Research on Operation Conflict of Auxiliary Transport Locomotive in Complex Mine Based on Extended Petri Net

Abstract

1. Introduction

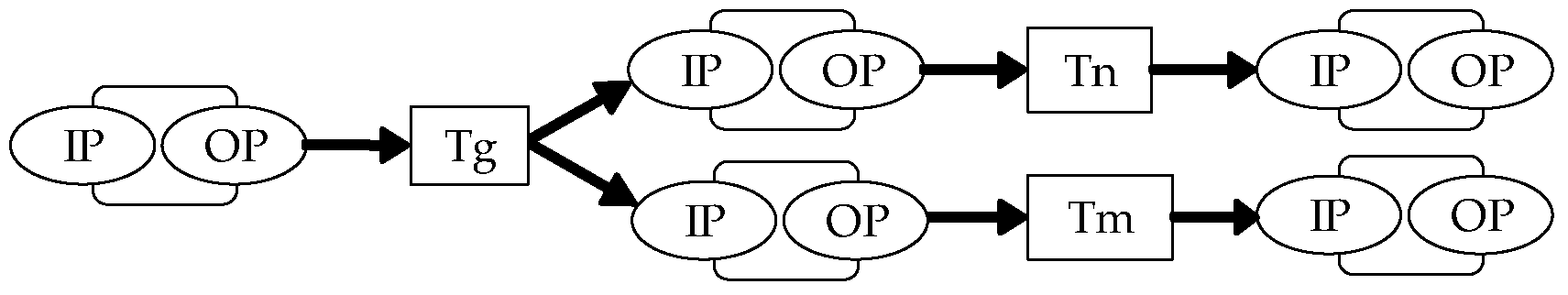

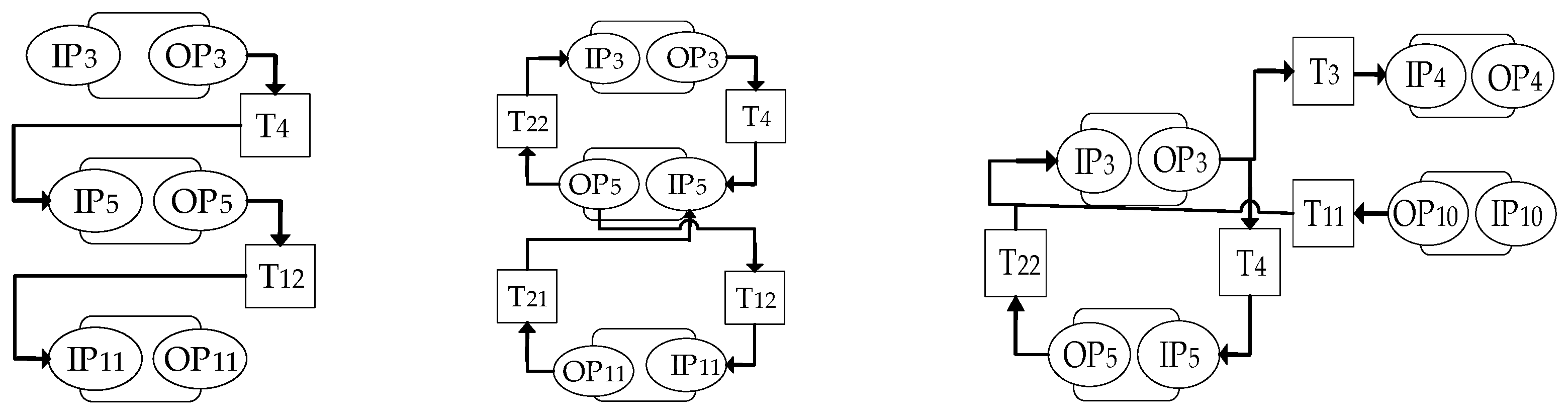

2. Scheduling Modeling of Auxiliary Transport Vehicles Based on HOTPN

2.1. Definition of HOTPN

2.2. HOTPN Model Construction

3. Analysis of Mine Locomotive Operation Conflict

3.1. Analysis of Locomotive Operation Rules

- Interlocking rules of locomotive approach interval scheduling:

- (1)

- Application for locomotive pre-occupation. The mine locomotive receives the operation instruction of the dispatching platform, and when the operation of the section is about to end, it will initiate the application for pre-occupation of the next section;

- (2)

- Scheduling platform approach interval interlocking calculation. The dispatching platform summarizes and reviews the application for pre-occupation of the locomotive’s approach interval, determines whether it meets the locomotive’s operation requirements according to the interlocking conditions, and rejects the application for pre-occupation that does not meet the requirements or re-plans the approach interval;

- (3)

- Pre-occupied interval locking. For the approach interval meeting the requirements, the dispatching platform will issue the permission to occupy the interval instruction to open the next approach interval for the locomotive.

- Wind door opening and closing interlock rules:

- (1)

- Application for wind door opening. When the transport locomotive is about to arrive at the wind door position, issue the wind door opening application to the dispatching platform;

- (2)

- Wind door interlocking calculation of dispatching platform. The dispatching platform receives the wind door opening application of the locomotive, and then determines whether the wind door is open or not according to the requirements of the wind door opening and closing interlock. For a situation that does not meet the requirements, the dispatching platform will reject the wind door opening application;

- (3)

- The wind door is closed. For a wind door opening application that meets the requirements, the dispatching platform will issue the wind door opening instruction, and the damper that receives the instruction from the dispatching platform will open and close each wind door successively to ensure the normal underground ventilation system.

- Interlocking rules of station transshipment:

- (1)

- Application for yard transshipment. When the locomotive arrives at the transfer station, the vehicle transfer application is issued to the dispatching platform;

- (2)

- Transfer judgment of dispatching platform. The dispatching platform will review the application for locomotive reprinting, judge whether the locomotive needs to reprint, and judge whether the reprinting device meets the reprinting requirements;

- (3)

- Locomotive transfer device is opened. The dispatch platform issues the locomotive transfer instruction, the automatic blocking device opens the fixed locomotive position, starts the transfer robot handling the standard container, and starts the material transfer;

- (4)

- Close the locomotive transfer device. After receiving the feedback signal of material transfer completion, the dispatching platform closes the blocking device, closes the transfer robot, and the locomotive starts to run after the transfer is finished.

- Other cases: the dispatching platform shuts down the allowable approach interval instruction of the locomotive, makes sound and light alarms and starts the emergency management function until the alarm is contacted, when faced with some locomotive incorrect operations, such as: personnel breaking into the locomotive running route, the vehicles breaking the red light, the locomotive moves into the track switch by mistake, the wind door is not opened and closed in time, etc.

3.2. Modeling of Running Route

- A single-line operation section means that locomotives are allowed to run in both directions;

- A double-line operation section allows the locomotive to run in one direction;

- A track switch operation section refers to the presence of switch nodes in locomotive operations, and the locomotive heads to different sections according to the direction of the switch. The switch includes a ground track switch and empty track switch;

- A wind door operation section refers to the three wind doors opening and closing successively when the locomotive runs to the location of the underground wind door.

3.3. Analysis of Locomotive Operation Conflict

3.3.1. Constraints on Locomotive Operation

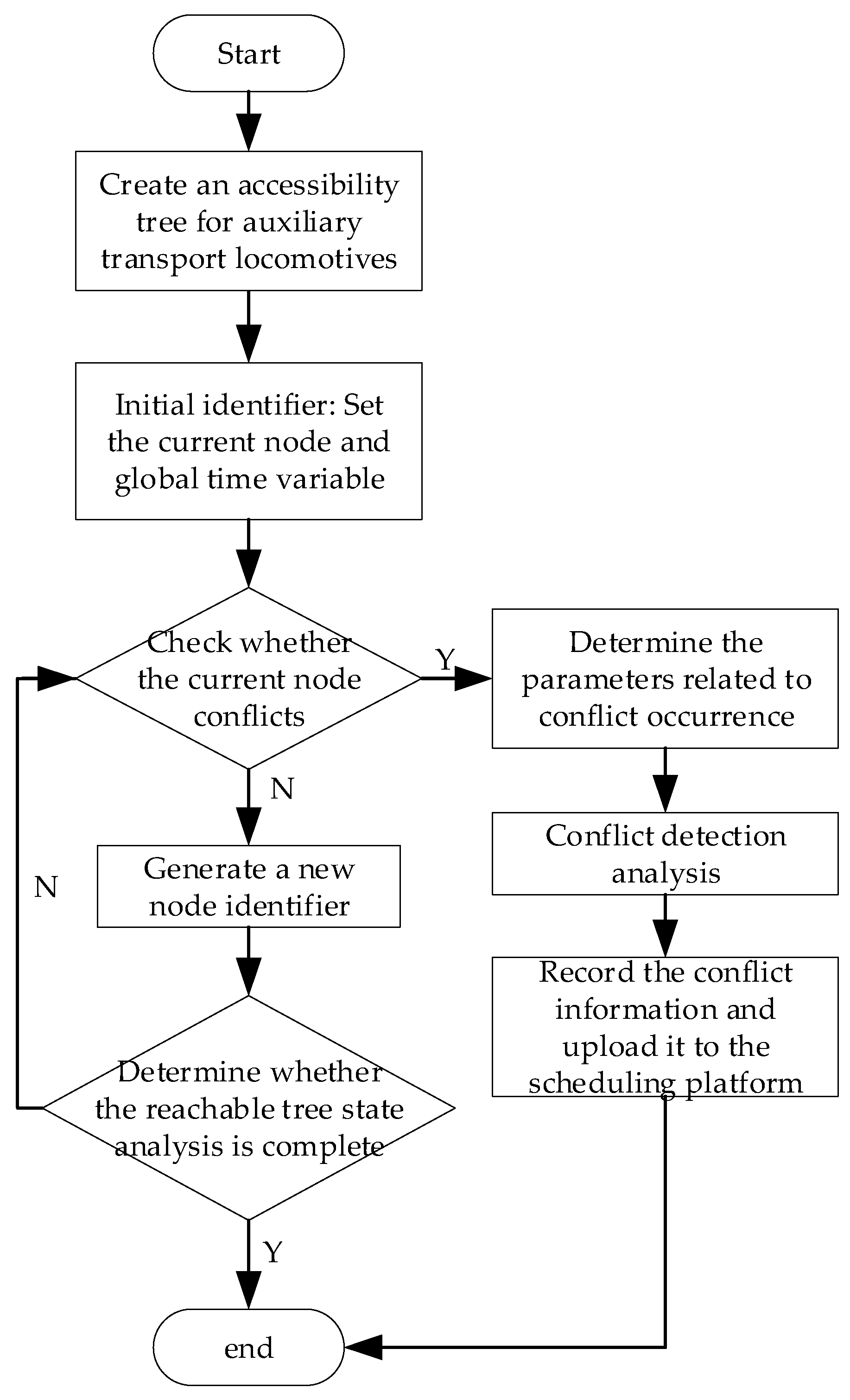

3.3.2. Accessibility Tree Analysis

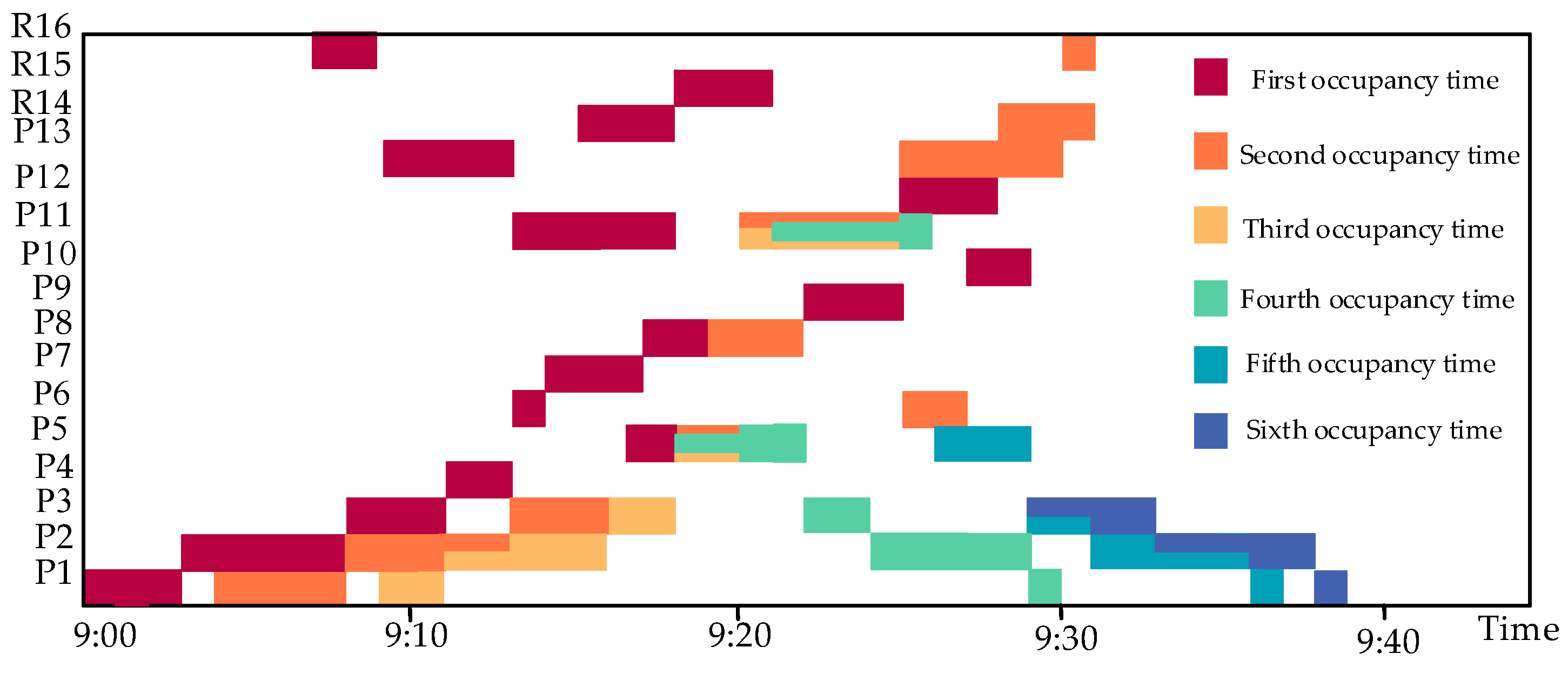

4. Case Analysis

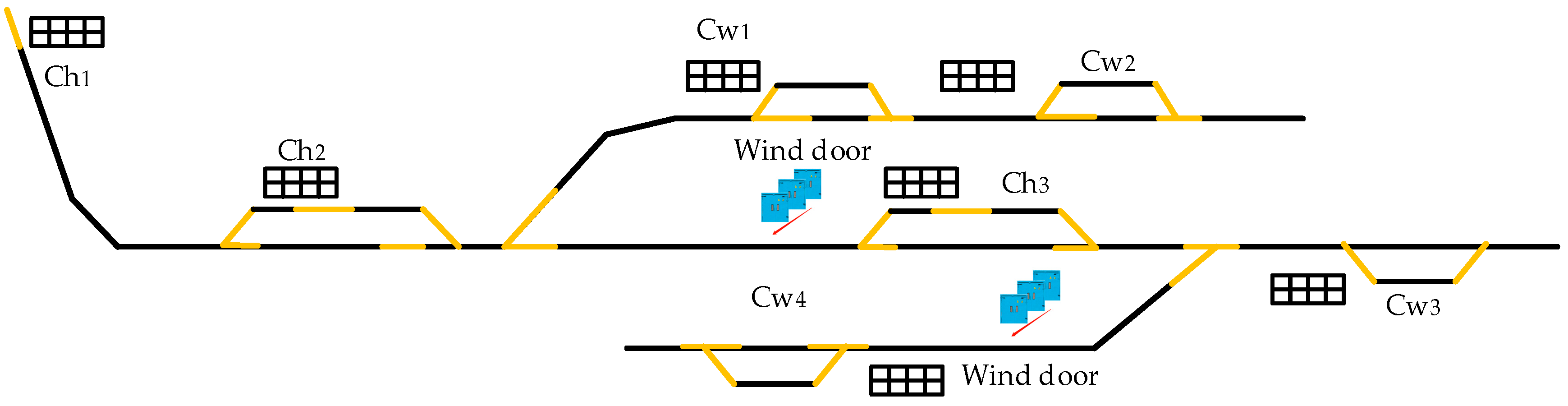

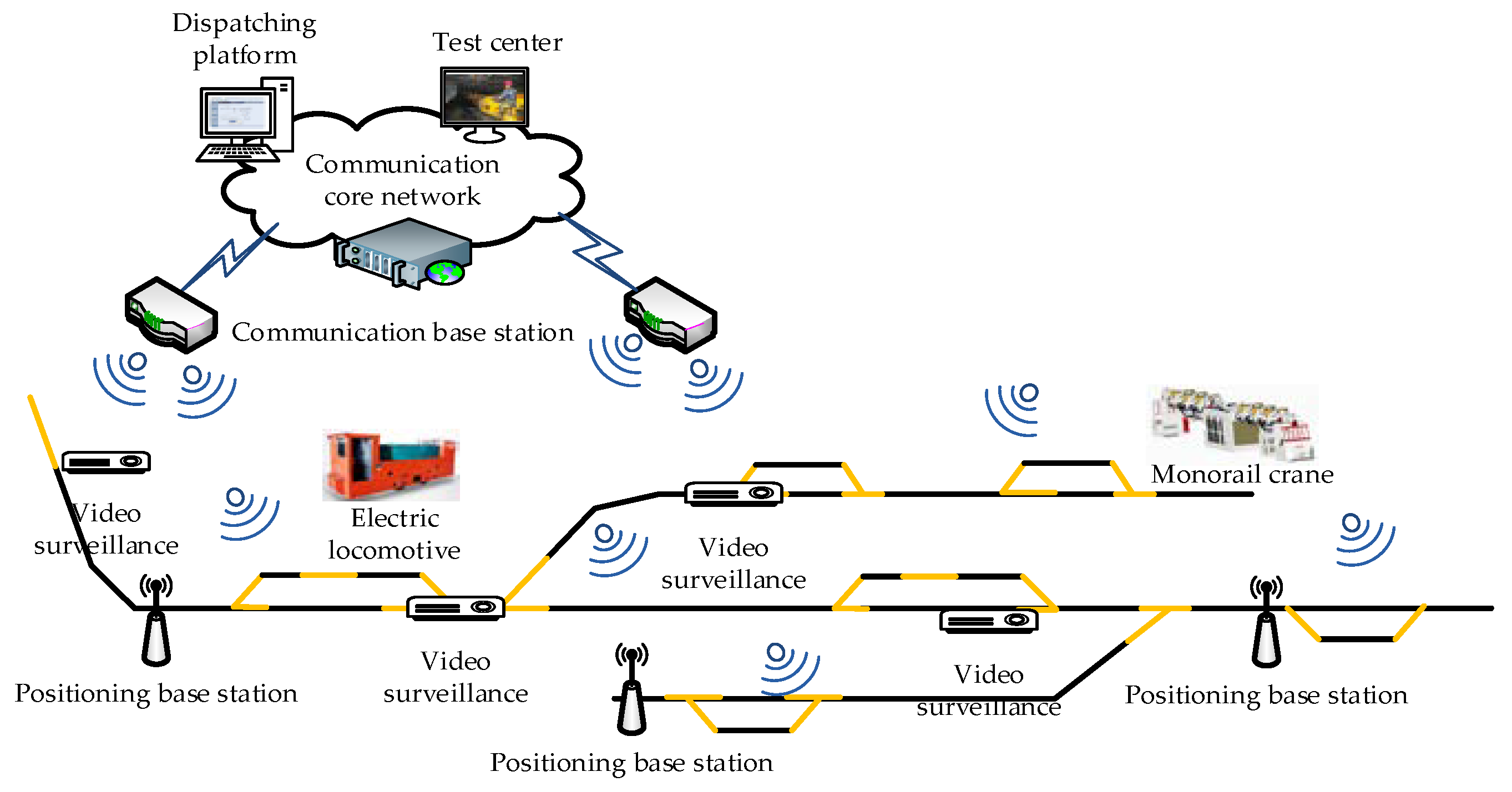

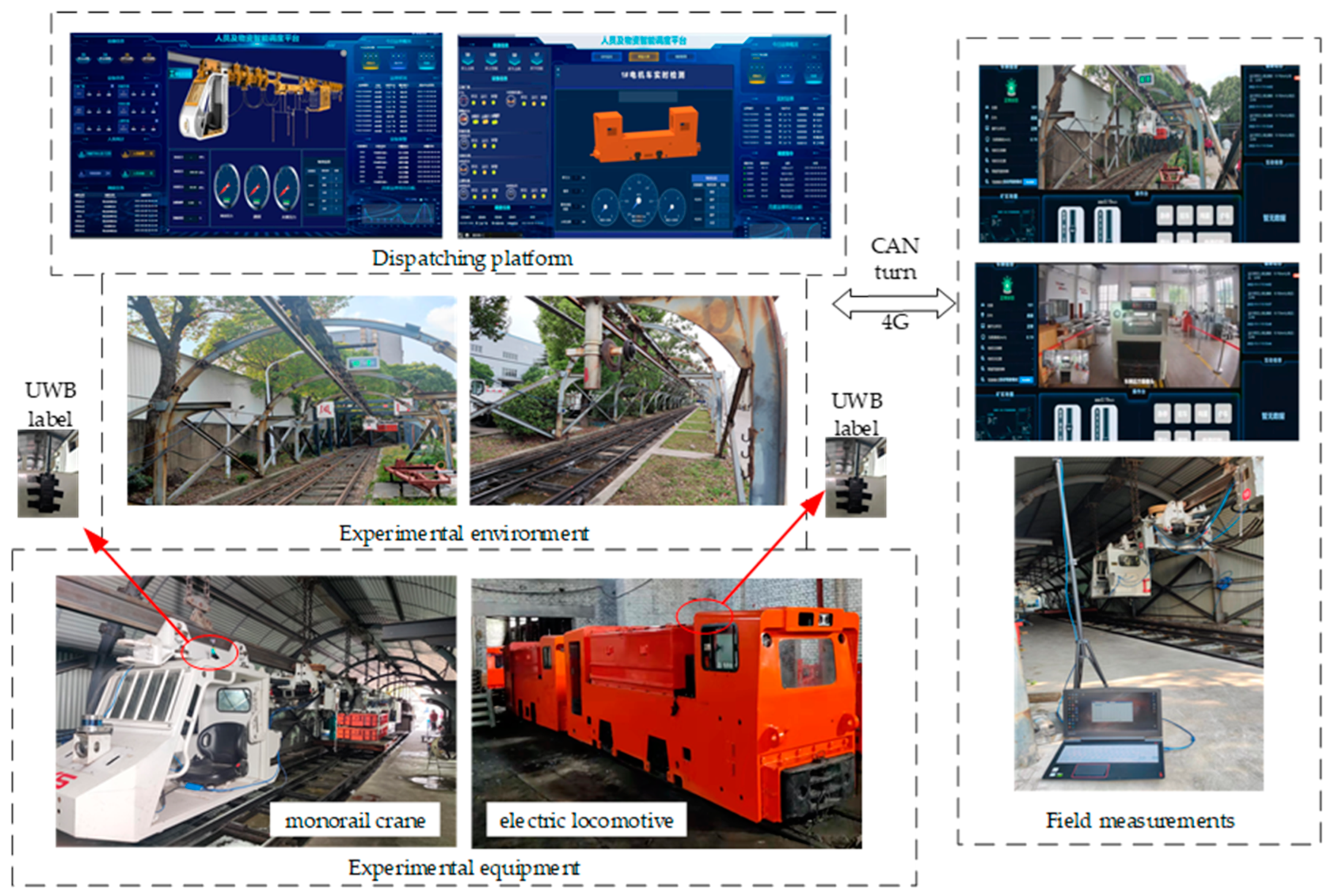

4.1. Operation Modeling of Auxiliary Transport Locomotive

4.2. Operation Modeling of Auxiliary Transport Locomotive

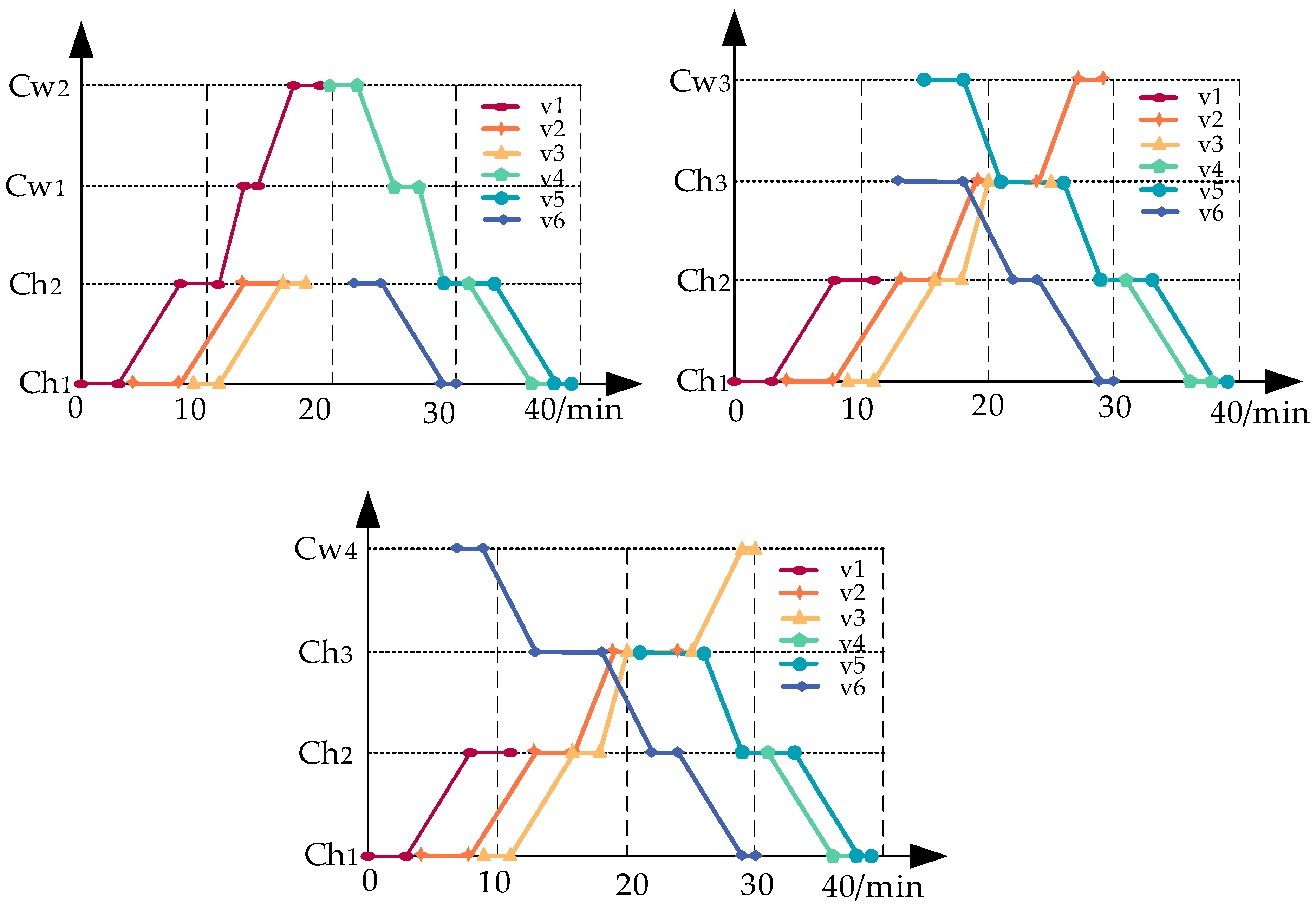

4.3. Reachable Tree Structure and Conflict Analysis

5. Experimental Verification

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, G.; Du, Y.; Ren, H.; Fan, J.; Wu, Q. Top level design and practice of smart coal mines. J. China Coal Soc. 2020, 45, 1909–1924. [Google Scholar]

- Li, W.; Zheng, J. Research on automatic scheduling strategy for downhole dispatching transportation. Control Theory Appl. 2021, 38, 757–765. [Google Scholar]

- Apkovi, F. Petri Nets at Modelling and Control of Discrete-Event Systems Containing Nondeter-minism—Part 1. Cent. Libr. Slovak Acad. Sci. 2018, 5, 1258–1292. [Google Scholar]

- Ran, N.; Kou, M.; Hao, Z.; Hao, J. A Petri net based modeling method for UAV logistics distribution. Electron. Meas. Technol. 2022, 45, 90–99. [Google Scholar]

- Yan, S.; Li, W.; Sun, Y. Optimization of Mine Locomotive Scheduling Based on Petri Net and Improved A* Search Algorithm. Sci. Technol. Eng. 2020, 20, 5990–5996. [Google Scholar]

- Manuel, S.; Júlvez, J.; Mahulea, C.; Vázquez, C.R. On fluidization of discrete event models: Observation and control of continuous Petri nets. Discret. Event Dyn. Syst. 2011, 21, 427–497. [Google Scholar]

- Yu, Q.; Yang, H.; Lin, K.; Li, L. Research on Load-Balancing Strategies with Multi-Layer Perceptron (MLP) for Scheduling Problems of Manufacturing Systems. J. Comput. Inf. Sci. Eng. 2019, 20, 1–23. [Google Scholar]

- Gu, Q.H.; Jing, S.G. Study on Vehicle Routing and Scheduling Problems in Underground Mine Based on Adaptively ACA. Appl. Mech. Mater. 2012, 157–158, 1293–1296. [Google Scholar] [CrossRef]

- Zhu, Q.; Wu, N.; Teng, S. Petri net modeling and deadlock analysis of multiclster tools in semiconductor manufacturing. J. Southeast Univ. (Nat. Sci. Ed.) 2010, 40, 267–271. [Google Scholar]

- D’Ariano, A.; Pacciarelli, D.; Pranzo, M. Assessment of flexible timetables in real-time traffic management of a railway bottleneck. Transp. Res. Part C Emerg. Technol. 2008, 16, 232–245. [Google Scholar] [CrossRef]

- Zhou, H.; Hu, H.; Li, Z.; Wu, N. Deadlock-Free Control of Automated Manufacturing Systems with Flexible Routes and Assembly Operations Using Petri Nets. Ind. Inform. IEEE Trans. 2013, 9, 109–121. [Google Scholar]

- Ran, N.; Wang, S.; Su, H.; Wang, C. Fault Diagnosis for Discrete Event Systems Modeled By Bounded Petri Nets. Asian J. Control 2017, 19, 1532–1541. [Google Scholar] [CrossRef]

- Hu, M.H.; Yang, S.H.; Chen, Y.F. Partial Reachability Graph Analysis of Petri Nets for Flexible Manufacturing Systems. IEEE Access 2020, 99, 925–935. [Google Scholar] [CrossRef]

- Nasr, E.A.; El-Tamimi, A.M.; Al-Ahmari, A.; Kaid, H. Comparison and Evaluation of Deadlock Prevention Methods for Different Size Automated Manufacturing Systems. Math. Probl. Eng. 2015, PT.17, 537893.1–537893.19. [Google Scholar]

- Yan, X.; Jin, H.; Kou, Z.; Zhang, L. Intelligent Scheduling Strategy of Electric Locomotive Robots for Underground Mining. IEEE Access 2021, 161, 533–545. [Google Scholar] [CrossRef]

- Cao, C.; Li, M.; Zhang, N. Modeling of Hierarchical Color Petri Net for Coal Mine Auxiliary Transportation Dispatching System. Ind. Eng. J. 2021, 24, 6. [Google Scholar]

- Cao, Z.; Yu, H.; Qiao, F. Petr-i Net and GA-Based Approach to Modeling and Optimize for Semiconductor Wafer Fabrication. Acta Electron. Sin. 2010, 38, 340–344. [Google Scholar]

- Bubalo, T.; Rajsman, M.; Korput, P. Modeling the Permeable Power of the Road on a Semaforized Crossing Using Petri Nets. Teh. Vjesn. 2020, 1, 314–319. [Google Scholar]

- An, Y.; Cong, Z.; Pei, C.; Li, Y. Modeling and analysis of transit signal priority control systems based on colored Petri nets. In Proceedings of the 2017 IEEE International Conference on Systems, Man and Cybernetics (SMC), Banff, AB, Canada, 5–8 October 2017. [Google Scholar]

- Chen, P.; Zeng, W.; Yu, G.; Wang, Y. Surrogate Safety Analysis of Pedestrian-Vehicle Conflict at Intersections Using Unmanned Aerial Vehicle Videos. J. Adv. Transp. 2017, 2017, 5202150. [Google Scholar] [CrossRef]

- Kahloul, L.; Chaoui, A.; Djouani, K. Modelling and Analysis of Mobile Computing Systems: An Extended Petri Nets Formalism. Int. J. Comput. Commun. Control 2015, 10, 211–221. [Google Scholar] [CrossRef]

- Zhong, C.; He, W.; Li, Z.; Wu, N.; Qu, T. Deadlock Analysis and Control Using Petri Net Decomposition Techniques. Inf. Sci. 2019, 482, 440–456. [Google Scholar] [CrossRef]

- Li, Z.; Wu, N.; Zhou, M. Deadlock Control of Automated Manufacturing Systems Based on Petri Nets—A Literature Review. IEEE Trans. Syst. Man Cybern. Part C 2012, 42, 437–462. [Google Scholar]

- Kaid, H.; Al-Ahmari, A.; Li, Z.; Davidrajuh, R. Single Controller-Based Colored Petri Nets for Deadlock Control in Automated Manufacturing Systems. Processes 2019, 8, 21. [Google Scholar] [CrossRef]

- Xu, J.; Ye, W.; Yang, B.; Liu, X. Assembly line modeling and balancing of aircraft based on extended Petri net. Comput. Integr. Manuf. Syst. 2015, 21, 2596–2603. [Google Scholar]

- Pla, A.; Gay, P.; Joaquim, M.; López, B. Petri net-based process monitoring: A workflow management system for process modelling and monitoring. J. Intell. Manuf. 2012, 25, 539–554. [Google Scholar] [CrossRef]

- Gu, H.; Sun, L. Modeling and algorithm of emergency traffic vehicles scheduling based on hierarchical colored Petri net. Comput. Eng. Appl. 2016, 52, 261–270. [Google Scholar]

- Li, R.; Li, Y. Modeling and Analysis of Object Oriented Timed Colored Petri Net in Flexible Manufacturing System. Mach. Des. Manuf. 2018, 10, 36–39. [Google Scholar]

- Cheng, Y.; Chen, H.; Yang, Q.; Qi, H.; Wang, H. Research on resource scheduling and application of complex product design based on timing constraint petri nets. Syst. Eng.-Theory Pract. 2019, 39, 1591–1601. [Google Scholar]

- Wang, P.; Ma, L.; Wang, Q.; Feng, X. Analysis of train operation conflict based on train group model using petri nets. J. China Railw. Soc. 2015, 37, 1–7. [Google Scholar]

- Rakhmanov, A.; Wiseman, Y. Compression of GNSS Data with the Aim of Speeding up Communication to Autonomous Vehicles. Remote Sens. 2023, 15, 2165. [Google Scholar] [CrossRef]

- Correia, S.D.; Perez, R.; Matos-Carvalho, J.; Leithardt, V.R.Q. µJSON, a Lightweight Compression Scheme for Embedded GNSS Data Transmission on IoT Nodes. In Proceedings of the 2022 5th Conference on Cloud and Internet of Things (CIoT), Marrakech, Morocco, 28–30 March 2022; pp. 232–238. [Google Scholar]

| Object | Input Information Place | Output Information Place |

|---|---|---|

| P1 | IP1a Ch1 to start loading supplies IP1b Standard container and flatbed car unlocked | OP1a Gantry crane loading completed OP1b Unloading of gantry crane is complete |

| P2 | IP2a The flatbed car began to hook standard containers IP2b Electric locomotives began to return to Ch1 | OP2a The electric locomotive hooks itself up and starts running OP2b The electric locomotive unloaded the standard container |

| P3 | IP3a The electric locomotive train arrives at Ch2 IP3b The electric locomotive train arrives at Ch2 | OP3a The electric locomotive train completed transshipment in Ch2 OP3b The electric locomotive train completed transshipment in Ch2 |

| P4 | IP4 The electric locomotive began to run | OP4 The electric locomotive arrives at CW1 |

| P5 | IP5a The electric locomotive began to run in Ch3 IP5b The electric locomotive began to run to Ch2 | OP5a The electric locomotive passes through the wind door to Ch3 OP5b Electric locomotive passes through the wind door to Ch2 |

| P6 | IP6a Electric locomotives began to remove their standard containers IP6bThe waste at the work face Cw1 is loaded into standard containers | OP6a Electric locomotive has removed its standard container OP6b Electric locomotives began to hook standard containers |

| P7 | IP7 The electric locomotive began to run | OP7 Electric locomotive arrives at Cw2 |

| P8 | IP8a Electric locomotives began to remove their standard containers IP8b Cw2 waste is loaded into standard containers | OP8a Electric locomotive has removed its standard container OP8b Electric locomotives began to hook standard containers |

| P9 | IP9 The electric locomotive began to run supplies | OP9 Electric locomotive arrives at Cw1 |

| P10 | IP10 Electric locomotives began to return mine waste | OP10 The electric locomotive arrives at Ch2 |

| P11 | IP11a The monorail begins to grab the standard container IP11b The monorail began to remove its standard container | OP11a Monorail crane has grabbed the standard container transfer completed OP11b Electric locomotive connected to flatbed car, transshipment |

| P12 | IP12 The monorail crane started running to Cw3 | OP12 Monorail crane arrives at Cw3 |

| P13 | IP13a The monorail crane starts to run towards Cw4 IP13bThe monorail crane started running in Ch3 | OP13a Monorail crane passes through the wind door to the Cw4 OP13b The monorail passes through the wind door to Ch3 |

| P14 | IP14a The monorail began to remove its standard container IP14b Ch3 waste is loaded into standard containers | OP14a Monorail crane unloading of a standard container is completed OP14b Monorail grabs a standard container |

| P15 | IP14 The monorail crane started running in Ch3 | OP15 Monorail crane arrives at Ch3 |

| P16 | IP16a The monorail began to remove its standard container IP16b Cw4 waste is loaded into standard containers | OP16a Monorail crane unloading of a standard container is completed OP16b Monorail grabs a standard container |

| The Locomotive Code Is Set Up in the Section | Starting Point—End Point | The Running Route Corresponds to the Place |

|---|---|---|

| R1 | Ch1~Cw2 | P1, P2, P3, P4, P6, P7, P8 |

| R2 | Ch1~Cw3 | P1, P2, P3, P5, P11, P12, P14 |

| R3 | Ch1~Cw4 | P1, P2, P3, P5, P11, P13, P16 |

| R4 | Cw2~Ch1 | P8, P9, P6, P10, P3, P2, P1 |

| R5 | Cw3~Ch1 | P14, P15, P11, P5, P3, P2, P1 |

| R6 | Cw4~Ch1 | P16, P13, P11, P5, P3, P2, P1 |

| R1 | R2 | R3 | R4 | R5 | R6 | R1 | R2 | R3 | R4 | R5 | R6 | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pm | 0 | 4 | 9 | 19 | 15 | 7 | P9 | - | - | - | 3 | - | - |

| P1 | 3 | 4 | 2 | 1 | 1 | 1 | P10 | - | - | - | 2 | - | - |

| P2, | 5 | 5 | 5 | 5 | 5 | 5 | P11 | - | 5 | 5 | - | 5 | 5 |

| P3 | 3 | 3 | 2 | 2 | 4 | 2 | P12 | - | 3 | - | - | - | - |

| P4 | 2 | - | - | - | - | - | P13 | - | - | 4 | - | - | 4 |

| P5 | - | 4 | 2 | - | 3 | 4 | P14 | - | 2 | - | - | 3 | - |

| P6 | 1 | - | - | 2 | - | - | P15 | - | - | - | - | 3 | - |

| P7 | 3 | - | - | - | - | - | P16 | - | - | 1 | - | - | 2 |

| P8 | 2 | - | - | 3 | - | - | Pn | - | - | - | - | - | - |

| Conflicting Information | Conflict Identification |

|---|---|

| C1 = (R1, R3, P5; 20) | |

| C2 = (R2, R3, R6; P5; 18) | |

| C3 = (R4, R5; P3; 29) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, G.; Yan, X.; Kou, Z.; Deng, H.; Wang, K. Research on Operation Conflict of Auxiliary Transport Locomotive in Complex Mine Based on Extended Petri Net. Machines 2023, 11, 552. https://doi.org/10.3390/machines11050552

Wang G, Yan X, Kou Z, Deng H, Wang K. Research on Operation Conflict of Auxiliary Transport Locomotive in Complex Mine Based on Extended Petri Net. Machines. 2023; 11(5):552. https://doi.org/10.3390/machines11050552

Chicago/Turabian StyleWang, Guorong, Xuanxuan Yan, Ziming Kou, Haishun Deng, and Kaisong Wang. 2023. "Research on Operation Conflict of Auxiliary Transport Locomotive in Complex Mine Based on Extended Petri Net" Machines 11, no. 5: 552. https://doi.org/10.3390/machines11050552

APA StyleWang, G., Yan, X., Kou, Z., Deng, H., & Wang, K. (2023). Research on Operation Conflict of Auxiliary Transport Locomotive in Complex Mine Based on Extended Petri Net. Machines, 11(5), 552. https://doi.org/10.3390/machines11050552