Order Reduction Adaptive Current Tracking Control with Proportional–Integral-Type Filter for MAGLEV Applications

Abstract

:1. Introduction

- The proposed proportional–integral (PI)-type filter for the current measurement extracts fundamental components without system model information and signal distortions (such as phase delay and magnitude distortion), ensuring the desired first-order filtering error convergence through the order reduction technique.

- Based on the filtered current signal, the proposed adaptive proportional (P)-type controller stabilizes the current error to accomplish the trajectory tracking mission along the desired first-order convergent system; only one design parameter determines its feedback and adaptation gains for the given performance specification through the order reduction technique.

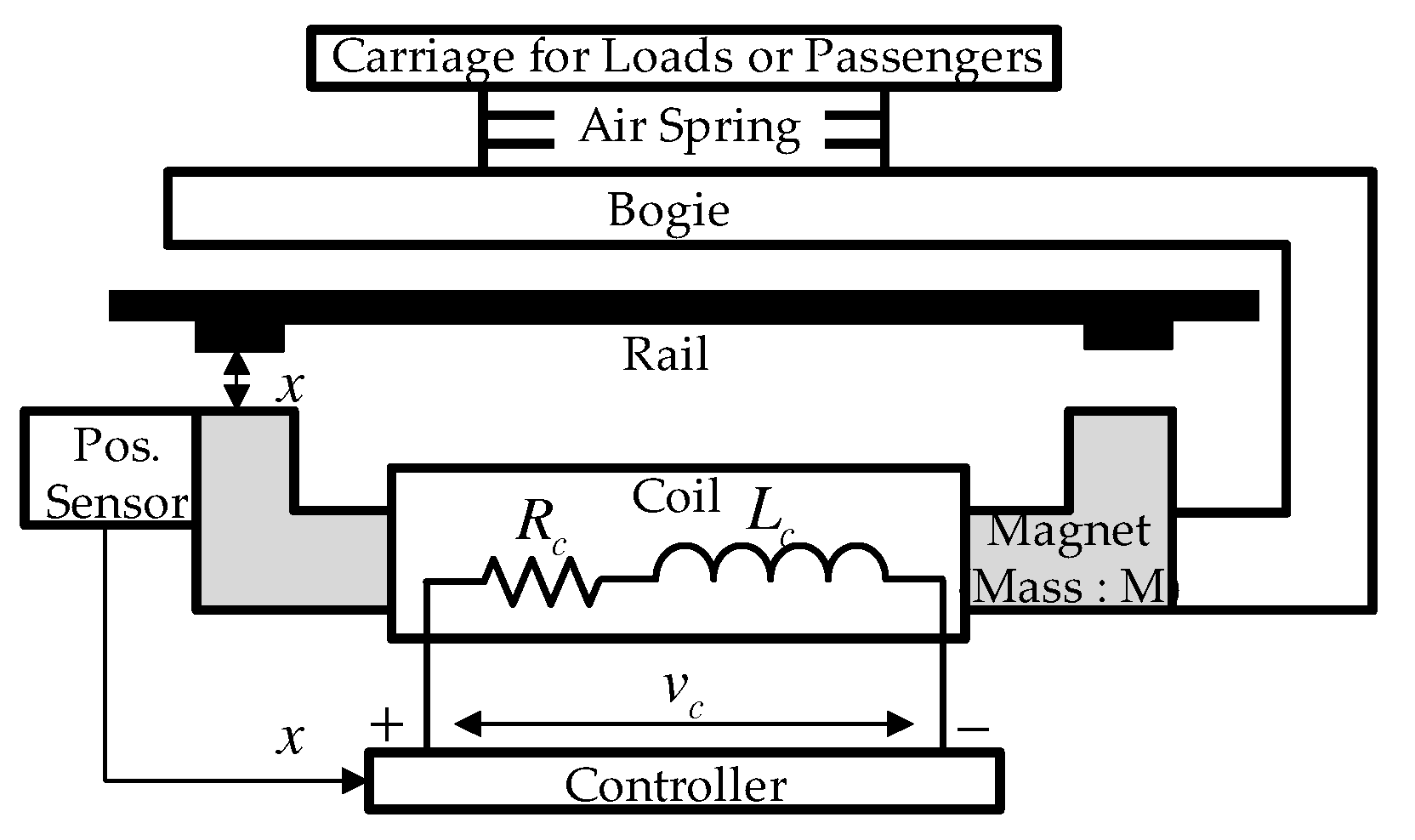

2. Nonlinear Dynamics of MAGLEVs

3. Structure of Proposed Feedback System

3.1. Design Purpose

3.2. Proposed PI-Type Filter-Based Adaptive Current Tracking Controller

3.2.1. PI-Type Filter for Current Measurement

- (simple structure) The first-order LPF defined as leads to the filtering error dynamics as where , suffering from the phase delay and magnitude distortion for an high-frequency input . The proposed PI-type filter forming the simple structure ensures the improved filtering error dynamics given byfor a small through the augmentation of the integral action and order reduction property by the nonlinear structured gain (12).

3.2.2. Adaptive Current Tracking Control Law

4. Closed-Loop Analysis Results

4.1. Analysis of Filtering Loop

4.2. Analysis of Control Loop

- (PI-type filter by Lemma 2)

- 1.

- Determine the desired filtering performance as for some .

- 2.

- Increase by observing , .

- (Adaptive current controller by Theorem 1)

- 1.

- Determine the desired coil current control performance for some .

- 2.

- Increase by observing , .

5. Simulations

- (P control for velocity reference)

- (PI control for acceleration reference)

- (Current reference calculation)

- (filter) for with and

- (controller) for with .

5.1. Rail Position Tracking Performance Evaluation

5.2. Rail Position Stabilization Performance Evaluation

5.3. Numerical Performance Comparison Results

5.4. Computational Time Consumption Comparison Results

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

References

- Li, A.; Cui, H.; Guan, Y.; Deng, J.; Zhang, Y.; Deng, W. Study on Aerodynamic Drag Reduction by Plasma Jets for 600 km/h Vacuum Tube Train Sets. Machines 2023, 11, 1078. [Google Scholar] [CrossRef]

- Wang, Y.; Gao, H. Simulation Analysis and Online Monitoring of Suspension Frame of Maglev Train. Machines 2023, 11, 607. [Google Scholar] [CrossRef]

- Wang, Z.; Li, X.; Xie, Y.; Long, Z. MAGLEV Train Signal Processing Architecture Based on Nonlinear Discrete Tracking Differentiator. Sensors 2018, 18, 1697. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, C.X.; Pham, T.D.; Lukynov, A.D.; Tran, P.C.; Truong, Q.D. Design embedded control system based controller of the quasi time optimization approach for a magnetic levitation system. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2021. [Google Scholar]

- Zhang, L.; Campbell, S.; Huang, L. Nonlinear analysis of a MAGLEV system with time-delayed feedback control. Phys. D Nonlinear Phenom. 2012, 240, 1761–1770. [Google Scholar] [CrossRef]

- Santos, M.; Ferreira, J.; Simoes, J.; Pascoal, R.; Torrao, J.; Xue, X.; Furlani, E. Magnetic levitation-based electromagnetic energy harvesting: A semi-analytical non-linear model for energy transduction. Sci. Rep. 2016, 6, 18579. [Google Scholar]

- Zhang, Z.; Zhang, L. Hopf bifurcation of time-delayed feedback control for MAGLEV system with flexible guideway. Appl. Math. Comput. 2013, 219, 6106–6112. [Google Scholar] [CrossRef]

- Lee, H.W.; Kim, K.C.; Lee, J. Review of MAGLEV train technologies. IEEE Trans. Magn. 2006, 42, 1917–1925. [Google Scholar]

- Zhang, Z.; Li, X. Real-Time Adaptive Control of a Magnetic Levitation System with a Large Range of Load Disturbance. Sensors 2018, 18, 1512. [Google Scholar] [CrossRef]

- Kim, C.H. Robust Control of Magnetic Levitation Systems Considering Disturbance Force by LSM Propulsion Systems. IEEE Trans. Magn. 2017, 53, 8300805. [Google Scholar] [CrossRef]

- Wai, R.J.; Lee, J.D.; Chuang, K.L. Real-time PID control strategy for MAGLEV transportation system via particle swarm optimization. IEEE Trans. Ind. Electron. 2011, 58, 629–646. [Google Scholar] [CrossRef]

- Shamma, J.S.; Athans, M. Analysis of gain scheduled control of nonlinear plants. IEEE Trans. Autom. Control 2002, 35, 898–907. [Google Scholar] [CrossRef]

- Olalla, C.; Leyva, R.; Queinnec, I.; Maksimovic, D. Robust Gain-Scheduled Control of Switched-Mode DC-DC Converters. IEEE Trans. Power Electron. 2012, 27, 3006–3019. [Google Scholar] [CrossRef]

- Yang, J.; Zolotas, A.; Chen, W.H.; Michail, K.; Li, S. Robust control of nonlinear MAGLEV suspension system with mismatched uncertainties via DOBC approach. ISA Trans. 2011, 50, 389–396. [Google Scholar] [CrossRef] [PubMed]

- Tian, Z.; Zhong, Q.C.; Ren, B.; Yuan, J. Stabilisability analysis and design of UDE-based robust control. IET Control Theory Appl. 2019, 13, 1445–1453. [Google Scholar] [CrossRef]

- Huang, G.; Huang, H.; Zhai, Y.; Tang, G.; Zhang, L.; Gao, X.; Huang, Y.; Ge, G. Multi-Sensor Fusion for Wheel-Inertial-Visual Systems Using a Fuzzification-Assisted Iterated Error State Kalman Filter. Sensors 2024, 24, 7619. [Google Scholar] [CrossRef]

- Liang, Z.; Fan, S.; Feng, J.; Yuan, P.; Xu, J.; Wang, X.; Wang, D. An Enhanced Adaptive Ensemble Kalman Filter for Autonomous Underwater Vehicle Integrated Navigation. Drones 2024, 8, 711. [Google Scholar] [CrossRef]

- Wu, J.; Li, Y.; Sun, Q.; Zhu, Y.; Xing, J.; Zhang, L. Joint Battery State of Charge Estimation Method Based on a Fractional-Order Model with an Improved Unscented Kalman Filter and Extended Kalman Filter for Full Parameter Updating. Fractal Fract. 2023, 8, 695. [Google Scholar] [CrossRef]

- Wai, R.J.; Lee, J.D. Backstepping-based levitation control design for linear magnetic levitation rail system. IET Control Theory Appl. 2008, 2, 72–86. [Google Scholar] [CrossRef]

- Kaloust, J.; Ham, C.; Siehling, J.; Jongekryg, E. Nonlinear robust control design for levitation and propulsion of a MAGLEV system. IET Control Theory Appl. 2004, 151, 460–464. [Google Scholar] [CrossRef]

- Sadek, U.; Sarja, A.; Chowdhury, A.; Cko, R.S. Improved adaptive fuzzy backstepping control of a magnetic levitation system based on symbiotic organism search. Appl. Soft Comput. 2017, 56, 19–33. [Google Scholar] [CrossRef]

- Sun, Y.; Li, W.; Xu, J.; Qiang, H.; Chen, C. Nonlinear dynamic modeling and fuzzy sliding-mode controlling of electromagnetic levitation system of low-speed MAGLEV train. J. Vibroeng. 2017, 19, 328–342. [Google Scholar] [CrossRef]

- Wai, R.J.; Lee, J.D. Robust Levitation Control for Linear MAGLEV Rail System Using Fuzzy Neural Network. IEEE Trans. Control Syst. Technol. 2009, 17, 4–14. [Google Scholar]

- Xu, J.; Du, Y.; Chen, Y.H.; Guo, H. Adaptive robust constrained state control for non-linear MAGLEV vehicle with guaranteed bounded airgap. IET Control Theory Appl. 2018, 12, 1573–1583. [Google Scholar] [CrossRef]

- Kim, S.K. Nonlinear Position Stabilizing Control with Active Damping Injection Technique for Magnetic Levitation Systems. Electronics 2019, 8, 221. [Google Scholar] [CrossRef]

- Kim, S.K.; Ahn, C.K. Variable Cut-Off Frequency Algorithm-Based Nonlinear Position Controller for Magnetic Levitation System Applications. IEEE Syst. Man Cybern. Syst. 2021, 51, 4599–4605. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, J.K.; Kim, D.; Kim, Y.; Kim, S.-K. Order Reduction Adaptive Current Tracking Control with Proportional–Integral-Type Filter for MAGLEV Applications. Machines 2024, 12, 880. https://doi.org/10.3390/machines12120880

Park JK, Kim D, Kim Y, Kim S-K. Order Reduction Adaptive Current Tracking Control with Proportional–Integral-Type Filter for MAGLEV Applications. Machines. 2024; 12(12):880. https://doi.org/10.3390/machines12120880

Chicago/Turabian StylePark, Jae Kyung, Dongpin Kim, Yonghun Kim, and Seok-Kyoon Kim. 2024. "Order Reduction Adaptive Current Tracking Control with Proportional–Integral-Type Filter for MAGLEV Applications" Machines 12, no. 12: 880. https://doi.org/10.3390/machines12120880

APA StylePark, J. K., Kim, D., Kim, Y., & Kim, S.-K. (2024). Order Reduction Adaptive Current Tracking Control with Proportional–Integral-Type Filter for MAGLEV Applications. Machines, 12(12), 880. https://doi.org/10.3390/machines12120880