Fault Diagnosis of Train Wheelset Bearing Roadside Acoustics Considering Sparse Operation with GA-RBF

Abstract

1. Introduction

2. Theoretical Foundation

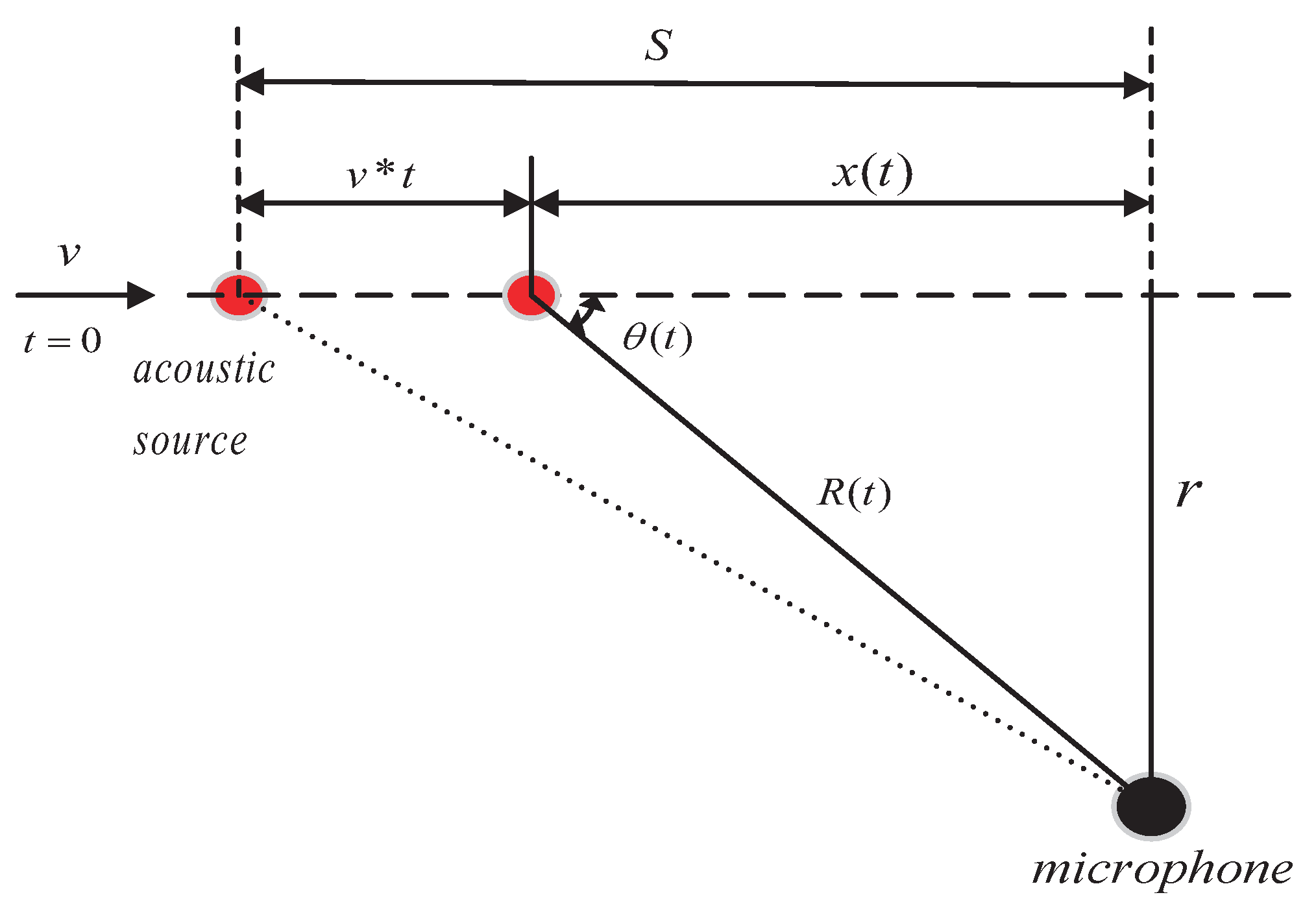

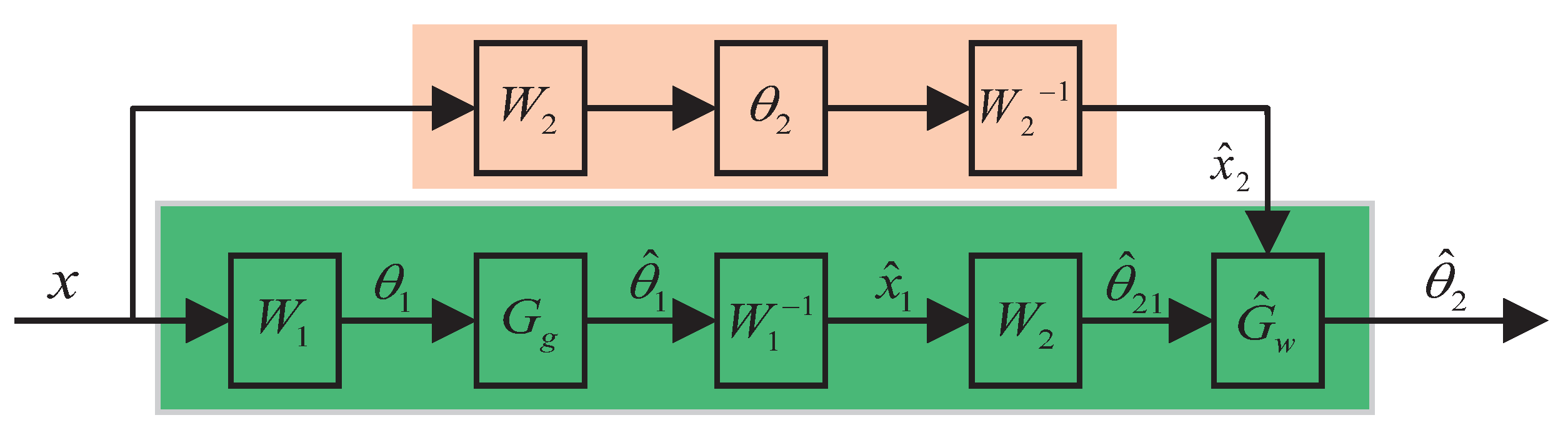

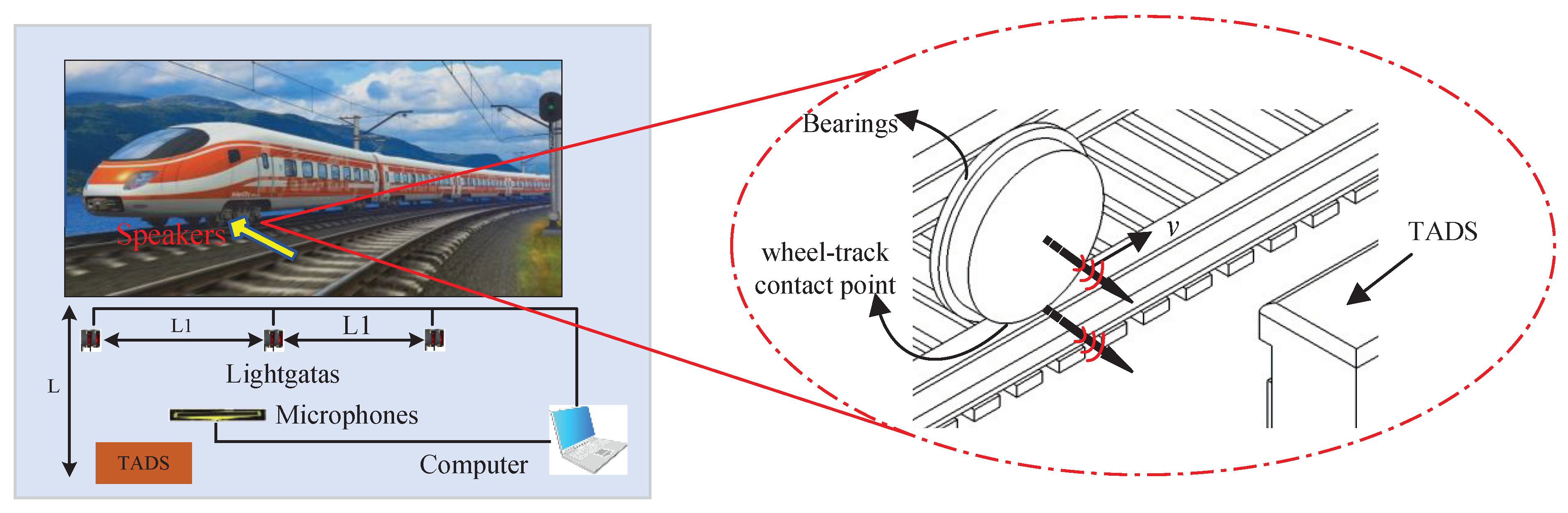

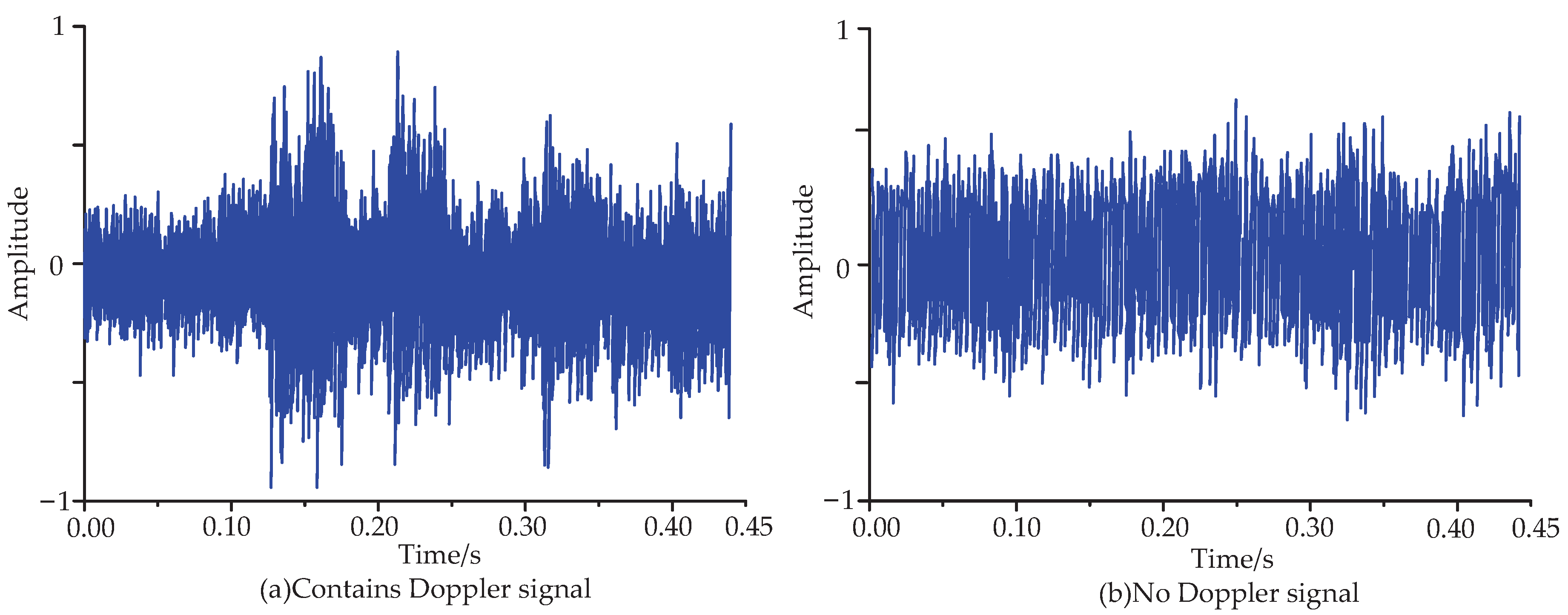

2.1. Doppler Aberration Correction

- The equation for the interpolated fitted time series is derived from the acoustic model motion relationship;

- The time series is determined from the resampling frequency;

- The interpolated fitted time series is calculated from the formula determined in the first two steps;

- Amplitude reduction is conducted on the Doppler distortion signals;

- The amplitude-reduced signal from step 4 is interpolated using the fitted time series from step 3 for signal correction.

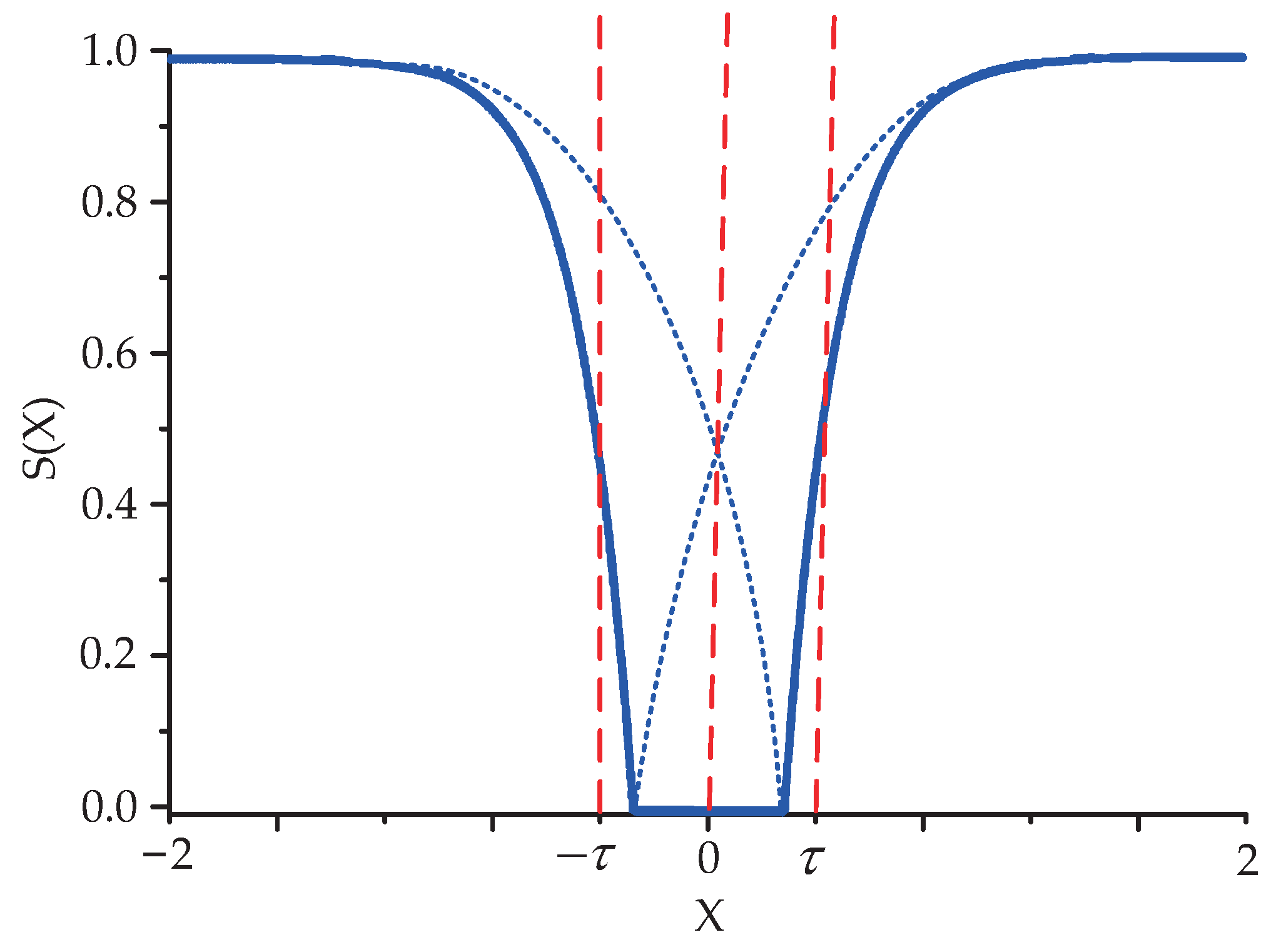

2.2. Sparse Representation Method

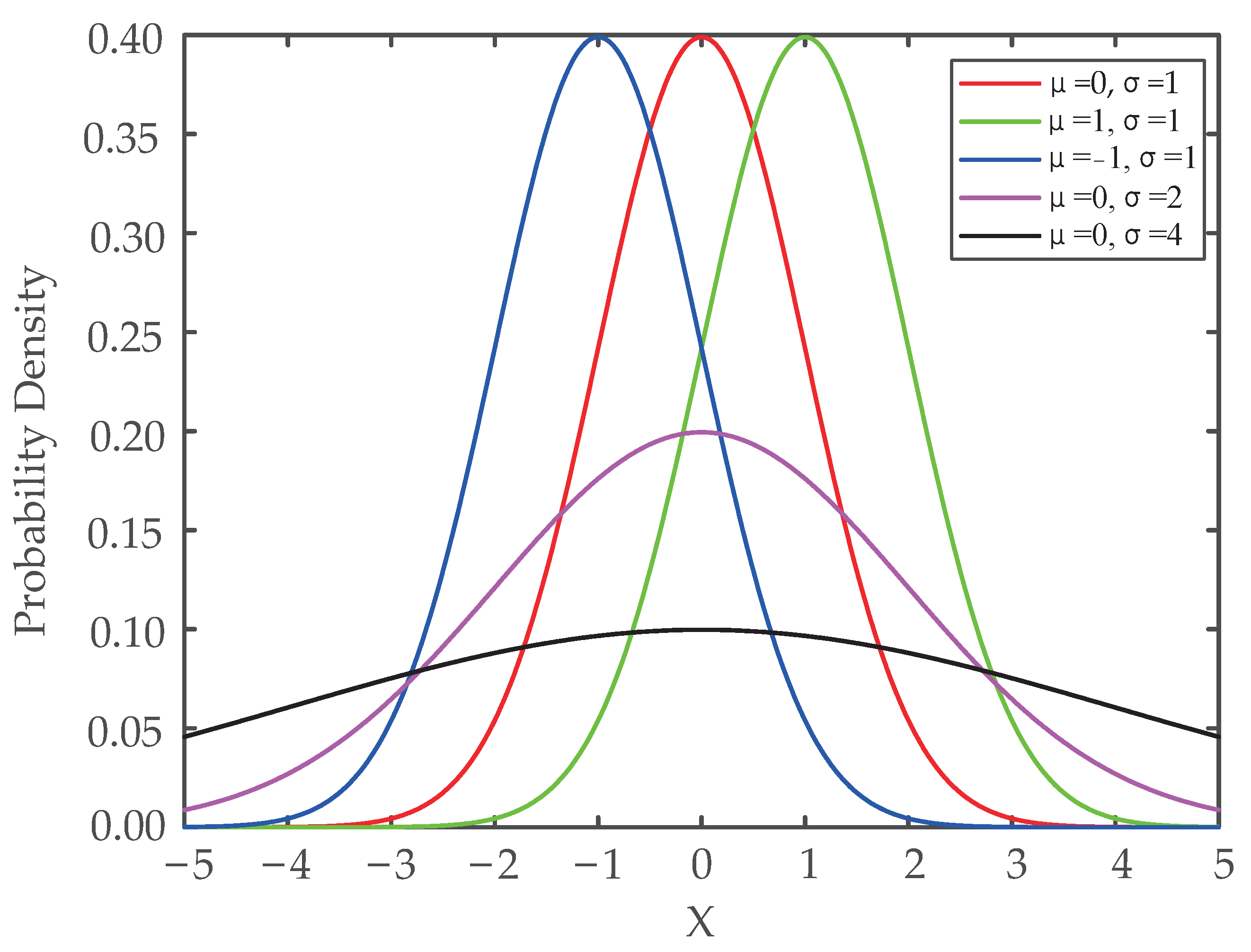

2.3. RBF Neural Network

3. Sparse Operation Processing

3.1. Wavelet Domain Sparse Representation

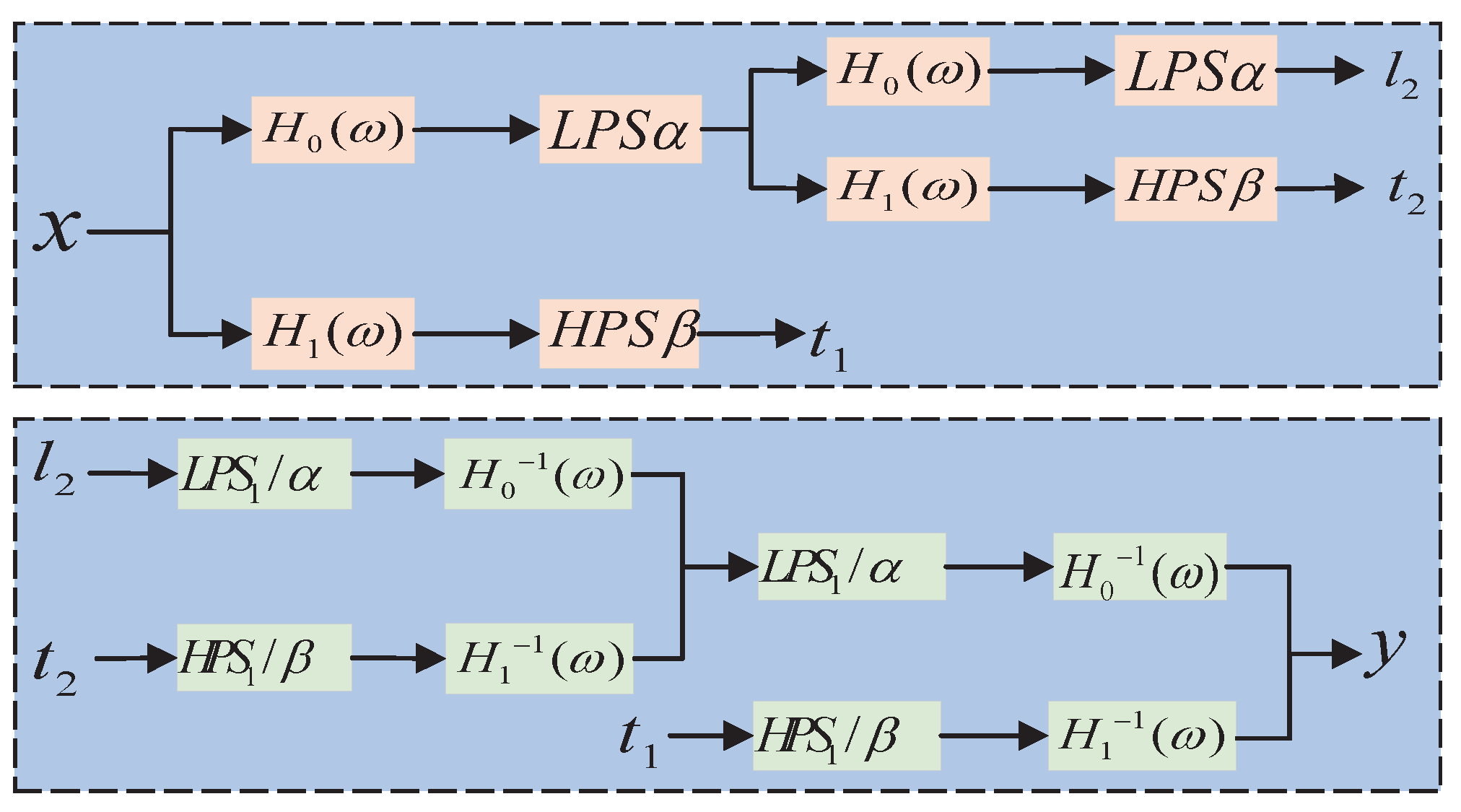

3.2. Resonant Sparse Signal Decomposition (RSSD)

3.3. Analog Signal Processing

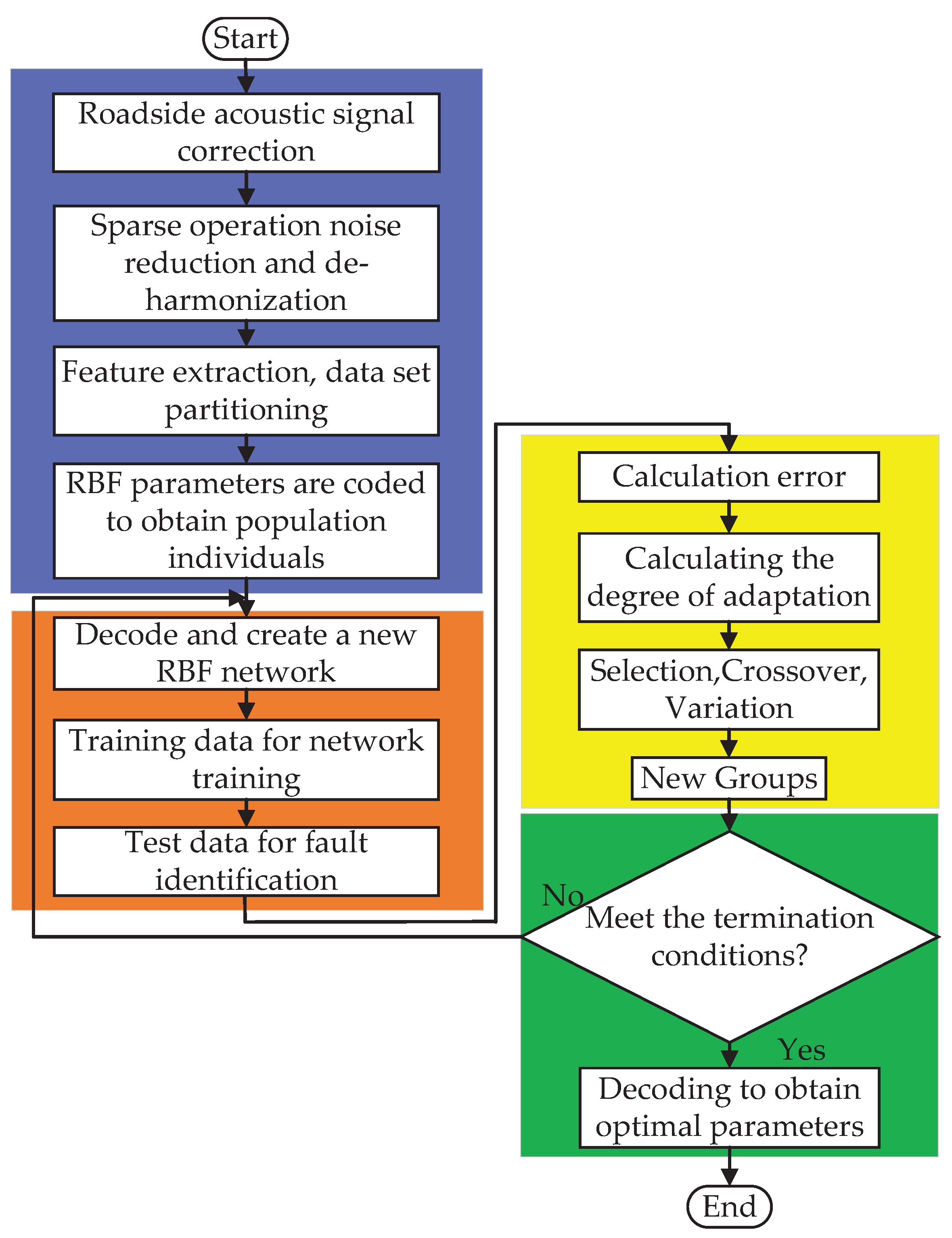

4. GA-RBFNN Diagnostic Model

5. Experimental Signal Analysis

5.1. Experimental Conditions

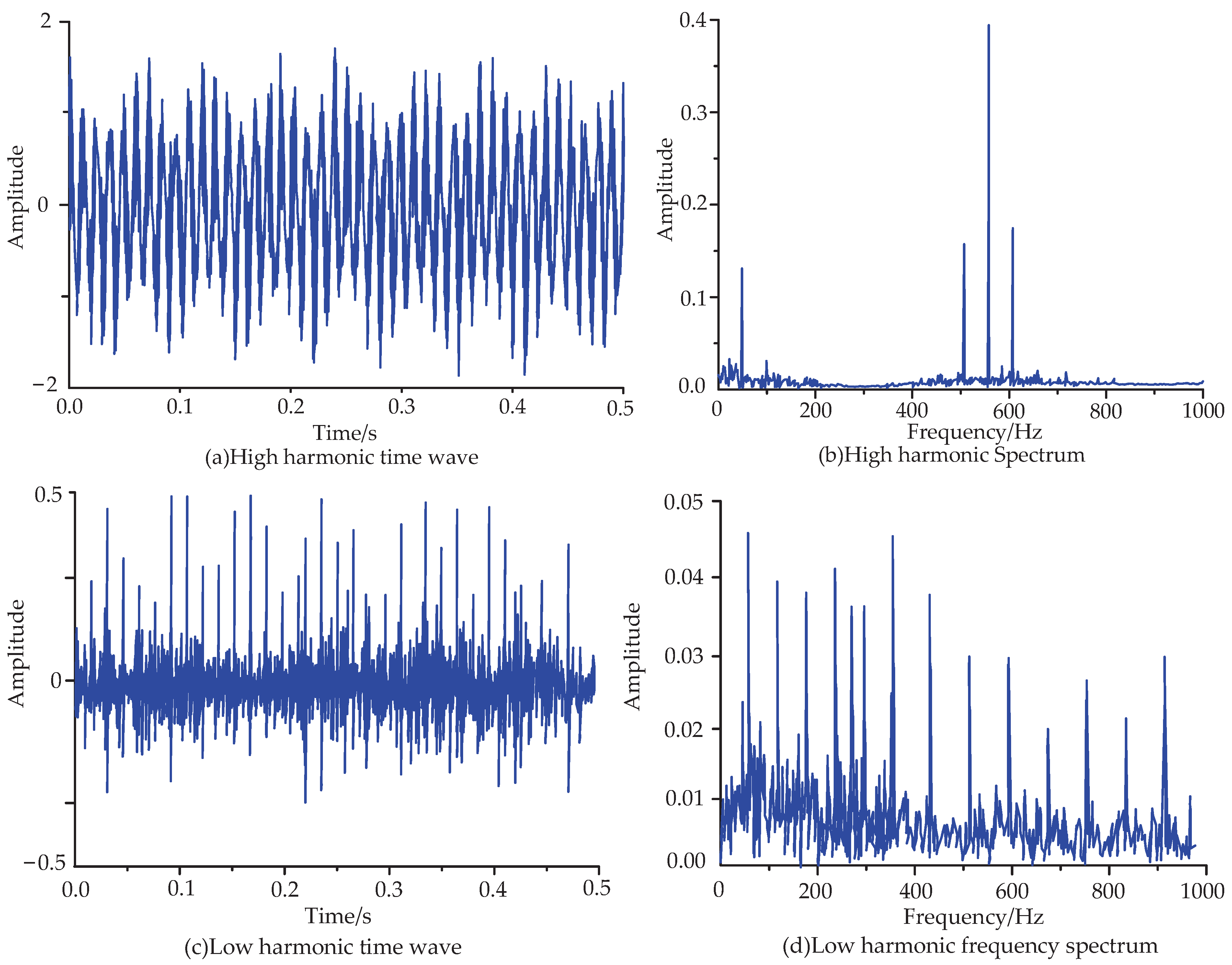

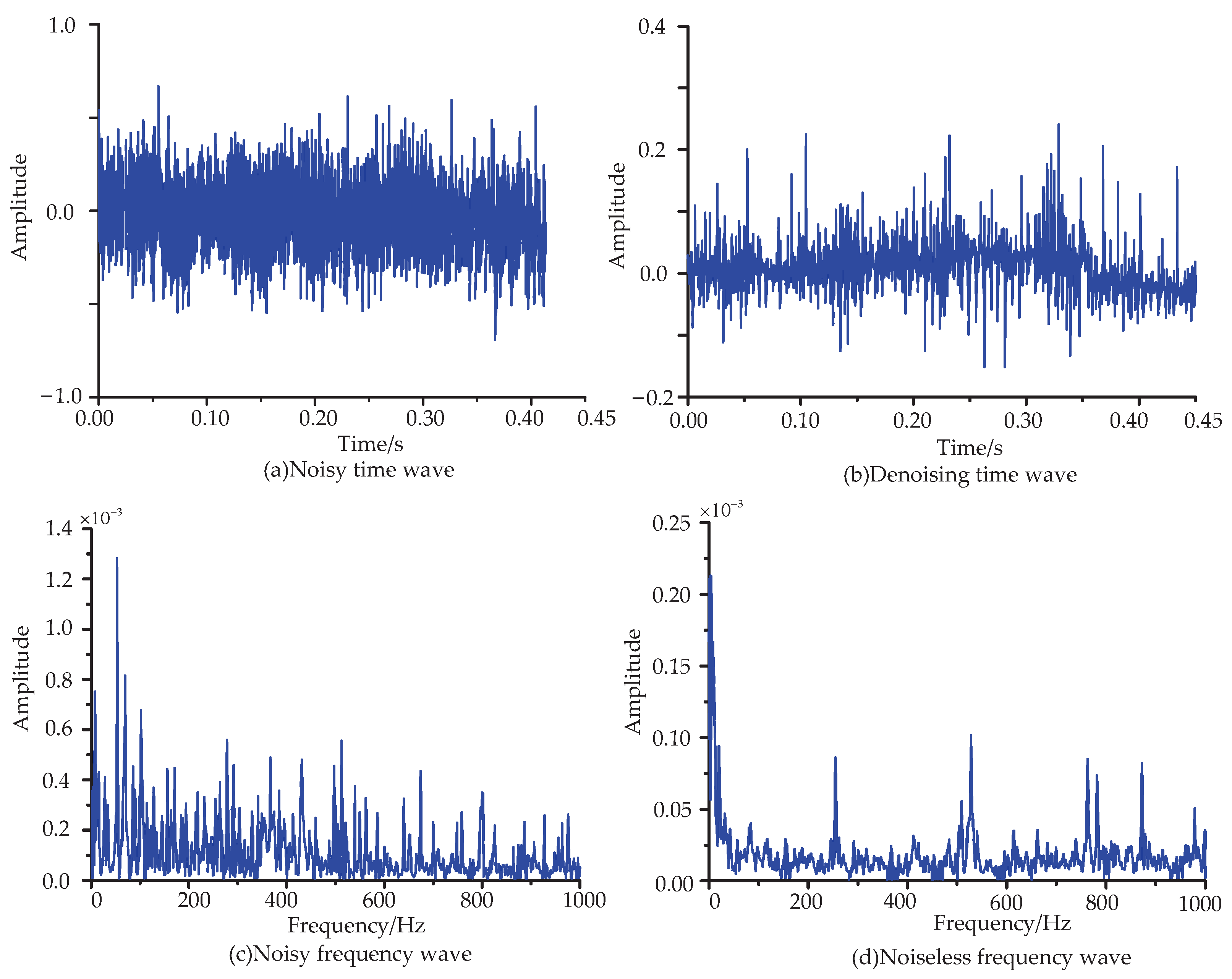

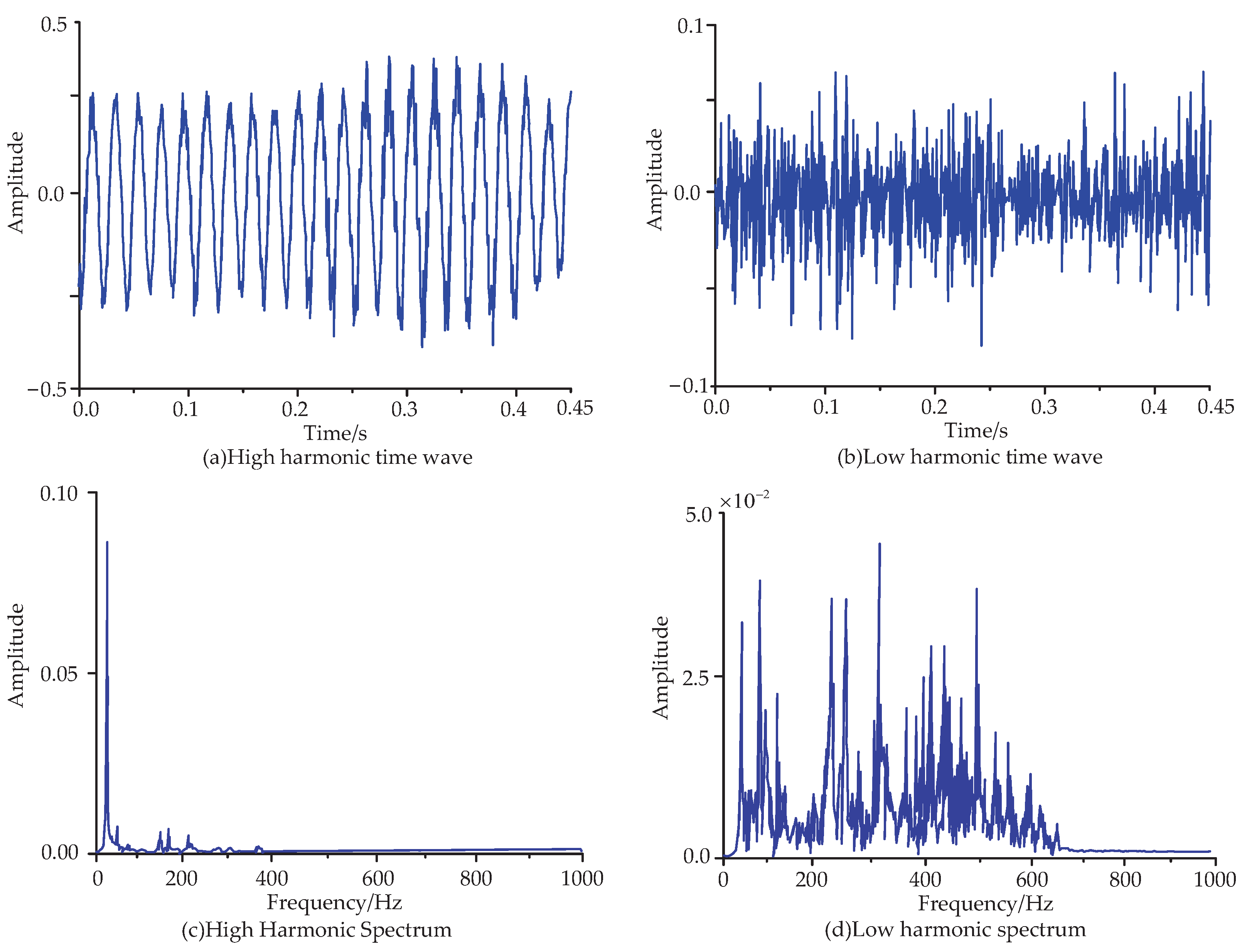

5.2. Roadside Acoustic Signal Sparse Operation

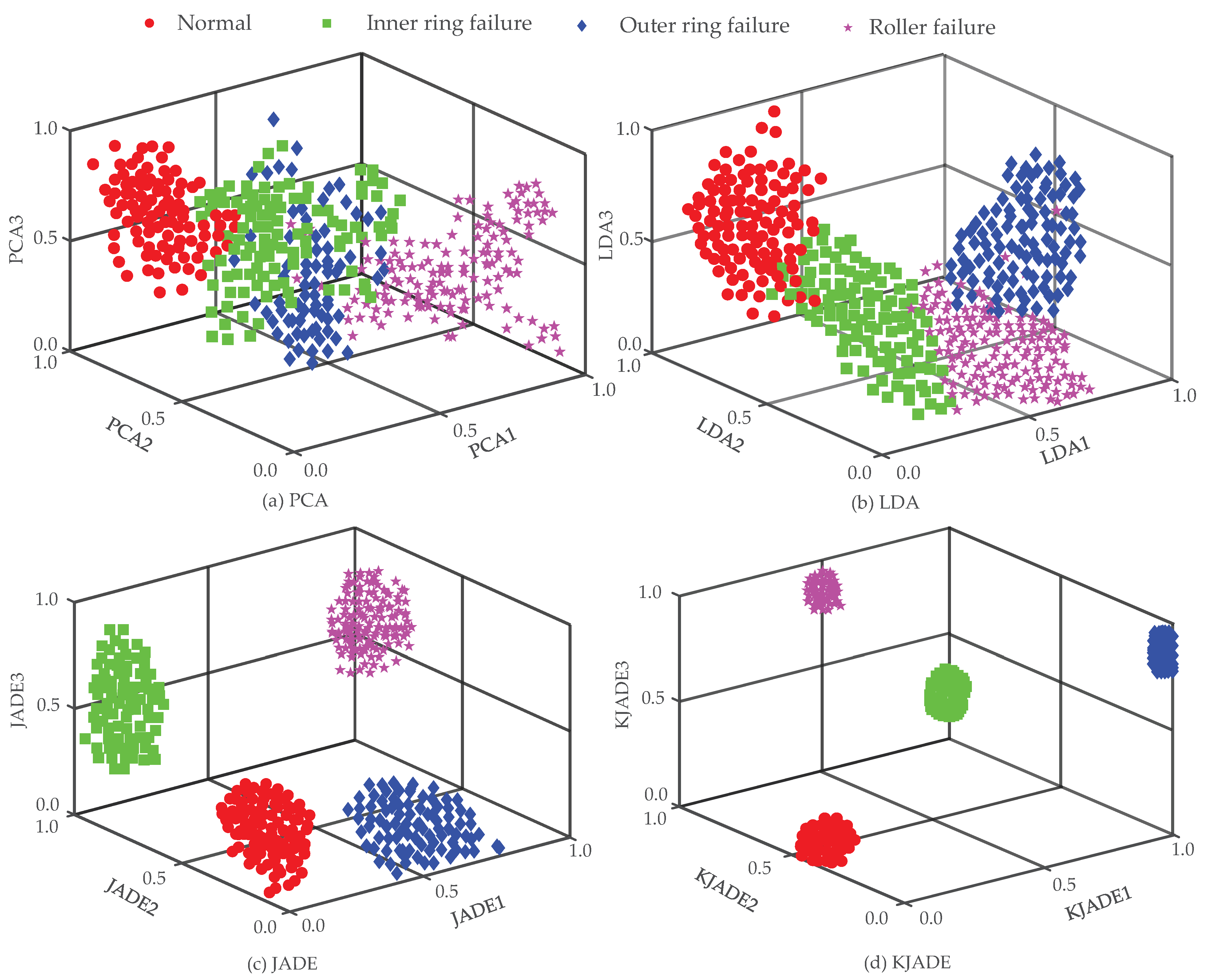

5.3. Feature Extraction

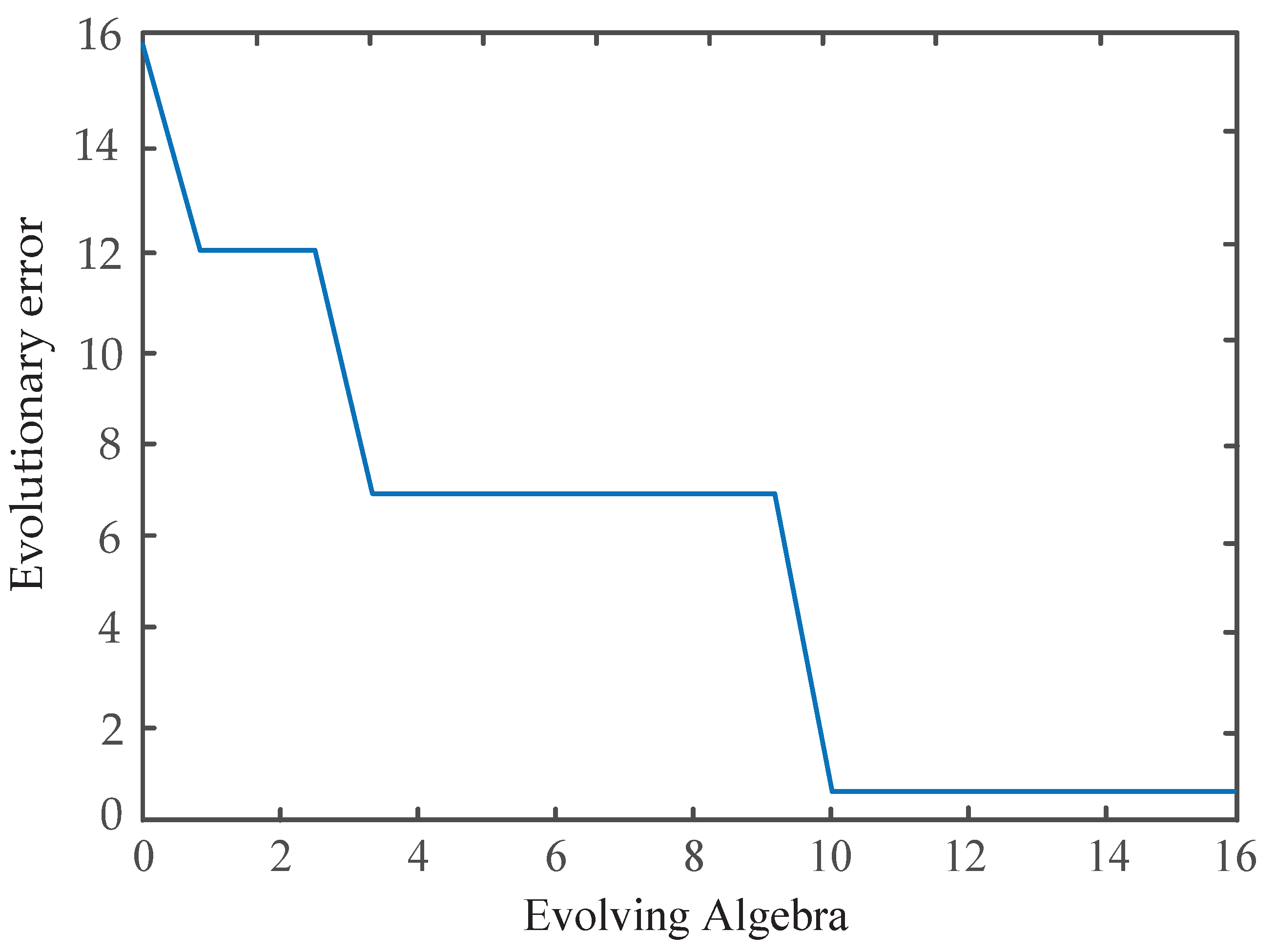

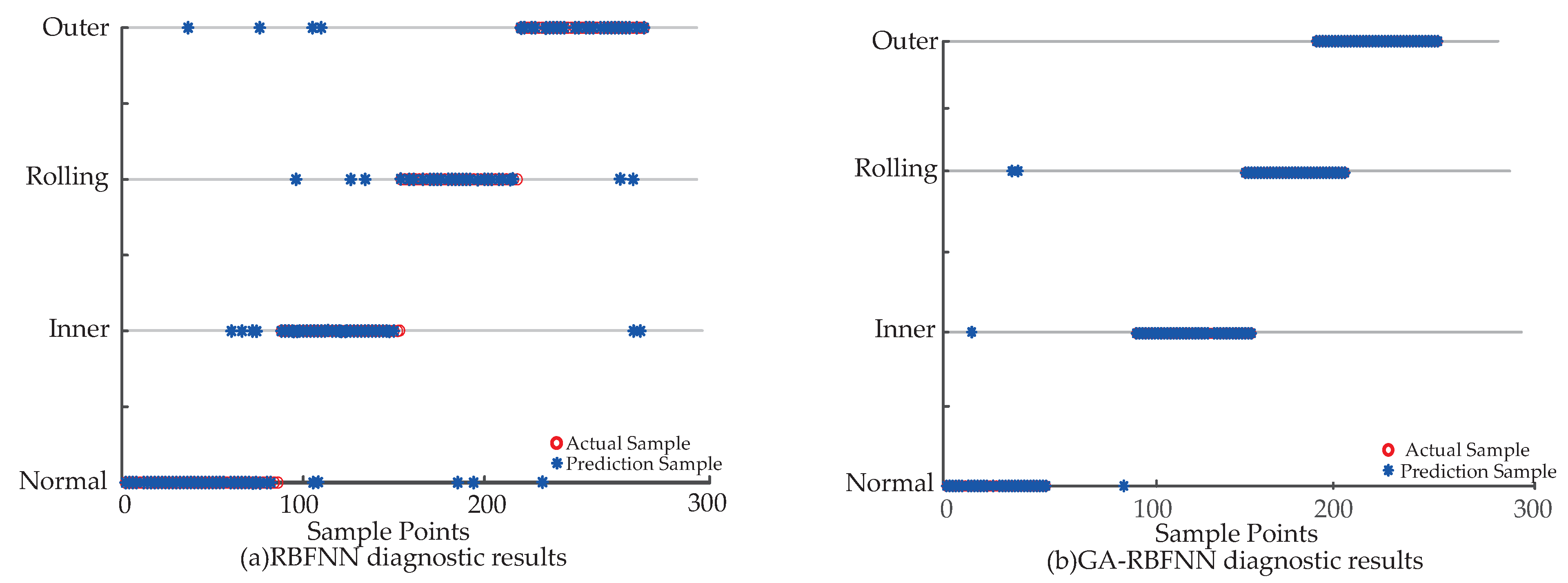

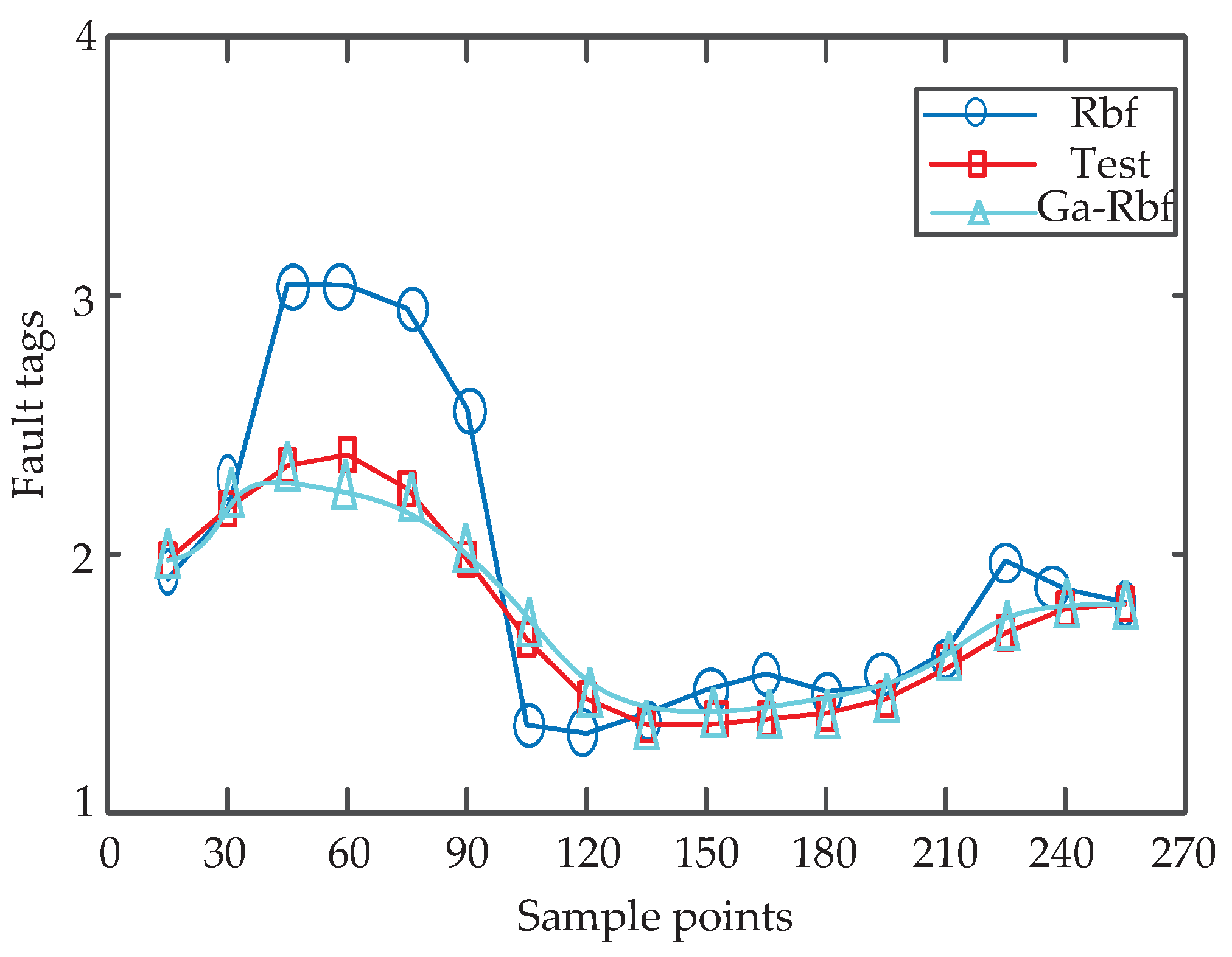

5.4. Analysis of the GA-RBFNN Diagnostic Results

6. Conclusions

- For the processing of the background noise and interference harmonics in roadside acoustic signals, this paper creatively utilizes the sparse representation method in the wavelet domain to completely remove the powerful reverberation noise in the roadside acoustic signal, while using the RSSD method to remove the interference harmonics, laying the foundation to be able to smoothly extract the features and the fault diagnosis of acoustic signals.

- For the premise of low-efficiency fault identification in roadside acoustic signals and less-researched methods, a GA-RBFNN model of roadside acoustic fault feature diagnosis was proposed. Using the characteristics of GA’s adaptability to large data processing and robustness, and RBNN’s simple structure and fast processing speed, the simulation experiments of TADS fault acoustic data in a railroad section site prove that, after a variety of time–frequency domain fusion clustering acoustic feature vector inputs, the model can achieve fast and accurate identification of the fault type, with a recognition accuracy as high as 97.22%. The superiority of the method is comprehensively demonstrated when comparing the diagnosis rate and accuracy with those of other diagnosis models.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cai, Q.H.; Peng, H.M. Bearings for railroad vehicles. Foreign Locomot. Roll. Stock. Technol. 2010, 2, 17–20. [Google Scholar]

- Qiao, Z.C.; Liu, Y.Q.; Liao, Y.Y. Application of improved MOMEDA method based on Teager energy operator in railroad wheelset bearing fault diagnosis. Bearing 2020, 4, 43–50. [Google Scholar]

- Cai, Y.; Lin, J.H.; Zhang, W.H.; Ding, J.M. Faults diagnostics of railway axle bearings based on IMF’s confidence index algorithm for ensemble EMD. Sensors 2015, 15, 10991–11011. [Google Scholar] [CrossRef] [PubMed]

- Li, X.M.; He, D.Q.; Tan, W.J.; Chen, E.H. Research on rolling bearing fault diagnosis of trains based on EEMD and RBFNN. J. Railw. Sci. Eng. 2017, 14, 1056–1062. [Google Scholar]

- Deng, F.Y.; Ding, H.; Lv, H.Y.; Hao, R.J.; Liu, Y.Q. A lightweight neural network-based fault diagnosis method for high-speed railway wheelset bearings. Chin. J. Eng. 2021, 43, 1482–1490. [Google Scholar]

- Miao, M.Q.; Sun, Y.H.; Yu, J.B. Deep sparse representation network for feature learning of vibration signals and its application in gearbox fault diagnosis. Knowl.-Based Syst. 2022, 240, 108116. [Google Scholar] [CrossRef]

- Li, H.K.; Wei, Y.Q.; Yang, G. A review of research on trackside acoustic fault diagnosis of rolling stock bearings. Bearing 2022, 11, 1–7. [Google Scholar]

- Zhang, S.B.; Zhang, H.B.; OuYang, K.S.; He, Q.B.; Kong, F.R. Doppler correction method for train bearing fault acoustic signals based on time-frequency amplitude matching. J. Vib. Shock 2016, 35, 101–106. [Google Scholar]

- Liu, F.; He, Q.B.; Shen, C.Q.; Hu, F.; Zhang, A.; Kong, F.R. A time-domain correction method for Doppler distortion signals of moving sound sources. Sheng Hsueh Hsueh Pao Acta Acust. 2014, 39, 185–190. [Google Scholar]

- Wu, Q.; He, Q.B.; Kong, F.R. Doppler distortion correction of roadside acoustic signals. J. Data Acquis. Process. 2014, 29, 309–315. [Google Scholar]

- Yuan, Z.Z.; Kong, F.R.; Zhang, H.B.; Hu, F.; Liu, F.; Zhu, P.L. A Doppler distortion acoustic signal correction method based on instantaneous frequency. Mach. Electron. 2013, 12, 36–39. [Google Scholar]

- Wu, Q.; Kong, F.R.; He, Q.B.; Liu, Y.B. Doppler distortion correction of acoustic signals based on resampling technique. J. Process. 2012, 28, 1308–1313. [Google Scholar]

- Ding, X.X.; Li, Y.L.; Xiao, J.W.; He, Q.B.; Yang, X.Q.; Shao, Y.M. Parametric Doppler correction analysis for wayside acoustic bearing fault diagnosis. Mech. Syst. Signal Process. 2022, 166, 108375. [Google Scholar] [CrossRef]

- Bi, C.X.; Li, Y.C.; Zhang, Y.B.; Zhang, X.Z.; Xu, L. Signal reconstruction of moving sound sources with a fixed microphone array. Mech. Syst. Signal Process. 2019, 118, 277–289. [Google Scholar] [CrossRef]

- Amarnath, M.; Krishna, I.P. Empirical mode decomposition of acoustic signals for diagnosis of faults in gears and rolling element bearings. IET Sci. Meas. Technol. 2012, 6, 279–287. [Google Scholar] [CrossRef]

- Zhang, J.Q.; Chen, Y.G.; Li, N.; Zhai, J.Y.; Han, Q.K.; Hou, Z.X. A Denoising Method of Micro-Turbine Acoustic Pressure Signal Based on CEEMDAN and Improved Variable Step-Size NLMS Algorithm. Machines 2022, 10, 444. [Google Scholar] [CrossRef]

- Lv, X. Advances in high performance acoustic filter technology. Digit. Design 2021, 4, 10. [Google Scholar]

- Liu, F.; Zhao, X.H.; Zhu, Z.H.; Zhai, Z.P.; Liu, Y.B. Dual-microphone active noise cancellation paved with Doppler assimilation for TADS. Mech. Syst. Signal Process. 2023, 184, 109727. [Google Scholar] [CrossRef]

- Xiao, D.Y.; Qin, C.J.; Yu, H.G.; Huang, Y.X.; Liu, C.L.; Zhang, J.W. Unsupervised machine fault diagnosis for noisy domain adaptation using marginal denoising autoencoder based on acoustic signals. Measurement 2021, 176, 109186. [Google Scholar] [CrossRef]

- Sun, Y.; Yuan, M.; Feng, H.H. A statistical model-based improved spectral noise reduction algorithm. Acoust. Tech. 2013, 32, 115–118. [Google Scholar]

- Niall, H.; Rickard, S. Comparing measures of sparsity. IEEE Trans. Inform. Theory 2009, 55, 4723–4741. [Google Scholar]

- Martin, G.; Kutyniok, G.; März, M. ℓ1-analysis minimization and generalized (co-) sparsity: When does recovery succeed? Appl. Comput. Harm. Anal. 2021, 52, 82–140. [Google Scholar]

- Zhang, Z.R.; Wang, J.R.; Li, S.M.; Han, B.K.; Jiang, X.X. Fast nonlinear blind deconvolution for rotating machinery fault diagnosis. Mech. Syst. Signal Process. 2023, 187, 109918. [Google Scholar] [CrossRef]

- Hou, Y.C.; Zhou, C.Q.; Tian, C.M.; Wang, D.; He, W.T.; Huang, W.J.; Wu, P.; Wu, D.Q. Acoustic feature enhancement in rolling bearing fault diagnosis using sparsity-oriented multipoint optimal minimum entropy deconvolution adjusted method. Appl. Acoust. 2022, 201, 109105. [Google Scholar] [CrossRef]

- Yu, G.Y.; Ge, Y.; Ma, B. Feature enhancement method of rolling bearing acoustic signal based on RLS-RSSD. Measurement 2022, 192, 110883. [Google Scholar] [CrossRef]

- Zhang, D.C.; Xie, M.; Hamadache, M.; Entezami, M.; Stewart, E. An adaptive graph morlet wavelet transform for railway wayside acoustic detection. J. Sound Vib. 2022, 529, 116965. [Google Scholar] [CrossRef]

- Glowacz, A. Acoustic fault analysis of three commutator motors. Mech. Syst. Signal Process. 2019, 133, 106226. [Google Scholar] [CrossRef]

- Glowacz, A.; Glowacz, W.; Glowacz, Z.; Kozik, J. Early fault diagnosis of bearing and stator faults of the single-phase induction motor using acoustic signals. Measurement 2018, 113, 1–9. [Google Scholar] [CrossRef]

- Lu, W.B.; Jiang, W.K.; Wu, H.J.; Hou, J.J. A fault diagnosis scheme of rolling element bearing based on near-field acoustic holography and gray level co-occurrence matrix. J. Sound Vib. 2012, 331, 3663–3774. [Google Scholar] [CrossRef]

- Lu, W.B.; Jiang, W.K.; Yuan, G.Q.; Li, Y. A gearbox fault diagnosis scheme based on near-field acoustic holography and spatial distribution features of sound field. J. Sound Vib. 2013, 332, 2593–2610. [Google Scholar] [CrossRef]

- Zhang, D.C.; Entezami, M.; Stewart, E.; Roberts, C.; Yu, D.J. Intelligent acoustic-based fault diagnosis of roller bearings using a deep graph convolutional network. Measurement 2020, 156, 107585. [Google Scholar] [CrossRef]

- Yang, J.M.; Zhou, W.J.; Song, T.X. Audio-based fault diagnosis for belt conveyor rollers. Neurocomputing 2020, 397, 447–456. [Google Scholar] [CrossRef]

- Wang, J.J.; Yang, S.P.; Liu, Y.Q.; Gui, L.W. Deep Subdomain Transfer Learning with Spatial Attention ConvLSTM Network for Fault Diagnosis of Wheelset Bearing in High-Speed Trains. Machines 2023, 11, 304. [Google Scholar] [CrossRef]

- Li, S.B.; Yao, Y.; Gui, G.; Li, X.; Hu, J.J. Gear fault diagnosis based on CNN and multi-channel acoustic signal. China Meas. Test. 2019, 45, 1–5. [Google Scholar]

- Yu, L.J.; Wang, R.; Liu, F.K. Acoustic Fault Diagnosis of Rolling Bearings Based on Blending Model Fusion of Multiple Convolutional Neural Network. Fail. Anal. Prev. 2021, 16, 238–245. [Google Scholar]

- Hasan, M.J.; Islam, M.M.M.; Kim, J.M. Acoustic spectral imaging and transfer learning for reliable bearing fault diagnosis under variable speed conditions. Measurement 2019, 138, 620–631. [Google Scholar] [CrossRef]

- Liu, Y.J.; Chen, B.F.; Ding, L.P. Fault diagnosis method of micro-motor based on acoustic features. March. Build. Automa 2022, 51, 190–194. [Google Scholar]

- Yao, Y.; Gui, G.; Yang, S.X.; Zhang, S. A Recursive Denoising Learning for Gear Fault Diagnosis Based on Acoustic Signal in Real Industrial Noise Condition. IEEE Trans. Instrum. Meas. 2021, 70, 1–15. [Google Scholar] [CrossRef]

- Ji, S.S.; Han, B.K.; Zhang, Z.Z.; Wang, J.R.; Lu, B.; Yang, J.W.; Jiang, X.X. Parallel sparse filtering for intelligent fault diagnosis using acoustic signal processing. Neurocomputing 2021, 462, 466–477. [Google Scholar] [CrossRef]

- Ntalampiras, S. One-shot learning for acoustic diagnosis of industrial machines. Expert Syst. Appl. 2021, 178, 114984. [Google Scholar] [CrossRef]

- Xu, T.; Wang, H.J. Rolling bearing fault diagnosis based on VMD transient energy and GA-RBF. J. Railw. Sci. Eng. 2020, 2, 74–78. [Google Scholar]

- Klinaku, S. The Doppler effect is the same for both optics and acoustics. Optik 2021, 244, 167565. [Google Scholar] [CrossRef]

- Fan, H.; Guo, P.; Wang, F.m. Research development of sparse representation of non-stationary signals. Comput. Eng. Appl. 2012, 1, 278–284. [Google Scholar]

- Liu, Y.; Zhang, L.Y. Implementation of BP and RBF neural networks and their performance comparison. Electr. Measur Tech. 2007, 30, 77–80. [Google Scholar]

- Qiu, J.D.; Jiang, Z.Y. Research on railroad freight volume forecasting based on NLAPSO-RBF. Comput. Eng. Appl. 2013, 49, 253–257. [Google Scholar]

- Zhao, Z.p.; Ceng, Y.G.; Chen, X.F. Sparse representation of signal based on wavelet-domain Wiener filter. J. Appl Sci. 2012, 30, 595–600. [Google Scholar]

- Zhang, D.C.; Entezami, M.; Stewart, E.; Roberts, C.; Yu, D.J. Adaptive fault feature extraction from wayside acoustic signals from train bearings. J. Sound Vib. 2018, 425, 221–238. [Google Scholar] [CrossRef]

- Žvokelj, M.; Zupan, S.; Prebil, I. EEMD-based multiscale ICA method for slewing bearing fault detection and diagnosis. J. Sound Vib. 2016, 370, 394–423. [Google Scholar] [CrossRef]

- Ni, Q.; Ji, J.C.; Ke, F.; Halkon, E. A fault information-guided variational mode decomposition (FIVMD) method for rolling element bearings diagnosis. Mech. Syst. Signal Process. 2022, 164, 108216. [Google Scholar] [CrossRef]

- Long, L.; He, B.; Liu, F.; Liu, Y.B.; Li, G.H.; Lu, S.L. Research on the acoustic diagnosis method of train bearing trackside based on KJADE. J. Vib. Mear. Diagn. 2020, 40, 781–787+828–829. [Google Scholar]

| Rotation frequency | Phases | Amplitude | Phases | Amplitude | |

| 50 | 90 | 10 | 180 | 5 | |

| Rotation frequency | Periodicity | Amplitude | Damping ratio | Phases | |

| 4250 | 1/85 | (0,1) | 0.03 | 270 | |

| Change frequency | Time | Damping ratio | Amplitude | \ | |

| ∼U (2000, 6000) | ∼U (0,5) | 0.025 | ∼U ( −2,2) | \ |

| No. | Fault Location | Fault Point Size (Length × Width × Depth) |

|---|---|---|

| 1 | Normal | / |

| 2 | Inner ring failure | 50 mm × 40 mm × 3 mm |

| 3 | Outer ring failure | 50 mm × 50 mm × 3 mm |

| 4 | Roller failure | 10 mm × 10 mm × 2 mm |

| Speed | Temperature | Humidity | ||

|---|---|---|---|---|

| Drive in | Drive out | |||

| First | 95 km/h | 96 km/h | 55 °C | 40% |

| Second | 97 km/h | 96 km/h | 61 °C | 47% |

| Third | 95 km/h | 96 km/h | 53 °C | 53% |

| Inner Diameter | Outer Diameter | Section Circle Diameter | Rolling Body Diameter | Roller Numbers |

|---|---|---|---|---|

| 170 mm | 310 mm | 277 mm | 58 mm | 14 |

| Time Domain | Frequency Domain |

|---|---|

| Model | Time/s | Error | Recognition Accuracy | |

|---|---|---|---|---|

| Training | Testing | |||

| GA-RBFNN | 497.93 | 13.73 | 9.00 | 97.22% |

| SVM | 531.60 | 16.79 | 136.00 | 54.60% |

| BPNN | 612.69 | 21.66 | 67.00 | 77.49% |

| GA-SVM | 454.00 | 11.82 | 87.00 | 71.32% |

| GA-BPNN | 511.61 | 16.47 | 11.00 | 96.50% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qiu, J.; Ran, J.; Tang, M.; Yu, F.; Zhang, Q. Fault Diagnosis of Train Wheelset Bearing Roadside Acoustics Considering Sparse Operation with GA-RBF. Machines 2023, 11, 765. https://doi.org/10.3390/machines11070765

Qiu J, Ran J, Tang M, Yu F, Zhang Q. Fault Diagnosis of Train Wheelset Bearing Roadside Acoustics Considering Sparse Operation with GA-RBF. Machines. 2023; 11(7):765. https://doi.org/10.3390/machines11070765

Chicago/Turabian StyleQiu, Jiandong, Jiajia Ran, Minan Tang, Fan Yu, and Qiang Zhang. 2023. "Fault Diagnosis of Train Wheelset Bearing Roadside Acoustics Considering Sparse Operation with GA-RBF" Machines 11, no. 7: 765. https://doi.org/10.3390/machines11070765

APA StyleQiu, J., Ran, J., Tang, M., Yu, F., & Zhang, Q. (2023). Fault Diagnosis of Train Wheelset Bearing Roadside Acoustics Considering Sparse Operation with GA-RBF. Machines, 11(7), 765. https://doi.org/10.3390/machines11070765