Study on the Effect of Cracks in Diaphragm Couplings on the Dynamic Characteristics of Shaft System †

Abstract

1. Introduction

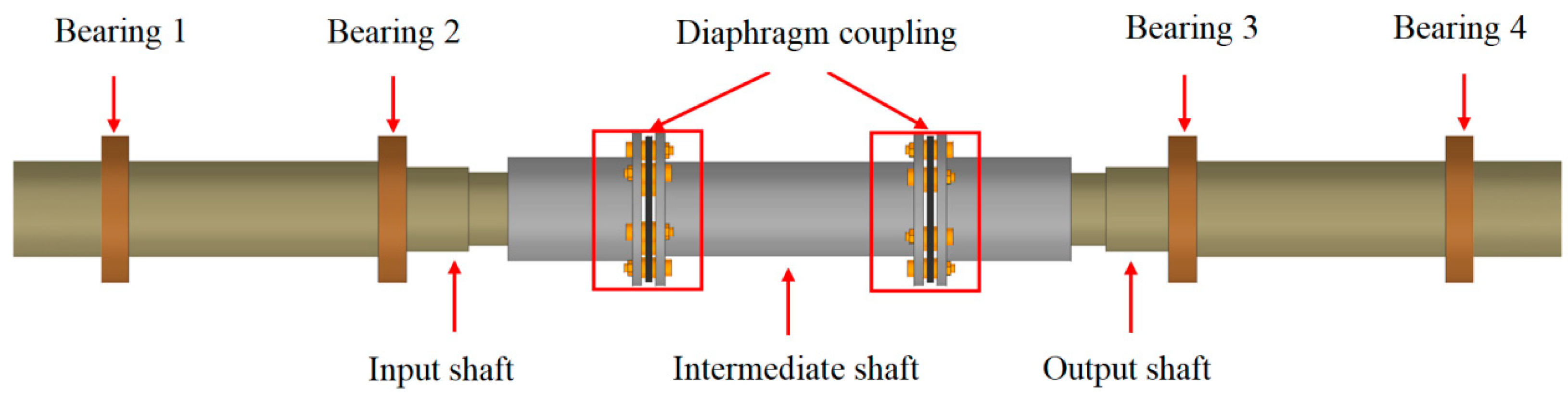

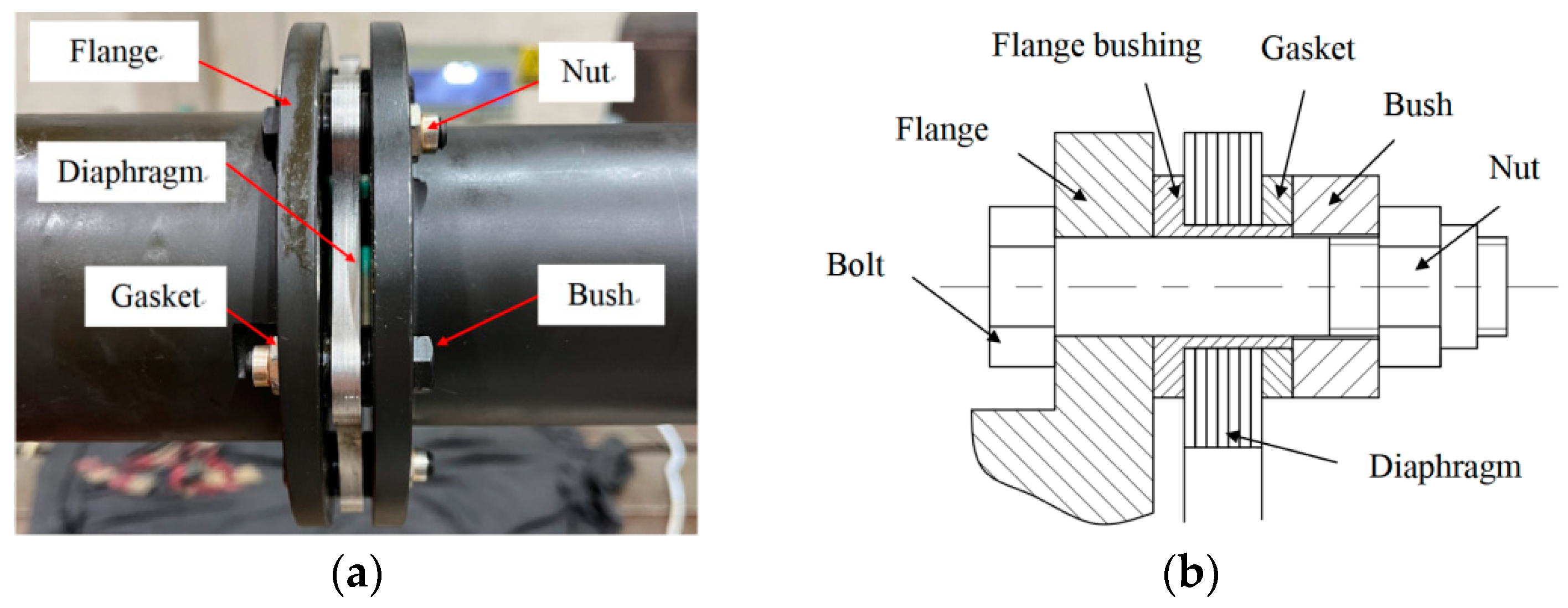

2. Dynamic Modeling

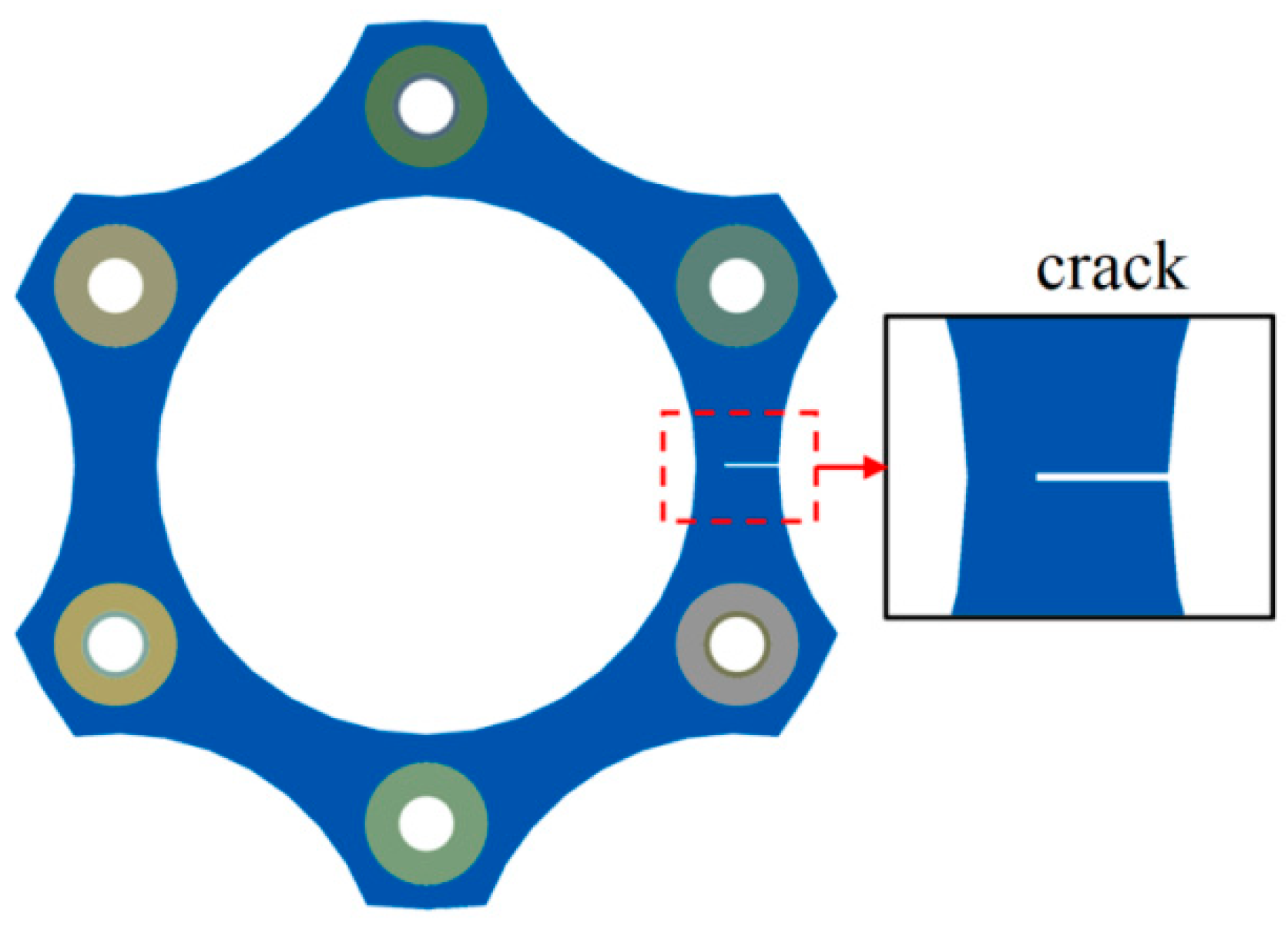

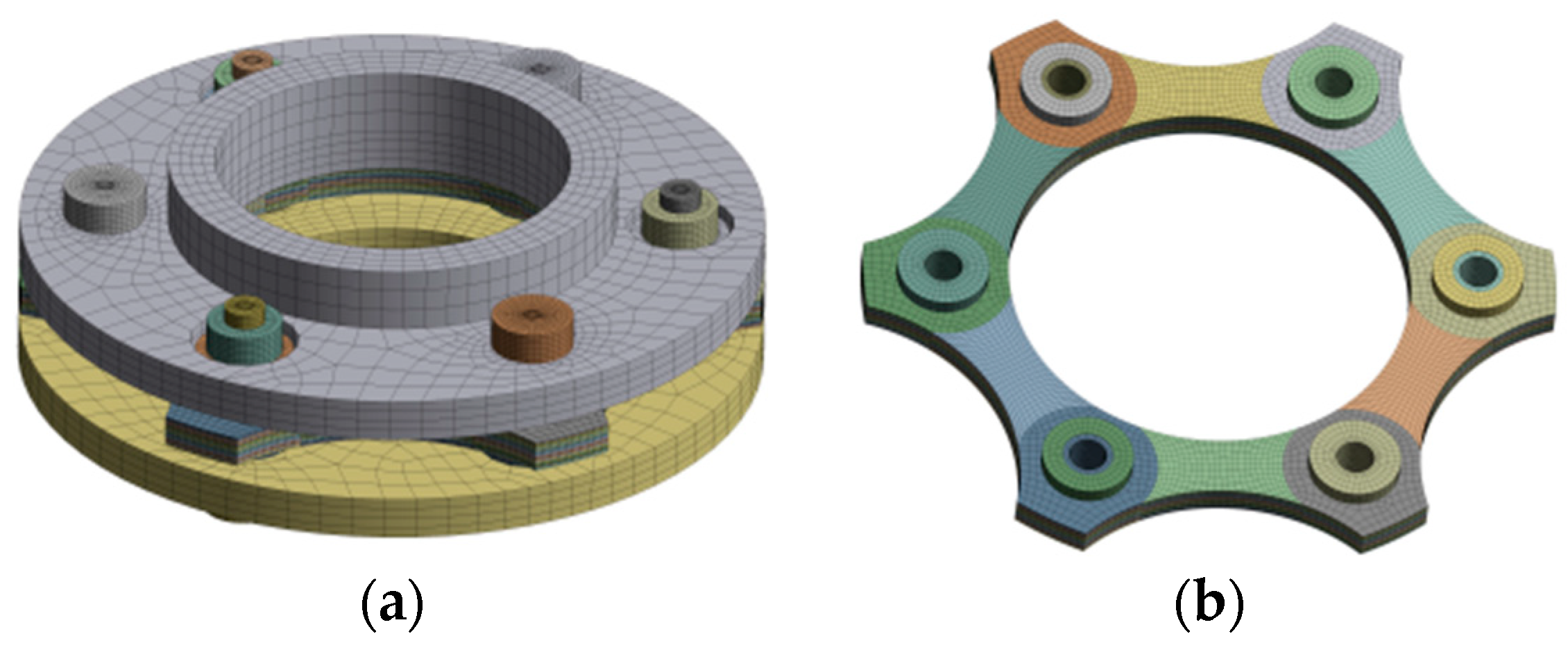

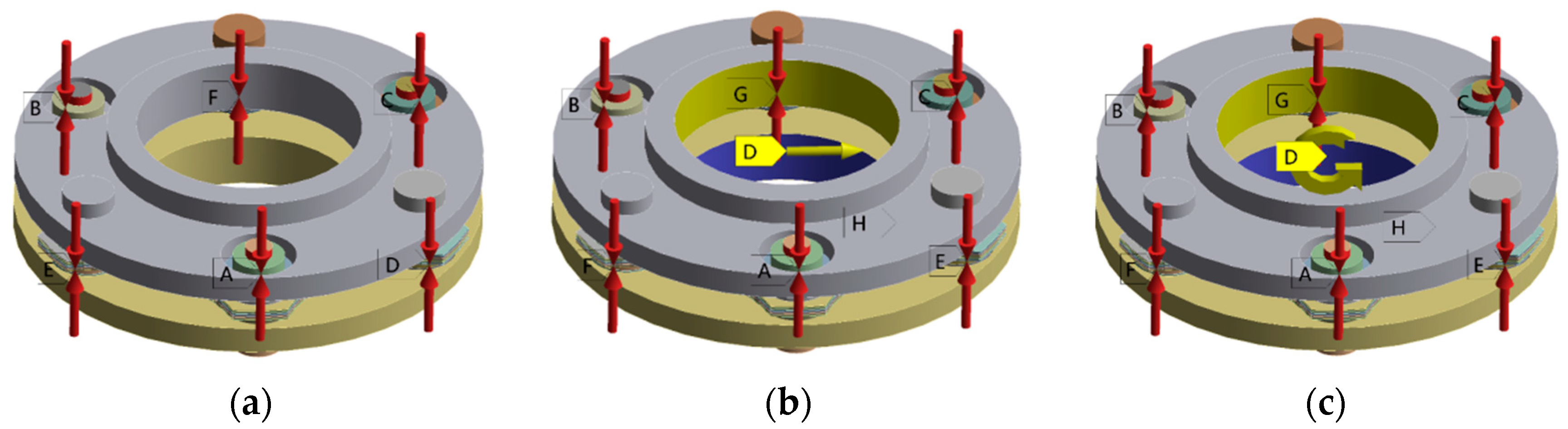

2.1. The Finite Element Model of the Diaphragm Coupling with Crack

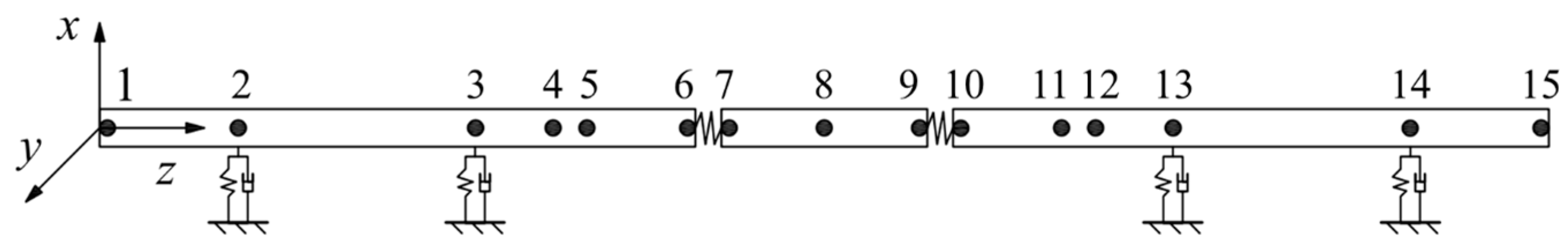

2.2. The System Dynamic Equation

3. Results and Discussion

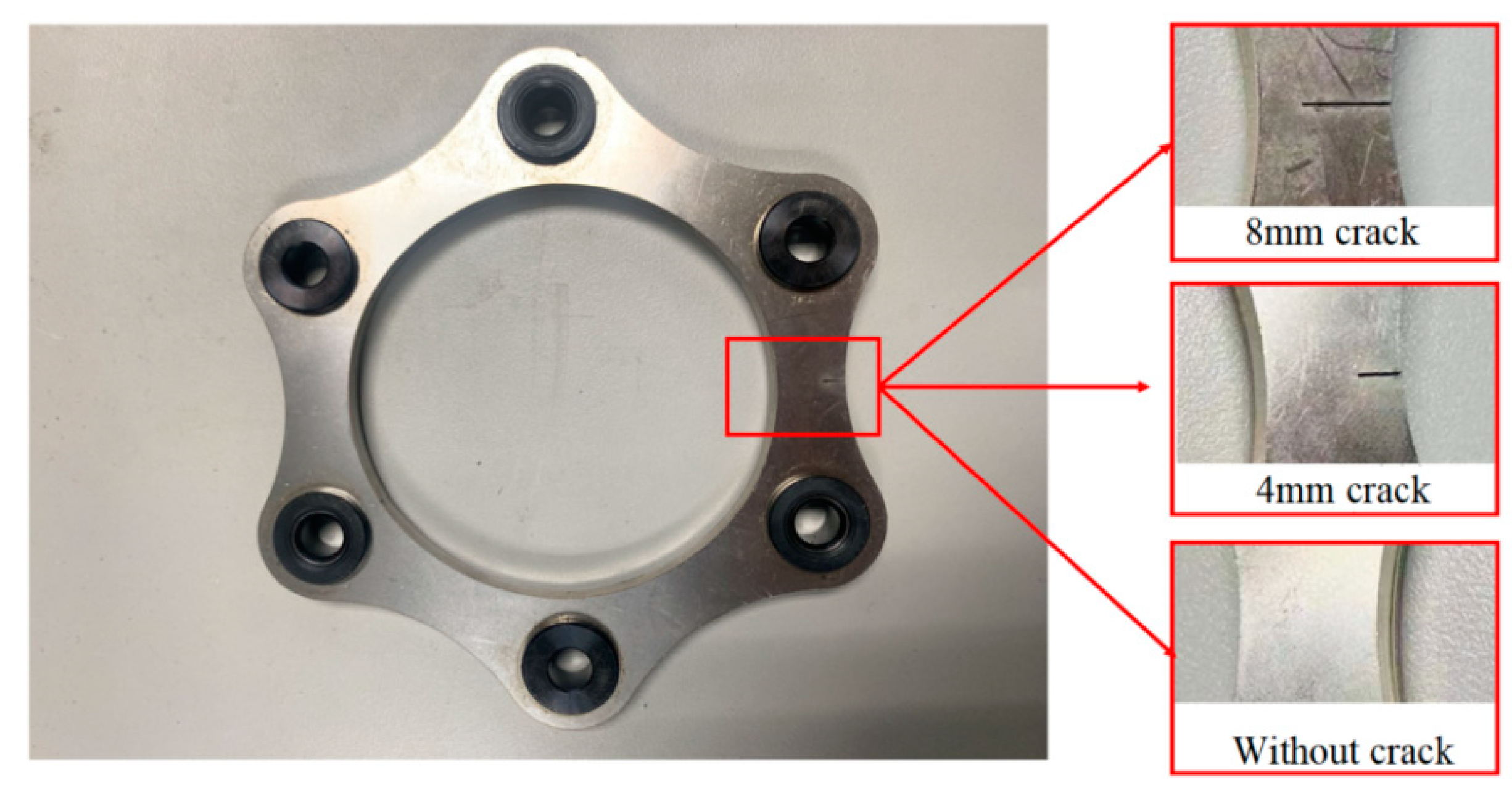

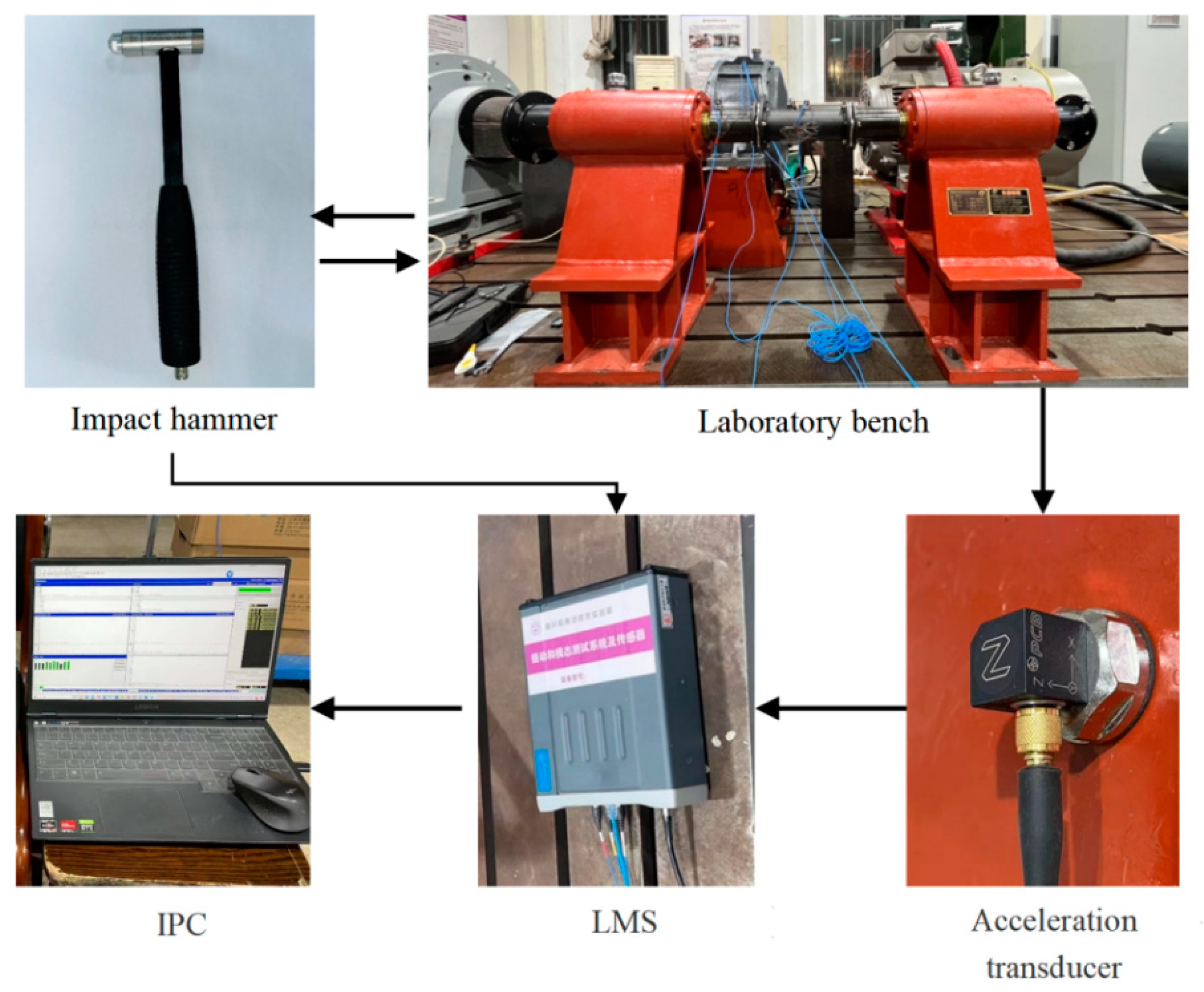

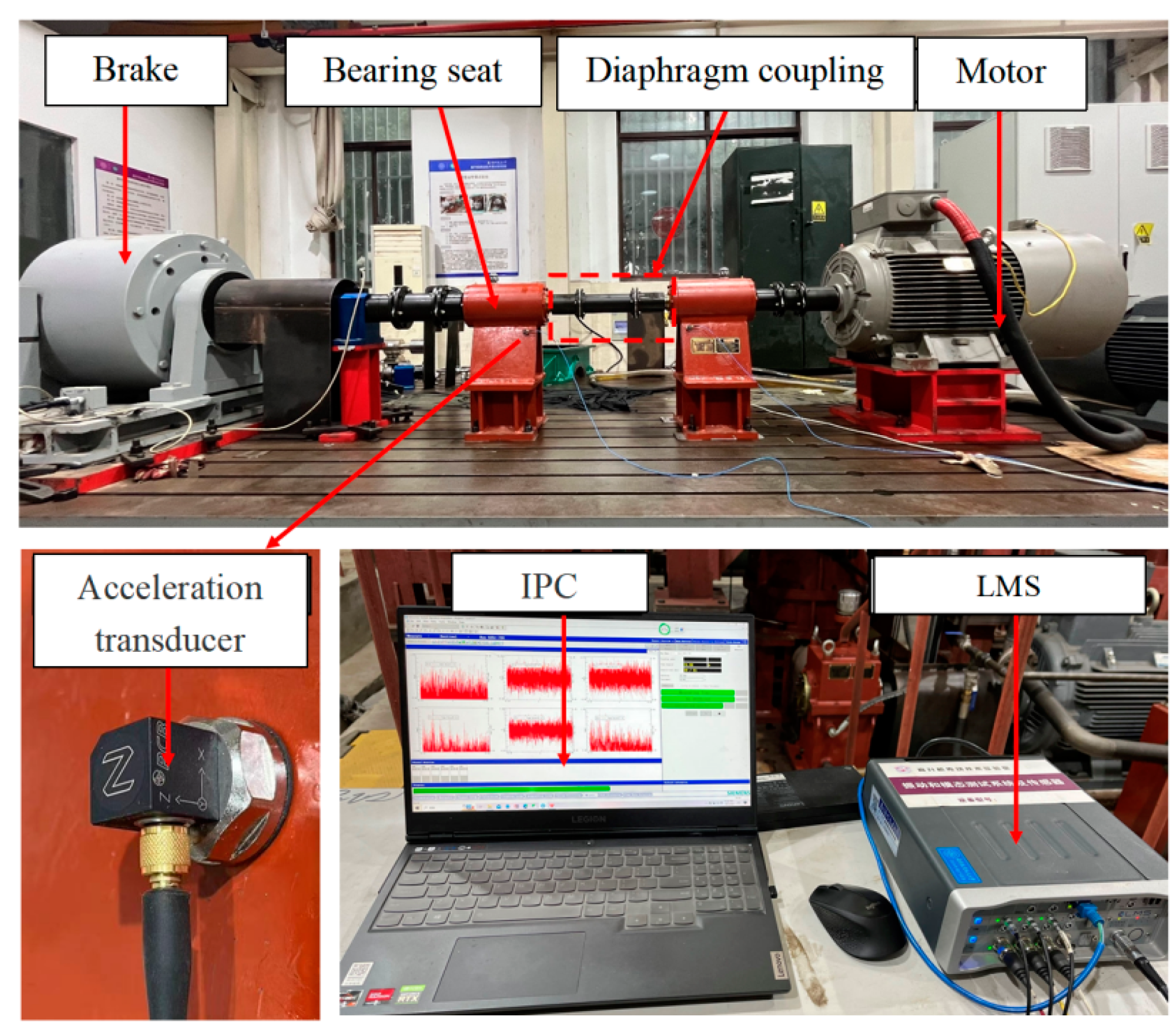

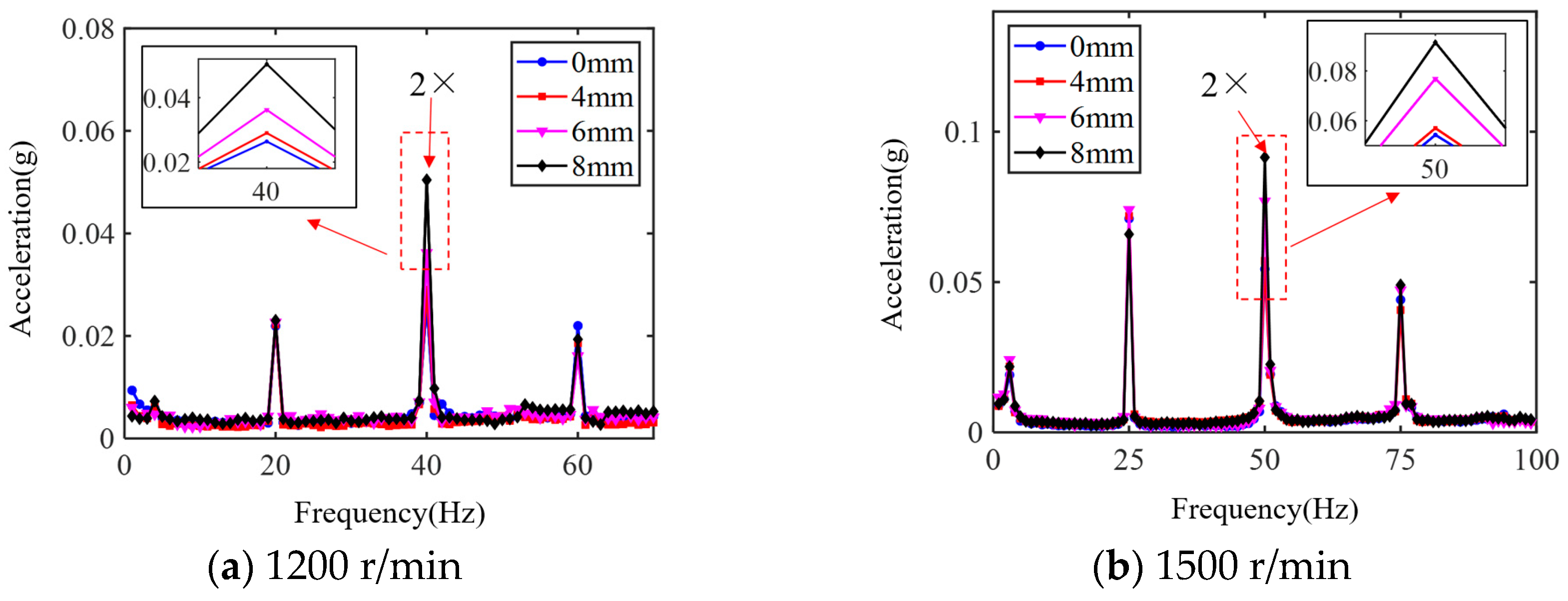

4. Experimental Verification

5. Conclusions

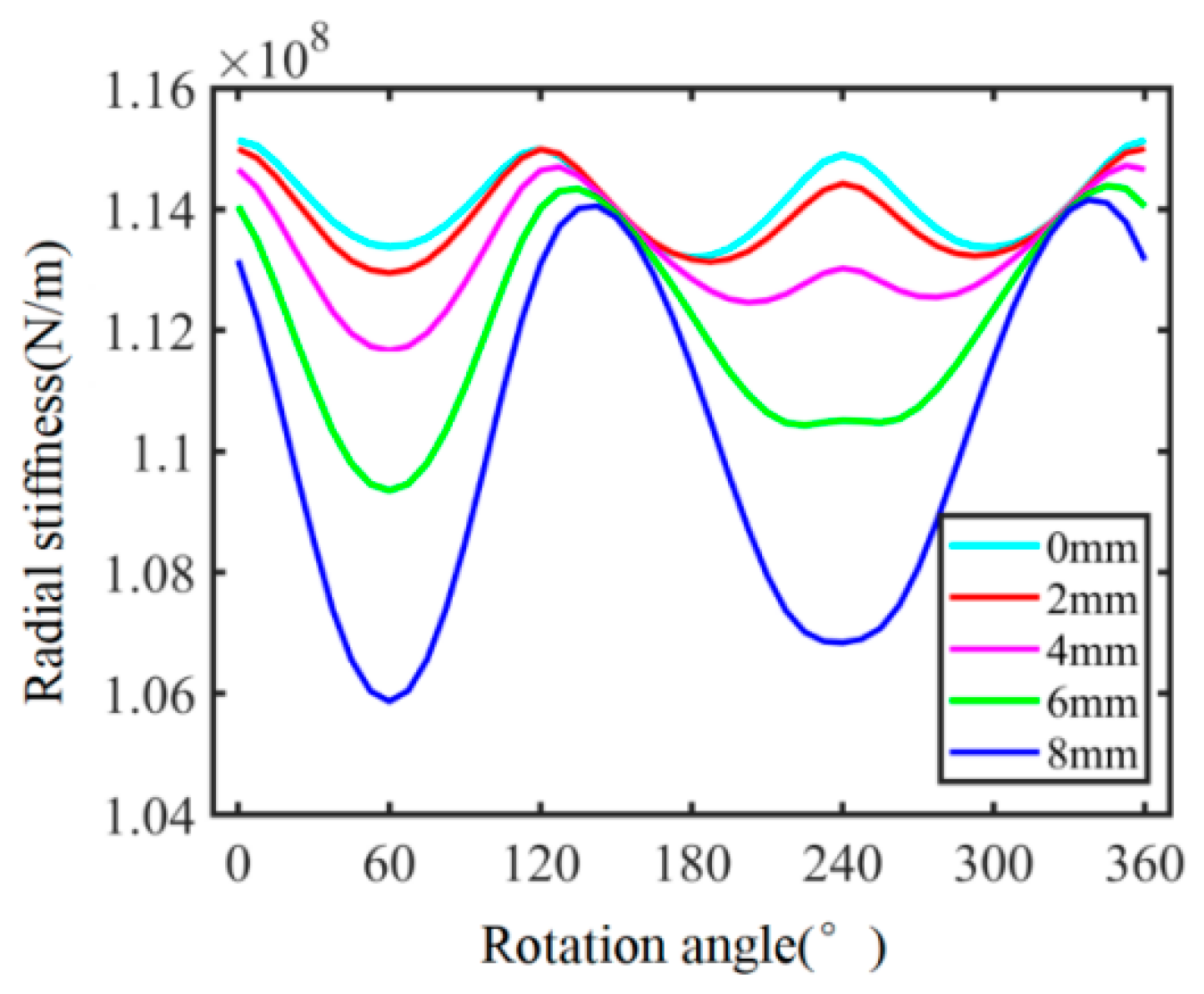

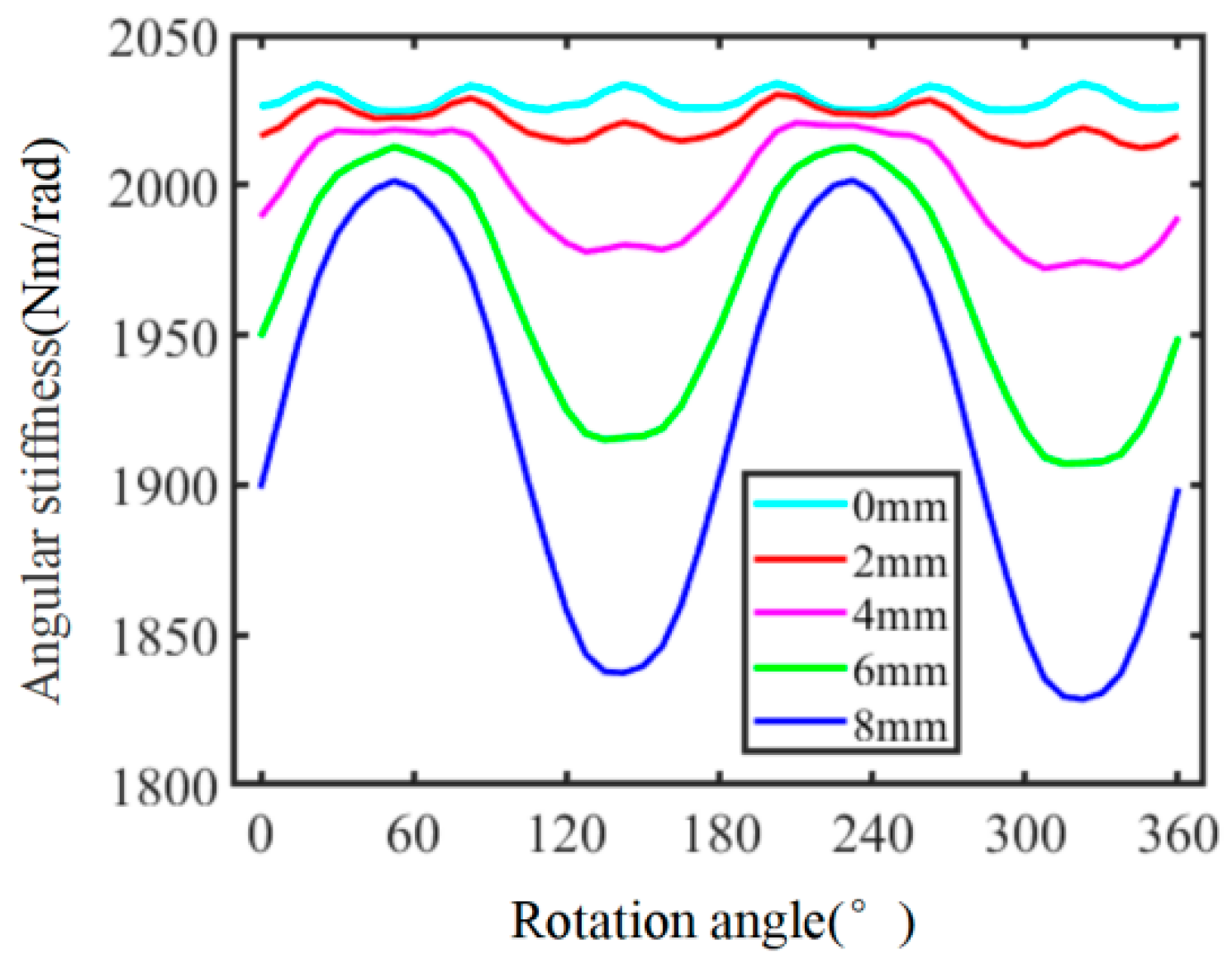

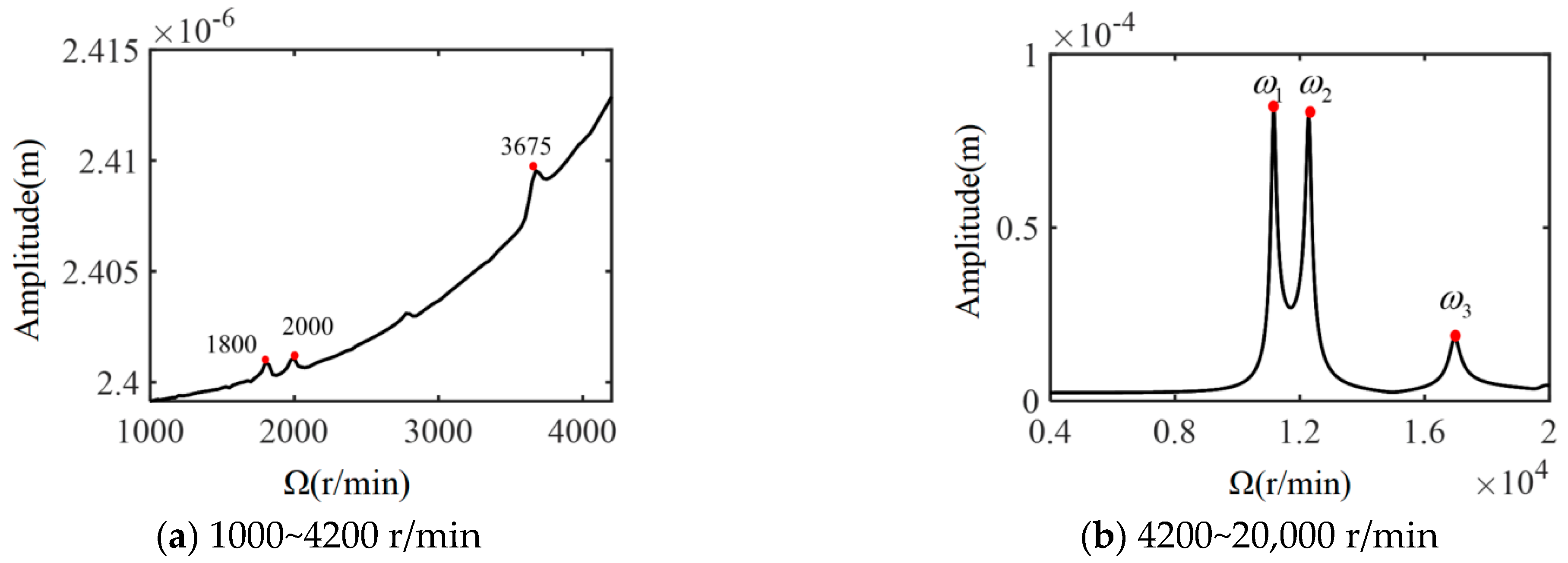

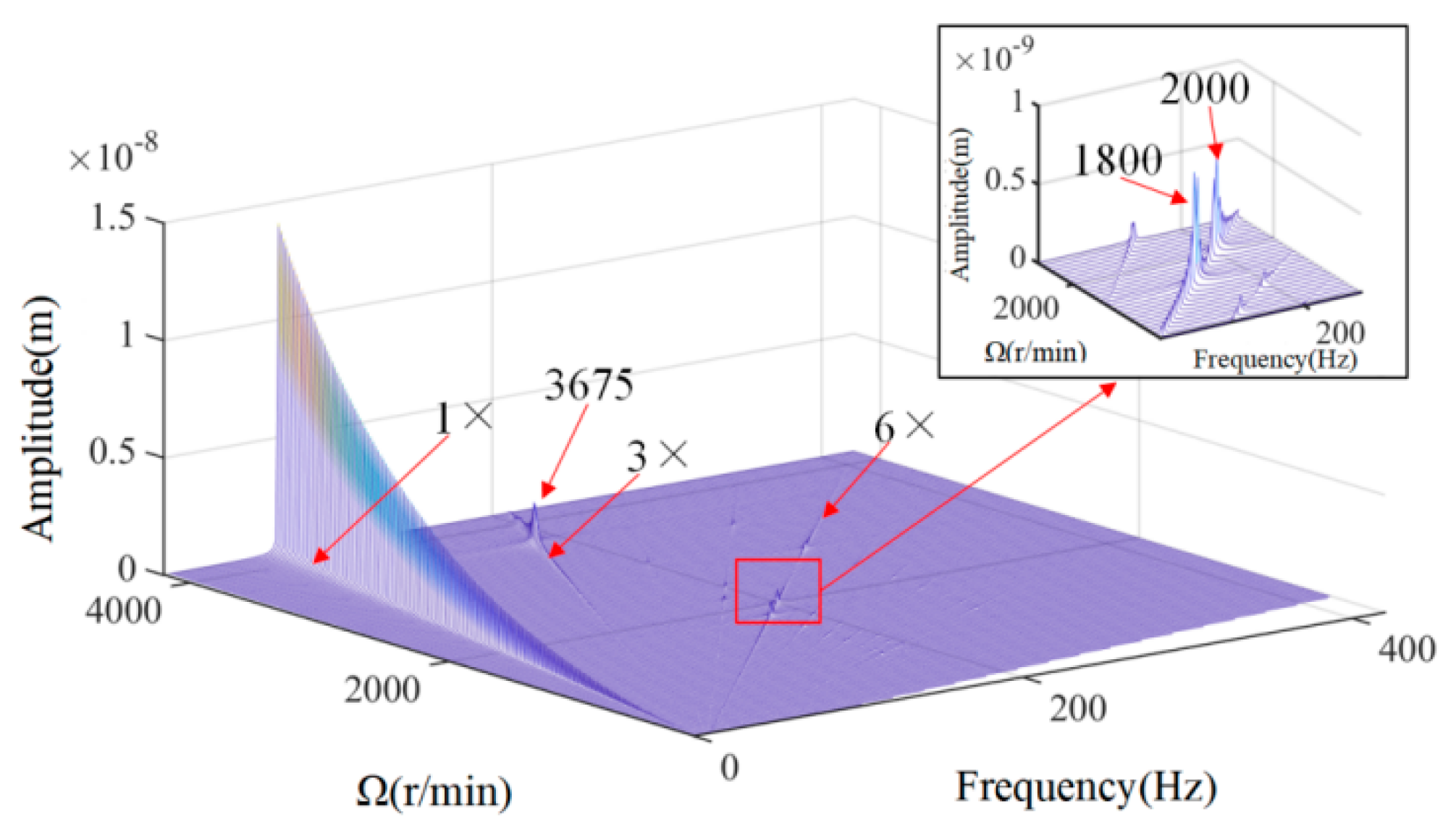

- The radial and angular stiffness rates of the diaphragm coupling have time-varying characteristics within one rotation cycle, with the radial stiffness showing 3× periodic changes and the angular stiffness showing 6× periodic changes. After the introduction of cracks at the girdle, the overall amplitude of radial and angular stiffness decreases, and the time-varying period of stiffness changes.

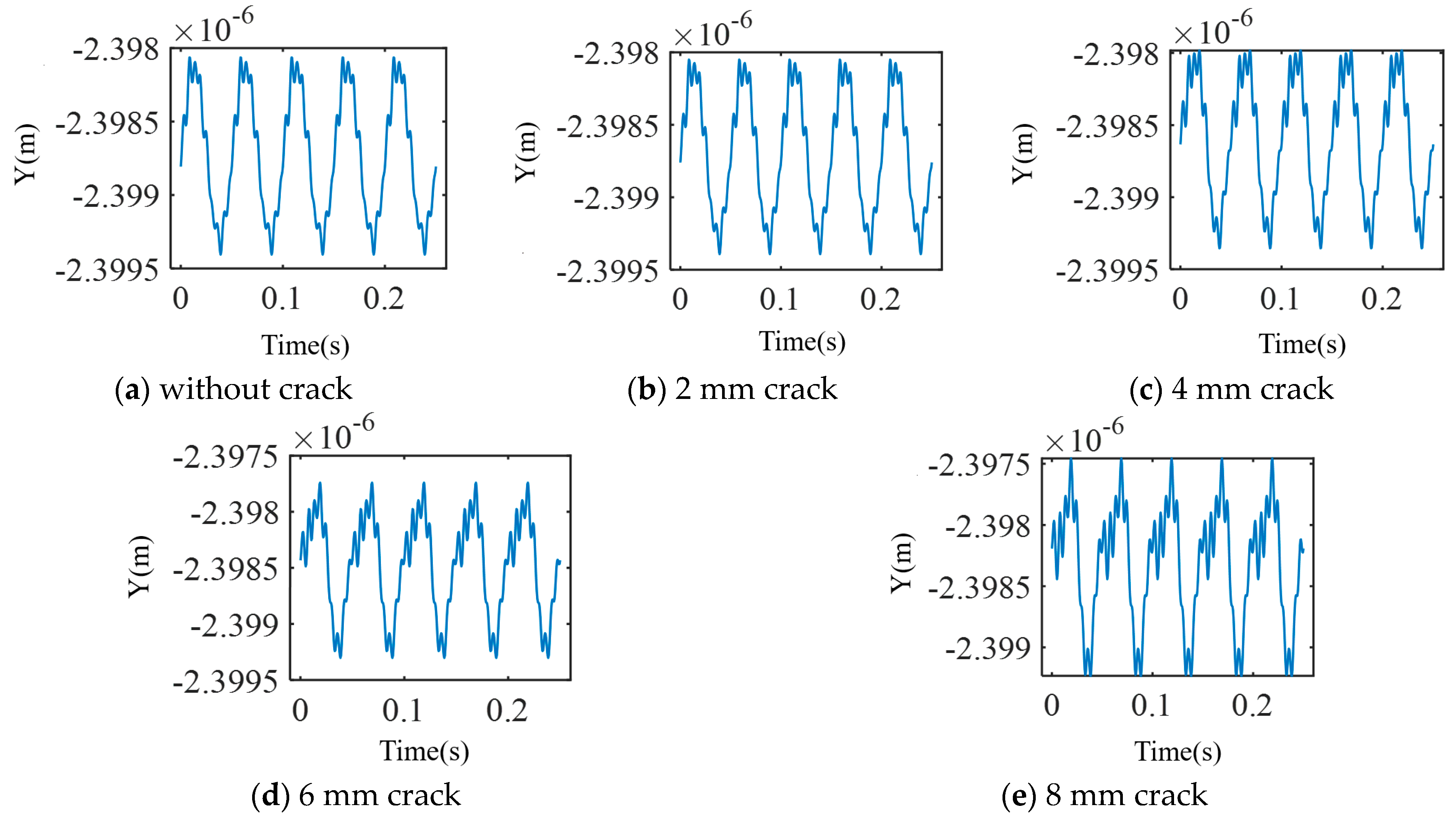

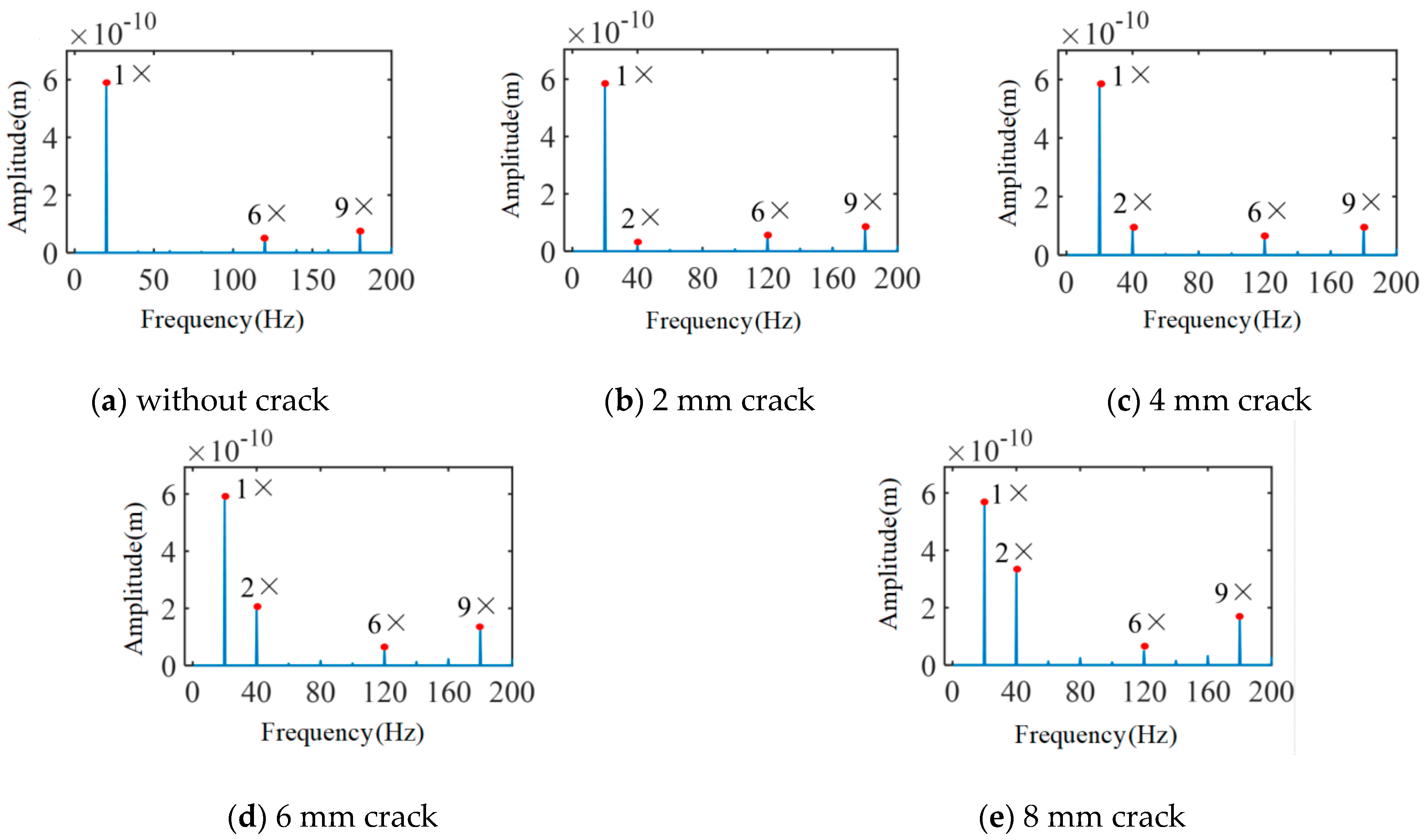

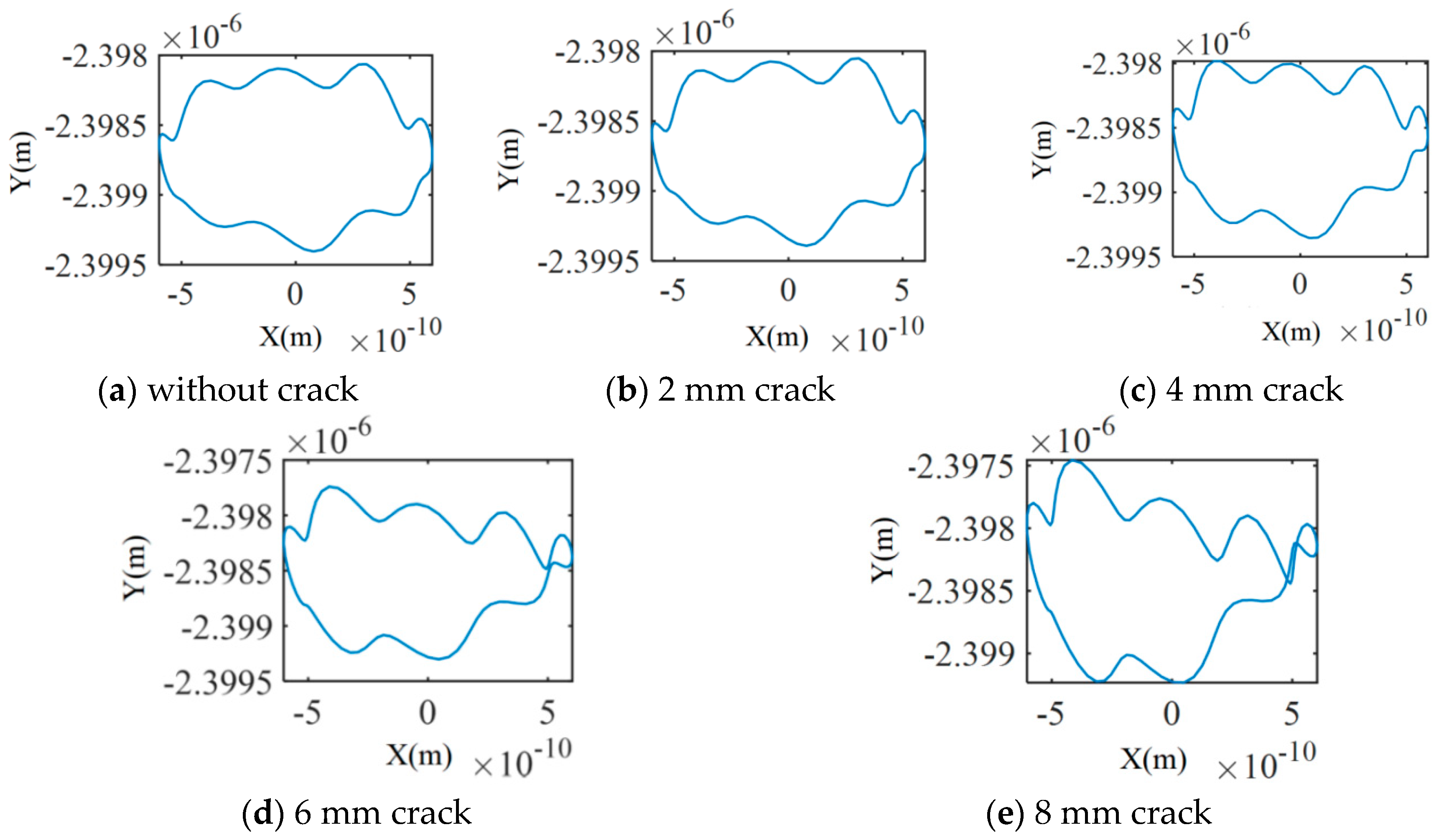

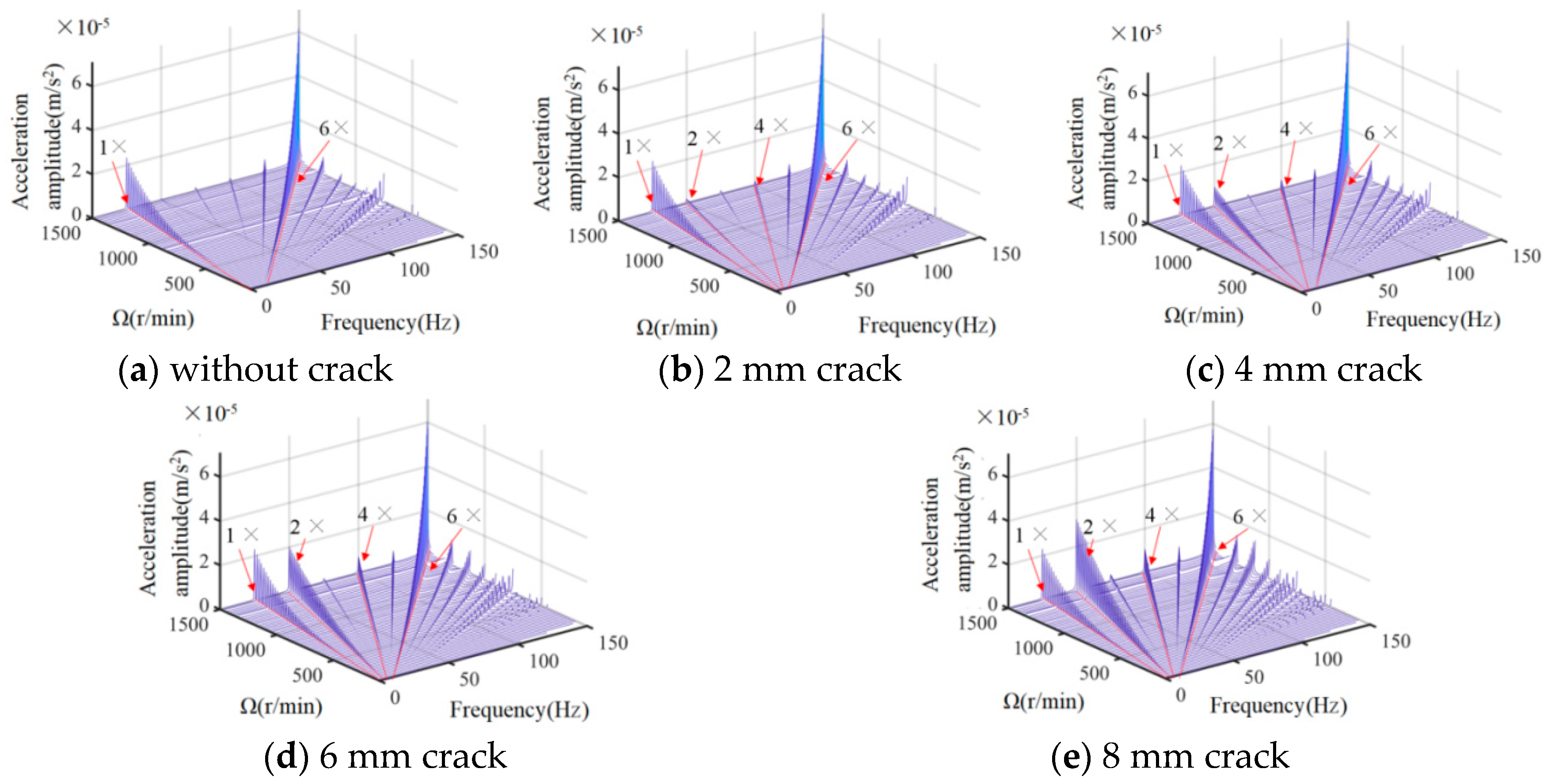

- The emergence of crack faults at the diaphragm girdle introduces a high transconductance component in the displacement spectrum, which makes the displacement axial trajectory complex; with the increase in crack length at the diaphragm girdle, the 2× transconductance component in the acceleration spectrum shows an obvious monotonous increasing trend, and the crack faults can be recognized by the change in the 2× transconductance component.

- This study is an exceptional starting point for further research in the field of crack failures in rotating machinery. The study of nonlinear dynamics of rotor systems with cracked diaphragm couplings is of great importance for the early detection of crack failures and for ensuring the safe operation of large rotating machinery.

- In this paper, the effect of diaphragm crack length on diaphragm coupling stiffness was only investigated for penetration cracks, but in fact, the forms of diaphragm coupling crack failures are diverse; they may be single diaphragm cracks, diagonal cracks, composite cracks, and other crack failures. Thus, the effect of different diaphragm crack failures on the stiffness value of the diaphragm couplings needs to be further investigated.

- In this paper, the effect of diaphragm cracks on the dynamic characteristics of the shaft system was investigated, but in practice, crack failures of the shaft system may also occur at the rotor shaft, bearings, and the connecting bolts of the diaphragm coupling. Thus, further research is needed to study the effects of single-crack failures and compound-crack failures on the dynamic response of the shaft system.

- When analyzing the effect of diaphragm crack faults on the dynamics of the shaft system with misalignment error, the dynamics of the shaft system at low rotational speeds was mainly studied, and the mechanism at high rotational speeds was less studied, which requires further research.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| Radial stiffness of diaphragm couplings | Angular stiffness of diaphragm couplings | ||

| Bearing unit stiffness matrix | Bearing damping matrix | ||

| Radial stiffness of the bearing in the X direction | Radial stiffness of the bearing in the Y direction | ||

| Angular stiffness of the bearing in the X direction | Angular stiffness of the bearing in the Y direction | ||

| Radial damping of the bearing in the X direction | Radial damping of the bearing in the Y direction | ||

| Angular damping of bearings in the X direction | Angular damping of bearings in the Y direction | ||

| Quality matrix of the system | Gyroscopic matrix of the system | ||

| Damping matrix of the system | The stiffness matrix of the system | ||

| External incentives for the system | Displacement vector of the system | ||

| The velocity vector of the system | Acceleration vector of the system | ||

| The density of the shaft | The elastic modulus of the shaft | ||

| The Poisson’s ratio of the shaft | Mass unbalance |

Appendix A

References

- Ganesan, S.; Padmanabhan, C. Modelling of parametric excitation of a flexible coupling–rotor system due to misalignment. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2011, 225, 2907–2918. [Google Scholar] [CrossRef]

- Gupta, T.C.; Gupta, K. Modeling of Flexible Coupling to Connect Misaligned Flexible Rotors Supported on Ball Bearings. Am. Soc. Mech. Eng. 2014, 7A, 1–14. [Google Scholar]

- Patel, T.H.; Darpe, A.K. Experimental investigations on vibration response of misaligned rotors. Mech. Syst. Signal Process. 2009, 23, 2236–2252. [Google Scholar] [CrossRef]

- Shentu, L.; Zhao, Q.; Yang, P. Nonlinear dynamics analysis of parallel unaligned laminated coupling system. Chin. J. Agric. Mech. Chem. 2016, 37, 130–135. [Google Scholar]

- Cui, Y.; Liu, Z.; Leng, S.; Han, W.; Huang, W. Study on nonlinear stability for a 200 MW turbo-generator rotor-bearing system. J. Mech. Eng. 2005, 41, 170–175. [Google Scholar] [CrossRef]

- Desouki, M.; Sassi, S.; Renno, J.; Gowid, S.A. Dynamic response of a rotating assembly under the coupled effects of misalignment and imbalance. Shock Vib. 2020, 2020, 8819676. [Google Scholar] [CrossRef]

- Lees, A. Misalignment in rigidly coupled rotors. J. Sound Vib. 2007, 305, 261–271. [Google Scholar] [CrossRef]

- Pennacchi, P.; Vania, A.; Chatterton, S. Nonlinear effects caused by coupling misalignment in rotors equipped with journal bearings. Mech. Syst. Signal Process. 2012, 30, 306–322. [Google Scholar] [CrossRef]

- Huang, Z.; Zhou, J.; Yang, M.; Zhang, Y. Vibration characteristics of a hydraulic generator unit rotor system with parallel misalignment and rub-impact. Arch. Appl. Mech. 2011, 81, 829–838. [Google Scholar] [CrossRef]

- Fu, X.Q.; Jia, W.T.; Xu, H.; Song, S.L. Imbalance-misalignment-rubbing coupling faults in hydraulic turbine vibration. Optik 2016, 127, 3708–3712. [Google Scholar] [CrossRef]

- Khorrami, H.; Rakheja, S.; Sedaghati, R. Vibration behavior of a two-crack shaft in a rotor disc-bearing system. Mech. Mach. Theory 2017, 113, 67–84. [Google Scholar] [CrossRef]

- Guo, D.; Peng, Z.K. Vibration analysis of a cracked rotor using Hilbert–Huang transform. Mech. Syst. Signal Process. 2007, 21, 3030–3041. [Google Scholar] [CrossRef]

- Li, Z.; Li, Y.; Wang, D.; Peng, Z.; Wang, H. Dynamic characteristics of rotor system with a slant crack based on fractional damping. Chin. J. Mech. Eng. 2021, 34, 27. [Google Scholar] [CrossRef]

- Prabhakar, S.; Sekhar, A.S.; Mohanty, A.R. Crack versus Coupling Misalignment in a Transient Rotor System. J. Sound Vib. 2002, 256, 773–786. [Google Scholar] [CrossRef]

- Zhenyong, L.; Shun, Z.; Huizheng, C.; Wang, X.; Han, J.; Wang, C. Nonlinear response analysis for a dual-rotor system supported by ball bearing. Int. J. Non-Linear Mech. 2021, 128, 103627. [Google Scholar]

- Sinou, J.; Lees, A.W. A non-linear study of a cracked rotor. Eur. J. Mech. A Solids 2007, 26, 152–170. [Google Scholar] [CrossRef]

- Sinou, J. Detection of cracks in rotor based on the 2× and 3× super-harmonic frequency components and the crack–unbalance interactions. Commun. Nonlinear Sci. Numer. Simul. 2008, 13, 2024–2040. [Google Scholar] [CrossRef]

- Zhonghe, H.; Jianping, T.; Chuliang, L.; Lu, X. Dynamic characteristics of a segmented supercritical driveline with flexible couplings and dry friction dampers. Symmetry 2021, 13, 281. [Google Scholar] [CrossRef]

- Yinxin, Y.; KangKang, D.; Tianyu, Z.; Li, K. Nonlinear dynamics of flexible diaphragm coupling’s rotor system during maneuvering flight. J. Strain Anal. Eng. Des. 2023, 58, 236–254. [Google Scholar]

- Mutra, R.R.; Reddy, M.D.; Rao, B.K. Crack fault diagnosis in rotor bearing system by transient and steady state time domain analysis. Measurement 2025, 241, 115667. [Google Scholar] [CrossRef]

- Lalanne, M.; Ferraris, G. Rotor Dynamics Prediction in Engineering, 2nd ed.; John Wiley and Sons: New York, NY, USA, 1998. [Google Scholar]

- Zhang, C.; Cao, P.; Zhu, R.; Chen, W.; Wang, D. Dynamic modeling and analysis of the spline joint-flexible coupling-rotor system with misalignment. J. Sound Vib. 2023, 554, 117696. [Google Scholar] [CrossRef]

| Parameters | Value |

|---|---|

| The density of the shaft, | 7850 kg/m3 |

| The elastic modulus of the shaft, | 200 Gpa |

| The Poisson’s ratio of the shaft, | 0.3 |

| Bearing angular stiffness, | 7.1 × 104 N/m |

| Bearing radial stiffness, | 1.15 × 108 N·m/rad |

| Bearing angular damping, | 800 N·s/rad |

| Bearing radial damping, | 1000 N·s/m |

| Mass unbalance, | 1 × 10−4 kgm |

| Order | Test Natural Frequency | Theoretical Natural Frequency | Relative Error |

|---|---|---|---|

| 1 | 177 Hz | 183 Hz | 4.5% |

| 2 | 201 Hz | 201 Hz | 5.5% |

| 3 | 278 Hz | 282 Hz | 1.1% |

| 4 | 344 Hz | 328 Hz | 5.4% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liao, M.; Zhang, L.; Nong, S.; Zhang, C.; Zhu, R.; Chen, W. Study on the Effect of Cracks in Diaphragm Couplings on the Dynamic Characteristics of Shaft System. Machines 2024, 12, 741. https://doi.org/10.3390/machines12100741

Liao M, Zhang L, Nong S, Zhang C, Zhu R, Chen W. Study on the Effect of Cracks in Diaphragm Couplings on the Dynamic Characteristics of Shaft System. Machines. 2024; 12(10):741. https://doi.org/10.3390/machines12100741

Chicago/Turabian StyleLiao, Meijun, Lan Zhang, Su Nong, Chao Zhang, Rupeng Zhu, and Weifang Chen. 2024. "Study on the Effect of Cracks in Diaphragm Couplings on the Dynamic Characteristics of Shaft System" Machines 12, no. 10: 741. https://doi.org/10.3390/machines12100741

APA StyleLiao, M., Zhang, L., Nong, S., Zhang, C., Zhu, R., & Chen, W. (2024). Study on the Effect of Cracks in Diaphragm Couplings on the Dynamic Characteristics of Shaft System. Machines, 12(10), 741. https://doi.org/10.3390/machines12100741