A Study on the Effect of Cutting Temperature on CFRP Hole Wall Damage in Continuous Drilling Process

Abstract

1. Introduction

2. Simulation Analysis of CFRP Drilling

2.1. Finite Element Modeling

2.1.1. Intrinsic Modeling of Composite Materials

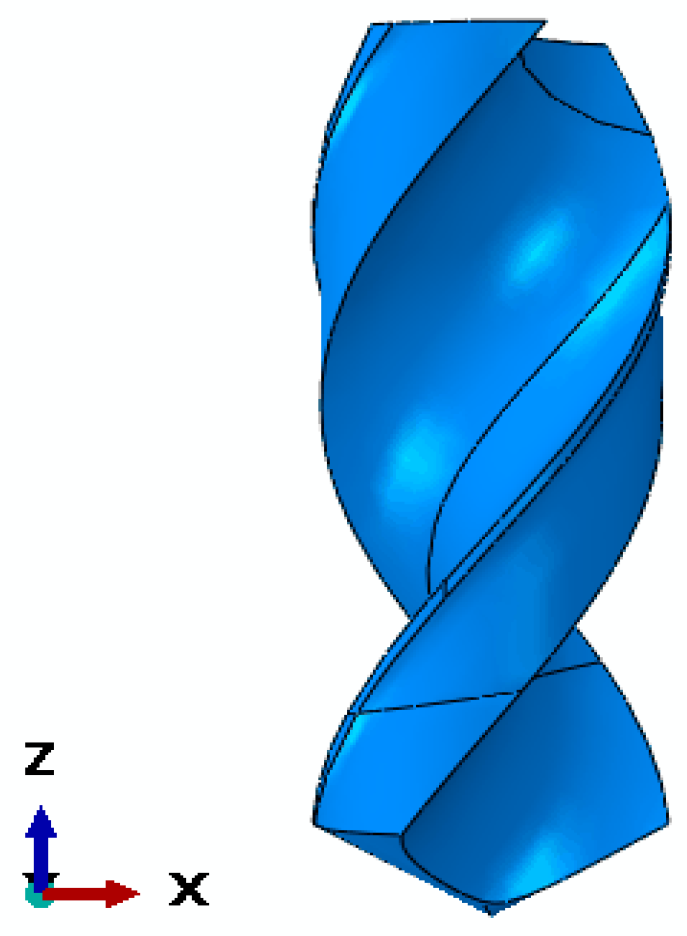

2.1.2. Geometric Modeling

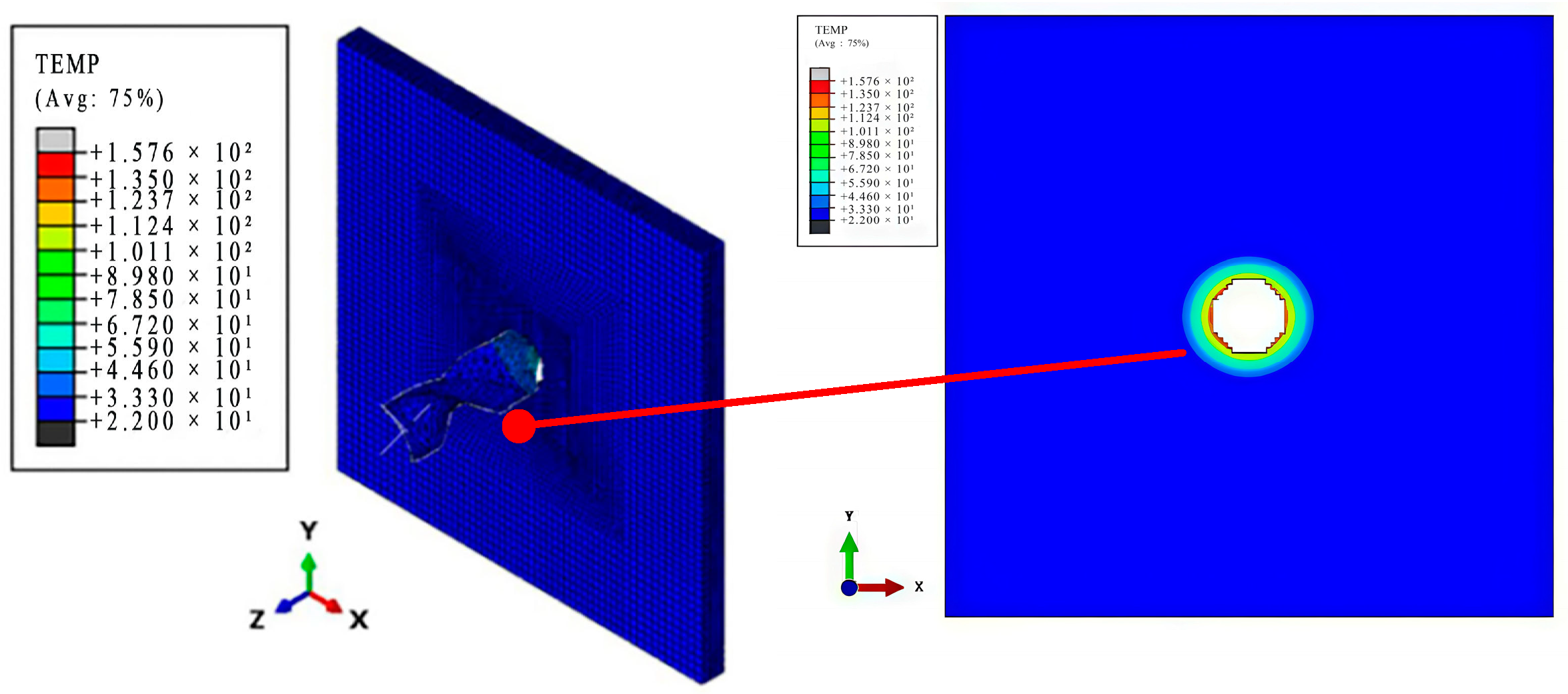

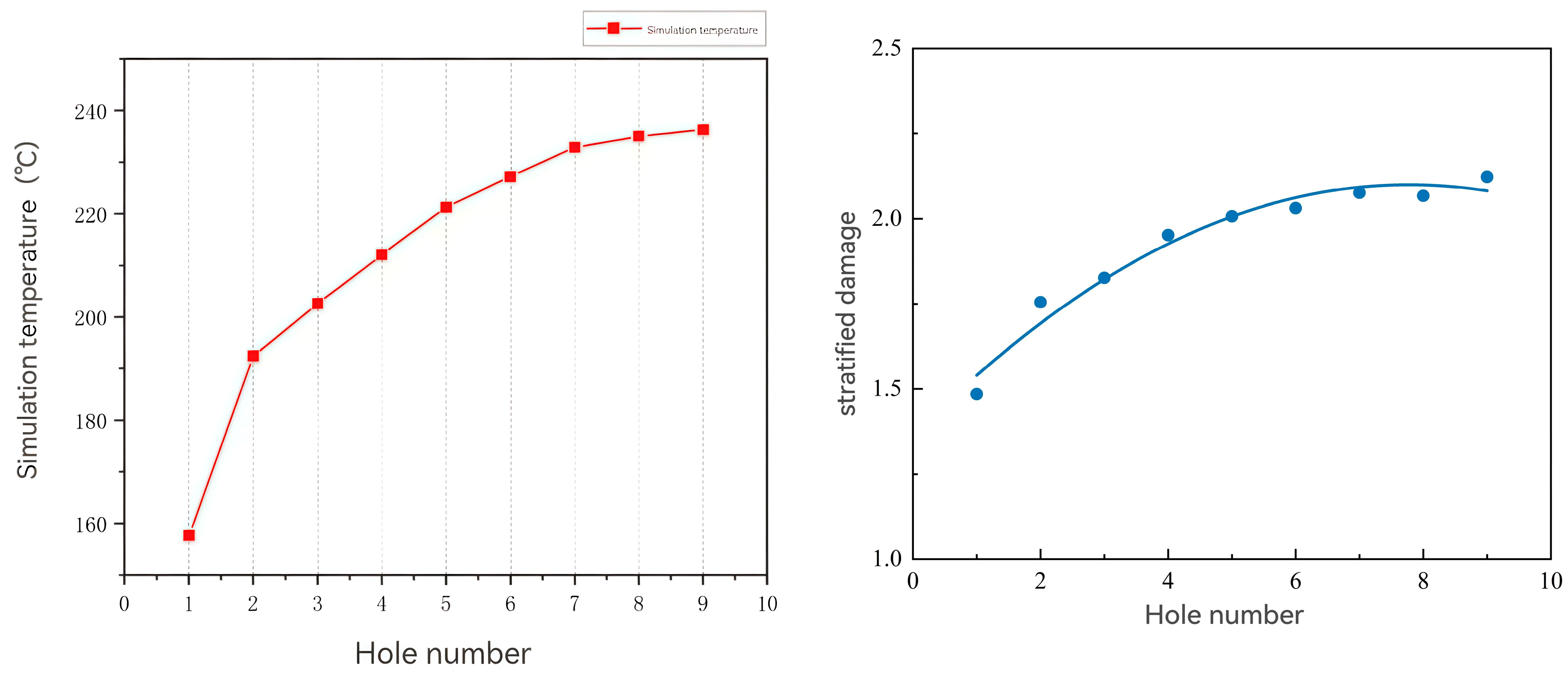

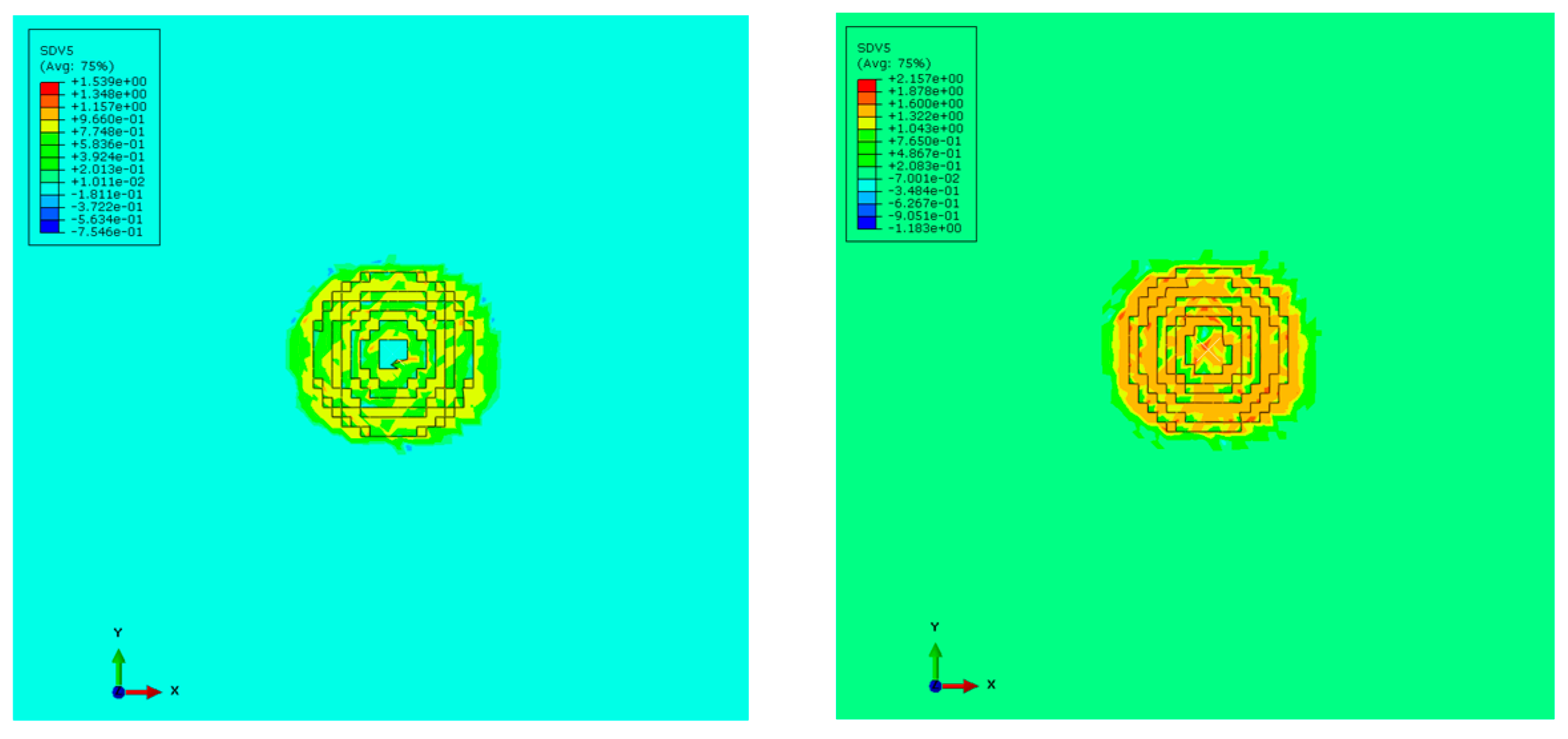

2.2. Model Analysis Results

2.2.1. Analysis of Single Drilling Process Results

2.2.2. Analysis of Continuous Drilling Process Results

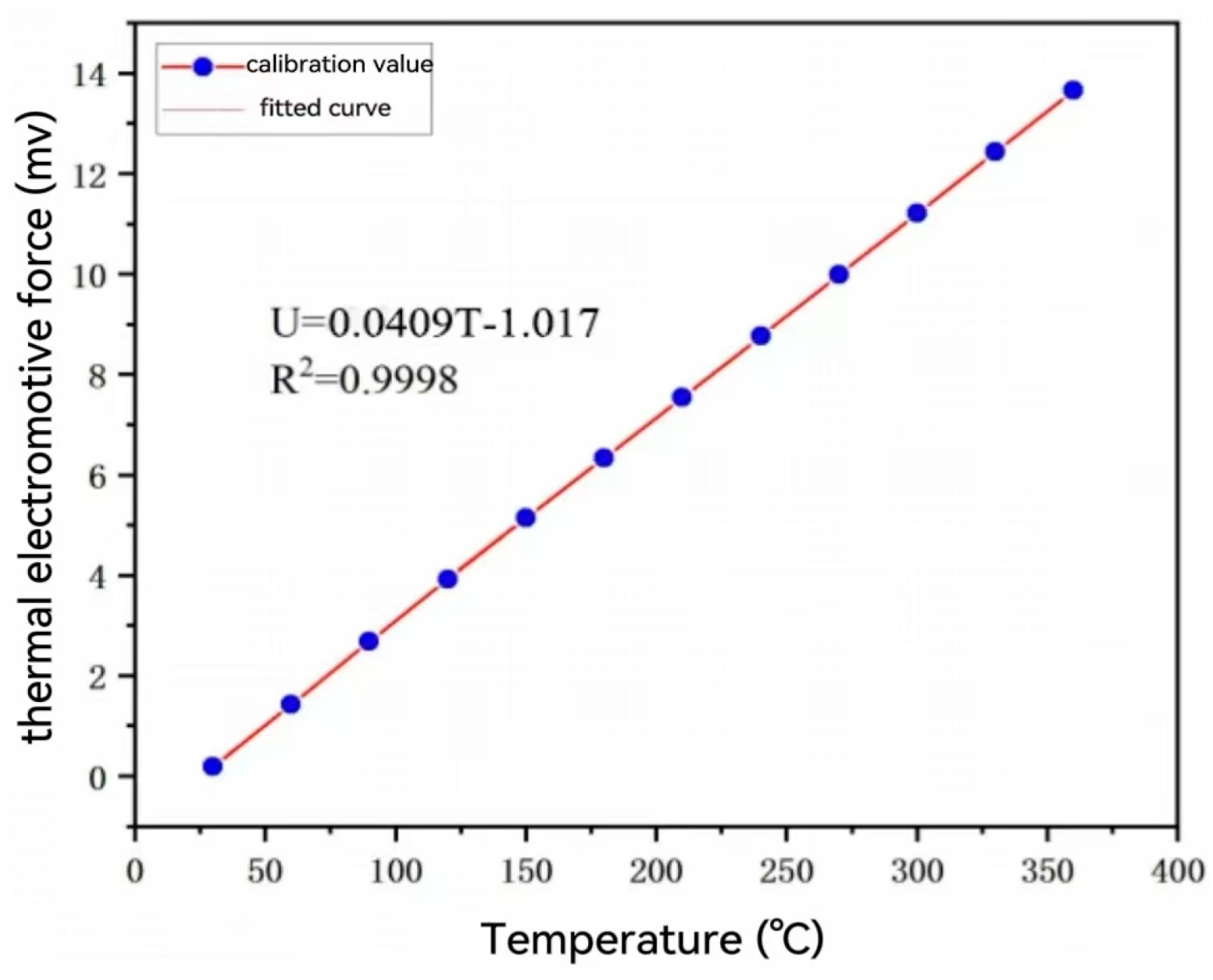

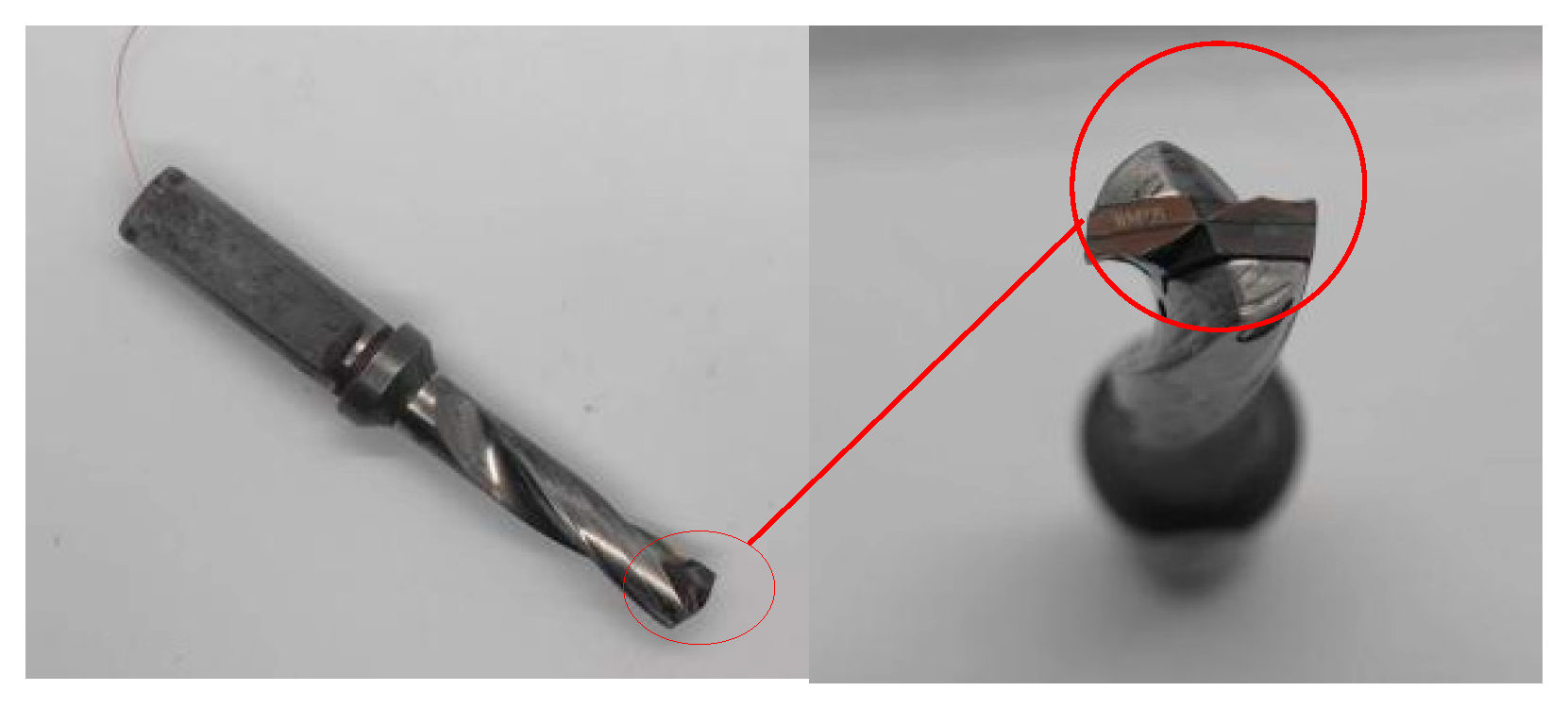

3. Temperature Measuring Tools and Experimental Details

3.1. Experimental Equipment

3.2. Experimental Details

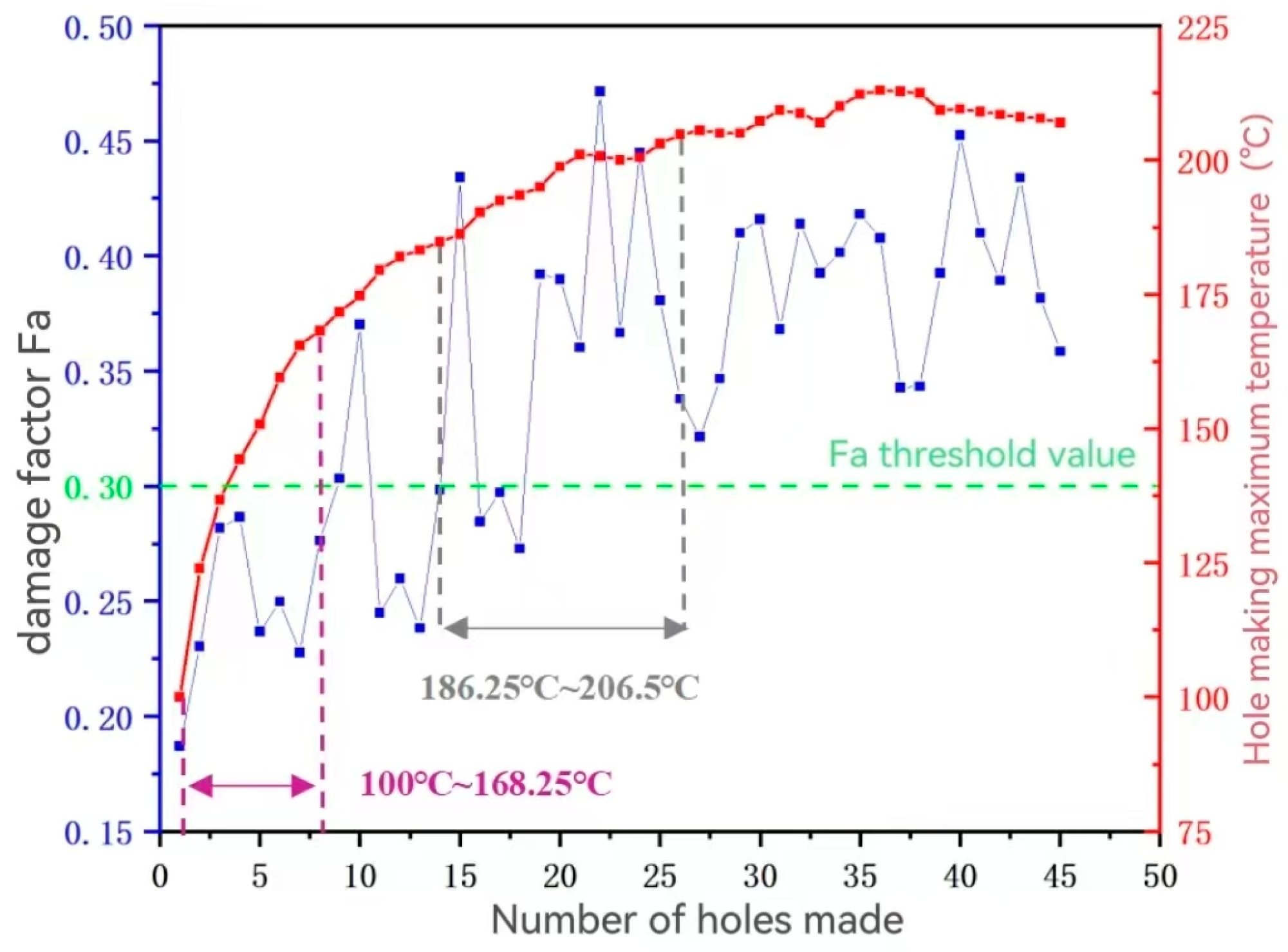

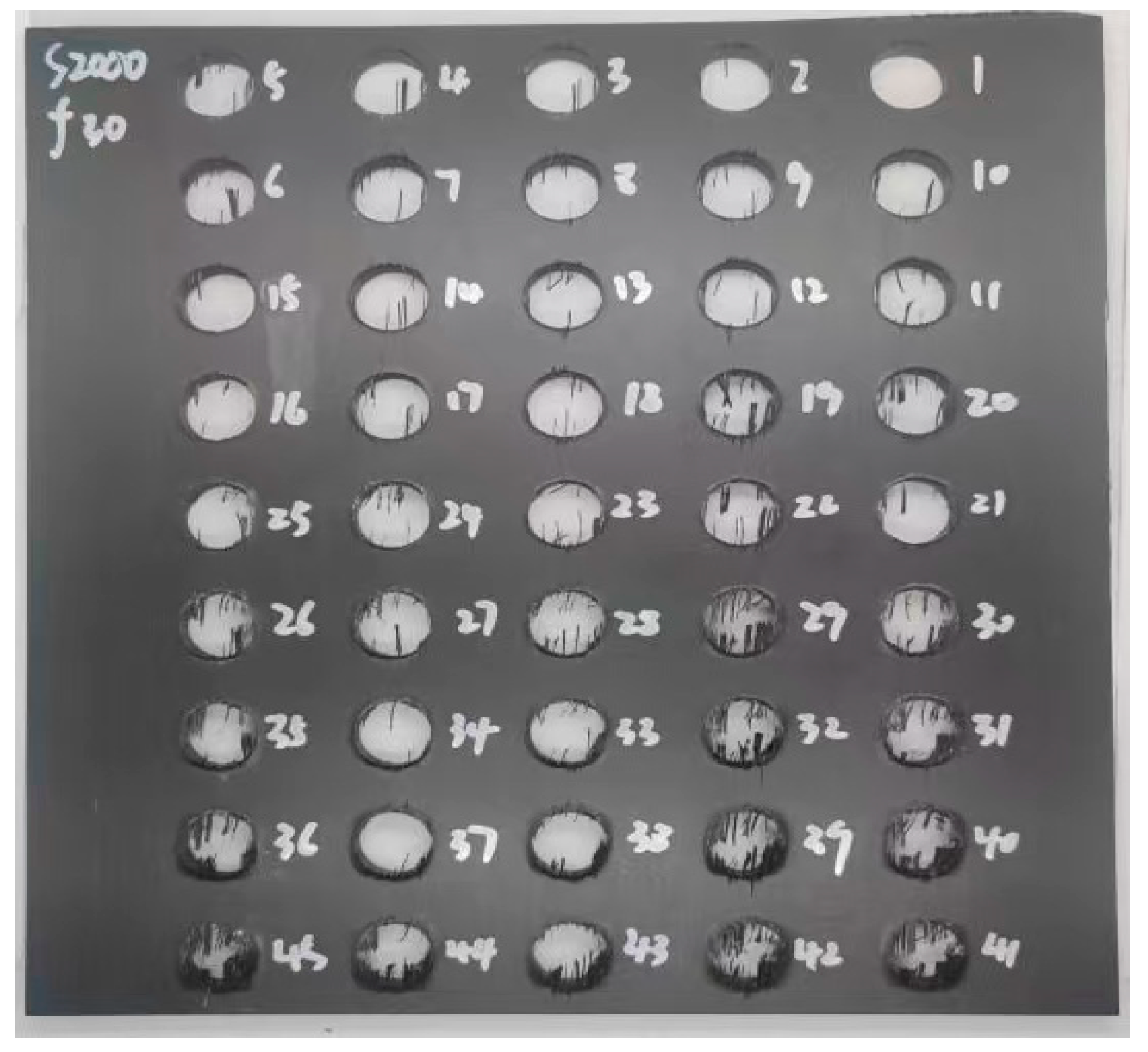

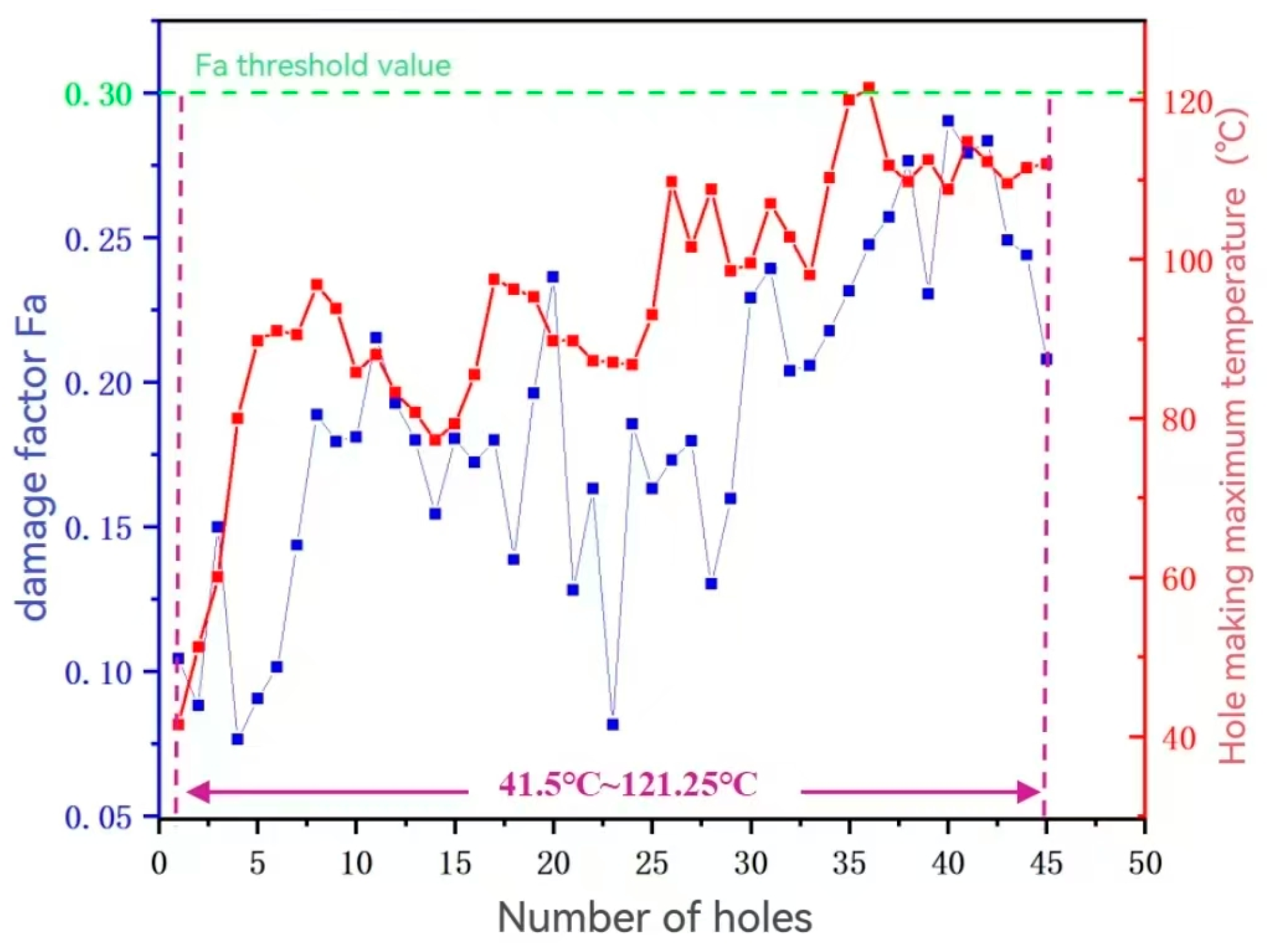

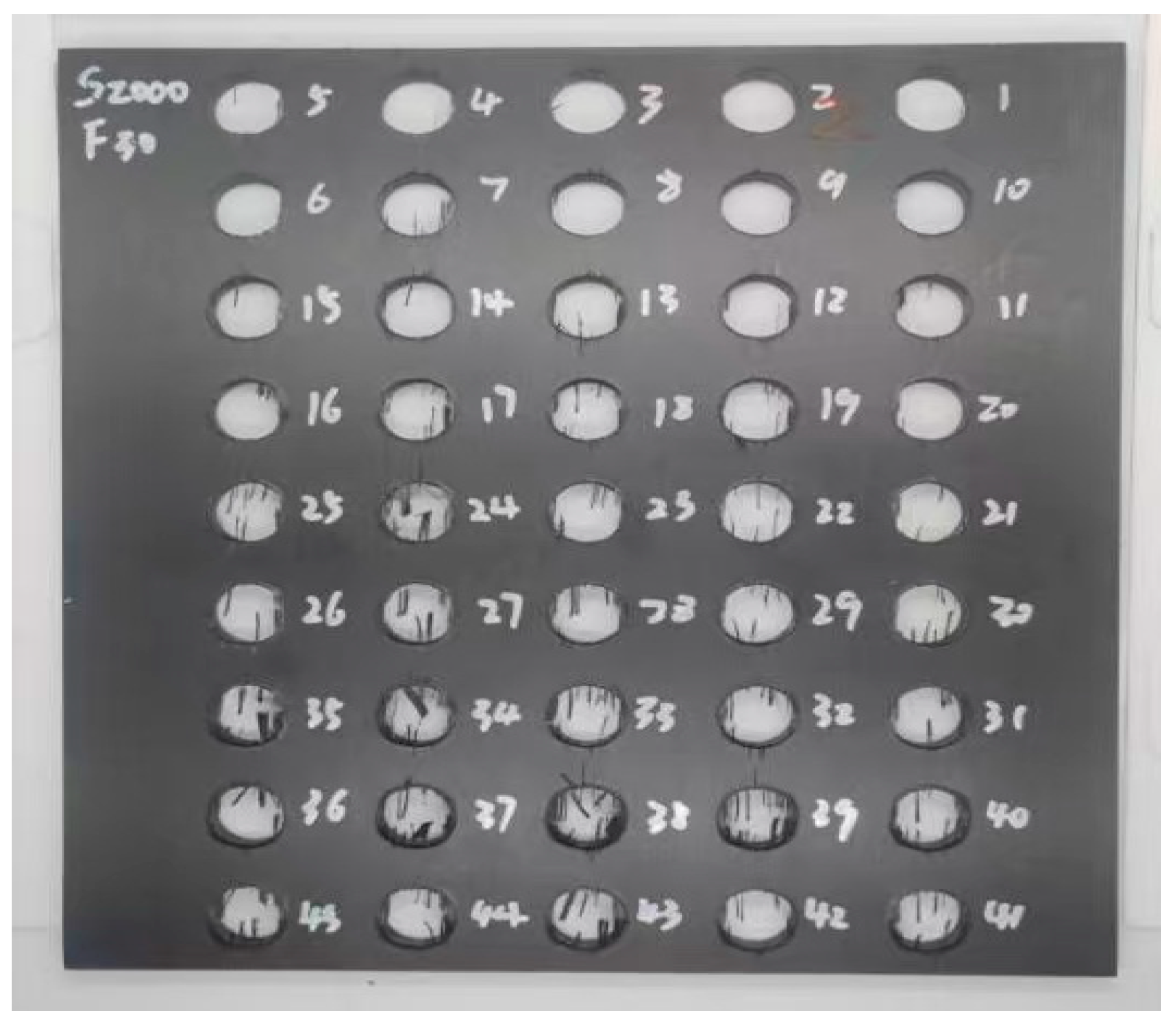

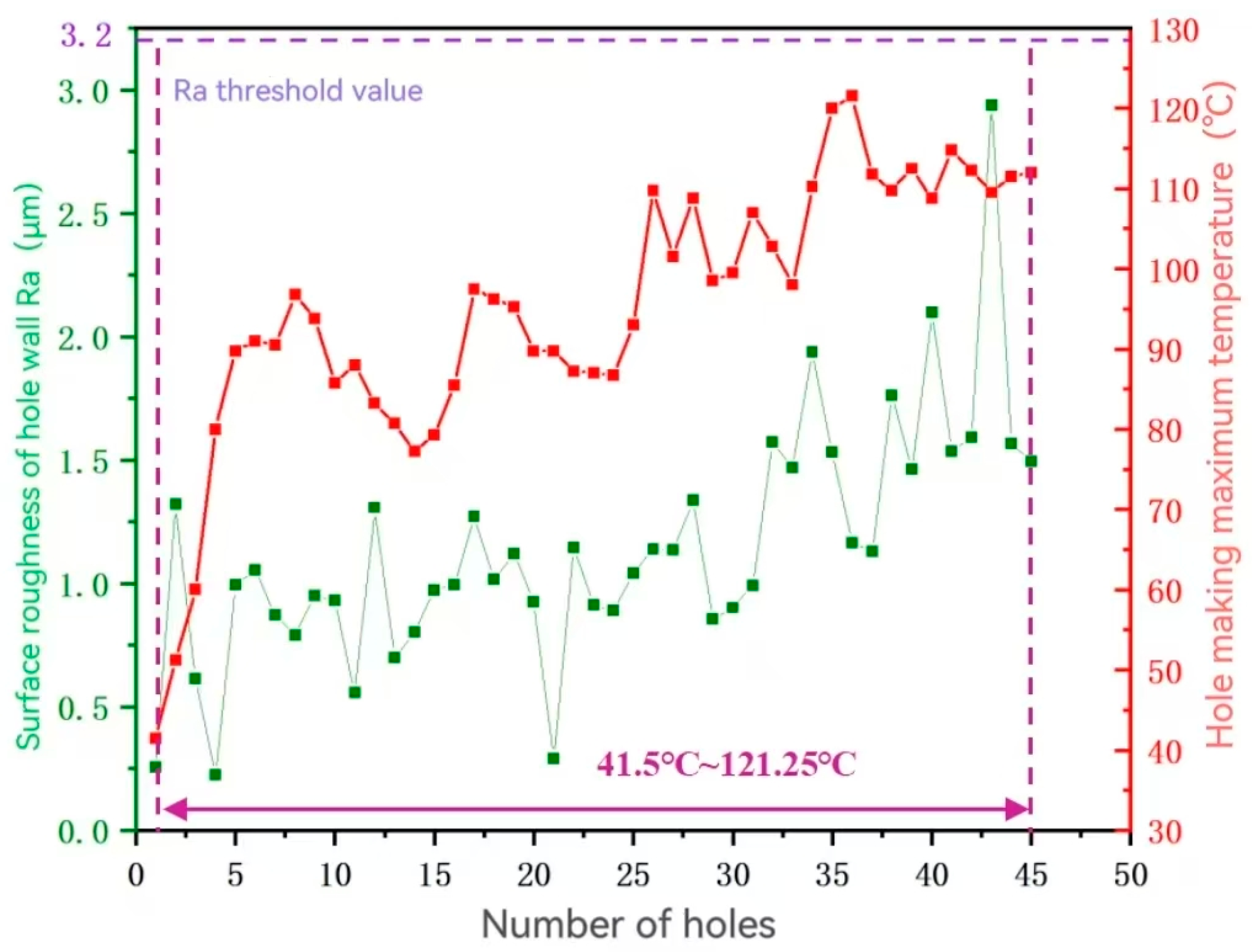

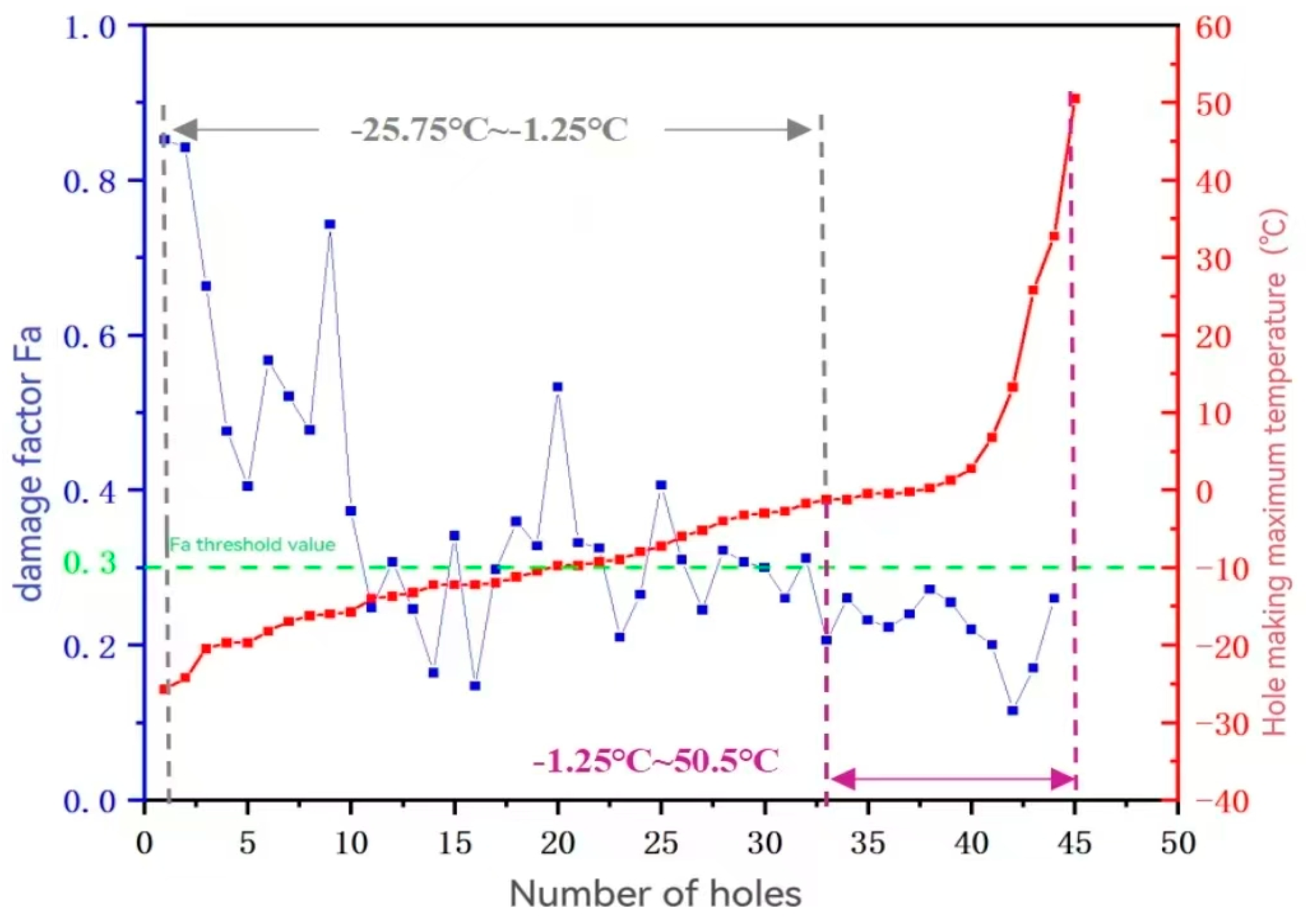

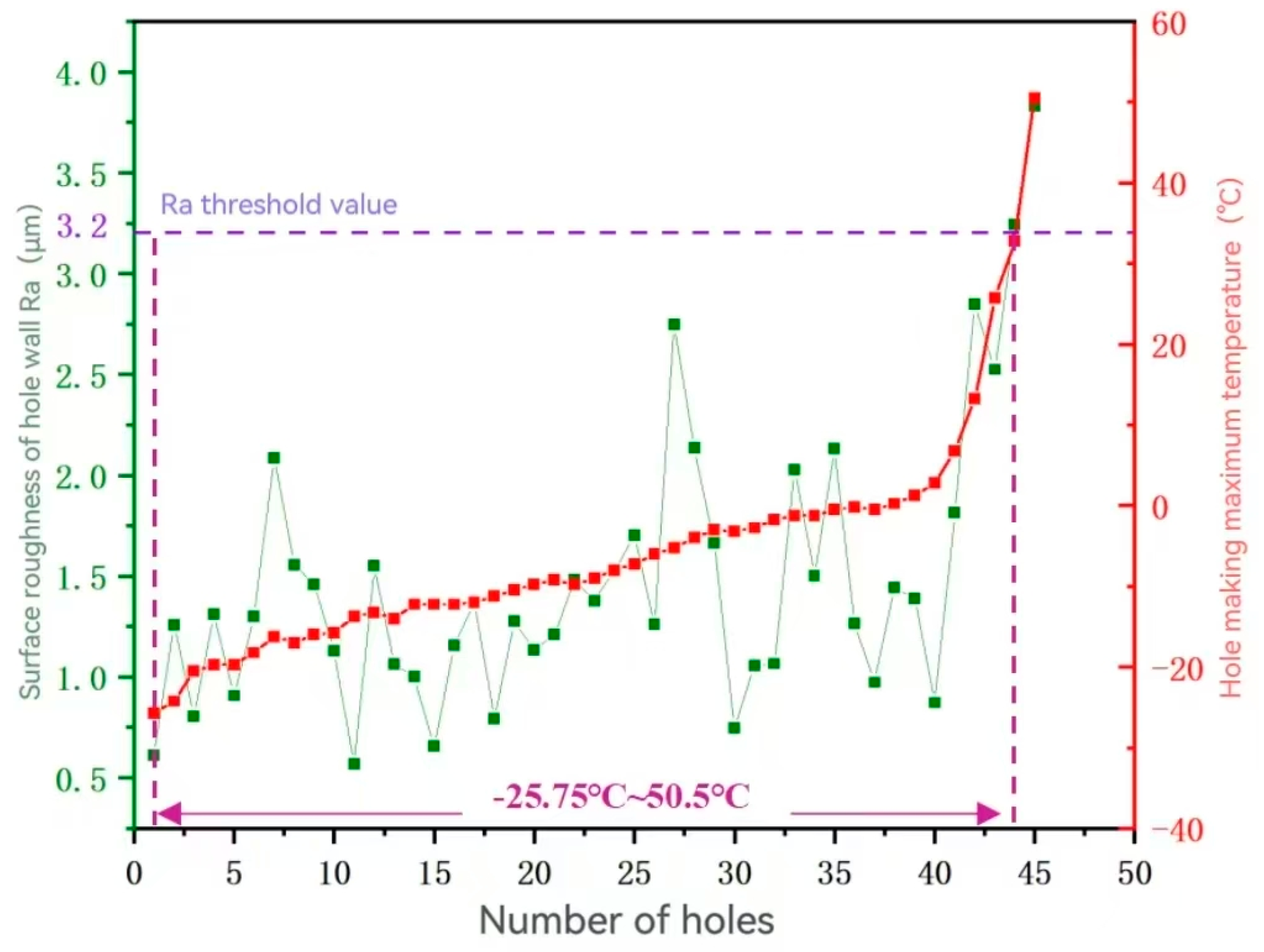

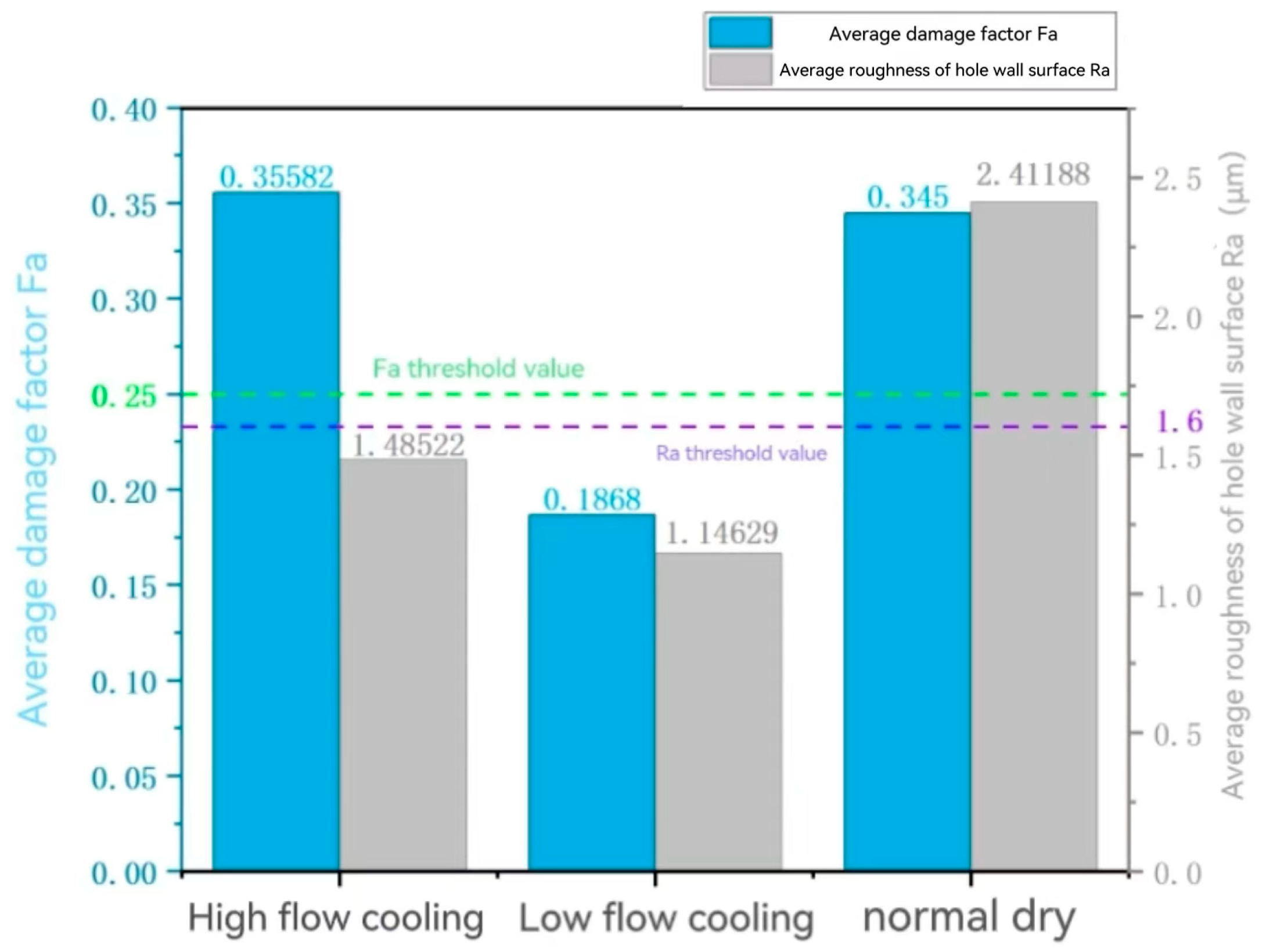

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhu, W.; Fu, H.; Li, F.; Ji, X.; Li, Y.; Bai, F. Optimization of CFRP drilling process: A review. Int. J. Adv. Manuf. Technol. 2022, 123, 1403–1432. [Google Scholar] [CrossRef]

- Xu, J.; Yin, Y.; Davim, J.P.; Li, L.; Ji, M.; Geier, N.; Chen, M. A critical review addressing drilling-induced damage of CFRP composites. Compos. Struct. 2022, 294, 115594. [Google Scholar] [CrossRef]

- Mathiyazhagan, V.; Meena, A. Machining-induced damages in the drilling of CFRP under dry and cryogenic environments. Int. J. Adv. Manuf. Technol. 2024, 134, 605–626. [Google Scholar] [CrossRef]

- Ramirez, C.; Poulachon, G.; Rossi, F.; M’Saoubi, R. Tool wear monitoring and hole surface quality during CFRP drilling. In Proceedings of the CIRP Conference on Surface Integrity, Nottingham, UK, 28–30 May 2014. [Google Scholar]

- Bluemel, S.; Staehr, R.; Jaeschke, P.; Stute, U. Determination of Corresponding Temperature Distribution within CFRP during Laser Cutting. Phys. Procedia 2013, 41, 408–414. [Google Scholar] [CrossRef]

- Tsao, C.C. Experimental study of drilling composite materials with step-core drill. Mater. Des. 2008, 29, 1740–1744. [Google Scholar] [CrossRef]

- Feito, N.; Munoz-Sanchez, A.; Diaz-Alvarez, A.; Miguelez, M. Multi-objective optimization analysis of cutting parameters when drilling composite materials with special geometry drills. Compos. Struct. 2019, 225, 111187. [Google Scholar] [CrossRef]

- Nie, P.; Ma, Y.; Liu, S. Research on CFRP inner wall roughness during vibration drilling of CFRP/Ti based on acoustic emission. J. Phys. Conf. Ser. 2021, 1952, 032060. [Google Scholar] [CrossRef]

- Pérez, J.L.M.; Hodzic, A.; Merson, E.; Ayvar-Soberanis, S. Induced thermo-mechanical damage in the drilling of thermoplastic-toughened CFRP composites. In Proceedings of the 20th International Conference on Composite Materials ICCM-20, Copenhagen, Denmark, 19–24 July 2015. [Google Scholar]

- Pérez, J.L.M.; Hodzic, A.; Ayvar, S.; Merson, E. The influence of heat during short ageing periods on the mechanical properties of CFRP composites. In Proceedings of the 16th European Conference on Composite Materials ECCM-16, Seville, Spain, 22–26 June 2014. [Google Scholar]

- Pérez, J.L.M.; Hodzic, A.; Ayvar-Soberanis, S.; Merson, E.; Ayvar-Soberanis, S. On the temperatures developed in CFRP drilling using uncoated WC-Co tools Part II: Nanomechanical study of thermally aged CFRP composites. Compos. Struct. 2015, 123, 30–34. [Google Scholar] [CrossRef]

- Chatterjee, A. Thermal degradation analysis of thermoset resins. J. Appl. Polym. Sci. 2009, 114, 1417–1425. [Google Scholar] [CrossRef]

- Liu, J.; Chen, G.; Ji, C.; Qin, X.; Li, H.; Ren, C. An investigation of workpiece temperature variation of helical milling for carbon fiber reinforced plastics (CFRP). Int. J. Mach. Tool Manufact. 2014, 86, 89–103. [Google Scholar] [CrossRef]

- Zhu, G.P.; Bao, Y.J.; Ga, H. Research on the drilling temperature field model of the unidirectional carbon fiber epoxy composites. Adv. Mater. Res. 2012, 565, 478–483. [Google Scholar] [CrossRef]

- Sadek, A.; Shi, B.; Meshreki, M.; Duquesne, J.; Attia, M.H. Prediction and control of drilling-induced damage in fibre-reinforced polymers using a new hybrid force and temperature modelling approach. CIRP Ann.-Manuf. Technol. 2015, 64, 89–92. [Google Scholar] [CrossRef]

- Chen, C.; Wang, A.; Zheng, Z.; Zhao, Q.; Shi, Z.; Bao, Y. A Study on Drilling of CFRP/Ti Stacks: Temperature Field and Thermal Damage of the Interface Region. Materials 2023, 16, 2586. [Google Scholar] [CrossRef] [PubMed]

- Luo, B.; Hou, G.; Zhang, K.; Cheng, H. Hole-wall temperature characteristics in thick UD-CFRP drilling by different condition. Mater. Manuf. Process. 2024, 39, 563–576. [Google Scholar] [CrossRef]

- Li, S.; Teng, H.; Dai, L.; Zhou, Y.; Li, C.; Li, P.; Ko, T. Comprehensive prediction model of drilling temperature of UD-CFRP laminates considering the combined action of main cutting edge and chisel edge. Compos. Struct. 2023, 313, 116899. [Google Scholar] [CrossRef]

- Wang, F.J.; Yin, J.W.; Ma, J.W.; Niu, B. Heat Partition in Dry Orthogonal Cutting of Unidirectional CFRP Composite Laminates. Compos. Struct. 2018, 197, 28–38. [Google Scholar] [CrossRef]

- Komanduri, R.; Hou, Z.B. A Review of the Experimental Techniques for the Measurement of Heat and Temperatures Generated in Some Manufacturing Processes and Tribology. Tribol. Int. 2001, 34, 653–682. [Google Scholar] [CrossRef]

- Brinksmeier, E.; Fangmann, S.; Rentsch, R. Drilling of Composites and Resulting Surface Integrity. CIRP Ann-Manuf. Technol. 2011, 60, 57–60. [Google Scholar] [CrossRef]

- Fu, R.; Jia, Z.; Wang, F.; Jin, Y.; Sun, D.; Yang, L.; Cheng, D. Drill-exit temperature characteristics in drilling of UD and MD CFRP composites based on infrared thermography. Int. J. Mach. Tools Manuf. Des. Res. Appl. 2018, 135, 24–37. [Google Scholar] [CrossRef]

- Hou, G.Y.; Luo, B.; Zhang, K.F.; Luo, Y.X.; Liu, P.; Cao, S.P.; Li, Y. Effects of Heat Accumulation on the Characteristics of Hole Wall Temperature and Damages in Drilling of UD CFRP. Int. J. Adv. Manuf. Technol. 2021, 115, 1529–1546. [Google Scholar] [CrossRef]

- Butler-Smith, P.W.; Axinte, D.A.; Daine, M.; Kennedy, A.R.; Harper, L.T.; Bucourt, J.F.; Ragueneau, R. A study of an improved cutting mechanism of composite materialsusing novel design of diamond micro-core drills. Int. J. Mach. Tool Manufact. 2015, 88, 175–183. [Google Scholar] [CrossRef]

- Choudhury, M.R.; Srinivas, M.S.; Debnath, K. Experimental investigations on drilling of lignocellulosic fiber reinforced composite laminates. J. Manuf. Process. 2018, 34, 51–61. [Google Scholar] [CrossRef]

- Wang, C.Y.; Ming, W.W.; An, Q.L.; Chen, M. Machinability Characteristics Evolution of CFRP in a Continuum of Fiber Orientation Angles. Mater. Manuf. Process. 2017, 32, 1041–1050. [Google Scholar] [CrossRef]

- Hintze, W.; Schutte, C.; Steinbach, S. Influence of the Fiber Cutting Angle on Work Piece Temperature in Drilling of Unidirectional CFRP. In New Production Technologies in Aerospace Industry: Proceedings of the 4th Machining Innovations Conference, Hannover, Germany, 18–19 September 2013; Springer: Cham, Switzerland, 2013; pp. 137–143. [Google Scholar]

- Xu, J.Y.; Zhou, J.; Chen, M.; Ren, F. Experimental Study on Mechanical Drilling of Carbon/Epoxy Composite-Ti6Al4V Stacks. Mater. Manuf. Process. 2019, 34, 715–725. [Google Scholar] [CrossRef]

- Wang, C.Y.; Chen, Y.H.; An, Q.L.; Cai, X.J.; Ming, W.W.; Chen, M. Drilling temperature and hole quality in drilling of CFRP/aluminum stacks using diamond coated drill. Int. J. Precis. Eng. Manuf. 2015, 16, 1689–1697. [Google Scholar] [CrossRef]

- Sato, M.; Aoki, T.; Tanaka, H.; Takeda, S. Measurement of temperature at bottom surface of hole in drilling of CFRP and titanium stack. In Proceedings of the International Conference on Leading Edge Manufacturing in 21st Century, Matsushima, Japan, 7–8 November 2013; Volume 7, pp. 448–451. [Google Scholar]

- Guo, Q.; Yao, W.; Li, W.; Gupta, N. Constitutive models for the structural analysis of composite materials for the finite element analysis: A review of recent practices. Compos. Struct. 2021, 260, 113267. [Google Scholar] [CrossRef]

- Trzepieciński, T.; Najm, S.M.; Lemu, H.G. Current concepts for cutting metal-based and polymer-based composite materials. J. Compos. Sci. 2022, 6, 150. [Google Scholar] [CrossRef]

- Lian, Y.; Chen, X.; Zhang, T.; Liu, C.; Lin, L.; Lin, F.; Li, Y.; Chen, Y.; Zhang, M.; Zhou, W. Temperature measurement performance of thin-film thermocouple cutting tool in turning titanium alloy. Ceram. Int. 2023, 49, 2250–2261. [Google Scholar] [CrossRef]

- Davim, J.; Reis, P. Study of delamination in drilling carbon fiber reinforced plastics (CFRP) using design experiments. Compos. Struct. 2003, 59, 481–487. [Google Scholar] [CrossRef]

- Chen, Y.; Guo, X.; Zhang, K.; Guo, D.; Zhou, C.; Gai, L. Study on the surface quality of CFRP machined by micro-textured milling tools. J. Manuf. Process. 2019, 37, 37114–37123. [Google Scholar] [CrossRef]

| Material Property | Material Temperature | Numerical Value |

|---|---|---|

| Density (g/cm3) | 1.58 | |

| Fiber volume fraction | 62 ± 0.3% | |

| Elastic property | ||

| Modulus of elasticity (GPa) | 22 °C | E11 = 114; E22 = E33 = 7.27; G12 = G13 = 4.54; G23 = 2.59; ν12 = ν12 = 0.29; ν23 = 0.4 |

| 180 °C | E11 = 107; E22 = E33 = 4.42; G12 = G13 = 4.22; G23 = 1.65; ν12 = ν12 = 0.29; ν23 = 0.4 | |

| Tensile strength (Mpa) | 22 °C | XT = 1677; XC = 1249; YT = ZT = 20; YC = ZC = 140; S12 = S13 = S23 = 129 |

| 180 °C | XT = 1240; XC = 439; YT = ZT = 15; YC = ZC = 100; S12 = S13 = S23 = 35 | |

| Thermal property | ||

| Heat conductivity (W/m·K) | 22 °C | k11 = 2.95; k22 = k33 = 0.64 |

| 180 °C | k11 = 4.13; k22 = k33 = 0.81 | |

| Specific heat capacity (J/Kg·K) | 22 °C | Cp = 750 |

| 180 °C | Cp = 1206 | |

| Damage parameter | ||

| Breaking energy (N/mm) | 22 °C | Gft = 133; Gfc = 40; Gmt = Gzmt = 0.6; Gmc = Gzmc = 2.1 |

| Geometric Parameter | Numerical Value |

|---|---|

| Diameter (mm) | 13 |

| Parietal angle (°) | 120 |

| Posterior angle (°) | 0.22 |

| Cutting edge width (mm) | 1.3 |

| Spiral angle (°) | 30 |

| Material Property | Numerical Value |

|---|---|

| Density (g/cm3) | 1.58 |

| Modulus of elasticity (GPa) | 580 |

| Poisson’s ratio | 0.22 |

| Thermal conductivity (W/m·K) | 62.8 |

| Specific heat capacity (J/Kg·K) | 460 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, C.; Chen, F.; Song, D.; Liu, J.; Xu, Q.; Zhou, Q.; Wang, H. A Study on the Effect of Cutting Temperature on CFRP Hole Wall Damage in Continuous Drilling Process. Machines 2024, 12, 809. https://doi.org/10.3390/machines12110809

Zhang C, Chen F, Song D, Liu J, Xu Q, Zhou Q, Wang H. A Study on the Effect of Cutting Temperature on CFRP Hole Wall Damage in Continuous Drilling Process. Machines. 2024; 12(11):809. https://doi.org/10.3390/machines12110809

Chicago/Turabian StyleZhang, Chong, Feiyu Chen, Dongxue Song, Jiale Liu, Qingsong Xu, Qunli Zhou, and Haoyu Wang. 2024. "A Study on the Effect of Cutting Temperature on CFRP Hole Wall Damage in Continuous Drilling Process" Machines 12, no. 11: 809. https://doi.org/10.3390/machines12110809

APA StyleZhang, C., Chen, F., Song, D., Liu, J., Xu, Q., Zhou, Q., & Wang, H. (2024). A Study on the Effect of Cutting Temperature on CFRP Hole Wall Damage in Continuous Drilling Process. Machines, 12(11), 809. https://doi.org/10.3390/machines12110809