Gear Crack Detection Based on Vibration Analysis Techniques and Statistical Process Control Charts (SPCC)

Abstract

1. Introduction

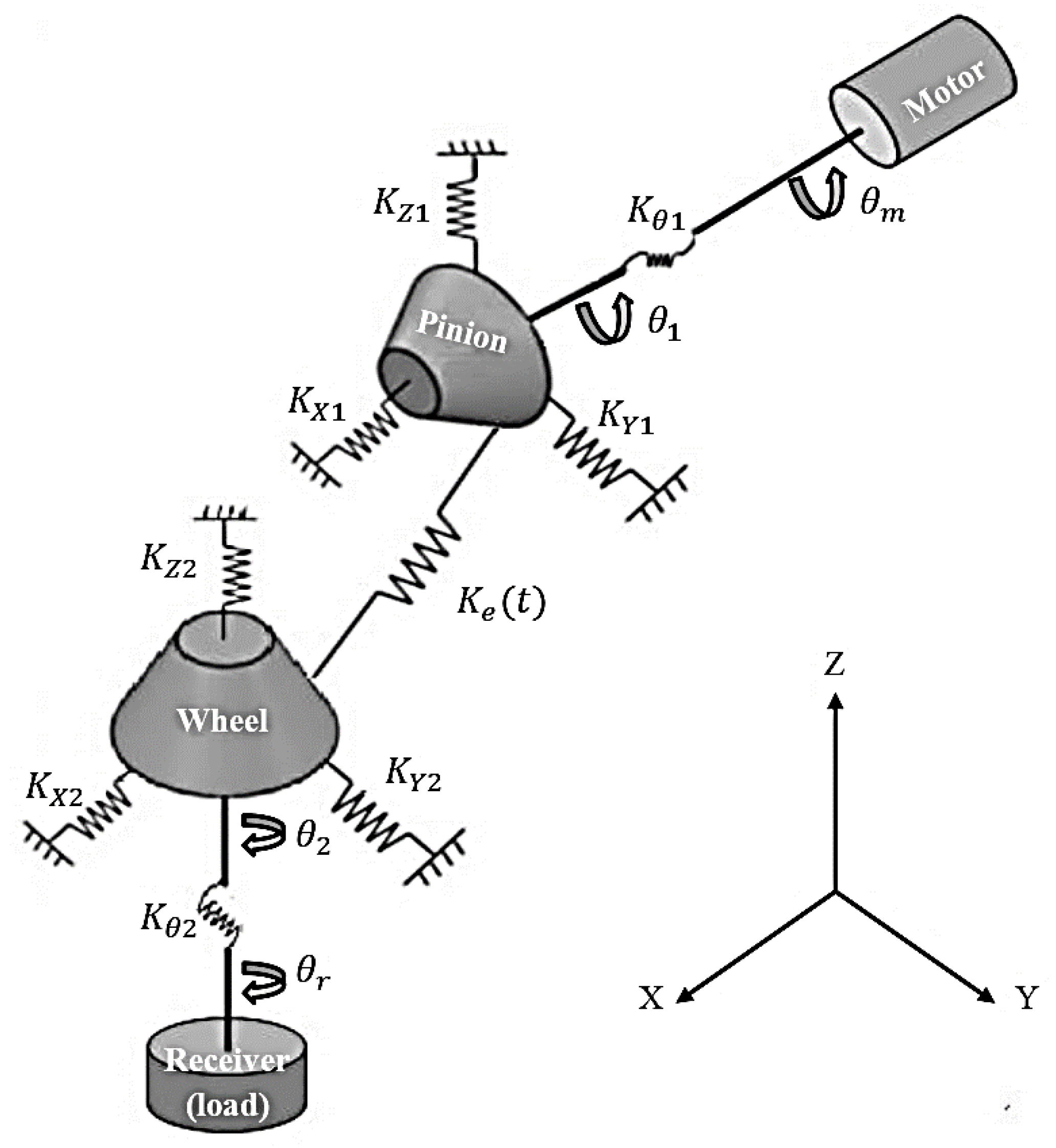

2. Theoretical Modeling of the Transmission System

2.1. Dynamic Modeling of a Spiral Bevel Gear System (SBGS)

- The transmission system operates under stationary conditions;

- Linear springs are used to represent the stiffness generated by the gears meshing;

- The frictional force effect that occurs while meshing is disregarded;

- Any effects of errors in assembly and manufacturing are neglected;

- There is no consideration for any transmission errors;

- Due to the low rotational speed, the Coriolis force was neglected;

- Damping is considered Rayleigh damping.

2.2. Equation of Motion of the System

2.3. Modeling of Gear Mesh Stiffness

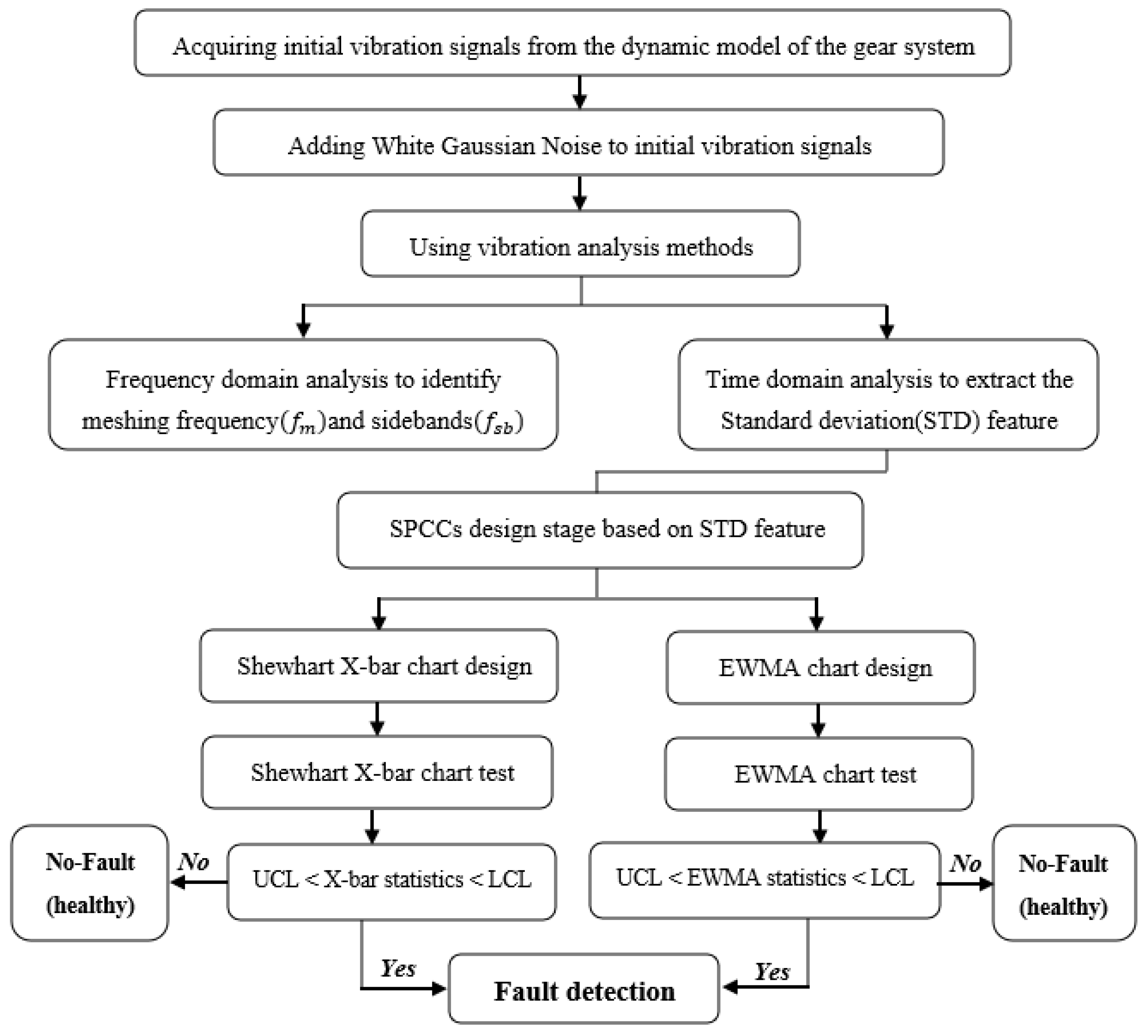

3. The Proposed Methodology for the Gear Fault Detection

- Data acquisition: the initial simulated vibration signals are obtained from the dynamic model described in Section 2. Next, as a first step, a noise-add simulation of the initial signals is performed using noise contrast and signal-to-noise ratio (SNR) to simulate work conditions for raw signals as in real practice;

- Data processing: Vibration analysis methods, including both time domain analysis and frequency domain analysis, are used for vibration signals after they are divided into segments as short-time signals. Firstly, the time-domain signal is analyzed to detect periodic pulse and calculate the standard deviation (STD) feature as a fault-sensitive statistical feature and then used to design and test the SPCC. Secondly, the vibration signal is analyzed in the frequency domain using fast Fourier transform (FFT) analysis to identify meshing frequency ( and sidebands ( that are associated with different crack levels.

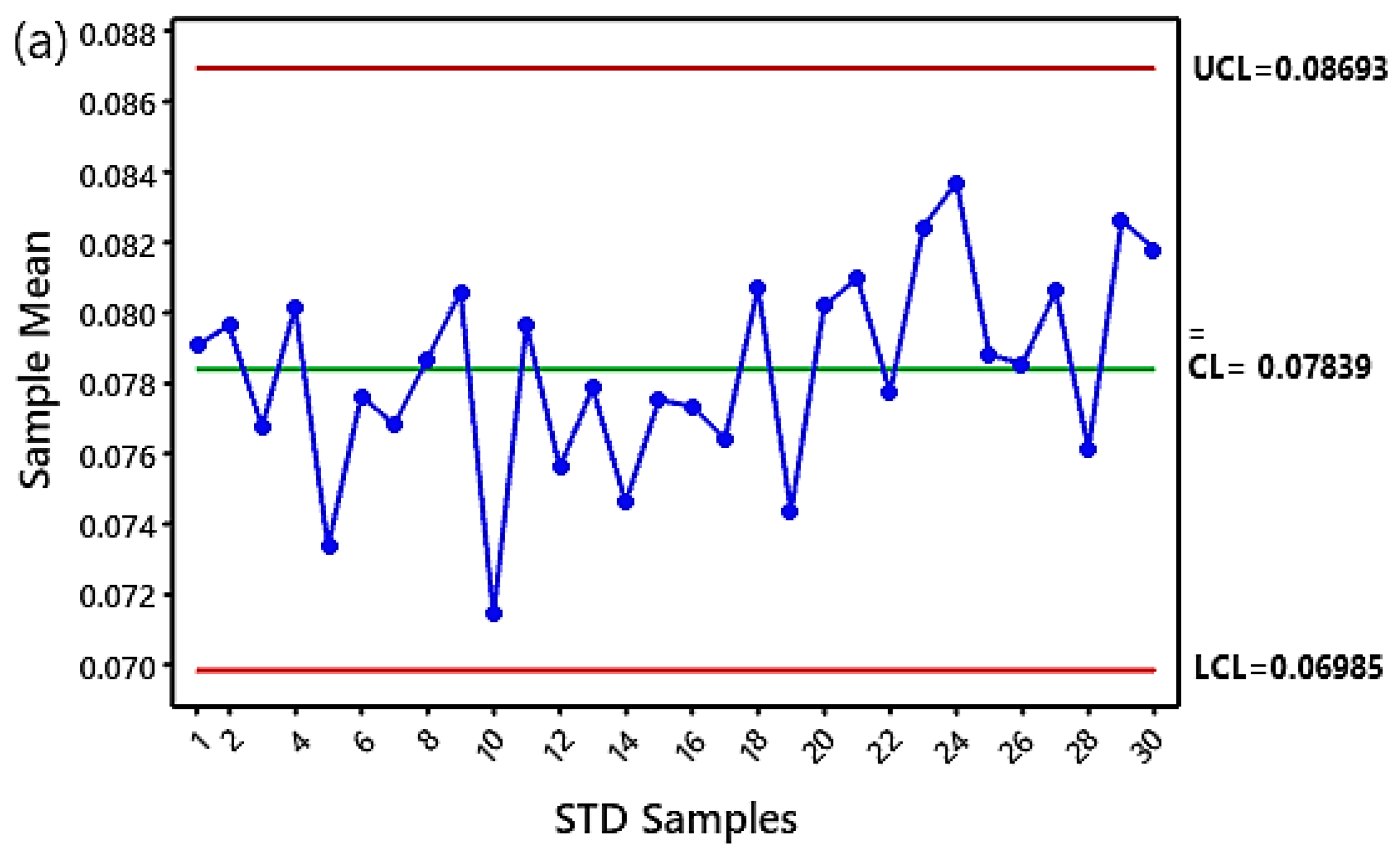

- The design stage of statistical process control charts (SPCC): Univariate statistical control charts are designed, each of the Shewhart X-bar chart and the exponentially weighted moving average (EWMA) chart, depending on the standard deviation (STD) feature under healthy gear system conditions and the establishment of upper control limits (UCL) and lower control limits (LCL) for the SPCC;

- The test stage for statistical process control charts (SPCC): In this step, Shewhart X-bar and EWMA control charts are tested using the same UCL and LCL as in the healthy status charts to detect different levels of the crack defect in the root tooth of the pinion.

3.1. Noise Simulation of Raw Signals

3.2. The Vibration Analysis Methods

3.2.1. Time Domain Analysis Method

3.2.2. Frequency Domain Analysis Method

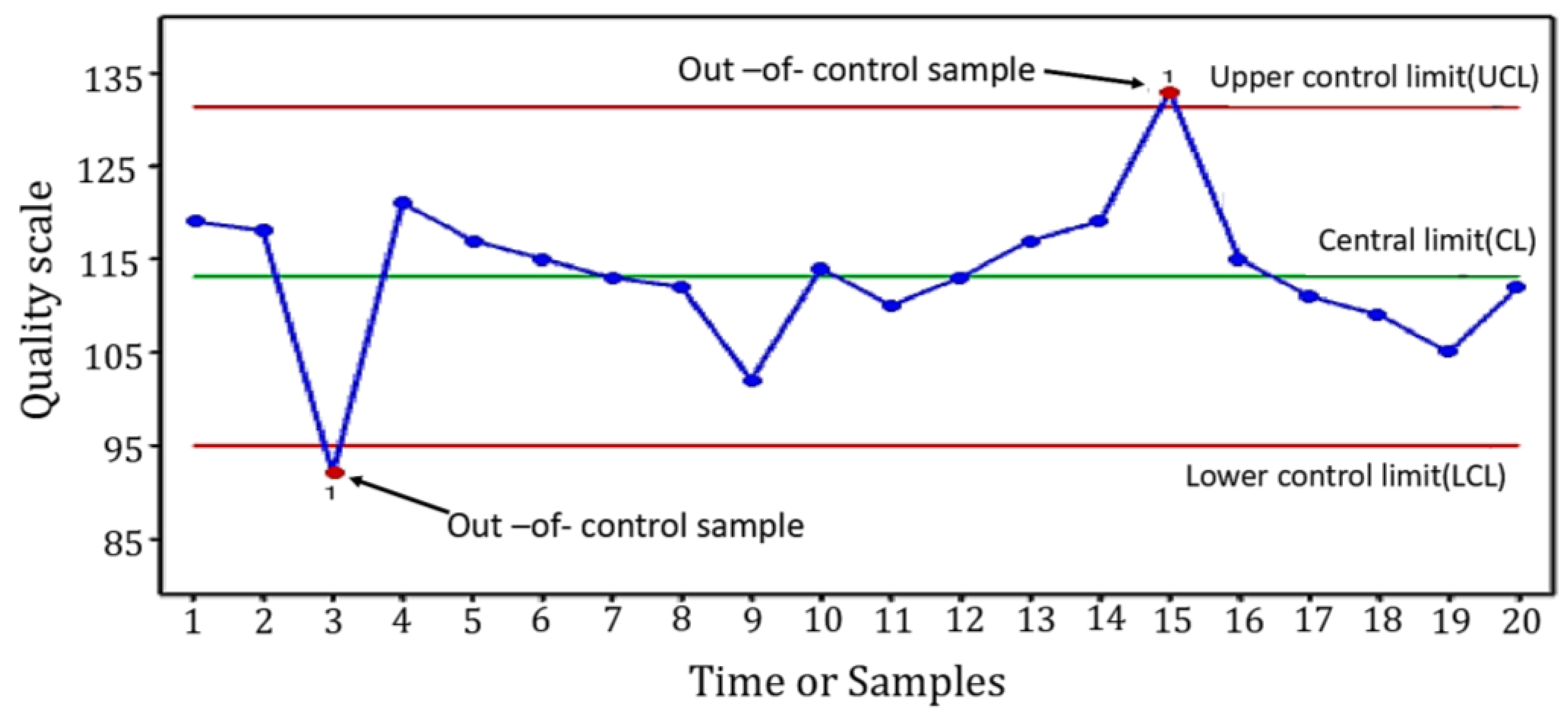

3.3. Statistical Process Control Charts (SPCC)

3.3.1. The Shewhart X-Bar Control Chart Principle

3.3.2. Exponentially Weighted Moving Average Control Chart Principle

4. Results and Discussion

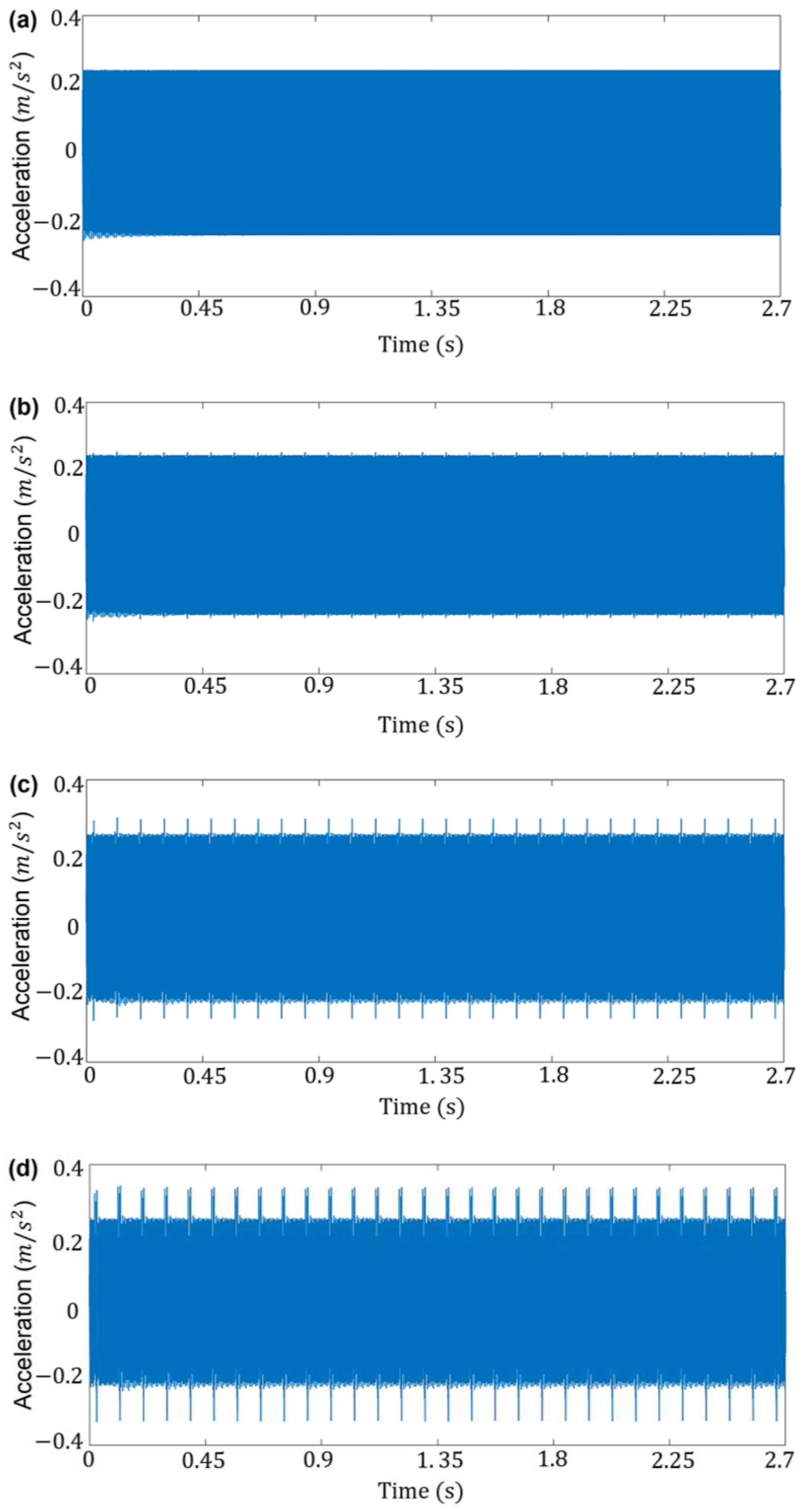

4.1. Numerical Simulation of Dynamic Behaviour

4.2. Vibration Analysis Methods Results

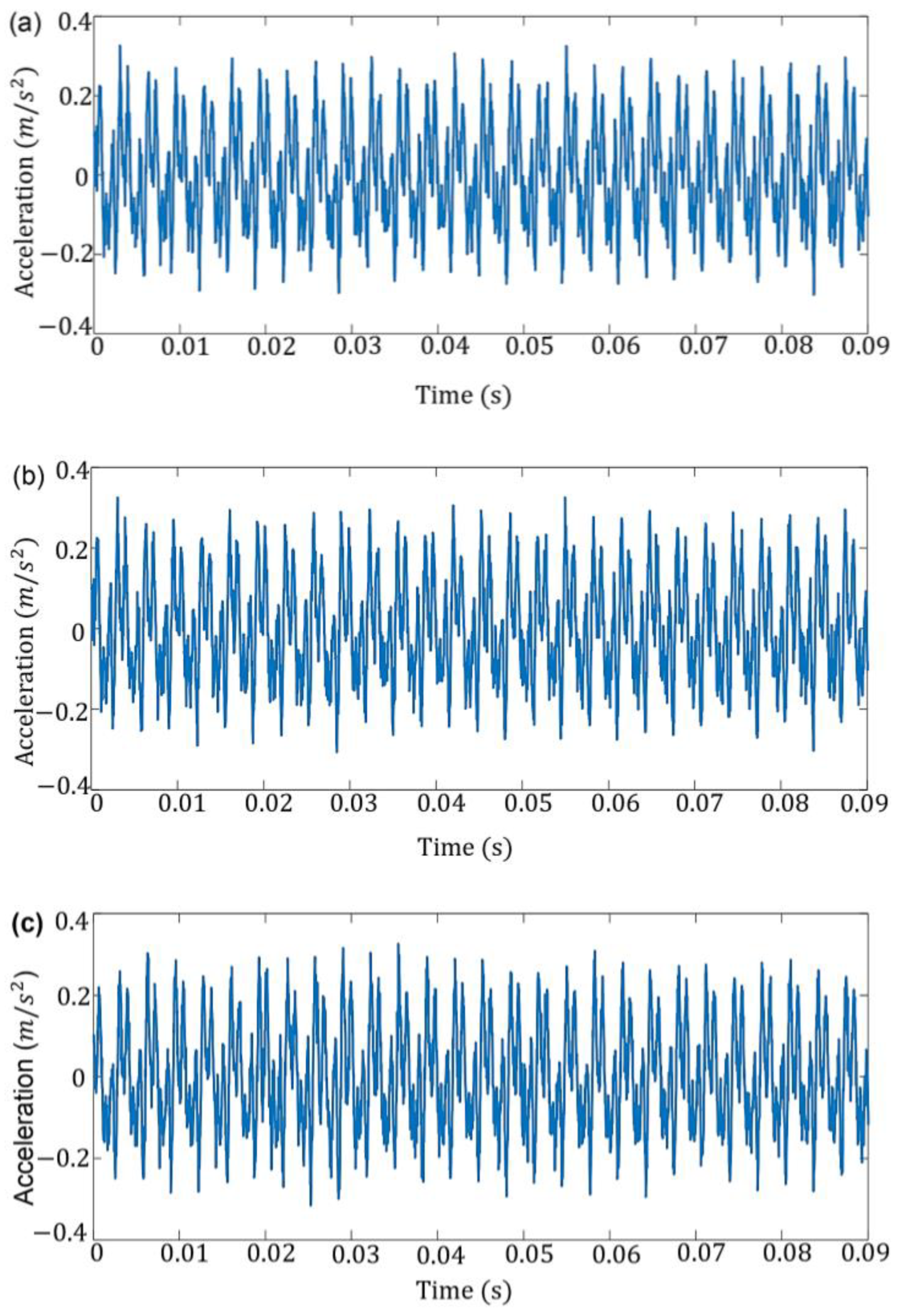

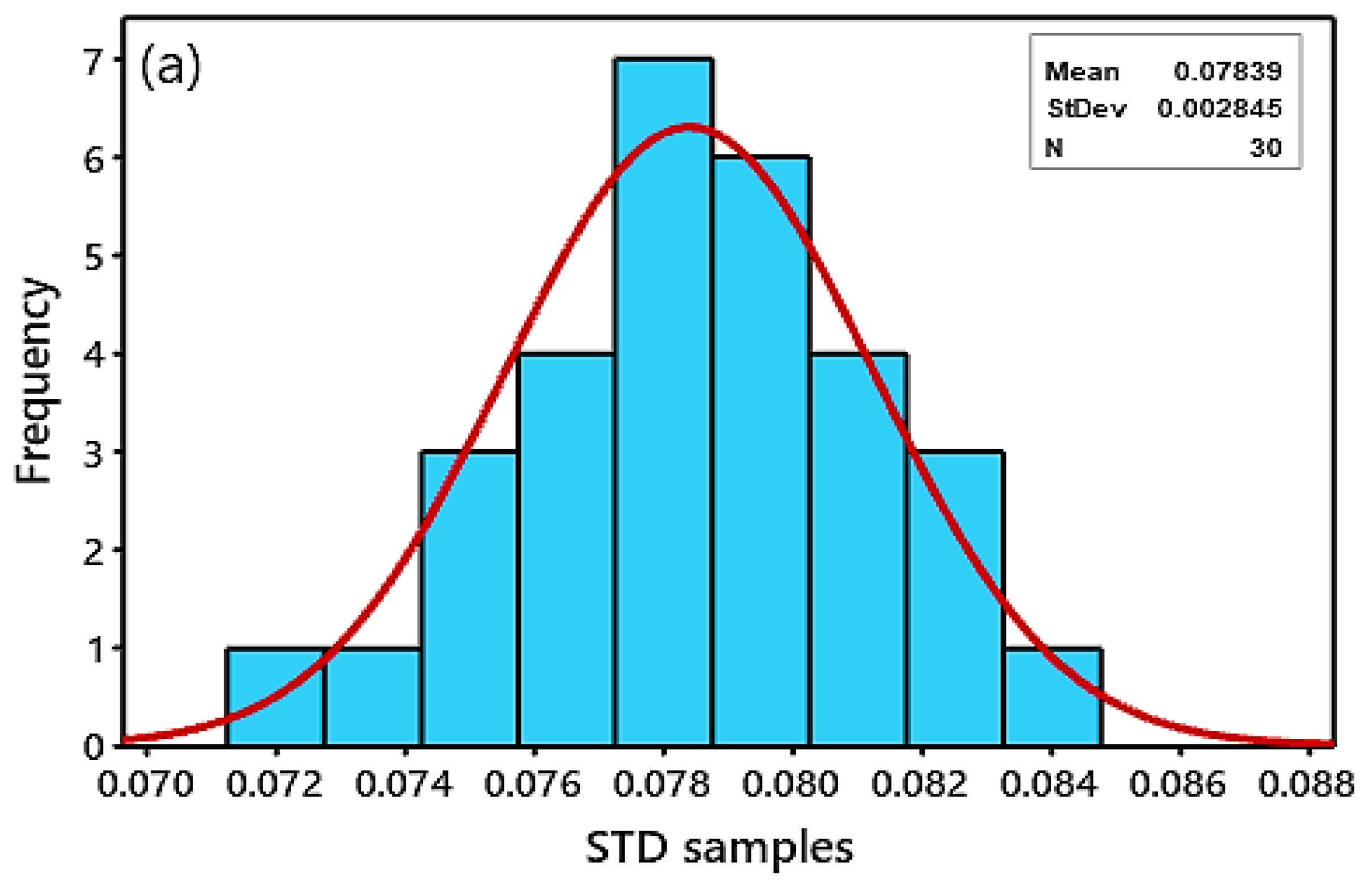

4.2.1. Time-Domain Analysis Method

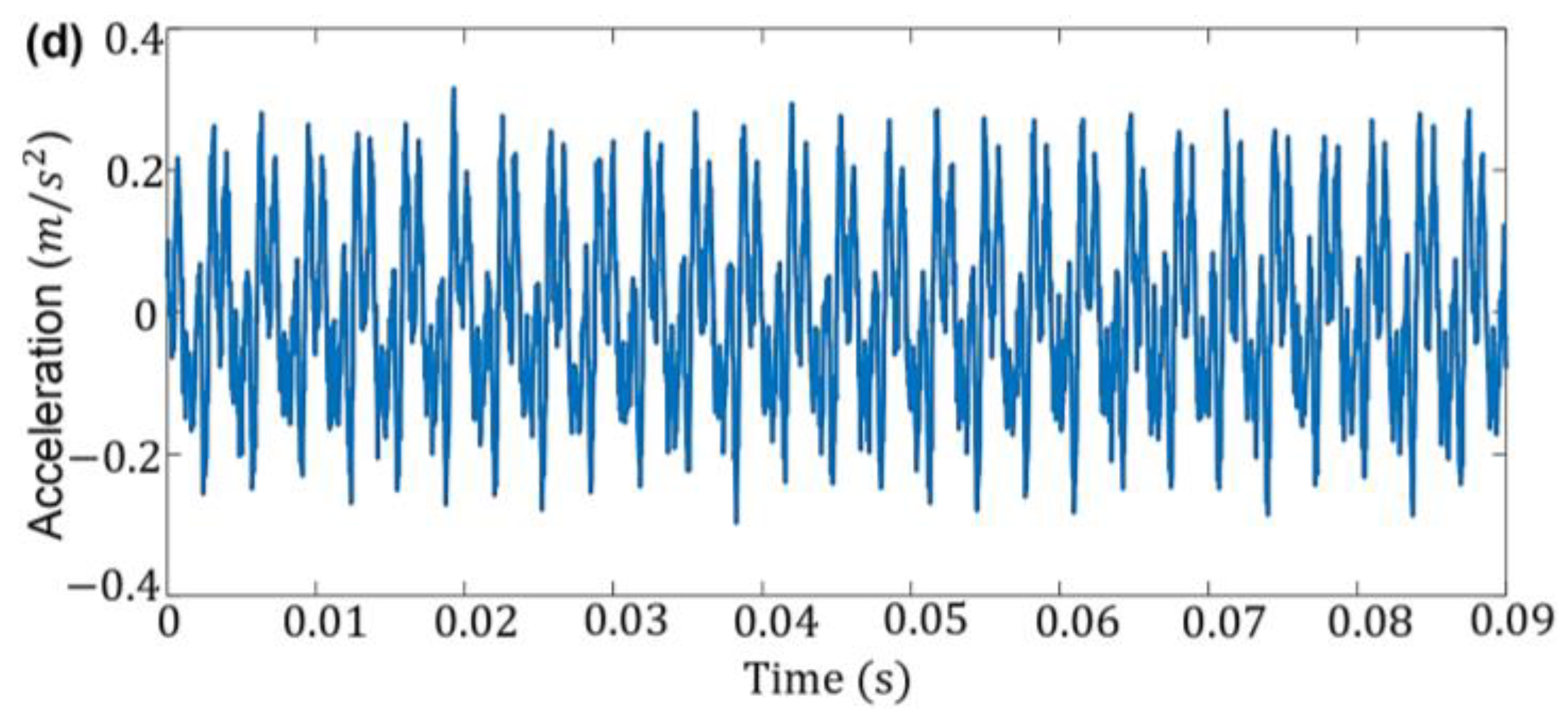

4.2.2. Frequency-Domain Analysis Method

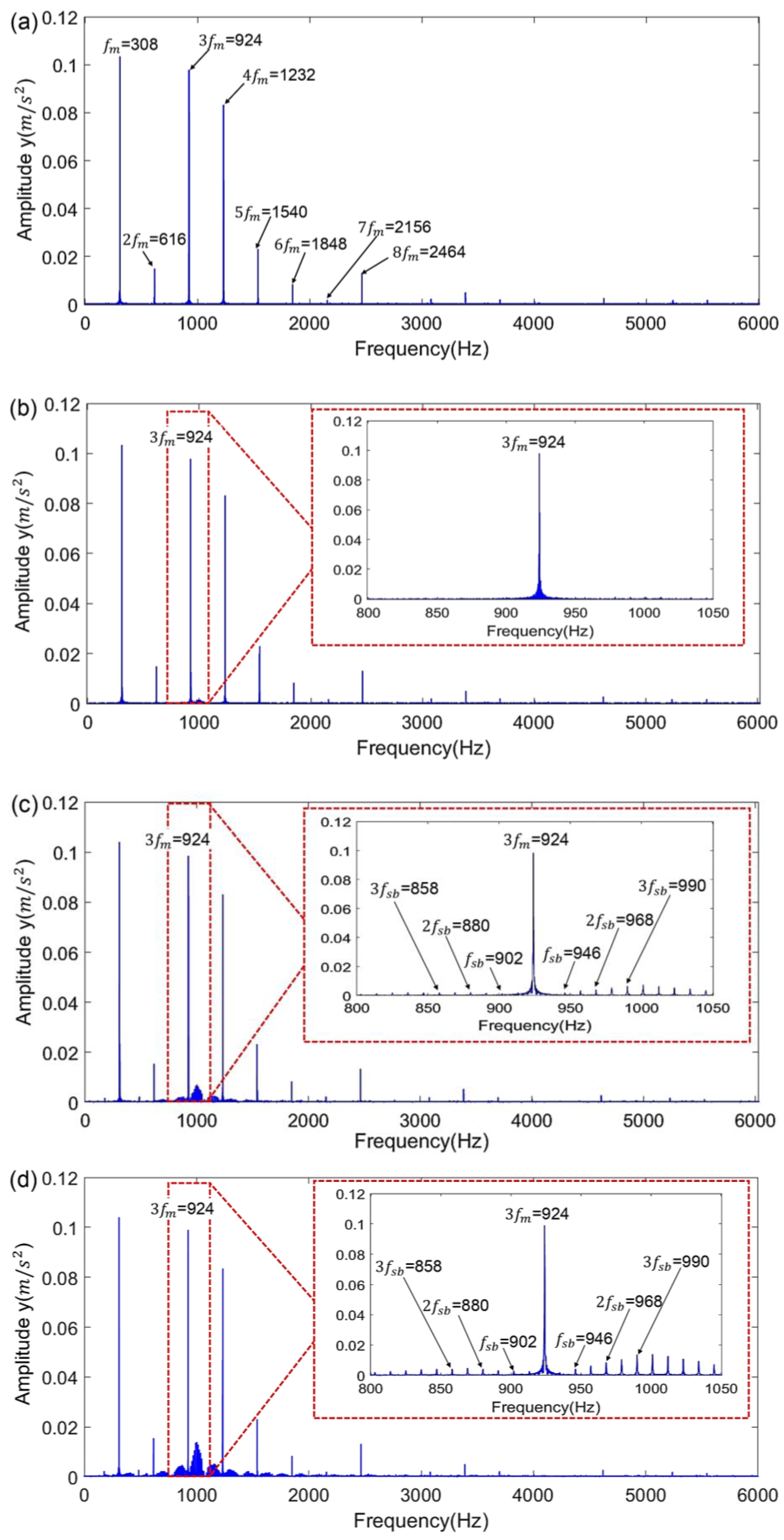

4.3. Designing Control Charts Results

4.4. Testing Control Charts Results

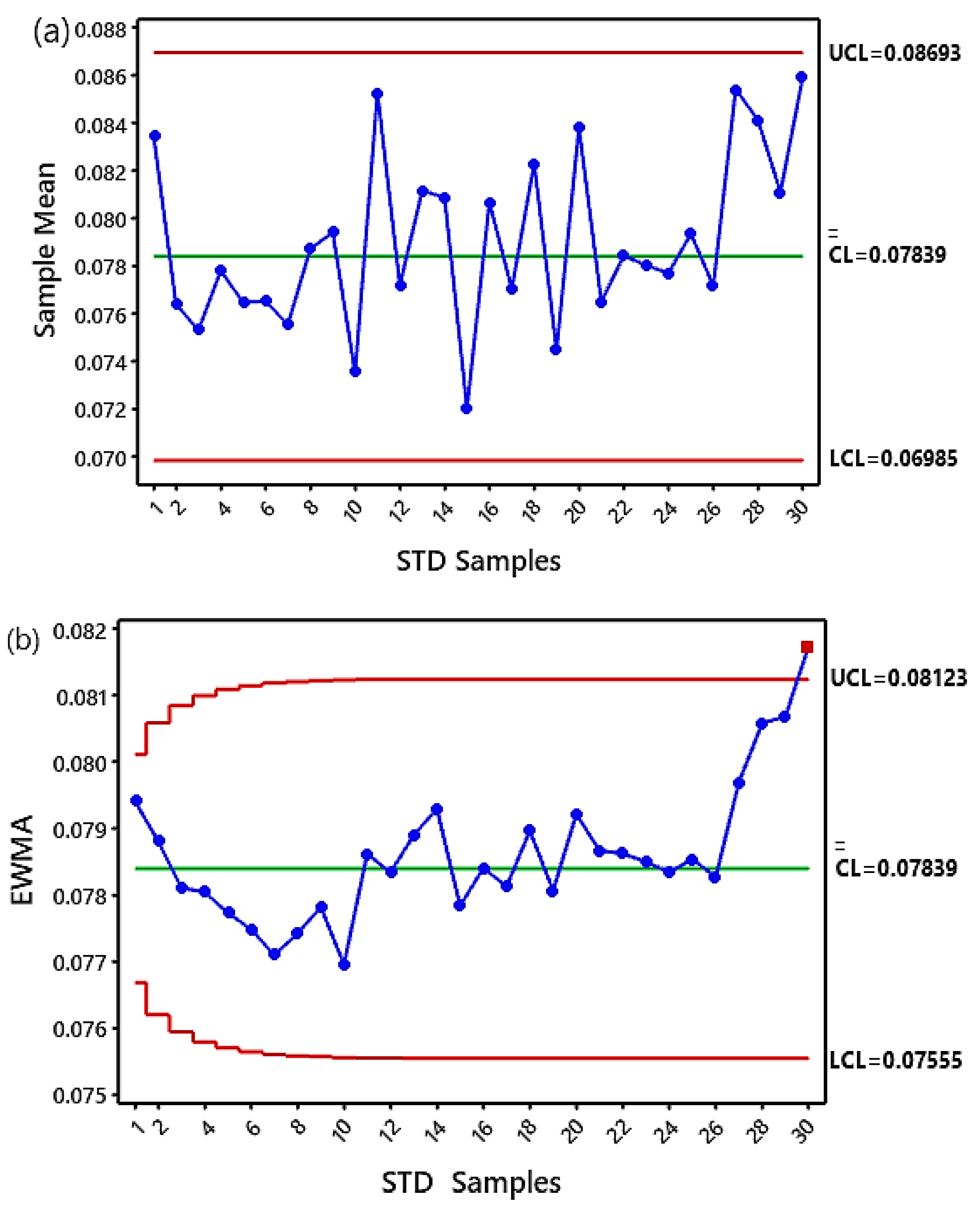

4.4.1. The Crack of Level 1 (1% Loss in Mesh Stiffness)

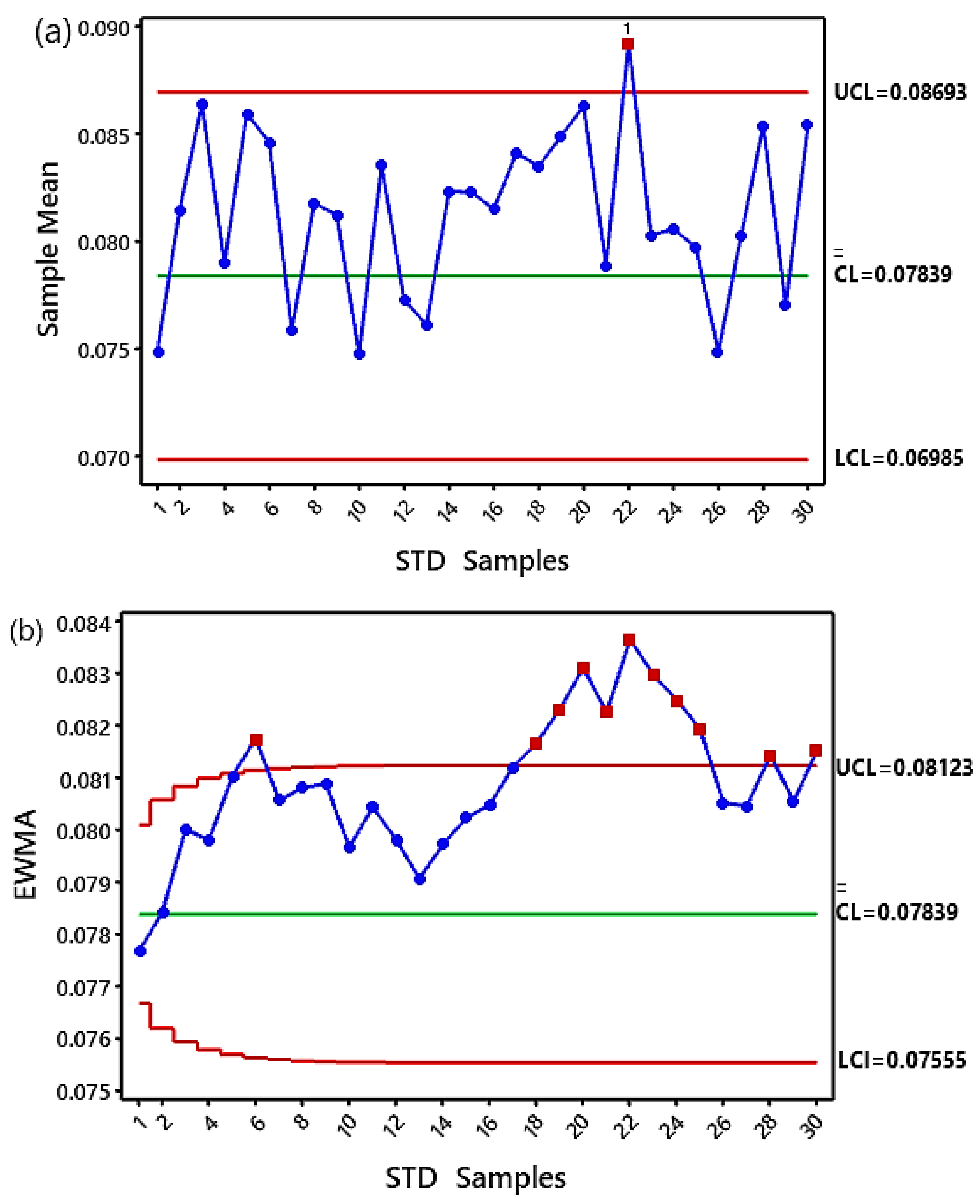

4.4.2. The Crack of Level 2 (5% Loss in Mesh Stiffness)

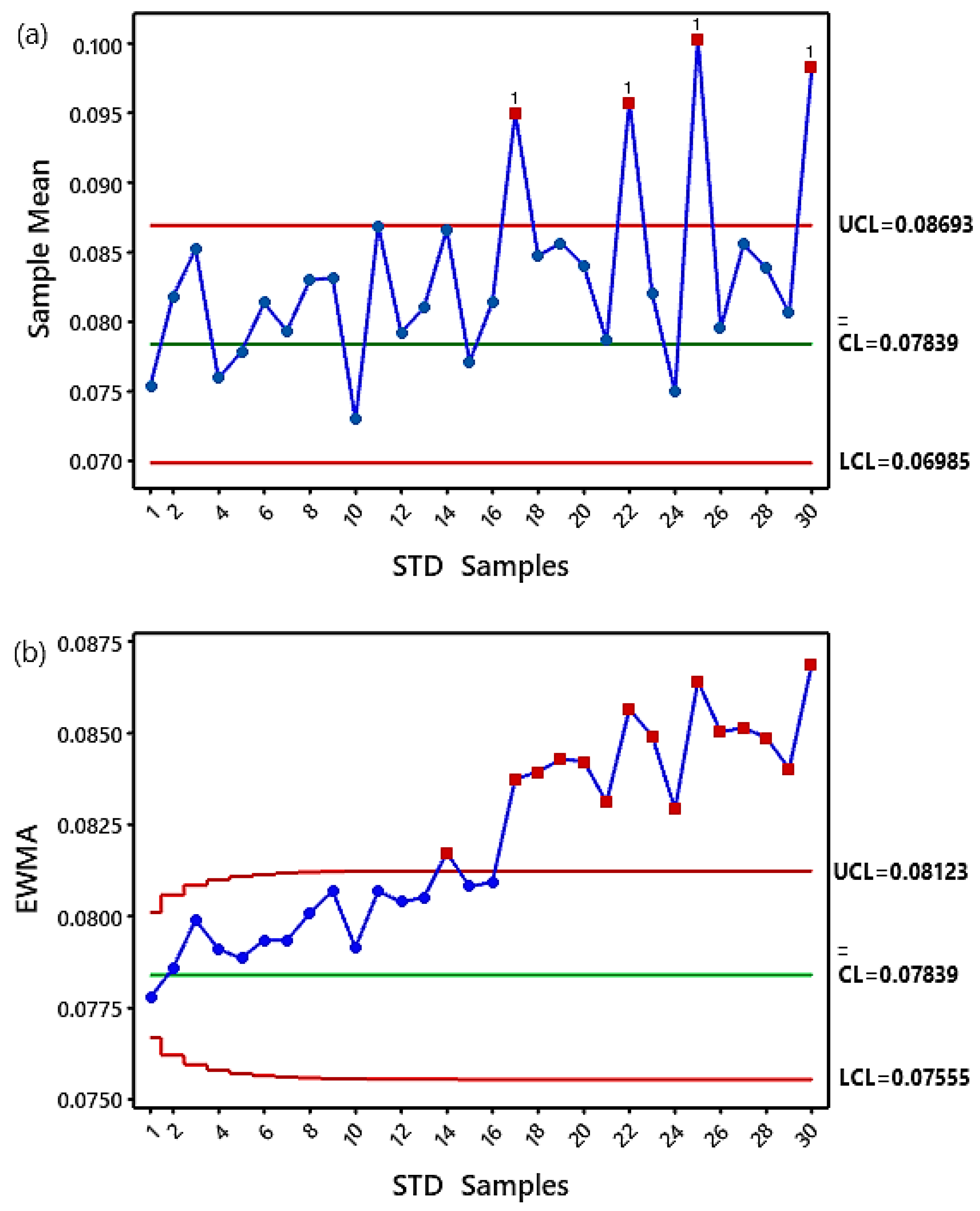

4.4.3. The Crack of Level 3 (10% Loss in Mesh Stiffness)

5. Conclusions

- Gaussian noise was added for initial acceleration vibration signals using different ratios of noise variance of 0.001, 0.002, and 0.003, respectively, to simulate them in real life. Then, the suitable noise level was chosen based on the highest signal-to-noise ratio (SNR);

- Vibration analysis methods, both time-domain and frequency-domain techniques, were applied to process signals and identify failing components. Time domain analysis of short-time signals revealed no failure components, such as a periodic pulse, as an indicator of the onset of crack occurrence and deterioration of its propagation levels. In contrast, one of the time domain features, the standard deviation (STD) feature, was extracted and calculated as a fault-sensitive statistical feature to be used in designing and testing an SPCC approach;

- 3.

- Shewhart X-bar and EWMA univariate statistical control charts were designed using a time domain feature known as standard deviation (STD). Listed below are the outcomes that the SPCC was able to achieve;

- The control chart results of the simulated vibration acceleration signals showed a strong relationship between the increase in the control chart limits (UCL, LCL) and the repeated reduction increase in time-varying meshing stiffness (TVMS)at 1%,5%, and 10% for crack detection;

- The EWMA chart’s performance proved superior to vibration analysis techniques in quickly detecting all levels of crack through a clear visual vision by increasing the number of STD feature samples outside the control chart limits;

- The EWMA chart showed better results than the X-bar chart. In two ways: firstly, the EWMA chart detected all small crack levels early stage, as evidenced by sequencing the number of STD feature samples outside the upper control limits (UCL), and secondly, the EWMA chart did not record any Type I or Type II errors;

- Furthermore, the advantage of the SPCC approach is that it is implemented using only system health status data, which are appropriate and applicable, especially in cases where there is a lack of defective status data. On the contrary, the main disadvantage of SPCC is that they can detect damage without locating it;

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Motahar, H.; Samani, F.S.; Molaie, M. Nonlinear vibration of the bevel gear with teeth profile modification. Nonlinear Dyn. 2016, 83, 1875–1884. [Google Scholar] [CrossRef]

- Chaari, F.; Fakhfakh, T.; Haddar, M. Analytical modelling of spur gear tooth crack and influence on gearmesh stiffness. Eur. J. Mech. A/Solids 2009, 28, 461–468. [Google Scholar] [CrossRef]

- Mohammed, S.A.; Ghazaly, N.M.; Abdo, J. Fault Diagnosis of Crack on Gearbox Using Vibration-Based Approaches. Symmetry 2022, 14, 417. [Google Scholar] [CrossRef]

- Ma, H.; Song, R.; Pang, X.; Wen, B. Time-varying mesh stiffness calculation of cracked spur gears. Eng. Fail. Anal. 2014, 44, 179–194. [Google Scholar] [CrossRef]

- Ma, H.; Zeng, J.; Feng, R.; Pang, X.; Wang, Q.; Wen, B. Review on dynamics of cracked gear systems. Eng. Fail. Anal. 2015, 55, 224–245. [Google Scholar] [CrossRef]

- Mohammed, O.D.; Rantatalo, M. Gear fault models and dynamics-based modelling for gear fault detection—A review. Eng. Fail. Anal. 2020, 117, 104798. [Google Scholar] [CrossRef]

- Chen, Z.; Shao, Y. Dynamic simulation of spur gear with tooth root crack propagating along tooth width and crack depth. Eng. Fail. Anal. 2011, 18, 2149–2164. [Google Scholar] [CrossRef]

- Mohammed, O.D.; Rantatalo, M.; Aidanpää, J.O.; Kumar, U. Vibration signal analysis for gear fault diagnosis with various crack progression scenarios. Mech. Syst. Signal Process. 2013, 41, 176–195. [Google Scholar] [CrossRef]

- Mohammed, O.D.; Rantatalo, M. Dynamic response and time-frequency analysis for gear tooth crack detection. Mech. Syst. Signal Process. 2016, 66–67, 612–624. [Google Scholar] [CrossRef]

- Jiang, H.; Liu, F. Analytical models of mesh stiffness for cracked spur gears considering gear body deflection and dynamic simulation. Meccanica 2019, 54, 1889–1909. [Google Scholar] [CrossRef]

- Wang, L.; Shao, Y. Fault mode analysis and detection for gear tooth crack during its propagating process based on dynamic simulation method. Eng. Fail. Anal. 2017, 71, 166–178. [Google Scholar] [CrossRef]

- Yassine, D.; Ahmed, H.; Lassaad, W.; Mohamed, H. Effects of gear mesh fluctuation and defaults on the dynamic behavior of two-stage straight bevel system. Mech. Mach. Theory 2014, 82, 71–86. [Google Scholar] [CrossRef]

- Figlus, T.; Wilk, A. Application of analysis of envelope’s spectrum for gearbox diagnosing. Int. Rev. Mech. Eng. 2012, 6, 1350–1355. [Google Scholar]

- Hu, C.; Smith, W.A.; Randall, R.B.; Peng, Z. Development of a gear vibration indicator and its application in gear wear monitoring. Mech. Syst. Signal Process. 2016, 76–77, 319–336. [Google Scholar] [CrossRef]

- Yang, D.; Chen, L.; Jiang, L.; Wang, P.; Tao, J. Research on the influence of time-varying excitation on vibration characteristics of the spiral bevel geared transmission system with broken teeth. Shock Vib. 2021, 1–10. [Google Scholar] [CrossRef]

- Figlus, T. A method for diagnosing gearboxes of means of transport using multi-stage filtering and entropy. Entropy 2019, 21, 441. [Google Scholar] [CrossRef] [PubMed]

- Dewangan, P.; Ramteke, D.S.; Parey, A. Smart Monitoring of Rotating Machinery for Industry 4.0. In Model Based Fault Diagnosis in Bevel Gearbox; Chaari, F., Chiementin, X., Zimroz, R., Bolaers, F., Haddar, M., Eds.; Springer Nature: Cham, Switzerland, 2022; pp. 117–133. ISBN 978-3-030-79518-4/978-3-030-79519-1. [Google Scholar]

- Han, H.; Ma, H.; Wang, H.; Zhu, J.; Li, Z.; Liu, Z. Dynamic Simulation of Cracked Spiral Bevel Gear Pair Considering Assembly Errors. Machines 2022, 10, 929. [Google Scholar] [CrossRef]

- Mauricio, A.; Wang, W.; Antoni, J.; Gryllias, K. Advanced signal processing techniques for helicopter’s gearbox monitoring. J. Phys. Conf. Ser. 2021, 1909, 012043. [Google Scholar] [CrossRef]

- Karray, M.; Chaari, F.; Khabou, M.T.; Haddar, M. Dynamic analysis of bevel gear in presence of local damage in nonstationary operating conditions. In Design and Modeling of Mechanical Systems—III; Lecture Notes in Mechanical Engineering; Springer: Cham, Switzerland, 2018; pp. 325–330. [Google Scholar] [CrossRef]

- Ziani, R.; Hammami, A.; Chaari, F.; Felkaoui, A.; Haddar, M. Gear fault diagnosis under non-stationary operating mode based on EMD, TKEO, and Shock Detector. Comptes Rendus—Mec. 2019, 347, 663–675. [Google Scholar] [CrossRef]

- Chaari, F.; Schmidt, S.; Hammami, A.; Heyns, P.S.; Haddar, M. Smart Monitoring of Rotating Machinery for Industry 4.0. In On the Use of Jerk for Condition Monitoring of Gearboxes in Non-Stationary Operations; Chaari, F., Chiementin, X., Zimroz, R., Bolaers, F., Haddar, M., Eds.; Springer Nature: Cham, Switzerland, 2022; ISBN 9783030795184. [Google Scholar]

- Zhu, H.; Chen, W.; Zhu, R.; Gao, J.; Liao, M. Modelling and Dynamic Analysis of the Spiral Bevel Gear-Shaft-Bearing-Gearbox Coupling System. Math. Probl. Eng. 2019, 2019, 9065215. [Google Scholar] [CrossRef]

- Peng, D.; Smith, W.A.; Borghesani, P.; Randall, R.B.; Peng, Z. Comprehensive planet gear diagnostics: Use of transmission error and mesh phasing to distinguish localised fault types and identify faulty gears. Mech. Syst. Signal Process. 2019, 127, 531–550. [Google Scholar] [CrossRef]

- Cao, W.; Pu, W.; Wang, J. Tribo-dynamic model and fatigue life analysis of spiral bevel gears. Eur. J. Mech. A/Solids 2019, 74, 124–138. [Google Scholar] [CrossRef]

- Molaie, M.; Samani, F.S.; Pellicano, F. Spiral Bevel Gears Nonlinear Vibration Having Radial and Axial Misalignments Effects. Vibration 2021, 4, 666–678. [Google Scholar] [CrossRef]

- Lal, H.; Kane, P.V. Gearbox Fault Detection Using Exponentially Weighted Moving Average Control Charts. In Machines, Mechanism and Robotics; Badodkar, D., Dwarakanath, T., Eds.; Lecture Notes in Mechanical Engineering; Springer: Singapore, 2019. [Google Scholar] [CrossRef]

- Maraş, S.; Arslan, H.; Birgören, B. Detection of Gear Wear and Faults in Spur Gear Systems Using Statistical Parameters and Univariate Statistical Process Control Charts. Arab. J. Sci. Eng. 2021, 46, 12221–12234. [Google Scholar] [CrossRef]

- Peng, T. Coupled Multi-Body Dynamic and Vibration Analysis of Hypoid and Bevel Geared Rotor System. Ph.D. Thesis, University of Cincinnati, Cincinnati, OH, USA, 2010. [Google Scholar]

- Karray, M.; Chaari, F.; Viadero, F.; del Rincon, A.F.; Haddar, M. Dynamic Response of Single Stage Bevel Gear Transmission in Presence of Local Damage. Mech. Mach. Sci. 2013, 7, 337–345. [Google Scholar] [CrossRef]

- Makovoz, D. Noise variance estimation in signal processing. In Proceedings of the 2006 IEEE International Symposium on Signal Processing and Information Technology, Vancouver, BC, Canada, 28–30 August 2006; pp. 364–369. [Google Scholar] [CrossRef]

- Fan, W.; Zhou, Q.; Li, J.; Zhu, Z. A Wavelet-Based Statistical Approach for Monitoring and Diagnosis of Compound Faults with Application to Rolling Bearings. IEEE Trans. Autom. Sci. Eng. 2018, 15, 1563–1572. [Google Scholar] [CrossRef]

- Jaber, A.A.; Bicker, R. Industrial robot fault detection based on statistical control chart. Am. J. Eng. Appl. Sci. 2016, 9, 251–263. [Google Scholar] [CrossRef]

- Jawad, S.M.; Jaber, A.A. Rolling Bearing Fault Detection Based on Vibration Signal Analysis and Cumulative Sum Control Chart. FME Trans. 2021, 49, 684–695. [Google Scholar] [CrossRef]

- Scheffer, C.; Girdhar, P. Practical Machinery Vibration Analysis and Predictive Maintenance; Elsevier: Amsterdam, The Netherlands, 2004; ISBN 0080480225. [Google Scholar]

- Montgomery, D.C. Introduction to Statistical Quality Control, 6th ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2009; ISBN 9780470169926. [Google Scholar]

- Selvamuthu, D.; Das, D. Introduction to Statistical Methods, Design of Experiments and Statistical Quality Control; Springer Nature: Singapore; Singapore Pte Ltd.: Singapore, 2018; ISBN 9789811317361. [Google Scholar]

- Roberts, S.W. Control Chart Tests Based on Geometric Moving Averages. Technometrics 2000, 42, 97–101. [Google Scholar] [CrossRef]

- Hynek, M.; Smetanová, D.; Stejskal, D.; Zvárová, J. Exponentially weighted moving average chart as a suitable tool for nuchal translucency quality review. Prenat. Diagn. 2014, 34, 367–376. [Google Scholar] [CrossRef]

- Morton, A.P.; Whitby, M.; McLaws, M.; Dobson, A.; McElwain, S.; Looke, D.; Stackelroth, J.; Sartor, A. The application of statistical process control charts to the detection and monitoring of hospital-acquired infections. J. Qual. Clin. Pract. 2001, 21, 112–117. [Google Scholar] [CrossRef] [PubMed]

- Montgomery, D.C.; Runger, G.C. Applied Statistics and Probability for Engineers; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2010; ISBN 0470053046. [Google Scholar]

- Wu, S.; Zuo, M.J.; Parey, A. Simulation of spur gear dynamics and estimation of fault growth. J. Sound Vib. 2008, 317, 608–624. [Google Scholar] [CrossRef]

- Yang, L.; Wang, L.; Yu, W.; Shao, Y. Investigation of tooth crack opening state on time varying meshing stiffness and dynamic response of spur gear pair. Eng. Fail. Anal. 2021, 121, 105181. [Google Scholar] [CrossRef]

| ( | ||

| ( | ( | |

| ( | ||

| Pinion | Gear | |

|---|---|---|

| Number of teeth Z | 14 | 45 |

| Module (m) | 0.0095 | |

| Teeth width(m) | 0.064 | |

| Pitch angle (rad) | 0.302 | 1.269 |

| Pressure angle ( | 20° | |

| Spiral teeth angle (rad) | 0.480 | |

| Pitch radius(m) | 0.067 | 0.215 |

| Mass (kg) | 24.7 | 122.6 |

| Shaft rotation speed (Hz) | 22 | 6.84 |

| Inertia moment of a torsional (Kg.m2) | 0.0585 | 1.91 |

| Inertia moment of a bending (kg·m2) | 0.501 | 2.07 |

| Axial stiffness (N/m) | 1 × 109 | 2.3 × 109 |

| Lateral stiffness (N/m) | 8.8 × 109 | 1.3 × 1010 |

| Torsional stiffness (Nm/rad) | 1.2 × 104 | 7.4 × 104 |

| Bending shaft & bearing stiffness (Nm/rad) | 3.1 × 107 | 9.8 × 107 |

| Maximum mesh stiffness value (Nm/rad) | 2.641 × 107 | |

| Minimum mesh stiffness value (Nm/rad) | 1.671 × 107 | |

| Mean mesh stiffness (N/m) | 2.156 × 107 | |

| The damping coefficient of mesh | 0.06 | |

| The damping coefficient | 0.02 | |

| SNR Ratios for Signals | |||

|---|---|---|---|

| SNR for signal healthy | 11.8163 | 8.7586 | 6.9950 |

| SNR for signal with crack level 1 | 11.8142 | 8.7812 | 7.0354 |

| SNR for signal with crack level 2 | 11.8769 | 8.8540 | 7.1109 |

| SNR for signal with crack level 3 | 12.0840 | 9.0398 | 7.3239 |

| Number of Out-of-Control Samples | X-Bar Chart | EWMA Chart |

|---|---|---|

| The number of STD samples that are out of control for a crack level 1. | Type-II error | 1 sample |

| The number of STD samples that are out of control for a crack level 2. | 1 sample | 11 samples |

| The number of STD samples that are out of control for a crack level 3. | 4 samples | 15 samples |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jorani, R.M.; Haddar, M.; Chaari, F.; Haddar, M. Gear Crack Detection Based on Vibration Analysis Techniques and Statistical Process Control Charts (SPCC). Machines 2023, 11, 312. https://doi.org/10.3390/machines11020312

Jorani RM, Haddar M, Chaari F, Haddar M. Gear Crack Detection Based on Vibration Analysis Techniques and Statistical Process Control Charts (SPCC). Machines. 2023; 11(2):312. https://doi.org/10.3390/machines11020312

Chicago/Turabian StyleJorani, Rasheed Majeed, Maroua Haddar, Fakher Chaari, and Mohamed Haddar. 2023. "Gear Crack Detection Based on Vibration Analysis Techniques and Statistical Process Control Charts (SPCC)" Machines 11, no. 2: 312. https://doi.org/10.3390/machines11020312

APA StyleJorani, R. M., Haddar, M., Chaari, F., & Haddar, M. (2023). Gear Crack Detection Based on Vibration Analysis Techniques and Statistical Process Control Charts (SPCC). Machines, 11(2), 312. https://doi.org/10.3390/machines11020312