1. Introduction

High-performance electric drive systems are now designed to fulfill the main requirements, such as fast transients, high power density, high efficiency, and low rotor inertia. On a large scale, the most popular electric machine is the induction one, but it has low efficiency and a low power range, which makes it inappropriate for this kind of application. A secondary option is represented by the permanent magnet synchronous machine, with various benefits such as high efficiency and low rotor inertia, but with the main drawback of the demagnetization phenomenon when operating at high temperatures. At last, the synchronous reluctance machine (SynRM) becomes an attractive solution for a large range of power and speed, being a low-cost machine with eco-friendly environmental impact and multiple benefits, such as compact sizes, low mass and rotor inertia, and the rotor having no electric windings, cage, or permanent magnets. For the modern applications of SynRM drives, advanced control algorithms are used to obtain high performances such as fast transient regimes, good tracking results, and efficient disturbance rejection [

1,

2].

For the efficient control of alternating current machines, their modeling is based on the

dq0 transformation [

3,

4], which generates

dq axes models. The main control strategies of SynRM based on the

dq axes model are divided into the following categories [

5,

6,

7]: constant

d-axis current control (when the torque is varied by the

q-axis current), current angle control (with the groups: fast torque response, maximum power factor control, maximum torque per ampere control), and active flux control. These control strategies are usually implemented using the field-oriented control (FOC) concept, which involves a cascade control structure with an outer loop for angular speed control and an inner loop for

d-axis and

q-axis current control. To control the

d-axis and

q-axis currents independently, decoupling feedforward components are frequently used in both current control loops.

For the FOC approach, simple control solutions, such as proportional–integral (PI) controllers, are dominant in many applications, but their main drawback is the inability to deal with constraints in a nonconservative way. For example, a cascade structure based on FOC that uses the constant

d-axis current strategy and whose two loop controllers are PI is given in [

8]. In [

6], the performances obtained with PI controllers are comparatively analyzed for the main control strategies of SynRM implemented in a cascade control structure based on FOC. An FOC strategy with PI controllers whose gains are designed using quantitative feedback theory for robust speed and current control of SynRMs under model uncertainty is presented in [

9]. The current control problem of the SynRM is a quadratically constrained problem, and for this reason, a solution was the use of model predictive control (MPC) algorithms that can automatically handle the constraints. However, at the beginning, the main problem with using MPC algorithms for SynRM control was the computational complexity. Compared to the conventional FOC structure with PI controllers, for which the computation time of the control law is around 10 microseconds, in the case of MPC controllers, the computation time increases approximately five times. However, at the same time, in conventional FOC schemes, other calculations are necessary to ensure safe operation regarding the physical limitation, which increases the execution time [

10]. In recent years, with advances in hardware and solver development, the MPC strategy has been successfully implemented in SynRM control systems [

6,

7,

8] without involving high costs. For predictive current control, based on the way in which the switching action of the power inverter is produced, the finite set or continuous set approach is used. Thus, in [

11], a current predictive control algorithm for a finite set of switching actions of the power inverter was introduced based on a one-step-ahead prediction model obtained by the discretization of the continuous time-coupled non-linear multivariable

dq current model with the forward Euler method. Using a cost function with soft constraints, the optimal switching vector for the inverter was selected. A similar current predictive control algorithm is presented in [

12], considering a coupled linear multivariable

dq current model by using a constant rotor electrical angular speed. The overcurrent protection is obtained by adding a variable to the cost function that considers the safety current limits. Recently, model-free MPC current controllers have been developed. Thus, this approach is presented in [

13] using a model-free MPC current controller based on a finite-set unconstrained approach. For current prediction, current measurements are continually updated and stored in a look-up table. A similar approach, where an improved unconstrained model-free MPC current control based on a flux-current map of SynRM is considered for considering the nonlinear magnetic features of SynRM, can be found in [

14]. A finite-state direct predictive control for SynRM drives is presented in [

15] based on the hierarchical selection strategy of the optimal voltage vector and the dynamic scaling of the voltage amplitude, which keeps the current ripple limited. Starting from the multivariable model of

dq currents and the monovariable one obtained by decoupling, in [

16], MPC current controllers with constraints based on the continuous set approach are designed and their performances are compared.

For the outer loop, meant to control the angular speed of SynRM, the PI controller is the most frequently used [

5,

6,

8]. Due to the difficulty of this controller regarding constraint handling, MPC algorithms are also used for speed control [

17].

Although the MPC with finite set control is widely used in SynRM control due to certain benefits, the high switching frequency required by this strategy [

18,

19] reduces the performance of practical applications, becoming an impediment for real-time implementation. At the same time, for MPC with a finite set control strategy, the handling of constraints is difficult. The overcurrent protection is usually obtained by adding a soft constraint set in the cost function that considers the safety current limits, while the voltage limitations are directly imposed by the searching algorithm, which generates a voltage magnitude in the admissible domain.

Regarding the continuous set approach used for field-oriented predictive control of SynRM, according to the authors’ knowledge, few results have been reported. Thus, in [

20], the design and implementation of a current controller for a SynRM based on the continuous set nonlinear model predictive control is described. For a permanent magnet assisted synchronous reluctance motor (PMA-SynRM), starting from the nonlinear dynamical model in [

21], the design of a continuous set MPC based on an augmented linearized model is presented.

For the design of the control algorithms from the above references, the ideal model of SynRM (i.e., no saturation and losses) was generally used, with few exceptions such as from [

6], where a non-ideal model mainly due to the saturation of the

d-axis was considered, or [

9], from which the model uncertainty was taken into account.

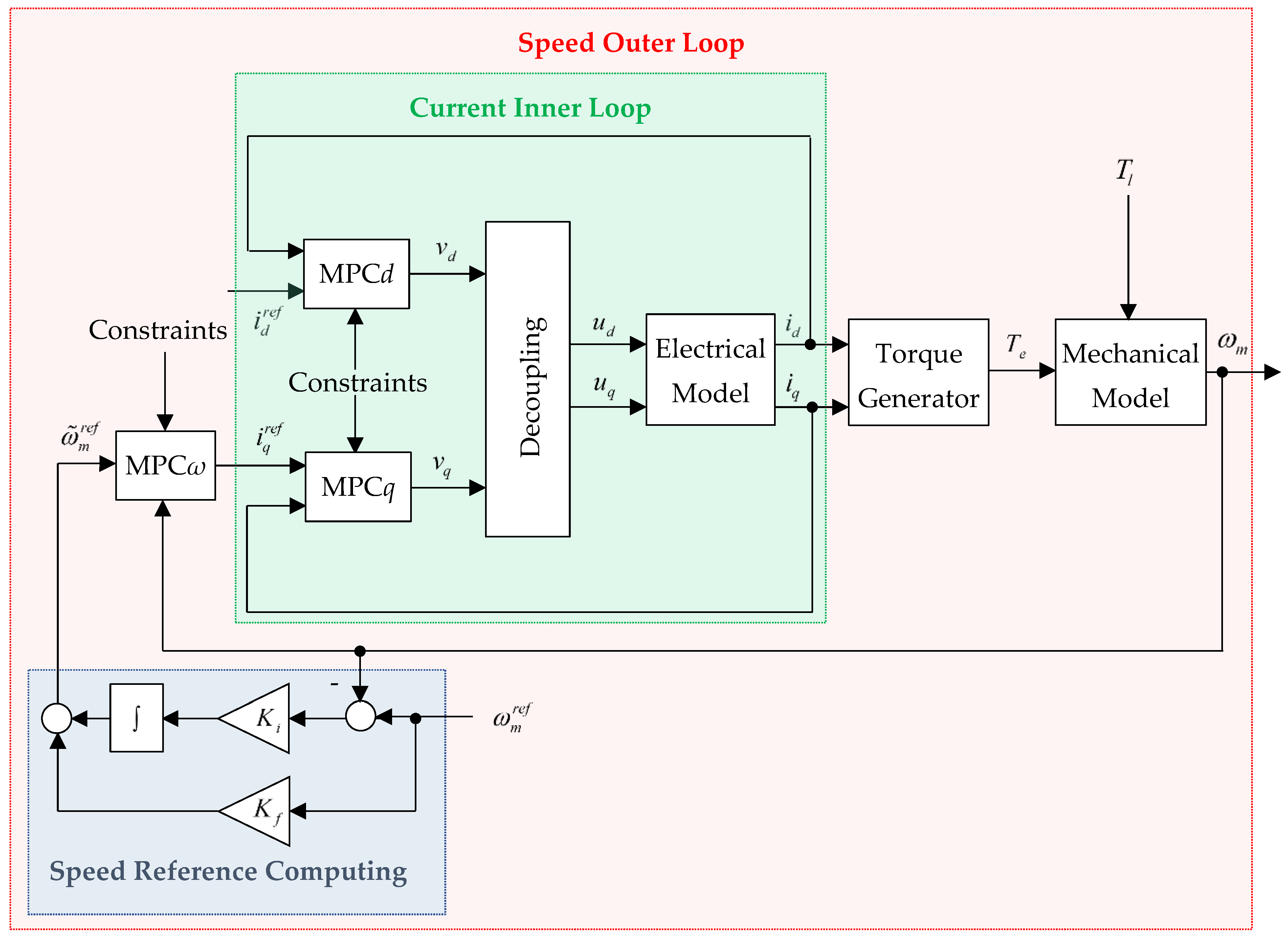

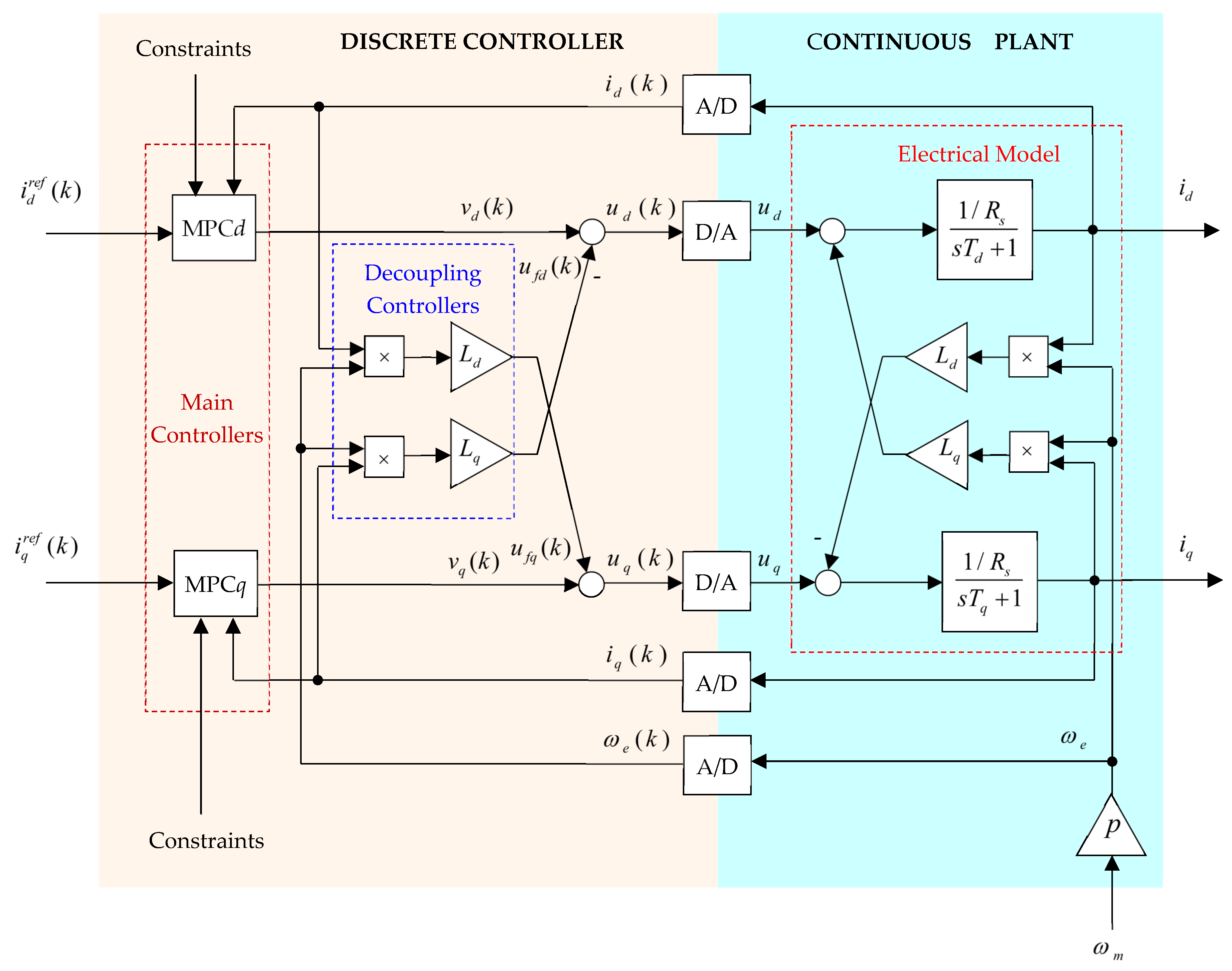

In this paper, a cascade predictive control structure based on FOC in the dq rotor reference frame for an ideal SynRM was proposed. Among the FOC-based SynRM control strategies, constant d-axis current control was chosen, which provides direct control of the electromagnetic torque through the q-axis current. Because the model of the two axes of currents from the inner loop is a coupled non-linear multivariable one, to control in a non-interaction and linear way the two currents, their decoupling was achieved through feedforward components. In this way, the dynamics of the d-axis current, which must be constant, are not influenced by the q-axis current variations. After decoupling, two independent monovariable linear systems resulted for the two current dynamics that were controlled using MPC algorithms due to their ability to automatically handle the bounds imposed on the states.

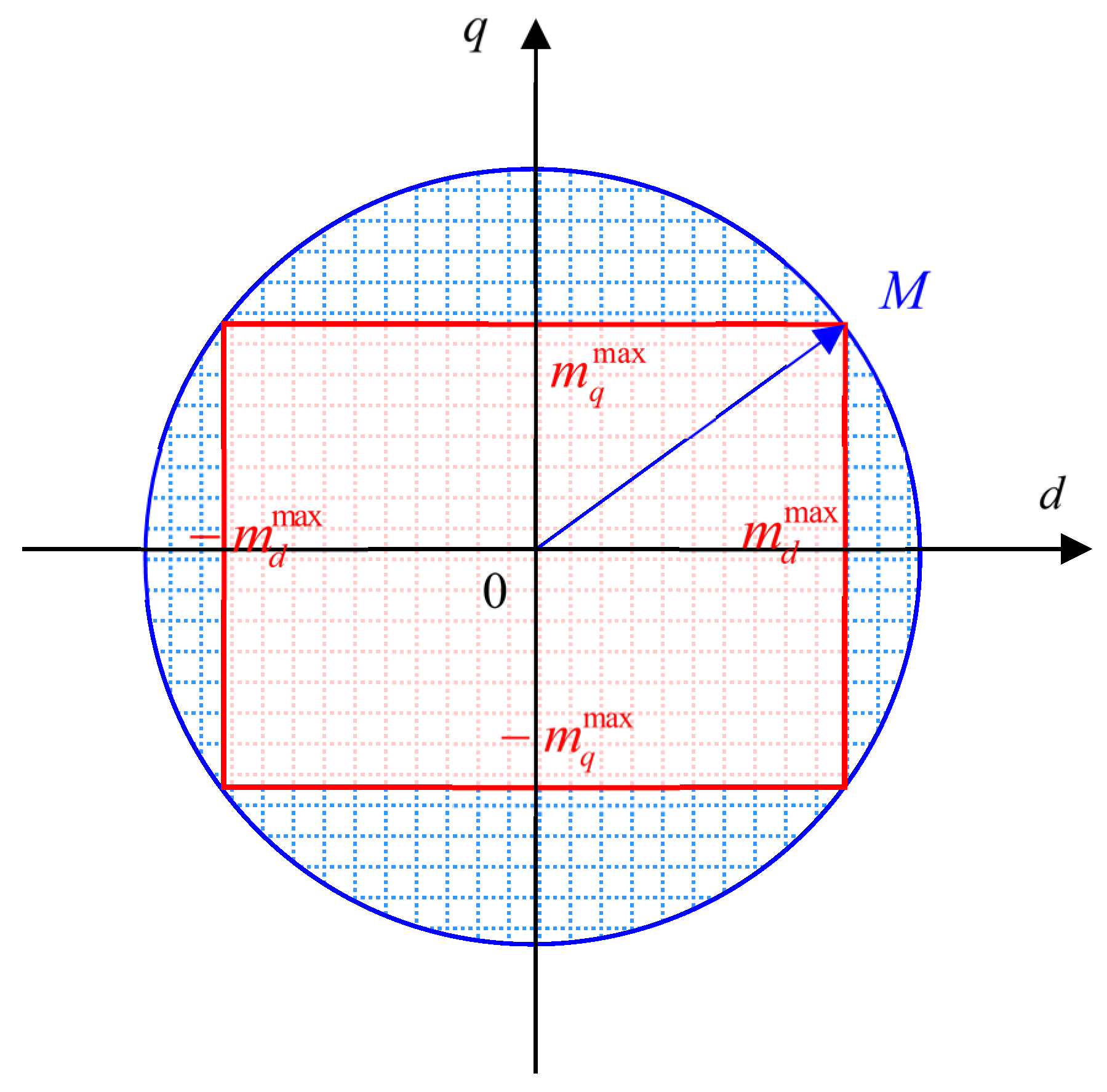

The most important bounds for SynRM are the limits imposed on currents and voltages, which in the dq plane correspond to circular regions. To avoid computational effort, linear limitations were adopted through polygonal approximations, resulting in rectangular regions in the dq plane. For the d-axis current, the upper limit was imposed as its reference, and thus, the parameter of the circular region transformation related to the currents into a rectangular one was defined by the ratio between the d-axis current reference and the maximum stator current. The transformation of the circular region related to the voltages into a rectangular one in the dq plane was carried out by a parameter chosen by the user. To obtain the constraints imposed on the outputs of the MPC current controllers, the voltage limitations in the dq plane were considered, to which the maximum values of the feedforward components were appropriately added. For the outer loop that controls the angular speed with a constrained MPC algorithm, the q-axis current closed-loop dynamics and the linear equation of the torque depending on the q-axis current were considered. To eliminate the steady-state speed error due to unmeasured disturbance generated by the load torque and modeling errors, the user speed reference of the MPC speed controller is replaced by adding an integral action and a feedforward component.

The MPC algorithms were designed in such a way to obtain reference tracking by adding an additional state to the plant model to obtain an input increment, which becomes an optimization variable. The cost functions and related constraints used for MPC algorithm design were transformed into a quadratic programming (QP) problem. To avoid the infeasibility of the QP problem, some constraints are treated as soft constraints by using a slack variable. The implementation is performed in Matlab-Simulink using the facilities offered by the MPC Designer from the Model Predictive Control Toolbox. To evaluate the performance of the proposed cascade predictive control structure based on FOC in the dq rotor reference frame for SynRM, a simulation study using MPC controllers versus PI ones was conducted. PI controllers, often used for the cascade control of SynRM in industrial applications, were designed using the pole-placement method, and to limit some variables imposed by the constraints, saturation-type blocks were introduced at the output of the controllers together with the related anti-windup mechanisms. Since the design method introduces a zero in the closed-loop system, a zero-cancelation ZC block was used in order not to alter the performances. Through a comparative analysis of the performances obtained with the MPC and ZC-PI controllers, respectively, the better-performing behavior of the predictive control cascade structure was revealed. In the end, it is analyzed if the performances are preserved when considering a non-ideal model of SynRM, mainly due to the saturation of the d-axis.

This paper proposes the following new contributions with respect to the state of the art:

- (i)

a new cascade FOC-based speed control of SynRM using MPC algorithms for both the inner current loop and the outer one, which allow to include the existing safety and hardware constraints directly in the optimization problem.

- (ii)

the current control with linear monovariable MPC algorithms, after the nonlinear multivariable model of the electrical system decoupling.

- (iii)

considering the dynamics of the inner current control loop in the design of the outer-loop controller.

- (iv)

transforming the upper limits on the current and voltage magnitude, which correspond to a circular limit in the dq plane, into linear limits through polygonal approximations with the computational effort decreasing.

- (v)

analysis of the cascade predictive control structure’s robustness to model uncertainty.

The rest of the paper is organized as follows: In

Section 2, the

dq SynRM model with physical limits and the cascade predictive control structure in the

dq rotor reference frame are presented.

Section 3 is dedicated to the design of the inner and outer loops of the proposed cascade predictive control structure. A comparative analysis of the performances obtained with the MPC and ZC-PI controllers is given in

Section 4. The conclusions of the paper are presented in

Section 5.

4. Illustrative Case Study

To evaluate the performance of the proposed cascade predictive control structure for SynRM, a simulation study was carried out using a Simulink model of the motor in dq coordinates and predictive controllers from the MPC Simulink Library.

The simulation results were compared with those obtained with a cascade regulation structure with ZC-PI controllers instead of MPC ones, often used in industrial applications. For the design of the PI controllers, the pole placement method was used [

28], considering the

R-L plant transfer function for the current controllers:

and the mechanical plant transfer function for the speed controller, neglecting the inner-loop dynamics:

Following the design of the PI controllers, the tuning parameters of the current and speed controllers resulted in:

where

is the natural frequency and

is the loop attenuation of the inner/outer-loop systems. Furthermore, a zero appears in the closed-loop transfer function, which can be canceled by introducing a zero-cancellation block ZC in the feedforward path [

25].

The saturation used for ZC-PI controllers output constraints requires an anti-windup mechanism [

29].

For the simulation study,

Table 1 with the specifications of the SynRM from [

12,

30] was used.

The sampling period for the controller design was chosen at Ts = 100 microseconds according to the requirements of the current loops’ dynamics.

With the SynRM parameters from

Table 1, the inner plant model used for MPC current controller design turns into:

and the outer plant model, including inner-loop dynamics for MPC speed controller design, becomes:

The simulation study is performed in a Matlab-Simulink environment, by using the MPC Designer block from the Model Predictive Control Toolbox. Since the control strategy based on keeping the current constant on the

d-axis was chosen for the cascade predictive control structure of SynRM, the reference for

id is calculated with

[

30].

The limit values of the constraints were determined based on the method from

Section 2, using the rectangular regions from

Figure 1. The circle radius

M for currents is given by

and for voltages by

. Since for the constant current on the

d-axis, the limitation

is imposed, the value

was adopted. For the voltages,

uj constraints,

was assumed, and for the

vj voltages, Equations (24) and (25) were used to obtain the imposed limitations.

For the speed reference computation, the following gain values are selected: and .

Thus,

Table 2 summarizes the tuning parameters and constraints for both MPC and PI controllers.

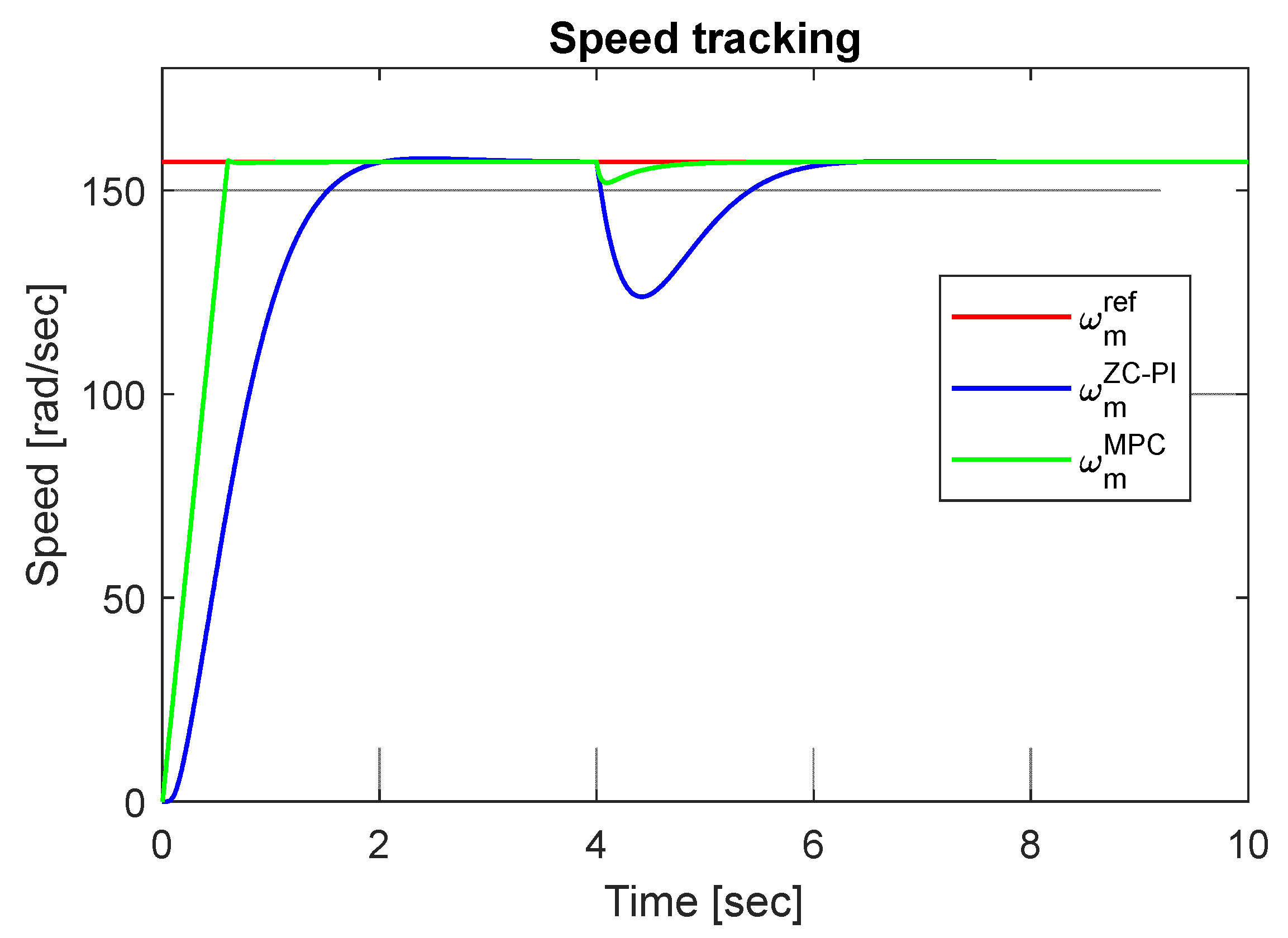

The outer speed-loop tracking results for both MPC and ZC-PI controllers of the SynRM cascade structure are depicted in

Figure 4. The speed reference is set at a constant value that corresponds to the nominal one

. A no-load start of SynRM is considered, and then, after 4 s, a load torque of value

is applied, which represents the main disturbance that acts on SynRM. As it can be seen in

Figure 4, for the MPC control the settling time

, which is much smaller than the settling time

achieved with the ZC-PI control. Additionally, ZC-PI speed control response has a very small overshoot, while MPC speed control has no overshoot.

Moreover, when the load torque is applied, the speed variations are much higher with ZC-PI control compared to MPC. It can be mentioned that in the no-load start conditions of SynRM, the fast outer speed closed-loop dynamics with MPCω generates a high value of the controller output, which will be limited by the imposed constraints. The same limitation is also applied to the

q-axis current reference. Therefore, the current references and their tracking, which are presented in

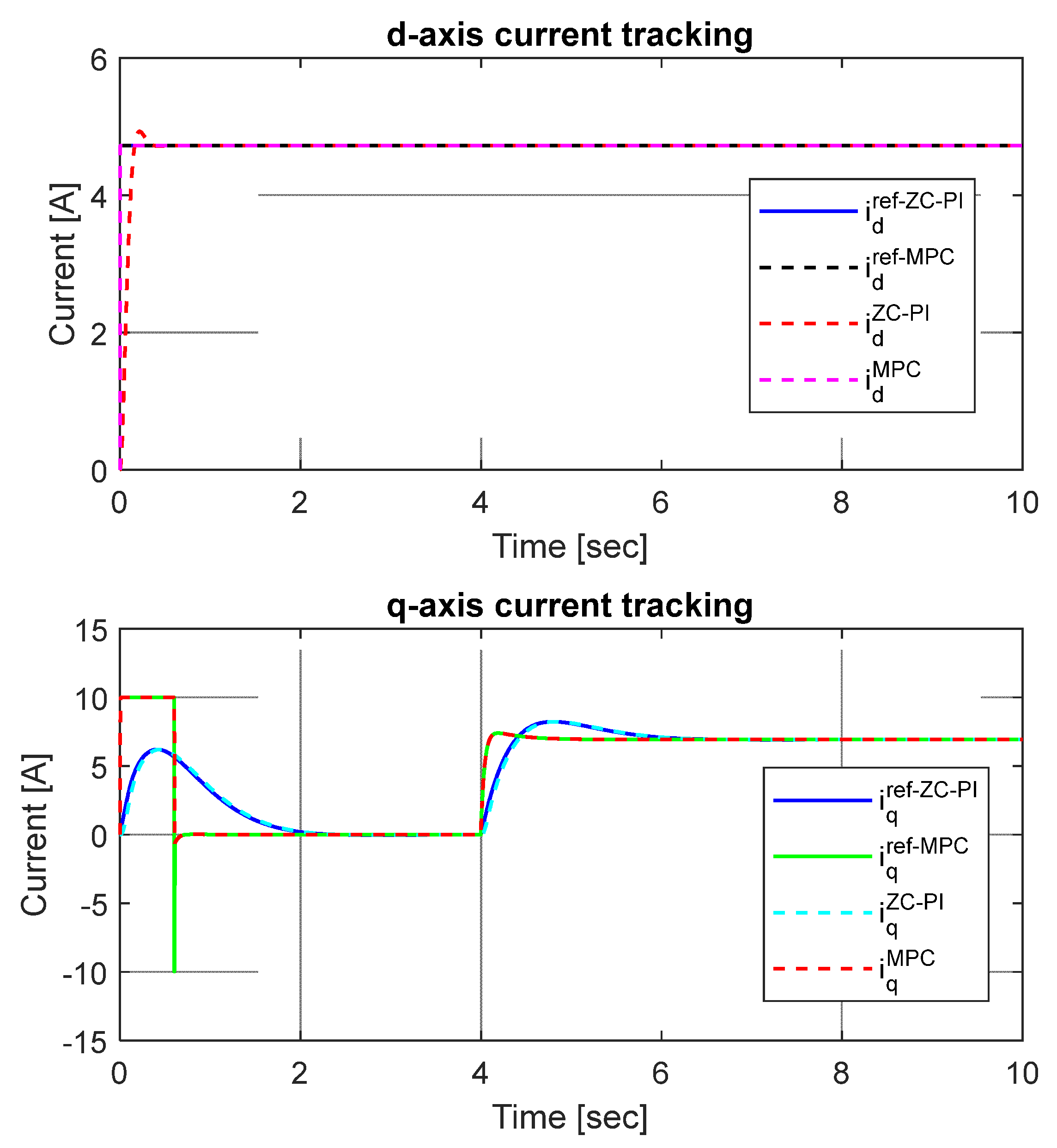

Figure 5, have a major influence on SynRM operation.

The current constraints are established according to

Table 2. For the

d-axis, the MPC current response

is faster than the corresponding ZC-PI one

. Moreover, compared with the ZC-PI current response

, the MPC current response presents no overshoot. On the

q-axis, both current responses,

and

, must track their current references

which are provided by the speed controller. At the start of the SynRM drive, the

q-axis MPC current response has a larger value than the ZC-PI one and is limited by the constraints. When the load torque is applied (

Figure 6), the response

is faster than the ZC-PI one

, and both responses present small overshoots.

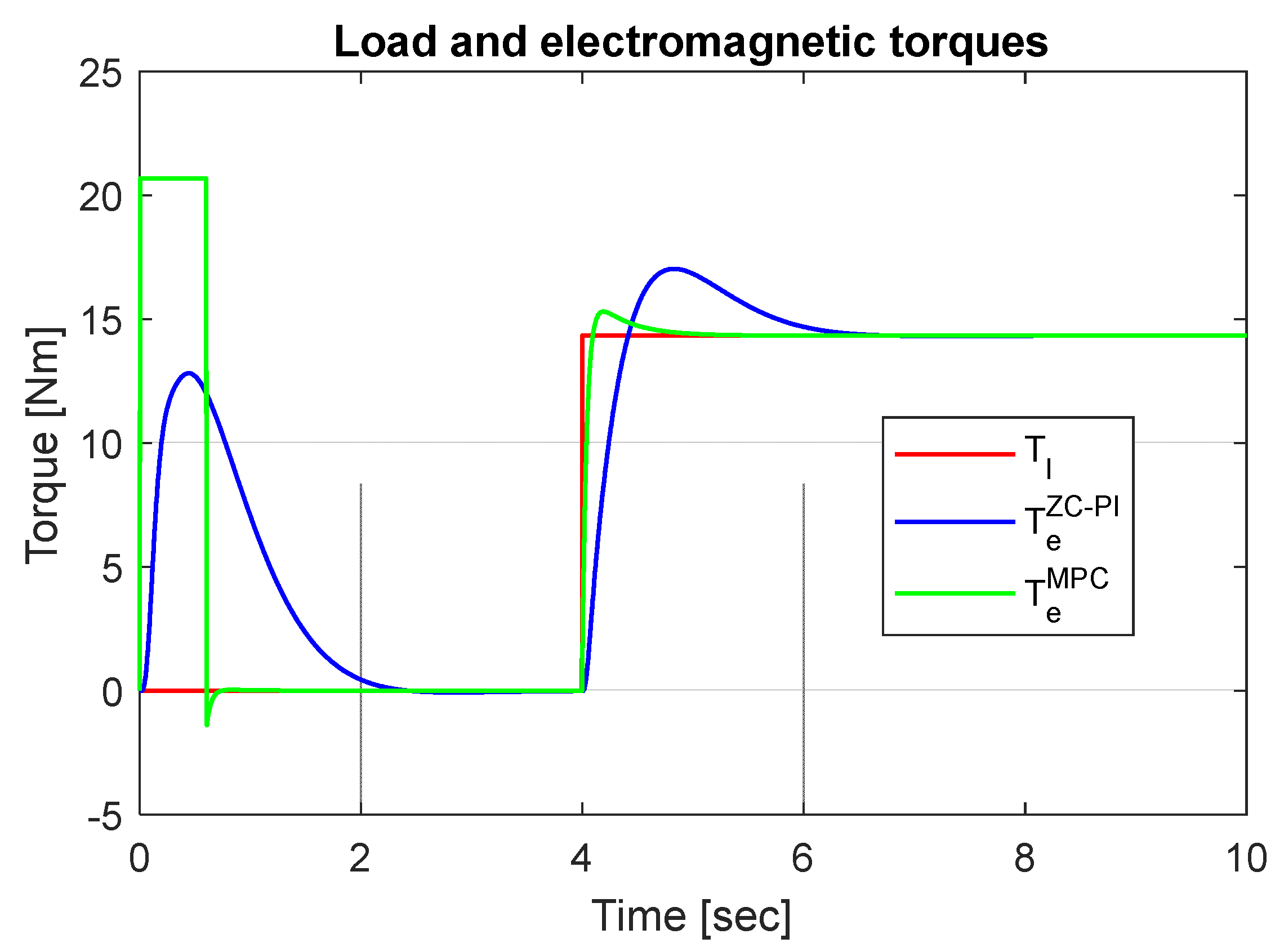

The electromagnetic and load torques are illustrated in

Figure 6. As a constant

d-axis current control was chosen, the electromagnetic torque depends linearly on the

q-axis current. Thus, for the no-load start conditions, when the

q-axis current of the MPC structure has its maximum value imposed by the constraints, the electromagnetic torque

presents a higher value in comparison with the one obtained by the ZC-PI controller

, which will lead to a smaller settling time. When the load torque is applied, a faster response of the electromagnetic torque related to the MPC structure is obtained, with a faster load rejection.

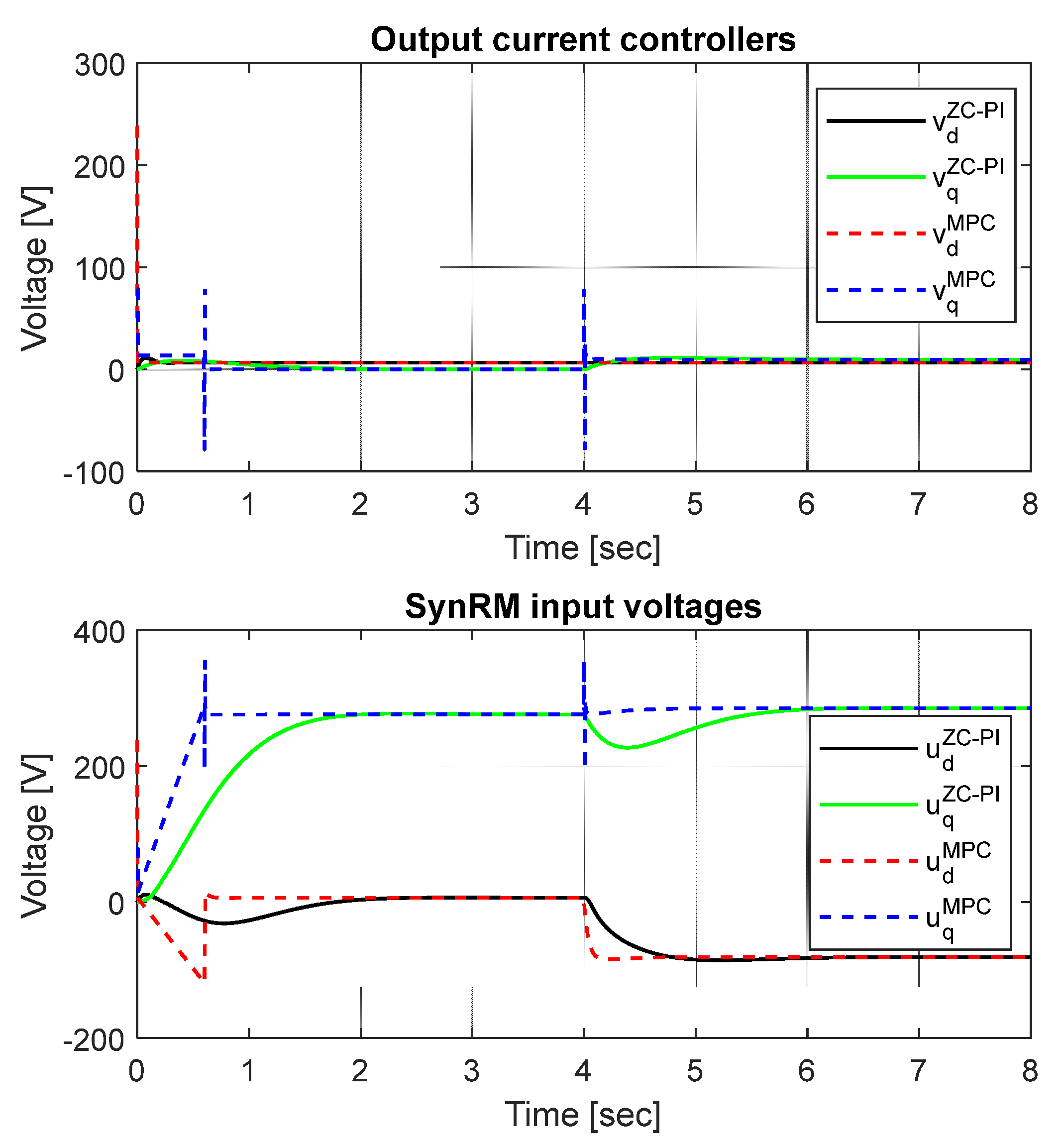

The output current controllers and the input voltages of the SynRM

dq model are illustrated in

Figure 7.

The MPC

d/

q controller outputs

are limited by the adopted constraints from

Table 2. However, in comparison with the ZC-PI controller outputs

, the MPC controller outputs

present high-variation components that are limited by the imposed constraints. Taking into account (23–24), the input voltages of the SynRM

dq model

and

depend on the controller outputs

and

, and on current limitations via the feedforward decoupling voltages. Therefore, due to current controller output constraints, the input voltages of the SynRM

dq model are limited.

Based on the above simulation results, it can be concluded that the MPC algorithms with related constraints used in the proposed FOC cascade control structure improve the dynamic performance in comparison with the classical PI control.

Since the design of the MPC controllers is based on the use of a SynRM ideal model, it is further analyzed to see if the performances are preserved for a non-ideal model, which includes saturation and iron losses. The effects of saturation and iron losses depend quite a lot on the type of machine, but studies carried out on machines have shown that iron loss effects can be ignored and only the saturation of the

d-axis can be taken into consideration. If the synRM rotor is axially laminated, the

q-axis has minimum saturation, and thus, the

Lq inductance can be considered to be the unsaturated value, and the

d-axis has a pronounced saturation that reduces the

Ld inductance when the machine operates near or at rated conditions [

6]. In what follows, the robustness of the proposed cascade predictive control structure for SynRM is analyzed when the value of the inductance

Ld changes due to saturation, as in [

6]. The robustness test consisted of considering the decreasing of the inductance

Ld from its nominal value

Ldn = 0.186 H to the two small values

Ldsat1 = 0.167 H and

Ldsat2 = 0.158 H due to saturation, while the model used for MPC and decoupling controllers’ synthesis uses the nominal parameters from

Table 1.

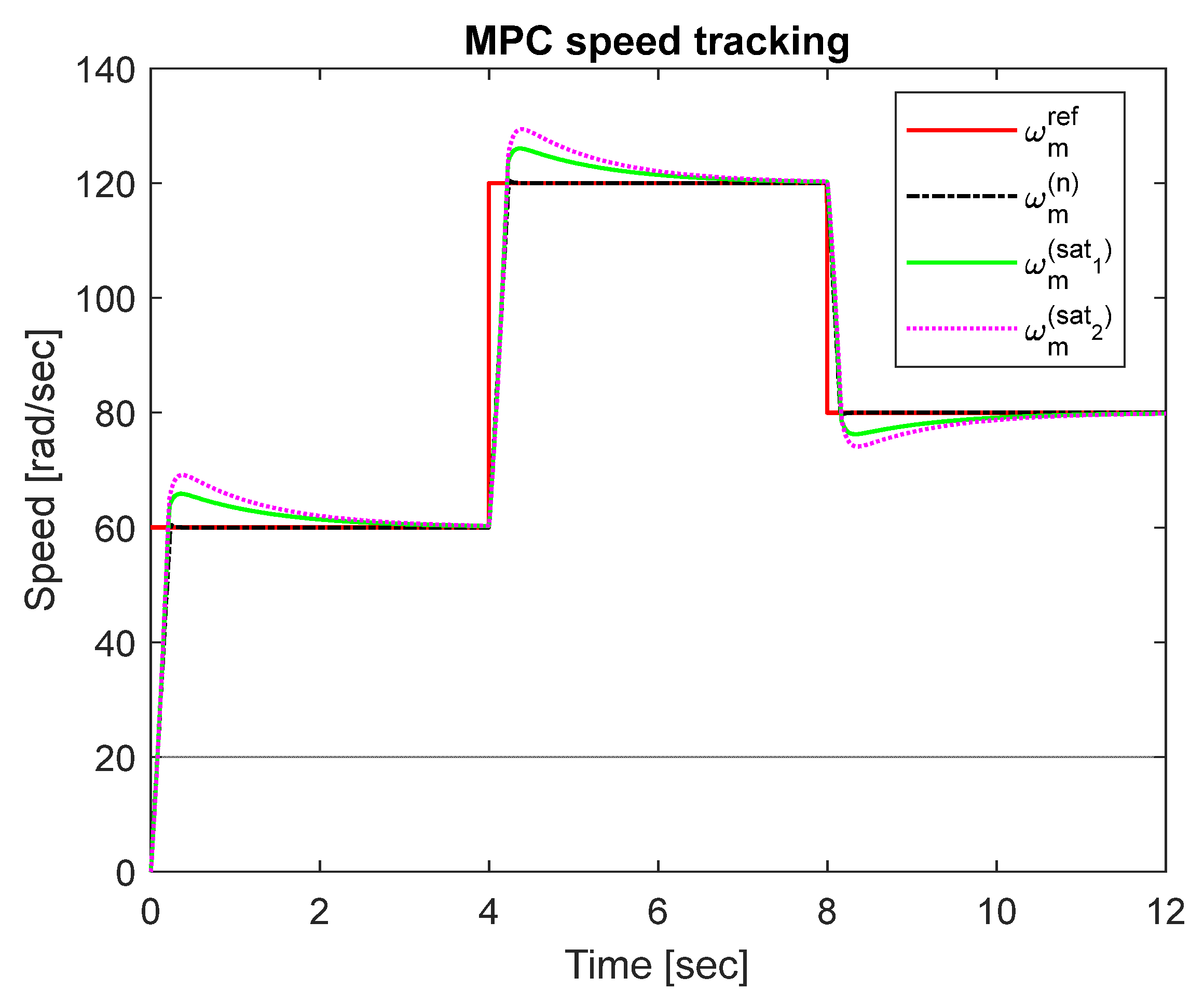

For the robustness testing, a speed reference containing three steps

, each with a duration of

N sampling periods, was used, and, for the performance evaluation, the following index was considered:

To appreciate how much the indices

vary in the two cases generated by saturation in relation to the nominal index

, the robustness overshoot is defined:

The speed tracking responses obtained with the nominal inductance

Ldn and those resulting from the two saturated inductances

Ldsat1 and

Ldsat2 are comparatively presented in

Figure 8, considering a speed reference with the step values

,

and

, each having the duration of

sampling periods.

For the responses related to the nominal and the two saturated inductances, the following performance indices: , and resulted. Based on these, the robustness overshoots were calculated: and . It is observed that the performance indices exceed their target as the inductance Lsati decreases, resulting in an increase in the robustness overshoots. The performance alteration due to saturation is mainly generated by the decoupling controllers. However, for small decreases in the inductance Ld, the proposed cascade predictive control structure for SynRM proves to be robust when considering the effect of saturation.