1. Introduction

Bearings are vital mechanical elements that support rotating shafts with minimal friction, ensuring the smooth functioning of machinery. They are extensively utilized in a variety of mechanical systems, especially in intricate and critical applications such as induction motors, automobiles, aircraft, and industrial machinery [

1,

2]. However, when bearings become damaged or fail, they can disrupt machine operations or even cause complete system shutdowns, leading to expensive repairs and significant losses in productivity. In fact, bearing problems are responsible for more than 40% of induction motor failures [

3,

4]. According to catalogs provided by major bearing manufacturers [

5,

6,

7], the causes of bearing failure include fatigue, insufficient lubrication, contamination, overloading, improper installation, thermal overload, and misalignment. These factors lead to wear on the key mechanical components within the bearing, such as the inner and outer races and the balls. While bearing failures can occur due to factors beyond mechanical elements, typically, severe wear on the mechanical components of the bearing results in its failure. Consequently, it is essential to continuously monitor the condition of bearings and detect any damage or anomalies at an early stage. By identifying potential issues before they escalate into severe damage, preventive actions can be taken to ensure stable machine operations. Early detection not only lowers maintenance costs but also maximizes machine uptime. Utilizing predictive maintenance technologies and diagnostic tools to anticipate bearing damage can effectively prevent unexpected breakdowns and the associated substantial financial losses [

8,

9,

10].

To address this need, recent research has explored condition monitoring techniques, including vibration spectrum analysis, sound waveform analysis, and temperature analysis, to detect rolling bearing damage. In industry, SKF has proposed the Proactive Reliability Maintenance (PRM) program, which offers a service to predict and address various potential failures in bearings within mechanical systems in advance. This service detects signals such as vibrations and temperatures generated by the system and uses them to identify issues with the bearings [

11]. However, this approach has not yet encompassed signal analysis through machine learning and the identification of the underlying causes of these problems. In academia, Tahmasbi et al. diagnosed bearing failures and performed root cause analysis through vibration investigations on a 2300 kW motor, identifying resonance and inadequate lubrication as key failure causes and implementing corrective actions that improved the time between failures from 3 to 11 months [

12]. Jakobson et al. presented a method for detecting insufficient lubrication in rolling bearings using a low-cost MEMS ultrasonic microphone, where vibration signals are analyzed under varying lubrication conditions and the viscosity ratio of the lubricant serves as a metric for oil-film quality, with results compared to predictions from regression and neural network models [

13]. Fang et al. suggested a method that integrates autocorrelation with wavelet transform and cyclostationary theory to effectively identify compound faults in rolling bearings of aeroengines, outperforming conventional methods in fault separation and detection regardless of sensor orientation [

14]. Xu et al. developed a digital twin-empowered discriminative graph learning network (DT-DGLN) for rolling bearing fault diagnosis using unlabeled industrial data, addressing the challenge of limited datasets by creating a detailed digital twin model and a framework that adapts knowledge from simulated to real signals for efficient fault recognition [

15]. Gunerkar et al. introduced a novel bearing fault diagnosis method that integrates vibration and acoustic emission sensors through data acquisition, signal processing, feature extraction, K-nearest neighbor classification, high-level data fusion, and decision-making steps, enabling the early detection of all rolling bearing faults by leveraging the unique strengths of each sensor type [

16]. Wang et al. used acoustic emissions and various sensing techniques to monitor and correlate wear mechanisms in oil-lubricated metal sliding contacts at the micro-scale [

17]. Chen et al. demonstrated that combining online vibration and electrostatic sensors with advanced data fusion techniques effectively detects bearing deterioration before failure and enhances anomaly detection by identifying key diagnostic variables [

18]. Yang et al. studied vibration characteristics resulting from cage damage by recording vibration and temperature data across the entire life cycle of two types of deep groove ball bearings (6210 and 6011) under abnormal load conditions [

19]. Additionally, Küçükoglu Dogan et al. evaluated the fault detection and lifespan of polymer hybrid ball bearings using both an accelerometer and load cell under varying load conditions, showing that these sensors can provide complementary insights for bearing condition monitoring [

20]. Zhang et al. synthesized CdTe/ZnS-SiO

2 nanocomposites to enhance the thermal stability and photoluminescence of CdTe quantum dots, enabling their effective use as reversible temperature sensors for thermal monitoring of bearing components in high-speed applications [

21]. However, challenges remain in implementing these monitoring systems in industrial settings, primarily due to the high costs and limited integration capabilities of these systems.

With advances in machine learning algorithms, recent research has increasingly applied machine learning models to nonlinear and complex physical systems for bearing fault diagnosis. Magadán et al. predicted the remaining useful life of electric motor bearings using a Stacked Variational Denoising Autoencoder (SVDAE) and Bidirectional Long Short-Term Memory (BiLSTM) network [

22]. Ma et al. proposed an ensemble deep learning diagnosis method that integrates a Convolution Residual Network (CRN), Deep Belief Network (DBN), and Deep Auto-Encoder (DAE) through a multi-objective optimization strategy, improving the diagnosis of rotor and bearing faults in rotating machinery compared to traditional models [

23]. Elforjani et al. applied three supervised machine learning techniques—support vector machine regression, multilayer artificial neural networks, and Gaussian process regression—to correlate acoustic emission features with the natural wear of slow-speed bearings, concluding that neural networks can effectively estimate the remaining useful life of components using appropriate data and structure [

24]. Hao et al. used a 1D Convolutional Long Short-Term Memory (1D CNN-LSTM) network to diagnose bearing conditions from vibration signals captured by multiple sensors [

25]. Zhang et al. investigated a new deep learning model for intelligent fault diagnosis that effectively operates in noisy environments and adapts to changing working loads without requiring time-consuming denoising preprocessing or domain adaptation algorithms, achieving high accuracy and providing insights into its performance through feature visualization [

26]. Yu et al. proposed a novel feature extraction method for improving bearing fault diagnosis accuracy by utilizing empirical mode decomposition and combining K-means clustering with standard deviation for selecting sensitive characteristics, along with a modified dimensionality reduction approach, ultimately demonstrating effective performance across 12 bearing fault conditions [

27]. Feng Jia et al. utilized deep neural networks (DNNs) for intelligent fault diagnosis in rotating machinery by analyzing large-scale vibration data from AE sensors [

28]. Guo et al. proposed a novel hierarchical learning-rate-adaptive deep convolutional neural network for accurately diagnosing bearing faults and evaluating their severity, achieving satisfactory results in fault-pattern recognition and fault-size assessment when tested on data from a test rig, outperforming existing methods [

29]. While most previous studies have focused on training machine learning models and improving their accuracy and performance, this research presents a method for diagnosing bearing faults using a DNN model and explains the reasons behind fault classification through the use of explainable AI (xAI) techniques.

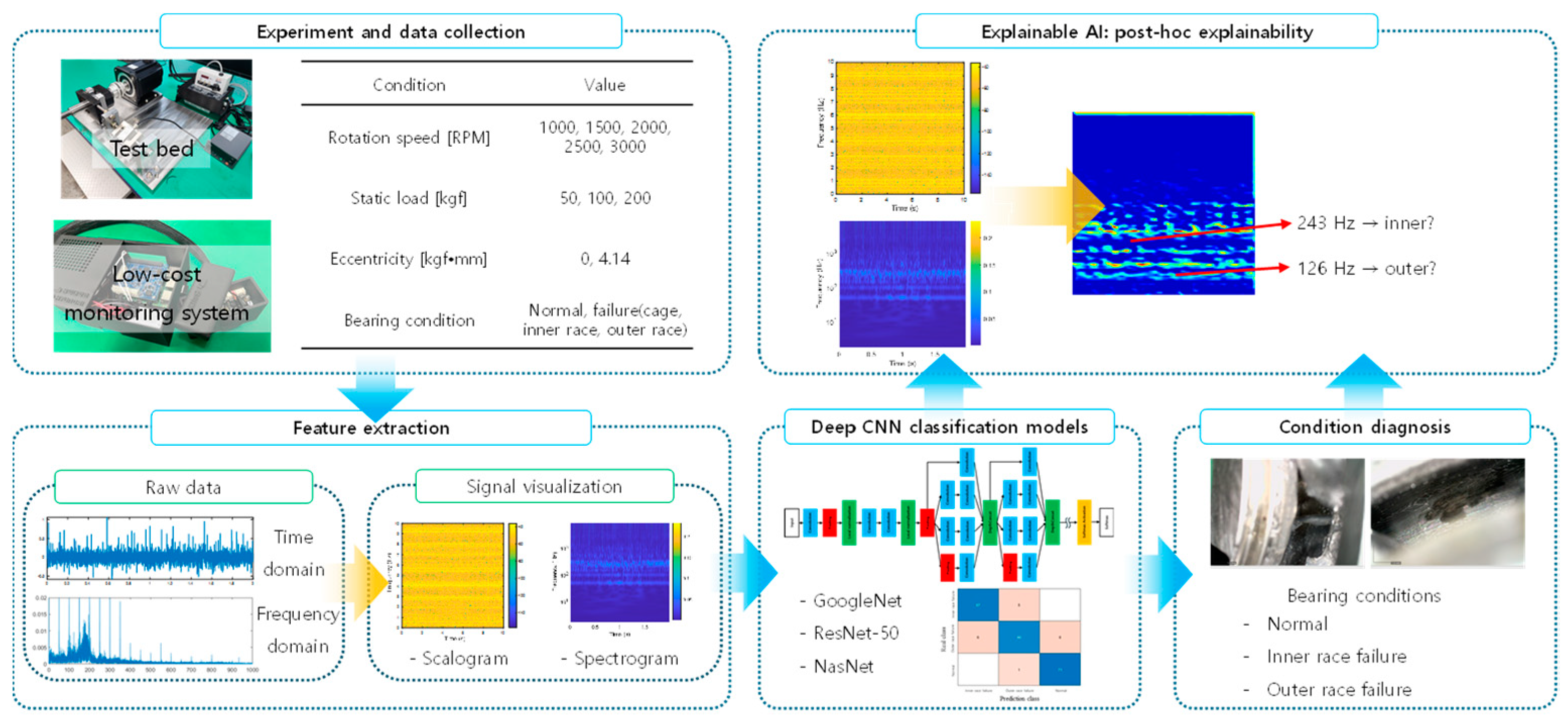

This study developed a cost-effective monitoring system using affordable sensors such as accelerometers, microphones, and piezo sensors, along with a budget-friendly data acquisition (DAQ) system, and validated its reliability against high-end systems. The low-cost monitoring setup was mounted on a test bed, where experiments were conducted under 72 different operating conditions to gather data. The collected data were visualized as scalograms and spectrograms, demonstrating that a deep neural network (DNN) model could accurately classify bearing faults and normal states. Additionally, the study proposed a method for extracting features from the trained DNN model using xAI, which confirmed the reliability of fault cause analysis by comparing the results with theoretical failure frequencies.

3. Bearing Fault Diagnosis via DNN

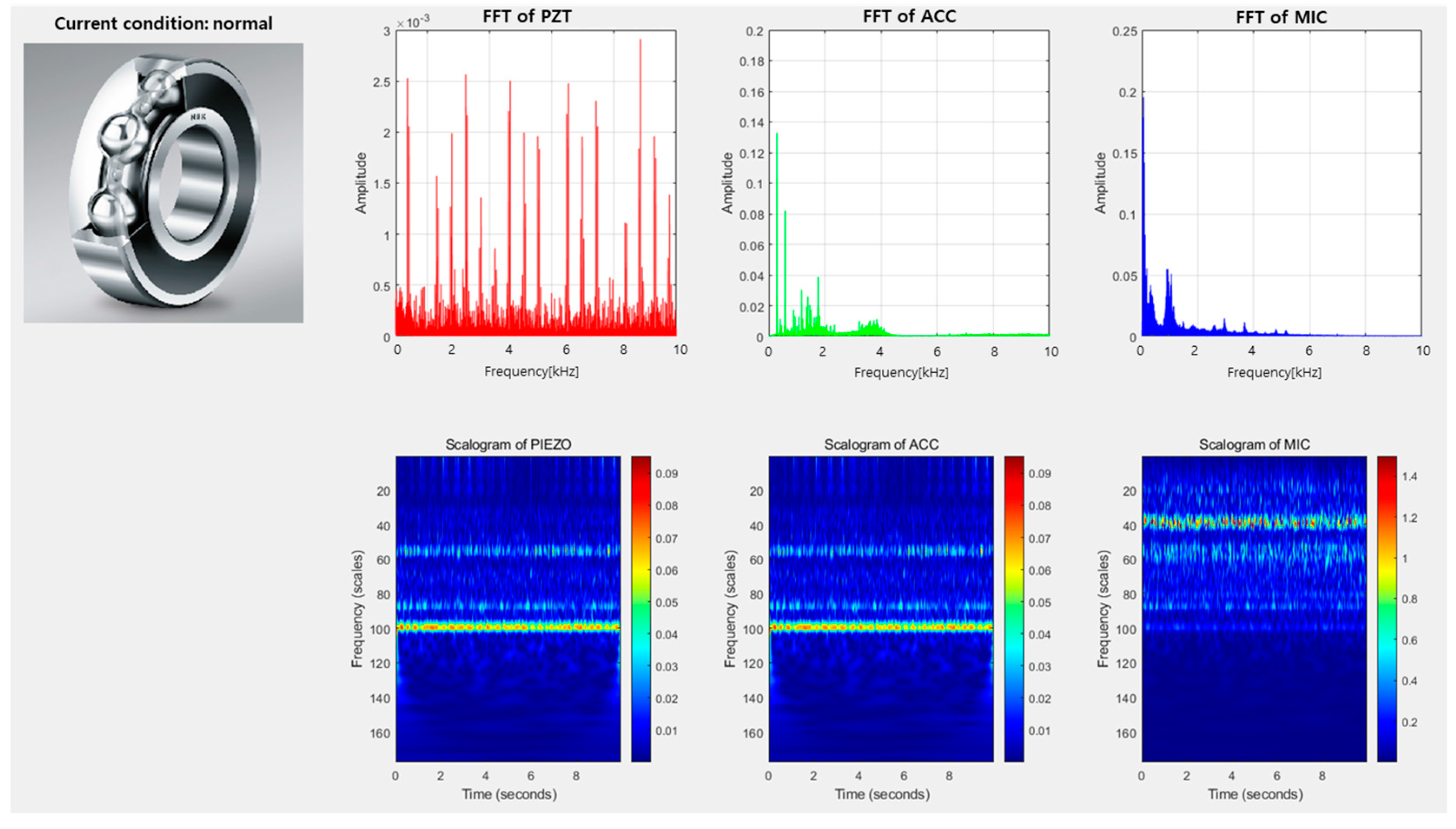

The process of bearing fault diagnosis is essential for maintaining the safety and efficiency of machinery. This procedure is structured into several key stages, beginning with the collection of monitoring data. Real-time data are acquired through an economical monitoring system equipped with three sensors, each possessing distinct characteristics and sensitivities, thereby enabling comprehensive data acquisition. The collected data then undergo a signal processing phase, where noise is eliminated and critical information is refined into a more usable form. Analysis revealed that measurements above 1 kHz did not provide meaningful features for differentiating between faulty and normal signals and were susceptible to external noise. Consequently, a cutoff frequency of 1 kHz was implemented for all sensors, effectively removing high-frequency components.

Following signal preprocessing, the data advance to the visualization stage, where they are transformed into graphical representations such as spectrograms and scalograms to facilitate the interpretation of data characteristics. A spectrogram typically employs the Fourier transform to convert the signal into the frequency domain, analyzing short segments of the signal to identify frequency components over time. In contrast, a scalogram utilizes the wavelet transform to temporally localize frequency components, capturing changes in specific frequency bands with higher resolution. This makes the scalogram particularly advantageous for analyzing the frequency components of non-stationary signals, thereby complementing the information provided by spectrograms. The visualization process generates a total of 4320 images, which are subsequently used to train deep neural network (DNN) models. Detailed descriptions of these processes are illustrated in

Figure 7.

In the fault diagnosis phase, the integration of data collected simultaneously from the three sensors is crucial for combining the prediction results of each model. To achieve this, a majority voting method, also known as an ensemble technique, is employed to merge the predictions from multiple models, ultimately determining the bearing condition. The data from the three sensors is visualized and utilized to train the DNN models to classify bearings as either normal or faulty. Each classification outcome is determined by the majority vote, effectively reflecting the characteristics extracted from the visualized data of each sensor. As depicted in

Figure 8, the user interface is designed to facilitate easy access to bearing condition diagnosis results by inputting new real-time data from the low-cost monitoring system into the trained DNN models. Additionally, various types of information, including sensor-specific FFT graphs, scalograms, and cumulative diagnosis counts, are updated and displayed in real-time, providing immediate access to insights regarding bearing analysis.

In this testbed, experiments were conducted under 72 distinct conditions, resulting in the collection of 2160 time-series signals from 10 bearings and 3 sensors. These signals were utilized to train deep neural network (DNN) models, thereby significantly enhancing the accuracy of bearing fault diagnosis. Recognizing that the fast Fourier transform (FFT) alone is limited in capturing the subtle distinctions between normal and faulty bearings, additional data visualization techniques such as spectrograms and scalograms were employed.

The spectrogram was generated using the following procedure. Initially, the signal was segmented into fixed-length frames (windows), and a window function was applied to each segment to minimize boundary effects. Subsequently, a Fourier transform was performed on each windowed frame, converting the signal from the time domain to the frequency domain. This transformation enabled the analysis of the frequency components within each frame, allowing for the extraction of both the magnitude and phase information of these components. The extracted data were then organized over time and visualized in a two-dimensional graphic, with frequency depicted on the Y-axis, time on the X-axis, and amplitude represented through variations in color or brightness.

The scalogram was produced using the following methodology. The signal underwent a wavelet transform, a technique that localizes frequency components in time, enabling high-resolution detection of changes in non-stationary signals. In this study, the Morlet wavelet was utilized. By applying the wavelet transform, the signal was transformed into the time–frequency domain, generating coefficients that depict the variation of frequency components over time. The visualization parameters included a signal length of 199,000 samples, a sampling frequency of 20,000 Hz, and 12 voices per octave. Utilizing these coefficients, the scalogram was created with time represented on the X-axis and frequency on the Y-axis, while the energy of each frequency band was visualized through color or brightness levels. In this visualization process, the intensity of each frequency band was depicted using a color map to represent the strength of the signal.

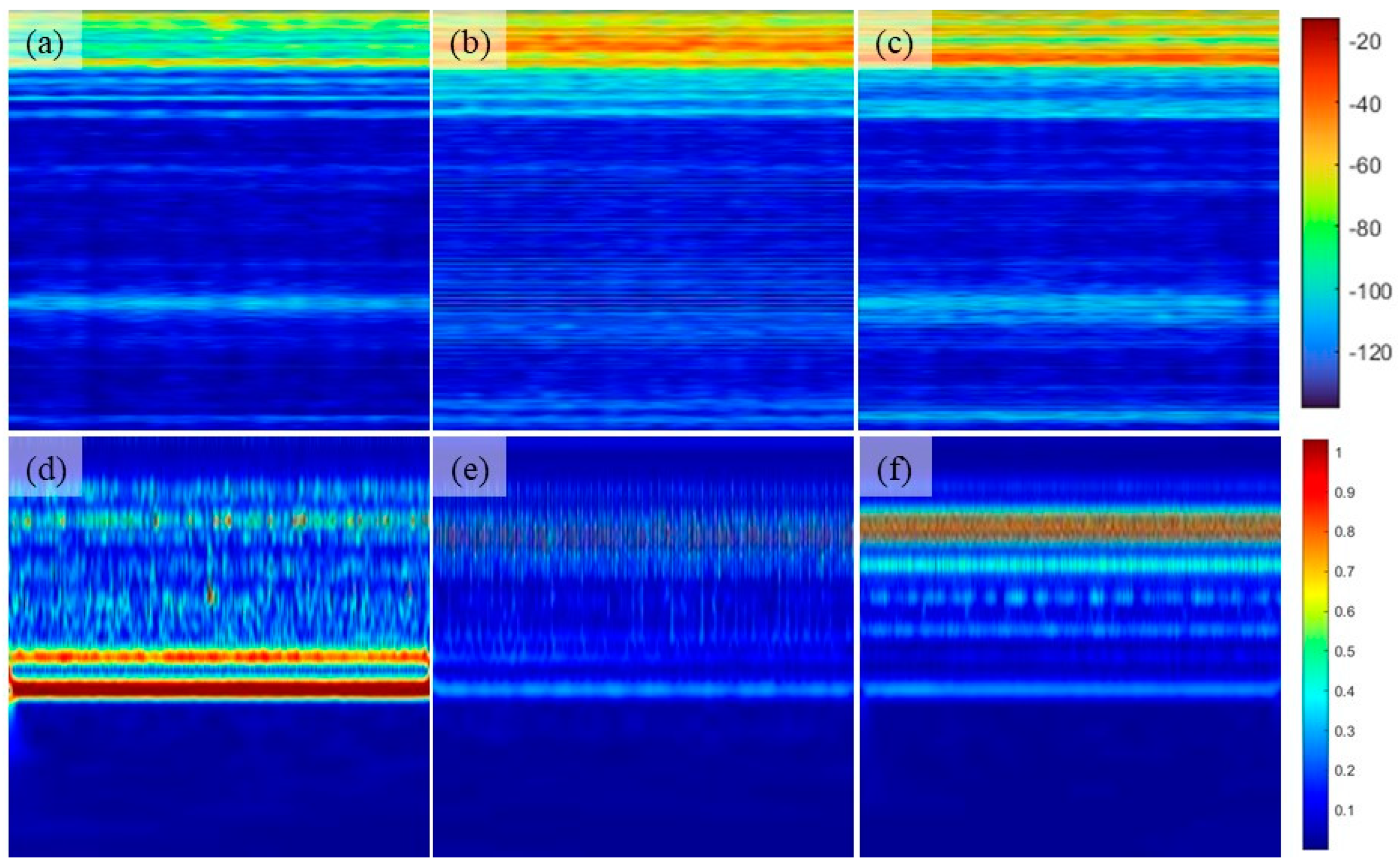

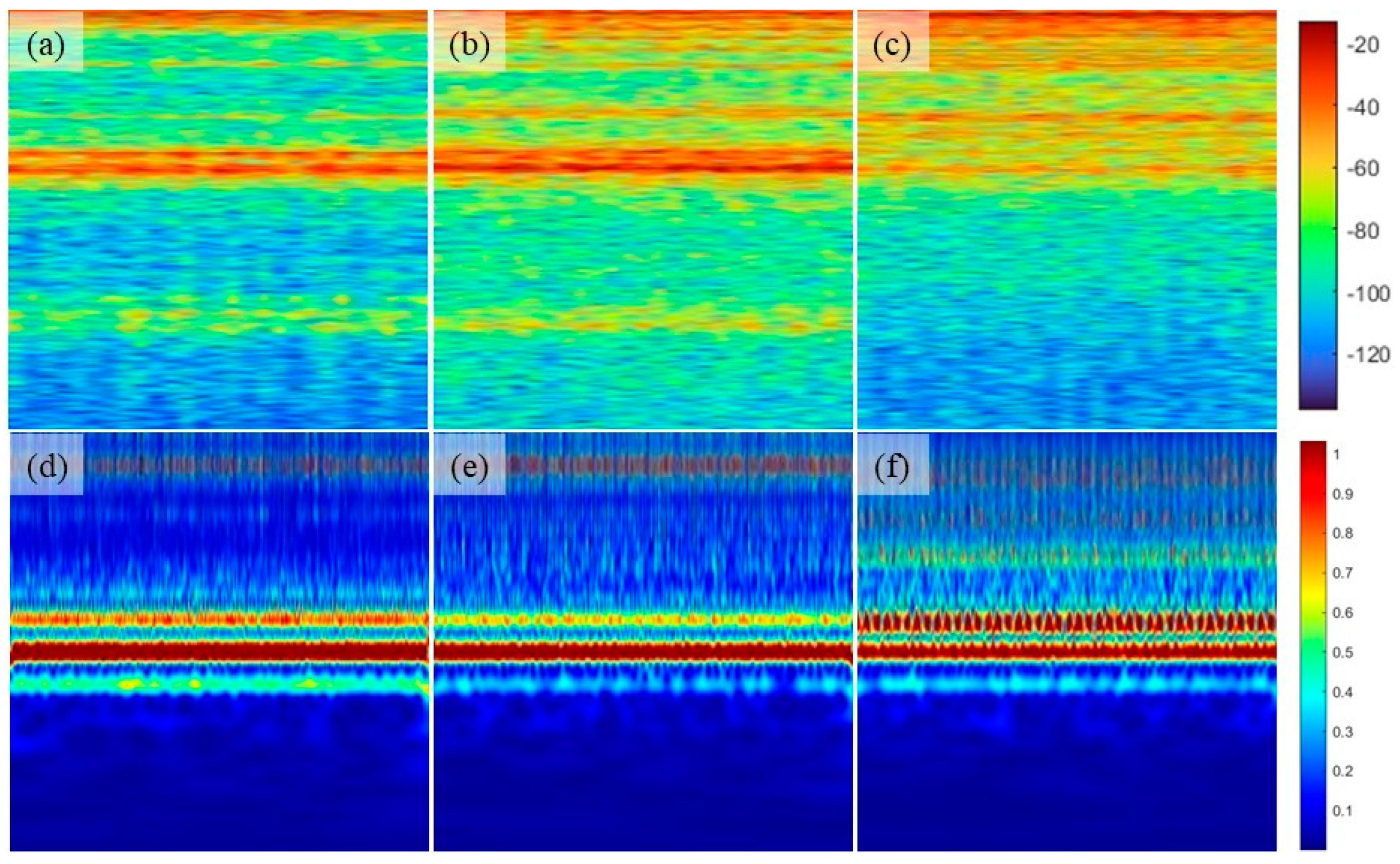

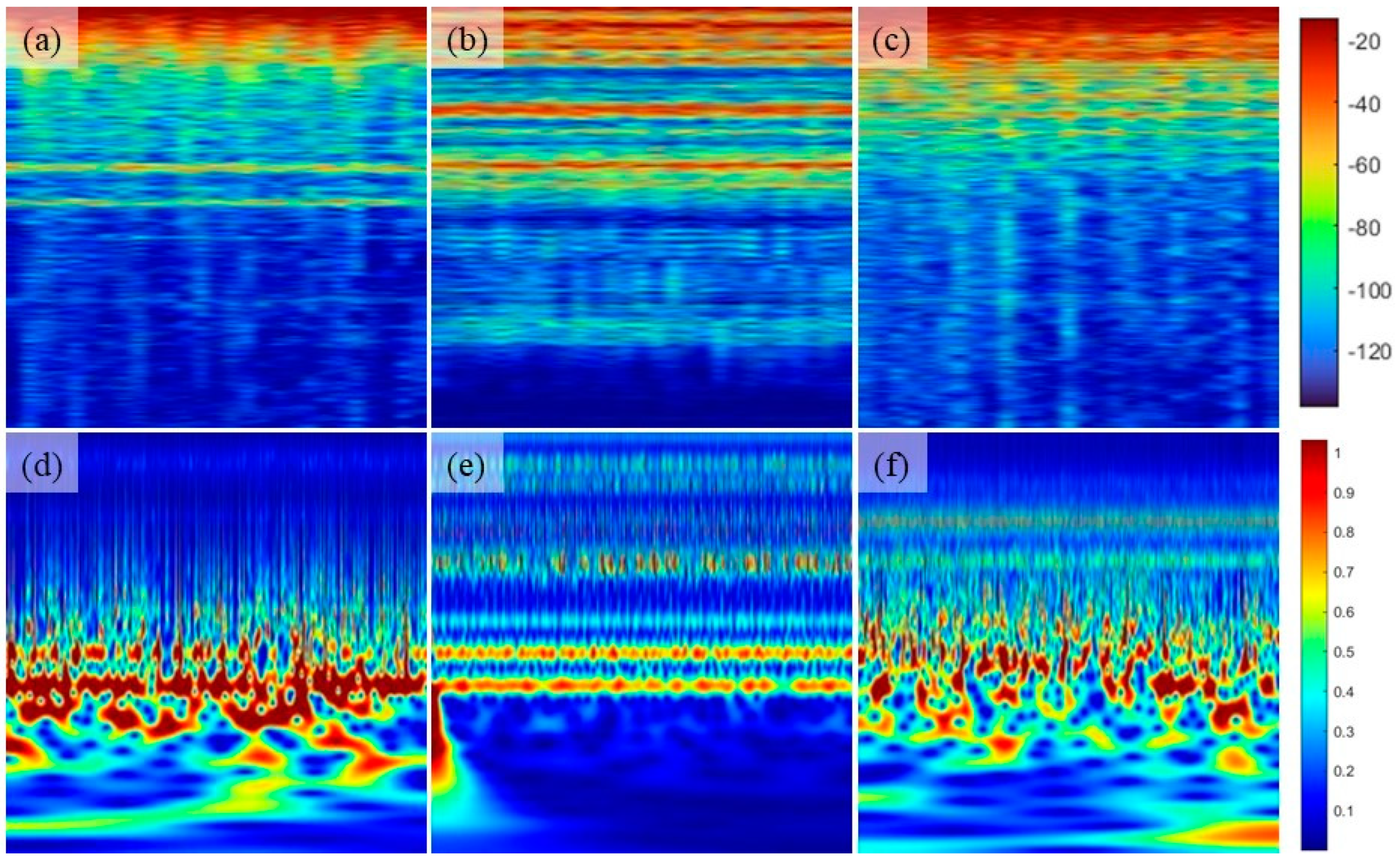

Figure 9,

Figure 10 and

Figure 11 display scalograms and spectrograms that clearly highlight amplitude variations and irregular patterns in data from faulty bearings over time. Each figure illustrates time-series data collected from the accelerometer, microphone, and piezo sensor, respectively. Across all figures, the scalograms demonstrate a noticeable visual distinction between normal and faulty conditions, a difference that is more pronounced than in the spectrograms. This enhanced distinction is attributed to the scalogram’s capability to analyze non-stationary signals at higher resolution, making anomalies in faulty bearings more evident. Conversely, while the spectrograms do not differentiate as distinctly between normal and faulty states, they do indicate that specific frequency values are significantly elevated in faulty bearings compared to their normal counterparts.

The aim of this study was to develop a model capable of distinguishing between faulty and normal bearings by training deep neural network (DNN) models using spectrogram and scalogram images derived from data visualization. The DNN architectures utilized in this research include GoogLeNet-V1, ResNet-50-V2, and NasNet-Mobile.

GoogLeNet, introduced by Google in 2014, features an innovative architecture centered around the Inception module. This design incorporates multiple kernel sizes (1 × 1, 3 × 3, 5 × 5) within the same layer to capture features at various scales. The network comprises 22 layers, including nine Inception modules, and employs global average pooling instead of fully connected layers at the end to mitigate overfitting. GoogLeNet is recognized for its computational efficiency and relatively low number of parameters, resulting in moderate training times. Its architecture makes it well suited for a wide range of image classification tasks and enables its application in real-time scenarios.

ResNet-50, developed by Microsoft in 2015, is a Residual Network that leverages residual learning to facilitate the training of deeper networks. The “50” in its name indicates the network’s depth, consisting of 50 layers. ResNet-50 utilizes skip connections that preserve the identity across 3 × 3 convolutional layers, allowing gradients to flow effectively without vanishing. This architecture has demonstrated exceptional performance in the ImageNet challenge and supports the training of very deep networks. Despite its depth, ResNet-50 benefits from skip connections that streamline training times relative to its complexity. It is extensively employed in various computer vision tasks requiring deep models, particularly in object detection and segmentation.

NasNet, introduced by Google in 2017, is a Neural Architecture Search Network developed through automated architecture search. It features a sophisticated architecture composed of repeated basic blocks or cells, enabling the model to learn more abstract features. NasNet generally achieves superior performance due to its optimized design, which is the result of automated search processes. However, its intricate architecture and larger number of parameters demand greater computational resources and can lead to longer training durations. Nonetheless, NasNet can be efficiently adapted for mobile applications. Designed for high-performance tasks, NasNet serves as a state-of-the-art model in challenging datasets and competitive environments.

By leveraging these advanced DNN architectures, this study aimed to enhance the accuracy and reliability of bearing fault diagnosis, facilitating early detection and maintenance in industrial applications.

A total of 2160 visualized images representing different bearing states were employed to train the three DNN models, and their classification accuracies were subsequently evaluated.

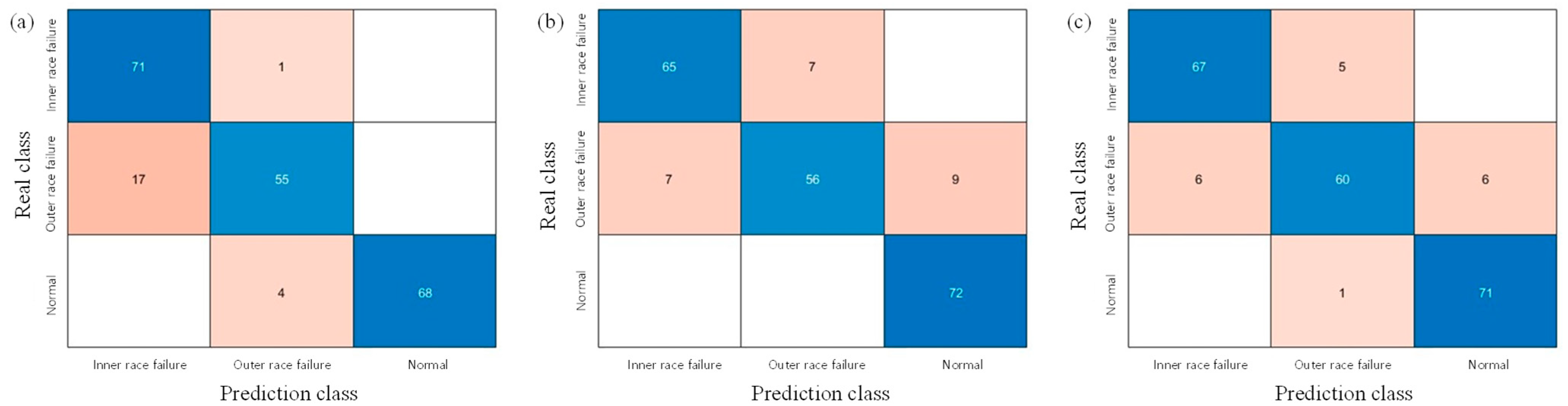

Table 5 provides a summary of the models’ accuracy and training speeds. The overall findings reveal that NasNet achieved the highest classification accuracy in differentiating between normal and faulty states. In contrast, GoogLeNet, with its relatively shallow architecture, demonstrated faster training times. Furthermore, the confusion matrices presented in

Figure 12 indicate that GoogLeNet exhibited a higher error rate in distinguishing between inner race and outer race defects compared to the other models. This suggests that GoogLeNet’s shallower structure may limit its ability to effectively extract the features necessary for accurately classifying faults in the inner and outer rings. On the other hand, ResNet-50 showed slightly lower performance in classifying normal versus faulty conditions compared to NasNet and GoogLeNet.

According to the confusion matrices in

Figure 12, all models exhibit errors when classifying damages to the outer race and inner race. This suggests that even in damaged states, the waveform differences between the outer and inner races are not significantly greater compared to normal conditions. While the differences between normal rotation and rotation with damage to the outer and inner races can be relatively easily classified using spectrograms or scalograms, it appears difficult to distinguish between damages to the outer and inner races when both are present.

To ensure the reliability of the DNN models in classifying bearing states, an explainable AI (xAI) technique was implemented to identify the features utilized for fault assessment. The xAI approach visually represents the scores predicted by the model for each image’s specific class and generates score maps that display class probabilities for each pixel by mapping scores across multiple classes. These score maps highlight the regions of the image that were most significant during the model’s analysis. Addressing the inherent ‘black box’ nature of DNN models, the xAI functionality facilitates a visual interpretation of the decision-making process, allowing for the assessment of how specific areas of the image influenced the model’s classifications. This functionality was implemented using MATLAB R2024a’s scoremap feature to evaluate the critical points contributing to the model’s decisions.

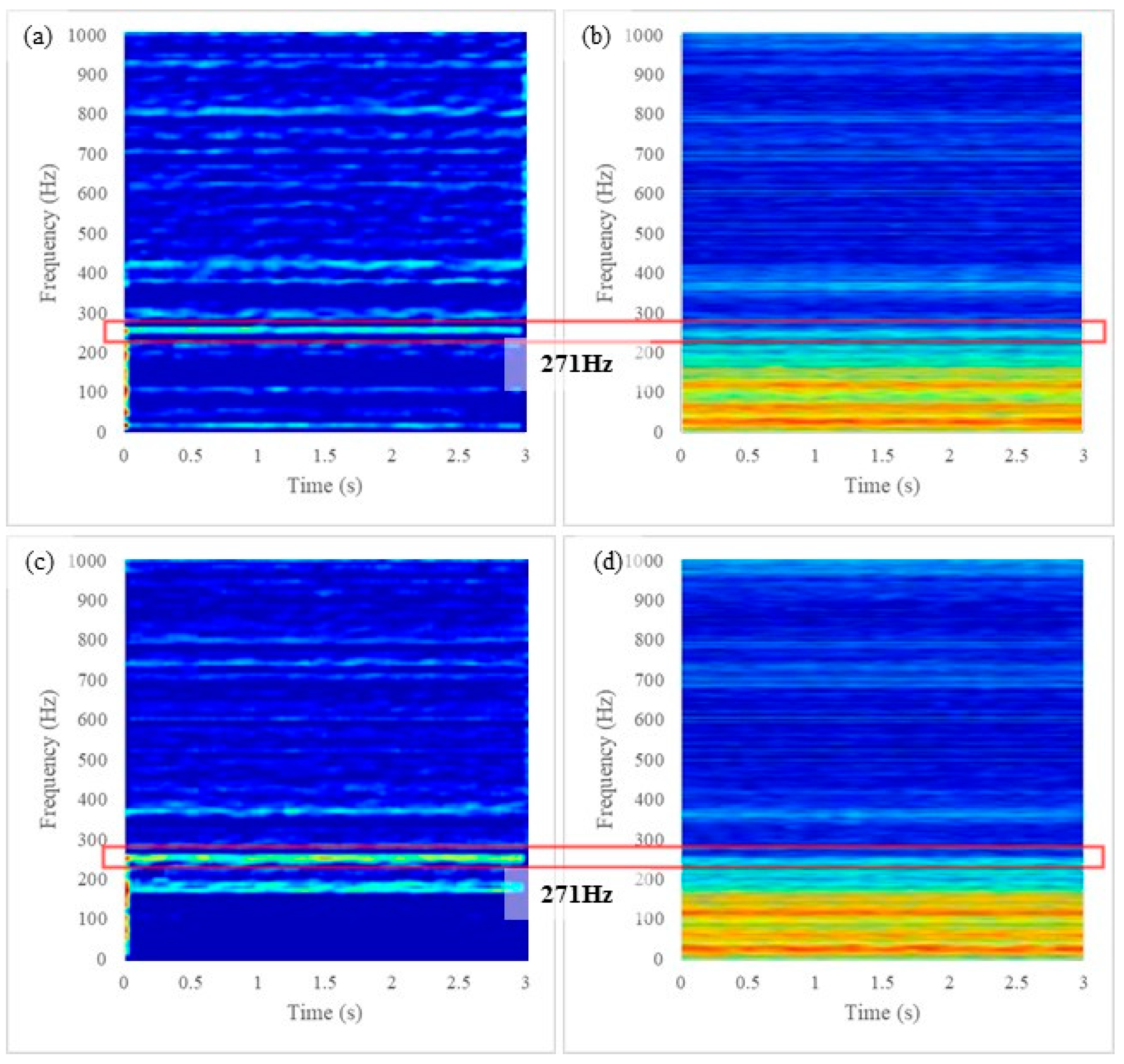

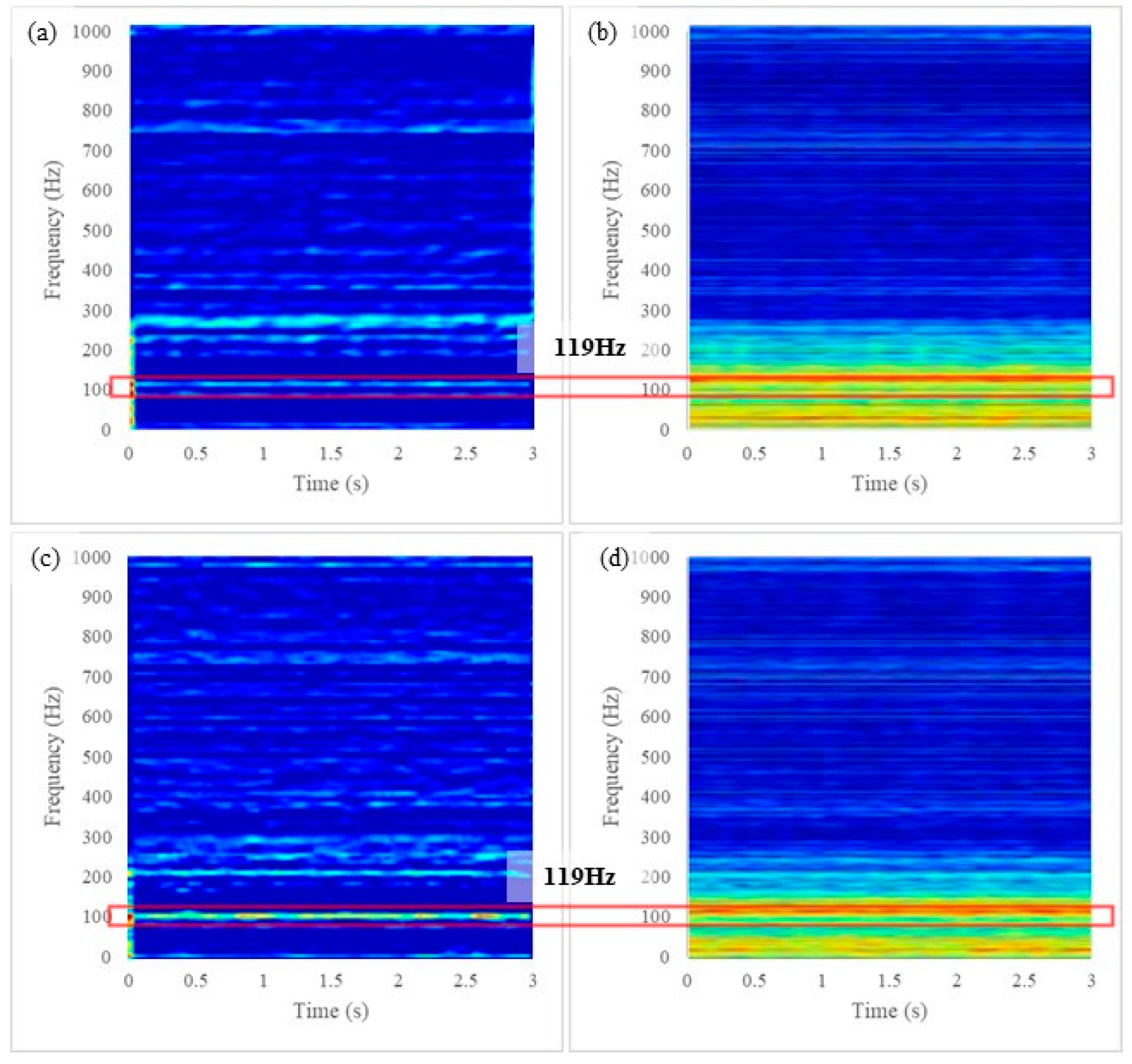

The model used for xAI analysis was NasNet, which has the highest classification accuracy. Spectrograms obtained from bearings in both inner race failure and outer race failure states were inputted into the trained NasNet, highlighting the regions considered in determining faults. As shown in

Figure 13,

Figure 14 and

Figure 15, the frequency regions with high scores for fault detection are clearly marked with high scores on the scoremap. These common high-scoring feature points were compared to the theoretical fault frequencies of the bearings. The theoretical fault frequencies are related to the inner race (

fi) and outer race (

fo) failures calculated in Equations (1) and (2) below:

where

N represents the static load,

fs is the rotation frequency,

Db is the ball bearing diameter,

Dc is the pitch diameter, and α is the contact angle [

30].

In

Figure 13, the primary indicator of inner race failure is detected around 181 Hz, which matches the theoretical fault frequency calculated from the equations. Similarly,

Figure 14 shows that at a rotation speed of 3000 RPM, the main fault frequency occurs at 271 Hz.

Figure 15 verifies that the prominent feature in the scoremap corresponds with the theoretical fault frequency of 119 Hz for outer race failure. The features commonly identified in fault scenarios beyond the theoretical fault frequencies are empirical and derived through machine learning. This suggests the potential to develop a theoretical framework that can explain these empirically obtained features based on experimental results.

4. Conclusions

This study was initiated by identifying the high costs associated with the data collection devices currently used in bearing fault diagnosis systems. To address this issue, a low-cost sensor module utilizing affordable sensors was designed and proposed. The research demonstrated that this economical sensor module can effectively replace more expensive sensors and data acquisition devices, offering significant cost savings compared to traditional high-priced equipment. Additionally, the module boasts versatility and ease of installation, allowing for straightforward attachment and removal, which enhances its practicality for various applications.

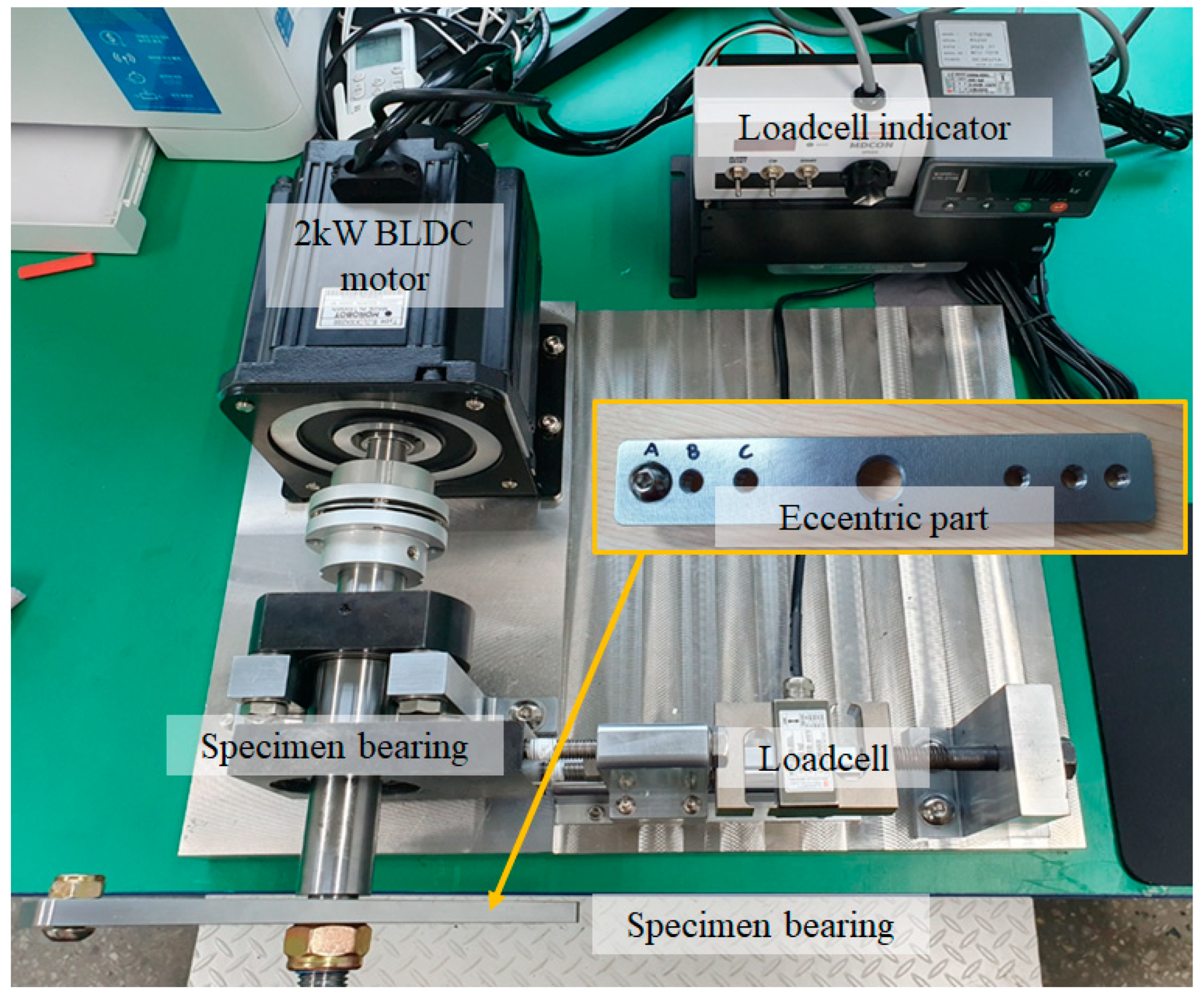

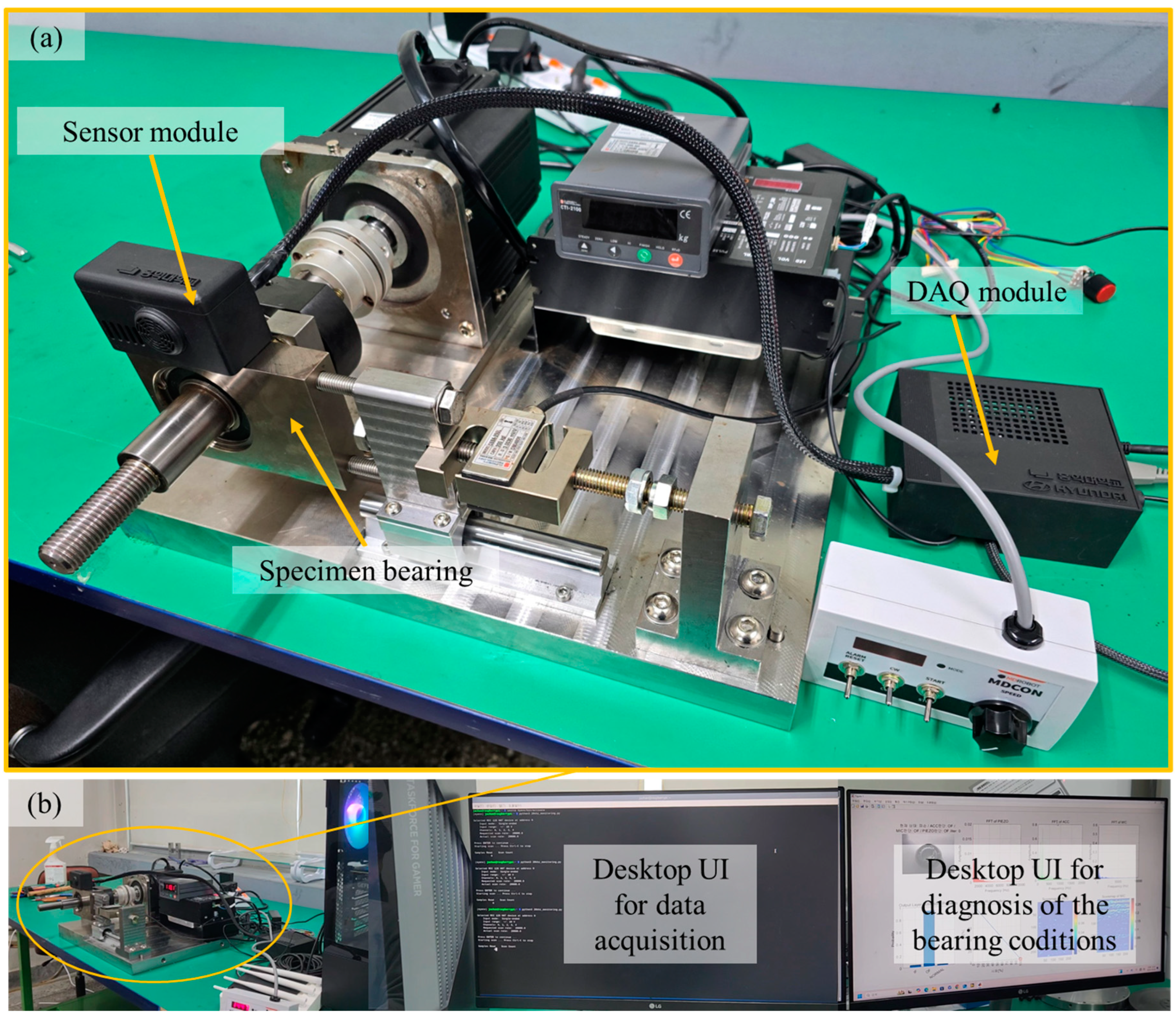

A test bed was assembled to emulate signals from both normal and faulty bearings. The setup included a motor, motor coupling, support bearings, specimen bearings, a rotating shaft, and a load cell, all constructed. Powered by a 2 kW BLDC motor capable of reaching up to 3000 RPM, the test bed effectively minimizes vibrations during high-speed rotation. Deep groove ball bearings were chosen as specimen bearings, while thrust needle bearings served as support bearings due to their higher safety factor for radial loads.

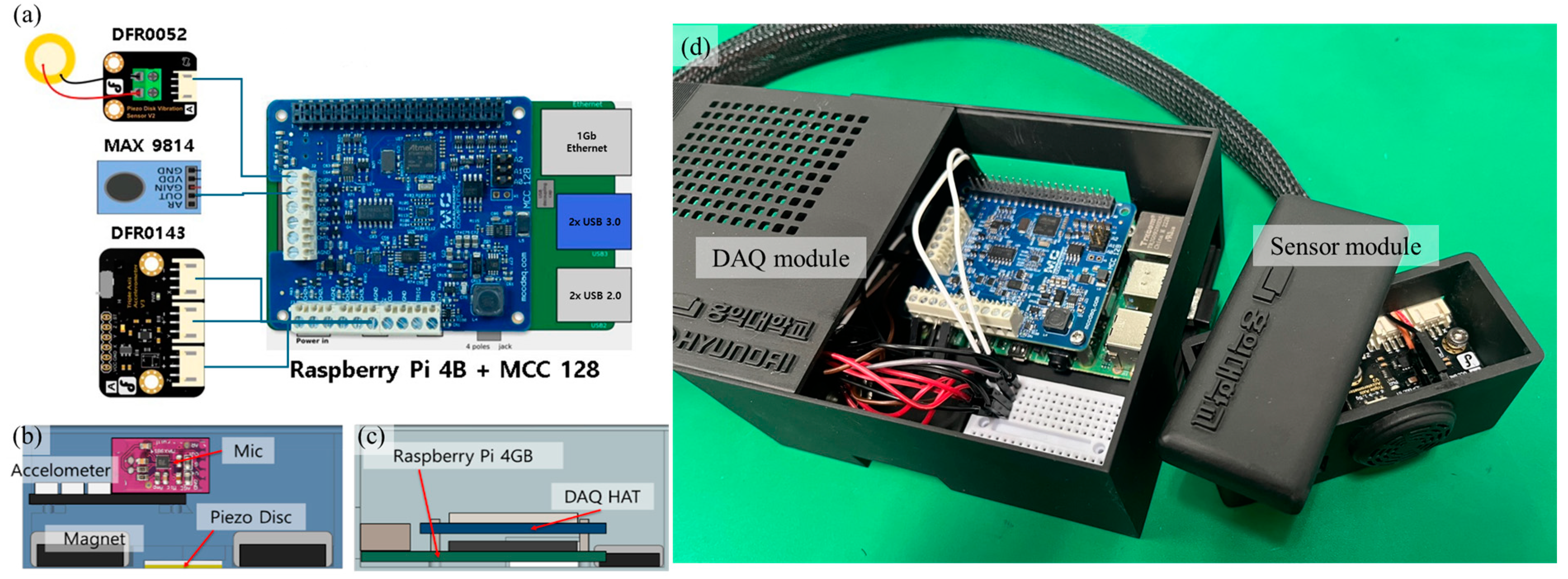

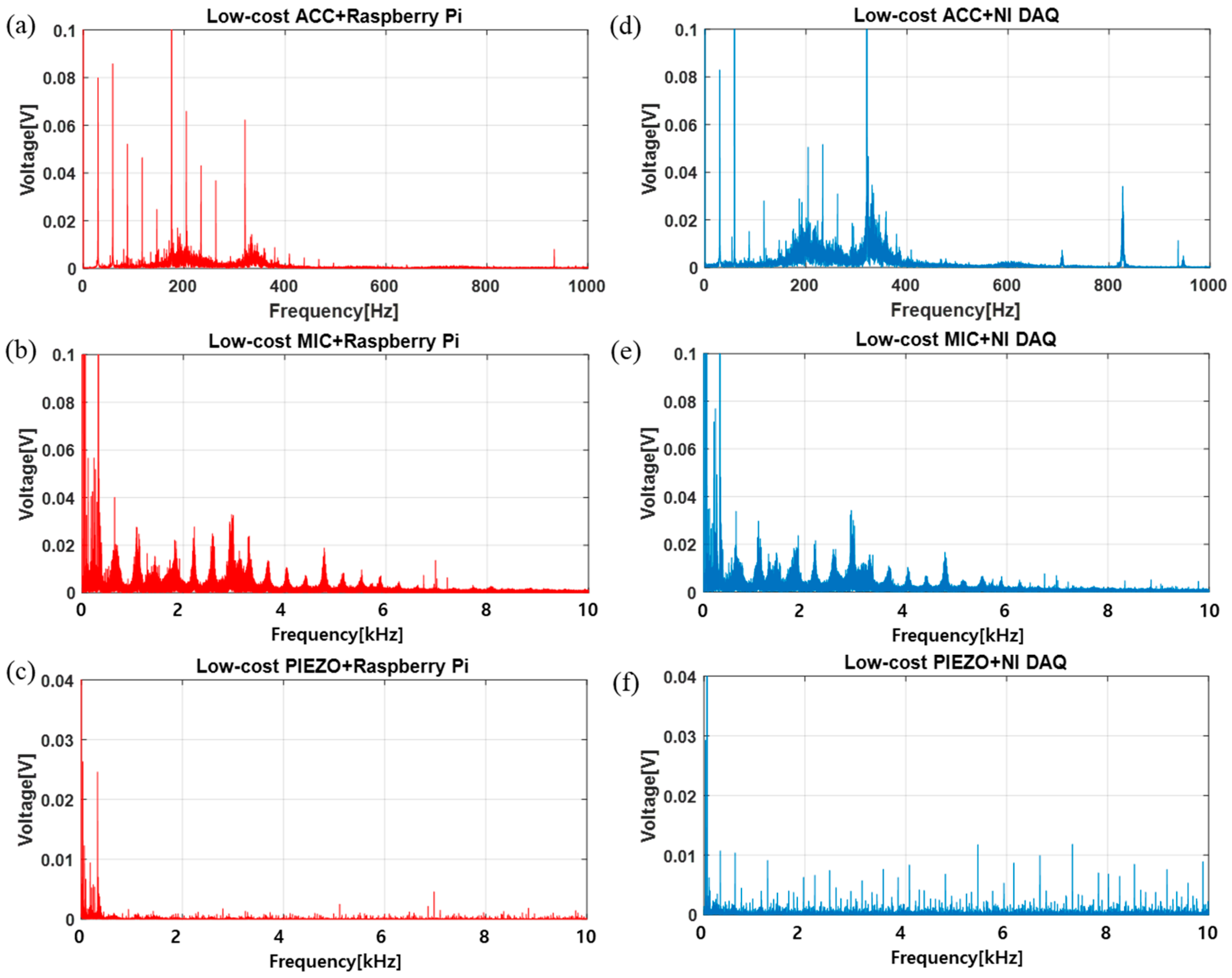

The low-cost monitoring system comprises a sensor module, which includes an accelerometer, microphone, and piezo disc, and a data acquisition module. A comparative study validated the reliability of the low-cost sensor against high-cost alternatives, revealing that the low-cost system costs approximately 3% of the price of expensive counterparts. Experimental results showed that the low-cost accelerometer performed similarly to high-cost versions at frequencies below 1 kHz, although some discrepancies were noted at higher frequencies. Additionally, the low-cost DAQ module demonstrated signal measurement performance comparable to that of high-cost systems, underscoring its potential as a viable replacement in industrial settings.

Data collection experiments were conducted under 72 different conditions, each repeated 10 times, resulting in 720 samples and 2160 time-series data points from three sensors. After preprocessing, the data were visualized as spectrograms and scalograms. The spectrograms utilized the Fourier transform to analyze frequency components over time, while the scalograms employed the wavelet transform for higher-resolution analysis of non-stationary signals. The visualized data, totaling 4320 images, were used to train DNN models. The study employed GoogLeNet, ResNet-50, and NasNet to classify bearings as either normal or faulty, with each model exhibiting distinct strengths. To enhance model reliability, an xAI technique was implemented to visualize the scores associated with each image, clarifying how the models made their decisions.

The research demonstrated that utilizing a low-cost monitoring system in conjunction with deep neural networks can effectively detect bearing failures, suggesting the potential for widespread implementation across various industrial sectors. Additionally, the study proposed a methodology using xAI techniques to understand the reasoning behind the DNN models’ fault assessments, indicating the potential for deriving new failure theories from the common characteristics identified by the models.

The proposed method aims to diagnose bearing faults using DNN based on data collected from low-cost sensors. However, the developed low-cost sensors have not undergone long-term reliability validation compared to high-cost sensors, necessitating a process for verifying their reliability over extended periods. Additionally, by miniaturizing the sensors and attaching them to flexible materials, enabling their application to machine surfaces of various shapes beyond traditional mounting methods, the effectiveness of the proposed approach is expected to be significantly enhanced in future work.

To verify the reliability of the proposed sensors and failure diagnosis methods, it is necessary to install them in a machine system that includes actual bearings and study whether they can detect signals generated when a bearing fails and analyze the failure in future work. Additionally, the research can be expanded to develop a model that predicts bearing life by detecting changes in signals as the bearing’s lifespan decreases.