1. Introduction

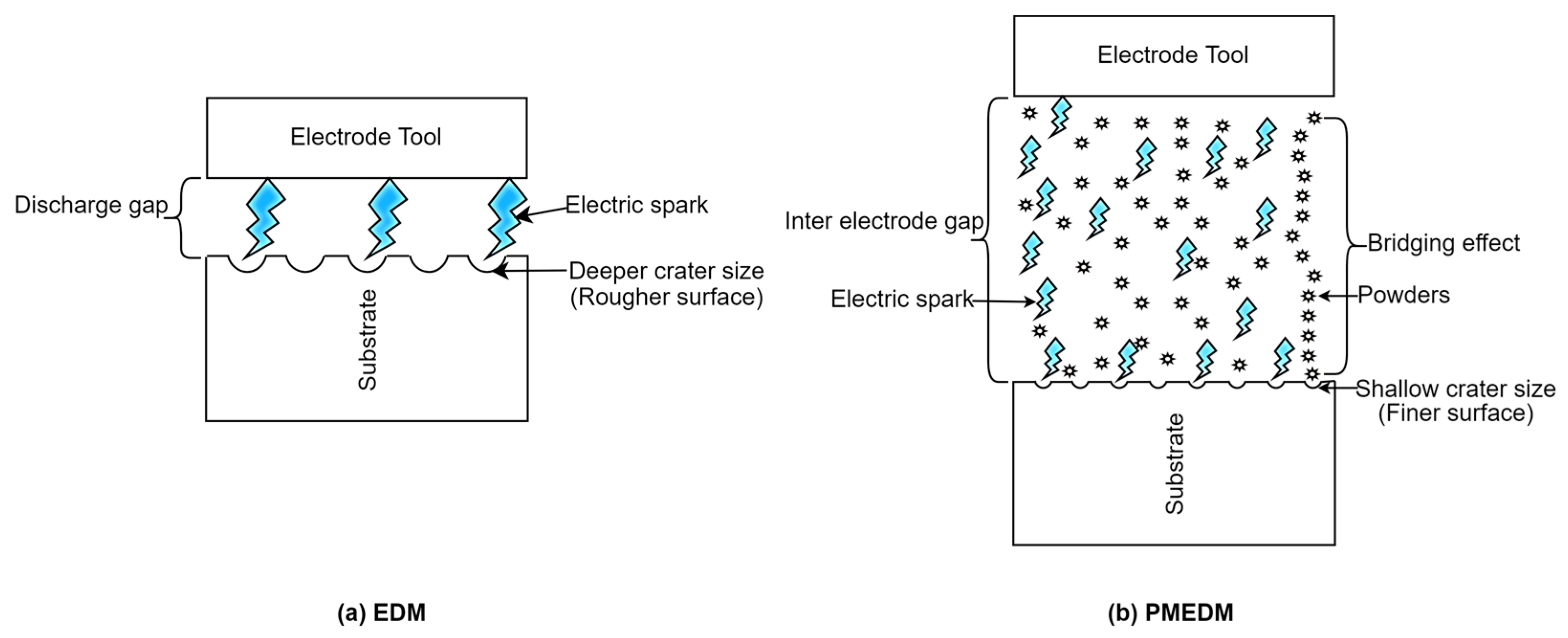

Electric Discharge Machining (EDM) technology has been applied efficiently in the die and mold-making industries, focusing on component precision rather than increased production [

1,

2,

3]. EDM is an electrothermal material erosion process that primarily uses electrical energy and converts it into thermal energy through a cycle of discontinuous electrical discharges ongoing among the tool and workpiece submerged in a dielectric medium. The thermal energy produces a plasma channel between the anode and cathode at extremely high temperatures (8000 °C to 12,000 °C) and pressure (20 MPa). During the machine work, the materials melt and evaporate in the presence of a dielectric which fulfils the requirement of coolant, insulation and flushing of microscopic debris [

4,

5]. EDM can efficiently machine hard, ductile, and brittle materials and create geometrically complicated shapes since there is no direct connection between the electrode and the workpiece [

6]. Nevertheless, the significant constraints, for instance, low material removal rate, inadequate surface quality, time-taking, and restriction to machine-only conductive materials, mitigate the employment of EDM [

7,

8,

9,

10].

The innovation of powder-mixed electric discharge machining (PMEDM) occurred in the late 1970s, and the initial publication was attained in the 1980s [

11]. Mitsubishi originated the revolutionary dual tanks for EDM in the additive process marketplace [

12]. The tank containing a dielectric only initiates the rough machining process, while the other tank comprising a powder-mixed dielectric provides the finish machining process. PMEDM is an innovative surface modification technique that can simultaneously machine and coat the workpiece and addresses the limitations to significant extent that exist in EDM. In PMEDM, thermally and electrically conductive powders are mixed with a dielectric fluid to strengthen the machining performance measures and altered surface characteristics by lowering the shielding strength of the dielectric fluid and augmenting the sparks among the tool and the workpiece. The gap between the electrode and workpiece was reported to be increased by 200%, enlarging the plasma channel and producing a shallow crater on the machined surface [

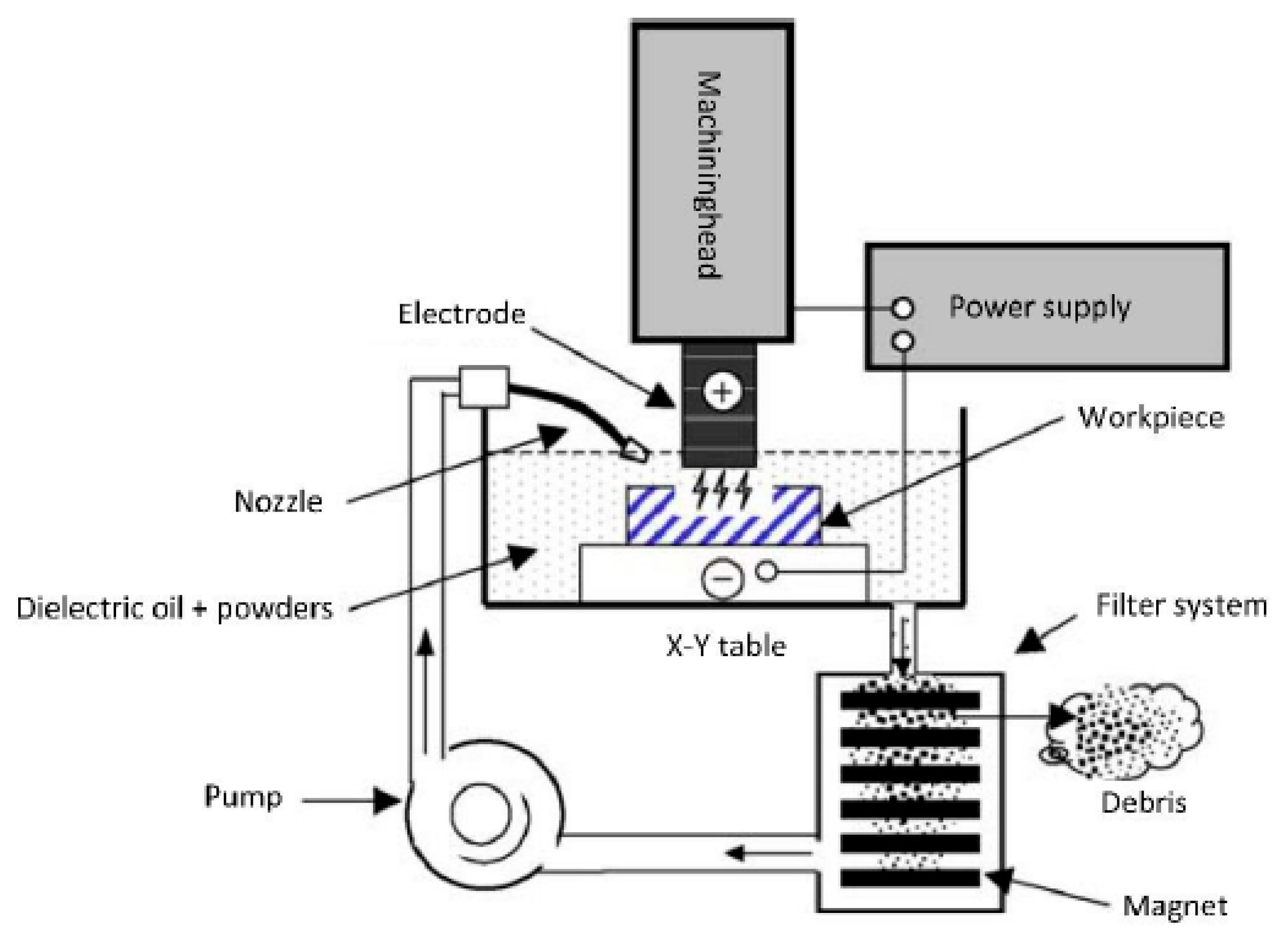

13]. This technological advancement draws researchers’ attention to significantly considering machined surfaces with alloy modification. A standard PMEDM arrangement, as shown in

Figure 1, is a slightly re-designed and upgraded version of the EDM setup.

In the PMEDM process, powder particles are suspended in a dielectric fluid with a powder circulation system via a stirrer and a set of permanent magnets to filter the remnants. Usually, a submersible pump is equipped to prevent the settlement of powder bits at the base of the working container. It also assists in avoiding the resting of powder particles on the component surface. A pair of permanent magnets enable the detachment of residues from the powder particles, which only applies when the workpiece is magnetic, and the powder material is non-magnetic. The add-on of appropriate powder particles to the dielectric contributes to a superior surface texture and improved production capability compared to the EDM that excludes powder-mixed dielectrics. The industrialization of PMEDM still requires a breakthrough. It can be accomplished by having a complete insight into its process mechanism, correlation, and influence of process factors on the performance responses.

The prime objective of this literature review study is to elucidate the PMEDM mechanism, the impact of powder characteristics and machining parameters on the PMEDM outcome and its potentiality in biomedical applications. Secondly, exploring the trend of additives employed in the PMEDM process, future research directions in the published literature and probing the opportunities for its commercialization.

2. Mechanism of PMEDM Process

The mechanism of PMEDM is yet to be explored, which involves the suspension of fine powder particles in the dielectric medium. An electrical field of 10

5–10

7 V/m is produced in the inter-electrode gap (IEG) of around 25–50 µm when adequate voltage (nearly 80–320 V) is used among the tool electrode and substrate. The powder particles get activated and build up in a random pattern, as illustrated in

Figure 2b. Under the sparking region, particles form chain-like formations between the electrode and substrate. The interlinking of the powder particles occurs in the current flow path. The chain-like arrangement of the molecules assists in bridging the spark gap between the electrode and the substrate and eventually reduces the insulating strength of the dielectric. The short-circuiting phenomenon causes a premature explosion in the IEG area, resulting in a series of discharges with rapid sparking and enhanced material removal rate [

14]. Concurrently, the added powder particles augment and broaden the discharge gap and passage with uniformly distributed sparking between the particles. It reduces spark current density, resulting in constant erosion with a finer finish on the machined surface [

15].

Mixing powder particles in the dielectric medium enables the enlargement and expansion of the machining gap, even the dispersal of sparks and alloying surface layer. The effect of Al powder particles in the kerosene dielectric medium during the machining operation is displayed in

Figure 3. From the representation, it can be observed that

Figure 3a depicts the sparking procedure of conventional EDM. In contrast, the steps in

Figure 3b–g represent the PMEDM process with an enlarged and widened discharge gap resulting in the formation of tiny craters due to the multiple discharges and bridging arrangement between the added Al particles.

Figure 3h shows the voltage waveform using the kerosene with Al powder particles during the single pulse duration [

13].

The electrical and physical characteristics of the powder particles portray a significant impact on the increase of the discharge gap. The available electrons lying in electrically conductive powders lessen the insulating strength of the dielectric. The enhanced conductivity results in the development of a spark from an enlarged distance and thus augments the discharge gap [

16]. Following the initial discharge, powder particles in IEG become excited and proceed promptly in conjunction with ions and electrons. These energetic powder particles impact dielectric molecules and trigger further ions and electrons [

17]. Therefore, a higher number of electrical charges are generated in PMEDM compared to traditional EDM.

Additionally, hydrostatic pressure operating on the plasma channel is lessened due to the discharge gap augmentation. The occurrences of these two incidents endorse the broadening of the discharge path. The severity of discharge strength lowered due to the increased and broadened discharge column, leading to substantial shallow cavities on the machined surface.

In a single pulse-on duration, a series of discharge pathways are examined in PMEDM caused by the abrupt zigzag displacement of the added powder particles, securing consistent energy dispersion and creating several minor craters. Unlike EDM, several fluctuating signals report various discharges in the PMEDM process during an individual pulse-on time [

18,

19]. When the dielectric fluid disintegrates, the carbon and oxygen molecules separate from it and blend with the partly melted powder particles and the residues of molten metal to shape carbides and oxides. Due to the exceptional amount of powder particles, the enervated debris could not flush out properly and suppresses in between the discharge gaps resulting in the relocation towards the substrate surface and infiltrating the molten pool until the curing occurs [

20]. Succeeded by additional discharges, the carbides and oxides speed up, generate negative pressure by electrophoresis, and migrate towards the machined surface. The coupled layer of carbides and oxides in the shape of micro-droplets develops a consolidated region on the upper surface of the machined substrate. Favorably, in parallel, an immense quantity of absorbed gas is expelled, which results in the making of pores and a smoother shape on the upper surface of the machined component, as stated by Peng et al. [

21].

Figure 3.

Influence of Al powder additive in kerosene dielectric medium during the machining process [

22].

Figure 3.

Influence of Al powder additive in kerosene dielectric medium during the machining process [

22].

The migrated coupled layer of oxides and carbides decreases micro-cracks generation on the modified coated surface and enhances the mechanical characteristics [

23]. The fundamental structure of material migration throughout the PMEDM process is demonstrated in

Figure 4. The schematic description of material migration during the PMEDM process is demonstrated in the subsequent steps: Step 1 indicates that the sparking develops the plasma channel of thermal flux among the powder particles and substrate surface; Step 2 demonstrates the assemblage of hydrocarbon (C) and oxygen bubbles (O) among the partly dissolved powder particles and molten metal micro-droplets (M); Step 3 shows the arrangement of carbides (MC, XC) and oxides (MO2, XO2) due to the existence of hydrocarbon (C), oxygen molecule (O), and powder particles (X) and Step 4 exhibits the infiltration of oxides and carbides in the molten pool area of the coated layer before curing on the substrate surface in PMEDM method. Janmanee et al. [

23] examined the deposition of a tough layer of tungsten carbide by EDM technique using titanium as a powder additive. The migrated, coupled layer diminishes the micro-cracks on the machined surface of the workpiece and enhances the mechanical features.

High heat generation and rapid quenching during the PMEDM process result in electrode materials melting, evaporation and re-solidifying. Due to this, surface modification naturally occurs in the PMEDM process with the stochastic behavioral response of process parameters.

3. Powder Characteristics and Its Utilization in the PMEDM Process

In the PMEDM process, the powder features play a crucial role in impacting several performance actions of the process. Therefore, it is imperative to assess powder characteristics and their interconnectivity with the EDM performance measures. Powder material, size and concentration are mainly essential features of the powder particles that influence the PMEDM process.

3.1. Powder Material

The essential thermophysical properties of the powder, i.e., particle density and electrical and thermal conductivity, significantly impact the performance measures of the PMEDM process. Wong et al. [

25] investigated the outcome of Graphite (Gr), Silicon (Si), Aluminum (Al), Silicon carbide (SiC), Molybdenum disulphide (MoS2) and crushed glass on PMEDM performance measures. They discovered that, except for crushed glass, all powders increased the discharge gap by at least two times and provided the near-mirror surface finish in machining SKH-51. The superior electrical and thermal conductivity of Al powder provided the major machining gap expansion by nearly 12 times and the best surface quality. The gap expansion attributes for Al powder are in harmony with the research by Chow et al. [

22] that assures the widening of the discharge gap and superior surface finish by adding Al powder particles to the dielectric medium. However, the influence of SiC additive is not in agreement because of its high electrical resistivity. Tzeng et al. [

26] pointed out that within Al, SiC and Cr powder particles, Cr provided the maximum material removal rate, followed by Al and SiC. In comparison, the tool wear rate was noticed with SiC, Al and Cr, respectively. Yih-Fong and Fu-Chen [

27] examined the Al, Cr, SiC and Cu powder particles and indicated that Al powder established the best surface finish and thinner white layers on the machined surface of SKD-11. Copper does not participate in the process due to its high particle density, which causes the powder to settle into the tank’s bottom. Adding Graphite (Gr) powder particles to the dielectric increases its electrical conductivity and offers exceptional lubricity. The suspended Gr powder particles deliver enhanced material erosion rate and lowered tool erosion rate, and its auspicious application lies in the micro-PMEDM [

16,

28,

29]. The utilization of Titanium (Ti) as an additive powder in the dielectric enhances the material erosion rate [

30], micro-hardness [

23], and surface quality. In contrast, it lowers the surface roughness and micro-cracks on the machined product. Likewise, Tungsten (W) powder-mixed dielectric boosts the micro-hardness of the machined surface by 100% [

31].

3.2. Powder Size

The size of the powder particle is considered a vital powder parameter to get desirable outcomes during the PMEDM process. Utilizing smaller powder particles in the dielectric fluid improves the metal erosion rate and surface condition of the modified surface compared to the larger powder particles [

26,

32,

33,

34]. According to the research by Tzeng and Lee [

26], smaller particles (70–80 nm) develop a minimal machining gap between the tool and the substrate, resulting in a more significant material removal rate and lower tool wear rate. Research by Yih-Fong et al. [

27] reported that the size or dimension of the powder particle is the decisive factor in the machined surface quality. Smaller particles result in a superior surface finish while augmenting the white layer thickness.

3.3. Powder Concentration

A suitable quantity of powder drives effective machining operations and stability. A higher amount of powder is useful in adding the number of discharges that increases the material removal rate [

35]. Increasing the powder concentration over the optimum value results in arching, short-circuiting, and unsteady machining due to unnecessary powder and residue particles [

26]. Moreover, the existence of excessive powder particles in the machining gap results in surface degradation and settlement issues [

36]. The estimation of powder concentration is crucial as its low value will not significantly influence the process dynamics and hence the outcome responses. Contrarily, the higher quantity of powder can induce particle settling, unrestrained bridging effects, and unsteady machining (short-circuiting and arcing), resulting in the degradation of the altered surfaces.

3.4. Powder Additives Utilization and Trend

Powder additives are added to the PMEDM process mainly for (i) to enhance the process efficiency and (ii) to upgrade the EDM process to surface coating technology. In the case of process efficiency, the prime process characteristics are material removal rate (MMR), tool wear rate (TWR), and inter-electrode gap (IEG). Subsequently, the surface modification process can improve microhardness, adhesion strength, coated layer thickness, surface roughness (SR), biocompatibility, wettability, corrosion and wear resistance.

Table 1 lists the powder additives used in the PMEDM process over the last decade and their purpose of utilization.

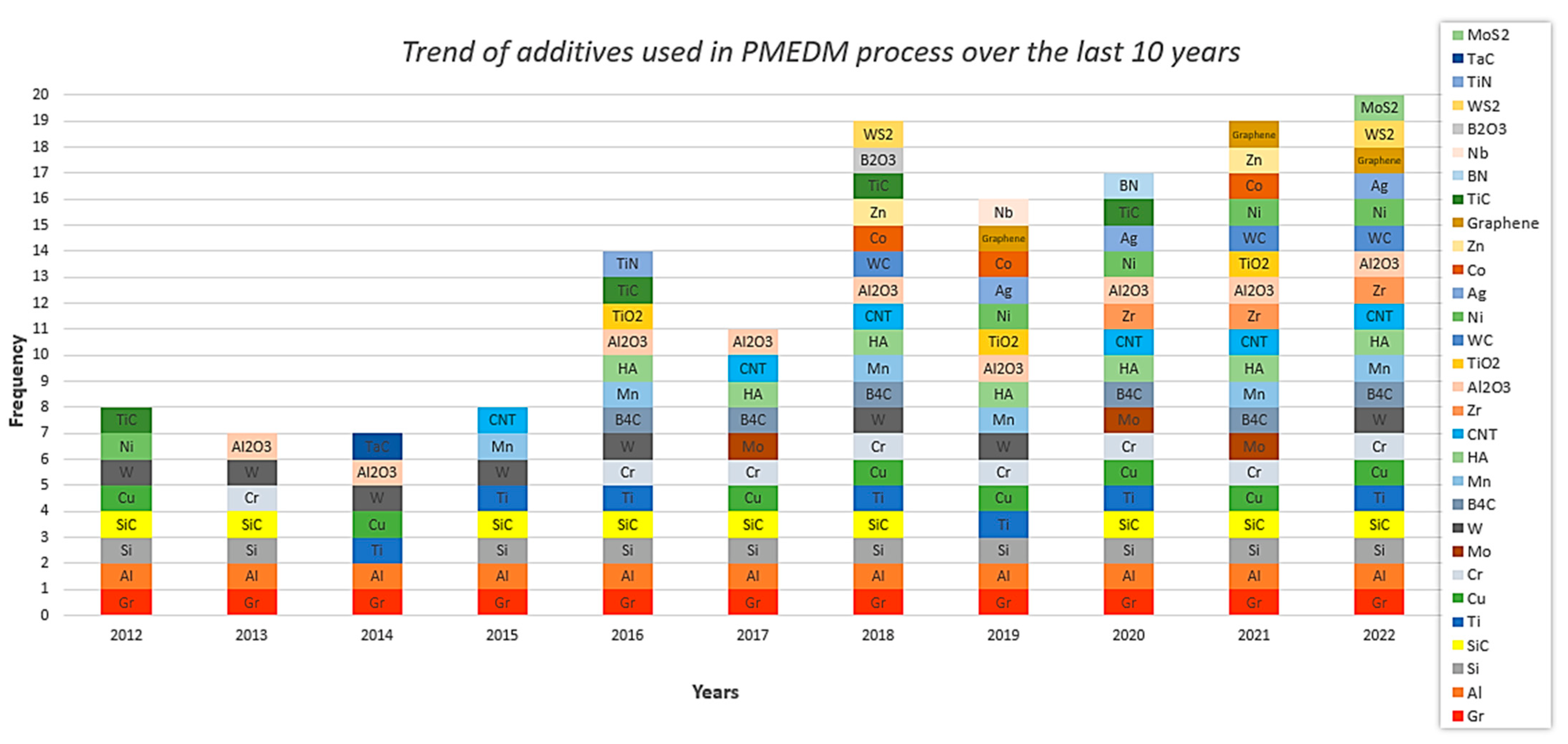

The PMEDM process trend is maximum in 2018, 2021 and 2022, with Gr, Al, Si and SiC powders being used most frequently during the last decade, as the bar chart representation is illustrated in

Figure 5. The frequency on the y-axis represents the number of articles in a given year describing the particular powder usage in the EDM process.

4. Influential Process Parameters in the PMEDM

The process factors (electrical and non-electrical) significantly affect PMEDM performance. Some of the significant process parameters can be classified in the following way:

4.1. Dielectric Type

Kerosene, mineral oil, and pure distilled water are generally used as dielectrics in the PMEDM process, and their significant properties are tabulated in

Table 2. Pure water possesses higher thermal conductivity and specific heat to withdraw heat from the machining area and ensure effective cooling [

37]. During the machining process, kerosene builds carbides, and pure water creates oxides on the altered surface of the workpiece [

38]. Carbides need higher thermal energy to dissolve than oxides, resulting in a better material removal rate, minimum tool wear rate for deionized water, and superior surface finish for kerosene as the dielectric.

4.2. Peak Current

Peak current is one of the most significant process parameters that must be optimally allocated as it directly impacts PMEDM performance. The increase in the peak current produces more electrons and ions in the machining area, which develops higher pressure in the plasma channel and increases the material removal rate due to the boost up of discharge energy [

40,

41,

42]. The peak current’s rise may result from increased tool wear, surface quality degradation, recast layer thickness, deep craters, etc. [

43,

44]. However, the instant heating and quenching at a high-level pulse current results in the improved micro-hardness of the altered surface [

45].

4.3. Pulse Duration

High pulse duration may lead to an unstable process and deteriorated surface quality by short-circuiting and insufficient debris exclusion from the machining region [

43,

46]. When the pulse duration exceeds the productive machining time, additional residues are formed and stick to the machined surface, causing an increase in the coated layer thickness [

38,

47]. The microhardness of the altered surface gradually improves with the increasing pulse duration due to the material transfer process [

45].

4.4. Voltage Gap

An upper increase in the voltage gap during the machining process takes more time to bridge the ions and electrons within the discharge gap, augments the spark gap and lessens the energy density resulting in a lowering of surface irregularity and material removal rate of the altered surface [

48,

49,

50]. A rise in gap voltage increases deposited layer thickness because of augmentation of the spark gap and reduction in coated layer thickness due to lowering the discharge column [

51].

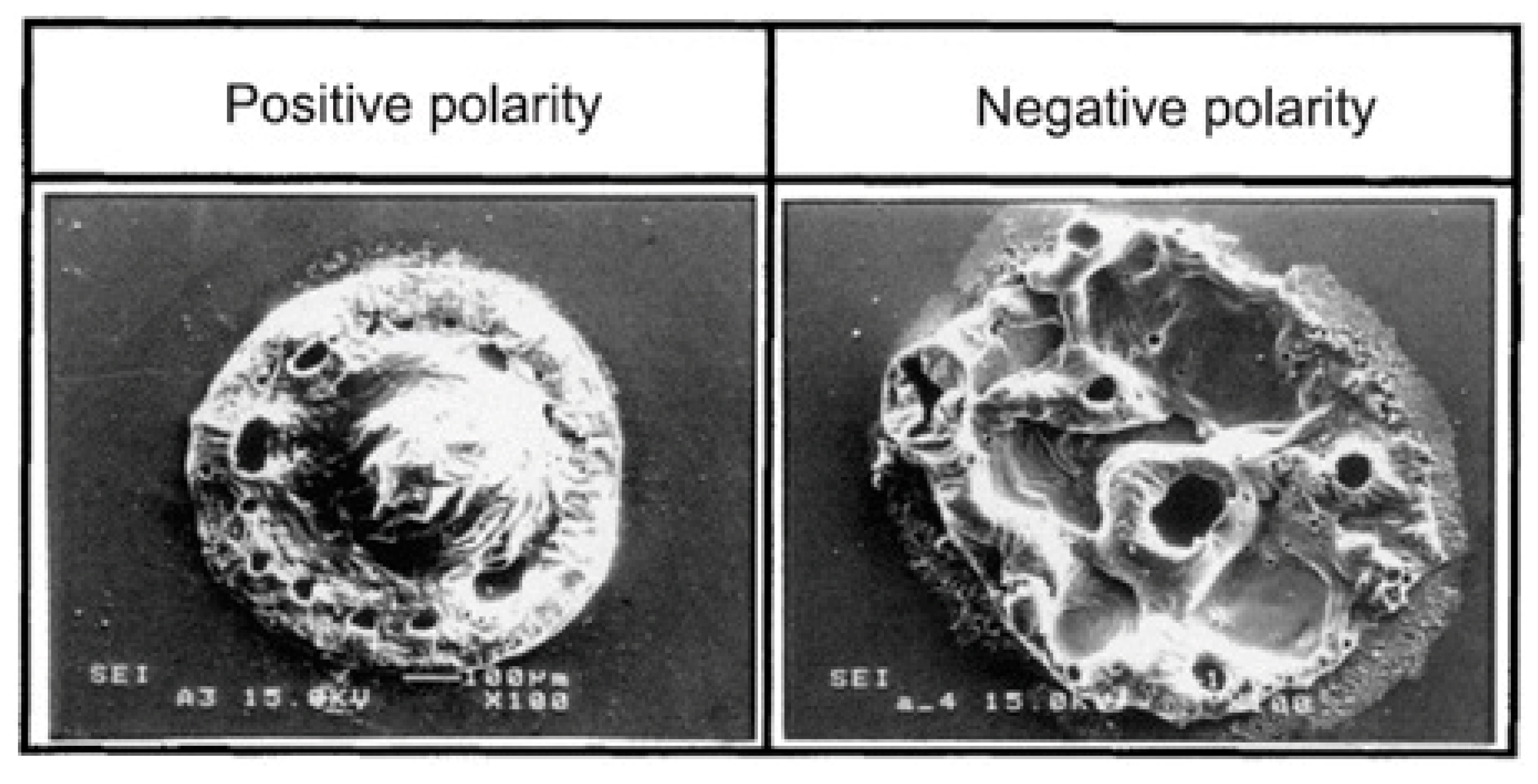

4.5. Polarity

The polarity designates the allocation of a cathode (−) and anode (+) onto the tool and workpiece. For achieving a better material erosion rate and lower tool wear rate, positive polarity on the workpiece with a shorter pulse duration and negative polarity with a longer pulse duration is preferable. The positive and negative polarities results were observed, as shown in

Figure 6, using Scanning Electron Microscopy (SEM) after performing the EDM of a Ti alloy in which SiC was used as an additive in the dielectric [

52]. The bulging response at the crater’s center is examined with positive polarity causing the buildup of powder material on the machined surface [

53]. In contrast, deep cavities were observed with negative polarity, resulting in a better erosion rate and a coarser surface finish [

52,

54].

4.6. Duty Cycle

An optimum selection of the duty cycle percentage leads to reasonably low surface irregularity and an improved material erosion rate. The extended duty cycle causes process instability, insufficient flushing of accumulated debris, and electrode wear [

48,

50].

4.7. Electrode Classification

The electrode tool is an essential parameter of the PMEDM process which demands a low tool wear rate during the machining phase and a moderate tool wear rate during the coating phase of the PMEDM process. The PMEDM electrode mainly relies on its material, shape and size. The machining process develops a mirror shape of the electrode on the workpiece. The finished size of the workpiece is achieved by setting an undersized amount during the machining process to compensate for the electrode wear. The formula for the undersize amount can be given as follows:

The undersized amount is incorporated in the electrode design, keeping the machining accuracy and projection area in view. The criteria for selecting the suitable electrode material for a specific output requirement depends on the properties tabulated in

Table 3.

4.8. Discharge Energy

Discharge energy is an essential factor that impacts surface topography, which refers to the profile shape and roughness of the altered surface. The energy of electric discharge is linked with other parameters of EDM and is a product of peak current, voltage, polarity and pulse duration [

56]. Discharge energy determines the crater size and shape in micro-EDM applications [

57]. This energy affects the coating thickness-to-roughness ratio, critically important when analyzing the coated layer on metallic biomaterials developed using the PMEDM process.

4.9. Surface Free Energy

The melting, vaporization and re-solidification of electrode material occur during the single discharge phase of the EDM process. During this process, energized debris gets deposited on the treated surface, a capacitive force is developed in the machining gap, and surface-free energy is acquired on the modified surface. A hydrophilic surface is formed due to the surface energy, shallow craters, and nanopores formation, improving biocompatibility and osseointegration at the bone-implant interface. The wettability of a coated surface is assessed based on the contact angle between the liquid and the solid surface. A surface is hydrophilic if the contact angle measurement is less than 90° and is desirable for bioimplant-coated surfaces [

58].

5. Common Metallic Biomaterials Investigated Using the PMEDM Process

Metallic biomaterials account for 70% of bioimplant base material manufacturing mainly due to the advantages of mechanical strength, ductility, corrosion and wear resistance [

59]. The surface modification of the biomaterials with biocompatible elements can develop a micron-level coating resulting in an effective bone-implant interface. Numerous physical and chemical coating methods are already established for surface modification of biomaterials, e.g., thermal spraying, laser cladding, sol-gel dip coating, electrochemical deposition, etc. [

60]. Most prior techniques incorporate weak bonding between the coating film and substrate, lack process controllability, and contain a special apparatus with high-temperature devices. All require the fabrication of bioimplants before the coating process [

61]. PMEDM is an emerging and ongoing research technique that can simultaneously perform the machining and coating process and possesses a high potential to serve as a cost-effective surface modification method to fulfil surface functional requirements, i.e., surface roughness, microhardness, corrosion resistance, biocompatibility, cracks-free and nano-porous surface for better osseointegration. Numerous studies have been commenced to explore the impact of multiple process factors indulged in powder-mixed EDM by investigating various combinations of work materials and powder additives. The research is still ongoing and requires a breakthrough in introducing the PMEDM process for the mass production of bio-implants in the marketplace.

5.1. Machined Surface of Biomaterial

The most frequently used biomaterials, for instance, Ti alloys, Mg alloys and 316L SS, possess exceptional mechanical properties but not satisfactory bio-function capabilities. During the PMEDM process, selecting appropriate electrodes, additive powder, and discharge energy significantly influence the substrate’s altered surface to enhance the material erosion rate and minimize electrode wear rate and surface topography [

13].

Bains et al. [

62] analyzed the machined surface of Ti-6Al-4V by employing Copper (Cu) as an electrode and Hydroxyapatite (HA) as an additive to the dielectric medium. It was noticed that the peak current and powder concentration are the significant process factors for enhancing the material removal rate. The highest erosion rate of 7.648 mg/min was estimated for the current of 12 A. Bui et al. [

63] assessed the machined surface of Ti alloy by utilizing Tungsten Carbide (WC) as an electrode tool and nano silver (Ag) particles as an additive to the dielectric medium. The high electrical and thermal conductivity of Ag powder particles results in a 185% increase in the material erosion rate and an 8.7% reduction in the electrode wear rate due to the WC’s elevated melting point and hardness. Prakash et al. [

64] assessed the machined surface of Ti-6Al-4V by using Cu as an electrode tool and Silicon (Si) powder as an additive to the dielectric medium. It was discovered that the peak current, pulse duration and powder concentration are the most influential process factors for the optimum machining performance measures. The maximum material erosion rate of 1.1872 mm

3/min and minimum electrode wear rate of 0.0750 mm

3/min were achieved with the optimum values of current intensity (9.55 A), pulse duration (255.95 s) and powder amount of (4 g/L). Moreover, Prakash et al. [

64] stated further reduction in the electrode wear rate by using pure Ti as an electrode, as the addition of Si powder tends to form TiC on the surface of the electrode. Shabgard and Khosrozadeh [

65] performed on the machined surface of Ti-6Al-4V by employing Cu as an electrode and carbon nanotube (CNT) as an additive to the dielectric medium. It was reported that initially, the material erosion rate was improved mainly due to the enlargement of the discharge gap as the CNT absorbed the machining heat due to its high electrical and thermal conductivity and afterwards both material removal rate and electrode wear rate were decreased.

Hourmand et al. [

66] quantified the machined surface of the Al-Mg2Si composite matrix by employing Cu as an electrode and nano Al particles as an additive to the dielectric medium. It was observed that potential voltage, current intensity, and pulse duration are the most impactful factors affecting the material erosion rate. The highest value of material erosion rate of 0.0736 g/min was accomplished at the current intensity of 15 A, pulse duration of 200 µs, a potential voltage of 80 V and duty cycle of 0.55%. Santosh et al. [

67] examined the machined surface of ZM21 Mg alloy by engaging Cu as an electrode and nano Gr particles as an additive to the dielectric medium. A valuable increase in the material erosion rate was noticed by adding the Gr particles with the current intensity of 11 A, pulse-on duration of 75 µs and pulse-off duration of 6 µs.

Santosh et al. [

67] investigated the influence of CNT addition to the dielectric fluid on stainless steel machining outcomes via the PMEDM process. It was revealed that the pulse duration and powder concentration significantly influence the material erosion rate. Most importantly, the machining rate of 0.2503 g/min was measured with the add-on of 0.3 g/L CNT, pulse-on time of 10 µs and a constant current of 6 A. Lamichhane et al. [

68] investigated the machined surface of 316L SS by adding the hydroxyapatite powder to the dielectric fluid. The study discovered an improved material erosion rate and electrode wear rate due to influential process factors such as current intensity, pulse duration and the powder amount. A 65.45% increase in material erosion rate was measured with a value of 19.01 g/min corresponding to the current intensity of 28 A, pulse-on duration of 60 µs and pulse-off duration of 120 µs. Moreover, a 53.07% growth in electrode wear rate was observed due to the higher value of powder quantity and pulse-off time. Banh et al. [

69] examined the performance measures of the Ti powder mixed EDM process for steel alloys utilizing two separate electrodes, namely Gr and Cu. This study ensured that the most impactful process factor is powder amount followed by current intensity, pulse-on time, polarity, workpiece material and pulse-off time, resulting in maximum material erosion and minimum electrode wear rates.

5.2. Coated Surface of Biomaterial

During the PMEDM process, the preference of the suitable tool and additive powder has a substantial effect on the modified or treated surface of the substrate to optimize the coating thickness, micro-hardness, surface roughness, adhesion strength, biocompatibility and resistance to wear and corrosion [

13].

Bains et al. [

62] studied the modified surface of Ti-6Al-4V by using Copper (Cu) as an electrode tool and Hydroxyapatite (HAp) as an additive to the dielectric medium. It was discovered that adding HAp resulted in a surface roughness reduction and a surge in wear resistance by 82%. The enhanced, modified surface of the Ti-alloy may result due to the placement of hard carbide and bio-ceramic layer. Prakash and Uddin [

70] explored the influence of MWCNT on HAp-mixed dielectric fluid on β-type Ti with the Gr as electrode via the PMEDM process. The research outcome claims that the mixture of MWCNT/HAp produces enhanced biocompatibility and surface integrity due to the uniform spark propagation during the machining process. Abdul-Rani et al. [

71] analyzed the treated surface of Ti-alloy in terms of surface roughness and morphology by employing tungsten and copper as a tool and nano-Al particles as an additive to the dielectric fluid. The addition of nano-Al powder by 3 g/L provided an exceptional increase in surface roughness by about 38.46% due to its high conductivity.

From the morphological point of view, micro-cracks and voids were improved on the modified surface. Prakash et al. [

72] evaluated the modified surface of Ti-alloy by using pure Ti as an electrode and Si powder as an additive to the dielectric fluid. In this research, a biocompatible and durable modified surface of 1080 HV was obtained by developing a 15 µm white layer thickness containing carbides and oxides at the peak current value of 15 A, pulse duration of 50 µs and Si powder amount of 8 g/L. Furthermore, the friction coefficient of the modified surface improved by 60% due to the development of TiC and SiC on the treated surface. Similarly, Farooq et al. [

73] assessed the modified surface of Ti-alloy by employing Cu as an electrode tool and Silicon (Si) powder as an additive to the dielectric medium. Due to the superior thermal conductivity of Si powder particles, the rapid sparking in the machining gap occurs, and the amount of additive contributed to the surface roughness and recast layer thickness of the modified surface. Moreover, the nano-porous surface of 50–200 nm was examined with the Si powder quantity of 5 g/L. Devgan and Sidhu [

74] investigated the altered surface of the Ti-alloy by utilizing the HAp-added dielectric. The add-on of HAp developed a bio-ceramic layer with exceptional micro-hardness, crack-free surface, corrosion resistance and biocompatibility.

Hourmand et al. [

66] estimated the modified surface of Mg-alloy by employing Mg-Ca as an electrode and HAp particles as an additive to the dielectric medium. It was perceived that the increased concentration of HAp enhances the micro-hardness and wear resistance, whereas it reduces the surface roughness. The biocompatibility of the treated surface was achieved due to the formation of oxides, and the deposition layer thickness increased as the amount of HAp was enhanced. Razak et al. [

75] assessed the modified surface of Mg-alloy by engaging Cu as an electrode tool and Zinc (Zn) powder particles as an additive to the dielectric medium. The high conductivity of Zn powder maintains the spark functioning and machining stability. Its optimum addition to the dielectric efficiently reduces surface roughness and wear resistance. Rout et al. [

76] analyzed the treated surface of the Mg-alloy by using three electrodes of brass, copper and stainless steel and Al powder particles as an additive to the dielectric medium. It was revealed that the brass and copper electrodes and suspended Al powder enhance surface roughness. The performance of brass and copper electrodes was better than stainless steel electrodes because of their higher conductivity and stability in the machining process.

Lamichhane et al. [

68] explored the impact of HAp addition to the dielectric medium to alter the surface of stainless steel using the PMEDM process. It was discovered that mixing HAp with the dielectric improves the surface roughness due to the scouring effect. A biocompatible surface was formed onto the modified surface because of the development of an oxide layer. Mohan et al. [

77] investigated the modified surface of 316L SS by using tungsten as an electrode and the TiO

2 powder particles as an additive to the dielectric fluid. The study revealed that forming hard oxide and carbide layers onto the treated surface provides hardness and wear resistance, respectively. G. Singh et al. [

78] evaluated the modified surface of 316L SS by utilizing Cu as an electrode and HAp powder particles as an additive to the dielectric fluid. In this research, the optimum add-on of HAp powder produces a hard and biocompatible oxide layer on the machine surface resulting in the enhanced micro-hardness and bioactivity of the developed bioimplants. Bhaumik and Maity [

79] assessed the modified surface of 316L SS by engaging W-C as an electrode tool and SiC powder particles as an additive to the dielectric medium. The research revealed that adding SiC forms a hard carbide layer that enhances surface hardness, wear resistance and surface roughness.

6. Methodologies for Optimization of PMEDM Process

The main objective of employing optimization methods in the PMEDM process is to find the values of the influential process parameters for optimising performance responses. The accomplishment of optimum settings for the machining parameters of the PMEDM process is unlike the EDM process due to the involvement of powder additives. Numerous researchers have employed tools like the design of experiment (DOE) methods, analysis of variance (ANOVA) and numerical techniques to discover the optimal values for the PMEDM process and performance parameters. Single and multiple objective optimization techniques estimate the best solution for a specific criterion.

6.1. Taguchi Method

Taguchi is a robust statistical tool to plan the experimentation for the best values of process factors. Assarzadeh and Ghoreishi [

48] used the Taguchi method to obtain the optimum process parameters by employing boron carbide-mixed electric discharge machining on the surface of titanium alloy. It was revealed via ANOVA that current intensity, pulse duration and powder quantity are the most influential factors contributing to the machining performance measures, i.e., material erosion rate and surface roughness. Kansal et al. [

80] applied the Taguchi method to attain the optimum process factors by engaging graphite powder particles in the kerosene oil dielectric for performing the rough machining process on the surface of die steel (AISI D2). The experimental investigative results reveal that the suitable addition of graphite particles to the dielectric enhances the material erosion rate and reduces electrode wear and surface irregularity. Ishfaq et al. [

81] employed graphene nanoparticles in the dielectric medium for sustainable EDM of Ti-alloy by using three different electrodes Al, Cu and Br. The study carried out the planning for the design of experimentation using Taguchi’s method and analyzed the experimental results using statistical tools. Bains et al. [

62] engaged Hydroxyapatite (HAp) powder particles in the dielectric medium to machinate Ti-6Al-4V. Experiments were executed based on Taguchi design with an orthogonal array of L16 to consider process parameters, i.e., current intensity, pulse-on and off time, electrode inner diameter and dielectric type concerning outcome responses in the form of surface irregularity and material erosion rate. The machining rate was statistically significant (

p < 0.05) by the factors of hole diameter, peak current, dielectric fluid, and the combination of current and dielectric. SR was statistically significant by current intensity, pulse duration and dielectric medium.

6.2. Response Surface Methodology (RSM)

RSM is a mathematical and statistical method used for modelling and analysing a process for an optimized response measure controlled by variable factors. Garg and Ojha [

82] studied the machined surface of EN-8 steel by adding chromium powder particles as an additive to the dielectric. The RSM method has been used to plan and analyse the experimentation for process variables and consider PMEDM performance in improved material removal rate and surface finish. Aliyu et al. [

83] investigated the Hydroxyapatite Deposition Rate (HDR) and Surface Roughness (SR) during the electro-discharge coating of Bulk Metallic Glass (BMG). Using a D-optimum customizable design approach, RSM was employed to generate the models and optimize the input factors. Optimum process parameters setting is essential in enhancing product performance and contributing to the commercial industries by lowering the component’s production time and expense.

6.3. Analytic Hierarchy Process (AHP)

AHP is a technique used to organise and indicate process variables’ importance on output performance with an analytical approach. Bhattacharya et al. [

84] executed a multi-objective optimization of material erosion rate, electrode wear rate and surface roughness during PMEDM of High Carbon High Chromium (HCHC), Hot Die Steel (HDS) and EN31 using the AHP approach.

6.4. Gray Relational Analysis (GRA)

GRA is an approach used to obtain optimum conditions of input variables to find the best-suited outcome with insufficient information. S. Singh and Yeh [

33] and Talla et al. [

85] employed the GRA technique to assess the efficacy of optimizing the variable performance measures of PMEDM for aluminum matrix composites with inadequate data.

6.5. Non-Sorted Genetic Algorithm (NSGA-II)

NSGA-II is an advanced evolutionary algorithm used for multi-objective optimization. Al-Amin et al. [

86,

87] investigated the effects of process variables (current intensity, pulse duration, powder amount, and duty cycle) on machining performance (material erosion rate) and surface features (surface irregularity and recast layer thickness) using multi-objective algorithms for optimal processing of MWCNT and HAp added ED machined surface of 316L SS. NSGA-II was used as a multi-objective optimisation tool and Pareto frontiers for optimal solution sets using MATLAB software. The LINMAP method selected the finest solution set outcomes based on defined objective functions. Padhee et al. [

88] carried out concurrent optimization of several targets using NSGA and provided multiple outcomes to the manufacturer for sorting the optimal combination from the approachable resources.

6.6. Hybrid Methods

The multi-objective optimization technique is used to optimize two or more opposing objectives. The concurrent employment of the single and multiple optimisation approaches leads to the hybrid response.

Tripathy and Tripathy [

89] performed the PMEDM process on the machined surface of H-11 die steel using chromium-mixed dielectric and copper electrodes. The Taguchi method, combined with TOPSIS and GRA, has been implemented to estimate the usefulness of enhancing numerous performance characteristics.

Prakash et al. [

90] estimated the optimal settings of PMEDM process factors to produce the biocompatible surface on β-phase Ti alloy by employing NSGA-II coupled with Taguchi-based RSM for the first time. The optimal condition was achieved with the desired requirement of high surface microhardness and low surface roughness.

6.7. Numerical Modeling

An emerging trend among researchers is heading towards the numerical modelling of the PMEDM process to simulate the temperature distribution and surface features onto the machined surface. Kansal et al. [

91] established an axisymmetric 2D thermal model for the PMEDM process using the Finite Element Method (FEM) technique. The study estimated the temperature distribution on the substrate and measured the material erosion rate from the temperature profiles. Bhattacharya et al. [

92] achieved a 3D FEM model to estimate the residual thermal stresses incorporated during the PMEDM process. Additionally, a mathematical model was developed by Bhattacharya and Batish [

93] for predicting the crater dimensions and volume removed during the PMEDM process. Tan and Yeo [

94] simulated a 3D FEM model for surface integrity features for obtaining enhanced surface roughness and reduced recast layer thickness using crater theories.

Wandra [

95] numerically simulated the material removal mechanism using the finite element analysis of the PMEDM process on the Ti-alloy. The simulation results found that the surface finish and crater geometry on the machined surface during powder-mixed EDM improved much compared to the EDM process. Tumer et al. [

96] investigated the mechanical properties of the graphene/CNT-coated Ti-6Al-4V and 316L SS using the finite element analysis approach.The loading impact on the femur, first screw and the plate with coated and uncoated conditions. Jampana [

97] examined the thermal analysis on powder-mixed EDM of stainless steel 630 using finite element and artificial neural network techniques for obtaining optimum performance parameters regarding material erosion rate and surface irregularity.

7. Applicability of the PMEDM Process

EDM can precisely manufacture critical components (i.e., impeller, fuel system, engine blocks, piston heads, etc.) for the aerospace and automobile industries. Still, on the contrary, it lacks the surface integrity features that can be potentially achieved using the PMEDM process. With enhanced dimensional accuracy, PMEDM introduces exceptional surface quality, biocompatibility and bioactivity, emerging to be an innovative advanced machining option for the manufacturing industries of bio-implants and surgical instruments. The potential application areas of PMEDM can be classified in the following way:

7.1. Rough Machining

The process parameter values of high current intensity and pulse duration mainly cause the rough machined surface [

98]. In this case, the problem arises with the rough machined surface in the form of inadequate flushing of debris and a high tool wear rate [

17]. These issues can be addressed efficiently by considering the optimal values of process factors. Mai et al. [

10] employed CNTs in the dielectric medium using PMEDM of NAK-80 die steel for evaluating the rough machining factors. It was revealed that long pulse duration and high peak current significantly increase the machining rate.

7.2. Fine Machining

Finish machining is one of the significant fields of application in the PMEDM process. The ability to produce a finely finished surface makes PMEDM a distinguished machining option that avoids finishing operations costs. A near-mirror surface finish can be achieved using the PMEDM process by increasing tool size and low discharge energy settings. Mohri et al. [

99] and Pecas and Henriques [

100] observed a high-quality surface finish during the electric discharge machining of H13 steel using Si-powder-mixed dielectric, as shown in

Figure 7, and the finish quality is further improved by increasing the machining time. A further study examined a mirror-like finish on the machined surface of SKH-54 by adding Al powder particles as an additive to the dielectric medium.

7.3. Micromachining

Technological advancements in micro-electro-mechanical systems (MEMS) initiate the demand for micromachining processes. The micro-mechanical accessories (e.g., mini pumps, engines, and robots) and application areas (e.g., drilling of micro-holes for cooling purposes on turbine blades) require precise micromachining procedures. Kibria and Bhattacharyya [

38,

101,

102] employed the µ-PMEDM approach for drilling holes on the Ti-alloy surface using boron carbide mixed with kerosene and pure water as a dielectric medium. Chow et al. [

18] revealed a potential application of the PMEDM process to fabricate a micro-heat scatter fin on the surface of Ti-6Al-4V, as displayed in

Figure 8. The optimum discharge conditions can be classified as peak current = 0.1 A, pulse-on time = 10 µs, workpiece size = 0.8 × 0.8 × 0.6 mm, copper as tool electrode and kerosene as dielectric fluid.

7.4. Surface Modification

Inaccuracies arising from high tool wear avoid the utilization of electro-discharge coating (EDC) as a powder deposition approach for surface coating and modification. PMEDM is an arising technique for simultaneously machining and alloy coating onto the modified surface with enhanced precision. Chen et al. [

103] enhanced biocompatibility by forming TiO on the modified surface of pure Ti using PMEDM with Ti-added pure water. Zain et al. [

40] accomplished exceptional microhardness on the modified surface of SUS 304 stainless steel using tantalum carbide powder as an additive to the dielectric. Bhattacharya et al. [

104] evaluated the influence of different tool and powder combinations on the micro-hardness of the modified surface. The study found that the merger of the W-Cu tool and W powder particles to the dielectric develops the hardest modified surface compared to the surfaces achieved using Gr and Si powder-mixed dielectrics.

7.5. Machining of Non-Conductive Materials

The machining of non-conductive materials in the PMEDM process is yet to be explored. Kucukturk & Cogun [

105] performed non-conductive ceramics via PMEDM by mixing Gr powder in the dielectric medium. The machined surface was coated with a conductive layer to ensure the sparking.

8. Future Research Directions of the PMEDM Process

In the past ten years, several researchers have published review articles on the potentiality of the electric discharge machining and coating process for surface modification and highlighted research directions yet to be explored. The ISI-indexed review articles based on journal citation reports (JCR) have been tabulated chronologically in

Table 4.

9. Challenges to Commercialize PMEDM Process

The PMEDM process is still open-ended and requires a technological breakthrough to enter the production market. Numerous researchers have claimed that superior surface quality and enhanced productivity can be achieved with the PMEDM process, but still, several challenges impede the embarkation of PMEDM industrialization.

9.1. Cost Effectiveness

The accumulation of powder particles at the tank’s base adds cost and alters the powder concentration during the machining process [

112]. The homogeneity of the powder particles in the dielectric medium can be explored by adding an effective surfactant to the powder-mixed dielectric, and ultrasonic vibration may prevent the settlement of powder particles. An effective PMEDM circulation system is desired that launches a commercially cost-efficient solution to restrain the powder agglomeration and deposition at the base of the machining tank [

112].

Figure 9 represents the illustration of the PMEDM circulation setup. The mixing of debris with the powder material may primarily affect the outcome. Magnetic filters can be introduced to separate the debris in the filter system to avoid mixing with the dielectric and powders.

9.2. Longevity of the Deposited Layer

The researchers do not claim the life span of the coated layer deposited by the PMEDM process. However, multiple research studies have evaluated the adhesion strength, micro-hardness, and degradability of the coated layer onto the machined surface [

112].

9.3. Reusability of the Powders

During the PMEDM process, the chemical transformation of the powders (micro and nano size) can occur, which restricts their re-use and may require procuring the powders in large quantities for experimentation. During the coating process, a minimal amount of powder is utilized on the substrate, and a significant amount is flushed out. Due to the stochasticity of the process, the justification for powder consumption and determination of powder concentration for a specific application is a challenge for the commercialization of the PMEDM process.

9.4. Machining Time

Industrial manufacturing processes are generally for lengthy durations. The experimental studies of the PMEDM process usually require a short machining time. For industrial applications, it would be a real challenge to introduce this process for the long period of machining and coating work.

9.5. In Situ Monitoring of the PMEDM Process

The addition of powders in the submerged machining process may obstruct the visibility of the ongoing process. With the technological advancements in manufacturing processes, advanced industries are pursuing on-stage monitoring to ensure the dimensional accuracy of manufactured parts. In the PMEDM process, adding the powder to the dielectric fluid makes it challenging to monitor and visualize the outcome during the machining and coating process.

9.6. Health, Safety and Environmental Considerations

The social responsibility of PMEDM users demands deliberation on health and environmental safety measures. The operator’s exposure to the fumes generated from powder mixed dielectric, the explosibility of powder materials, and discarding dielectric are critical factors that require specific working procedures. International standards can be developed and implemented after certification from the regulatory authorities.

10. Limitation

This review study has a potential limitation that covers only the general understanding of the PMEDM process and its effectiveness. The transition from EDM to PMEDM discovered an emerging technological approach to simultaneously machine and coat materials, i.e., still at the early research stage. This technology got the attention of researchers to functionalize it on biomaterials for easy, inexpensive and standard compliance manufacturing of bioimplants. Therefore, this article also demonstrates the utilization of the PMEDM process for the machining and coating metallic biomaterials.

11. Summary

From the deliberations, the PMEDM method is recommended as an efficient emerging manufacturing process that can perform concurrent coating and machining of biomaterials. The performance parameters of the PMEDM process, such as MRR, TWR, surface roughness, recast layer thickness, bonding/adhesion strength, microhardness, biocompatibility, and resistance to wear and corrosion depend significantly on the correlated process factors due to its stochastic behavioral mechanism. Consequently, appropriate formulation of the process factors and the additive powders are required to achieve the significant performance measures of this process before its industrialization.

This article reviews the PMEDM process, applicability, trend, and futuristic perspective based on the current research study. It highlights the mechanism of the PMEDM process, the impact of powder attributes and EDM process parameters on the performance parameters. It also reviews the influence of tool electrodes and additive powders on the machined and modified surface of commonly used biomaterials. Furthermore, the study represents the most used methods for optimising the PMEDM process, futuristic research directions, challenges, and research trends over the past decade.

Author Contributions

Conceptualization, Visualization, Writing—original draft, Manuscript preparation, I.A.G.; Supervision, Review and Editing, Project management, Funding acquisition, A.M.A.-R.; Review and Editing, Resources, M.A.-A.; Review and Editing, E.G. All authors have read and agreed to the published version of the manuscript.

Funding

This research study was supported by the Malaysian Ministry of Higher Education Fundamental Research Grant Scheme (FRGS/1/2020/TK0/UTP/02/39) and YUTP (Cost center: 015LC0-385).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

On behalf of the institution, the authors articulate their profound appreciation to the Malaysian Ministry of Higher Education Fundamental Research Grant Scheme (FRGS/1/2020/TK0/UTP/02/39) and YUTP (Cost center: 015LC0-385) for providing the research work opportunity. The authors would also like to thank the UTP Mechanical Engineering Department for their assistance.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Schumacher, B.; Krampitz, R.; Kruth, J.-P. Historical Phases of EDM Development Driven by the Dual Influence of “Market Pull” and “Science Push”. Procedia CIRP 2013, 6, 5–12. [Google Scholar] [CrossRef]

- Luis, C.; Puertas, I.; Villa, G. Material removal rate and electrode wear study on the EDM of silicon carbide. J. Mater. Process. Technol. 2005, 164–165, 889–896. [Google Scholar] [CrossRef]

- Mahajan, A.; Sidhu, S.S. Enhancing biocompatibility of Co-Cr alloy implants via electrical discharge process. Mater. Technol. 2018, 33, 524–531. [Google Scholar] [CrossRef]

- Ho, K.; Newman, S. State of the art electrical discharge machining (EDM). Int. J. Mach. Tools Manuf. 2003, 43, 1287–1300. [Google Scholar] [CrossRef]

- Abdulkareem, S.; Khan, A.A.; Konneh, M. Cooling Effect on Electrode and Process Parameters in EDM. Mater. Manuf. Process. 2010, 25, 462–466. [Google Scholar] [CrossRef]

- Abu Qudeiri, J.E.; Saleh, A.; Ziout, A.; Mourad, A.-H.I.; Abidi, M.H.; Elkaseer, A. Advanced Electric Discharge Machining of Stainless Steels: Assessment of the State of the Art, Gaps and Future Prospect. Materials 2019, 12, 907. [Google Scholar] [CrossRef]

- Razak, M.A.; Abdul-Rani, A.M.; Nanimina, A.M. Improving EDM Efficiency with Silicon Carbide Powder-Mixed Dielectric Fluid. Int. J. Mater. Mech. Manuf. 2015, 3, 40–43. [Google Scholar] [CrossRef]

- Sonawane, H.A.; Pawade, R.S. Effects of powder mixed dielectric on electro discharge machining (PMEDM) of HSS tool steel. Int. J. Mechatronics Manuf. Syst. 2012, 5, 431. [Google Scholar] [CrossRef]

- Puertas, I.; Luis, C. A study on the machining parameters optimisation of electrical discharge machining. J. Mater. Process. Technol. 2003, 143–144, 521–526. [Google Scholar] [CrossRef]

- Mai, C.; Hocheng, H.; Huang, S. Advantages of carbon nanotubes in electrical discharge machining. Int. J. Adv. Manuf. Technol. 2011, 59, 111–117. [Google Scholar] [CrossRef]

- Erden, A.; Bilgin, S. Role of Impurities in Electric Discharge Machining. In Proceedings of the Twenty-First International Machine Tool Design and Research Conference, Swansea, UK, 8–12 September 1980; pp. 345–350. [Google Scholar] [CrossRef]

- Silicon Powder Additives Proven Safe and Effective in EDM|Modern Machine Shop. Available online: https://www.mmsonline.com/articles/silicon-powder-additives-proven-safe-and-effective-in-edm (accessed on 11 November 2022).

- Amin, A.; Abdul-Rani, A.M.; Danish, M.; Thompson, H.M.; Aliyu, A.A.A.; Hastuty, S.; Zohura, F.T.; Bryant, M.G.; Rubaiee, S.; Rao, T. Assessment of PM-EDM cycle factors influence on machining responses and surface properties of biomaterials: A comprehensive review. Precis. Eng. 2020, 66, 531–549. [Google Scholar] [CrossRef]

- Talla, G.; Gangopadhayay, S.; Biswas, C. State of the art in powder-mixed electric discharge machining: A review. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2016, 231, 2511–2526. [Google Scholar] [CrossRef]

- Kumar, H. Development of mirror like surface characteristics using nano powder mixed electric discharge machining (NPMEDM). Int. J. Adv. Manuf. Technol. 2014, 76, 105–113. [Google Scholar] [CrossRef]

- Prihandana, G.S.; Mahardika, M.; Hamdi, M.; Wong, Y.S.; Mitsui, K. Accuracy improvement in nanographite powder-suspended dielectric fluid for micro-electrical discharge machining processes. Int. J. Adv. Manuf. Technol. 2011, 56, 143–149. [Google Scholar] [CrossRef]

- Zhao, W.; Meng, Q.; Wang, Z. The application of research on powder mixed EDM in rough machining. J. Mater. Process. Technol. 2002, 129, 30–33. [Google Scholar] [CrossRef]

- Chow, H.-M.; Yang, L.-D.; Lin, C.-T.; Chen, Y.-F. The use of SiC powder in water as dielectric for micro-slit EDM machining. J. Mater. Process. Technol. 2008, 195, 160–170. [Google Scholar] [CrossRef]

- Kung, K.-Y.; Horng, J.-T.; Chiang, K.-T. Material removal rate and electrode wear ratio study on the powder mixed electrical discharge machining of cobalt-bonded tungsten carbide. Int. J. Adv. Manuf. Technol. 2007, 40, 95–104. [Google Scholar] [CrossRef]

- Ekmekci, B.; Ersöz, Y. How Suspended Particles Affect Surface Morphology in Powder Mixed Electrical Discharge Machining (PMEDM). Met. Mater. Trans. B 2012, 43, 1138–1148. [Google Scholar] [CrossRef]

- Peng, H.; Yu, D.; Zhang, X.; Wang, S.; Wen, Y. Fabrication of hollow nickel micro-spheres with high degree of hollowness by silicon powder-mixed spark erosion. Int. J. Mach. Tools Manuf. 2014, 85, 131–134. [Google Scholar] [CrossRef]

- Chow, H.-M.; Yan, B.-H.; Huang, F.-Y.; Hung, J.-C. Study of added powder in kerosene for the micro-slit machining of titanium alloy using electro-discharge machining. J. Mater. Process. Technol. 2000, 101, 95–103. [Google Scholar] [CrossRef]

- Janmanee, P.; Muttamara, A. Surface modification of tungsten carbide by electrical discharge coating (EDC) using a titanium powder suspension. Appl. Surf. Sci. 2012, 258, 7255–7265. [Google Scholar] [CrossRef]

- Prakash, C.; Kansal, H.K.; Pabla, B.; Puri, S.; Aggarwal, A. Electric discharge machining—A potential choice for surface modification of metallic implants for orthopedic applications: A review. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2015, 230, 331–353. [Google Scholar] [CrossRef]

- Wong, Y.; Lim, L.; Rahuman, I.; Tee, W. Near-mirror-finish phenomenon in EDM using powder-mixed dielectric. J. Mater. Process. Technol. 1998, 79, 30–40. [Google Scholar] [CrossRef]

- Tzeng, Y.-F.; Lee, C.-Y. Effects of Powder Characteristics on Electrodischarge Machining Efficiency. Int. J. Adv. Manuf. Technol. 2001, 17, 586–592. [Google Scholar] [CrossRef]

- Yih-Fong, T.; Fu-Chen, C. Investigation into some surface characteristics of electrical discharge machined SKD-11 using powder-suspension dielectric oil. J. Mater. Process. Technol. 2005, 170, 385–391. [Google Scholar] [CrossRef]

- Jeswani, M. Effect of the addition of graphite powder to kerosene used as the dielectric fluid in electrical discharge machining. Wear 1981, 70, 133–139. [Google Scholar] [CrossRef]

- Prihandana, G.S.; Mahardika, M.; Hamdi, M.; Wong, Y.S.; Miki, N.; Mitsui, K. Study of workpiece vibration in powder-suspended dielectric fluid in micro-EDM processes. Int. J. Precis. Eng. Manuf. 2013, 14, 1817–1822. [Google Scholar] [CrossRef]

- Marashi, H.; Sarhan, A.A.; Hamdi, M. Employing Ti nano-powder dielectric to enhance surface characteristics in electrical discharge machining of AISI D2 steel. Appl. Surf. Sci. 2015, 357, 892–907. [Google Scholar] [CrossRef]

- Kumar, S.; Batra, U. Surface modification of die steel materials by EDM method using tungsten powder-mixed dielectric. J. Manuf. Process. 2012, 14, 35–40. [Google Scholar] [CrossRef]

- Kumar, A.; Maheshwari, S.; Sharma, C.; Beri, N. Analysis of Machining Characteristics in Additive Mixed Electric Discharge Machining of Nickel-Based Super Alloy Inconel 718. Mater. Manuf. Process. 2011, 26, 1011–1018. [Google Scholar] [CrossRef]

- Singh, S.; Yeh, M.F. Optimization of Abrasive Powder Mixed EDM of Aluminum Matrix Composites with Multiple Responses Using Gray Relational Analysis. J. Mater. Eng. Perform. 2011, 21, 481–491. [Google Scholar] [CrossRef]

- KSyed, H.; Kuppan, P. Studies on recast-layer in EDM using aluminium powder mixed distilled water dielectric fluid. Int. J. Eng. Technol. 2013, 5, 1775–1780. [Google Scholar]

- Kumar, H.; Davim, J.P. Role of Powder in the Machining of Al-10%Sicp Metal Matrix Composites by Powder Mixed Electric Discharge Machining. J. Compos. Mater. 2010, 45, 133–151. [Google Scholar] [CrossRef]

- Jahan, M.P.; Rahman, M.; Wong, Y.S. Study on the nano-powder-mixed sinking and milling micro-EDM of WC-Co. Int. J. Adv. Manuf. Technol. 2010, 53, 167–180. [Google Scholar] [CrossRef]

- Lin, Y.C.; Yan, B.H.; Chang, Y.S. Machining characteristics of titanium alloy (Ti–6Al–4V) using a combination process of EDM with USM. J. Mater. Process. Technol. 2000, 104, 171–177. [Google Scholar] [CrossRef]

- Kibria, G.; Sarkar, B.R.; Pradhan, B.B.; Bhattacharyya, B. Comparative study of different dielectrics for micro-EDM performance during microhole machining of Ti-6Al-4V alloy. Int. J. Adv. Manuf. Technol. 2009, 48, 557–570. [Google Scholar] [CrossRef]

- Joshi, A.Y.; Joshi, A.Y. A systematic review on powder mixed electrical discharge machining. Heliyon 2019, 5, e02963. [Google Scholar] [CrossRef]

- Zain, Z.M.; Ndaliman, M.B.; Khan, A.A.; Ali, M. Improving micro-hardness of stainless steel through powder-mixed electrical discharge machining. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2014, 228, 3374–3380. [Google Scholar] [CrossRef]

- Zain, Z.M.; Ndaliman, M.B.; Khan, A.A.; Ali, M.Y. Electro-Discharge Machining of SUS 304 Stainless Steel with TaC Powder-Mixed Dielectric. Adv. Mater. Res. 2012, 576, 72–75. [Google Scholar] [CrossRef]

- Wang, J.L.; Yang, H.; Li, M. Study on Discharge Parameters of Surface Strengthening with Powder Mixed Near Dry EDM for H13 Steel. Appl. Mech. Mater. 2014, 602–605, 757–760. [Google Scholar] [CrossRef]

- Wu, K.L.; Yan, B.H.; Huang, F.Y.; Chen, S.C. Improvement of surface finish on SKD steel using electro-discharge machining with aluminum and surfactant added dielectric. Int. J. Mach. Tools Manuf. 2005, 45, 1195–1201. [Google Scholar] [CrossRef]

- Yan, B.H.; Tsai, H.C.; Huang, F.Y. The effect in EDM of a dielectric of a urea solution in water on modifying the surface of titanium. Int. J. Mach. Tools Manuf. 2005, 45, 194–200. [Google Scholar] [CrossRef]

- Kumar, S.; Singh, R. Investigating surface properties of OHNS die steel after electrical discharge machining with manganese powder mixed in the dielectric. Int. J. Adv. Manuf. Technol. 2010, 50, 625–633. [Google Scholar] [CrossRef]

- Kansal, H.; Singh, S.; Kumar, P. Effect of Silicon Powder Mixed EDM on Machining Rate of AISI D2 Die Steel. J. Manuf. Process. 2007, 9, 13–22. [Google Scholar] [CrossRef]

- Tan, P.C.; Yeo, S.H. Investigation of recast layers generated by a powder-mixed dielectric micro electrical discharge machining process. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2011, 225, 1051–1062. [Google Scholar] [CrossRef]

- Assarzadeh, S.; Ghoreishi, M. A dual response surface-desirability approach to process modeling and optimization of Al2O3 powder-mixed electrical discharge machining (PMEDM) parameters. Int. J. Adv. Manuf. Technol. 2012, 64, 1459–1477. [Google Scholar] [CrossRef]

- Singh, B.; Kumar, J.; Kumar, S. Experimental Investigation on Surface Characteristics in Powder-Mixed Electrodischarge Machining of AA6061/10%SiC Composite. Mater. Manuf. Process. 2014, 29, 287–297. [Google Scholar] [CrossRef]

- Wu, K.L.; Yan, B.H.; Lee, J.-W.; Ding, C.G. Study on the characteristics of electrical discharge machining using dielectric with surfactant. J. Mater. Process. Technol. 2009, 209, 3783–3789. [Google Scholar] [CrossRef]

- Chen, Y.-F.; Lin, Y.-C. Surface modifications of Al–Zn–Mg alloy using combined EDM with ultrasonic machining and addition of TiC particles into the dielectric. J. Mater. Process. Technol. 2009, 209, 4343–4350. [Google Scholar] [CrossRef]

- Lin, Y.C.; Yan, B.H.; Huang, F.Y. Surface modification of Al–Zn–Mg aluminum alloy using the combined process of EDM with USM. J. Mater. Process. Technol. 2001, 115, 359–366. [Google Scholar] [CrossRef]

- Furutania, K.; Saneto, A.; Takezawa, H.; Mohri, N.; Miyake, H. Accretion of titanium carbide by electrical discharge machining with powder suspended in working fluid. Precis. Eng. 2001, 25, 138–144. [Google Scholar] [CrossRef]

- Wang, Y.G.; Zhao, F.L.; Liu, Y. Behaviors of Suspended Powder in Powder Mixed EDM. Key Eng. Mater. 2008, 375–376, 36–41. [Google Scholar] [CrossRef]

- Czelusniak, T.; Higa, C.F.; Torres, R.D.; Laurindo, C.A.H.; Júnior, J.M.F.D.P.; Lohrengel, A.; Amorim, F.L. Materials used for sinking EDM electrodes: A review. J. Braz. Soc. Mech. Sci. Eng. 2018, 41, 14. [Google Scholar] [CrossRef]

- Peta, K.; Mendak, M.; Bartkowiak, T. Discharge Energy as a Key Contributing Factor Determining Microgeometry of Aluminum Samples Created by Electrical Discharge Machining. Crystals 2021, 11, 1371. [Google Scholar] [CrossRef]

- Liu, Q.; Zhang, Q.; Zhang, M.; Yang, F. Study on the Discharge Characteristics of Single-Pulse Discharge in Micro-EDM. Micromachines 2020, 11, 55. [Google Scholar] [CrossRef] [PubMed]

- Amin, A.; Rani, A.M.A.; Aliyu, A.A.A.; Razak, M.A.A.; Hastuty, S.; Bryant, M.G. Powder mixed-EDM for potential biomedical applications: A critical review. Mater. Manuf. Process. 2020, 35, 1789–1811. [Google Scholar] [CrossRef]

- Bisaria, H.; Patra, B.B.; Mohanty, S. Surface modification during hydroxyapatite powder mixed electric discharge machining of metallic biomaterials: A review. Surf. Eng. 2022, 1–27. [Google Scholar] [CrossRef]

- Beig, B.; Liaqat, U.; Niazi, M.; Douna, I.; Zahoor, M.; Niazi, M. Current Challenges and Innovative Developments in Hydroxyapatite-Based Coatings on Metallic Materials for Bone Implantation: A Review. Coatings 2020, 10, 1249. [Google Scholar] [CrossRef]

- Tyagi, R.; Mandal, A.; Das, A.K.; Tripathi, A.; Prakash, C.; Campilho, R.; Saxena, K.K. Electrical Discharge Coating a Potential Surface Engineering Technique: A State of the Art. Processes 2022, 10, 1971. [Google Scholar] [CrossRef]

- Bains, P.S.; Bahraminasab, M.; Sidhu, S.S.; Singh, G. On the machinability and properties of Ti–6Al–4V biomaterial with n-HAp powder–mixed ED machining. Proc. Inst. Mech. Eng. Part H J. Eng. Med. 2019, 234, 232–242. [Google Scholar] [CrossRef]

- Bui, V.D.; Mwangi, J.W.; Meinshausen, A.-K.; Mueller, A.J.; Bertrand, J.; Schubert, A. Antibacterial coating of Ti-6Al-4V surfaces using silver nano-powder mixed electrical discharge machining. Surf. Coat. Technol. 2019, 383, 125254. [Google Scholar] [CrossRef]

- Prakash, C.; Kansal, H.K.; Pabla, B.S.; Puri, S. Experimental investigations in powder mixed electric discharge machining of Ti–35Nb–7Ta–5Zrβ-titanium alloy. Mater. Manuf. Process. 2016, 32, 274–285. [Google Scholar] [CrossRef]

- Shabgard, M.; Khosrozadeh, B. Investigation of carbon nanotube added dielectric on the surface characteristics and machining performance of Ti–6Al–4V alloy in EDM process. J. Manuf. Process. 2017, 25, 212–219. [Google Scholar] [CrossRef]

- Hourmand, M.; Sarhan, A.A.D.; Farahany, S.; Sayuti, M. Microstructure characterization and maximization of the material removal rate in nano-powder mixed EDM of Al-Mg2Si metal matrix composite—ANFIS and RSM approaches. Int. J. Adv. Manuf. Technol. 2018, 101, 2723–2737. [Google Scholar] [CrossRef]

- Santosh, S.; Ibrahim, S.J.S.; Saravanamuthukumar, P.; Rajkumar, K.; Harikrishna, K.L. Nano Graphite Powder Assisted Electric Discharge Machining Characteristics of ZM21 Magnesium Alloy. Appl. Mech. Mater. 2015, 787, 406–410. [Google Scholar] [CrossRef]

- Lamichhane, Y.; Singh, G.; Bhui, A.S.; Mukhiya, P.; Kumar, P.; Thapa, B. Surface modification of 316L SS with HAp nano-particles using PMEDM for enhanced Biocompatibility. Mater. Today Proc. 2019, 15, 336–343. [Google Scholar] [CrossRef]

- Banh, T.-L.; Nguyen, H.-P.; Ngo, C.; Nguyen, D.-T. Characteristics optimization of powder mixed electric discharge machining using titanium powder for die steel materials. Proc. Inst. Mech. Eng. Part E J. Process. Mech. Eng. 2017, 232, 281–298. [Google Scholar] [CrossRef]

- Prakash, C.; Uddin, M. Surface modification of β-phase Ti implant by hydroaxyapatite mixed electric discharge machining to enhance the corrosion resistance and in-vitro bioactivity. Surf. Coat. Technol. 2017, 326, 134–145. [Google Scholar] [CrossRef]

- Abdul-Rani, A.; Nanimina, A.; Ginta, T.; Razak, M. Machined Surface Quality in Nano Aluminum Mixed Electrical Discharge Machining. Procedia Manuf. 2017, 7, 510–517. [Google Scholar] [CrossRef]

- Prakash, C.; Kansal, H.; Pabla, B.; Puri, S. Potential of Silicon Powder-Mixed Electro Spark Alloying for Surface Modification of β-Phase Titanium Alloy for Orthopedic Applications. Mater. Today Proc. 2017, 4, 10080–10083. [Google Scholar] [CrossRef]

- Farooq, M.U.; Mughal, M.P.; Ahmed, N.; Mufti, N.A.; Al-Ahmari, A.M.; He, Y. On the Investigation of Surface Integrity of Ti6Al4V ELI Using Si-Mixed Electric Discharge Machining. Materials 2020, 13, 1549. [Google Scholar] [CrossRef] [PubMed]

- Devgan, S.; Sidhu, S.S. Surface modification of β-type titanium with multi-walled CNTs/μ-HAp powder mixed Electro Discharge Treatment process. Mater. Chem. Phys. 2020, 239, 122005. [Google Scholar] [CrossRef]

- Razak, M.A.; Rani, A.M.A.; Saad, N.M.; Littlefair, G.; Aliyu, A.A. Controlling corrosion rate of Magnesium alloy using powder mixed electrical discharge machining. IOP Conf. Ser. Mater. Sci. Eng. 2018, 344, 012010. [Google Scholar] [CrossRef]

- Rout, P.K.; Surekha, B.; Jena, P.C.; Arko, G.N. Experimental studies on aluminum powder mixed electro discharge machining of ultra-light weight Mg-6Al alloy. Mater. Today Proc. 2020, 26, 2379–2387. [Google Scholar] [CrossRef]

- Mohan, D.G.; Gopi, S.; Rajasekar, V.; Krishnan, K.; Mohan, D.G.; Gopi, S.; Selvarajan, L.; Rajavel, R.; Prakash, B.; Mohan, D.G.; et al. Accepted Mus pt. Mater. Today Proc. 2019, 27. [Google Scholar] [CrossRef]

- Singh, G.; Lamichhane, Y.; Bhui, A.S.; Sidhu, S.S.; Bains, P.S.; Mukhiya, P. Surface morphology and microhardness behavior of 316l in hap-pmedm. Facta Univ. Ser. Mech. Eng. 2019, 17, 445–454. [Google Scholar] [CrossRef]

- Bhaumik, M.; Maity, K. Effect of machining parameter on the surface roughness of AISI 304 in silicon carbide powder mixed EDM. Decis. Sci. Lett. 2017, 261–268. [Google Scholar] [CrossRef]

- Kansal, H.; Singh, S.; Kumar, P. Application of Taguchi method for optimisation of powder mixed electrical discharge machining. Int. J. Manuf. Technol. Manag. 2005, 7, 329. [Google Scholar] [CrossRef]

- Ishfaq, K.; Asad, M.; Anwar, S.; Pruncu, C.I.; Saleh, M.; Ahmad, S. A Comprehensive Analysis of the Effect of Graphene-Based Dielectric for Sustainable Electric Discharge Machining of Ti-6Al-4V. Materials 2020, 14, 23. [Google Scholar] [CrossRef]

- Garg, R.K.; Ojha, K. Parametric Optimization of PMEDM Process with Chromium Powder Suspended Dielectric for Triangular Electrodes. Adv. Mater. Res. 2013, 816–817, 23–27. [Google Scholar] [CrossRef]

- Aliyu, A.A.; Abdul-Rani, A.M.; Rubaiee, S.; Danish, M.; Bryant, M.; Hastuty, S.; Razak, M.A.; Ali, S. Electro-Discharge Machining of Zr67Cu11Ni10Ti9Be3: An Investigation on Hydroxyapatite Deposition and Surface Roughness. Processes 2020, 8, 635. [Google Scholar] [CrossRef]

- Bhattacharya, A.; Batish, A.; Singh, G. Optimization of powder mixed electric discharge machining using dummy treated experimental design with analytic hierarchy process. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2011, 226, 103–116. [Google Scholar] [CrossRef]

- Talla, G.; Gangopadhyay, S.; Biswas, C.K. Multi Response Optimization of Powder Mixed Electric Discharge Machining of Aluminum/Alumina Metal Matrix Composite Using Grey Relation Analysis. Procedia Mater. Sci. 2014, 5, 1633–1639. [Google Scholar] [CrossRef]

- Amin, A.; Abdul-Rani, A.M.; Ahmed, R.; Rao, T.V.V.L.N. Multiple-objective optimization of hydroxyapatite-added EDM technique for processing of 316L-steel. Mater. Manuf. Process. 2021, 1–12. [Google Scholar] [CrossRef]

- Amin, A.; Abdul-Rani, A.M.; Ahmed, R.; Shahid, M.U.; Zohura, F.T.; Rani, M.D.B.A. Multi-objective optimization of process variables for MWCNT-added electro-discharge machining of 316L steel. Int. J. Adv. Manuf. Technol. 2021, 115, 179–198. [Google Scholar] [CrossRef]

- Padhee, S.; Nayak, N.; Panda, S.K.; Dhal, P.R.; Mahapatra, S.S. Multi-objective parametric optimization of powder mixed electro-discharge machining using response surface methodology and non-dominated sorting genetic algorithm. Sadhana 2012, 37, 223–240. [Google Scholar] [CrossRef]

- Tripathy, S.; Tripathy, D. Multi-attribute optimization of machining process parameters in powder mixed electro-discharge machining using TOPSIS and grey relational analysis. Eng. Sci. Technol. Int. J. 2016, 19, 62–70. [Google Scholar] [CrossRef]

- Prakash, C.; Kansal, H.K.; Pabla, B.S.; Puri, S. Multi-objective optimization of powder mixed electric discharge machining parameters for fabrication of biocompatible layer on β-Ti alloy using NSGA-II coupled with Taguchi based response surface methodology. J. Mech. Sci. Technol. 2016, 30, 4195–4204. [Google Scholar] [CrossRef]

- Kansal, H.; Singh, S.; Kumar, P. Numerical simulation of powder mixed electric discharge machining (PMEDM) using finite element method. Math. Comput. Model. 2008, 47, 1217–1237. [Google Scholar] [CrossRef]

- Bhattacharya, A.; Batish, A.; Singh, K. Fe simulation and experimental validation of powder mixed edm process for estimating the temperature distribution and volume removed in single crater. Int. J. Model. Simul. Sci. Comput. 2012, 3, 1250006. [Google Scholar] [CrossRef]

- Bhattacharya, A.; Batish, A. Predictor Equations for Estimating Crater Dimensions in PMEDM Process Using Fem Simulation and Experimental Validation. Mater. Sci. Forum 2013, 751, 45–60. [Google Scholar] [CrossRef]

- Tan, P.C.; Yeo, S.H. Simulation of Surface Integrity for Nanopowder-Mixed Dielectric in Micro Electrical Discharge Machining. Met. Mater. Trans. B 2013, 44, 711–721. [Google Scholar] [CrossRef]

- Wandra, R. Finite element analysis of powder mixed electric discharge machining on Ti-alloy. Mater. Today Proc. 2021, 50, 593–599. [Google Scholar] [CrossRef]

- Tümer, D.; Güngörürler, M.; Havıtçıoğlu, H.; Arman, Y. Investigation of effective coating of the Ti–6Al–4V alloy and 316L stainless steel with graphene or carbon nanotubes with finite element methods. J. Mater. Res. Technol. 2020, 9, 15880–15893. [Google Scholar] [CrossRef]

- Jampana, V.N.R.; Rao, P.S.V.R.; Sampathkumar, A. Experimental and Thermal Investigation on Powder Mixed EDM Using FEM and Artificial Neural Networks. Adv. Mater. Sci. Eng. 2021, 2021, 8138294. [Google Scholar] [CrossRef]

- Bhattacharya, A.; Batish, A.; Singh, G.; Singla, V.K. Optimal parameter settings for rough and finish machining of die steels in powder-mixed EDM. Int. J. Adv. Manuf. Technol. 2011, 61, 537–548. [Google Scholar] [CrossRef]

- Mohri, N.; Saito, N.; Higashi, M.; Kinoshita, N. A New Process of Finish Machining on Free Surface by EDM Methods. CIRP Ann. 1991, 40, 207–210. [Google Scholar] [CrossRef]

- Peças, P.; Henriques, E. Influence of silicon powder-mixed dielectric on conventional electrical discharge machining. Int. J. Mach. Tools Manuf. 2003, 43, 1465–1471. [Google Scholar] [CrossRef]

- Kibria, G.; Bhattacharyya, B. Investigation into micro-hole geometrical accuracy during micro-EDM of Ti-6Al-4V employing different dielectrics. Int. J. Mach. Mach. Mater. 2011, 10, 310. [Google Scholar] [CrossRef]

- Kibria, G.; Bhattacharyya, B.; Chinesta, F.; Chastel, Y.; El Mansori, M. Analysis on Geometrical Accuracy of Microhole during Micro-EDM of Ti-6Al-4V using Different Dielectrics. AIP Conf. Proc. 2011, 1315, 155. [Google Scholar] [CrossRef]

- Chen, S.-L.; Lin, M.-H.; Huang, G.-X.; Wang, C.-C. Research of the recast layer on implant surface modified by micro-current electrical discharge machining using deionized water mixed with titanium powder as dielectric solvent. Appl. Surf. Sci. 2014, 311, 47–53. [Google Scholar] [CrossRef]

- Bhattacharya, A.; Batish, A.; Kumar, N. Surface characterization and material migration during surface modification of die steels with silicon, graphite and tungsten powder in EDM process. J. Mech. Sci. Technol. 2013, 27, 133–140. [Google Scholar] [CrossRef]

- Kucukturk, G.; Cogun, C. A new method for machining of electrically nonconductive workpieces using electric discharge machining technique. Mach. Sci. Technol. 2010, 14, 189–207. [Google Scholar] [CrossRef]

- Srivastava, S.; Vishnoi, M.; Gangadhar, M.T.; Kukshal, V. An insight on Powder Mixed Electric Discharge Machining: A state of the art review. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2022. [Google Scholar] [CrossRef]

- Al-Amin, M.; Abdul-Rani, A.M.; Danish, M.; Rubaiee, S.; Mahfouz, A.B.; Thompson, H.M.; Ali, S.; Unune, D.R.; Sulaiman, M.H. Investigation of Coatings, Corrosion and Wear Characteristics of Machined Biomaterials through Hydroxyapatite Mixed-EDM Process: A Review. Materials 2021, 14, 3597. [Google Scholar] [CrossRef]

- Philip, J.T.; Mathew, J.; Kuriachen, B. Transition from EDM to PMEDM—Impact of suspended particulates in the dielectric on Ti6Al4V and other distinct material surfaces: A review. J. Manuf. Process. 2021, 64, 1105–1142. [Google Scholar] [CrossRef]

- Al Amin, M.; Rani, A.M.A.; Aliyu, A.A.A.; Bryant, M.G.; Danish, M.; Ahmad, A. Bio-ceramic coatings adhesion and roughness of biomaterials through PM-EDM: A comprehensive review. Mater. Manuf. Process. 2020, 35, 1157–1180. [Google Scholar] [CrossRef]

- Abdudeen, A.; Abu Qudeiri, J.E.; Kareem, A.; Ahammed, T.; Ziout, A. Recent Advances and Perceptive Insights into Powder-Mixed Dielectric Fluid of EDM. Micromachines 2020, 11, 754. [Google Scholar] [CrossRef]

- Aliyu, A.A.; Abdul-Rani, A.M.; Ginta, T.L.; Prakash, C.; Axinte, E.; Razak, M.A.; Ali, S. A Review of Additive Mixed-Electric Discharge Machining: Current Status and Future Perspectives for Surface Modification of Biomedical Implants. Adv. Mater. Sci. Eng. 2017, 2017, 8723239. [Google Scholar] [CrossRef]