Hydrodynamic Processes in Angular Fitting Connections of a Transport Machine’s Hydraulic Drive

Abstract

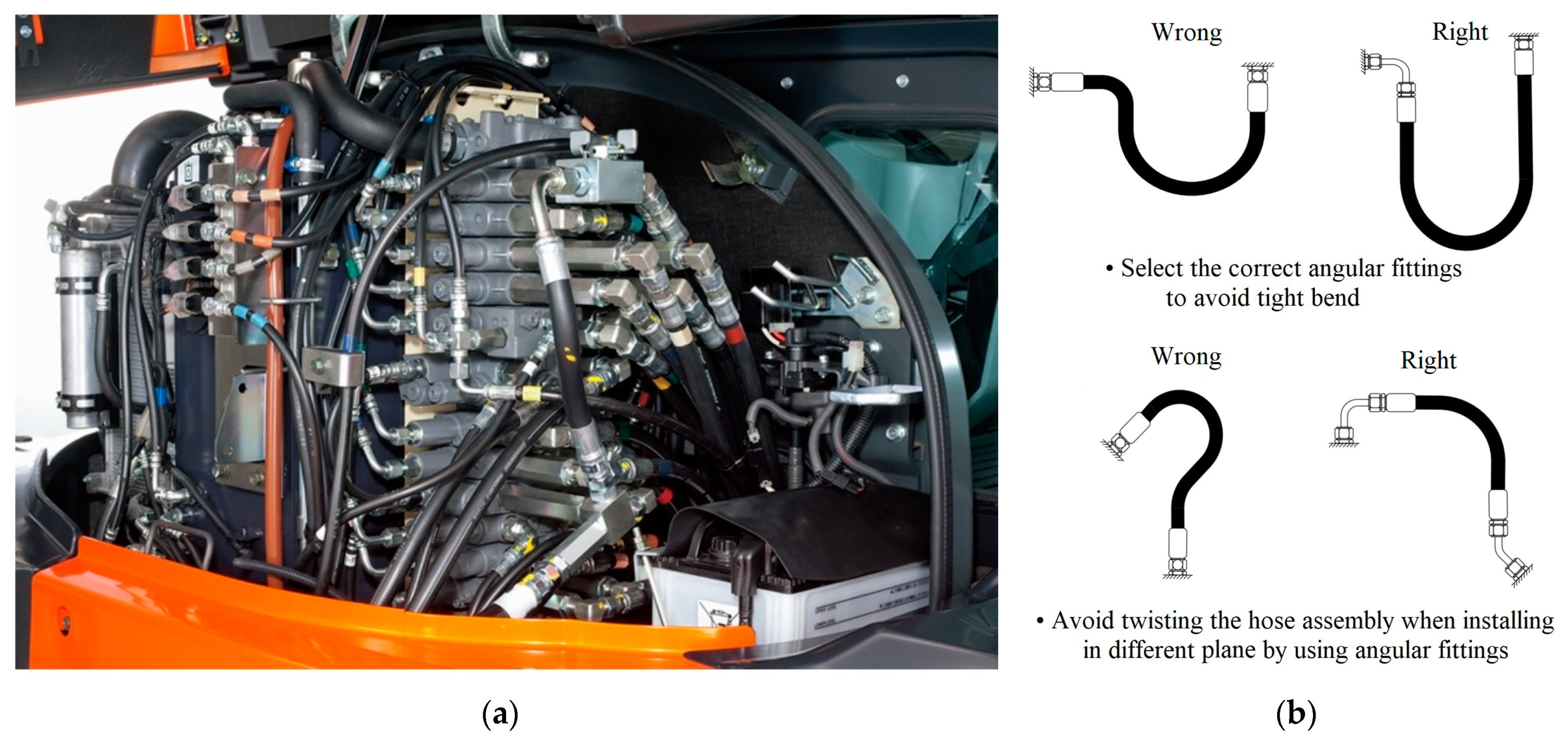

1. Introduction

2. A Review of Related Research

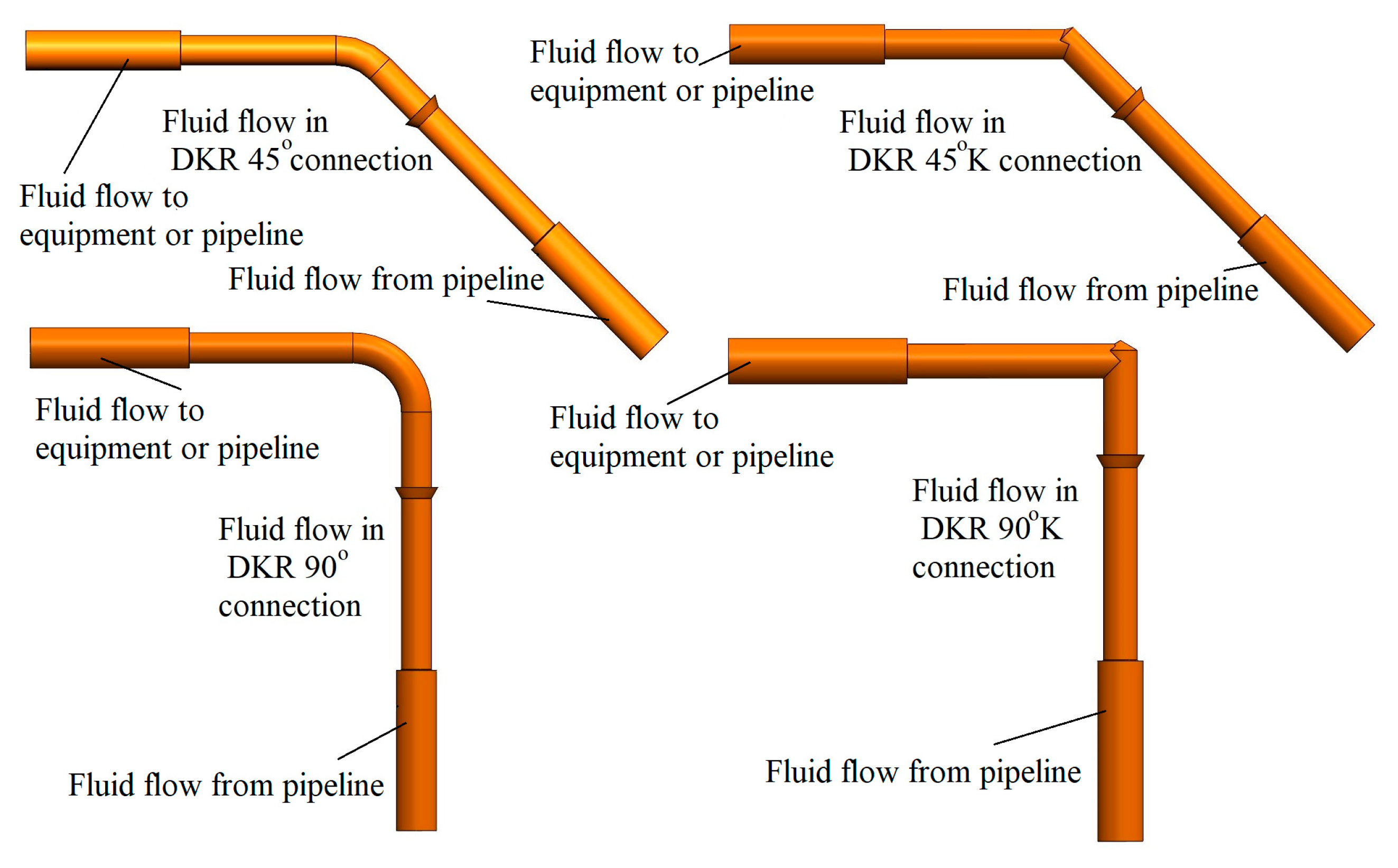

3. The Research Objects

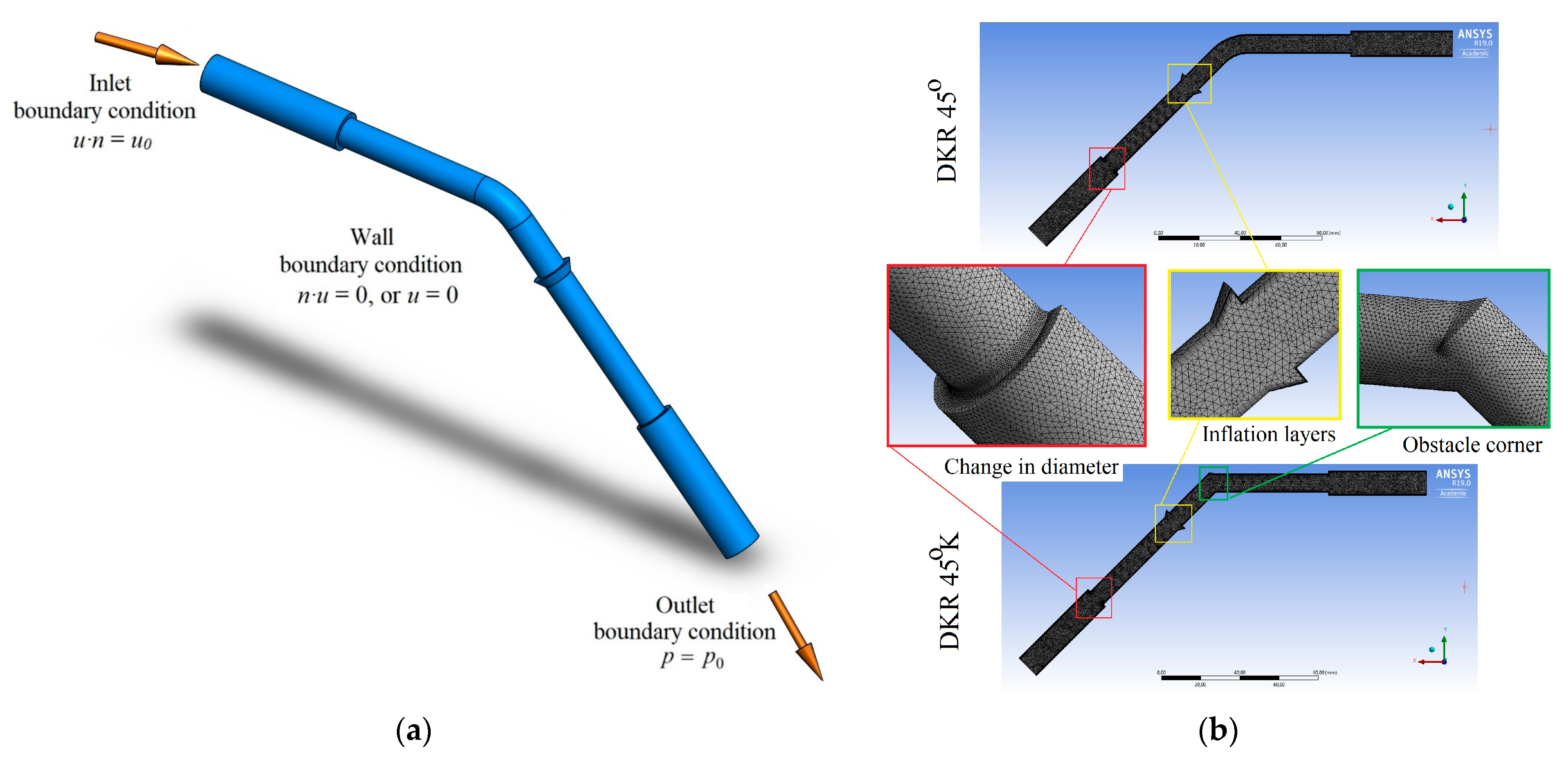

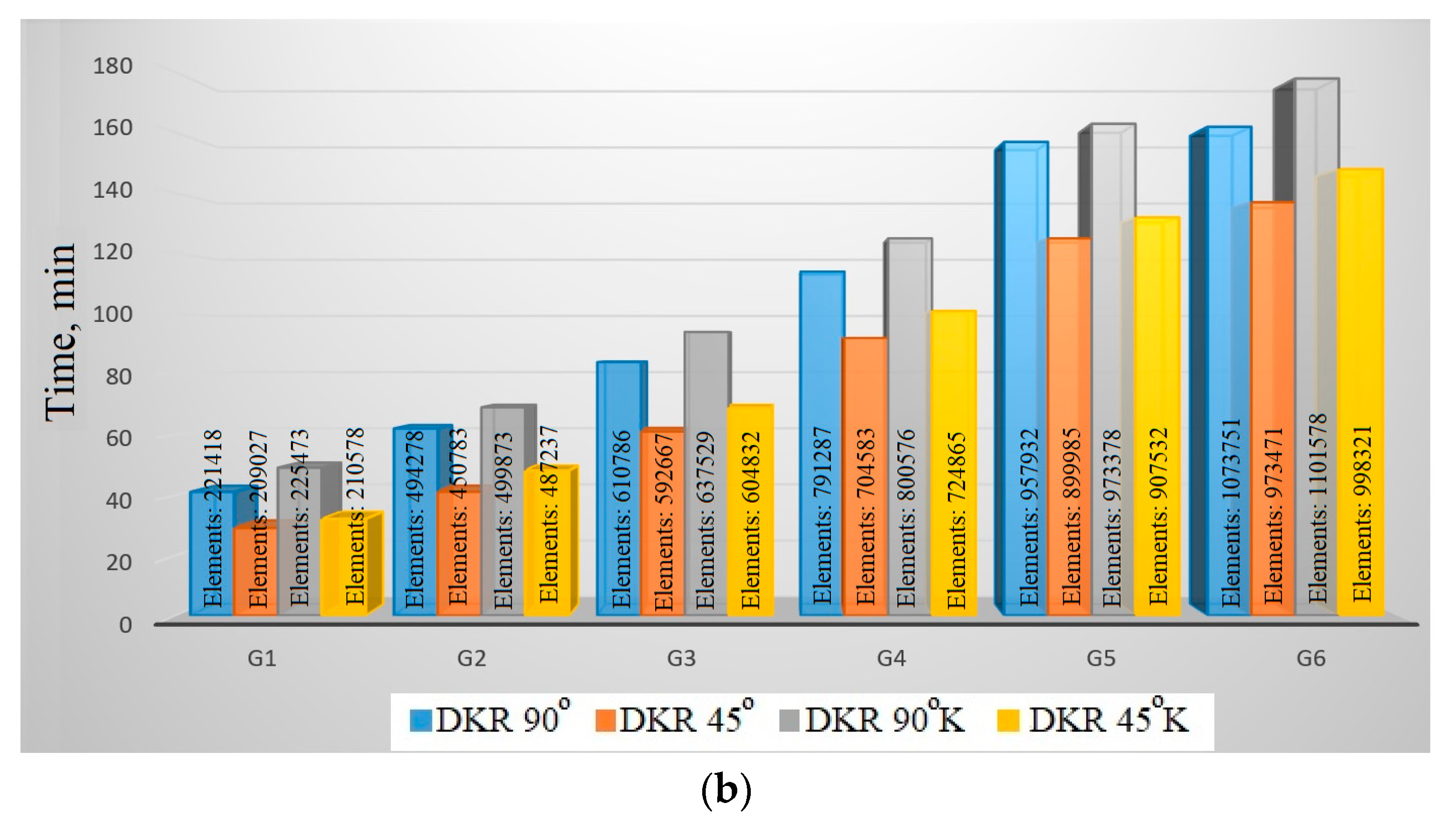

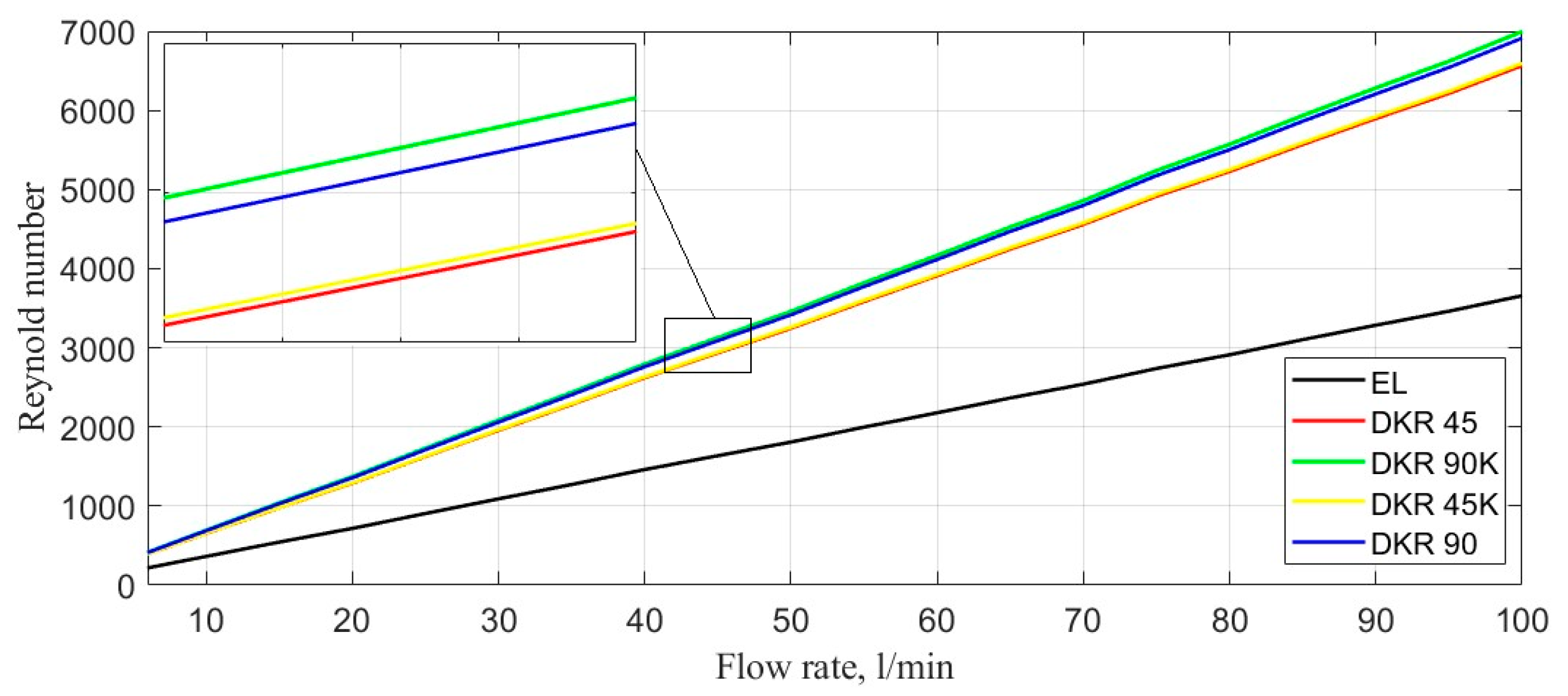

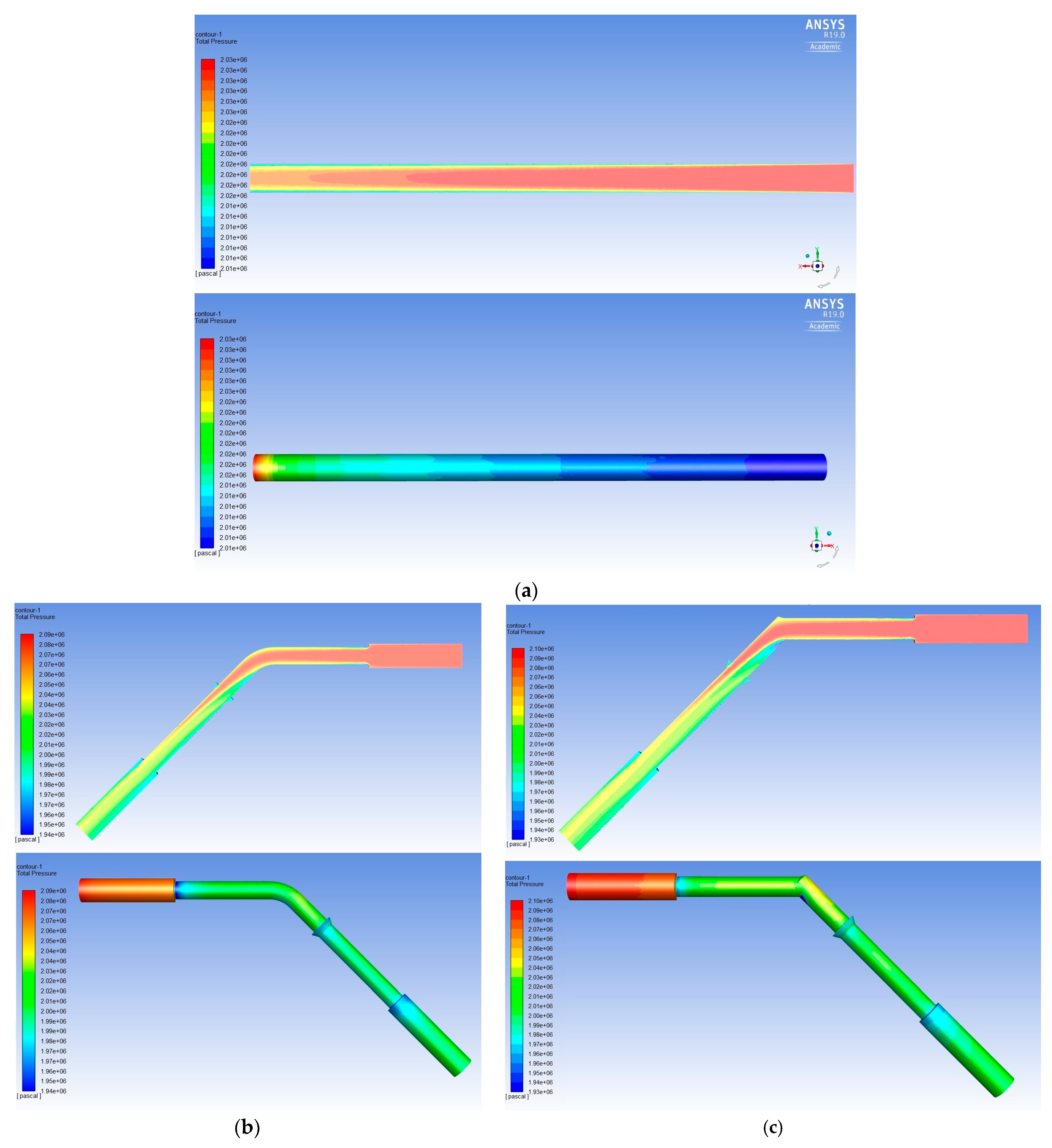

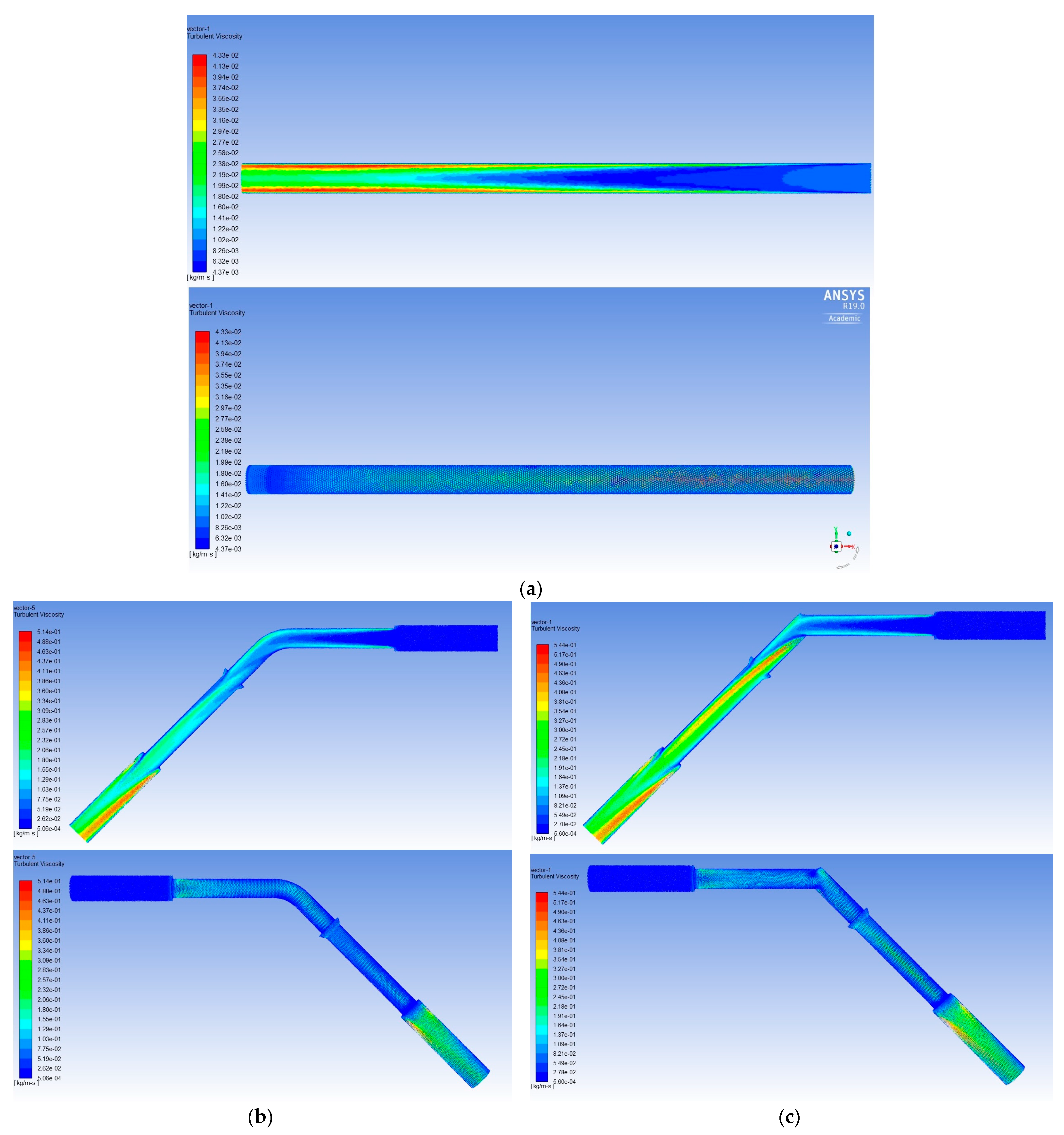

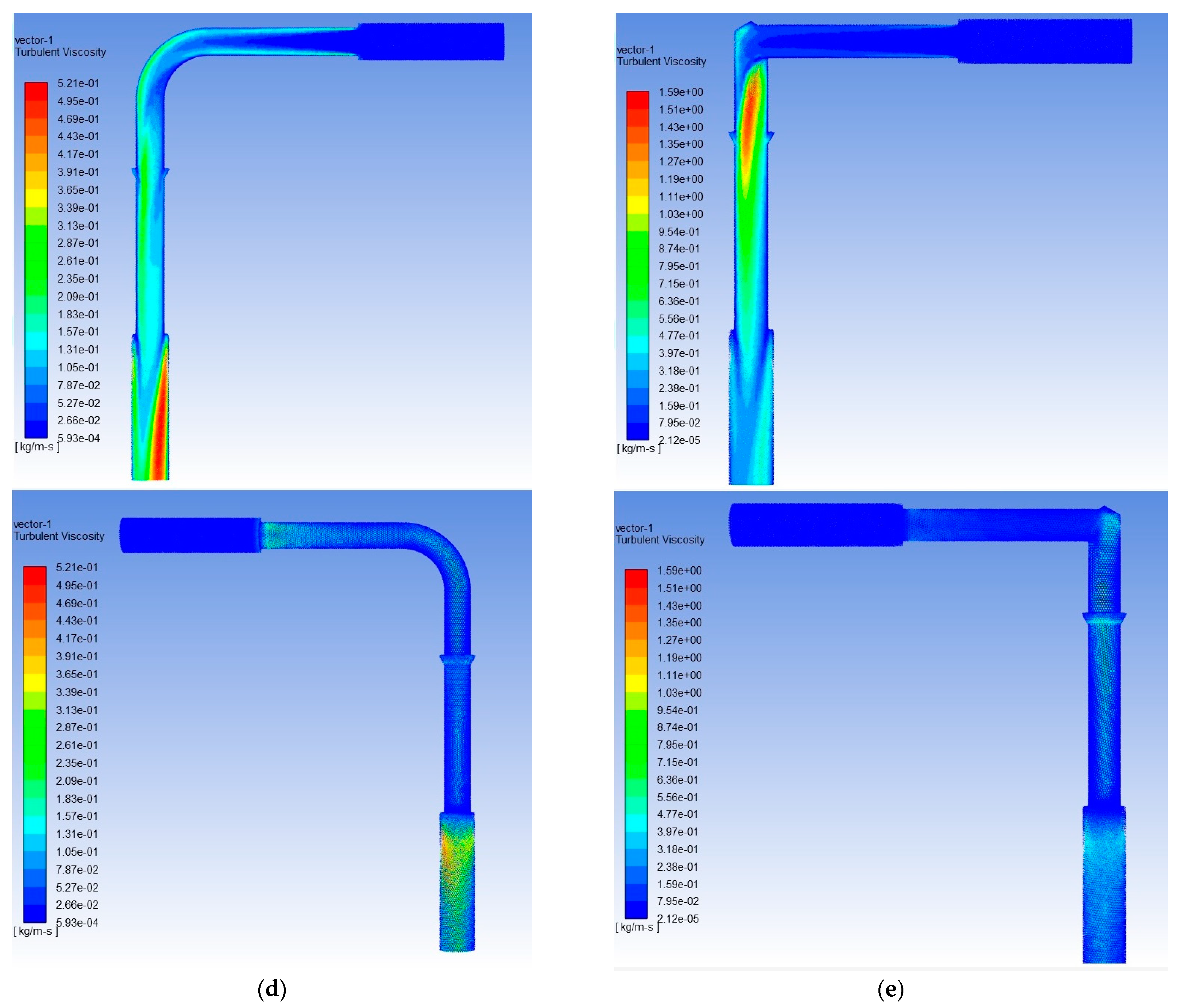

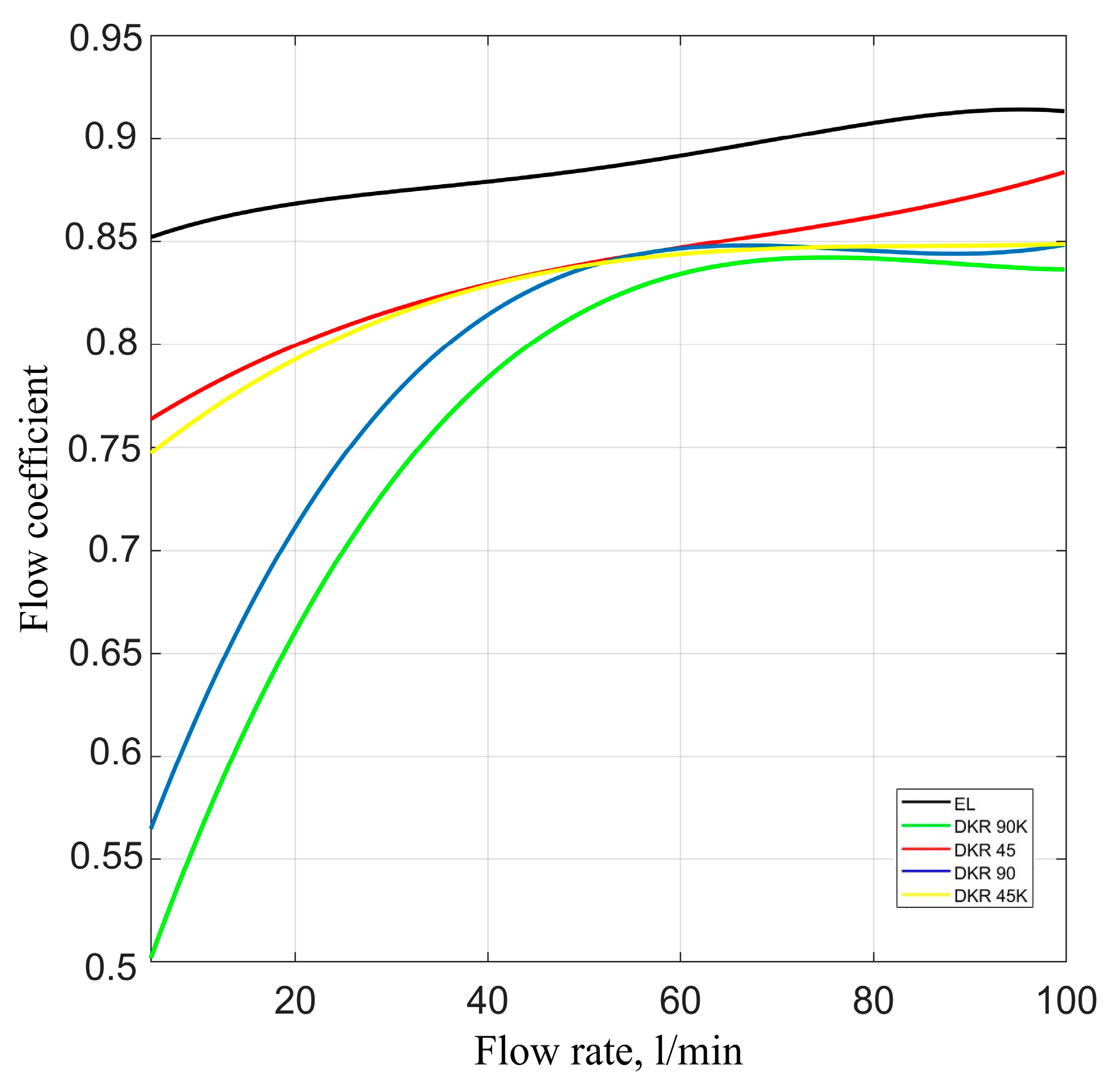

4. Fluid Flow Simulation inside Angular Fitting Connections

4.1. Numerical Formulation

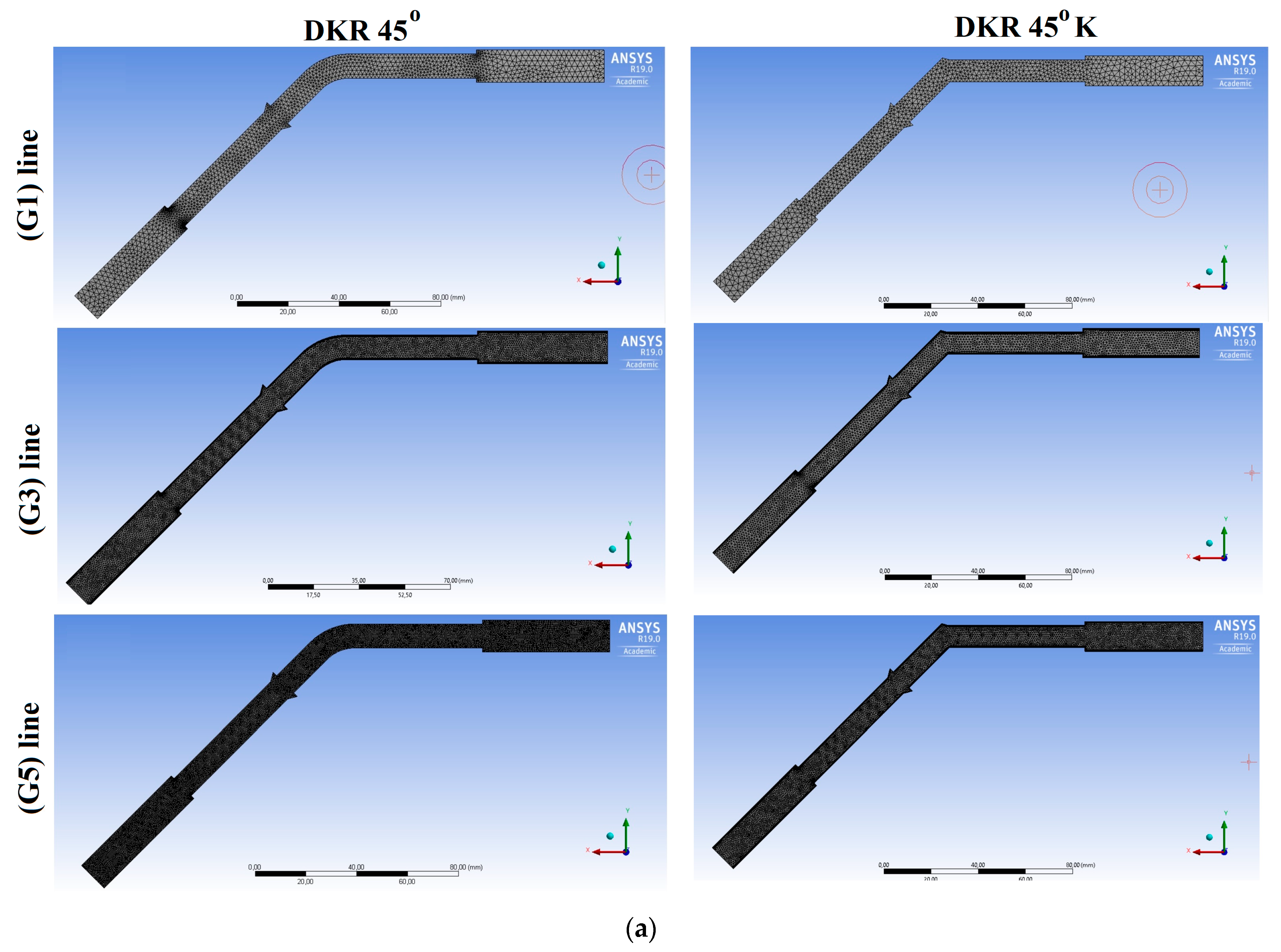

4.2. Fluid Parameters and Numerical Model

5. Results from the Numerical Simulation

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Karpenko, M.; Bogdevičius, M. Review of energy-saving technologies in modern hydraulic drives. Sci. Future Lith. Moksl. Liet. Ateitis 2017, 9, 553–558. [Google Scholar] [CrossRef]

- Bogdevičius, P.; Prentkovskis, O.; Bogdevičius, M. Transmission with cardan joint parametre influence to centrifugal pump characteristics. Moksl. Liet. Ateitis/Sci. Future Lith. 2017, 9, 559–564. [Google Scholar] [CrossRef]

- Parvaresh, A.; Mardani, M. Model predictive control of a hydraulic actuator in torque applying system of a mechanically closed-loop test rig for the helicopter gearbox. Aviation 2019, 23, 143–153. [Google Scholar] [CrossRef]

- Di Gialleonardo, E.; Santelia, M.; Bruni, S.; Zolotas, A. A simple active carbody roll scheme for hydraulically actuated railway vehicles using internal model control. ISA Trans. 2021, 120, 55–69. [Google Scholar] [CrossRef]

- Wei, Q.; Huailiang, Z.; Wenqian, S.; Wei, L. Stress response of the hydraulic composite pipe subjected to random vibration. Compos. Struct. 2021, 255, 112958. [Google Scholar] [CrossRef]

- Lubecki, M.; Stosiak, M.; Bocian, M.; Urbanowicz, K. Analysis of selected dynamic properties of the composite hydraulic microhose. Eng. Fail. Anal. 2021, 125, 105431. [Google Scholar] [CrossRef]

- Nishimura, S.; Matsunaga, T. Analysis of response lag in hydraulic power steering system. JSAE Rev. 2000, 21, 41–46. [Google Scholar] [CrossRef]

- European Commission. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions. Brussels, Belgium, 2011. Available online: https://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=COM:2011:0885:FIN:EN:PDF (accessed on 20 January 2023).

- Yan, X.; Chen, B.; Zhang, D.; Wu, C.; Luo, W. An energy-saving method to reduce the installed power of hydraulic press machines. J. Clean. Prod. 2019, 233, 538–545. [Google Scholar] [CrossRef]

- Moraesa, M.; Muiños, D. Experimental quantification of the head loss coefficient K for fittings and semi-industrial pipe cross section solid concentration profile in pneumatic conveying of polypropylene pellets in dilute phase. Int. J. Sci. Technol. Powder Technol. 2017, 310, 250–263. [Google Scholar] [CrossRef]

- Zhao, K.; Liu, Z.; Yu, S.; Li, X.; Huang, H.; Li, B. Analytical energy dissipation in large and medium-sized hydraulic press. J. Clean. Prod. 2015, 103, 908–915. [Google Scholar] [CrossRef]

- Kong, X.; Majumdar, H.; Zang, F.; Jiang, S.; Wu, Q.; Zhang, W. A multi-switching mode intelligent hybrid control of electro-hydraulic proportional systems. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2019, 233, 120–131. [Google Scholar] [CrossRef]

- Karpenko, M.; Bogdevičius, M. Investigation into the hydrodynamic pro-cesses of fitting connections for determining pressure losses of transport hydraulic drive. Transport 2020, 35, 108–120. [Google Scholar] [CrossRef]

- EN 853 2SN:2015; Rubber hoses and hose assemblies. Wire braid reinforced hydraulic type. European Commission on Standardisation: Geneva, Switzerland, 2015; 17p.

- ISO 8331:2016; Rubber and plastics hoses and hose assemblies—Guidelines for selection, storage, use and maintenance. International Standard Organisation: Geneva, Switzerland, 2016; 13p.

- Parker Hannifin Ltd. Hydraulic Hoses, Fittings and Equipment. Technical Handbook, 2019; 84. Bulletin BUL/C4400-A/UK. Available online: https://www.parker.com/Literature/Polymer%20Hose%20Division%20Europe/Sales%20and%20Marketing%20Bulletins/4400_Rubber%20Hydraulic/Technical%20Handbook-UK.pdf (accessed on 21 January 2023).

- Yokohama Rubber Co. Hose and Fittings, the Products of YOKOHAMA. Catalog Number 905-1, 2014; 106. Available online: https://www.y-yokohama.com/global/mb/pdf/resource/hose-and-fittings.pdf (accessed on 21 January 2023).

- Speedflow. AN Hose and Fitting Guide. 2014. Available online: https://anfittingguide.com/wp-content/uploads/2014/01/AN-hose-and-fitting-guide-v21.pdf (accessed on 23 January 2023).

- Gates Corporation. A Guide to Preventive Maintenance & Safety for Hydraulic Hose & Couplings. Tomkins Company. 2009. Available online: http://www.marshall-equipement.com/Library/SafeHydraulics.pdf (accessed on 22 January 2023).

- Eaton. Eaton Hydraulic Hose and Tubing. Safety Guide. 2020, p. 12. Available online: https://www.eaton.com/ecm/groups/public/@pub/@eaton/@hyd/documents/content/pct_4085913.pdf (accessed on 18 January 2023).

- Błażejewski, R.; Matz, R.; Nawrot, T.; Rudzik, D. Reliability and optimal replacement interval of flexible hose assemblies in drinking water installations. Eng. Fail. Anal. 2020, 109, 104327. [Google Scholar] [CrossRef]

- Chuang, G.; Ferng, Y. Investigating effects of injection angles and velocity ratios on thermal-hydraulic behavior and thermal striping in a T-junction. Int. J. Therm. Sci. 2018, 126, 74–81. [Google Scholar] [CrossRef]

- Crane Co. Flow of Fluids through Valves, Fittings and Pipe. Metric Edition—Si Units; Technical Paper; Crane Co.: New York, NY, USA, 1982; 133p. [Google Scholar]

- Bojko, M.; Kozubkova, M. Investigation of hydraulic fitting losses. In Proceedings of the XXI International Scientific Conference—The Application of Experimental and Numerical Methods in Fluid Mechanics and Energy, Cracow, Poland, 25–27 November 2018; Volume 168, pp. 1–10. [Google Scholar] [CrossRef]

- Valdes, J.; Rodrigues, J.; Saumell, J.; Putz, T. A methodology for the parametric modelling of the flow coefficients and flow rate in hydraulic valves. Energy Convers. Manag. 2017, 88, 598–611. [Google Scholar] [CrossRef]

- Crane Valve Co. Flow of Fluids Through Valves, Fittings, and Pipe; Technical Paper no. 410; Crane Co.: New York, NY, USA, 1998; 132p. [Google Scholar]

- Hooper, W. The two-K method predicts head losses in pipe fittings. Chem. Eng. 1981, 88, 96–100. [Google Scholar]

- Stosiak, M.; Skačkauskas, P.; Towarnicki, K.; Deptuła, A.; Deptuła, A.M.; Prażnowski, K.; Grzywacz, Ż.; Karpenko, M.; Urbanowicz, K.; Łapka, M. Analysis of the Impact of Vibrations on a Micro-Hydraulic Valve Using a Modified Induction Algorithm. Machines 2023, 11, 184. [Google Scholar] [CrossRef]

- Catellani, C.; Cazzoli, G.; Falfari, S.; Forte, C.; Bianchi, G. Large eddy simulation of a steady flow test bench using OpenFOAM. Energy Procedia 2016, 101, 622–629. [Google Scholar] [CrossRef]

- Li, D.; Fu, X.; Zuo, Z.; Wang, H.; Li, Z.; Liu, S.; Wei, X. Investigation methods for analysis of transient phenomena concerning design and operation of hydraulic-machine systems—A review. Renew. Sustain. Energy Rev. 2019, 101, 26–46. [Google Scholar] [CrossRef]

- Gai, Y.; Kimiabeigi, M.; Chong, Y.; Widmer, J.; Deng, X.; Popescu, M. Cooling of automotive traction motors: Schemes, examples and computation methods—A review. IEEE Trans. Ind. Electron. 2019, 66, 1681–1692. [Google Scholar] [CrossRef]

- Akin, A.; Kahveci, H. Effect of turbulence modeling for the prediction of flow and heat transfer in rotorcraft avionics bay. Aerosp. Sci. Technol. 2019, 95, 105453. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, X.; Quan, L.; Zhang, H. Research on energy consumption of injection molding machine driven by five different types of electro-hydraulic power units. J. Clean. Prod. 2020, 242, 118355. [Google Scholar] [CrossRef]

- BS EN 10226-2:2005; Pipe threads where pressure-tight joints are not made on the threads—Part 1: Dimensions, tolerances and designation. British National Standard: London, UK; European Committee for Standardization: Brussels, Belgium, 2005; 16p.

- Kim, B.; Siddique, M.; Samad, A.; Hu, G.; Lee, D. Optimization of centrifugal pump impeller for pumping viscous Fluids Using Direct Design Optimization Technique. Machines 2022, 10, 774. [Google Scholar] [CrossRef]

- Urbanowicz, K.; Bergant, A.; Stosiak, M.; Deptuła, A.; Karpenko, M. Navier-Stokes Solutions for Accelerating Pipe Flow—A Review of Analytical Models. Energies 2023, 16, 1407. [Google Scholar] [CrossRef]

- Santos, F.; Brito, A.; de Castro, A.; Almeida, M.; da Cunha Lima, A.; Zebende, G.; da Cunha Lima, I. Detection of the persistency of the blockages symmetry on the multi-scale cross-correlations of the velocity fields in internal turbulent flows in pipelines. Phys. A Stat. Mech. Appl. 2018, 509, 294–301. [Google Scholar] [CrossRef]

- DIN 51524-2; Pressure Fluids—Hydraulic oils—Part 2: HLP Hydraulic oils, Minimum Requirements. German National Standard. Standard Specification; DIN Deutsches Institut für Normung e. V.: Berlin, Germany, 2017; 11p.

- Karpenko, M.; Prentkovskis, O.; Šukevičius, Š. Research on high-pressure hose with repairing fitting and influence on energy parameter of the hydraulic drive. Eksploat. Niezawodn. Maint. Reliab. 2022, 24, 25–32. [Google Scholar] [CrossRef]

- Karpenko, M. Investigation of Energy Efficiency of Mobile Machinery Hydraulic Drives. Ph.D. Thesis, Vilnius Gediminas Technical University, Vilnius, Lithuania, 2021; 164p. [Google Scholar] [CrossRef]

- ISO 5167-1:2022; Measurement of Fluid Flow by Means of Orifice Plates, Nozzles, and Venturi Tubes Inserted in Circular Cross Section Conduits Running Full. European Commission on Standardisation: Geneva, Switzerland, 2022; p. 42.

| Flow Rate (l/min) | Pipeline (W) | DKR 90° (W) | DKR 90°K (W) | DKR 45° (W) | DKR 45°K (W) |

|---|---|---|---|---|---|

| 5 | 1.52·10−3 | 5.22·10−3 | 5.91·10−3 | 3.81·10−3 | 4.24·10−3 |

| 10 | 1.22·10−2 | 3.84·10−2 | 4.08·10−2 | 2.42·10−2 | 2.98·10−2 |

| 15 | 4.21·10−2 | 7.76·10−2 | 9.26·10−2 | 5.77·10−2 | 6.29·10−2 |

| 20 | 0.125 | 0.343 | 0.378 | 0.241 | 0.283 |

| 25 | 0.238 | 0.452 | 0.498 | 0.322 | 0.391 |

| 30 | 0.353 | 0.597 | 0.677 | 0.366 | 0.413 |

| 35 | 0.558 | 0.825 | 0.995 | 0.632 | 0.708 |

| 40 | 0.465 | 1.023 | 1.237 | 0.897 | 0.934 |

| 45 | 1.212 | 1.598 | 1.778 | 1.223 | 1.409 |

| 50 | 1.367 | 1.887 | 2.078 | 1.573 | 1.669 |

| 55 | 1.768 | 2.451 | 2.642 | 2.284 | 2.327 |

| 60 | 2.312 | 3.207 | 3.482 | 2.798 | 2.988 |

| 65 | 2.671 | 3.846 | 3.998 | 3.562 | 3.629 |

| 70 | 3.523 | 4.745 | 4.955 | 4.532 | 4.707 |

| 75 | 4.624 | 5.923 | 6.073 | 5.182 | 5.496 |

| 80 | 5.735 | 7.121 | 7.411 | 6.247 | 6.724 |

| 85 | 7.989 | 8.998 | 9.209 | 8.273 | 8.629 |

| 90 | 8.557 | 10.875 | 11.342 | 9.057 | 9.522 |

| 95 | 10.142 | 13.517 | 13.782 | 11.347 | 11.808 |

| 100 | 11.177 | 16.261 | 16.663 | 13.438 | 14.113 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Karpenko, M.; Stosiak, M.; Šukevičius, Š.; Skačkauskas, P.; Urbanowicz, K.; Deptuła, A. Hydrodynamic Processes in Angular Fitting Connections of a Transport Machine’s Hydraulic Drive. Machines 2023, 11, 355. https://doi.org/10.3390/machines11030355

Karpenko M, Stosiak M, Šukevičius Š, Skačkauskas P, Urbanowicz K, Deptuła A. Hydrodynamic Processes in Angular Fitting Connections of a Transport Machine’s Hydraulic Drive. Machines. 2023; 11(3):355. https://doi.org/10.3390/machines11030355

Chicago/Turabian StyleKarpenko, Mykola, Michał Stosiak, Šarūnas Šukevičius, Paulius Skačkauskas, Kamil Urbanowicz, and Adam Deptuła. 2023. "Hydrodynamic Processes in Angular Fitting Connections of a Transport Machine’s Hydraulic Drive" Machines 11, no. 3: 355. https://doi.org/10.3390/machines11030355

APA StyleKarpenko, M., Stosiak, M., Šukevičius, Š., Skačkauskas, P., Urbanowicz, K., & Deptuła, A. (2023). Hydrodynamic Processes in Angular Fitting Connections of a Transport Machine’s Hydraulic Drive. Machines, 11(3), 355. https://doi.org/10.3390/machines11030355