1. Introduction

Chaos phenomena are wide-spread in nonlinear mechanical systems, such as gear systems [

1], cam-follower mechanisms [

2], rigid–flexible mechanisms [

3], parallel mechanisms [

4], planar mechanisms [

5], under-actuated systems [

6], and others [

7,

8]. In these areas of research, dynamic analysis and force analysis in a chaotic state are current hot spots [

9,

10,

11]. However, there is little research on how to evaluate the chaos intensity of a system and realize the change in the chaos intensity of the system through a small change in the parameters of the mechanism, so that the chaos intensity and motion state of the mechanism can meet the actual needs. This paper mainly analyzes the dynamic modeling of under-actuated mechanisms, the influence of the driving speed and linkage length on the chaos intensity, and the optimization of the chaos intensity based on particle swarm optimization (PSO).

To improve the performance of a nonlinear system, many scholars use optimization [

12], parameter design [

13], force analysis [

14], control [

15,

16], external disturbance [

17], and other methods [

18,

19]. In the meantime, the majority of these works have concentrated on mathematical modeling and numerical simulation of the system’s dynamic behavior, so that a great deal of work has been conducted in this field [

20,

21]. In general, chaos control and force control of nonlinear mechanisms are realized by changing the size of clearance, driving speed, and joint friction in the mechanism with clearance, which is the main research method at present [

22,

23]. In these studies, some relatively novel methods are also used. To achieve the suppression of chaos intensity, Wu et al. [

24] successfully suppressed the chaos intensity of a system under various parameters by adjusting the vibro-impact oscillator of the planar slider mechanism with a clearance joint. Arian and Taghvaei [

25] mainly studied the modeling and analysis of chaotic dynamics of spur gear transmission systems with an idler and controlled the range of strange attractors of the system through the idler to achieve the suppression of chaotic phenomena of the system. In order to achieve chaos control of the pendulum, Kudra et al. [

26] successfully achieved the goal of chaos suppression of the pendulum by installing a DC motor on the slider and using a phase diagram and bifurcation diagrams at the same time. To determine the parameter conditions of the transformation between chaotic motion and periodic motion in nonlinear systems, Li et al. [

27] analyzed the motion states of the closed-chain under-actuated five-bar mechanism under different driving speeds and linkage lengths using permutation entropy and the Lyapunov exponent. This is also a reliable way to control the chaos of the system by changing the position of the center of mass of the linkage mechanism and changing the moment of inertia of the system [

28,

29].

Synthesizing the above studies, the mechanism chaos phenomena in nonlinear mechanisms have been analyzed widely, but there are few studies on how to judge the chaos intensity. Therefore, the main goal of this paper is to conduct a study on chaos intensity; thus, uniformity is chosen. Uniformity theory is a new conception proposed by the Chinese scholar Chuanwen Luo [

30]. This theory focuses on describing the degree of dispersion of limited data within predefined boundaries, as well as the degree of spatial separation between points. Although this theory has the advantage of chaotic intensity judgment, it has not attracted the attention of scholars. To illustrate the correctness of uniformity, the bifurcations of logistic mapping and the Duffing oscillator are used, and the results prove that uniformity can be used to judge the chaos intensity.

According to the research results of previous scholars, the chaotic state of a nonlinear mechanism system can be transformed by changing the structural parameters of the system, such as the driving speed, the size of the clearance joints, and the force of the joint. Inspired by the above methods, this paper changes the chaos intensity of the system by changing the linkage length and drive speed of a closed-chain under-actuated five-bar mechanism. Compared with the common chaos caused by a clearance joint, the chaos caused by an under-actuated mechanism is more controllable, has a smaller impact force, and leads to less joint wear [

27]. However, there is little research on the chaos phenomena caused by under-actuated mechanisms, which is mainly in the theoretical research stage at present, and the utilization of its chaos intensity will be the research focus at a later stage. Therefore, the main objective of this article is to establish a correct dynamic model of a closed-chain under-actuated five-bar mechanism and analyze the chaos intensity of the system through uniformity. In the last section, based on the uniformity theory and PSO, the chaos enhancement and suppression of the closed-chain under-actuated five-bar mechanism under certain conditions are successfully realized by optimizing the length of the linkage. This conclusion is also verified by the experimental platform.

2. Theoretical Framework of Uniformity and Examples

In Euclidean n-dimensional space, suppose is a finite set in ; let , , and . If is simply connected and , and the polyhedron is considered to be the boundary polyhedron of , then denote (●) as capacity and (A) = . Use M(x) = mid (x, y) to represent the minimum distance between two Euclidean points. By denoting , the proximity distance is expressed by . A space sphere, whose center point is and radius is , is called the monopolized sphere, which is expressed as and its volume is .

The volume of the space sphere is

where

is the

-function, and

n = 1, 2, …,

r is the radius of the space sphere.

By substituting

in Equation (1), we obtain the following:

where

is the volume of the unit sphere in

.

Let

have

k points; then, the entire monopolized sphere volume,

, in

is

There are many

n-dimensional cubes with the monopolized sphere as the inner sphere, but their volume is the same. Choosing any

n-dimensional cube as the monopolized body of

, its volume

is

Then, the uniformity (

L) is

Additional instructions for Equations (1)–(5) are as follows:

(1) If n = 1, the monopolized sphere should be called the monopolized line, and if n = 2, the monopolized sphere should be called the monopolized circle.

(2) The points in are finite and non-coincident, the monopolized spheres are only tangential or separated from each other, and there is no intersection.

(3) The range of uniformity, L, is (0, 1); a bigger value of L means a more discrete distribution of points in .

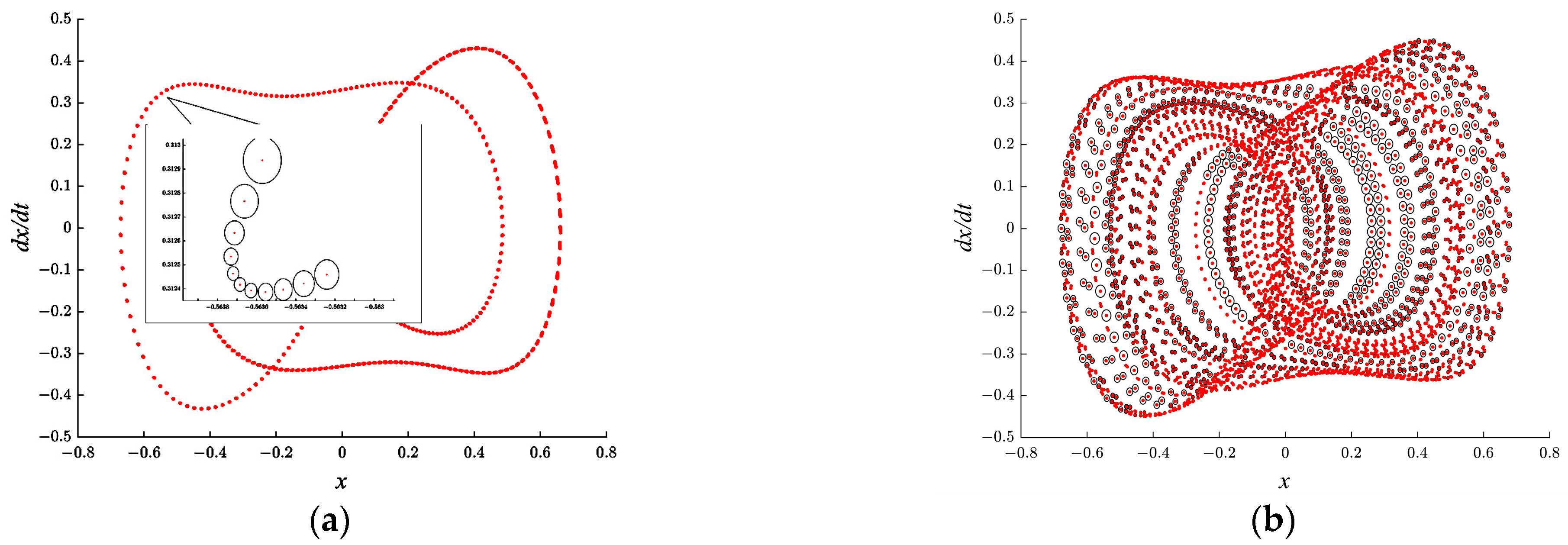

An example of different values of

L with the same data points is shown in

Figure 1.

The number of points in

Figure 1 is 4000; the red dots represent the position of the points in the phase portrait, and the black circles represent the monopolized circles. The points in

Figure 1a are more concentrated and have a smaller value of

L of 0.00014, while the data in

Figure 1b are more divergent and have a larger value of

L of 0.1469. The results in

Figure 1 show that under the condition of the same points, the degree of dispersion of data points will affect the chaos intensity of the system, and the value of

L can evaluate its intensity.

2.1. Logistic Mapping Example

The logistic mapping equation is

where n = 0, 1, 2, …, k is the system parameter.

Let

= 0.1; the simulation step size is 0.005, and iteration occurs every 2000 steps. The bifurcation diagram and

L of the logistic mapping are shown in

Figure 2.

In

Figure 2, when the data points in

Figure 2a change from one status to another, e.g.,

k = 3.83, the status changes from chaotic motion to periodic motion; meanwhile, in

Figure 2b,

L diminishes immediately. By comparing

Figure 2a,b, it can be seen that when the system is in a state of periodic phenomena, the value of

L is small and approaches 0, while when the system is in a state of chaotic phenomena, the value of

L is large. The value of

L in

Figure 2b is consistent with the distribution of the bifurcation diagram points in

Figure 2a, which indicates that the value of

L can reflect the chaos intensity of the system.

2.2. Duffing Oscillator Example

The Duffing oscillator equation is as follows:

where

t is the time;

F is the excitation amplitude; and

r = 1,

k = 1, and

s = 5.

Let 0.2 ≤

F ≤ 1 and let its value increase by 0.002 each time; the initial values of

x and

y are set to 0, the simulation step of

t is

/50, and its period is

. According to the initial values of

x and

y, and using Equation (7), the bifurcation diagram of the Duffing oscillator is obtained by using the Runge–Kutta method in MATLAB, as shown in

Figure 3.

It can be seen from

Figure 3 that the Duffing oscillator has multiple regions of single and multiple periods, and it alternates between periods and chaos. Within the chaotic interval of logistic maps,

L is greater than zero, and the maps increase or decrease at almost the same time. Both

Figure 2 and

Figure 3 show that the value of

L can reflect the chaos intensity.

Further analysis of

Figure 3b reveals that uniformity has successfully monitored the variation in chaos intensity in the system. For example, when

F = 0.465, the system exhibits chaos suppression, and when

F = 0.493, the system exhibits chaos enhancement. The results are shown in

Figure 4.

In the results shown in

Figure 4, only the system parameter

F exhibits a small difference, but the chaos intensity of the system shows a large difference. The results of

Figure 3 and

Figure 4 prove the superiority of uniformity in determining the chaos intensity of nonlinear systems.

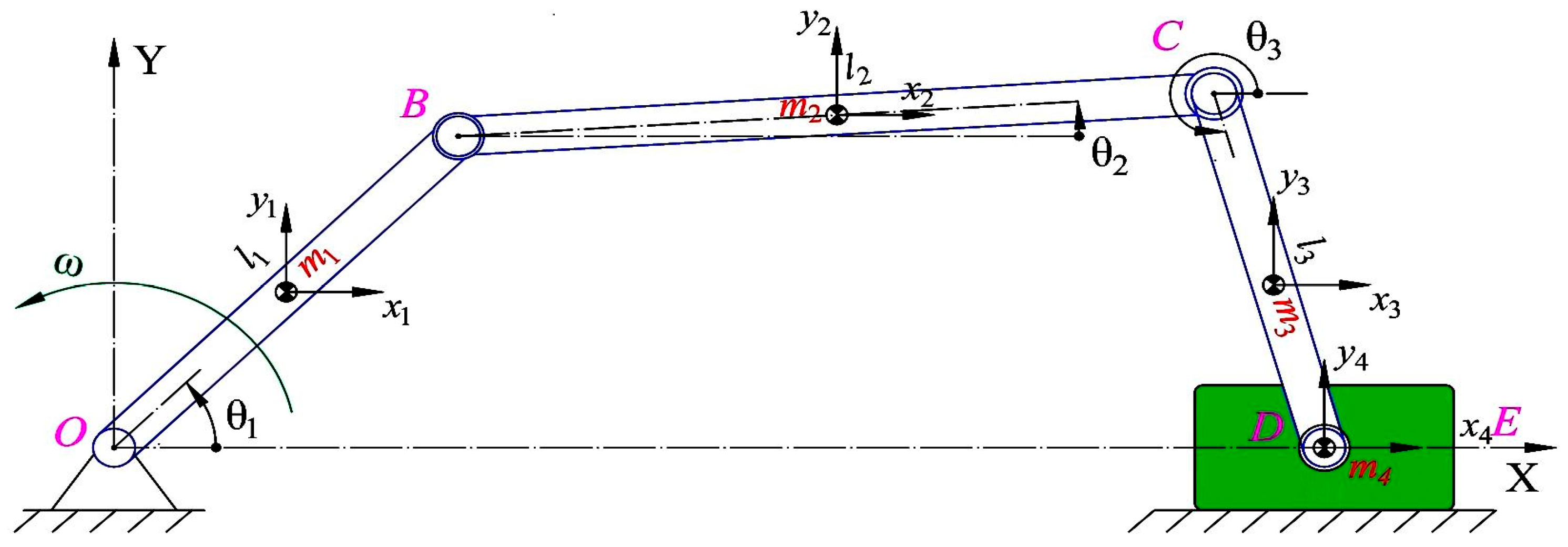

3. Dynamic Equations of the Planar Closed-Chain Under-Actuated Mechanism

The schematic diagram of the planar closed-chain under-actuated mechanism is shown in

Figure 5. In

Figure 5, four rotating joints and one translational joint are expressed as O, B, C, D, and E. At the same time, O is both the origin of coordinates and the driving joint. The lengths of the linkages OB, BC, and CD are labeled as

l1,

l2, and

l3, while their respective masses are represented by

m1,

m2, and

m3. The mass of the slider

E is represented by

m4.

3.1. Numerical Equations

The device in

Figure 5 is a special mechanism that has five degrees of freedom. In this paper, the Lagrange equation of the first kind is used to build the dynamic equations. Therefore, the generalized coordinates,

, and constraint equations,

, are chosen as follows:

The equation of motion is given as follows [

31]:

where

T is the system’s kinetic energy,

is the generalized force,

is the Lagrange multiplier, and

is the system constraint equation.

The kinetic energy of the mechanism is given as follows:

in which

Then, Equation (11) can be written as follows:

Based on Equations (9), (10), and (12), the acceleration equations for the generalized coordinates

,

, and

are derived as follows:

where

and

represent the external torque applied to joint

and

, respectively, and

represents the frictional resistance of slider

E.

Since represents the driving speed, its speed is a fixed value, and its acceleration is zero.

Based on the Baumgarte approach, Equation (9) can be written as follows:

Here, and are important parameters in the Baumgarte approach, whose values are and , respectively, while h is the simulation step size, whose value is 1 × 10−5.

Based on Equations (13)–(17), the acceleration of

,

and

are derived as follows:

in which

3.2. Numerical Solution and Analysis

In this section, based on Equations (18)–(22), described in

Section 3.1, the Runge–Kutta method is used to solve the dynamic behavior of the planar closed-chain under-actuated mechanism. The parameters of the mechanism are listed in

Table 1.

Because the under-actuated mechanism is sensitive to the initial value, it is important to ensure that the initial conditions of each dynamic calculation and experiment are the same. The initial angles of

,

, and

are all zero, and the slider

E is on the right. The schematic diagram of the initial state of the system is shown in

Figure 6.

The initial value is important for the Runge–Kutta method. In

Figure 6,

= 0,

= 0,

= 0, and

=

l1 +

l2 +

l3; meanwhile,

,

= 0,

, and

. By changing the driving speed,

, and the length of

l3, the chaos intensity curves of the system under different parameters are obtained, as shown in

Figure 7.

Figure 7 shows that with the change in driving speed and the length of

l3, the chaos intensity of the system undergoes significant change, especially when the driving speed is 1200 r/min, at which point the chaos intensity of the system is obviously suppressed and enhanced. When

200 r/min,

l3 = 0.06 m, and the system exhibits chaos suppression, and when

200 r/min,

l3 = 0.151 m, and the system exhibits chaos enhancement. The results are shown in

Figure 8a and

Figure 8b, respectively.

In order to ensure the proportional coordination of the phase diagram in

Figure 8, the unit of the displacement of the slider

E(

x4) is decimeters. In

Figure 8a, the distribution of data points is relatively concentrated, indicating that the chaos intensity of the system is suppressed. In

Figure 8b, the distribution of data points is relatively divergent, indicating that the chaos intensity of the system is enhanced.

4. Optimization Example

According to the analysis in

Section 3, in the closed-chain under-actuated five-bar mechanism, the length of the linkage and the size of the driving speed will cause a change in the chaos intensity of the system. In order to suppress and enhance the chaos intensity of the system, based on PSO, the maximum and minimum of the uniformity value are taken as the optimization objectives, and the linkage length and driving speed of the mechanism are taken as the optimal calculation parameters. This optimization mainly considers changing the force of the end slider by optimizing the lengths of the linkages, thus changing its mass and center of gravity position [

28]. The optimization algorithm is shown in

Table 2.

In

Table 2, due to the limitation of our experimental equipment,

;

is the inertia factor,

and

are acceleration constants; generally,

=

[0, 4]; random (0, 1) indicates a random number in the range of 0 to 1;

represents the individual extreme value of the ith variable; and

represents the global optimal solution.

According to

Table 1, the suppression and enhancement of chaotic phenomena in the system will be realized. In order to test the reliability of the dynamic simulation, based on the schematic diagram shown in

Figure 6 and the parameters in

Table 1, the experimental platform shown in

Figure 9 was established.

In the system shown in

Figure 9, the displacement data collected by the grating ruler are transmitted to LabVIEW through STM32. STM32 is a series of 32-bit microcontrollers (MCUs) produced by STMicroelectronics. This paper mainly uses the chip to collect data; then, the collected data are used to calculate the system speed based on time.

4.1. Chaos Suppression

When the chaos intensity value of the system is small, the force on the end slider

E of the mechanism is uniform. As shown in

Figure 10, the phenomenon is that the trajectory of the phase diagram composed of the displacement and velocity is smooth, and the data points are concentrated. In order to achieve the above purpose,

L is taken as the optimization objective, the initial population number is 10, and the optimization algebra is 10 generations. The optimization result is that when the driving speed is 292.325 r/min,

= 0.0592 m and the chaos intensity of the system is suppressed. The optimization phase diagram and optimal fitness evolution process are shown in

Figure 10.

In

Figure 10a, the data points of the phase diagram are concentrated, and the motion curve is smooth, which indicates that the force of the end slider is uniform during movement.

Figure 10b shows that PSO has been looking for system parameters with low values of

L. In

Figure 10, the numerical simulation and experimental results show that the chaos intensity of the system is suppressed under this parameter.

4.2. Chaos Enhancement

When the chaos intensity value of the system is high, the force variation of the end slider

E of the mechanism is strong. As shown in

Figure 11, the mechanism is that the phase diagram trajectory composed of the displacement and velocity has a large and irregular variation interval, and the data points are relatively divergent. In order to achieve the above purpose,

L is taken as the optimization objective, the initial population number is 10, and the optimization algebra is 10 generations. The optimization result is that when the drive speed is 391.255 r/min,

= 0.0592 m, which indicates that the chaos intensity of the system is enhanced. The optimization phase diagram and the evolution process of optimal fitness are shown in

Figure 11.

In

Figure 11a, the data points of the phase diagram diverge, and the motion curves are irregular, which indicates that the force of the end slider changes significantly during movement.

Figure 11b shows that PSO has been looking for system parameters with higher values of

L. In

Figure 11, the numerical simulation and experimental results show that the chaotic motion intensity of the system is improved under these parameters.

Figure 11b shows that the optimization of the system has reached stability.

It can be seen from

Figure 10 and

Figure 11 that uniformity and PSO are used to successfully suppress and enhance the chaos intensity of a planar closed-chain under-actuated mechanism, and the experimental results verify the accuracy of dynamic modeling and the reliability of uniformity in determining the chaos intensity of the system.

5. Conclusions

In this paper, uniformity is used to determine the chaos intensity of nonlinear mechanical systems for the first time. With the help of a closed-chain under-actuated five-bar mechanism, the chaos intensity is suppressed and strengthened under different parameters. Uniformity achieves the suppression and enhancement of system’s chaos intensity by monitoring the distribution of data points in the phase diagram composed of the displacement and velocity caused by different driving speeds and connecting rod lengths. At the end of the article, the PSO is successfully applied to enhance and suppress the chaos intensity of the system.

In the dynamic analysis, the first Lagrange equation is used to establish the dynamic equation of the system, and the Runge–Kutta method is the solution of the system. The experimental platform verifies the optimization results of the PSO and also proves the accuracy of the dynamic modeling method and the high efficiency of the uniformity used to determine the chaotic intensity of the system.

This paper successfully applies the uniformity theory to the judgment of chaos intensity of nonlinear mechanical systems for the first time, which provides a new way for other scholars to analyze nonlinear systems. In the future, how to apply the chaos intensity determination method to different systems, reduce the impact of the difference in the amount of system data points on the results, and improve the accuracy of this method will have high research value.