Experimental Investigation of Vibration Reduction Effect of High-Pressure Air Compressor Using Composite Damping Base

Abstract

:1. Introduction

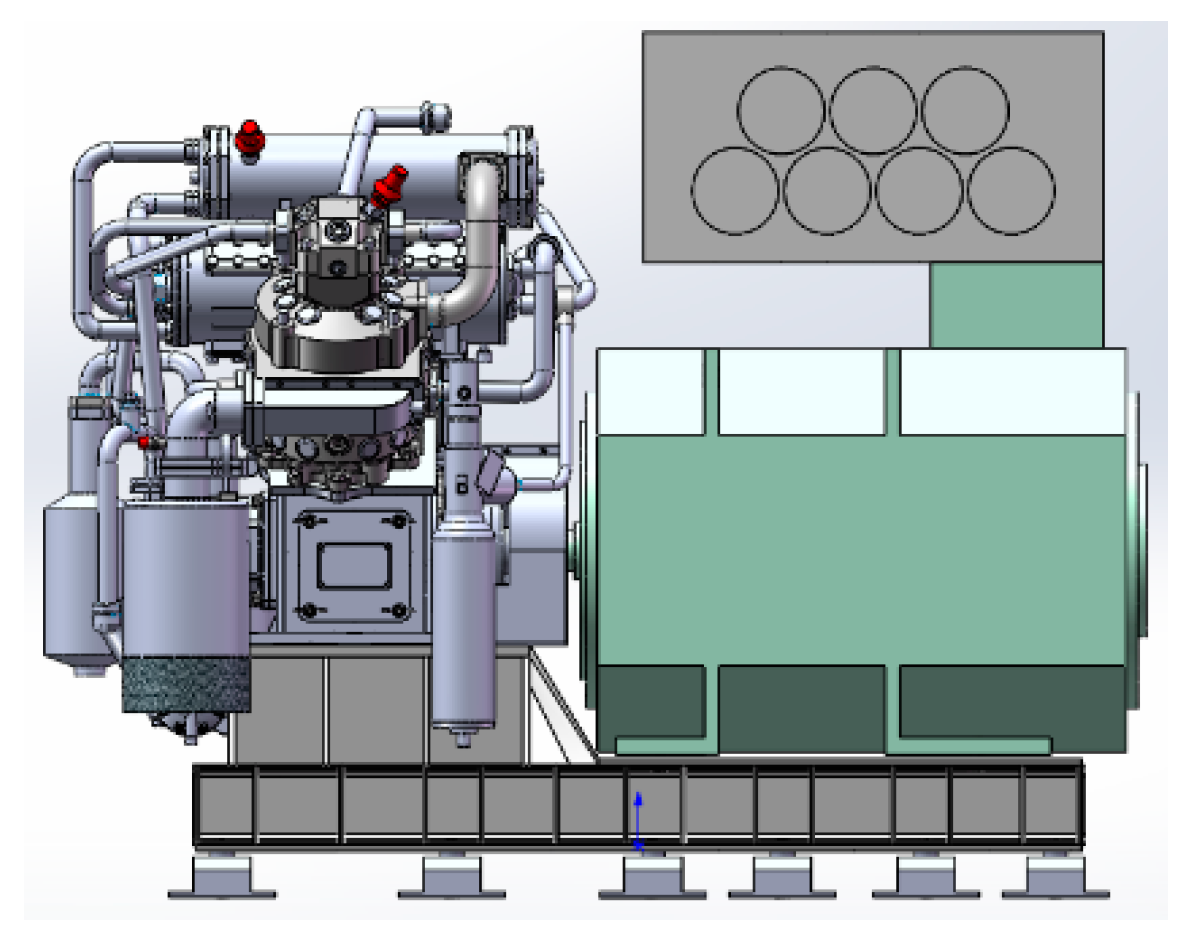

2. Analysis of Vibration Principle of Air Compressor

2.1. Vibration Source of Air Compressor

2.2. Vibration Transfer Path of Air Compressor

- The transfer path of mechanical vibration caused by reciprocating inertia force and the unbalanced moment, which is: shaft—connecting rod—piston—body—support—base structure;

- The transfer path of electromagnetic vibration led by the air compressor, which is: motor—support—base structure.

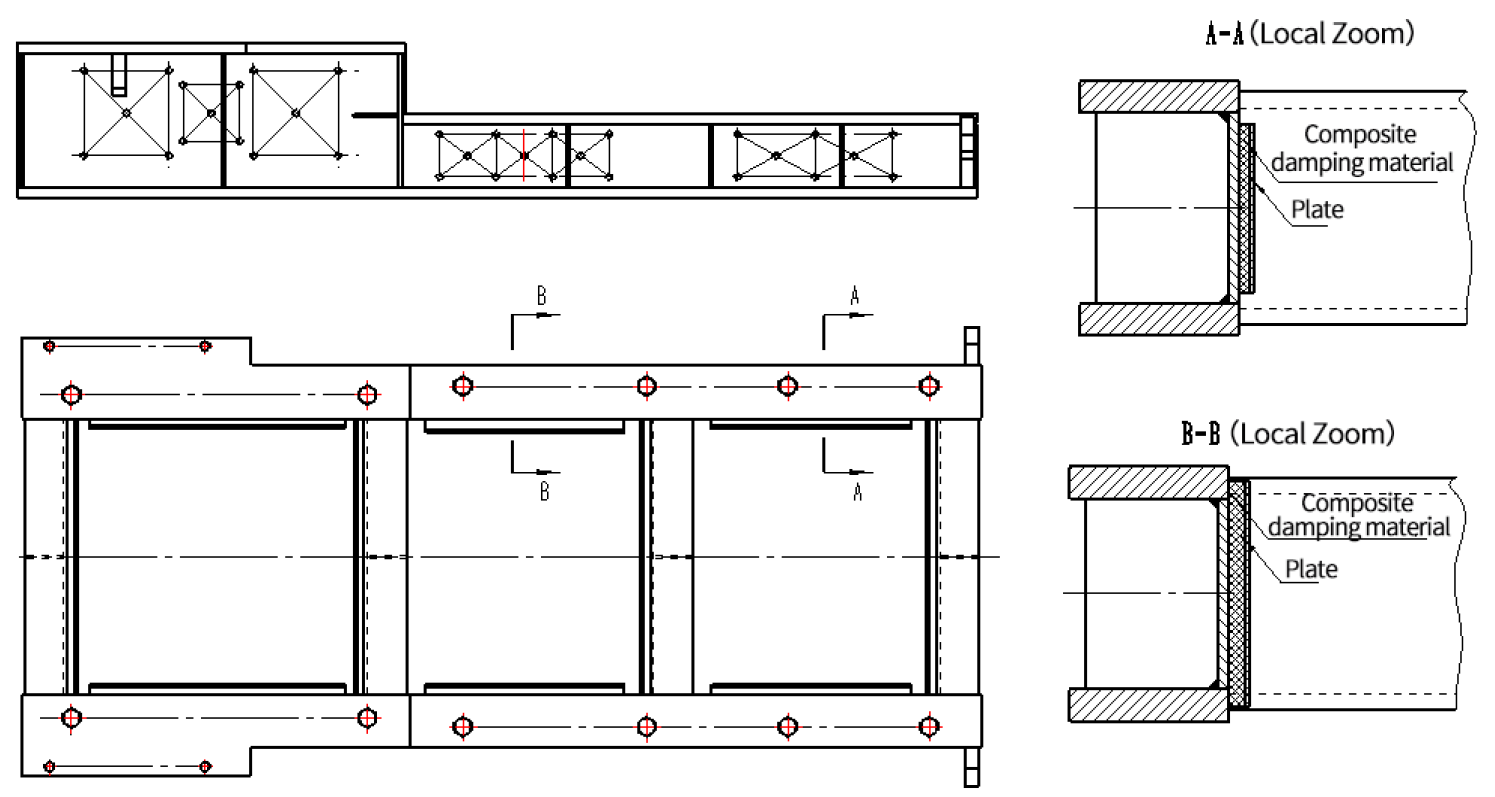

3. Analysis of the Vibration Reduction Principle Based on Composite Damping Base

3.1. Application Research Status of Constrained Damping

3.2. Vibration Reduction Principle of Composite Damping Base

4. Influence of Different Materials on Vibration of Composite Damping Base

4.1. Test Method

- (1)

- Preliminary test of the natural frequency of specimens based on the hammer method

- (2)

- Measurement of natural frequency and loss factor coefficient of specimens based on the method of the sinusoidal frequency sweep

- (3)

- Dynamic response test of the specimen under resonant excitation

- (4)

- Dynamic response test of the specimen under random excitation

4.2. Test Process

- (1)

- According to experimental requirements, the specimen is installed, and measuring points are arranged.

- (2)

- The specimen is tested by hammer method.

- (3)

- Sweep frequency test is carried out on the specimen.

- (4)

- Constant frequency test is carried out on the specimen.

- (5)

- Random excitation test is carried out on the specimen.

4.3. Test Results

- (1)

- Natural frequency of specimen obtained from modal test by hammering method

- (2)

- Test results of the dynamic response of specimen under resonant excitation

- (3)

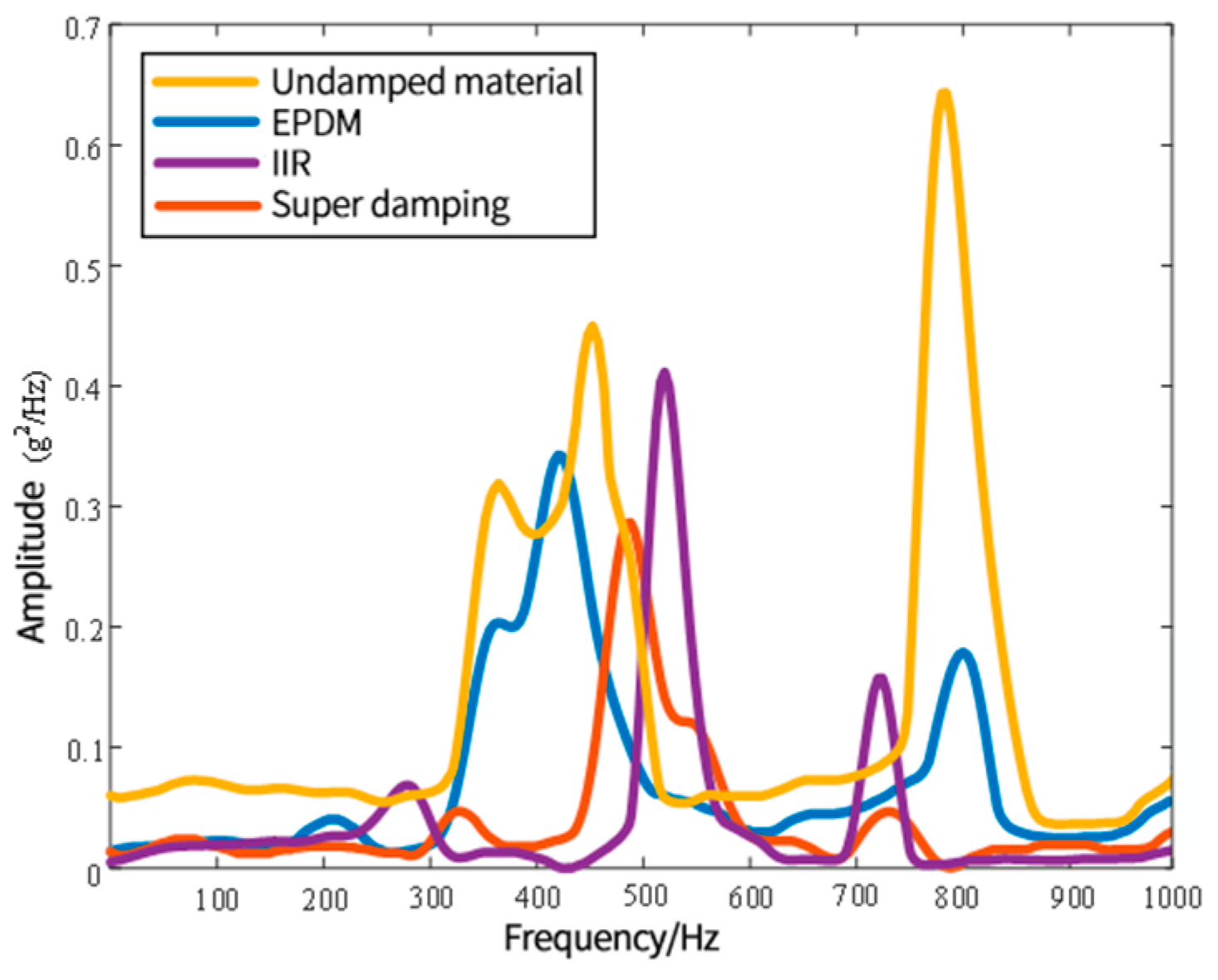

- The shaker table is used to test the dynamic response of four types of specimens with different damping materials under random excitation.

4.4. Comparison of Different Damping Materials in Composite Damping Base

- (1)

- The test results of different specimens are compared and sorted according to the loss factor coefficients. The loss factor coefficient of the specimen filled with supper damping rubber is the highest. IIR is next, and EPDM is poor.

- (2)

- Through comparative analysis of resonance response test results of specimens filled with different damping materials, the following conclusions can be drawn. The specimen filled with supper damping rubber has a better vibration suppression effect.

- (3)

- By analyzing the response data of the first three peaks of the four specimens under random excitation, the following conclusions can be drawn. In most cases, the specimen filled with supper damping rubber has the best damping effect.

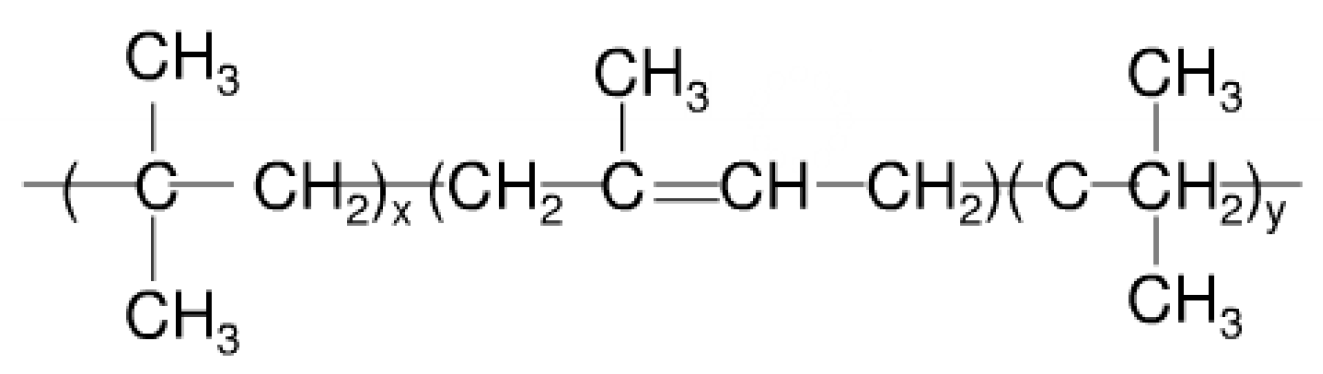

5. Vibration Reduction Mechanism of Super Damping Rubber

- The molecular chain structure is close. And the air tightness is very good;

- The unsaturated degree is very low, and the structure is stable. It has good heat resistance and aging resistance;

- It is difficult to crystallize at low temperatures, so the cold resistance is very good.

6. Harmonic Response Analysis and Vibration Test Verification

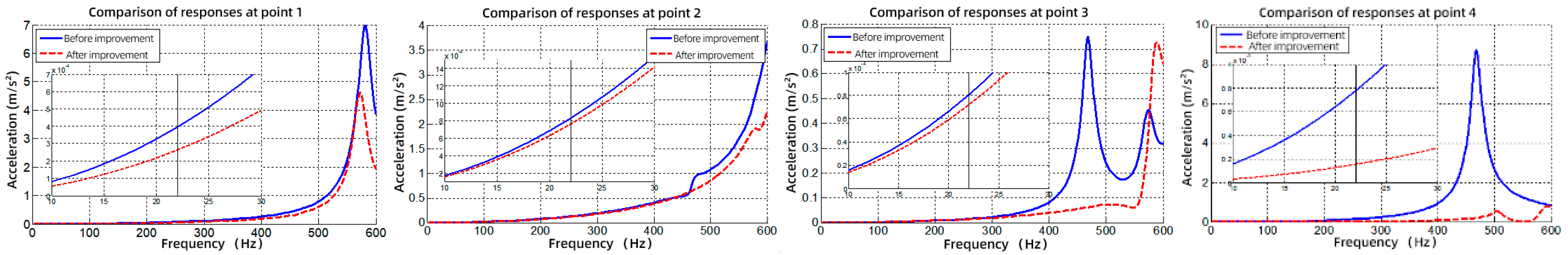

6.1. Comparison and Analysis of Harmonic Response of Composite Damping Base

- Harmonic loads of magnitude and frequency such as force, pressure, or forced displacement;

- Multiple loads at the same frequency may be in one phase or in different phases.

- The harmonic displacement on each degree of freedom is usually in a different phase from the applied load;

- Various other derived quantities, such as stress and strain, etc.

6.2. Vibration Test Verification

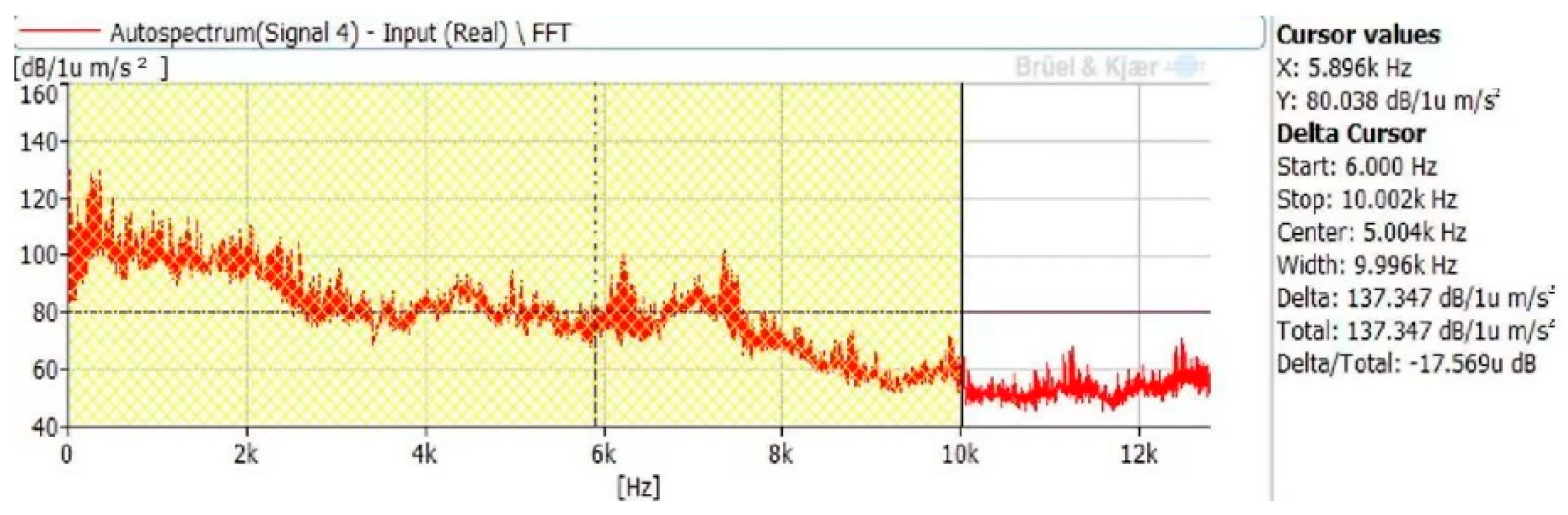

- The measurement results of the acceleration level of the initial base feet are shown in Figure 10. The average vibration acceleration level is 137.3 dB;

- The measurement results of the acceleration level of the improved base are shown in Figure 11. The average vibration acceleration level is 130.4 dB.

7. Conclusions

- The vibration sources of the air compressor are described. The vibration transfer path from the air compressor to the base structure is analyzed. The vibration energy composition of the base is as follows: the low-frequency vibration is caused by the rotating parts, and the high-frequency vibration is caused by the electromagnetism of the motor.

- For the base structure, the constrained damping material can be used to absorb its vibration, and the vibration energy can be converted into heat energy by such damping material.

- Compared to EPDM and IIR, the composite base filled with super-damping rubber possesses the best damping performance since the structure of the molecular formula of such damping rubber has a strong ability to reduce vibration.

- Finally, vibration test verification data indicates that the application of super damping rubber to the base structure is feasible since the overall vibration acceleration level of the improved base is lower than 131 dB, which meets the design requirements of the air compressor.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Xue, H.Q.; Zhang, G.J.; Hu, L.F.; Zheng, L.P. Calculation and Analysis of Radiation Noise Characteristics of a Type of Marine Air Compressors. J. Noise Vib. Control 2021, 41, 115–121. [Google Scholar]

- Xu, H. Research on Structure Vibration and Noise Prediction of Marine Air Compressor. Master’s Thesis, Wuhan University of Technology, Wuhan, China, 2015. [Google Scholar]

- Ke, X.Y. Structural Vibration Analysis of Marine Air Compressor and Research on its Vibration and Noise Reduction Technology. Master’s Thesis, Jimei University, Xiamen, China, 2020. [Google Scholar]

- Zhu, B.; Zhang, Z.; Zhang, C.; Li, X.; Xing, Z.; Tan, Y. Analysis and Experimental Research of Marine Vertical High Pressure Air Compressor. J. Fluid Mach. 2020, 48, 43–47. [Google Scholar] [CrossRef]

- Kerwin, E.M. Damping of Flexural Waves by a Constrained Viscoelastic Layer. J. Acoust. Soc. Am. 1959, 31, 952–962. [Google Scholar] [CrossRef]

- Ross, D.; Ungar, E.; Kerwin, E.M. Damping of Plate Flexural Vibrations by Means of Viscoelastic Laminate in Structural Damping; American Society of Mechanical Engineers: New York, NY, USA, 1959. [Google Scholar]

- Ditaranto, R.A. Theory of Vibratory Bending for Elastic and Viscoelastic Layered Finite Length Beams. J. Appl. Mech. 1965, 87, 881–886. [Google Scholar] [CrossRef]

- Mead, D.J.; Markus, S. The Forced Vibration of a Three-Layer Damping Sandwich Beam with Arbitrary Boundary Conditions. J. Sound Vib. 1969, 10, 163–175. [Google Scholar] [CrossRef]

- Douglas, B.E.; Yang, J.C.S. Transverse Compressional Damping in Vibratory Response of Elastic-Viscoelastic-elastic Beams. AIAA 1978, 20, 925–930. [Google Scholar] [CrossRef]

- Lu, Y.P.; Everstine, G.C. Vibrations of three layered damped sandwich plate composites. J. Sound Vib. 1979, 64, 63–71. [Google Scholar] [CrossRef]

- Johnson, C.D.; Kienholz, D. Finite element prediction of damping in structures with constrained viscoelastic layers. AIAA 1981, 20, 1284–1290. [Google Scholar] [CrossRef]

- Singh, S.P.; Gupta, K. Composite shaft rotor dynamic analysis using a layer wise theory. J. Sound Vib. 1996, 191, 739–756. [Google Scholar] [CrossRef]

- Kim, W.; Argento, A.; Scott, R.A. Free Vibration of a rotating tapered composite Timoshenko shaft. J. Sound Vib. 1999, 226, 125–147. [Google Scholar] [CrossRef]

- Leung, A.Y.; Zhu, B.; Zheng, J.; Yang, H. Two-dimensional vibration by analytic Fourier p-elments. Thin-Walled Struct. 2003, 41, 1159–1170. [Google Scholar] [CrossRef]

- Zhang, Q.J.; Sainsbury, M.G. The gale kin element method applied to the vibration of rectangular damped sandwich plates. Comput. Struct. 2000, 71, 717–730. [Google Scholar] [CrossRef]

- Alvedid, M.; Enelund, M. Modelling of constrained thin rubber layer with emphasis on damping. J. Sound Vib. 2007, 300, 662–675. [Google Scholar] [CrossRef]

| Damping Materials | Frequency (Hz) | Loss Factor | ||||

|---|---|---|---|---|---|---|

| 1st | 2nd | 3rd | 1st | 2nd | 3rd | |

| Sample 1 | 276 | 384 | 871 | 0.011 | 0.029 | 0.012 |

| Sample 2 | 236 | 338 | 786 | 0.021 | 0.054 | 0.023 |

| Sample 3 | 234 | 338 | 740 | 0.024 | 0.060 | 0.022 |

| Sample 4 | 224 | 332 | 746 | 0.054 | 0.068 | 0.024 |

| Damping Materials | 1g (dB) | 3g (dB) | ||||

|---|---|---|---|---|---|---|

| 1st | 2nd | 3rd | 1st | 2nd | 3rd | |

| Sample 1 | 14.87 | 13.73 | 2.14 | 21.44 | 18.55 | 11.41 |

| Sample 2 | 10.29 | 8.63 | 1.44 | 18.93 | 13.33 | 9.94 |

| Sample 3 | 6.53 | 8.56 | 6.94 | 19.23 | 15.03 | 11.91 |

| Sample 4 | 5.71 | 1.59 | 7.98 | 17.18 | 10.73 | 3.41 |

| Damping Materials | 1g (dB) | 3g (dB) | ||||

|---|---|---|---|---|---|---|

| 1st | 2nd | 3rd | 1st | 2nd | 3rd | |

| Sample 1 | - | - | - | - | - | - |

| Sample 2 | 4.58 | 5.10 | 0.70 | 2.51 | 5.22 | 1.47 |

| Sample 3 | 8.34 | 5.17 | 9.08 | 2.21 | 3.52 | 6.5 |

| Sample 4 | 9.16 | 12.14 | 10.12 | 4.26 | 7.82 | 8.00 |

| Damping Materials | Peak (Hz) | Response (g2/Hz) | ||||

|---|---|---|---|---|---|---|

| 1st | 2nd | 3rd | 1st | 2nd | 3rd | |

| Sample 1 | 374 | 465 | 805 | 0.33 | 0.47 | 0.65 |

| Sample 2 | 227 | 438 | 799 | 0.04 | 0.34 | 0.22 |

| Sample 3 | 286 | 523 | 709 | 0.06 | 0.43 | 0.18 |

| Sample 4 | 226 | 504 | 724 | 0.05 | 0.27 | 0.05 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, F.; Li, H.; Li, H.; Liu, D. Experimental Investigation of Vibration Reduction Effect of High-Pressure Air Compressor Using Composite Damping Base. Machines 2023, 11, 229. https://doi.org/10.3390/machines11020229

Zhao F, Li H, Li H, Liu D. Experimental Investigation of Vibration Reduction Effect of High-Pressure Air Compressor Using Composite Damping Base. Machines. 2023; 11(2):229. https://doi.org/10.3390/machines11020229

Chicago/Turabian StyleZhao, Feng, He Li, Hui Li, and Duo Liu. 2023. "Experimental Investigation of Vibration Reduction Effect of High-Pressure Air Compressor Using Composite Damping Base" Machines 11, no. 2: 229. https://doi.org/10.3390/machines11020229

APA StyleZhao, F., Li, H., Li, H., & Liu, D. (2023). Experimental Investigation of Vibration Reduction Effect of High-Pressure Air Compressor Using Composite Damping Base. Machines, 11(2), 229. https://doi.org/10.3390/machines11020229