Green Machining of NFRP Material

Abstract

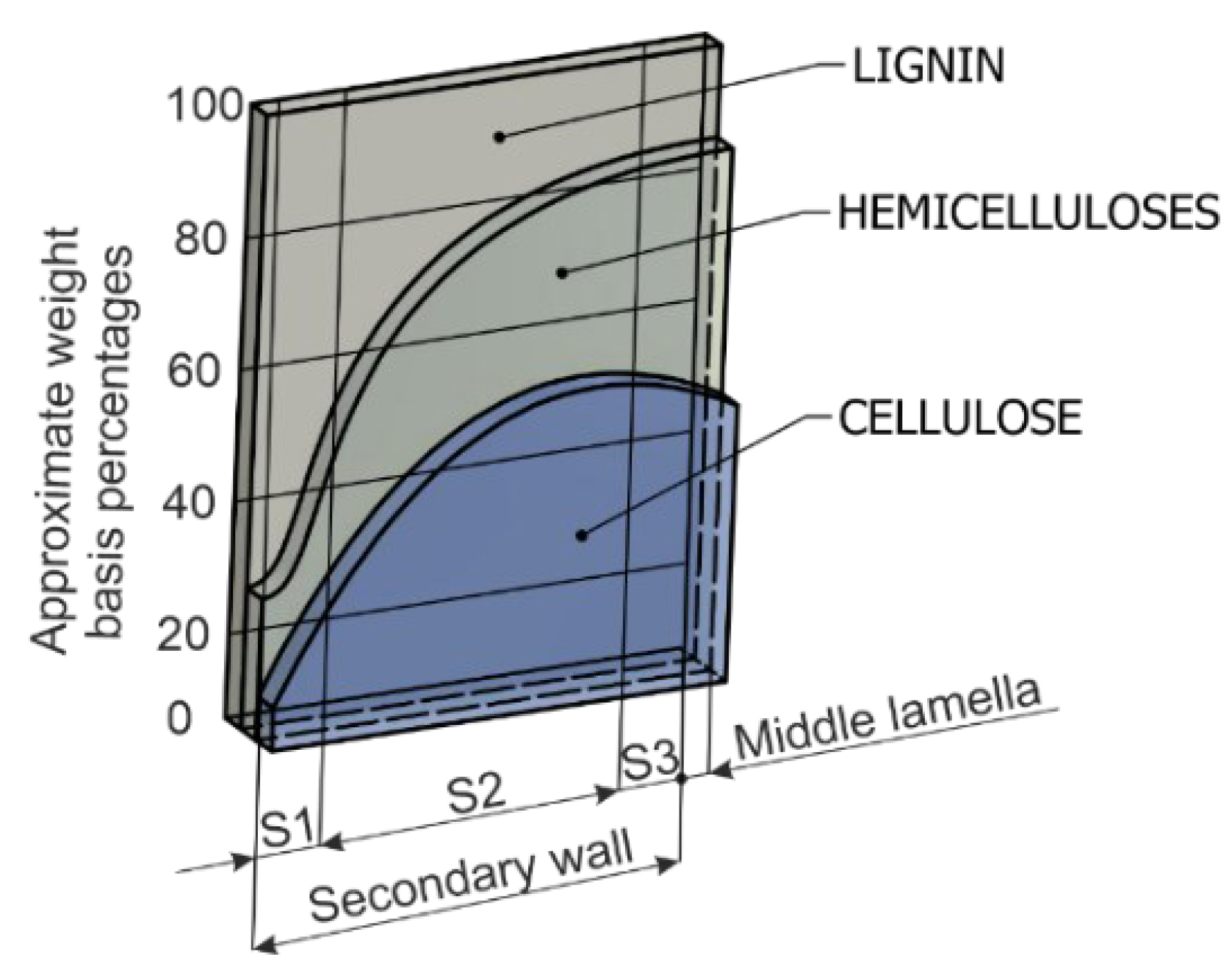

1. Introduction

- Type of applied polymer matrix;

- The percentage of organic reinforcement (type of wood or plant fibres), the morphology of particles, their physical properties and moisture content;

- Percentage of individual additives;

- Technology and conditions of production process;

- The origin of raw components (possibility of applied plastic recycled, materials, geographical location, etc.);

- Interaction between components.

- Extrusion—for linear profile (technology applied in up to 97% of manufactured WPC products);

- Injection moulding—for 3D parts of regular or irregular shapes, application in mass production, suitable for polymers with low molecular weight. The production process is fundamentally like the production of injected plastics, (disadvantages of the technology: high procurement costs, imperfect compounding of the components of WPC composite material/advantages: minimal waste, short cycle time, observe required dimensional tolerances);

- Compression moulding—cost-effective production of complex parts (disadvantages of technology: complex mould design, the ratio of applied resin and fibre is difficult to control, advantages: no need of qualified staff);

- Calandering—special way of “rolling” in floor production.

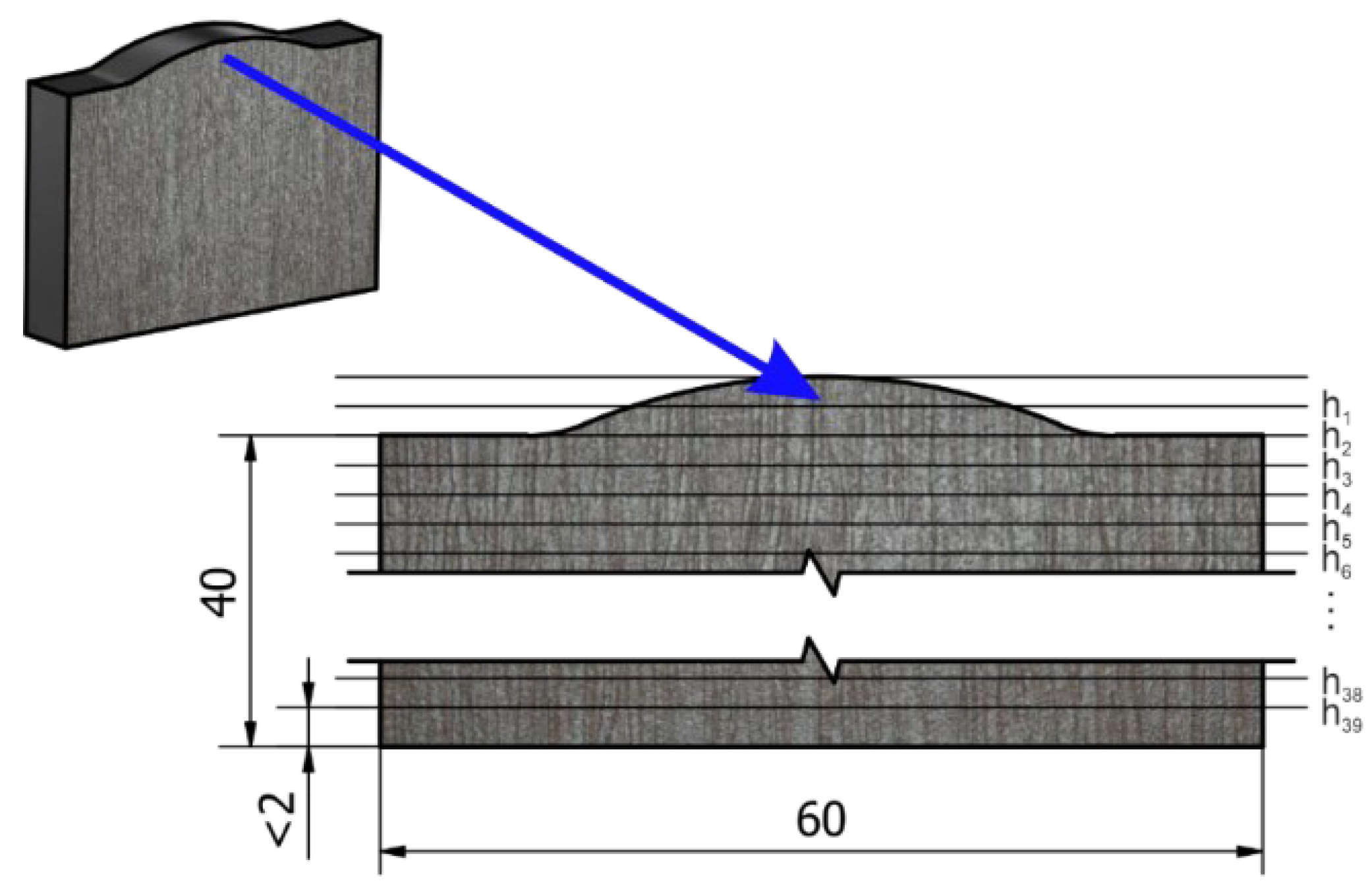

2. Materials and Methods

- Abrasive mass flow rate ma [g·min−1];

- Traverse speed of cutting head vf [mm·min−1].

| Parameters | Value | Unit |

|---|---|---|

| Water pressure p | 400 | MPa |

| Water orifice diameter d0 | 0.3 | mm |

| Focusing tube diameter df | 0.9 | mm |

| Standoff distance | 4 | mm |

| Abrasive mass flow rate ma | 150–300 | g·min−1 |

| Traverse speed vf | Variable 2 | mm·min−1 |

| Abrasive material | - | Australian Garnet |

| Abrasive particle | 80 | MESH |

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hodzic, A.; Shanks, R. Natural Fibre Composites: Materials, Processes and Properties, 1st ed.; Woodhead Publishing: Sawston, UK, 2014; pp. 4–27. [Google Scholar]

- Taiwo, E.M.; Yahya, K.; Haron, Z. Potential of using natural fiber for building acoustic absorber: A review. J. Phys. Conf. Ser. 2019, 1262, 012017. [Google Scholar] [CrossRef]

- Hernandes Diat, D.; Villar-Ribera, R.; Haron, Z.; Julián, F.; Hernández-Abad, V.; Delgado-Aguilar, M. Impact Properties and Water Uptake Behavior of Old Newspaper Recycled Fibers-Reinforced Polypropylene Composites. Materials 2020, 13, 1079. [Google Scholar] [CrossRef] [PubMed]

- Campilho, R.D.S.G. Natural Fiber Composites; Taylor & Francis Group: Boca Raton, FL, USA, 2016; p. 117. [Google Scholar]

- Available online: https://www.baxcompany.com (accessed on 15 April 2023).

- Kumar, S.P.; Sharma, S. Effect of Alkali Treatment on Jute Fibre Composites. Ph.D. Thesis, National Institute of Technology, Rourkela, India, 2007. [Google Scholar]

- Lu, N.; Swan, J.R.; Ferguson, I. Composition, structure, and mechanical properties of hemp fiber reinforced composite with recycled high-density polyethylene matrix. J. Compos. Mater. 2012, 46, 1915–1924. [Google Scholar] [CrossRef]

- Shahria, S. Fabrication and property evaluation of hemp-flax fiber reinforced hybrid composite. Cellulose 2019, 7, 17–23. [Google Scholar] [CrossRef]

- Venkateshwaran, N.; Elayapemural, A. Mechanial and water absorption properties of woven jute/banana hybrid composites. Fibers Polym. 2012, 13, 907–914. [Google Scholar] [CrossRef]

- Klyosov, A. Foreword-Overview: Wood-Plastic Composites. In Wood-Plastic Composites, 1st ed.; John Wiley and Sons: Hoboken, NJ, USA, 2007; pp. 42–45. [Google Scholar]

- Chow, P.; Nakayama, F.S.; Youngquist, J.A.; Muehl, J.H.; Krzysik, A.M. Durability of wood/plastic composites made from Parthenium species. In Thirty-Third Annual Meeting of the International Research Group on Wood Preservation; IRG Secretariat: Stockholm, Sweden, 2002; pp. 2–11. [Google Scholar]

- Stark, N.M.; Rowlands, R.E. Effect of wood fiber characteristics on mechanical properties of wood/polypropylene composites. Wood Fiber Sci. 2003, 54, 167–174. [Google Scholar]

- Murayama, K.; Ueno, T.; Kobori, H.; Kojima, Y.; Suzuki, S.; Aoki, K.; Ito, H.; Ogoe, S.; Okamoto, M. Mechanical properties of wood/plastic composites formed using wood flour produced by wet ball-milling under various milling times and drying methods. J. Wood Sci. 2019, 65, 1–10. [Google Scholar] [CrossRef]

- Schwarzkopf, M.J.; Burnard, N.D. Wood-plastic composites-Performance and environmental impacts. Eviron. Impacts Tradit. Innov. For.-Based Bioprod. 2016, 19–43. [Google Scholar]

- Mordor Intelligence. Available online: https://www.mordorintelligence.com/industry-reports/europe-wood-plastic-composite-market (accessed on 5 May 2023).

- ENKEV. Available online: https://enkev.com/natural-products/cocolok (accessed on 6 May 2023).

- Niu, S.; Chang, Q.; He, W.; Zhao, D.; Xie, Y.; Deng, X. Mechanically Strong, Hydrostable, and Biodegradable Strach-Cellulose Composite Materials for Tableware. Starke 2022, 74, 2200019. [Google Scholar] [CrossRef]

- Chegdani, F.; El Mansori, M. New Multiscale Approach for Machining Analysis of Natural Fiber Reinforced Bio-Composites. J. Manuf. Sci. Eng. 2019, 141, 011004. [Google Scholar] [CrossRef]

- Zajac, J.; Hutyrova, Z.; Orlovsky, I. Investigation of surface roughness after turning of one kind of the bio-materials with thermoplastic matrix and natural fibers. Adv. Mater. Res. 2014, 941, 275–279. [Google Scholar] [CrossRef]

- Caggiano, A. Machining of fibre reinforced plastic composite materials. Materials 2018, 11, 442. [Google Scholar] [CrossRef] [PubMed]

- Babu, D.; Babu, K.S.; Gowd, B. Drilling uni-directional fiber-reinforced plastics manufactured by hand lay-up influence of fibers. JMST 2012, 1, 1–12. [Google Scholar] [CrossRef]

- Babu, D.; Babu, K.S.; Gowd, B. Determination of delamination and tensile strength of drilled natural fiber reinforced composites. Appl. Mech. Mater. 2014, 592, 134. [Google Scholar] [CrossRef]

- Abilash, N.; Sivapragash, M. Optimizing the delamination failure in bamboo fiber reinforced polyester composite. Jksues 2016, 28, 92–102. [Google Scholar] [CrossRef]

- Gupta, J. Abrasive Water Jet Machining of Polymer Composites. In Abrasive Water Jet Machining of Engineering Materials, 1st ed.; Springer: Cham, Switzerland, 2020; pp. 33–49. [Google Scholar]

- Vigneshwaran, S.; Uthayakumar, M.; Arumugaprabu, V. Abrasive water jet machining of fiber-reinforced composite materials. J. Reif. Plast Compos. 2018, 37, 230–237. [Google Scholar] [CrossRef]

- Masoud, F.; Sapuan, S.M.; Mohd Ariffin, M.K.A.; Nukman, Y.; Bayraktar, E. Cutting process of natural fiber-reinforced polymer composites. Polymers 2020, 12, 1332. [Google Scholar] [CrossRef]

- Cuha, D.; Hatala, M. Effect of a modified impact angle of an ultrasonically generated pulsating water jet on aluminium alloy erosion using upward and downward stairs trajectory. Wear 2022, 500, 204369. [Google Scholar] [CrossRef]

- Boopathi, S.; Thillaivanan, A.; Azeem, M.A.; Shanmugam, P.; Pramod, V.R. Experimental investigation on abrasive water jet machining of neem wood plastic composite. Funct. Compos. Struct. 2022, 4, 025001. [Google Scholar] [CrossRef]

- Jagadish, S.B.; Amitava, R. Prediction of surface roughness quality of green abrasive water jet machining: A soft computing approach. J. Intell. Manuf. 2015, 30, 2965–2979. [Google Scholar] [CrossRef]

- Hutyrova, Z. Turning of wood plastic composite by water jet and abrasive water jet. Int. J. Adv. Manuf. Technol. 2015, 84, 1615–1623. [Google Scholar] [CrossRef]

- ISO 21920-2:2021; Geometrical Product Specifications (GPS)—Surface Texture: Profile—Part 2: Terms, Definitions and Surface Texture Parameters. ISO: Geneva, Switzerland, 2021.

- ISO 16610-21:2011; Geometrical Product Specifications (GPS)—Filtration-Part 21: Linear Profile Filters: Gaussian Filters. ISO: Genava, Switzerland, 2011.

- SN 214001:2010; Contact-Free Cutting—Water Jet Cutting—Geometrical Specification and Quality. Swiss Standards-Vereiningung: Zurich, Switzerland, 2013.

- Hloch, S.; Valicek, H. Vplv Faktorov na Topografiu Povrchov Vytvorených Hydroabrazívnym Delením, 1st ed.; SH: Presov, Slovakia, 2008; pp. 66–99. [Google Scholar]

| Characteristics | Natural Fibres (NF) | Synthetic Fibres (e.g., Glass Fibre) |

|---|---|---|

| Cost | ↓ Low | ↑ higher compared to NF |

| Density | ↓ Low | ↑ double compared NF |

| Recyclability | ✓ Yes | ✗ No |

| Renewability | ✓ Yes | ✗ No |

| CO2 neutrality | ✓ Yes | ✗ No |

| Abrasion to machines | ✗ No | ✓ Yes |

| Health risk associated with production | ✗ No | ✓ Yes |

| Disposal | Biodegradable | Non-biodegradable |

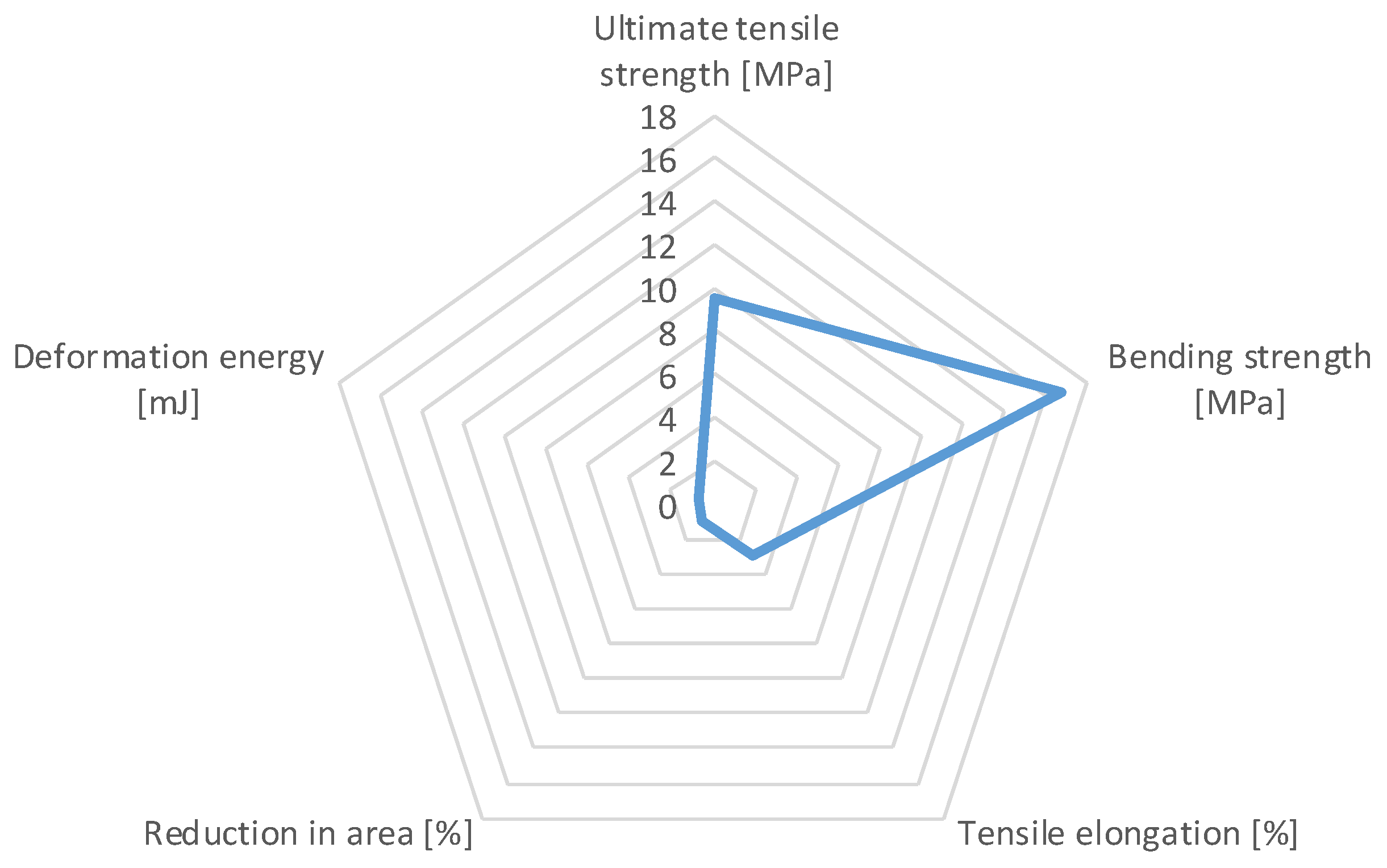

| Fibre Type 1 | Tensile Strength [MPa] | Tensibility [%] | Young’s Modulus [GPa] | Study |

|---|---|---|---|---|

| Jute fibre | 393–773 | 1.5–1.8 | 26.5 | Kumar and Sharma, 2007 [6] |

| Hemp fibre | 550–900 | 2.0–3.0 | 70 | Lu et al., 2012 [7] |

| Flax fibre | 800–1500 | 2.7–3.2 | 60–80 | Shashria, 2019 [8] |

| Banana fibre | 540–900 | - | 34.8 | Narayanan and Elazaperumal, 2012 [9] |

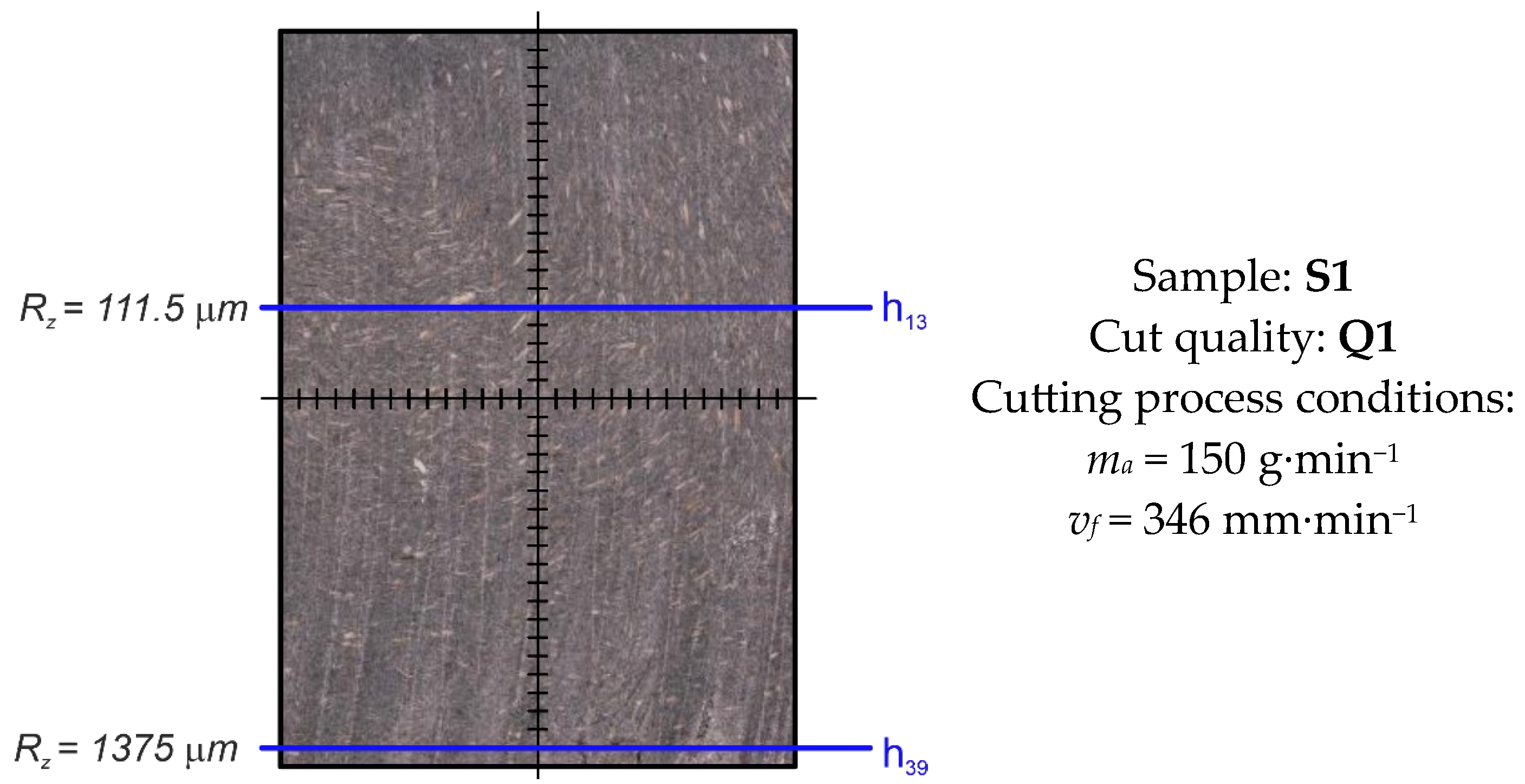

| Sample No. | Abrasive Mass Flow Rate ma [g·min−1] | Traverse Speed vf [mm·min−1] |

|---|---|---|

| S1 | 150 | 346 |

| S2 | 200 | 387 |

| S3 | 250 | 423 |

| S4 | 300 | 455 |

| . | Q5 |

| . |  | |

| . | ||

| Q1 | . | |

| S17 | 150 | 80 |

| S18 | 200 | 90 |

| S19 | 250 | 100 |

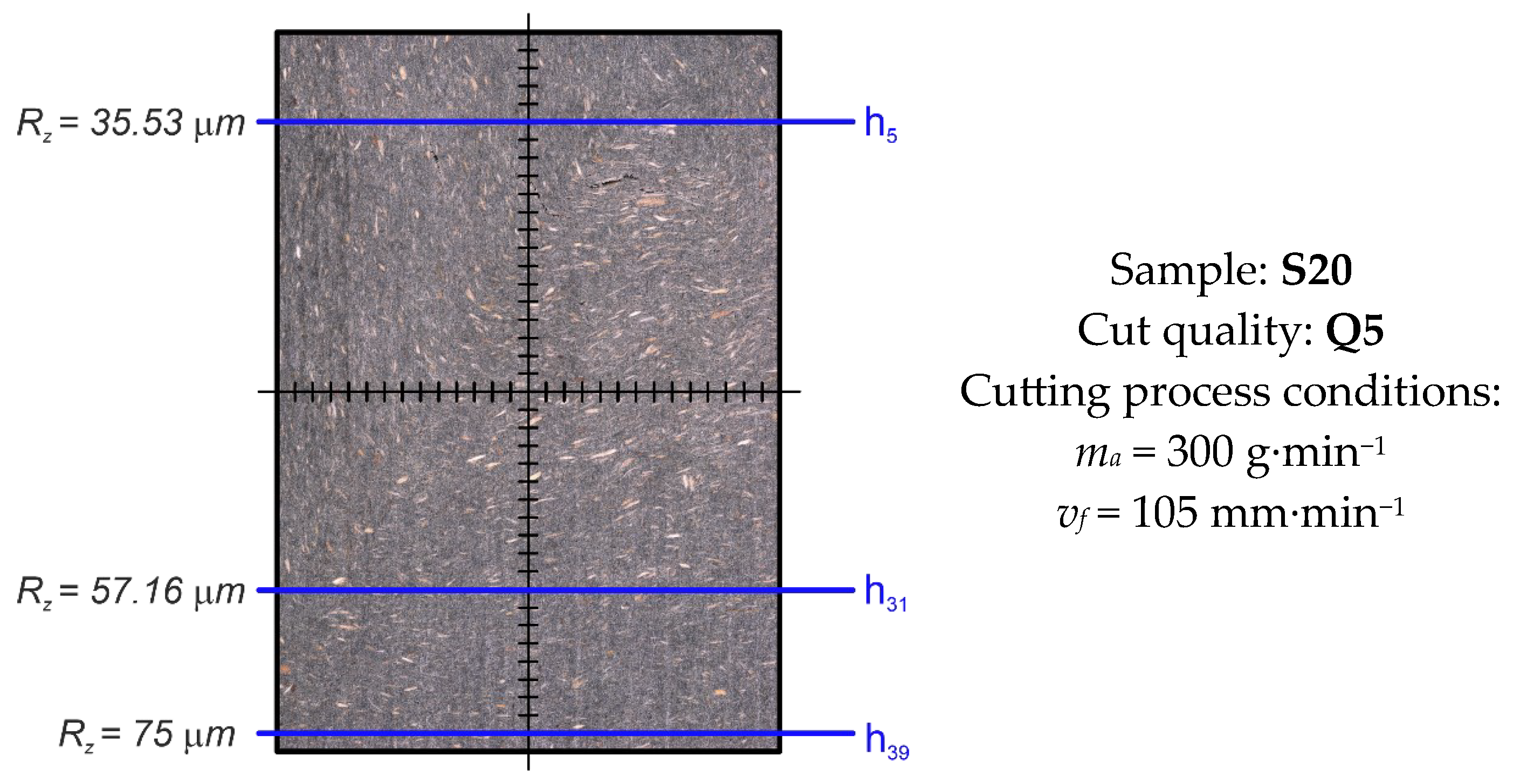

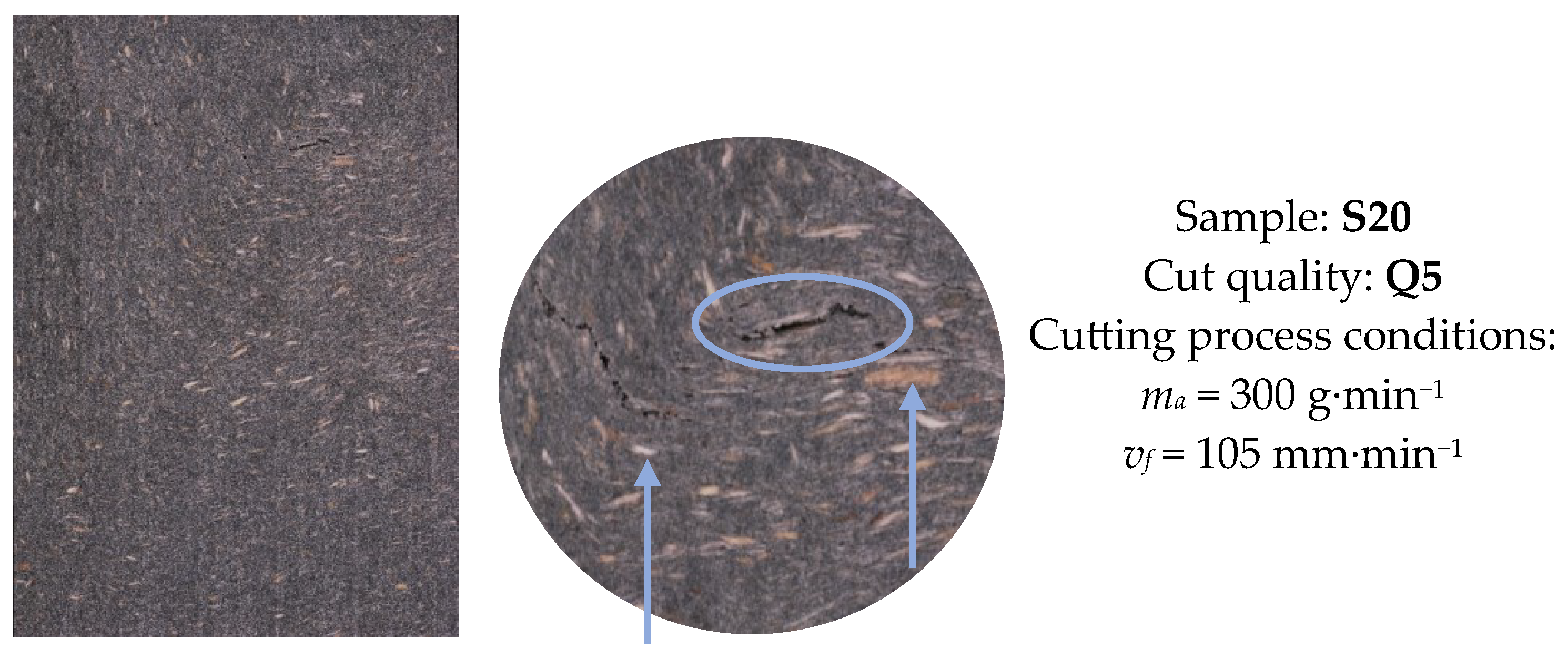

| S20 | 300 | 105 |

| Sample No. | Equation of the Rz Dependence in Relation to the Depth Line |

|---|---|

| S1 | y = 28.304e0.1914x/R2 = 0.9578 |

| S2 | y = 22.113e0.1931x/R2 = 0.9151 |

| S3 | y = 36.013e0.1748x/R2 = 0.9838 |

| S4 | y = 39.418e0.1529x/R2 = 0.9756 |

| Line Number hx | Sample S1 (Cut Quality: Q1) | Sample S2 (Cut Quality: Q1) | Sample S3 (Cut Quality: Q1) | Sample S4 (Cut Quality: Q1) |

|---|---|---|---|---|

| h13 | 111.5 µm | 53.05 µm | 123.50 µm | 120.60 µm |

| h39 | 1375.0 µm | 1341.0 µm | 1536.0 µm | 989.7 µm |

| Line Number hx | Sample S17 (Cut Quality: Q5) | Sample S18 (Cut Quality: Q5) | Sample S19 (Cut Quality: Q5) | Sample S20 (Cut Quality: Q5) |

| h5 | 37.00 µm | 35.80 µm | 35.67 µm | 34.53 µm |

| h31 | 71.89 µm | 68.14 µm | 63.93 µm | 57.16 µm |

| h39 | 144.70 µm | 136.70 µm | 125.00 µm | 75.00 µm |

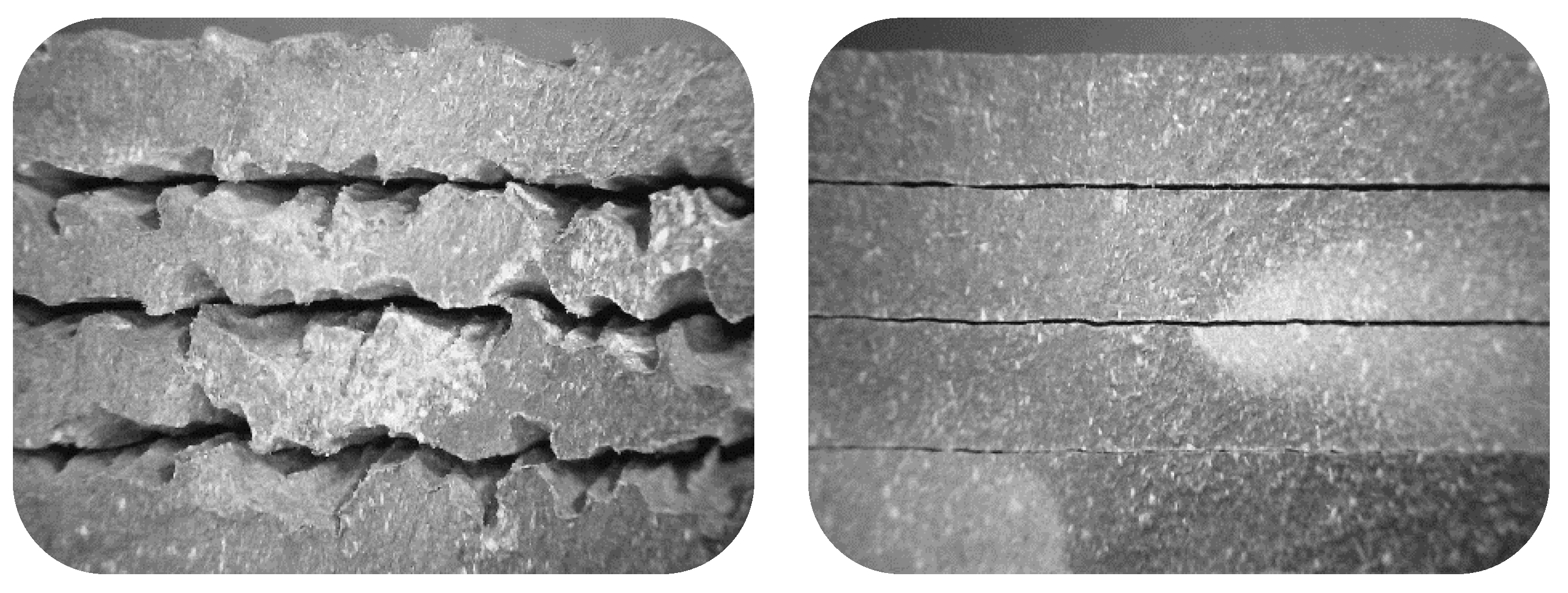

| S1 (Cut Quality: Q1) | S2 (Cut Quality: Q1) | S3 (Cut Quality: Q1) | S4 (Cut Quality: Q1) |

|---|---|---|---|

|  |  |  |

| S17 (Cut Quality:Q5) | S18 (Cut Quality: Q5) | S19 (Cut Quality: Q5) | S20 (Cut Quality: Q5) |

|  |  |  |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mitaľová, Z.; Klichová, D.; Botko, F.; Litecká, J.; Vandžura, R.; Mitaľ, D. Green Machining of NFRP Material. Machines 2023, 11, 692. https://doi.org/10.3390/machines11070692

Mitaľová Z, Klichová D, Botko F, Litecká J, Vandžura R, Mitaľ D. Green Machining of NFRP Material. Machines. 2023; 11(7):692. https://doi.org/10.3390/machines11070692

Chicago/Turabian StyleMitaľová, Zuzana, Dagmar Klichová, František Botko, Juliána Litecká, Radoslav Vandžura, and Dušan Mitaľ. 2023. "Green Machining of NFRP Material" Machines 11, no. 7: 692. https://doi.org/10.3390/machines11070692

APA StyleMitaľová, Z., Klichová, D., Botko, F., Litecká, J., Vandžura, R., & Mitaľ, D. (2023). Green Machining of NFRP Material. Machines, 11(7), 692. https://doi.org/10.3390/machines11070692