A Novel Feature for Fault Classification of Rotating Machinery: Ternary Approximate Entropy for Original, Shuffle and Surrogate Data

Abstract

1. Introduction

2. Materials and Methods

2.1. ApEn

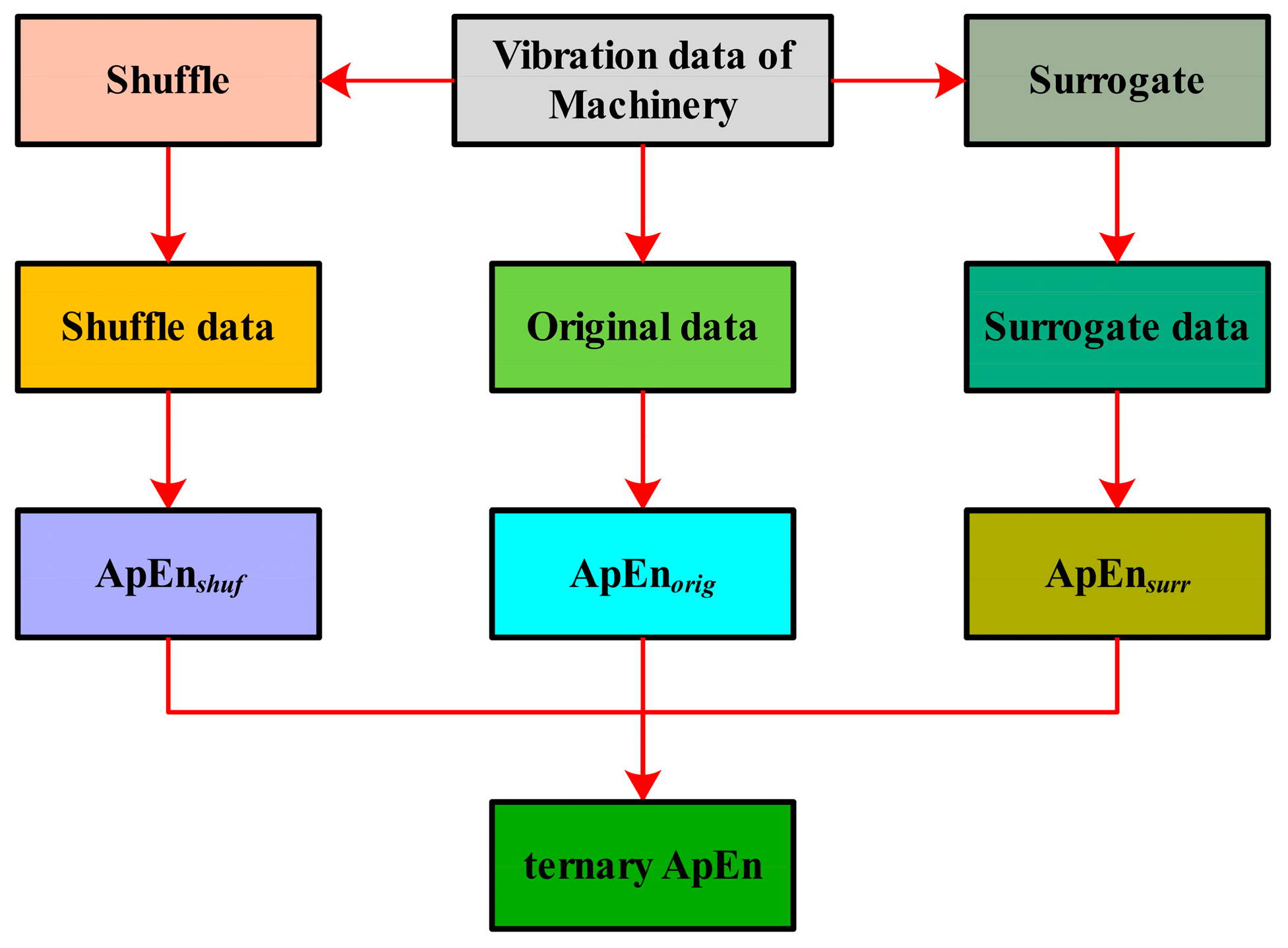

2.2. Fault Classification of Rotating Machinery Based on Ternary ApEn

3. Results

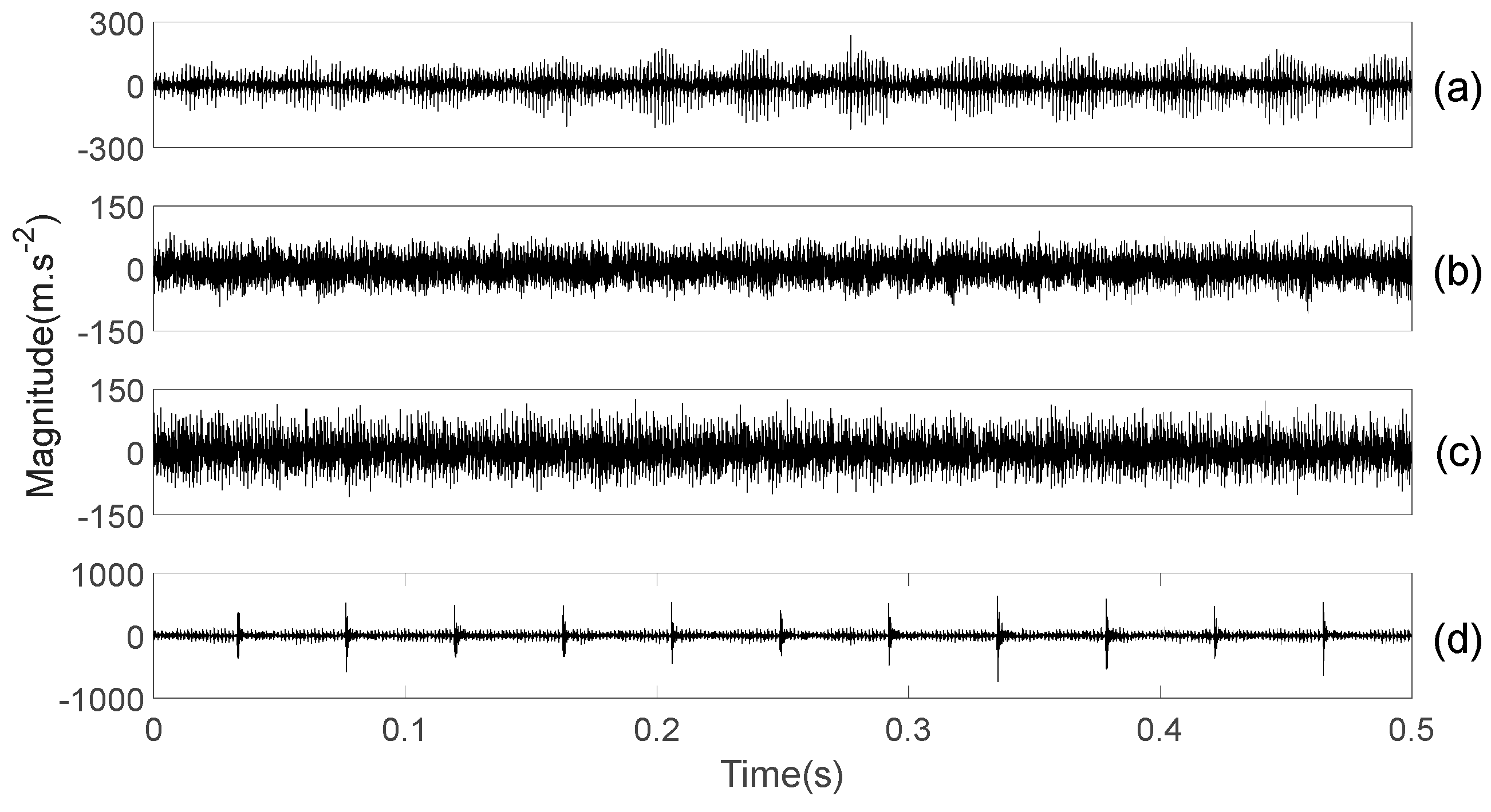

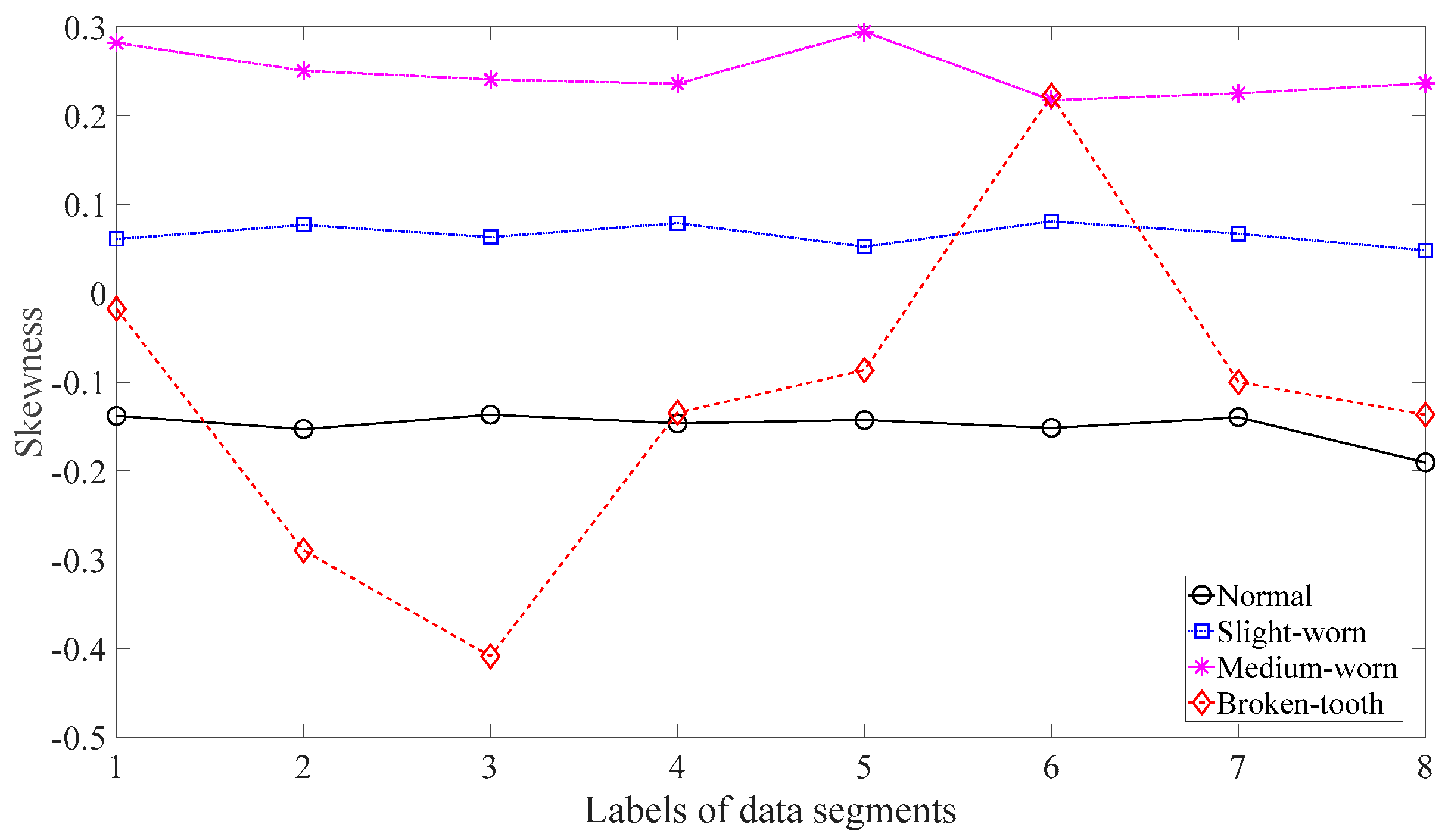

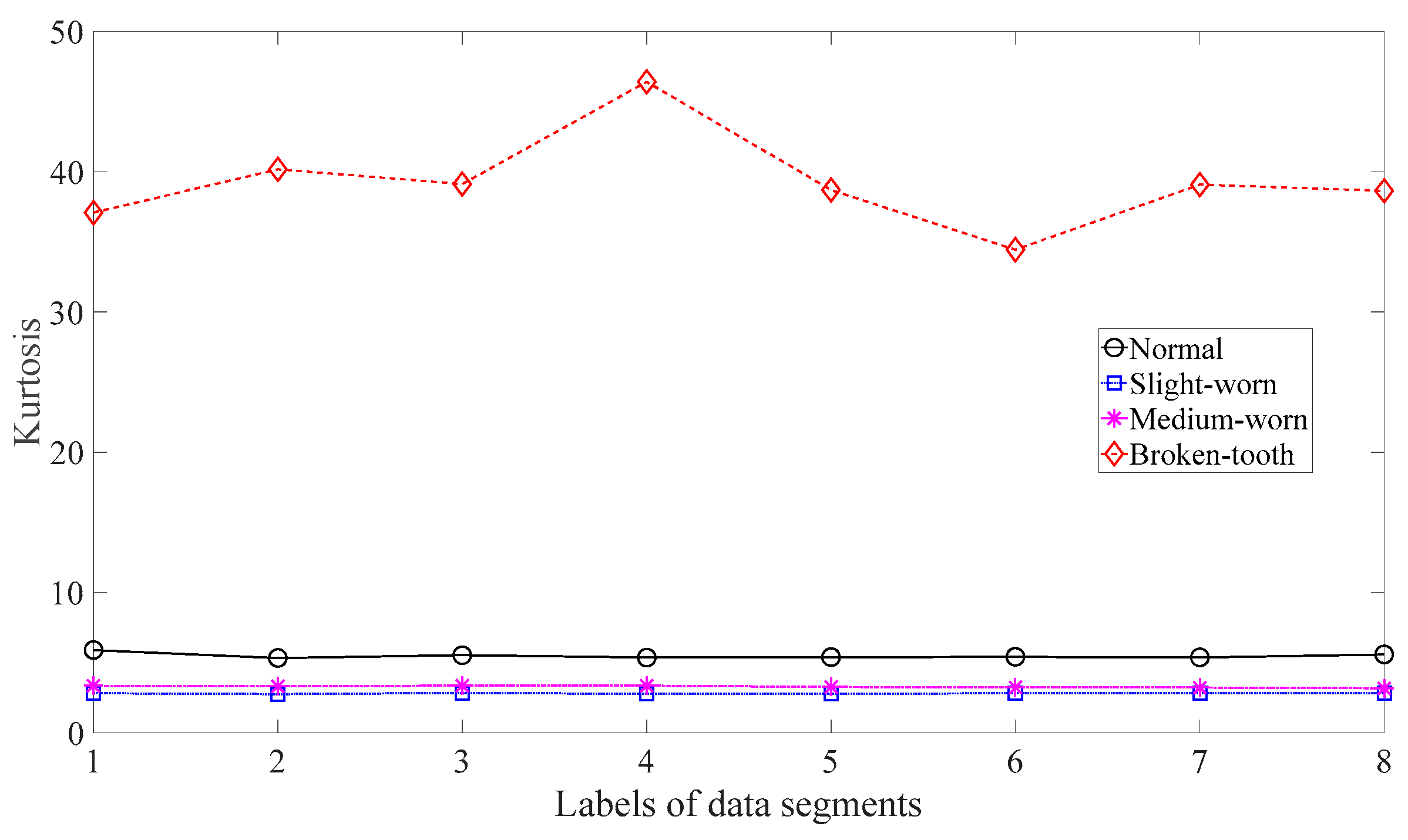

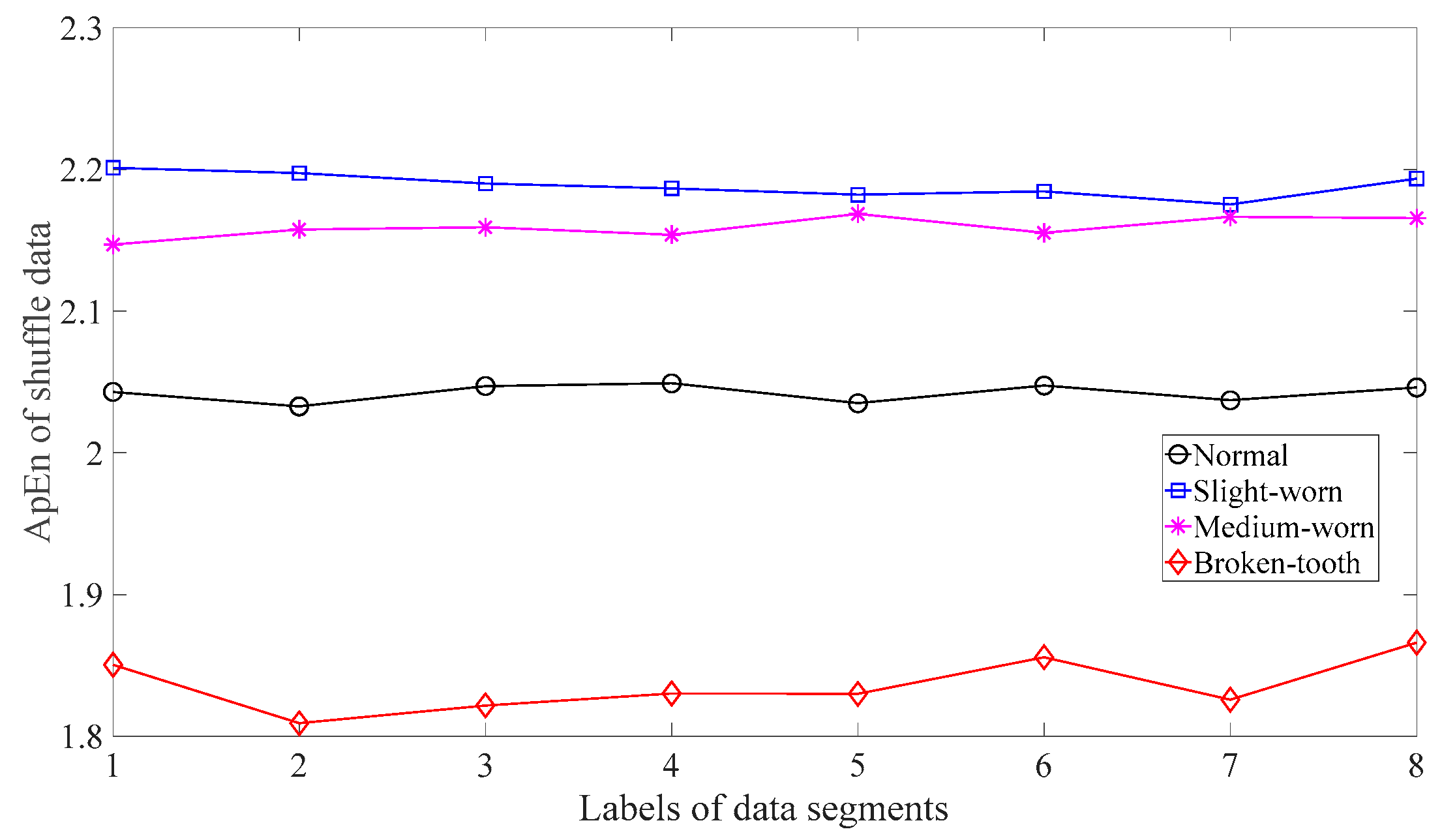

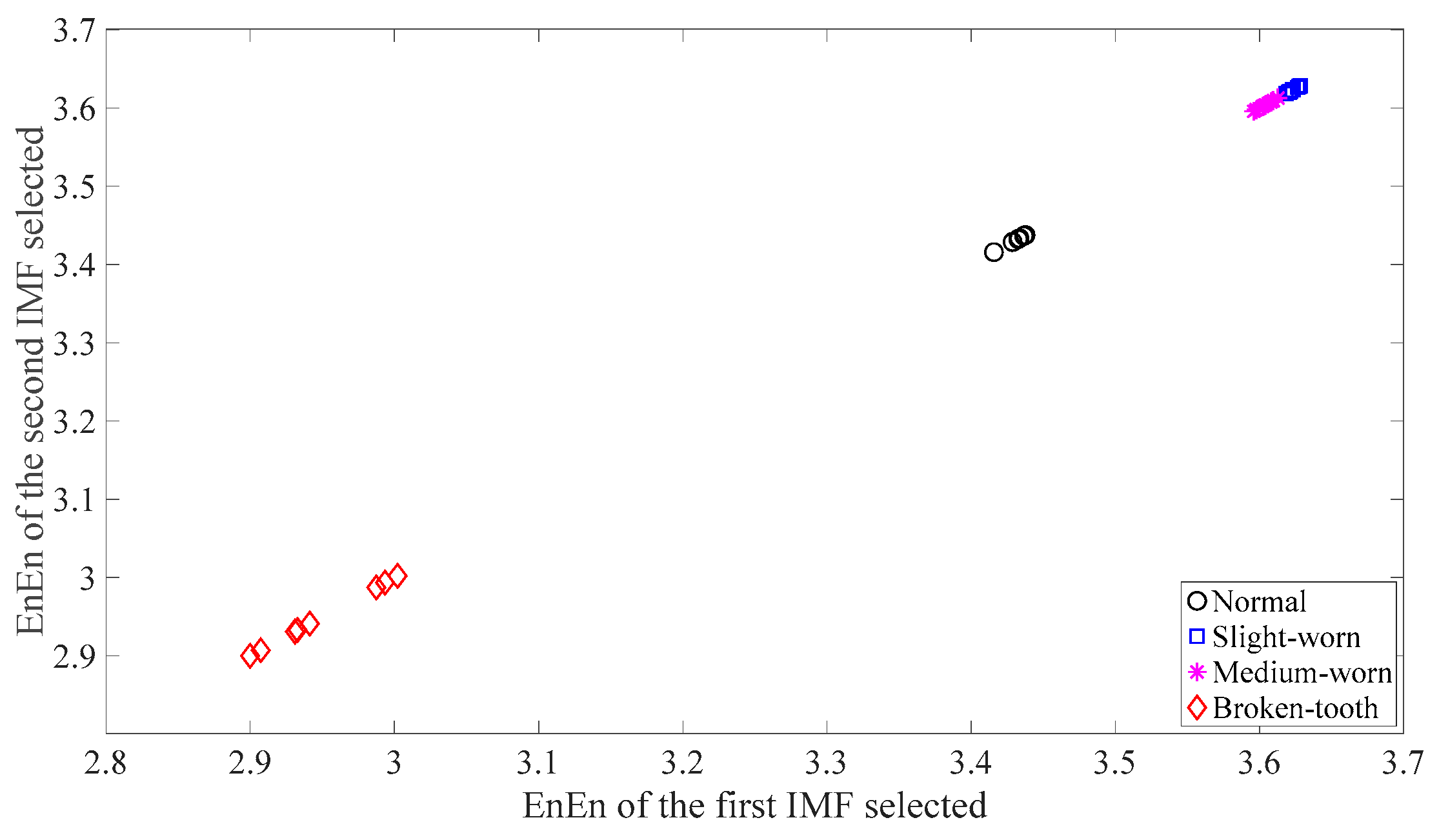

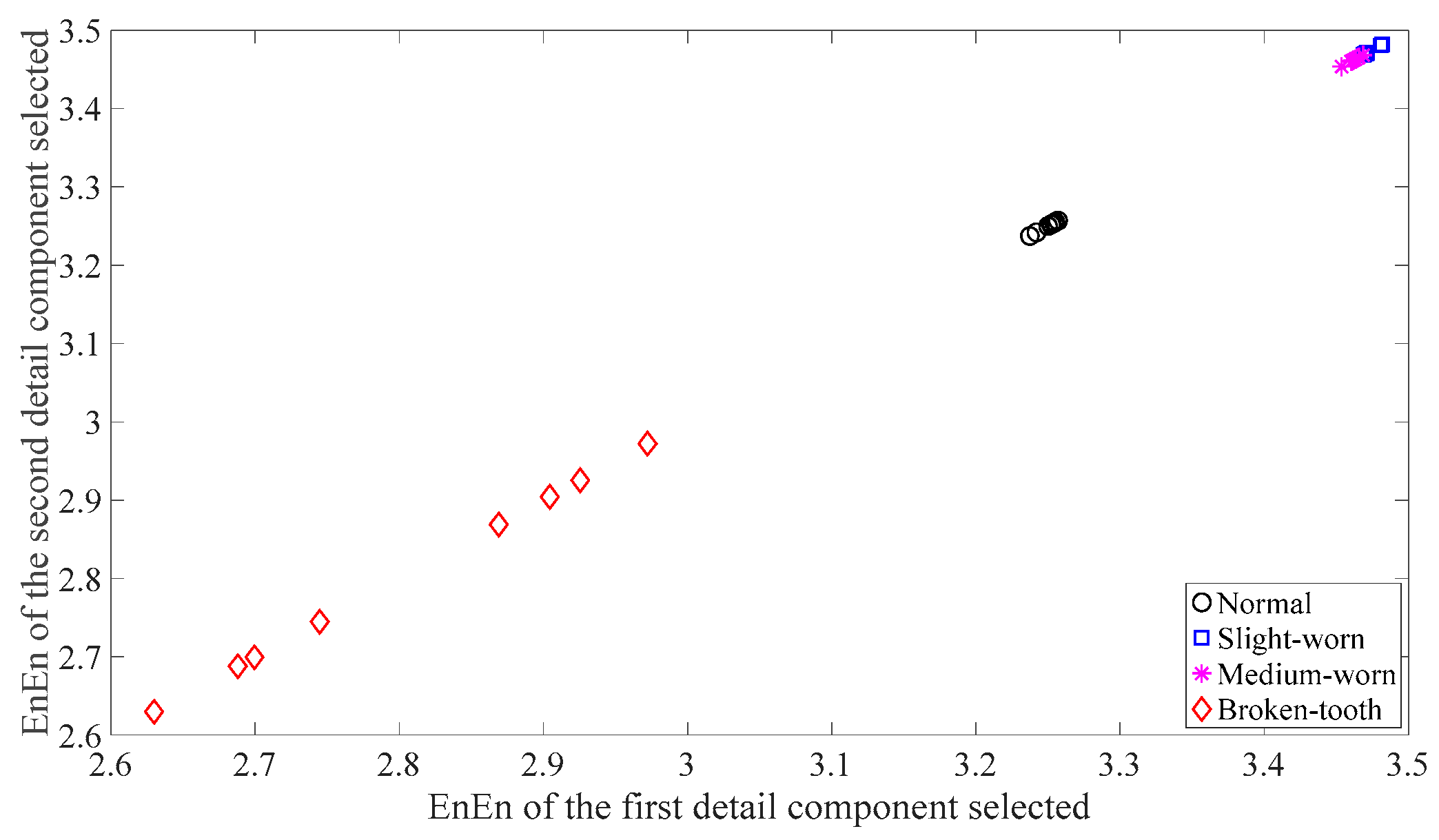

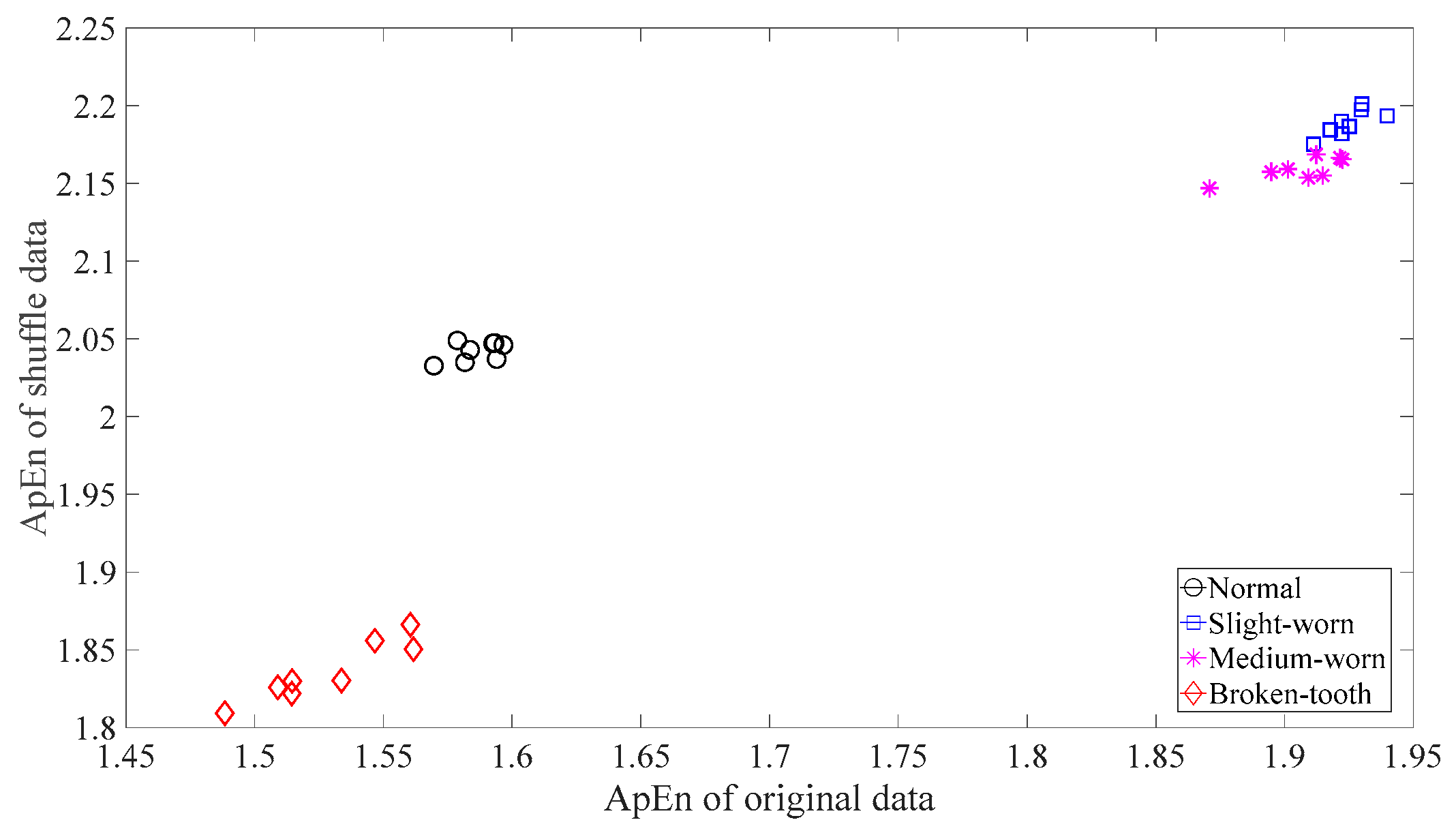

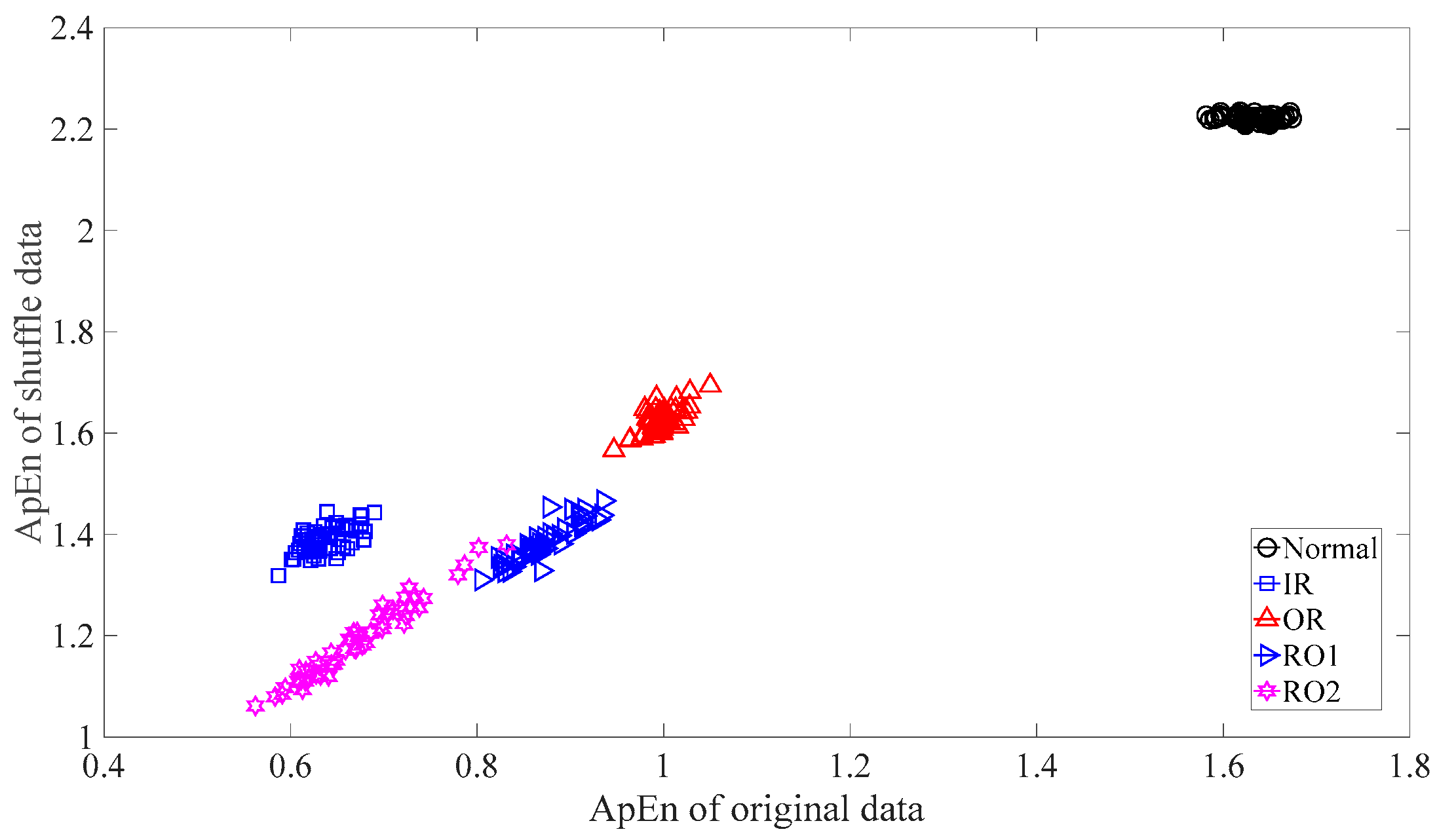

3.1. Fault Classification of Gears

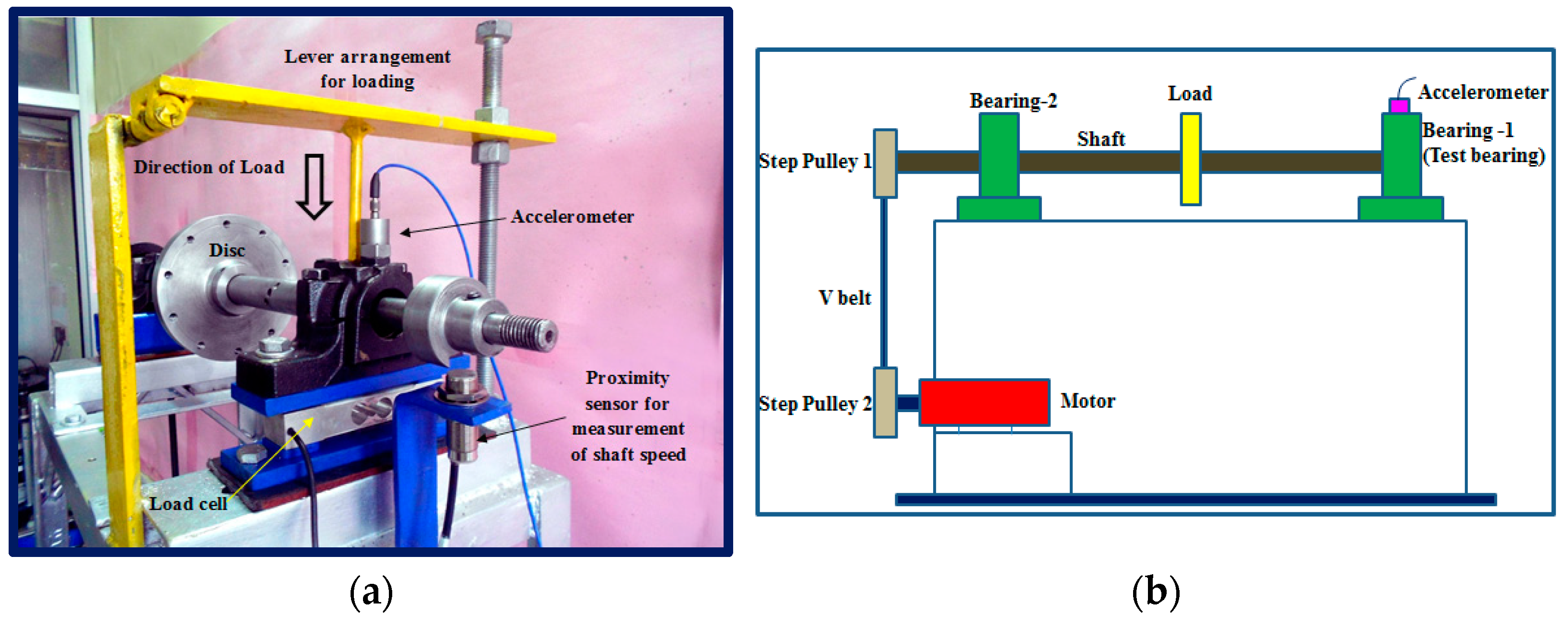

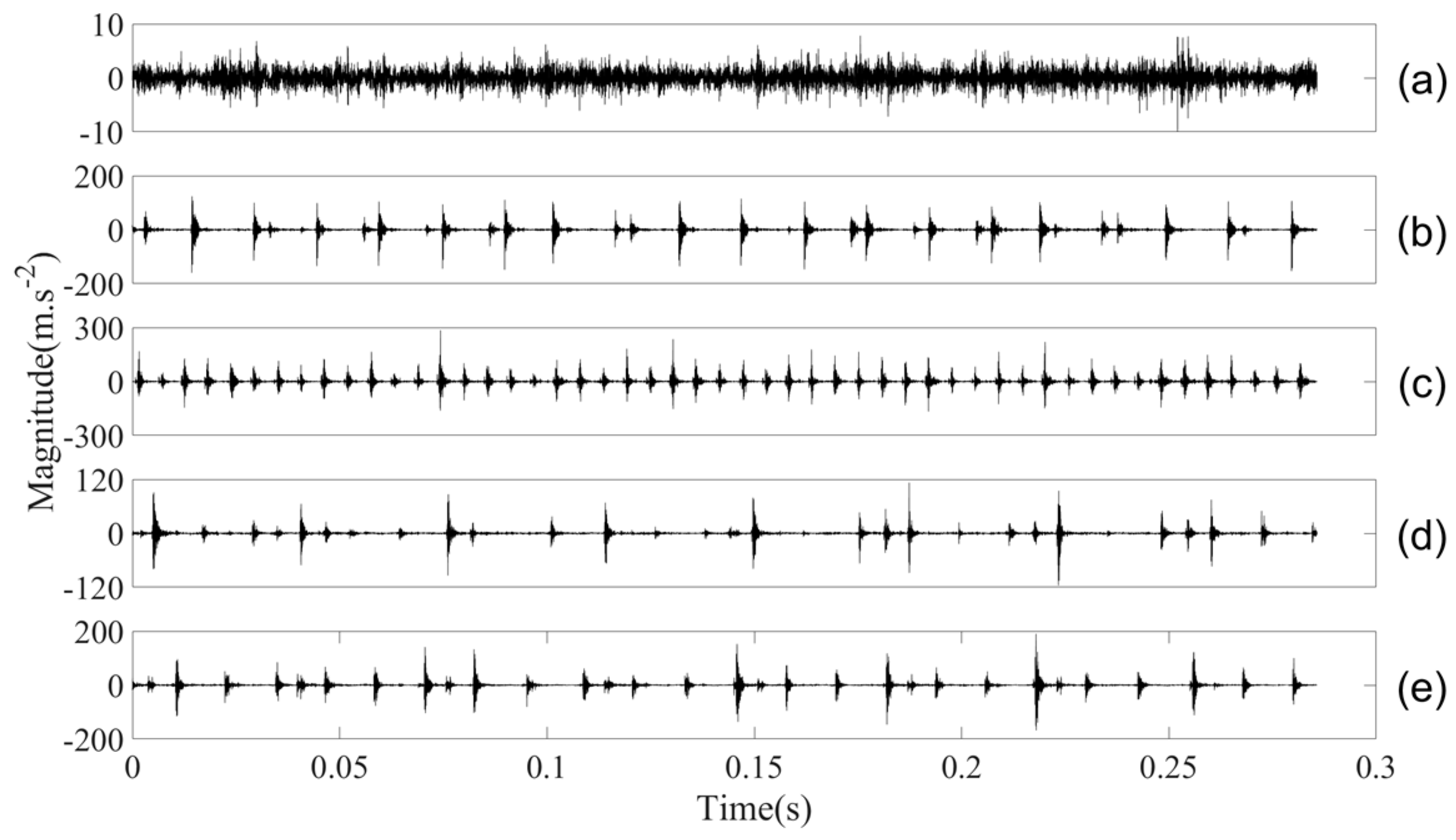

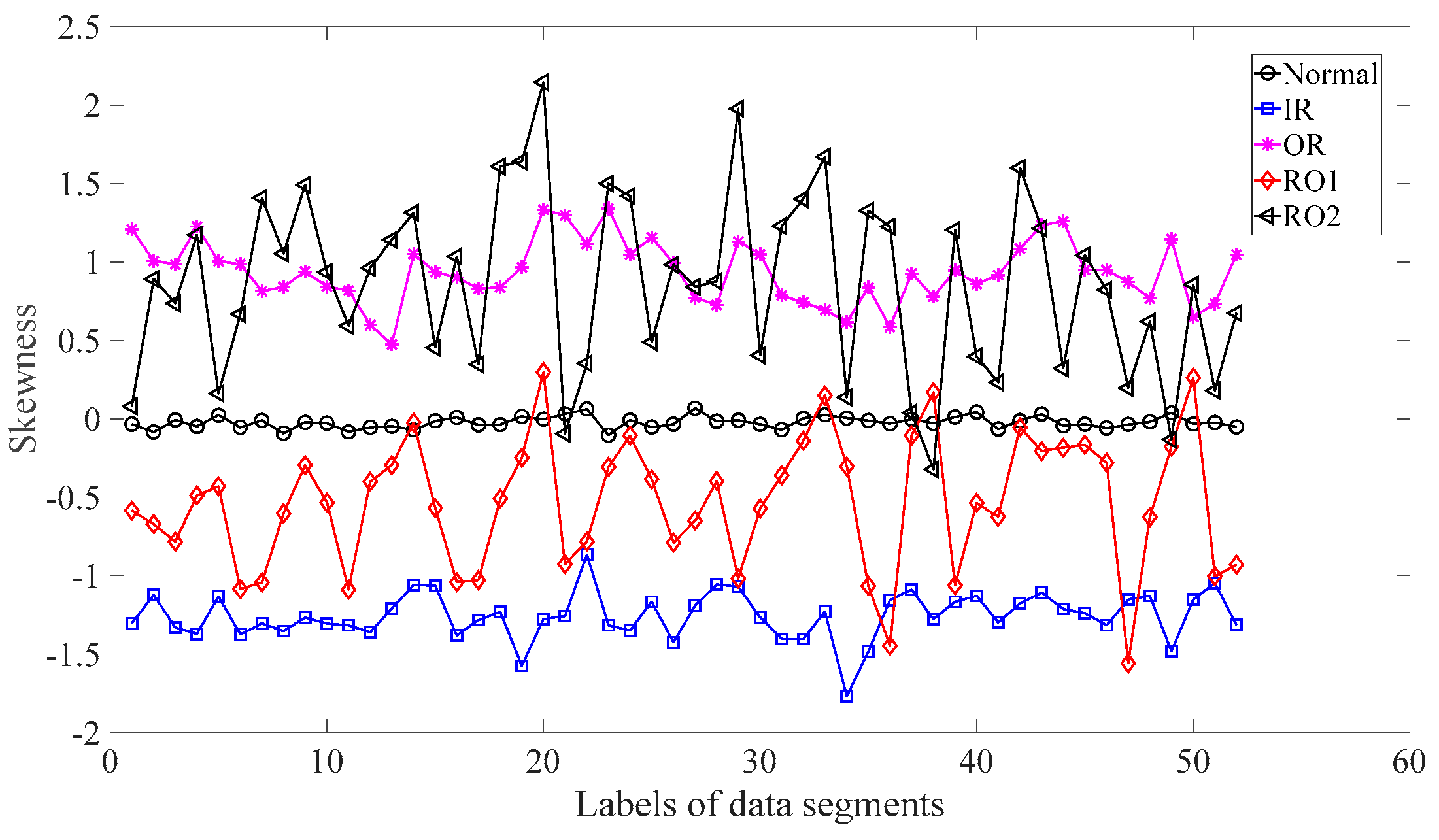

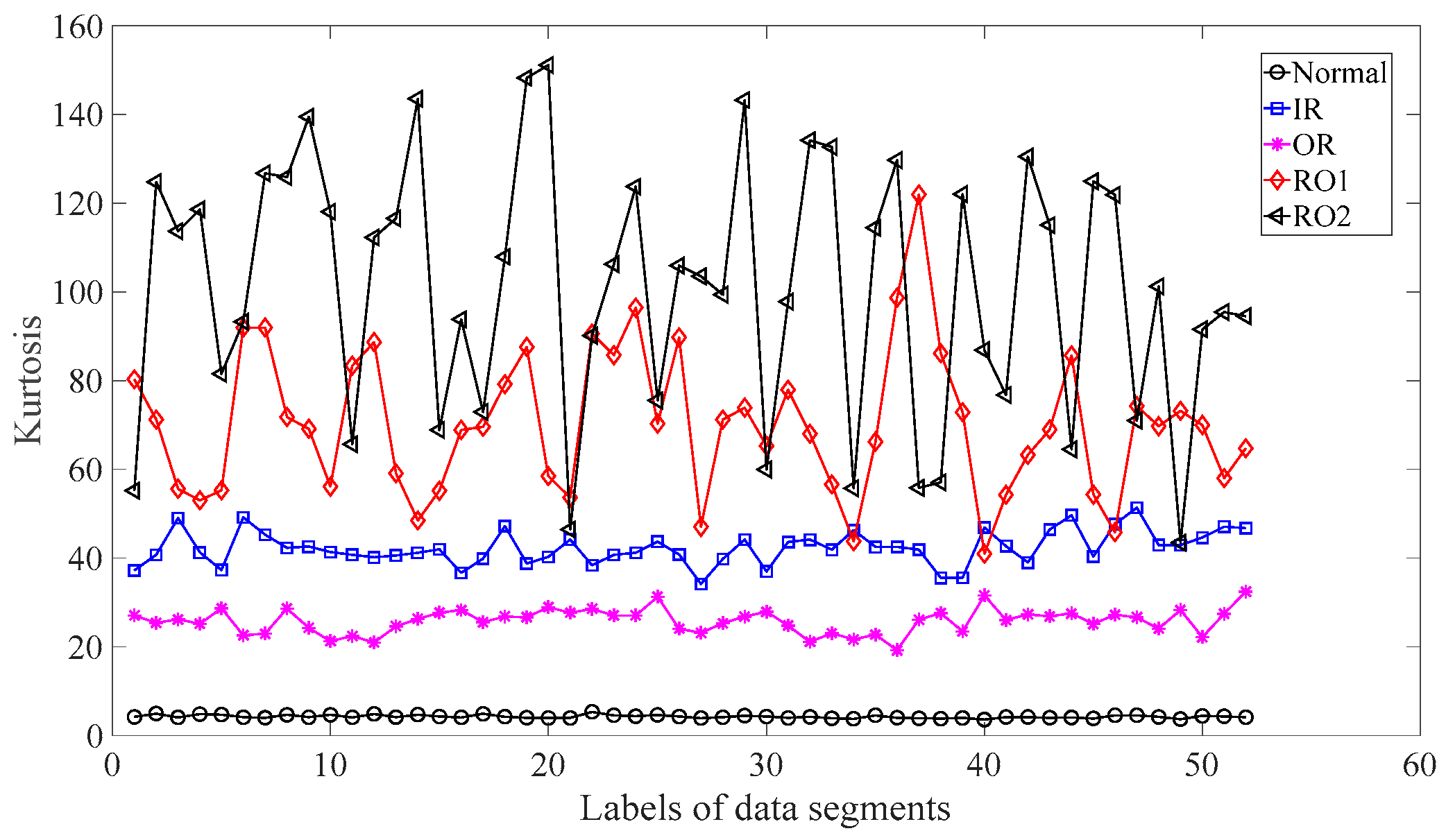

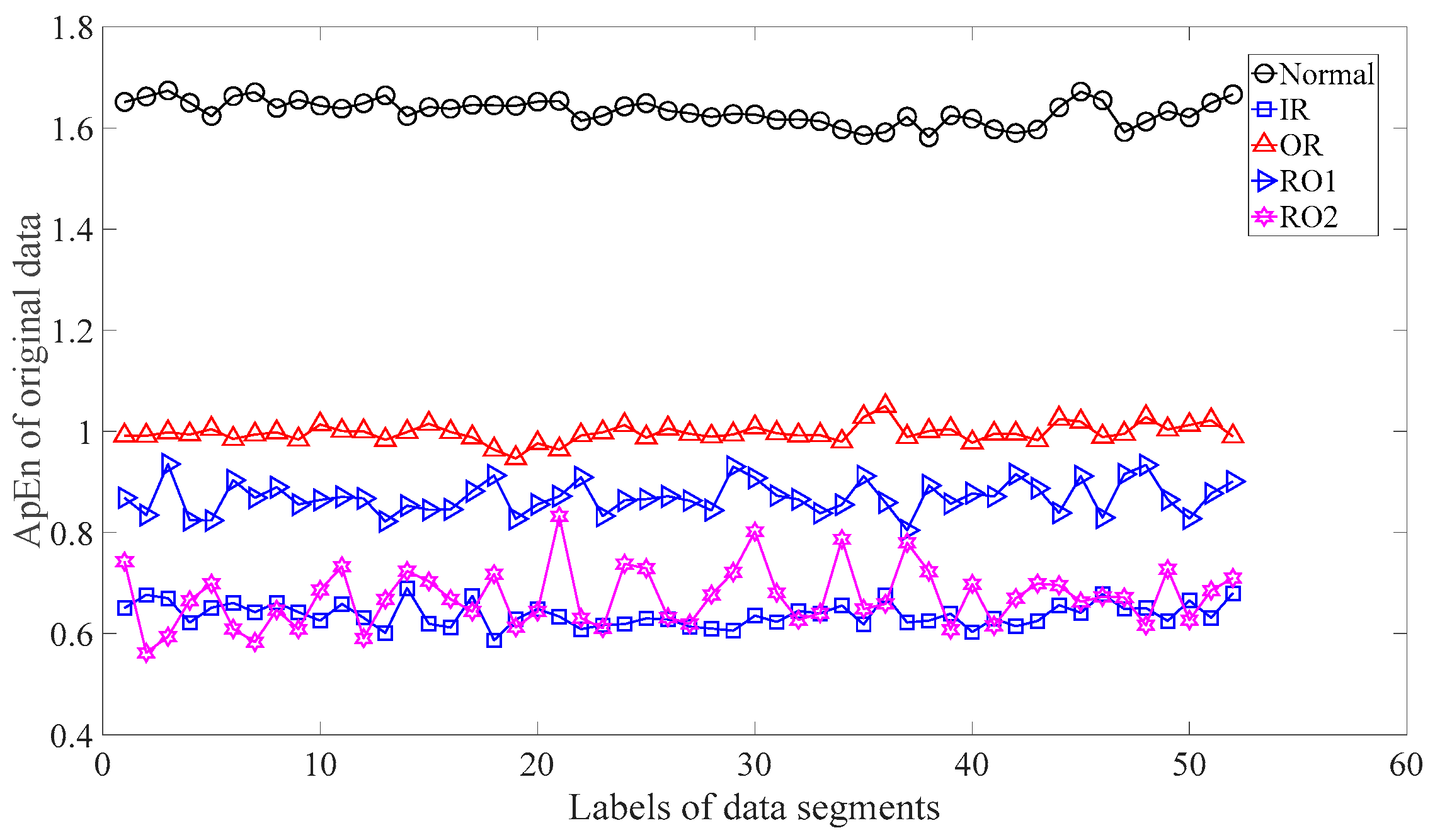

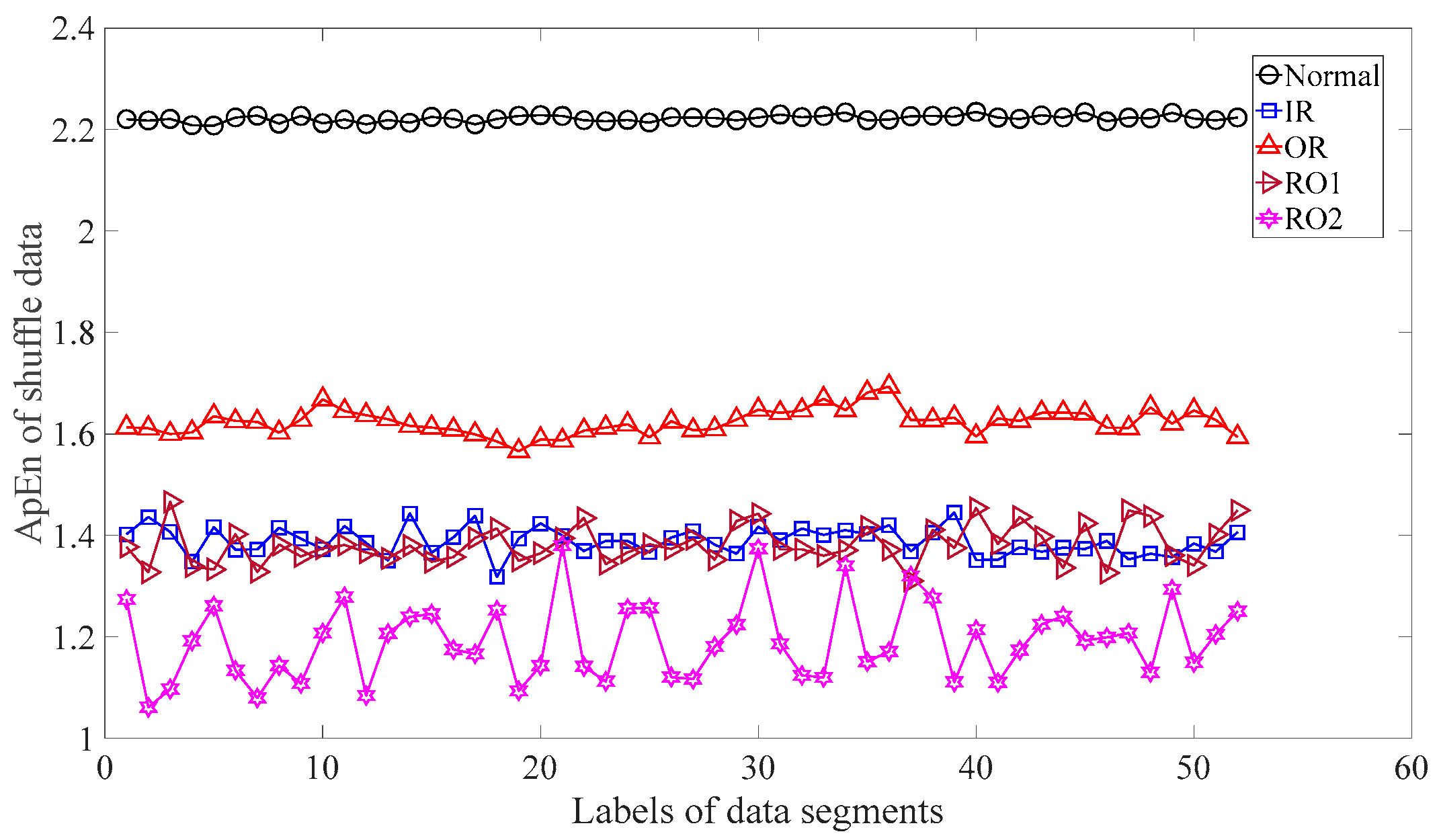

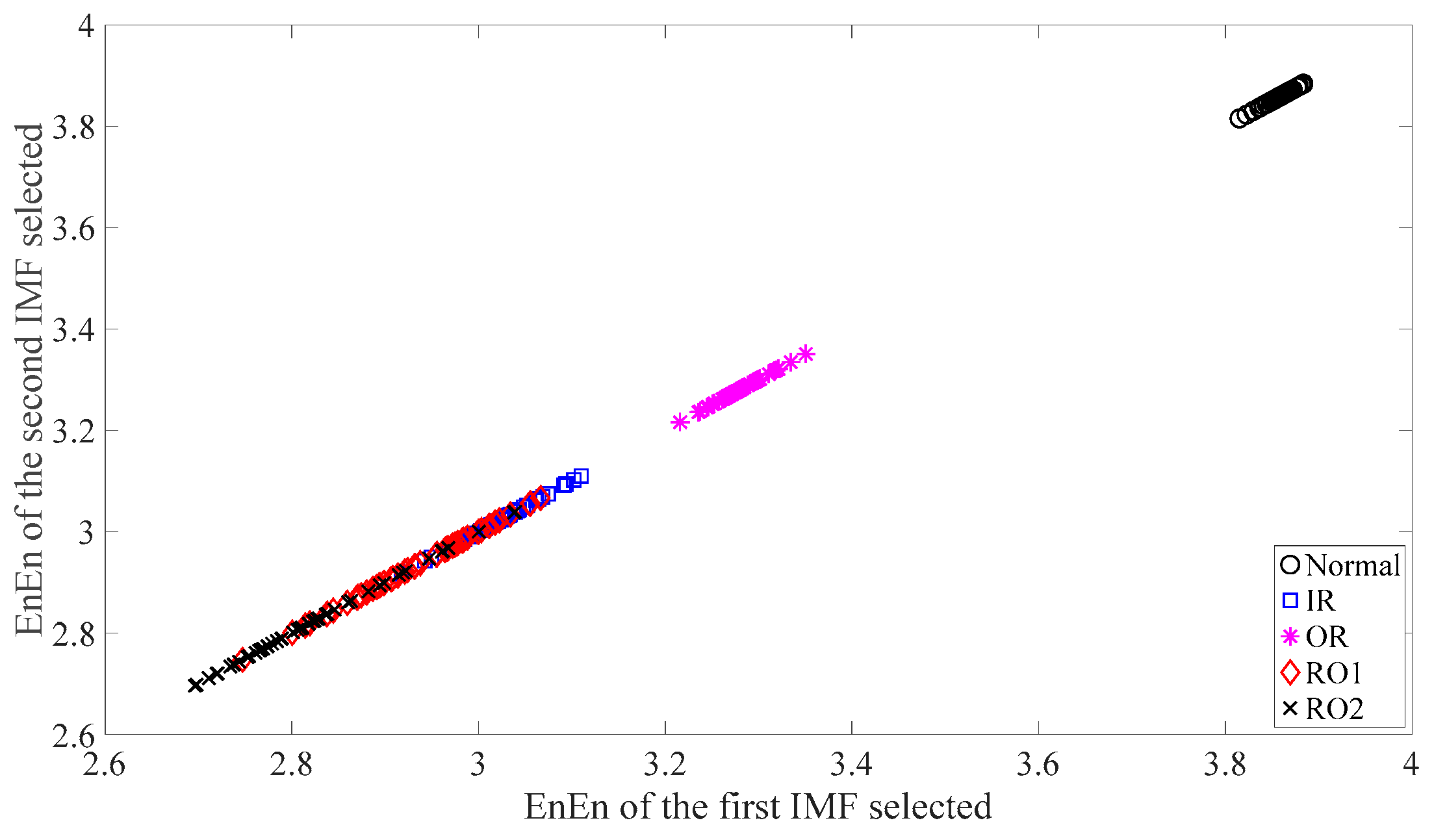

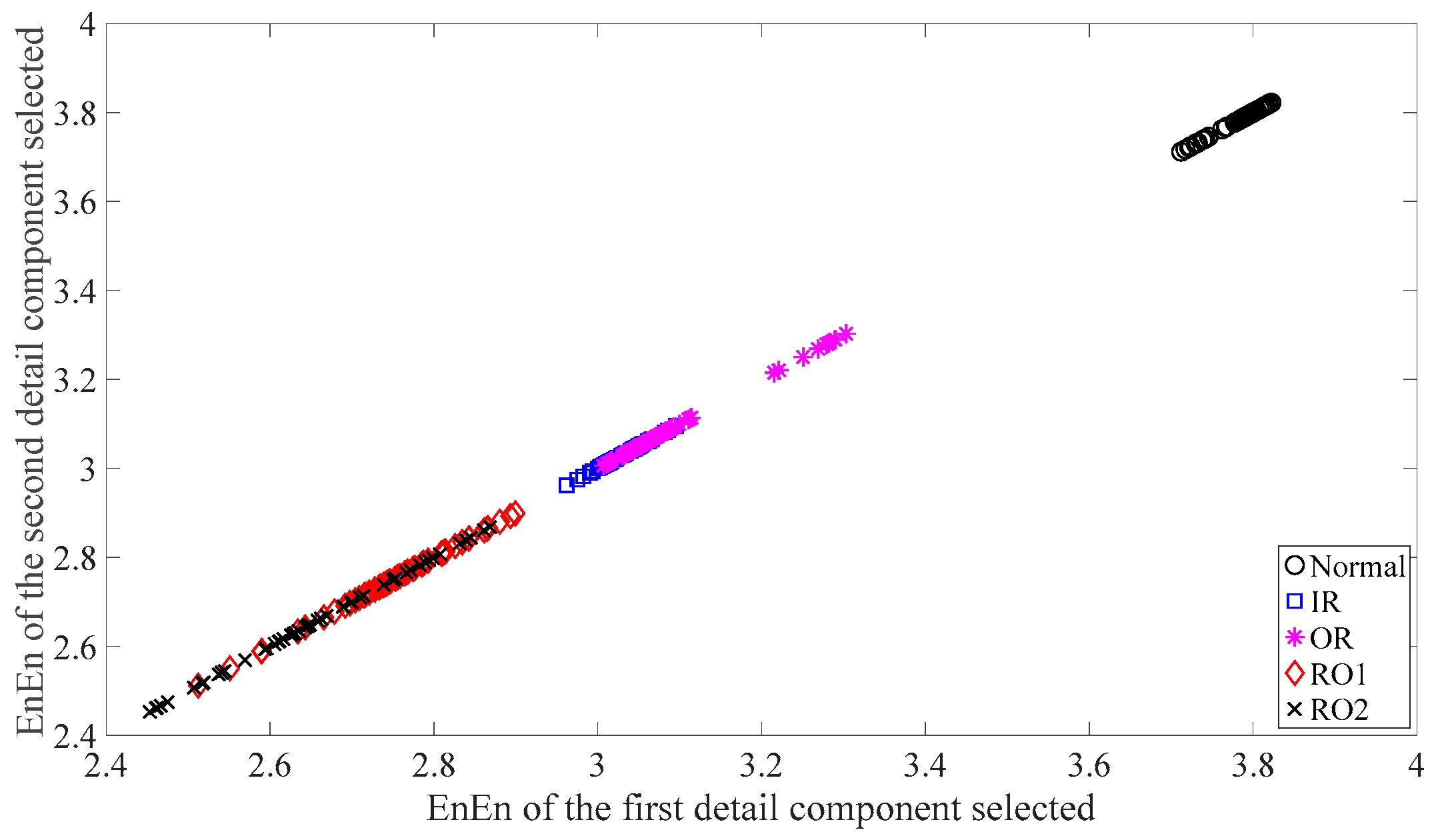

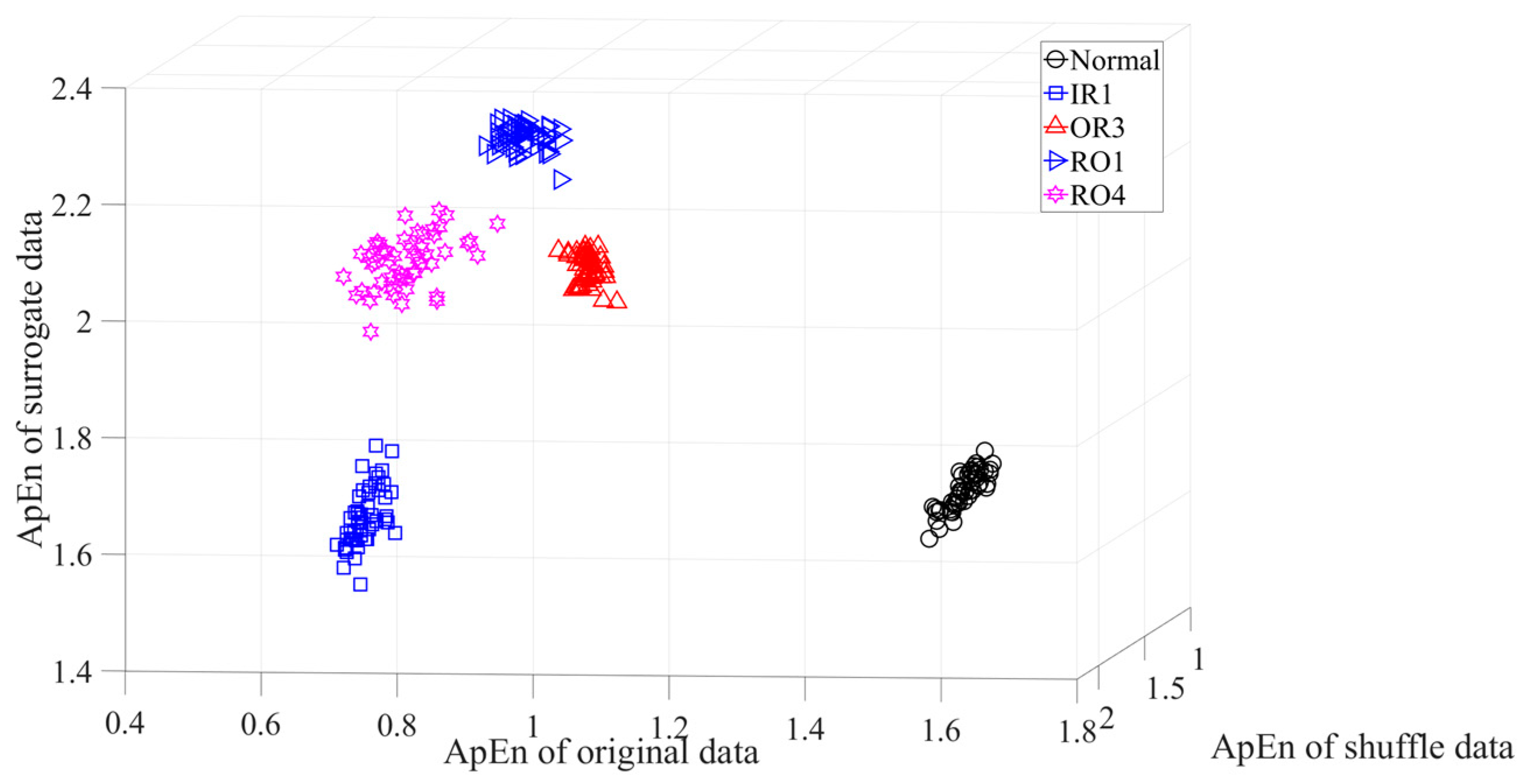

3.2. Fault Classification of Roller-Bearings

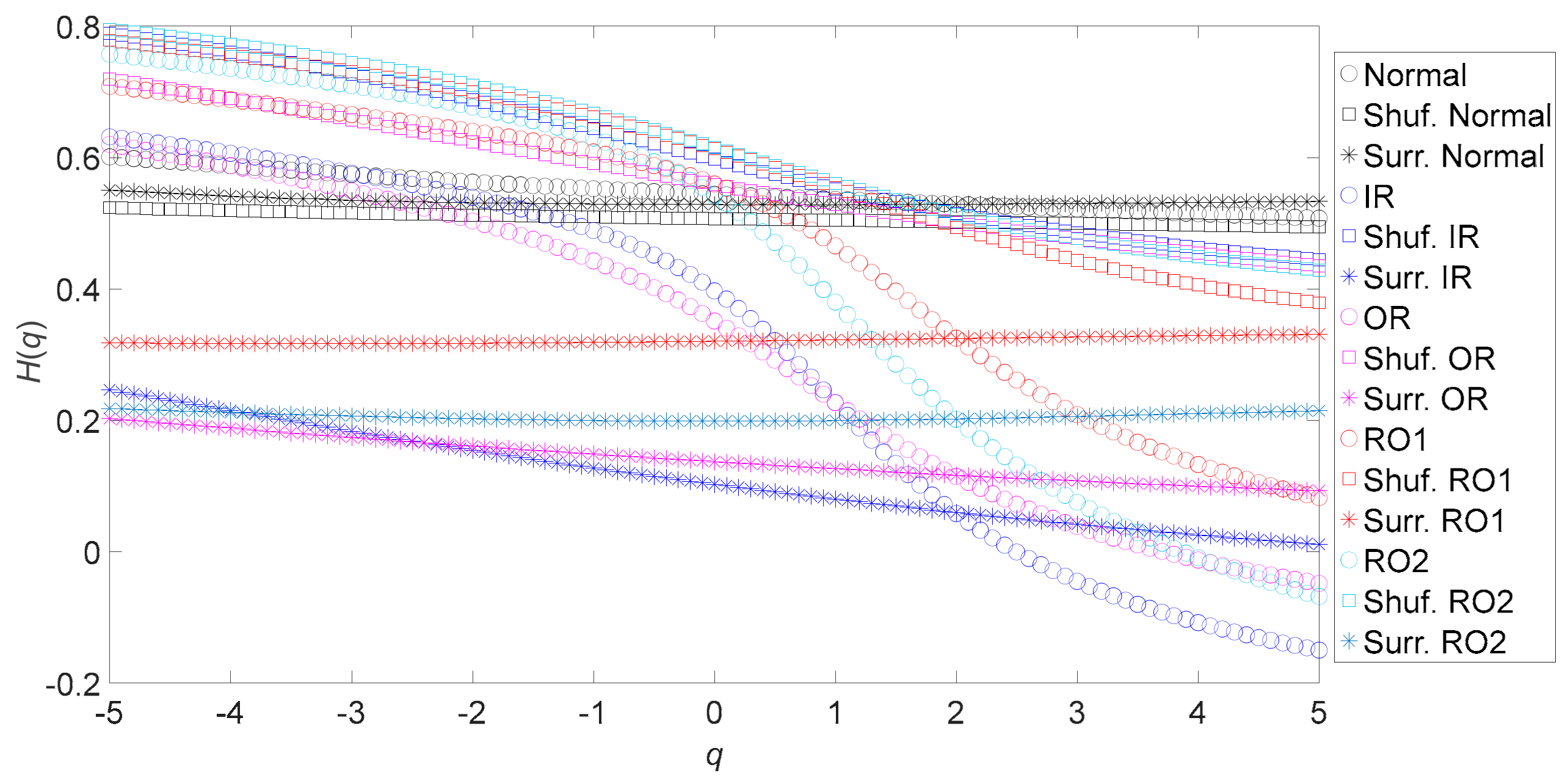

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

- function shufData = shuffle(data)

- N=length(data);

- shuf=randperm(N);

- shufData=data(shuf);

- end

Appendix B

- function surrData=surrogate(data)

- data=data(:);

- N=length(data);

- Coef=fft(data);

- Amp=abs(Coef);

- Ang=angle(Coef);

- i=sqrt(-1);

- half=floor(N/2);

- if rem(N,2)==0

- Angran=rand(half-1,1)*2*pi;

- Ang(2:N)=[Angran’ Ang(half+1) -flipud(Angran)’];

- Amp=[Amp(1:half+1);flipud(Amp(2:half))];

- else

- Angran=rand(half,1)*2*pi;

- Ang(2:N)=[Angran -flipud(Angran)];

- end

- surrPhase=Amp.*exp(i*Ang);

- surrData =real(ifft(surrPhase));

- end

Appendix C

- function energyEntropy = EnEn(data)

- N=length(data);

- probVec=data.^2/sum(data.^2);

- energyEntropy=0;

- for jElement=1:N

- energyEntropy=energyEntropy-probVec(jElement)*log10(probVec(jElement));

- end

- end

References

- Jalayer, M.; Orsenigo, C.; Vercellis, C. Fault detection and diagnosis for rotating machinery: A model based on convolutional LSTM, Fast Fourier and continuous wavelet transforms. Comput. Ind. 2021, 125, 103378. [Google Scholar] [CrossRef]

- Patange, A.D.; Jegadeeshwaran, R. A machine learning approach for vibration-based multipoint tool insert health prediction on vertical machining centre (VMC). Measurement 2021, 173, 108649. [Google Scholar] [CrossRef]

- Patange, A.D.; Jegadeeshwaran, R. Application of bayesian family classifiers for cutting tool inserts health monitoring on CNC milling. Int. J. Progn. Health Manag. 2020, 11, 16. [Google Scholar] [CrossRef]

- Zhang, K.; Ma, C.; Xu, Y.; Chen, P.; Du, J. Feature extraction method based on adaptive and concise empirical wavelet transform and its applications in bearing fault diagnosis. Measurement 2021, 172, 108976. [Google Scholar] [CrossRef]

- Sun, Y.; Li, S.; Wang, Y.; Wang, X. Fault diagnosis of rolling bearing based on empirical mode decomposition and improved manhattan distance in symmetrized dot pattern image. Mech. Syst. Signal Process. 2021, 159, 107817. [Google Scholar] [CrossRef]

- He, X.; Zhou, X.; Yu, W.; Hou, Y.; Mechefske, C.K. Adaptive variational mode decomposition and its application to multi-fault detection using mechanical vibration signals. ISA Trans. 2021, 111, 360–375. [Google Scholar] [CrossRef]

- Huang, N.E.; Shen, Z.; Long, S.R.; Wu, M.L.C.; Shih, H.H.; Zheng, Q.N.; Yen, N.C.; Tung, C.C.; Liu, H.H. The empirical mode decomposition and the Hilbert spectrum for nonlinear and non-stationary time series analysis. Proc. R. Soc. London Ser. A Math. Phys. Eng. Sci. 1998, 454, 903–995. [Google Scholar] [CrossRef]

- Pincus, S.M. Approximate entropy as a measure of system complexity. Proc. Natl. Acad. Sci. USA 1991, 88, 2297–2301. [Google Scholar] [CrossRef]

- Lake, D.E.; Richman, J.S.; Griffin, M.P.; Moorman, J.R. Sample entropy analysis of neonatal heart rate variability. Am. J. Physiol.-Regul. Integr. Comp. Physiol. 2002, 283, R789–R797. [Google Scholar] [CrossRef]

- Bandt, C.; Pompe, B. Permutation entropy: A natural complexity measure for time series. Phys. Rev. Lett. 2002, 88, 174102. [Google Scholar] [CrossRef]

- Li, K.; He, S.; Li, B.; Liu, H.; Mao, X.; Shi, C. A novel online chatter detection method in milling process based on multiscale entropy and gradient tree boosting. Mech. Syst. Signal Process. 2020, 135, 106385. [Google Scholar] [CrossRef]

- Aziz, W.; Arif, M. Multiscale permutation entropy of physiological time series. In Proceedings of the 2005 Pakistan Section Multitopic Conference, Karachi, Pakistan, 24–25 December 2005; pp. 1–6. [Google Scholar]

- He, Y.; Fu, Y.; Qiao, Z.; Kang, Y. Chaotic resonance in a fractional-order oscillator system with application to mechanical fault diagnosis. Chaos Solitons Fractals 2021, 142, 110536. [Google Scholar] [CrossRef]

- Zhang, Y.; Ren, G.; Wu, D.; Wang, H. Rolling bearing fault diagnosis utilizing variational mode decomposition based fractal dimension estimation method. Measurement 2021, 181, 109614. [Google Scholar] [CrossRef]

- Lin, J.; Dou, C.; Liu, Y. Feature extraction based on generalized permutation entropy for condition monitoring of rotating machinery. Nonlinear Dynam. 2021, 107, 855–870. [Google Scholar] [CrossRef]

- Lin, J.; Dou, C.; Liu, Y. Multifractal detrended fluctuation analysis based on optimized empirical mode decomposition for complex signal analysis. Nonlinear Dynam. 2021, 103, 2461–2474. [Google Scholar] [CrossRef]

- Peng, C.K.; Havlin, S.; Stanley, H.E.; Goldberger, A.L. Quantification of scaling exponents and crossover phenomena in nonstationary heartbeat time series. Chaos 1995, 5, 82–87. [Google Scholar] [CrossRef]

- Kantelhardt, J.W.; Zschiegner, S.A.; Koscielny-Bunde, E.; Havlin, S.; Bunde, A.; Stanley, H.E. Multifractal detrended fluctuation analysis of nonstationary time series. Phys. A Stat. Mech. Its Appl. 2002, 316, 87–114. [Google Scholar] [CrossRef]

- Lei, Y.; Yang, B.; Jiang, X.; Jia, F.; Li, N.; Nandi, A.K. Applications of machine learning to machine fault diagnosis: A review and roadmap. Mech. Syst. Signal Process. 2020, 138, 106587. [Google Scholar] [CrossRef]

- Iqbal, R.; Maniak, T.; Doctor, F.; Karyotis, C. Fault detection and isolation in industrial processes using deep learning approaches. IEEE Trans. Ind. Inform. 2019, 15, 3077–3084. [Google Scholar] [CrossRef]

- Hoang, D.-T.; Kang, H.-J. A survey on deep learning based bearing fault diagnosis. Neurocomputing 2019, 335, 327–335. [Google Scholar] [CrossRef]

- Lin, J.; Chen, Q. Fault diagnosis of rolling bearings based on multifractal detrended fluctuation analysis and Mahalanobis distance criterion. Mech. Syst. Signal Process. 2013, 38, 515–533. [Google Scholar] [CrossRef]

- Dou, C.; Wei, X.; Lin, J. Fault diagnosis of gearboxes using nonlinearity and determinism by generalized Hurst exponents of shuffle and surrogate data. Entropy 2018, 20, 364. [Google Scholar] [CrossRef]

- Sadegh Movahed, M.; Jafari, G.; Ghasemi, F.; Rahvar, S.; Reza Rahimi Tabar, M. Multifractal detrended fluctuation analysis of sunspot time series. J. Stat. Mech. -Theory Eperiment 2006, 2006, P02003. [Google Scholar] [CrossRef]

- Rafiee, J.; Tse, P. Use of autocorrelation of wavelet coefficients for fault diagnosis. Mech. Syst. Signal Process. 2009, 23, 1554–1572. [Google Scholar] [CrossRef]

- Rafiee, J.; Arvani, F.; Harifi, A.; Sadeghi, M. Intelligent condition monitoring of a gearbox using artificial neural network. Mech. Syst. Signal Process. 2007, 21, 1746–1754. [Google Scholar] [CrossRef]

- Kumar, A.; Zhou, Y.; Gandhi, C.; Kumar, R.; Xiang, J. Bearing defect size assessment using wavelet transform based Deep Convolutional Neural Network (DCNN). Alex. Eng. J. 2020, 59, 999–1012. [Google Scholar] [CrossRef]

- Kumar, A.; Kumar, R. Enhancing weak defect features using undecimated and adaptive wavelet transform for estimation of roller defect size in a bearing. Tribol. Trans. 2017, 60, 794–806. [Google Scholar] [CrossRef]

- Kumar, A.; Gandhi, C.; Zhou, Y.; Tang, H.; Xiang, J. Fault diagnosis of rolling element bearing based on symmetric cross entropy of neutrosophic sets. Measurement 2020, 152, 107318. [Google Scholar] [CrossRef]

- Lin, J.; Chen, Q. A novel method for feature extraction using crossover characteristics of nonlinear data and its application to fault diagnosis of rotary machinery. Mech. Syst. Signal Process. 2014, 48, 174–187. [Google Scholar] [CrossRef]

- Lin, J.; Dou, C. The diagnostic line: A novel criterion for condition monitoring of rotating machinery. ISA Trans. 2015, 59, 232–242. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dou, C.; Lin, J.; Guo, L. A Novel Feature for Fault Classification of Rotating Machinery: Ternary Approximate Entropy for Original, Shuffle and Surrogate Data. Machines 2023, 11, 172. https://doi.org/10.3390/machines11020172

Dou C, Lin J, Guo L. A Novel Feature for Fault Classification of Rotating Machinery: Ternary Approximate Entropy for Original, Shuffle and Surrogate Data. Machines. 2023; 11(2):172. https://doi.org/10.3390/machines11020172

Chicago/Turabian StyleDou, Chunhong, Jinshan Lin, and Lijun Guo. 2023. "A Novel Feature for Fault Classification of Rotating Machinery: Ternary Approximate Entropy for Original, Shuffle and Surrogate Data" Machines 11, no. 2: 172. https://doi.org/10.3390/machines11020172

APA StyleDou, C., Lin, J., & Guo, L. (2023). A Novel Feature for Fault Classification of Rotating Machinery: Ternary Approximate Entropy for Original, Shuffle and Surrogate Data. Machines, 11(2), 172. https://doi.org/10.3390/machines11020172