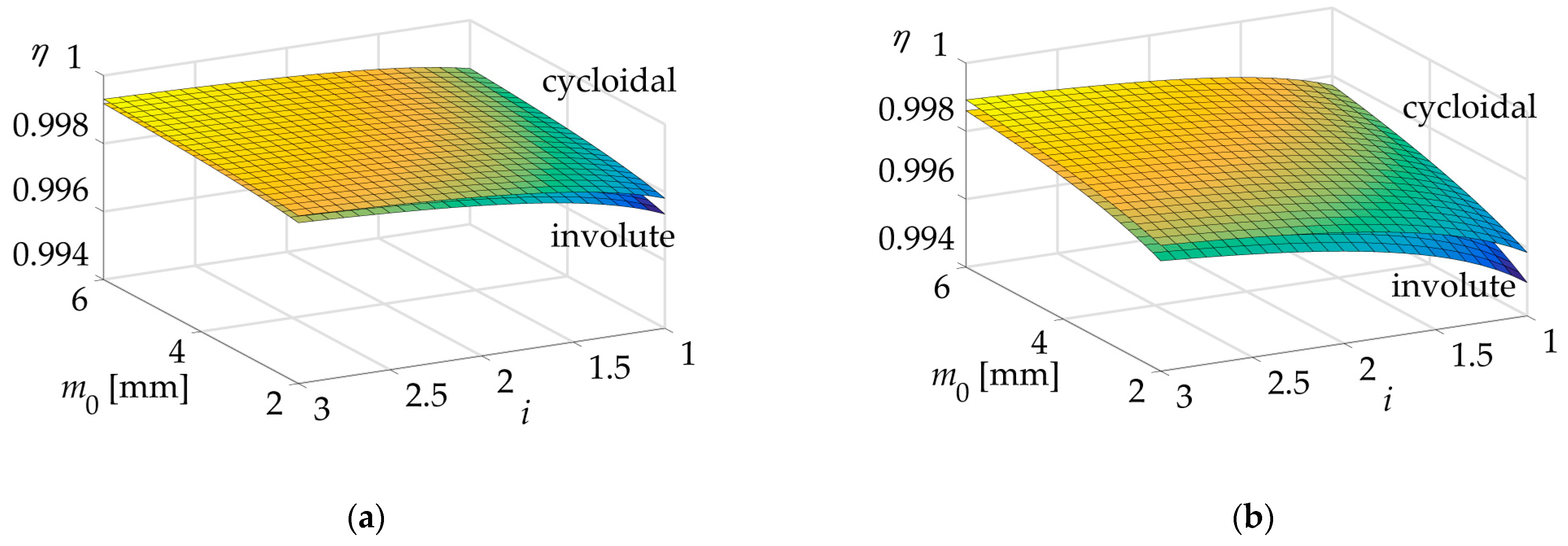

3.3. Contact Conditions, Torque Ratio, and Efficiency Comparison Between Involute and Cycloidal Profiles

4. Conclusions

- A unitary contact ratio.

- No bending deformation.

- Nominal profile dimensions without tolerances.

- The cycloidal profile exhibits a performance nearly identical to that of the involute profile for both lubrication models, with observed differences being less than 0.01%.

- The efficiency of both profiles increases with larger sizes and/or higher gear ratios for both models.

- The efficiency of both profiles tends to converge to a constant value as the size and gear ratios increase in all cases.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A. Curvature Radii at the Contact Point of a Cycloidal Profile

Appendix A.1. Approach Action (ψ1 < 0)

Appendix A.2. Recess Action (ψ1 ≥ 0)

References

- Anderson, N.E.; Loewenthal, S.H. Effect of geometry and operating conditions on spur gear system power loss. J. Mech. Des. 1981, 103, 151–159. [Google Scholar] [CrossRef]

- Anderson, N.E.; Loewenthal, S.H. Design of spur gears for improved efficiency. J. Mech. Des. 1982, 104, 767–774. [Google Scholar] [CrossRef]

- Gupta, K.; Laubscher, R.F.; Davim, J.P.; Jain, N.K. Recent developments in sustainable manufacturing of gears: A review. J. Clean. Prod. 2016, 112, 3320–3330. [Google Scholar] [CrossRef]

- Pabiszczak, S.; Kowal, M. Efficiency of the eccentric rolling transmission. Mech. Mach. Theory 2022, 169, 104655. [Google Scholar] [CrossRef]

- Zhang, Y.; Hou, X.; Zhang, H.; Zhao, J. Numerical simulation on windage power loss of high-speed spur gear with baffles. Machines 2022, 10, 416. [Google Scholar] [CrossRef]

- Townsend, D.P. Lubrication and cooling for high speed gears. In Proceedings of the Original Equipment Manufacturing Design Conference, Philadelphia, PA, USA, 9–11 September 1985. [Google Scholar]

- Heingartner, P.; Mba, D. Determining power losses in helical gear mesh: Case study. In Proceedings of the ASME International Design Engineering Technical Conferences and Computers and Information in Engineering, Chicago, IL, USA, 2–6 September 2003. [Google Scholar]

- Anderson, N.E.; Loewenthal, S.H. Spur-Gear-System Efficiency at Part and Full Load; NASA Technical Paper: 1622; NASA Lewis Research Center: Cleveland, OH, USA, 1980; Volume 79, pp. 1–40.

- Britton, R.D.; Elcoate, C.D.; Alanou, M.P.; Evans, H.P.; Snidle, R.W. Effect of surface finish on gear tooth friction. J. Tribol. 2000, 122, 354–360. [Google Scholar] [CrossRef]

- Diab, Y.; Ville, F.; Velex, P. Prediction of power losses due to tooth friction in gears. Tribol. Trans. 2006, 49, 260–270. [Google Scholar] [CrossRef]

- Kalay, O.C.; Doğan, O.; Yılmaz, T.G.; Yüce, C.; Karpat, F. A comparative experimental study on the impact strength of standard and asymmetric involute spur gears. Measurement 2021, 172, 108950. [Google Scholar] [CrossRef]

- Jia, C.; He, Q.; Xiao, J.; Dong, H. Design and Analysis of Novel Non-Involute Cylindrical Gears with a Curved Path of Contact. Mathematics 2022, 10, 4290. [Google Scholar] [CrossRef]

- Liu, L.; Meng, F.; Ni, J. A novel non-involute gear designed based on control of relative curvature. Mech. Mach. Theory 2019, 140, 144–158. [Google Scholar] [CrossRef]

- Liu, L.; Ni, J. An efficient dynamics model of spur gear drive with curved path of contact in mixed elastohydrodynamic lubrication. Mech. Ind. 2022, 23, 1–12. [Google Scholar] [CrossRef]

- Ikejo, K.; Nagamura, K.; Tutulan, F.G. Friction loss of non-involute tooth profile gears. In Proceedings of the ASME International Design Engineering Technical Conferences and Computers and Information in Engineering, Long Beach, CA, USA, 24–28 September 2005. [Google Scholar]

- Peng, Y.; Song, A.; Shen, Y.; Lin, X. A novel arc-tooth-trace cycloid cylindrical gear. Mech. Mach. Theory 2017, 118, 180–193. [Google Scholar] [CrossRef]

- Novikov, M.L. USSR Patent No. 109750. 1956. [Google Scholar]

- Marques, P.M.T.; Martins, R.C.; Seabra, J.H.O. Power loss and load distribution models including frictional effects for spur and helical gears. Mech. Mach. Theory 2016, 96, 1–25. [Google Scholar] [CrossRef]

- Diez-Ibarbia, A.; Fernandez-del-Rincon, A.; De-Juan, A.; Iglesias, M.; Garcia, P.; Viadero, F. Frictional power losses on spur gears with tip reliefs. The friction coefficient role. Mech. Mach. Theory 2018, 121, 15–27. [Google Scholar] [CrossRef]

- Yue, K.; Kang, Z.; Zhang, M.; Wang, L.; Shao, Y.; Chen, Z. Study on gear meshing power loss calculation considering the coupling effect of friction and dynamic characteristics. Tribol. Int. 2023, 183, 108378. [Google Scholar] [CrossRef]

- Mughal, H.; Dolatabadi, N.; Rahmani, R. An integrated tribodynamic model for investigation of efficiency, durability and NVH attributes of gear mesh in electric vehicle powertrains. Tribol. Int. 2023, 189, 108977. [Google Scholar] [CrossRef]

- Liu, L.; Kong, R.; Chen, Z. Prediction of mechanical efficiency of spur gear pairs based on tribo-dynamics model of multi-tooth meshing. Proc. Inst. Mech. Eng. Part J J. Eng. Trib. 2024, 238, 880–893. [Google Scholar] [CrossRef]

- Fang, S.; Liu, Y.; Wang, H.; Taguchi, T.; Takeda, R. Research on the compensation method for the measurement error of cycloidal gear tooth flank. Int. J. Precis. Eng. Manuf. 2014, 15, 2065–2069. [Google Scholar] [CrossRef]

- Abdulkareem, A.A.; Abdullah, M.Q. Theoretical Formulation of Maximum Bending Stress Value and Location for Cycloid Teeth Spur Gear. J. Mech. Eng. Res. Dev. 2021, 44, 303–314. [Google Scholar]

- Hmoad, M.; Hamza, N.R.; Abdulkareem, T.M.; Abdullah, A.A. The Effect of Different Design Parameters on the Cycloid Teeth-Straight Bevel Gear Bending Stress. J. Mech. Eng. Res. Dev. 2020, 43, 109–118. [Google Scholar]

- Tariq, H.; Galym, Z.; Amrin, A.; Spitas, C. Assessment of contact forces and stresses, torque ripple and efficiency of a cycloidal gear drive and its involute kinematical equivalent. Mech. Based Des. Struct. Mach. 2022, 52, 1304–1323. [Google Scholar] [CrossRef]

- Antoniak, P.; Bednarczyk, S. Determination of mechanical power loss of the output mechanisms with serially arranged rollers in cycloidal gears while taking into account manufacturing tolerances. Machines 2024, 12, 345. [Google Scholar] [CrossRef]

- Wang, X.; Wang, H.; Li, L.; Hao, L. An improved transmission efficiency prediction method for nonlinear characteristics of the cycloid reducer. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2024, 238, 10266–10284. [Google Scholar] [CrossRef]

- Zhao, Z.; Yang, Y.; Han, H.; Ma, H.; Wang, H.; Li, Z. Meshing characteristics of spur gears considering three-dimensional fractal rough surface under elastohydrodynamic lubrication. Machines 2022, 10, 705. [Google Scholar] [CrossRef]

- Rebbechi, B.; Oswald, F.B.; Townsend, D.P. Measurement of gear tooth dynamic friction. In Proceedings of the Seventh International Power Transmission and Gearing Conference Sponsored by the American Society of Mechanical Engineers, San Diego, CA, USA, 6–9 October 1996. [Google Scholar]

- Park, C.I.L. Tooth friction force and transmission error of spur gears due to sliding friction. J. Mech. Sci. Technol. 2019, 33, 1311–1319. [Google Scholar] [CrossRef]

- He, S.; Gunda, R.; Singh, R. Effect of sliding friction on the dynamics of spur gear pair with realistic time-varying stiffness. J. Sound Vib. 2007, 301, 927–949. [Google Scholar] [CrossRef]

- He, S.; Cho, S.; Singh, R. Prediction of dynamic friction forces in spur gears using alternate sliding friction formulations. J. Sound Vib. 2008, 309, 843–851. [Google Scholar] [CrossRef]

- Misharin, J.A. Influence of the Friction Conditions on the Magnitude of the Friction Coefficient in the Case of Rolling with Sliding. In Proceedings of the International Conference on Gearing, London, UK, 23–25 September 1958. [Google Scholar]

- ISO/TC 60/SC 2 Gear Capacity Calculation. Available online: https://www.iso.org/es/contents/data/committee/04/92/49242.html (accessed on 20 December 2024).

- Benedict, G.H.; Kelley, B.W. Instantaneous coefficients of gear tooth friction. ASLE Trans. 1961, 4, 59–70. [Google Scholar] [CrossRef]

- O’donoghue, J.P.; Cameron, A. Friction and temperature in rolling sliding contacts. ASLE Trans. 1966, 9, 186–194. [Google Scholar] [CrossRef]

- Drozdov, Y.N.; Gavrikov, Y.A. Friction and scoring under the conditions of simultaneous rolling and sliding of bodies. Wear 1968, 11, 291–302. [Google Scholar] [CrossRef]

- Xu, H. Development of a Generalized Mechanical Efficiency Prediction Methodology for Gear Pairs. Ph.D. Thesis, Ohio State University, Columbus, OH, USA, 2005. [Google Scholar]

- Xu, H.; Kahraman, A.; Anderson, N.E.; Maddock, D.G. Prediction of mechanical efficiency of parallel-axis gear pairs. J. Mech. Des. 2007, 129, 58–68. [Google Scholar] [CrossRef]

- Masjedi, M.; Khonsari, M.M. An engineering approach for rapid evaluation of traction coefficient and wear in mixed EHL. Tribol. Int. 2015, 92, 184–190. [Google Scholar] [CrossRef]

- Tian, X.; Kennedy Jr, F.E. Maximum and average flash temperatures in sliding contacts. J. Tribol. 1994, 116, 167–174. [Google Scholar] [CrossRef]

- Masjedi, M.; Khonsari, M.M. Film thickness and asperity load formulas for line-contact elastohydrodynamic lubrication with provision for surface roughness. J. Tribol. 2012, 134, 011503. [Google Scholar] [CrossRef]

- Roelands, C.J.A. Correlational Aspects of the Viscosity-Temperature-Pressure Relationship of Lubricating Oils. Ph.D. Thesis, Technical University of Delft, Delft, The Netherlands, 1966. [Google Scholar]

- Jiang, H.; Liu, F. Dynamic modeling and analysis of spur gears considering friction–vibration interactions. J. Braz. Soc. Mech. Sci. Eng. 2017, 39, 4911–4920. [Google Scholar] [CrossRef]

- Litvin, F.L.; Fuentes, A. Gear Geometry and Applied Theory, 2nd ed.; Cambridge University Press: Cambridge, UK, 2004. [Google Scholar]

| Parameter | Measured Temperature | Value |

|---|---|---|

| Density | 100 °C | 0.78 kg/L |

| Kinematic viscosity | 40 °C | 97.5 cSt |

| 100 °C | 14.31 cSt | |

| Specific gravity | 15.6 °C | 0.86 |

| Specific heat | 100 °C | 2.29 kJ/(kg·C) |

| Flash point | Not applicable | 207 °C |

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| R 1 | 5 mm | cp 2 | 434 J/(kgK) |

| Ve 1 | 5 m/s | Λlim 4 | 0.06 |

| pH 1 | 2.0 GPa | z 4 | 0.58 |

| fc 1 | 0.12 | ρ 4 | 769.2 kg/m3 |

| E′ 2 | 231 GPa | KT 4 | 0.03 K−1 |

| S 2 | 0.20 μm | α 4 | 1.5 × 10−8 m2/N |

| σ 2 | 0.20 μm | ν0 4 | 10 cP |

| Hv 2,3 | 6.0 GPa | νk 4 | 13 cSt |

| K1,2 2 | 60.5 W/(mK) |

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| z1 1 | 27 teeth | σ 2 | 0.20 μm |

| i 1 | [1.0; 3.0] | Hv 2,3 | 6.0 GPa |

| m0 1 | [2.0; 6.0] | K1,2 2 | 60.5 W/(mK) |

| α′ 1 | 20° (for involute profile) | cp 2 | 434 J/(kgK) |

| b/d′1 1 | 0.8 | Λlim 4 | 0.06 |

| εα 1 | 1.0 | z 4 | 0.58 |

| v′t 1 | 12.5 m/s | ρ 4 | 769.2 kg/m3 |

| pH 1 | 668 N/mm2 (at pitch point of involute profile) | KT 4 | 0.03 K−1 |

| fc 1 | 0.12 | α 4 | 1.5 × 10−8 m2/N |

| E′ 2 | 231 GPa | ν0 4 | 10 cP |

| S 2 | 0.20 μm | νk 4 | 13 cSt |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Veciana, J.M.; Salvadó, P.; Català, P.; Jordi, L. Analysis of Energy Efficiency in Spur Gear Transmissions: Cycloidal Versus Involute Profiles. Machines 2024, 12, 943. https://doi.org/10.3390/machines12120943

Veciana JM, Salvadó P, Català P, Jordi L. Analysis of Energy Efficiency in Spur Gear Transmissions: Cycloidal Versus Involute Profiles. Machines. 2024; 12(12):943. https://doi.org/10.3390/machines12120943

Chicago/Turabian StyleVeciana, Joaquim Maria, Pau Salvadó, Pau Català, and Lluïsa Jordi. 2024. "Analysis of Energy Efficiency in Spur Gear Transmissions: Cycloidal Versus Involute Profiles" Machines 12, no. 12: 943. https://doi.org/10.3390/machines12120943

APA StyleVeciana, J. M., Salvadó, P., Català, P., & Jordi, L. (2024). Analysis of Energy Efficiency in Spur Gear Transmissions: Cycloidal Versus Involute Profiles. Machines, 12(12), 943. https://doi.org/10.3390/machines12120943