A Two-Step Approach to Scheduling a Class of Two-Stage Flow Shops in Automotive Glass Manufacturing

Abstract

1. Introduction

- (1)

- We present a method to determine the minimal size of each batch such that the second stage can continuously keep working without interruption if the sizes of all batches are same;

- (2)

- The conditions under which a feasible schedule exists are derived;

- (3)

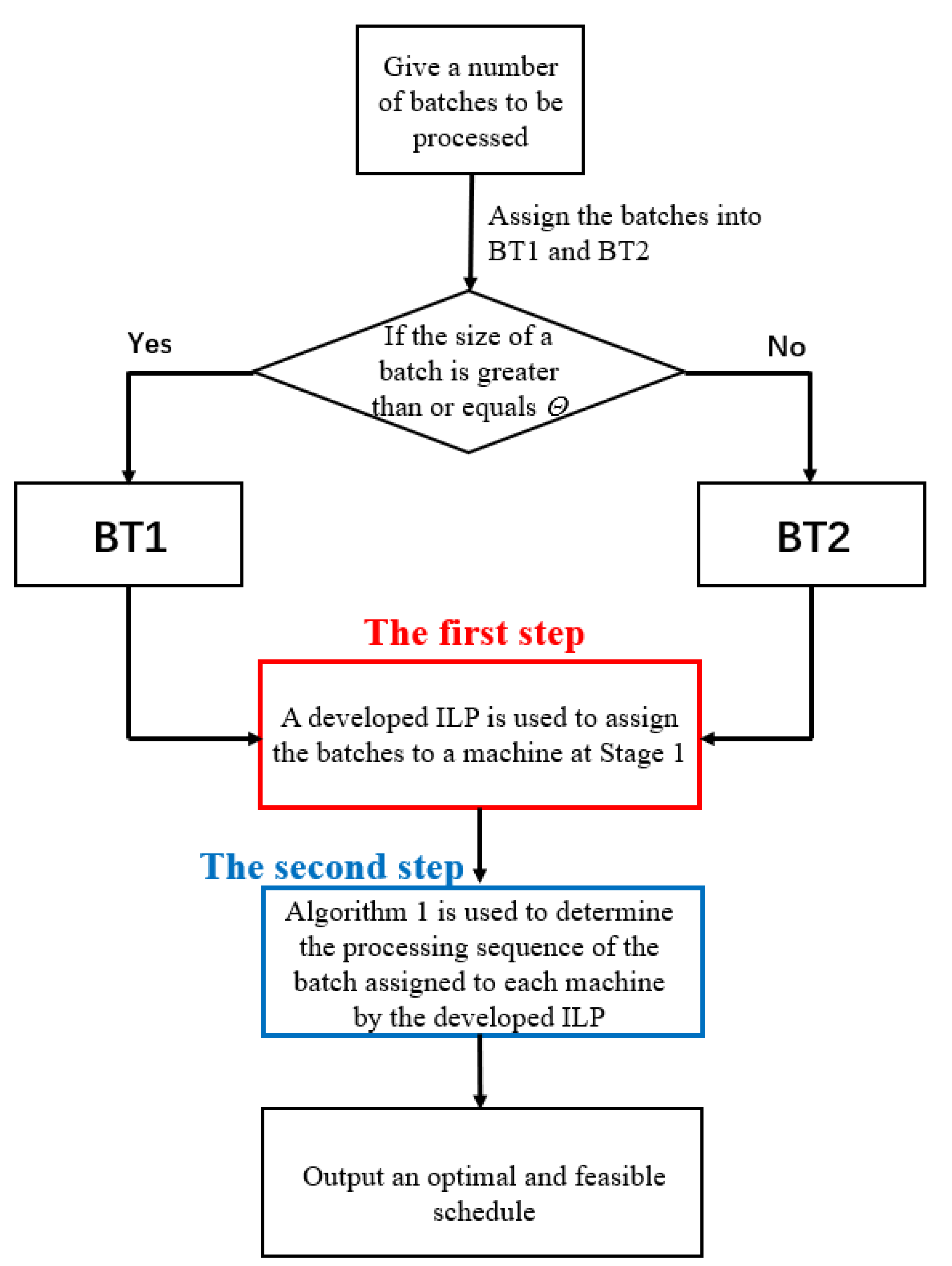

- Based on the conditions, we are able to develop a two-step solution method;

- (3.1)

- At the first step, an integer linear program (ILP) is formulated for handling the batch allocation problem at the first stage.

- (3.2)

- At the second step, the batches assigned to each machine at the first stage are optimally sequenced by an algorithm with polynomial complexity.

2. Literature Review

3. Scheduling Analysis

3.1. System Description

- (1)

- There are parallel multiple machines with same processing functions at each stage;

- (2)

- Only one product can be processed by a machine at a time;

- (3)

- At Stage 1, a batch should be processed by a single machine without splitting;

- (4)

- Stage 2 is the bottleneck;

- (5)

- Stage 1 has the setup time;

- (6)

- Each batch contains identical products;

- (7)

- For any two batches, their product types are different, with the result that if one batch is just processed at Stage 1, setup time is required before another one is processed next; and

- (8)

- After its completion at Stage 1, a product is ready to be processed immediately by a machine at Stage 2.

3.2. Properties of the System

4. Two-Step Solution Method

4.1. Formulating the ILP

4.2. Batch Sequencing for Machines at Stage 1

| Algorithm 1: | Batch sequencing for M1i, i∈ℕg, based on the solution of ILP. |

| Input: | η(i), Θ, and Λi, i∈ℕg |

| Output: | BHij, i∈ℕg and j∈ℕη(i)−1 |

| 1: | Λi′ = ∅ /*initialize the sequenced batches*/; |

| 2: | Choose a batch in Λi and set it to be BHi1 such that ξi + bi1 ≥ Θ; |

| 3: | Λi′ ←Λi′ ∪{BHi1}; |

| 4: | Λi ←Λi\{BHi1}; |

| 5: | s = 2; |

| 6: | While s ≤ η(i) − 1 |

| 7: | Choose a batch in Λi and set it to be BHis such that ξi + ≥ s × Θ; |

| 8: | Λi′ ←Λi′ ∪{BHis}; |

| 9: | Λi ←Λi\{BHis}; |

| 10: | s = s +1; |

| 11: | End; |

5. Experimental Results

- (1)

- At the first step, according to the customer orders, a relatively rough schedule is developed for a relatively long-time horizon that typically lasts for a month. This scheduling horizon is divided into several uniform slots with each slot lasting for 5–7 days. Then, with the capacity of the AGMS considered, this schedule determines the batches to be produced in each time slot by using simple heuristic algorithms, such that the batches can be produced by the due date.

- (2)

- At the second step, detailed schedules are generated to realize the rough schedule for each time slot. Such detailed schedules are also called short-term schedules. For each detailed schedule, it needs to schedule all the activities in an AGMS just as performed in this paper such that the process constraints are satisfied and the productivity of the system is maximized to optimize the profit.

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Abbreviations: | |

| AGMS | Automotive glass manufacturing system |

| BT1 | Batch Type 1 |

| BT2 | Batch Type 2 |

| ILP | Integer linear program |

| PVB | Polyvinyl Butyral |

| TMFS | Two-machine flow shop |

| TSFS | Two-stage flow-shop |

| TSFFS | Two-stage flexible flow-shop |

| Notation: | |

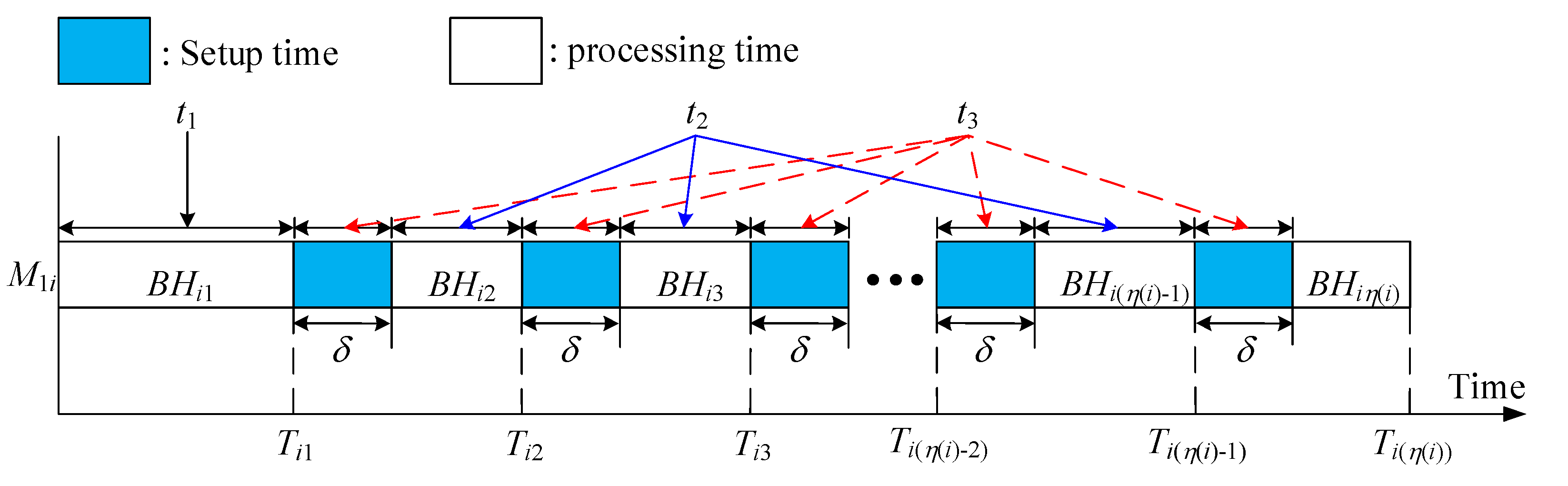

| BHij | The j-th processed batch at M1i |

| bij | Batch size of the j-th batch (i.e., BHij) to be processed at M1i |

| f1(x) | = a × x/(b × x + c), a > 0, b > 0, and c > 0 |

| f2(x) | = x/(α × x + u × δ) |

| g | The number of machines at Stage 1 |

| h | The number of machines at Stage 2 |

| M1i | The i-th machine at Stage 1 |

| M2j | The j-th machine at Stage 2 |

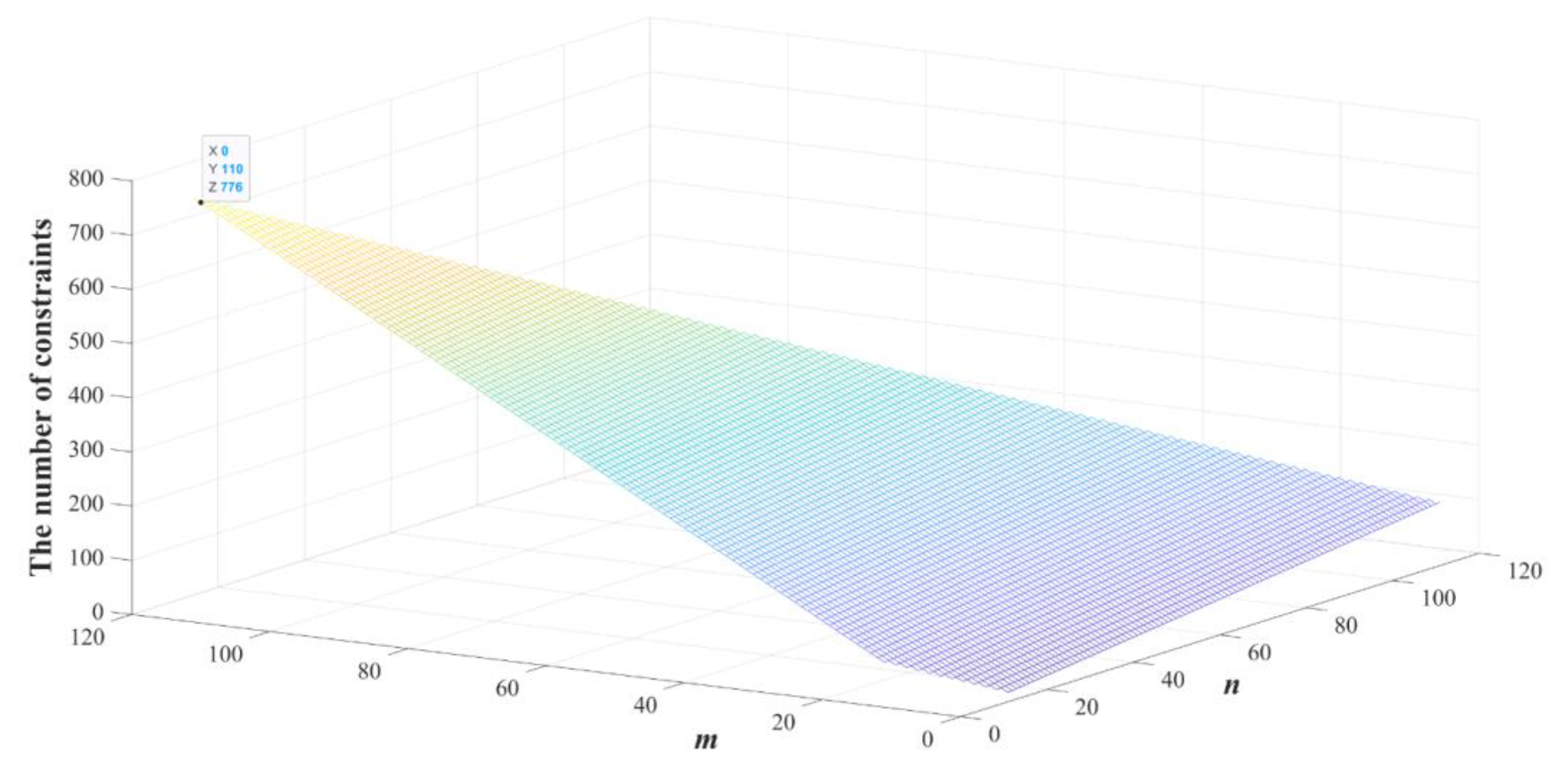

| m | The number of batches in BT2 whose batch size is smaller than Θ |

| ℕk | = {1, 2, …, k} |

| Numsolved | The number of cases that ILP can solve within 3600 s |

| Numunsolved | The number of cases that ILP cannot solve within 3600 s |

| Oi (≥ Θ) | The size of the i-th batch in BT1 |

| Tij | Time point when BHij has just been completed at M1i |

| Tmin | = min(Tiη(i)| i∈ℕg) |

| α | Time units to complete a product by a machine at Stage 1 |

| β | = μ/h |

| δ | Setup time for a machine at Stage 1 |

| Θ | = δ/(gβ − α) |

| η(i) | The number of processed batches at M1i |

| Λi | Set of batches assigned to M1i obtained by solving an ILP except the one belonging to BT2 with zij = 1 |

| μ | Processing time of a machine at Stage 2 |

| ϑit | Average productivity at M1i during time interval [0, t] |

| ζ | The number of batches to be scheduled |

| Φj (< Θ) | The size of the j-th batch in BT2 |

| Variables in the developed ILP: | |

| xij | Binary variable, 1 if the j-th batch in BT1 is processed at M1i, zero otherwise |

| yij | Binary variable, 1 if the j-th batch in BT2 is processed at M1i, zero otherwise |

| zij | Binary variable, 1 if the j-th batch with size Φj is processed at M1i at last, zero otherwise |

| ξi | Integer variable representing the number of extra products to be processed at M1i with their type being same as the one in BHi1 |

| Γ | Time needed to complete the processing of all batches at Stage 1 |

References

- Gharbi, A.; Ladhari, T.; Msakni, M.K.; Serairi, M. The two-machine flow-shop scheduling problem with sequence-independent setup times: New lower bounding strategies. Eur. J. Oper. Res. 2013, 231, 69–78. [Google Scholar] [CrossRef]

- Lee, T.; Loong, Y. A review of scheduling problem and resolution methods in flexible flow shop. Int. J. Ind. Eng. Comput. 2019, 10, 67–88. [Google Scholar] [CrossRef]

- Zhao, Z.; Zhou, M.; Liu, S. Iterated Greedy Algorithms for Flow-Shop Scheduling Problems: A Tutorial. IEEE Trans. Autom. Sci. Eng. 2022, 19, 1941–1959. [Google Scholar] [CrossRef]

- Vasilis, S.; Nikos, N.; Kosmas, A.; Dimitris, M. A toolbox of agents for scheduling the paint shop in bicycle industry. Procedia CIRP 2022, 107, 1156–1161. [Google Scholar] [CrossRef]

- Rooeinfar, R.; Raissi, S.; Ghezavati, V. Stochastic flexible flow shop scheduling problem with limited buffers and fixed interval preventive maintenance: A hybrid approach of simulation and metaheuristic algorithms. Simulation 2019, 95, 509–528. [Google Scholar] [CrossRef]

- Li, J.; Bai, S.; Duan, P.; Sang, H.; Han, Y.; Zheng, Z. An improved artificial bee colony algorithm for addressing distributed flow shop with distance coefficient in a prefabricated system. Int. J. Prod. Res. 2019, 57, 6922–6942. [Google Scholar] [CrossRef]

- Missaoui, A.; Ruiz, R. A parameter-Less iterated greedy method for the hybrid flowshop scheduling problem with setup times and due date windows. Eur. J. Oper. Res. 2022, 303, 99–113. [Google Scholar] [CrossRef]

- Fattahi, P.; Hosseini, S.M.H.; Jolai, F. A mathematical model and extension algorithm for assembly flexible flow shop scheduling problem. Int. J. Adv. Manuf. Technol. 2013, 65, 787–802. [Google Scholar] [CrossRef]

- Umam, M.S.; Mustafid, M.; Suryono, S. A hybrid genetic algorithm and tabu search for minimizing makespan in flow shop scheduling problem. J. King Saud Univ.-Comput. Inf. Sci. 2022, 34, 7459–7467. [Google Scholar] [CrossRef]

- Lalas, C.; Mourtzis, D.; Papakostas, N.; Chryssolouris, G. A Simulation-Based Hybrid Backwards Scheduling Framework for Manufacturing Systems. Int. J. Comput. Integr. Manuf. 2006, 19, 762–774. [Google Scholar] [CrossRef]

- Papakostas, N.; Chryssolouris, G. A Scheduling Policy for Improving Tardiness Performance. Asian Int. J. Sci. Technol. 2009, 2, 79–89. [Google Scholar]

- Miyata, H.H.; Nagano, M.S. The blocking flow shop scheduling problem: A comprehensive and conceptual review. Expert Syst. Appl. 2019, 137, 130–156. [Google Scholar] [CrossRef]

- Tosun, Ö.; Marichelvam, M.K.; Tosun, N. A literature review on hybrid flow shop scheduling. Int. J. Adv. Oper. Manag. 2020, 12, 156–194. [Google Scholar] [CrossRef]

- Mirabi, M.; Fatemi Ghomi, S.M.T.; Jolai, F. A two-stage hybrid flowshop scheduling problem in machine breakdown condition. J. Intell. Manuf. 2013, 24, 193–199. [Google Scholar] [CrossRef]

- Gupta, D.; Goel, S.; Mangla, N. Optimization of production scheduling in two stage flow shop scheduling problem with m equipotential machines at first stage. Int. J. Syst. Assur. Eng. Manag. 2021, 13, 1162–1169. [Google Scholar] [CrossRef]

- Chen, Z.; Zheng, X.; Zhou, S.C.; Liu, C.; Chen, H.P. Quantum-inspired ant colony optimization algorithm for a two-stage permutation flow shop with batch processing machines. Int. J. Prod. Res. 2019, 58, 5945–5963. [Google Scholar] [CrossRef]

- Zheng, X.; Zhou, S.C.; Xu, R.; Chen, H.P. Energy-efficient scheduling for multi-objective two-stage flow shop using a hybrid ant colony optimization algorithm. Int. J. Prod. Res. 2019, 58, 4103–4120. [Google Scholar] [CrossRef]

- Dong, J.; Pan, H.; Ye, C.; Tong, W.; Hu, J. No-wait two-stage flowshop problem with multi-task flexibility of the first machine. Inf. Sci. 2021, 544, 25–38. [Google Scholar] [CrossRef]

- Jemmali, M.; Hidri, L.; Alourani, A. Two-stage hybrid flowshop scheduling problem with independent setup times. Int. J. Simul. Model. 2022, 21, 5–16. [Google Scholar] [CrossRef]

- Lei, D.M.; Xi, B.J. Diversified teaching-learning-based optimization for fuzzy two-stage hybrid flow shop scheduling with setup time. J. Intell. Fuzzy Syst. 2021, 41, 4159–4173. [Google Scholar] [CrossRef]

- Gerpott, F.T.; Lang, S.; Reggelin, T.; Zadek, H.; Chaopaisarn, P.; Ramingwong, S. Integration of the A2C algorithm for production scheduling in a two-stage hybrid flow shop environment. Procedia Comput. Sci. 2022, 200, 585–594. [Google Scholar] [CrossRef]

- Han, J.-H.; Lee, J.-Y. Heuristics for a two-stage assembly-type flow shop with limited waiting time constraints. Appl. Sci.-Basel 2021, 11, 11240. [Google Scholar] [CrossRef]

- Pourhejazy, P.; Cheng, C.Y.; Ying, K.C.; Nam, N.H. Meta-Lamarckian-based iterated greedy for optimizing distributed two-stage assembly flowshops with mixed setups. Ann. Oper. Res. 2022. [Google Scholar] [CrossRef]

- Talens, C.; Fernandez-Viagas, V.; Perez-Gonzalez, P.; Framinan, J.M. New efficient constructive heuristics for the two-stage multi-machine assembly scheduling problem. Comput. Ind. Eng. 2020, 140, 106223. [Google Scholar] [CrossRef]

- Zhang, Z.; Tang, Q. Integrating flexible preventive maintenance activities into two-stage assembly flow shop scheduling with multiple assembly machines. Comput. Ind. Eng. 2021, 159, 107493. [Google Scholar] [CrossRef]

- An, Y.J.; Kim, Y.D.; Choi, S.W. Minimizing makespan in a two-machine flowshop with a limited waiting time constraint and sequence-dependent setup times. Comput. Oper. Res. 2016, 71, 127–136. [Google Scholar] [CrossRef]

- Kalczynski, P.J.; Kamburowski, J. An empirical analysis of heuristics for sovling the two-machine flow shop problem with release times. Comput. Oper. Res. 2012, 39, 2659–2665. [Google Scholar] [CrossRef]

- Liu, P.; Lu, X. A best possible on-line algorithm for two-machine flow shop scheduling to minimize makespan. Comput. Oper. Res. 2014, 51, 251–256. [Google Scholar] [CrossRef]

- Agrebi, I.; Jemmali, M.; Alquhayz, H.; Ladhari, T. Metaheuristic algorithms for the two-machine flowshop scheduling problem with release dates and blocking constraint. J. Chin. Inst. Eng. 2021, 44, 573–582. [Google Scholar] [CrossRef]

- Schaller, J.; Valente, J. Branch-and-bound algorithms for minimizing total earliness and tardiness in a two-machine permutation flow shop with unforced idle allowed. Comput. Oper. Res. 2019, 109, 1–11. [Google Scholar] [CrossRef]

- Bank, M.; Fatemi Ghomi, S.M.T.; Jolai, F.; Behnamian, J. Two-machine flow shop total tardiness scheduling problem with deteriorating jobs. Appl. Math. Model. 2012, 36, 5418–5426. [Google Scholar] [CrossRef]

- Cheng, M.; Tadikamalla, P.R.; Shang, J.; Zhang, S. Bicriteria hierarchical optimization of two-machine flow shop scheduling problem with time-dependent deteriorating jobs. Eur. J. Oper. Res. 2014, 234, 650–657. [Google Scholar] [CrossRef]

- Qiao, Y.; Wu, N.Q.; He, Y.F.; Li, Z.W.; Chen, T. Adaptive genetic algorithm for two-stage hybrid flow-shop scheduling with sequence-independent setup time and no-interruption requirement. Expert Syst. Appl. 2022, 208, 1–13. [Google Scholar] [CrossRef]

- Fridman, I.; Pesch, E.; Shafransky, Y. Minimizing maximum cost for a single machine under uncertainty of processing times. Eur. J. Oper. Res. 2020, 286, 444–457. [Google Scholar] [CrossRef]

- Ghaleb, M.; Taghipour, S.; Sharifi, M.; Zolfagharinia, H. Integrated production and maintenance scheduling for a single degrading machine with deterioration-based failures. Comput. Ind. Eng. 2020, 143, 106432. [Google Scholar] [CrossRef]

- Goldengorin, B.; Romanuke, V. Online heuristic for the preemptive single machine scheduling problem to minimize the total weighted tardiness. Comput. Ind. Eng. 2021, 155, 107090. [Google Scholar] [CrossRef]

- Luo, W.C.; Xu, Y.; Tong, W.T.; Lin, G.H. Single-machine scheduling with job-dependent machine deterioration. J. Sched. 2019, 22, 691–707. [Google Scholar] [CrossRef]

- Mor, B.; Mosheiov, G. Minmax due-date assignment on a two-machine flowshop. Ann. Oper. Res. 2021, 305, 191–209. [Google Scholar] [CrossRef]

- Perez-Gonzalez, P.; Framinan, J.M. Single machine interfering jobs problem with flowtime objective. J. Intell. Manuf. 2018, 29, 953–972. [Google Scholar] [CrossRef]

- Wan, L.; Yuan, J. Single-machine scheduling with operator non-availability to minimize total weighted completion time. Inf. Sci. 2018, 445–446, 1–5. [Google Scholar] [CrossRef]

- Telles, E.S.; Lacerda, D.P.; Morandi, M.I.W.; Piran, F.A.S. Drum-buffer-rope in an engineering-to-order system: An analysis of an aerospace manufacturer using data envelopment analysis (DEA). Int. J. Prod. Econ. 2020, 222, 107500. [Google Scholar] [CrossRef]

- Telles, E.S.; Lacerda, D.P.; Morandi, M.I.W.; Ellwanger, R.; Souza, F.B.; Piran, F.S. Drum-Buffer-Rope in an engineering-to-order productive system: A case study in a Brazilian aerospace company. J. Manuf. Technol. Manag. 2022, 33, 1190–1209. [Google Scholar] [CrossRef]

| ζ | ILP | |

|---|---|---|

| Ave. Running Time (s) | Numsolved | |

| 11 | 0.15 | 30 |

| 12 | 0.19 | 30 |

| 13 | 0.35 | 30 |

| 14 | 0.17 | 30 |

| 15 | 0.20 | 30 |

| 16 | 1.15 | 30 |

| 17 | 0.58 | 30 |

| 18 | 0.90 | 30 |

| 19 | 22.73 | 30 |

| 20 | 4.64 | 30 |

| 21 | 7.02 | 30 |

| 22 | 122.98 | 30 |

| 23 | 224.28 | 30 |

| 24 | 118.15 | 30 |

| ζ | ILP | |||

|---|---|---|---|---|

| Numsolved | Ave. Running Time (s) | Numunsolved | Running Time (s) | |

| 25 | 27 | 366.66 | 3 | 3600 |

| 26 | 19 | 298.31 | 11 | 3600 |

| 27 | 23 | 356.15 | 7 | 3600 |

| 28 | 15 | 124.76 | 15 | 3600 |

| 29 | 18 | 257.70 | 12 | 3600 |

| 30 | 18 | 98.07 | 12 | 3600 |

| ζ | ILP | ||

|---|---|---|---|

| Numunsolved | Average Gap | Maximum Gap | |

| 25 | 3 | 1.17% | 1.7789% |

| 26 | 11 | 1.019% | 2.2558% |

| 27 | 7 | 0.0094% | 0.1115% |

| 28 | 15 | 0.8524% | 5.2856% |

| 29 | 12 | 0.3864% | 2.6207% |

| 30 | 12 | 0.0083% | 0.0106% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qiao, Y.; Wu, N.; Li, Z.; Al-Ahmari, A.M.; El-Tamimi, A.-A.; Kaid, H. A Two-Step Approach to Scheduling a Class of Two-Stage Flow Shops in Automotive Glass Manufacturing. Machines 2023, 11, 292. https://doi.org/10.3390/machines11020292

Qiao Y, Wu N, Li Z, Al-Ahmari AM, El-Tamimi A-A, Kaid H. A Two-Step Approach to Scheduling a Class of Two-Stage Flow Shops in Automotive Glass Manufacturing. Machines. 2023; 11(2):292. https://doi.org/10.3390/machines11020292

Chicago/Turabian StyleQiao, Yan, Naiqi Wu, Zhiwu Li, Abdulrahman M. Al-Ahmari, Abdul-Aziz El-Tamimi, and Husam Kaid. 2023. "A Two-Step Approach to Scheduling a Class of Two-Stage Flow Shops in Automotive Glass Manufacturing" Machines 11, no. 2: 292. https://doi.org/10.3390/machines11020292

APA StyleQiao, Y., Wu, N., Li, Z., Al-Ahmari, A. M., El-Tamimi, A.-A., & Kaid, H. (2023). A Two-Step Approach to Scheduling a Class of Two-Stage Flow Shops in Automotive Glass Manufacturing. Machines, 11(2), 292. https://doi.org/10.3390/machines11020292