Overview of Selective Laser Melting for Industry 5.0: Toward Customizable, Sustainable, and Human-Centric Technologies

Abstract

1. Introduction

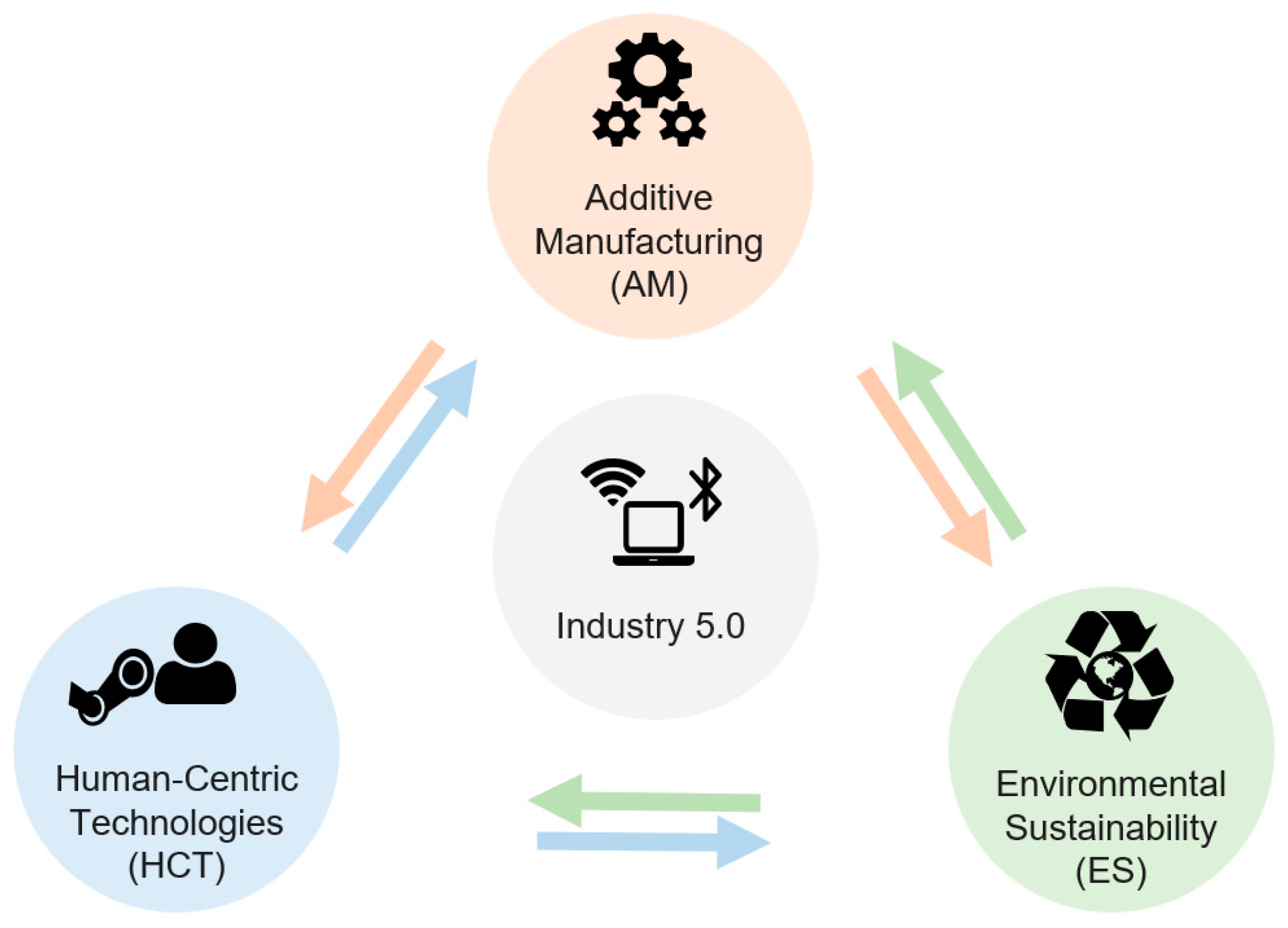

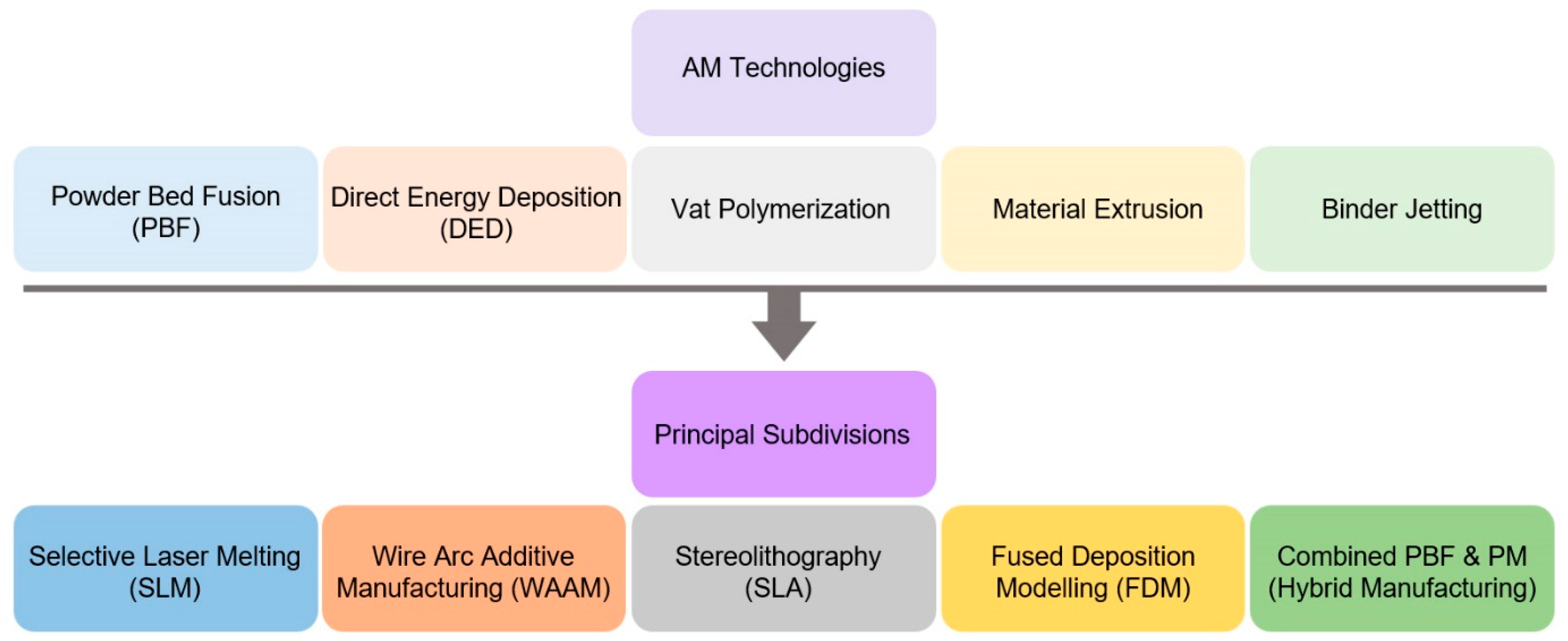

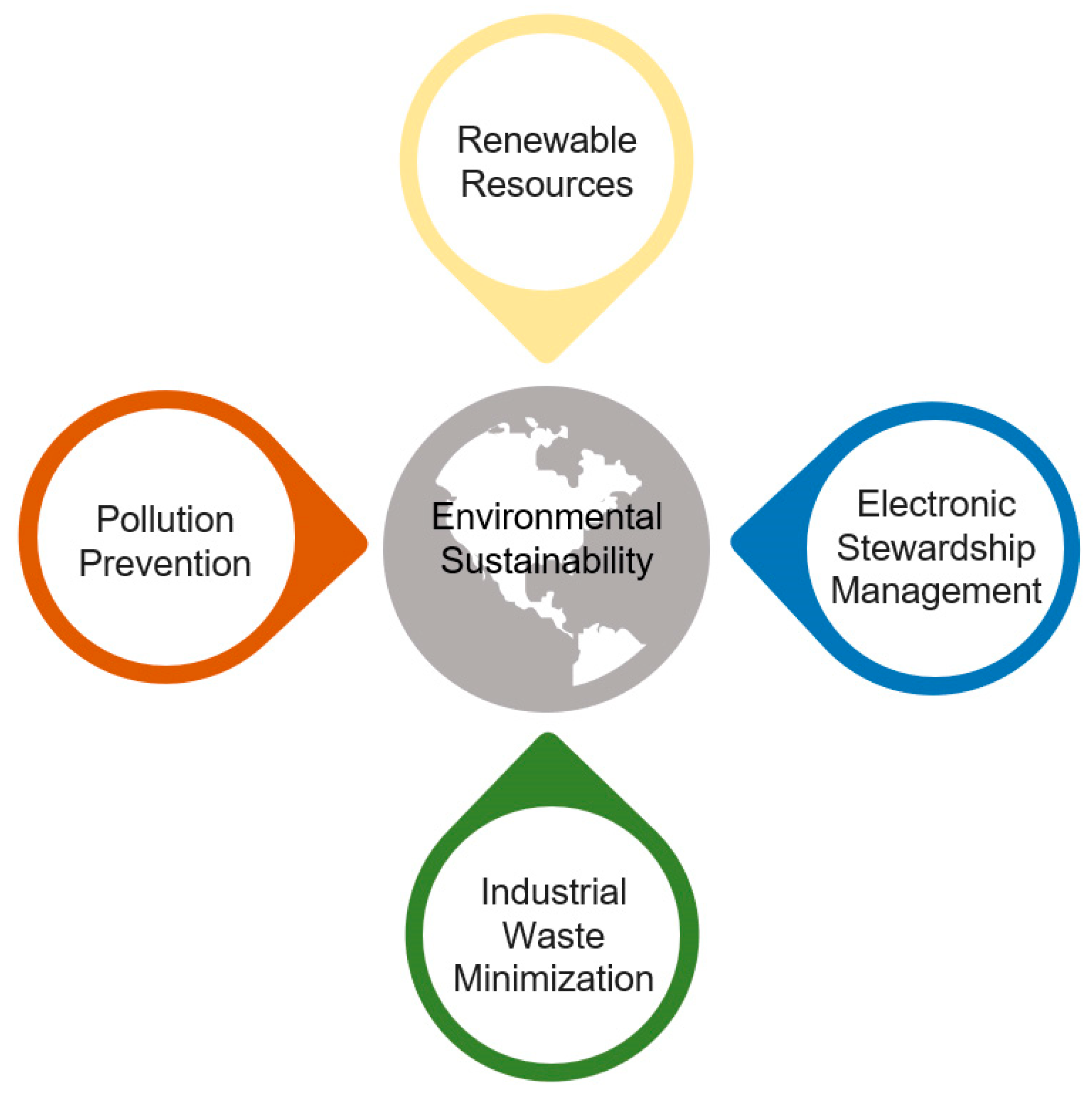

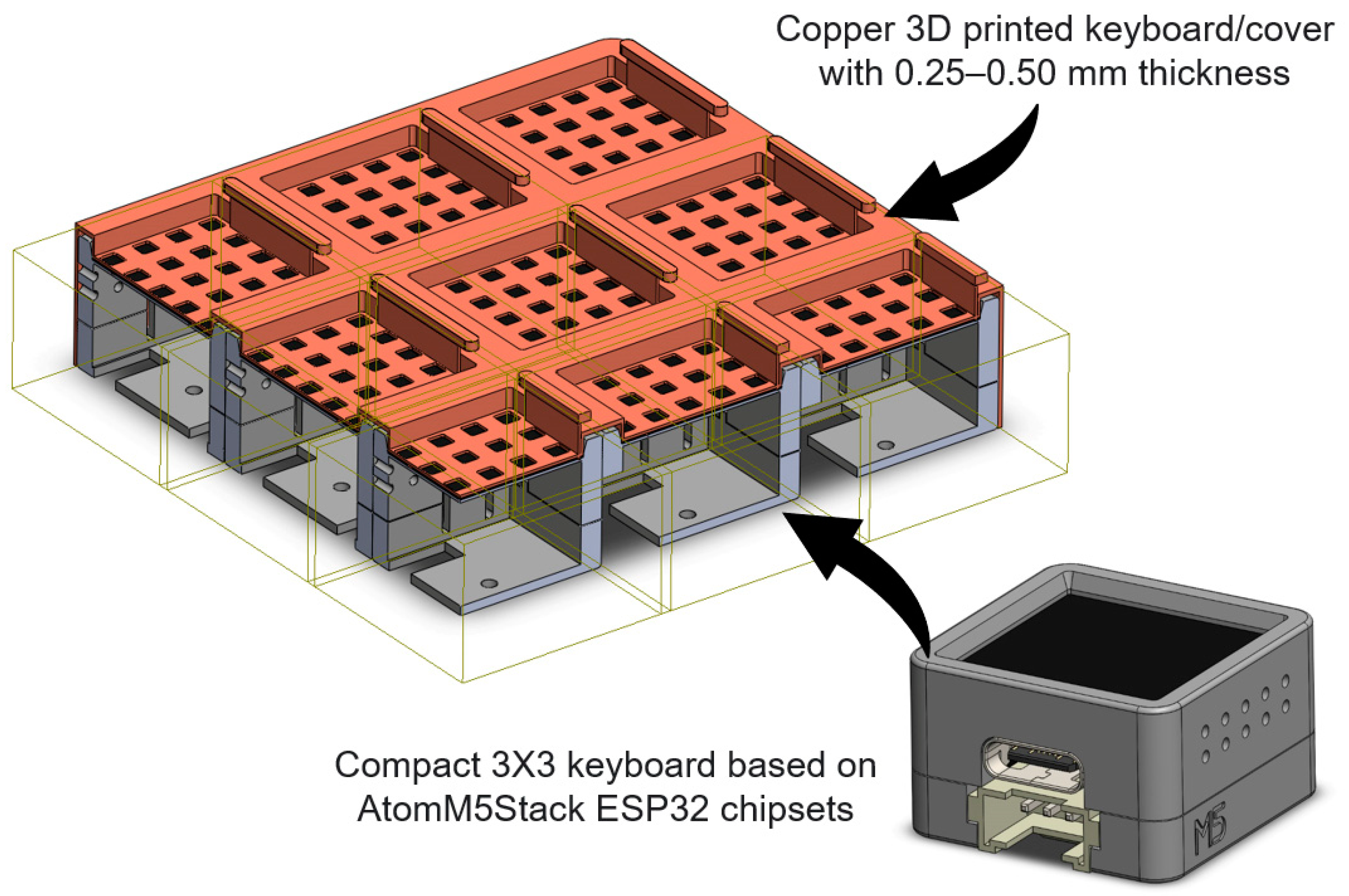

2. Industry 5.0: HCT, AM, and ES

- The fabrication of lightweight structures (material minimizing);

- Reductions in fabrication time (energy minimizing);

- Using double- or quadruple-laser sources to enhance production rates (time efficiency);

- Standardizing the process (cost efficiency).

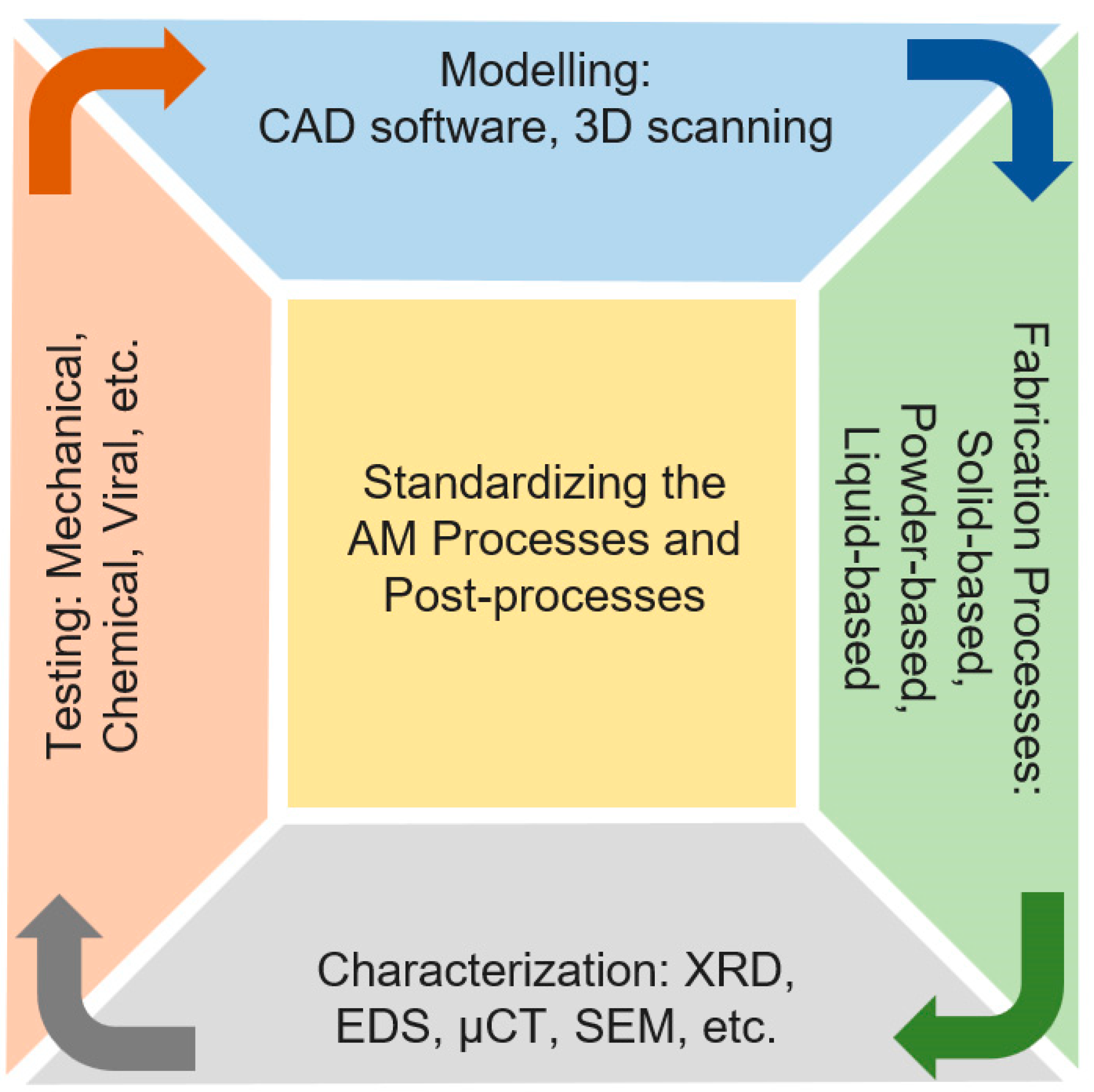

- Modeling: The 3D scanning of a (present) part or the CAD modeling of a new model; design software and portable scanners are important for CC.

- Fabrication: Material properties and specifications for all kinds of AM processes.

- Characterization: Macro- or microstructure investigations, density measurements, etc.

- Testing: This includes defining testing protocols, mechanical properties, and inspection criteria and certifying parts for their application.

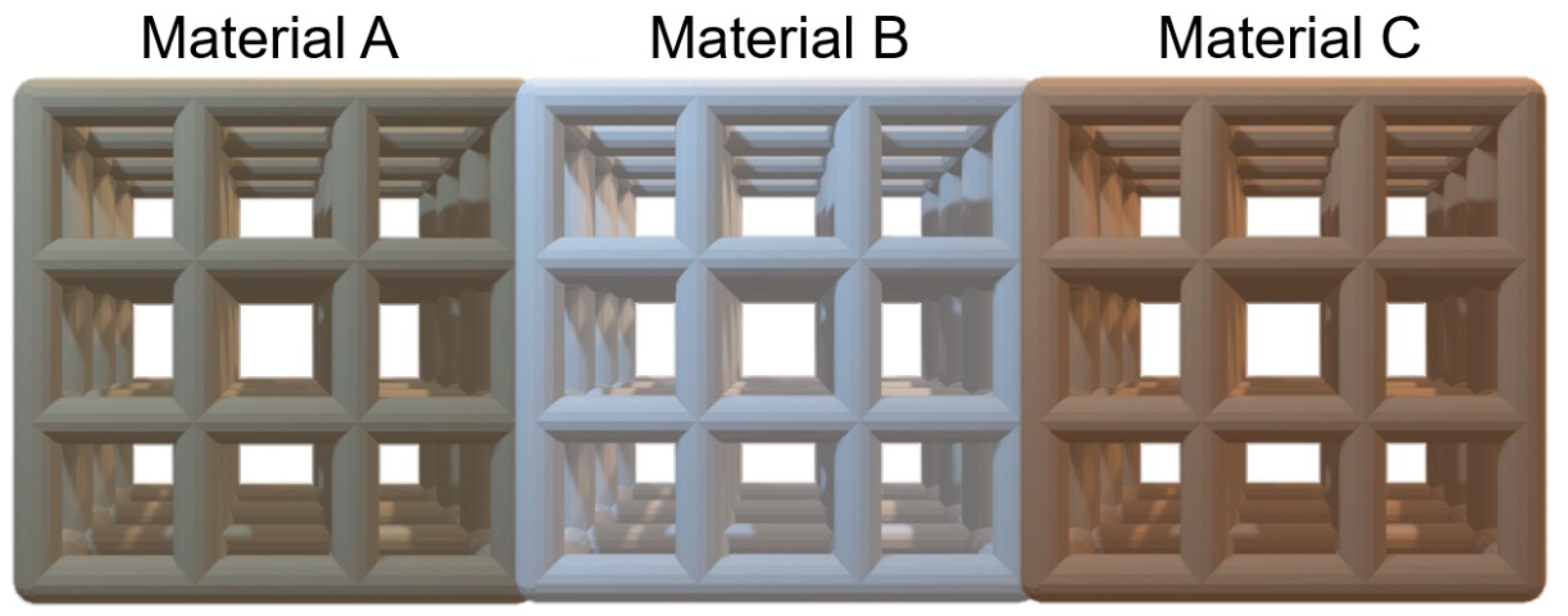

3. Industry 5.0: Fabrication of Multi-Material AM Objects with Complex Geometries

- High thermal conductivity: Copper alloys have high thermal conductivity, which can lead to heat dissipation and insufficient energy input during the SLM process. This can result in poor fusion, porosity, and a lack of adhesion between layers.

- Oxidation: Copper alloys are prone to oxidation, which can occur during the SLM process due to exposure to oxygen in the atmosphere. This can lead to the formation of oxides and porosity in the final product.

- Residual stresses: The SLM process can introduce residual stresses into the part due to the rapid heating and cooling cycles. In copper alloys, these residual stresses can lead to distortion and cracking in the final product.

- Real-time monitoring: Sensors can be used to monitor the temperature and energy input during the SLM process to ensure that the parameters are optimized for copper alloys. This can help prevent heat dissipation and insufficient energy input.

- Inert gas environment: Industry 5.0 can enable the use of an inert gas environment during the SLM process to prevent oxidation and reduce porosity in the final product.

- Automated post-processing: Industry 5.0 can enable the automated post-processing of parts to reduce residual stresses and distortion. This can include heat treatment, machining, and surface finishing.

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Abbreviation | Name |

| AI | Artificial Intelligence |

| AM | Additive Manufacturing |

| BJ | Binder Jetting |

| CAD | Computer-Aided Design |

| CAE | Computer-Aided Engineering |

| CAM | Computer-Aided Manufacturing |

| CC | Cloud Computing |

| CR | Collaborative Robots |

| CS | Collaborative Software |

| DED | Direct Energy Deposition |

| EDS | Energy Dispersive Spectroscopy |

| EMS | Electronic Stewardship Management |

| ES | Environmental Sustainability |

| FDM | Fused Deposition Modeling |

| FFF | Fused Filament Fabrication |

| HCT | Human-Centric Technologies |

| HMI | Human–Machine Interface |

| IoT | Internet of Things |

| IS | Interdisciplinary Software |

| ISS | International Space Station |

| IWM | Industrial Waste Minimization |

| LPBF | Laser Powder Bed Fusion |

| MMAM | Multi-Material Additive Manufacturing |

| ML | Machine Learning |

| NASA | National Aeronautics and Space Administration |

| PBF-LB | Laser-Based Powder Bed Fusion |

| PBF | Powder Bed Fusion |

| PM | Powder Metallurgy |

| PP | Pollution Prevention |

| ROC | Return of Capital |

| RR | Renewable Resources |

| SEM | Scanning Electron Microscope |

| SLA | Stereolithography |

| SLM | Selective Laser Melting |

| SPS | Spark Plasma Sintering |

| SRM | Sensor Robotic Manufacturing |

| VR | Virtual Reality |

| WAAM | Wire Arc Additive Manufacturing |

| XRD | X-Ray Diffraction |

| µCT | Micro-Computed Tomography |

References

- Xu, X.; Lu, Y.; Vogel-Heuser, B.; Wang, L. Industry 4.0 and Industry 5.0—Inception, conception and perception. J. Manuf. Syst. 2021, 61, 530–535. [Google Scholar] [CrossRef]

- Leng, J.; Sha, W.; Wang, B.; Zheng, P.; Zhuang, C.; Liu, Q.; Wuest, T.; Mourtzis, D.; Wang, L. Industry 5.0: Prospect and retrospect. J. Manuf. Syst. 2022, 65, 279–295. [Google Scholar] [CrossRef]

- Kong, X.T.R.; Luo, H.; Huang, G.Q.; Yang, X. Industrial wearable system: The human-centric empowering technology in Industry 4.0. J. Intell. Manuf. 2018, 30, 2853–2869. [Google Scholar] [CrossRef]

- Nahavandi, S. Industry 5.0—A Human-Centric Solution. Sustainability 2019, 11, 4371. [Google Scholar] [CrossRef]

- Gopal, M.; Lemu, H.G.; Gutema, E.M. Sustainable Additive Manufacturing and Environmental Implications: Literature Review. Sustainability 2022, 15, 504. [Google Scholar] [CrossRef]

- Karimi, J.; Antonov, M.; Kollo, L.; Prashanth, K. Role of laser remelting and heat treatment in mechanical and tribological properties of selective laser melted Ti6Al4V alloy. J. Alloys Compd. 2022, 5, 20–48. [Google Scholar] [CrossRef]

- Peng, T.; Kellens, K.; Tang, R.; Chen, C.; Chen, G. Sustainability of additive manufacturing: An overview on its energy demand and environmental impact. Addit. Manuf. 2018, 21, 694–704. [Google Scholar] [CrossRef]

- Rahmani, R.; Antonov, M.; Kamboj, N. Modelling of impact-abrasive wear of ceramic, metallic, and composite materials. Proc. Est. Acad. Sci. 2019, 68, 191. [Google Scholar] [CrossRef]

- Rahmani, R.; Antonov, M.; Kollo, L. Selective Laser Melting of Diamond-Containing or Postnitrided Materials Intended for Impact-Abrasive Conditions: Experimental and Analytical Study. Adv. Mater. Sci. Eng. 2019, 2019, 4210762. [Google Scholar] [CrossRef]

- Karimi, J.; Antonov, M.; Prashanth, K.G. Effect of Wear Debris Entrapment on the Tribological Performance of AlCoCrFeNi Produced by Selective Laser Melting or Spark Plasma Sintering. Met. Mater. Trans. A 2022, 53, 4004–4010. [Google Scholar] [CrossRef]

- Karimi, J.; Xie, M.; Wang, Z.; Prashanth, K. Influence of substructures on the selective laser melted Ti-6Al-4V alloy as a function of laser re-melting. J. Manuf. Process. 2021, 68, 1387–1394. [Google Scholar] [CrossRef]

- Tiberto, D.; Klotz, U.E.; Held, F.; Wolf, G. Additive manufacturing of copper alloys: Influence of process parameters and alloying elements. Mater. Sci. Technol. 2019, 35, 969–977. [Google Scholar] [CrossRef]

- Lu, Y.; Zheng, H.; Chand, S.; Xia, W.; Liu, Z.; Xu, X.; Wang, L.; Qin, Z.; Bao, J. Outlook on human-centric manufacturing towards Industry 5.0. J. Manuf. Syst. 2022, 62, 612–627. [Google Scholar] [CrossRef]

- Reeves, P.; Tuck, C.; Hague, R. Additive Manufacturing for Mass Customization. In Mass Customization: Engineering and Managing Global Operations; Springer: Berlin, Germany, 2011; pp. 275–289. [Google Scholar] [CrossRef]

- Chappells, H.; Shove, E. Debating the future of comfort: Environmental sustainability, energy consumption and the indoor environment. Build. Res. Inf. 2005, 33, 32–40. [Google Scholar] [CrossRef]

- Hancke, T.; Besant, C.; Ristic, M.; Husband, T. Human-Centred Technology. IFAC Proc. Vol. 1990, 23, 59–66. [Google Scholar] [CrossRef]

- Duggal, A.S.; Malik, P.K.; Gehlot, A.; Singh, R.; Gaba, G.S.; Masud, M.; Al-Amri, J.F. A sequential roadmap to Industry 6.0: Exploring future manufacturing trends. IET Commun. 2021, 16, 521–531. [Google Scholar] [CrossRef]

- Heilala, J.; Singh, K. Evaluation Planning for Artificial Intelligence-based Industry 6.0 Metaverse Integration. In Intelligent Human Systems Integration (IHSI 2023): Integrating People and Intelligent Systems (IHSI International Conference, USA); AHFE International: New York, NY, USA, 2023; Volume 69. [Google Scholar] [CrossRef]

- Rahmani, R.; Antonov, M.; Kollo, L.; Holovenko, Y.; Prashanth, K.G. Mechanical Behavior of Ti6Al4V Scaffolds Filled with CaSiO3 for Implant Applications. Appl. Sci. 2019, 9, 3844. [Google Scholar] [CrossRef]

- Rahmani, R.; Rosenberg, M.; Ivask, A.; Kollo, L. Comparison of Mechanical and Antibacterial Properties of TiO2/Ag Ceramics and Ti6Al4V-TiO2/Ag Composite Materials Using Combined SLM-SPS Techniques. Metals 2019, 9, 874. [Google Scholar] [CrossRef]

- Adel, A. Future of industry 5.0 in society: Human-centric solutions, challenges and prospective research areas. J. Cloud Comput. 2022, 11, 1–15. [Google Scholar] [CrossRef]

- Prater, T.; Werkheiser, N.; Ledbetter, F.; Timucin, D.; Wheeler, K.; Snyder, M. 3D Printing in Zero G Technology Demonstration Mission: Complete experimental results and summary of related material modeling efforts. Int. J. Adv. Manuf. Technol. 2018, 101, 391–417. [Google Scholar] [CrossRef]

- Özdemir, V.; Hekim, N. Birth of Industry 5.0: Making Sense of Big Data with Artificial Intelligence, “The Internet of Things” and Next-Generation Technology Policy. OMICS A J. Integr. Biol. 2018, 22, 65–76. [Google Scholar] [CrossRef] [PubMed]

- Martínez-Plumed, F.; Gómez, E.; Hernández-Orallo, J. Futures of artificial intelligence through technology readiness levels. Telemat. Inform. 2021, 85, 101525. [Google Scholar] [CrossRef]

- McGurk, Z.; Nowak, A.; Hall, J.C. Stock returns and investor sentiment: Textual analysis and social media. J. Econ. Financ. 2019, 44, 458–485. [Google Scholar] [CrossRef]

- Tayles, M.; Webster, M.; Sugden, D.; Bramley, A. Accounting “gets real” in dealing with virtual manufacturing. J. Intellect. Cap. 2005, 6, 322–338. [Google Scholar] [CrossRef]

- Xiong, Y.; Tang, Y.; Kim, S.; Rosen, D.W. Human-machine collaborative additive manufacturing. J. Manuf. Syst. 2023, 66, 82–91. [Google Scholar] [CrossRef]

- Alves, J.; Lima, T.M.; Gaspar, P.D. Is Industry 5.0 a Human-Centred Approach? A Systematic Review. Processes 2023, 11, 193. [Google Scholar] [CrossRef]

- Sealy, M.P.; Madireddy, G.; Williams, R.E.; Rao, P.; Toursangsaraki, M. Hybrid Processes in Additive Manufacturing. J. Manuf. Sci. Eng. 2018, 140, 060801. [Google Scholar] [CrossRef]

- Rahmani, R.; Antonov, M.; Kollo, L. Wear Resistance of (Diamond-Ni)-Ti6Al4V Gradient Materials Prepared by Combined Selective Laser Melting and Spark Plasma Sintering Techniques. Adv. Tribol. 2019, 2019, 1–12. [Google Scholar] [CrossRef]

- Karimi, J.; Kollo, L.; Rahmani, R.; Ma, P.; Jia, Y.; Prashanth, K. Selective laser melting of in-situ CoCrFeMnNi high entropy alloy: Effect of remelting. J. Manuf. Process. 2022, 84, 55–63. [Google Scholar] [CrossRef]

- Rahmani, R.; Kamboj, N.; Brojan, M.; Antonov, M.; Prashanth, K.G. Hybrid metal-ceramic biomaterials fabricated through powder bed fusion and powder metallurgy for improved impact resistance of craniofacial implants. Materialia 2022, 24, 101465. [Google Scholar] [CrossRef]

- Piscopo, G.; Iuliano, L. Current research and industrial application of laser powder directed energy deposition. Int. J. Adv. Manuf. Technol. 2022, 119, 6893–6917. [Google Scholar] [CrossRef]

- Dass, A.; Moridi, A. State of the Art in Directed Energy Deposition: From Additive Manufacturing to Materials Design. Coatings 2019, 9, 418. [Google Scholar] [CrossRef]

- Derekar, K.S. A review of wire arc additive manufacturing and advances in wire arc additive manufacturing of aluminium. Mater. Sci. Technol. 2018, 34, 895–916. [Google Scholar] [CrossRef]

- Cunningham, C.; Flynn, J.; Shokrani, A.; Dhokia, V.; Newman, S. Invited review article: Strategies and processes for high quality wire arc additive manufacturing. Addit. Manuf. 2018, 22, 672–686. [Google Scholar] [CrossRef]

- Navarro, M.; Matar, A.; Diltemiz, S.F.; Eshraghi, M. Development of a Low-Cost Wire Arc Additive Manufacturing System. J. Manuf. Mater. Process. 2021, 6, 3. [Google Scholar] [CrossRef]

- Zimermann, R.; Mohseni, E.; Vasilev, M.; Loukas, C.; Vithanage, R.K.W.; Macleod, C.N.; Lines, D.; Javadi, Y.; Espirindio E Silva, M.P.; Fitzpatrick, S.; et al. Collaborative Robotic Wire + Arc Additive Manufacture and Sensor-Enabled In-Process Ultrasonic Non-Destructive Evaluation. Sensors 2022, 22, 4203. [Google Scholar] [CrossRef]

- Available online: https://digitalmetal.tech/ (accessed on 10 March 2023).

- Available online: https://www.exone.com/ (accessed on 10 March 2023).

- Schneck, M.; Horn, M.; Schmitt, M.; Seidel, C.; Schlick, G.; Reinhart, G. Review on additive hybrid- and multi-material-manufacturing of metals by powder bed fusion: State of technology and development potential. Prog. Addit. Manuf. 2021, 6, 881–894. [Google Scholar] [CrossRef]

- Chueh, Y.-H.; Zhang, X.; Ke, J.C.-R.; Li, Q.; Wei, C.; Li, L. Additive manufacturing of hybrid metal/polymer objects via multiple-material laser powder bed fusion. Addit. Manuf. 2020, 36, 101465. [Google Scholar] [CrossRef]

- Molan, K.; Rahmani, R.; Krklec, D.; Brojan, M.; Stopar, D. Phi 6 Bacteriophage Inactivation by Metal Salts, Metal Powders, and Metal Surfaces. Viruses 2022, 14, 204. [Google Scholar] [CrossRef]

- Rahmani, R.; Molan, K.; Brojan, M.; Prashanth, K.G.; Stopar, D. High virucidal potential of novel ceramic–metal composites fabricated via hybrid selective laser melting and spark plasma sintering routes. Int. J. Adv. Manuf. Technol. 2022, 120, 975–988. [Google Scholar] [CrossRef]

- Zhu, Y.; Romain, C.; Williams, C.K. Sustainable polymers from renewable resources. Nature 2016, 540, 354–362. [Google Scholar] [CrossRef] [PubMed]

- Elleuch, B.; Bouhamed, F.; Elloussaief, M.; Jaghbir, M. Environmental sustainability and pollution prevention. Environ. Sci. Pollut. Res. 2018, 25, 18223–18225. [Google Scholar] [CrossRef] [PubMed]

- Sun, L.; Jiang, X.; Ren, H.; Guo, Y. Edge-Cloud Computing and Artificial Intelligence in Internet of Medical Things: Architecture, Technology and Application. IEEE Access 2020, 8, 101079–101092. [Google Scholar] [CrossRef]

- Wan, J.; Yang, J.; Wang, Z.; Hua, Q. Artificial Intelligence for Cloud-Assisted Smart Factory. IEEE Access 2018, 6, 55419–55430. [Google Scholar] [CrossRef]

- Ikeshoji, T.-T.; Nakamura, K.; Yonehara, M.; Imai, K.; Kyogoku, H. Selective Laser Melting of Pure Copper. JOM 2017, 70, 396–400. [Google Scholar] [CrossRef]

- Jadhav, S.; Dadbakhsh, S.; Goossens, L.; Kruth, J.-P.; Van Humbeeck, J.; Vanmeensel, K. Influence of selective laser melting process parameters on texture evolution in pure copper. J. Mater. Process. Technol. 2019, 270, 47–58. [Google Scholar] [CrossRef]

- Lingqin, X.; Guang, C.; Luyu, Z.; Pan, L. Explore the feasibility of fabricating pure copper parts with low-laser energy by selective laser melting. Mater. Res. Express 2020, 7, 106509. [Google Scholar] [CrossRef]

- Rahmani, R.; Brojan, M.; Antonov, M.; Prashanth, K.G. Perspectives of metal-diamond composites additive manufacturing using SLM-SPS and other techniques for increased wear-impact resistance. Int. J. Refract. Met. Hard Mater. 2020, 88, 105192. [Google Scholar] [CrossRef]

- Rahmani, R.; Antonov, M.; Brojan, M. Lightweight 3D printed Ti6Al4V-AlSi10Mg hybrid composite for impact resistance and armor piercing shielding. J. Mater. Res. Technol. 2020, 9, 13842–13854. [Google Scholar] [CrossRef]

- Rahmani, R.; Antonov, M.; Prashanth, K.G. The Impact Resistance of Highly Densified Metal Alloys Manufactured from Gas-Atomized Pre-Alloyed Powders. Coatings 2021, 11, 216. [Google Scholar] [CrossRef]

- Holovenko, Y.; Kollo, L.; Saarna, M.; Rahmani, R.; Soloviova, T.; Antonov, M.; Prashanth, K.G.; Cygan, S.; Veinthal, R. Effect of lattice surface treatment on performance of hardmetal-titanium interpenetrating phase composites. Int. J. Refract. Met. Hard Mater. 2019, 86, 105087. [Google Scholar] [CrossRef]

- Chen, J.; Yang, Y.; Song, C.; Zhang, M.; Wu, S.; Wang, D. Interfacial microstructure and mechanical properties of 316L/CuSn10 multi-material bimetallic structure fabricated by selective laser melting. Mater. Sci. Eng. A 2019, 752, 75–85. [Google Scholar] [CrossRef]

- Andani, M.T.; Dehghani, R.; Karamooz-Ravari, M.R.; Mirzaeifar, R.; Ni, J. Spatter formation in selective laser melting process using multi-laser technology. Mater. Des. 2017, 131, 460–469. [Google Scholar] [CrossRef]

- Zou, S.; Xiao, H.; Ye, F.; Li, Z.; Tang, W.; Zhu, F.; Chen, C.; Zhu, C. Numerical analysis of the effect of the scan strategy on the residual stress in the multi-laser selective laser melting. Results Phys. 2020, 16, 103005. [Google Scholar] [CrossRef]

- Zhang, C.; Zhu, H.; Hu, Z.; Zhang, L.; Zeng, X. A comparative study on single-laser and multi-laser selective laser melting AlSi10Mg: Defects, microstructure and mechanical properties. Mater. Sci. Eng. A 2019, 746, 416–423. [Google Scholar] [CrossRef]

- Li, Z.; Kuai, Z.; Bai, P.; Nie, Y.; Fu, G.; Liu, W.; Yang, S. Microstructure and Tensile Properties of AlSi10Mg Alloy Manufactured by Multi-Laser Beam Selective Laser Melting (SLM). Metals 2019, 9, 1337. [Google Scholar] [CrossRef]

- Antonov, M.; Ivanov, R.; Holovenko, Y.; Goljandin, D.; Rahmaniahranjani, R.; Kollo, L.; Hussainova, I. 3D Printing of Plain and Gradient Cermets with Efficient Use of Raw Materials. Key Eng. Mater. 2019, 799, 239–245. [Google Scholar]

- Aksa, H.C.; Hacısalihoğlu, İ.; Yıldız, F.; Varol, T.; Güler, O.; Kaya, G.; Akçay, S.B. Effects of fabrication parameters and post-processing treatments on the mechanical and tribological behavior of surface-enhanced copper based materials by selective laser melting. J. Mater. Process. Technol. 2022, 304, 117564. [Google Scholar] [CrossRef]

- Rahmani, R.; Karimi, J.; Kamboj, N.; Kumar, R.; Brojan, M.; Tchórz, A.; Skrabalak, G.; Lopes, S.I. Fabrication of localized diamond-filled copper structures via selective laser melting and spark plasma sintering. Diam. Relat. Mater. 2023, 109916. [Google Scholar] [CrossRef]

- Kaden, L.; Matthäus, G.; Ullsperger, T.; Engelhardt, H.; Rettenmayr, M.; Tünnermann, A.; Nolte, S. Selective laser melting of copper using ultrashort laser pulses. Appl. Phys. A 2017, 123, 1–6. [Google Scholar] [CrossRef]

- Available online: https://www.trumpf.com/en_INT/products/laser/disk-lasers (accessed on 15 April 2023).

- Jia, H.; Sun, H.; Wang, H.; Wu, Y.; Wang, H. Scanning strategy in selective laser melting (SLM): A review. Int. J. Adv. Manuf. Technol. 2021, 113, 2413–2435. [Google Scholar] [CrossRef]

- Lo, Y.-L.; Liu, B.-Y.; Tran, H.-C. Optimized hatch space selection in double-scanning track selective laser melting process. Int. J. Adv. Manuf. Technol. 2019, 105, 2989–3006. [Google Scholar] [CrossRef]

- Gebbe, C.; Lutter-Günther, M.; Greiff, B.; Glasschröder, J.; Reinhart, G. Measurement of the Resource Consumption of a Selective Laser Melting Process. Appl. Mech. Mater. 2015, 805, 205–212. [Google Scholar]

- Zeng, K. Optimization of Support Structures for Selective Laser Melting. Master’s Thesis, University of Louisville, Louisville, KY, USA, 2016. [Google Scholar] [CrossRef]

- Shipley, H.; McDonnell, D.; Culleton, M.; Coull, R.; Lupoi, R.; O’Donnell, G.; Trimble, D. Optimisation of process parameters to address fundamental challenges during selective laser melting of Ti-6Al-4V: A review. Int. J. Mach. Tools Manuf. 2018, 128, 1–20. [Google Scholar] [CrossRef]

- Kamboj, N.; Kazantseva, J.; Rahmani, R.; Rodríguez, M.A.; Hussainova, I. Selective laser sintered bio-inspired silicon-wollastonite scaffolds for bone tissue engineering. Mater. Sci. Eng. C 2020, 116, 111223. [Google Scholar] [CrossRef]

- Kamboj, N.; Rodríguez, M.A.; Rahmani, R.; Prashanth, K.G.; Hussainova, I. Bioceramic scaffolds by additive manufacturing for controlled delivery of the antibiotic vancomycin. Proc. Est. Acad. Sci. 2019, 68, 185–190. [Google Scholar] [CrossRef]

- Available online: https://scheftner.dental/cocr-powder.html (accessed on 15 April 2023).

- Zhang, S.; Zhu, H.; Hu, Z.; Zeng, X.; Zhong, F. Selective Laser Melting of Cu 10Zn alloy powder using high laser power. Powder Technol. 2018, 342, 613–620. [Google Scholar] [CrossRef]

- Yan, X.; Chang, C.; Dong, D.; Gao, S.; Ma, W.; Liu, M.; Liao, H.; Yin, S. Microstructure and mechanical properties of pure copper manufactured by selective laser melting. Mater. Sci. Eng. A 2020, 789, 139615. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rahmani, R.; Karimi, J.; Resende, P.R.; Abrantes, J.C.C.; Lopes, S.I. Overview of Selective Laser Melting for Industry 5.0: Toward Customizable, Sustainable, and Human-Centric Technologies. Machines 2023, 11, 522. https://doi.org/10.3390/machines11050522

Rahmani R, Karimi J, Resende PR, Abrantes JCC, Lopes SI. Overview of Selective Laser Melting for Industry 5.0: Toward Customizable, Sustainable, and Human-Centric Technologies. Machines. 2023; 11(5):522. https://doi.org/10.3390/machines11050522

Chicago/Turabian StyleRahmani, Ramin, Javad Karimi, Pedro R. Resende, João C. C. Abrantes, and Sérgio I. Lopes. 2023. "Overview of Selective Laser Melting for Industry 5.0: Toward Customizable, Sustainable, and Human-Centric Technologies" Machines 11, no. 5: 522. https://doi.org/10.3390/machines11050522

APA StyleRahmani, R., Karimi, J., Resende, P. R., Abrantes, J. C. C., & Lopes, S. I. (2023). Overview of Selective Laser Melting for Industry 5.0: Toward Customizable, Sustainable, and Human-Centric Technologies. Machines, 11(5), 522. https://doi.org/10.3390/machines11050522