Kinematic Analysis of a Cam-Follower-Type Transplanting Mechanism for a 1.54 kW Biodegradable Potted Cabbage Transplanter

Abstract

1. Introduction

2. Materials and Methods

2.1. Selection of Biodegradable Pot Seedling and Properties

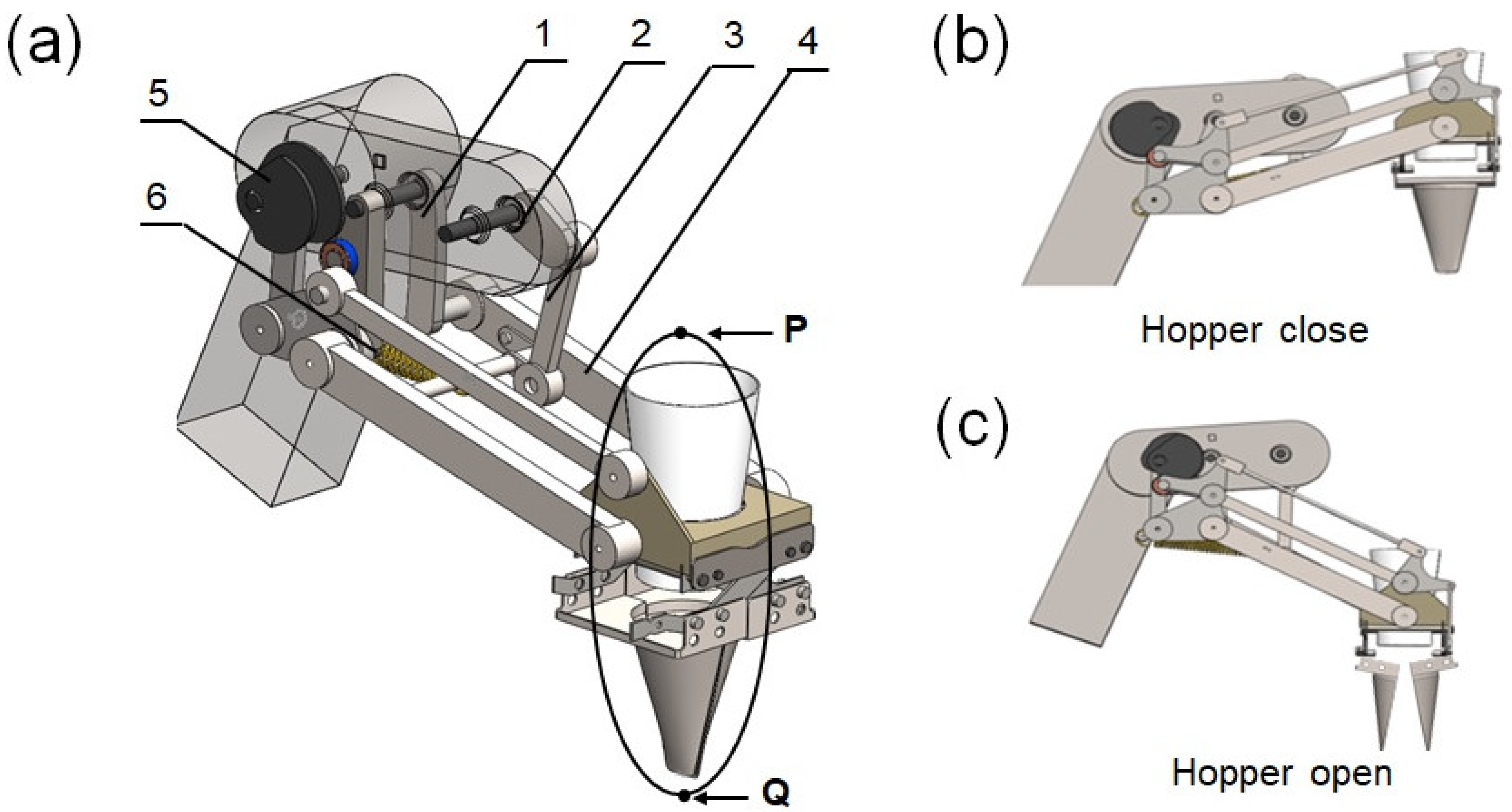

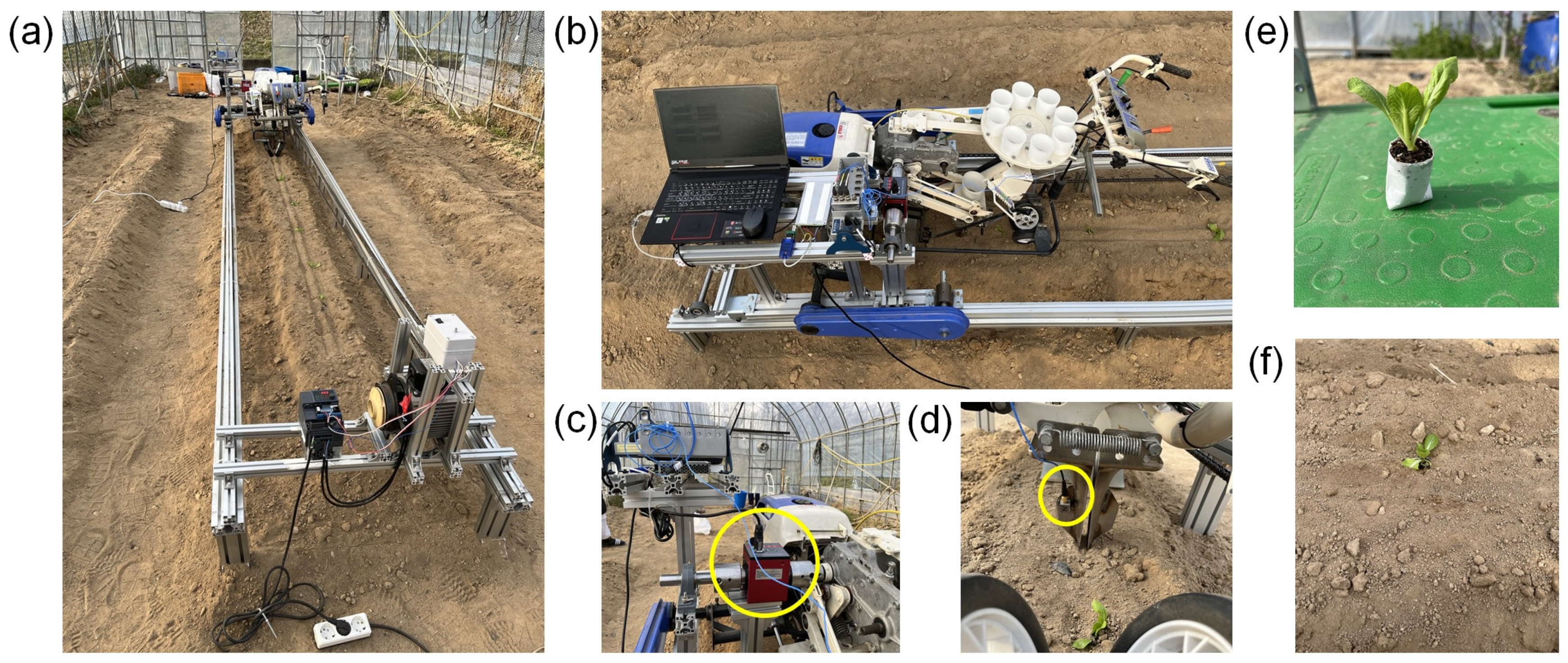

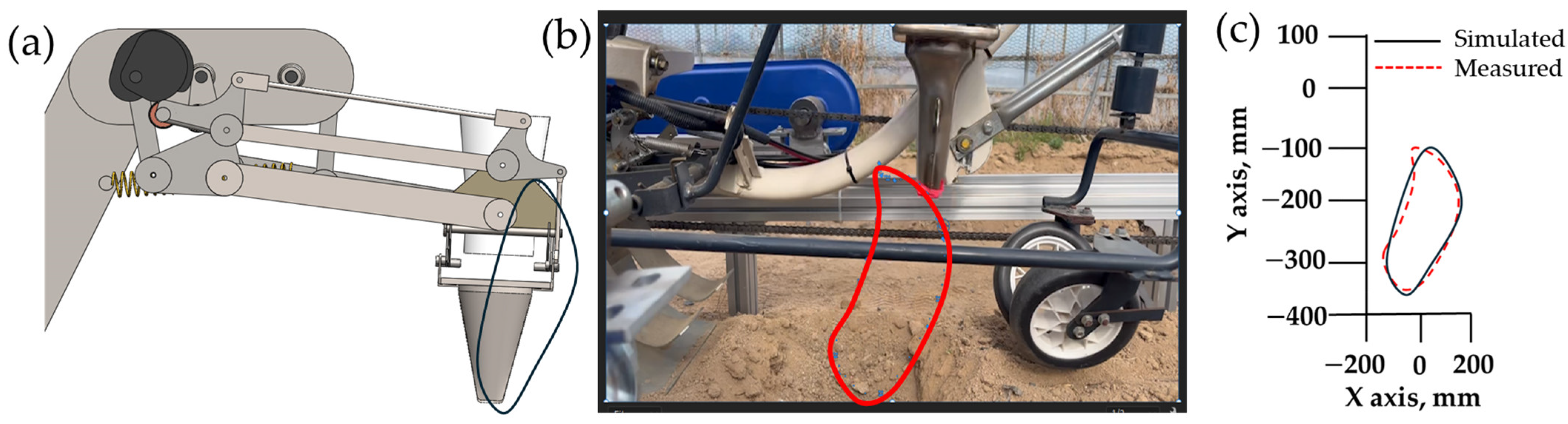

2.2. Design and Operational Mechanism of the Prototype Cabbage Transplanter

2.3. Design Requirements

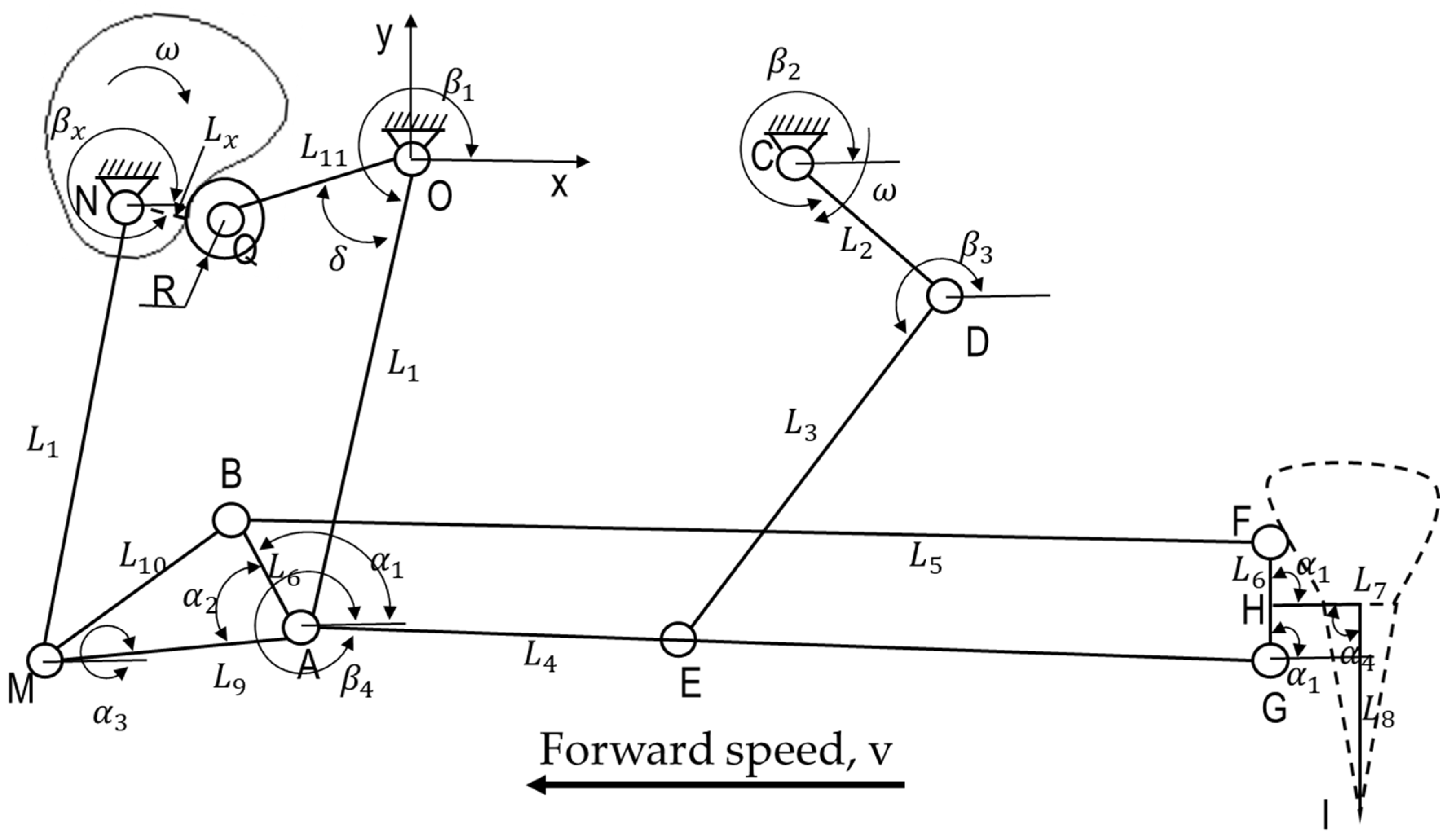

2.4. Kinematic Model of the Transplanting Mechanism

2.4.1. Position Models

2.4.2. Velocity and Acceleration Models

2.4.3. Simulation and Validation Procedures of the Planting Mechanism

3. Results

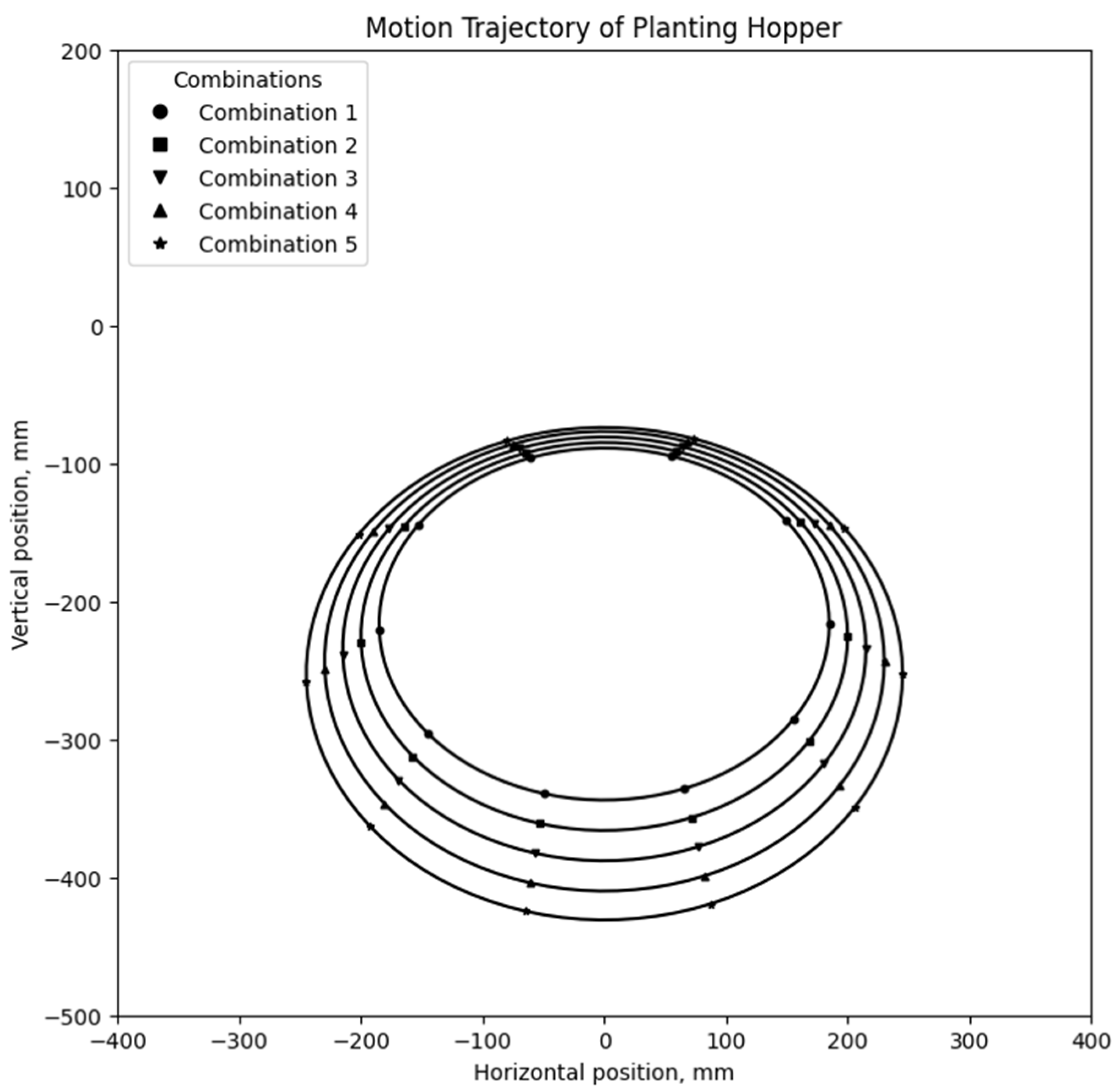

3.1. Motion Path Analysis of the Dibbling Hopper

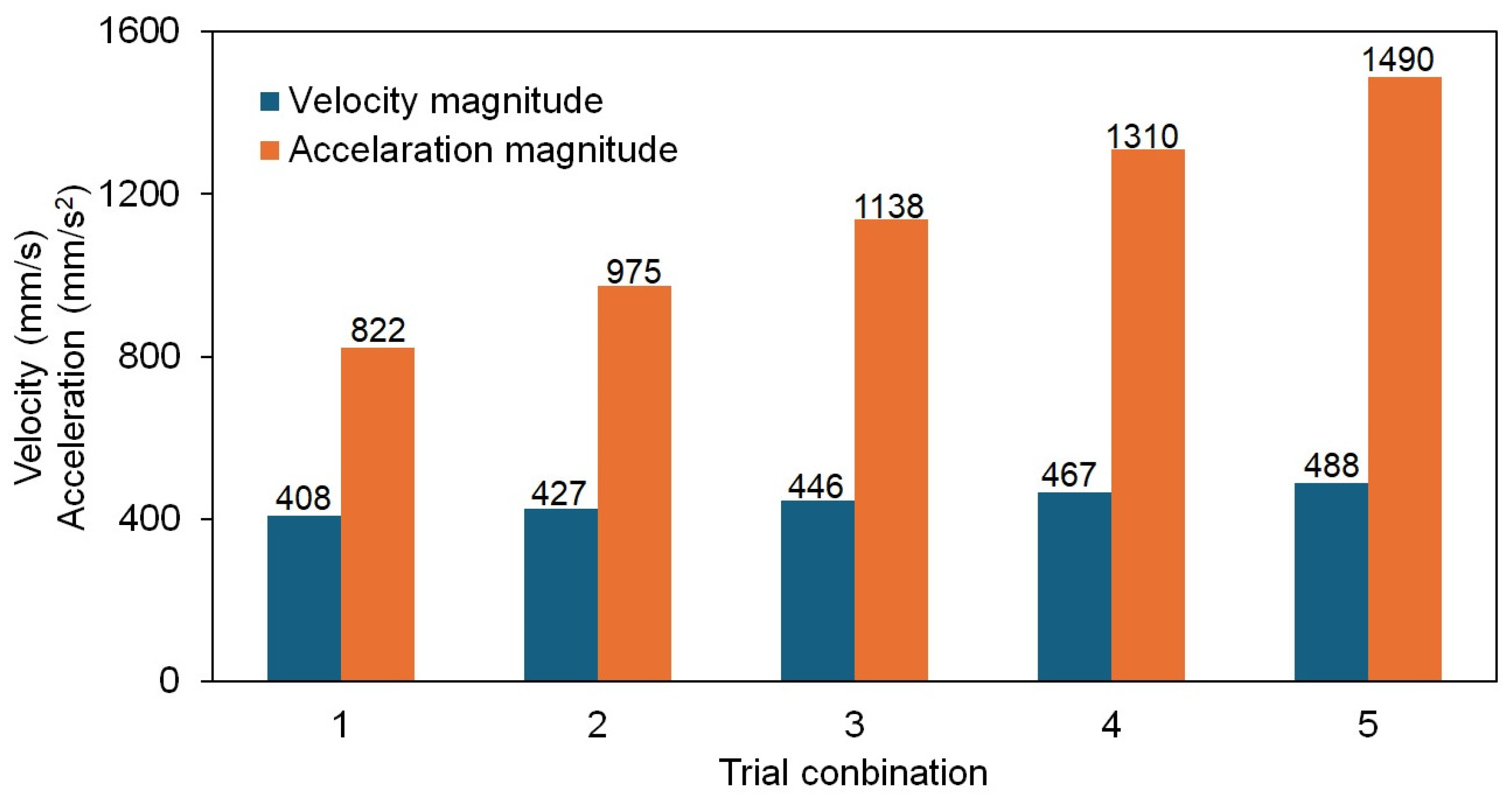

3.2. Analysis of Dibbling Hopper Velocity and Acceleration

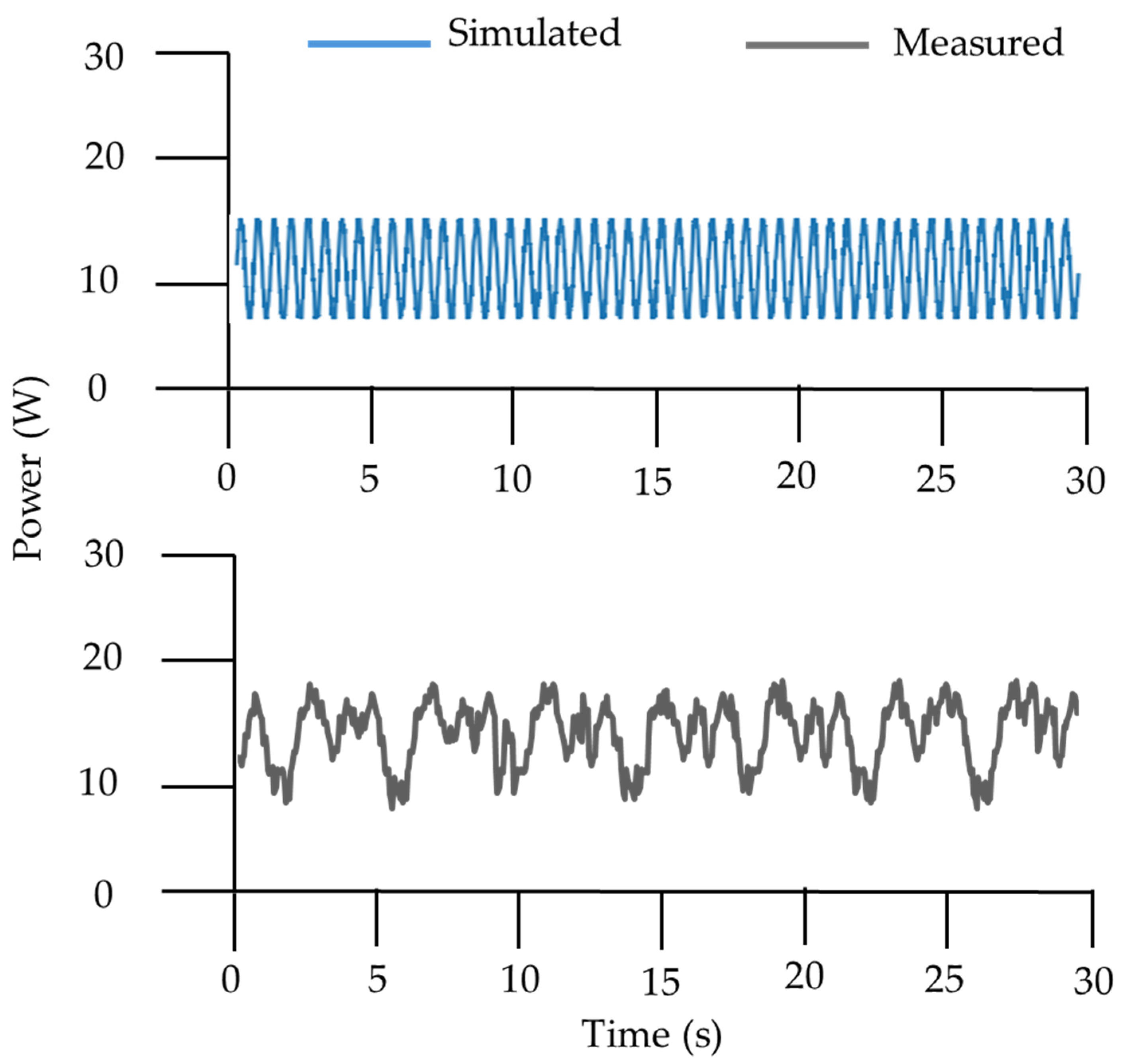

3.3. Power Requirements for Transplanting Mechanism

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Jang, D.J.; Chung, K.R.; Yang, H.J.; Kim, K.S.; Kwon, D.Y. Discussion on the origin of kimchi, representative of Korean unique fermented vegetables. J. Ethn. Foods 2015, 2, 126–136. [Google Scholar] [CrossRef]

- KOSTAT. Production of Autumn Cabbages, Autumn Radishes, Beans, Apples and Pears in 2023. Available online: https://sri.kostat.go.kr/board.es?mid=a20102010000&bid=11712&tag=&act=view&list_no=429198&ref_bid= (accessed on 26 September 2024).

- Habineza, E.; Ali, M.; Reza, M.N.; Woo, J.K.; Chung, S.O.; Hou, Y. Vegetable transplanters and kinematic analysis of major mechanisms: A review. Korean J. Agric. Sci. 2023, 50, 113–129. [Google Scholar] [CrossRef]

- Ali, M.R.; Ali, M.; Reza, M.N.; Jang, G.H.; Kang, B.S.; Choi, I.J.; Koo, J.M. Trends of vegetable transplanting mechanism for biodegradable seedling pots: A review. Precis. Agric. Sci. Technol. 2024, 6, 179–194. [Google Scholar]

- Khadatkar, S.M.; Mathur, M.; Gaikwad, B.B. Automation in transplanting: A smart way of vegetable cultivation. Curr. Sci. 2018, 115, 1884–1892. [Google Scholar] [CrossRef]

- Brodhagen, M.; Goldberger, J.R.; Hayes, D.G.; Inglis, D.A.; Marsh, T.L.; Miles, C. Policy considerations for limiting unin-tended residual plastic in agricultural soils. Environ. Sci. Pol. 2017, 69, 81–84. [Google Scholar] [CrossRef]

- Zumstein, M.T.; Schintlmeister, A.; Nelson, T.F.; Baumgartner, R.; Woebken, D.; Wagner, M.; Kohler, H.P.E.; McNeill, K.; Sander, M. Biodegradation of synthetic polymers in soils: Tracking carbon into CO2 and microbial biomass. Sci. Adv. 2018, 4, eaas9024. [Google Scholar] [CrossRef] [PubMed]

- Liu, E.K.; He, W.Q.; Yan, C.R. ‘White revolution’ to ‘white pollution’—Agricultural plastic film mulch in China. Environ. Res. Lett. 2014, 9, 091001. [Google Scholar] [CrossRef]

- Gaylor, M.O.; Harvey, E.; Hale, R.C. Polybrominated diphenyl ether (PBDE) accumulation by earthworms (Eisenia fetida) exposed to biosolids-, polyurethane foam microparticle-, and penta-BDE-amended soils. Environ. Sci. Technol. 2013, 47, 13831–13839. [Google Scholar] [CrossRef]

- Huerta Lwanga, E.; Gertsen, H.; Gooren, H.; Peters, P.; Salanki, T.; van der Ploeg, M.; Besseling, E.; Koelmans, A.A.; Geissen, V. Incorporation of microplastics from litter into burrows of Lumbricus terrestris. Environ. Pollut. 2017, 220, 523–531. [Google Scholar] [CrossRef] [PubMed]

- Meng, Y.; Guo, Z.; Yao, H.; Yeung, K.W.; Thiyagarajan, V. Calcium carbonate unit realignment under acidification: A potential compensatory mechanism in an edible estuarine oyster. Mar. Pollut. Bull. 2019, 139, 141–149. [Google Scholar] [CrossRef] [PubMed]

- Tomadoni, B.; Merino, D.; Alvarez, V.A. Biodegradable materials for planting pots. In Advanced Applications of Bio-Degradable Green Composites; Materials Research Forum LLC: Millersville PA, USA, 2020; Volume 68, p. 85. [Google Scholar]

- Juanga-Labayen, J.P.; Labayen, I.V.; Yuan, Q. A review on textile recycling practices and challenges. Textiles 2022, 2, 174–188. [Google Scholar] [CrossRef]

- Han, L.; Mao, H.; Kumi, F.; Hu, J. Development of a Multi-Task Robotic Transplanting Workcell for Greenhouse Seedlings. Appl. Eng. Agric. 2018, 34, 335–342. [Google Scholar] [CrossRef]

- Prasanna Kumar, G.V.; Raheman, H. Volume of vermicompost-based potting mix for vegetable transplants determined using fuzzy biomass growth index. Int. J. Veg. Sci. 2010, 16, 335–350. [Google Scholar] [CrossRef]

- Nandede, B.M.; Raheman, H.; Kumar, G.P. Standardization of potting mix and pot volume for the production of vegetable seedlings in paper pot. J. Plant Nutr. 2014, 37, 1214–1226. [Google Scholar] [CrossRef]

- Jang, Y.N.; An, S.W.; Chun, H.; Lee, H.J.; Wi, S.H. The growth of cucumber seedlings grown in paper pot trays affected by nutrient management during seedling period, seedling age, and night temperature after transplanting. J. Bio-Environ. Control. 2019, 28, 396–403. [Google Scholar] [CrossRef]

- Park, J.H.; Lee, G.H.; Lee, H.M.; Madhavi, B.G.K.; Arulmozhi, E.; Bhujel, A.; Moon, B.E.; Kim, H.T. Physical properties and plant growth according to the content of additives in the biodegradable pot for mechanical transplanter. JALS 2022, 56, 129–134. [Google Scholar] [CrossRef]

- Wang, X.D.; Feng, J. State and development of transplanting mechanization with mulch film at home and abroad. Chin. Agric. Mech. 2005, 3, 25–28. [Google Scholar]

- Prasanna Kumar, G.V.; Raheman, H. Vegetable transplanters for use in developing countries—A review. Int. J. Veg. Sci. 2008, 14, 232–255. [Google Scholar] [CrossRef]

- Yu, X.T.; Hu, L.L.; Hu, Z.C. Development trend and general situation of nonirrigated farmland transplanting mechanization in China. J. Anhui Agric. Sci. 2012, 40, 614–616. [Google Scholar]

- Nambu, T.; Tanimura, M. Development of automatic transplanter using chain pot for vegetable crops. Int. Symp. Transpl. Prod. Syst. 1992, 319, 541–546. [Google Scholar] [CrossRef]

- Suggs, C.W.; Thomas, T.N.; Eddington, D.L.; Peel, H.B.; Seaboch, T.R.; Gore, J.W. Self-feeding transplanter for tobacco and vegetable crops. Appl. Eng. Agric. 1987, 3, 148–152. [Google Scholar] [CrossRef]

- Kumar, G.V.P.; Raheman, H. Development of a walk-behind type hand tractor-powered vegetable transplanter for paper pot seedlings. Biosyst. Eng. 2011, 110, 189–197. [Google Scholar] [CrossRef]

- Lee, M.H.; Moon, B.E.; Jo, J.M.; Choi, T.H.; Kim, H.T. Development of automatic type transplanter for biodegradable seed-ling pot. Proc. Conf. Korean Soc. Agric. 2017, 22, 136. [Google Scholar]

- Paudel, B.; Basak, J.K.; Jeon, S.W.; Deb, N.C.; Karki, S.; Kim, H.T. Development and field testing of biodegradable seedling plug-tray cutting mechanism for automated vegetable transplanter. J. Agric. Eng. 2024, 55. [Google Scholar] [CrossRef]

- Jin, X.; Li, D.Y.; Ma, H.; Ji, J.T.; Zhao, K.X.; Pang, J. Development of single row automatic transplanting device for potted vegetable seedlings. Int. J. Agric. Biol. Eng. 2018, 11, 67–75. [Google Scholar] [CrossRef]

- Paradkar, V.; Raheman, H.; Rahul, K. Development of a metering mechanism with serial robotic arm for handling paper pot seedlings in a vegetable transplanter. Artif. Intell. Agric. 2021, 5, 52–63. [Google Scholar] [CrossRef]

- Chen, B.; Hu, G.; Sun, S.; Xiao, M.; Sun, C. Design and experimental study of intermittent automatic grouping dropping plug seedling mechanism of fixed seedling cups. Appl. Sci. 2022, 12, 11125. [Google Scholar] [CrossRef]

- Du, X.; Yun, Z.; Jin, X.; Li, P.; Gao, K. Design and experiment of automatic adjustable transplanting end-effector based on double-Cam. Agriculture 2023, 13, 987. [Google Scholar] [CrossRef]

- Dihingia, P.C.; Prasanna Kumar, G.V.; Sarma, P.K. Development of a hopper-type planting device for a walk-behind hand-tractor-powered vegetable transplanter. J. Biosyst. Eng. 2016, 41, 21–33. [Google Scholar] [CrossRef]

- Iqbal, M.Z.; Islam, M.N.; Chowdhury, M.; Islam, S.; Park, T.; Kim, Y.J.; Chung, S.O. Working speed analysis of the gear-driven dibbling mechanism of a 2.6 kW walking-type automatic pepper transplanter. Machines 2021, 9, 6. [Google Scholar] [CrossRef]

- Markumningsih, S.; Hwang, S.J.; Kim, J.H.; Jang, M.K.; Shin, C.S.; Nam, J.S. Comparison of consumed power and safety of two types of semi-automatic vegetable transplanter: Cam and four-bar link. Agriculture 2023, 13, 588. [Google Scholar] [CrossRef]

- Choi, W.C.; Kim, D.C.; Ryu, I.H.; Kim, K.U. Development of a seedling pick-up device for vegetable transplanters. Trans. Am. Soc. Agric. Biol. Eng. 2002, 45, 13–19. [Google Scholar]

- Kim, S.; Rho, H.Y.; Kim, S. The effects of climate change on heading type Chinese cabbage (Brassica rapa L. ssp. pekinensis) economic production in South Korea. Agronomy 2022, 12, 3172. [Google Scholar] [CrossRef]

- Seo, T.C.; An, S.W.; Kim, S.M.; Nam, C.W.; Chun, H.; Kim, Y.C.; Kang, T.K.; Woo, S.K.; Jeon, S.G.; Jang, K.S. Effect of the seedlings difference in cylindrical paper pot trays on initial root growth and yield of pepper. J. Bio-Environ. Control. 2017, 26, 368–377. [Google Scholar] [CrossRef]

- Kim, H.C.; Cho, Y.H.; Ku, Y.G.; Bae, J.H. Seedling qualities of hot pepper according to seedling growth periods and growth and yield after planting. Korean J. Hortic. Sci. Technol. 2015, 33, 839–844. [Google Scholar] [CrossRef]

- Sharma, A.; Khar, S. Design and development of a vegetable plug seedling transplanting mechanism for a semi-automatic transplanter. Sci. Hortic. 2024, 326, 112773. [Google Scholar] [CrossRef]

- Islam, M.N.; Iqbal, M.Z.; Ali, M.; Chowdhury, M.; Kabir, M.S.N.; Park, T.; Kim, Y.J.; Chung, S.O. Kinematic analysis of a clamp-type picking device for an automatic pepper transplanter. Agriculture 2020, 10, 627. [Google Scholar] [CrossRef]

- Xu, G.; Fang, H.; Song, Y.; Du, W.; Wang, N. Performance improvement of a geared five-bar transplanting mechanism for Salvia miltiorrhiza by orthogonal design based on an interactive human–computer auxiliary interface. Sustainability 2023, 15, 2219. [Google Scholar] [CrossRef]

- Zhao, X.; Guo, J.; Li, K.; Dai, L.; Chen, J. Optimal design and experiment of 2-DoF five-bar mechanism for flower seedling transplanting. Comput. Electron. Agric. 2020, 178, 105746. [Google Scholar] [CrossRef]

- He, Y.; Li, S.; Yang, X.; Yan, H.; Wang, W. Kinematic analysis and performance experiment of cam-swing link planting mechanism. Trans. Chin. Soc. Agric. Eng. 2016, 32, 34–41. [Google Scholar]

- Rohrer, R.A.; Luck, J.D.; Pitla, S.K.; Hoy, R. Evaluation of the accuracy of machine-reported CAN data for engine torque and speed. Trans. ASAE 2018, 61, 1547–1557. [Google Scholar] [CrossRef]

- Paraforos, D.S.; Griepentrog, H.W.; Vougioukas, S.G. Methodology for designing accelerated structural durability tests on agricultural machinery. Biosyst. Eng. 2016, 149, 24–37. [Google Scholar] [CrossRef]

- Rasool, K.; Ali, M.; Chowdhury, M.; Kwon, H.; Swe, K.M.; Chung, S.O. Theoretical analysis of velocity, acceleration, and torque calculation of a five-bar onion transplanting mechanism. In IOP Conference Series: Earth and Environmental Science, Proceedings of the International Conference on Green Agro-Industry and Bioeconomy, Malang, Indonesia, 25 August 2020; IOP Publishing: Bristol, UK, 2021; p. 012019. [Google Scholar]

- Reza, M.N.; Islam, M.N.; Chowdhury, M.; Ali, M.; Islam, S.; Kiraga, S.; Lim, S.J.; Choi, I.S.; Chung, S.O. Kinematic analysis of a gear-driven rotary planting mechanism for a six-row self-propelled onion transplanter. Machines 2021, 9, 183. [Google Scholar] [CrossRef]

- Zhu, Z.; Wu, G.; Ye, B.; Zhang, Y. Reverse design and tests of vegetable plug seedling pick-up mechanism of planetary gear train with non-circular gears. Int. J. Agric. Biol. Eng. 2023, 16, 96–102. [Google Scholar] [CrossRef]

- Shao, Y.; Zhang, H.; Xuan, G.; Zhang, T.; Guan, X.; Wang, F. Simulation and experiment of a transplanting mechanism for sweet potato seedlings with ‘boat-bottom’ transplanting trajectory. Int. J. Agric. Biol. Eng. 2023, 16, 96–101. [Google Scholar] [CrossRef]

- Jiaodi, L.; Weibin, C.; Dongyang, T.; Haiyang, T.; Hongzheng, Z. Kinematic analysis and experiment of planetary five-bar planting mechanism for zero-speed transplanting on mulch film. Int. J. Agric. Biol. Eng. 2016, 9, 84–91. [Google Scholar]

- Reza, M.N.; Ali, M.; Habineza, E.; Kabir, M.S.; Kabir, M.S.N.; Lim, S.J.; Choi, I.S.; Chung, S.O. Analysis of operating speed and power consumption of a gear-driven rotary planting mechanism for a 12-kW six-row self-propelled onion transplanter. Span. J. Agric. Res. 2023, 21, e0207. [Google Scholar] [CrossRef]

- Rahul, K.; Raheman, H.; Paradkar, V. Design and development of a 5R 2DOF parallel robot arm for handling paper pot seedlings in a vegetable transplanter. Comput. Electron. Agric. 2019, 166, 105014. [Google Scholar] [CrossRef]

| Parameter | Numerical Value | Unit |

|---|---|---|

| Plant height | 85 | mm |

| Seedling leaf width | 32 | mm |

| Seedling weight | 20 | g |

| Seedling age | 30 | day |

| Number of leaves | 4–5 | leaf |

| Notation | Definition and Measurement Unit |

|---|---|

| L1 | Linear distance between points O and A (mm) |

| L2 | Linear distance between points C and D (mm) |

| L3 | Linear distance between points D and E (mm) |

| L4 | Linear distance between points A and E (mm) |

| L5 | Linear distance between points A and G (mm) |

| L6 | Linear distance between points F and G (mm) |

| L7 | Linear distance between points H and J (mm) |

| L8 | Linear distance between points J and I (mm) |

| L9 | Linear distance between points A and M (mm) |

| L10 | Linear distance between points B and M (mm) |

| L11 | Linear distance between points O and Q (mm) |

| LX | Instantaneous radius of the cam profile (mm) |

| R | Roller radius Q (mm) |

| ω | Angular motion of the cam (degree/s) |

| 1 | Initial phase angle of OA (degree) |

| 2 | Initial phase angle of CD (degree) |

| 3 | Angular motion of DE (degree) |

| 4 | Angular motion of AEG (degree) |

| X | Initial phase angle of the cam (degree) |

| 1 | Initial phase angle of AB (degree) |

| 2 | Angle between AB and AM (degree) |

| 3 | Angle between AM and X-axis (degree) |

| 4 | Angle between HJ and JI (degree) |

| Angle between QO and OA (degree) |

| Number of Trials | Crank Length (mm) | Coupler Length (mm) | Follower Length (mm) | End-Effector Length (mm) | Fixed Bar Length (mm) | Velocity in X-Axis (mm/s) | Velocity in Y-Axis (mm/s) | Acceleration in X-Axis (mm/s2) | Acceleration in Y-Axis (mm/s2) |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 45 | 130 | 115 | 210 | 110 | 408 | 471 | 822 | 1818 |

| 2 | 50 | 140 | 120 | 220 | 120 | 427 | 532 | 975 | 2091 |

| 3 | 55 | 150 | 125 | 230 | 130 | 446 | 594 | 1138 | 2379 |

| 4 | 60 | 160 | 130 | 240 | 140 | 467 | 657 | 1310 | 2683 |

| 5 | 65 | 170 | 135 | 250 | 150 | 488 | 720 | 1490 | 3000 |

| Fixed Parameters | Variables |

|---|---|

| Forward speed | Main arm lengths |

| Planting interval | Rotating speed of the mechanism |

| Planting depth | - |

| Parameters | Velocity | Acceleration | ||

|---|---|---|---|---|

| Direction | Simulation (mm/s) | Experiment (mm/s) | Simulation (mm/s2) | Experiment (mm/s2) |

| X-component | ±256.15 | +276.56 to −284.34 | ±972.45 | +990.56.87 to −1241.46 |

| Y-component | ±1243.18 | +1296.25 to −1379.17 | ±6847.57 | +8751.27 to −8664.38 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ali, M.R.; Reza, M.N.; Samsuzzaman; Habineza, E.; Haque, M.A.; Kang, B.-S.; Chung, S.-O. Kinematic Analysis of a Cam-Follower-Type Transplanting Mechanism for a 1.54 kW Biodegradable Potted Cabbage Transplanter. Machines 2024, 12, 925. https://doi.org/10.3390/machines12120925

Ali MR, Reza MN, Samsuzzaman, Habineza E, Haque MA, Kang B-S, Chung S-O. Kinematic Analysis of a Cam-Follower-Type Transplanting Mechanism for a 1.54 kW Biodegradable Potted Cabbage Transplanter. Machines. 2024; 12(12):925. https://doi.org/10.3390/machines12120925

Chicago/Turabian StyleAli, Md Razob, Md Nasim Reza, Samsuzzaman, Eliezel Habineza, Md Asrakul Haque, Beom-Sun Kang, and Sun-Ok Chung. 2024. "Kinematic Analysis of a Cam-Follower-Type Transplanting Mechanism for a 1.54 kW Biodegradable Potted Cabbage Transplanter" Machines 12, no. 12: 925. https://doi.org/10.3390/machines12120925

APA StyleAli, M. R., Reza, M. N., Samsuzzaman, Habineza, E., Haque, M. A., Kang, B.-S., & Chung, S.-O. (2024). Kinematic Analysis of a Cam-Follower-Type Transplanting Mechanism for a 1.54 kW Biodegradable Potted Cabbage Transplanter. Machines, 12(12), 925. https://doi.org/10.3390/machines12120925