4.1. Overview of IVHM

An integrated vehicle health management (IVHM) system normally uses sensor data to detect faults in components and subsystems (i.e., diagnostics), to predict the remaining useful life (i.e., prognostics) and assist maintenance engineers and operators. Many discoveries on diagnosis, prognosis, and the mitigation of faults in different aircraft systems are achieved through the model-based [

27] and signal-based fault detection and isolation techniques. For example, as a signal-based method for diagnosis, ref. [

17,

28,

29] used signal processing to provide promising tools in the form of decomposition algorithms, benefiting from their low computation cost, empirical mode decomposition, and variational mode decomposition. These qualities allowed the researchers to undertake a real-time diagnosis with an on-line, electrical signal time-series data analysis. Thus, the input variables were the current and voltage collected, and weather data simulated by a regional climate model. Decomposition algorithms, such as the fast Fourier transform and wavelet transform algorithms, were used to extract additional features from time series. The information collected comprised the gain and the phase of the signal for each frequency value. These characteristics carried information that was not available for the data in the time domain. However, the scope of the research was limited to stationary or periodic signals. Although the wavelet transform (WT) tool, which is applicable to non-stationary and transient signals was used, its usage is highly dependent on the time series characteristics and cannot be easily deployed for a HFCAS.

The use of a signal-based fault diagnosis for system models evolves from the need to condition sensor measurements and real-time domain analyses to identify measured variables that are sensitive to faults and features extraction [

30]. Here, time series signal processing, such as a fast Fourier transform, that changes data into a frequency domain, —which carries characteristics that are not found in the time domain for fault diagnosis—is analysed [

31]. This enables the selection of the most suitable tool for highlighting the symptoms (data processing) and interpreting the symptoms to make a diagnosis. Therefore, ref. [

31] uses signal-based methods for extracting features and further inputs these features into a classifier for fault recognition.

In a research study, ref. [

32] the diagnosis of a faulty ignition system due to degradation was discussed. The researchers evaluated the possible fault effects caused by the starter motor or fuel-igniter system in a feasibility study. The methodology used involved the signal processing of acoustic data, for which microphones were used as the sensing elements. It was suggested that the derived parameters could be compared to find healthy limits in detecting fault and degradation in systems. This technique was used on an auxiliary power unit of an aircraft; however, as the sensor data used was acoustic, the technique’s possible application in evaluating a HPFCAS diagnosis remains to be investigated.

One disadvantage is that, in the case of signal processing, the features are manually designed and thus may have a lack of objectivity. Secondly, feature extraction and pattern recognition are conducted using independent models, which cannot be jointly optimized globally for all systems. Machine-learning algorithms could therefore be adopted by these methods, which would enhance their capacity to deeply mine the essential features of a fault. A breakthrough in artificial intelligent (AI), shows that deep learning, a component of the AI, holds the potentials to overcome such deficiencies.

Based on deep learning, deep neural networks can automatically learn the complex, nonlinear relations implied in a signal, which can then be globally optimized. This will achieve the high-level features of multi-dimensional data in a complex system such as a HPFCAS, whose characteristics of strong fault concealment, powerful, nonlinear time-varying signals, and a complex vibration transmission mechanism for fault diagnosis exist. These qualities have spurred a substantial research interest and efforts in the IVHM approach to systems. Thus, IVHM has become diverse across many investigations, so that it can be applied to different systems such as the FCAS. Consequently, different model-based methods have been identified, amongst which are mathematical or physics models, data-driven models, and combinations of the two methods, known as hybrid models [

22].

In model-based fault diagnosis methods, models are developed and deployed based on some fundamental understanding of the physics of the plant or process [

33]. These methods can further be classified as qualitative or quantitative. The role of a specialist with expert knowledge is extremely valuable. Thus, the model hypotheses and goals must be clearly stated. The characteristics of the target engineering application will determine the type of modelling and its degree of sophistication [

22,

26,

34]. In the quest for model-based diagnosis methods, questions, such as: how complex is the system? Is the physics well understood? What kind of data are available, and what is the acquisition rate? Is it a real time application? What is the level of uncertainty (of inputs, parameters, models, and outputs)? Come to mind [

12]. Thus, ref. [

30] used these approaches, which required many technical aspects, such as data, mathematical expressions, equations, and algorithms to combine with signal processing in the diagnosis of a hydraulic system. Hydraulic state parameters, such as the state of the hydraulic actuator and hydraulic system leakage, were measured and used to extract corresponding features using a mathematical model. Other parameters included: the change in flow of a hydraulic system, the vibrations and noises occurring in hydraulic system components (such as the hydraulic pump), and the pressure signal of the hydraulic cylinder, valves, and the hydraulic actuator.

Thus, the corresponding relationship between the measured signals and faults to achieve a diagnosis is described. This type of fault diagnosis compensates for the inefficiency of using manual data statistics for applying an objective parameter measurement and the advantage of signal processing. However, these are not sufficient for a model-based approach to be totally useful. Hydraulic FCASs are non-linear, time-varying systems with shortcomings, such as their difficulties with feature extraction. Therefore, unless the knowledge of the model creation establishes a complex mathematical model, other factors are known for subsequent application.

It is important that a model-based fault-diagnosis approach deals with the correct issue and help to solve the correct problem. Hence, a high-quality model will not be helpful if it relates to an issue that is not the main concern of the approach [

22]. Conversely, asking a model to answer increasingly detailed questions can be counterproductive, because this would require even more features of the real system to be included in the model.

Thus, since the model-based approach adopts mathematical or physics modelling, models need to be “requisite”; that is, they must have an identified context and purpose, with a well-understood knowledge base. They must also be supervised by users and audiences, and possibly developed within a particular time constraint. Today, this is solved by the application of some machine-learning techniques if historic data is available; the models are otherwise tested on required physics assets [

35]. In modern-day research activities, the application of AI in the field of machine learning under unsupervised learning can be used for such model-based approaches to diagnostics.

In the data-driven diagnosis and prognostics method, which usually uses a large amount of data to learn the degradation pattern (nominal model), a learning model that can utilize historic data and predict future health [

33,

36,

37,

38] is required. Usually, this run-to-failure data is typically accelerated data produced in a laboratory environment, from which healthy and degraded data are collected under emulated operational conditions. In [

13], it was shown that understanding a system’s fault modes can provide feedback for the design of new products. This can easily be achieved by working with required data, which can then be made more robust to faults. These data will enable intelligent fault-detection features to be embedded in the system. This is corroborated by [

22], in which a data-driven model was chosen based on machine learning and statistical algorithms to identify and evaluate system faults. Data was collected, extracted, and analysed from a real system—the auxiliary power unit of an aircraft. Recognized patterns were detected in the data, and these were correlated with known fault modes, after which statistical methods were used to assigned probabilities to components being either healthy or faulty.

Data-driven diagnosis models are purely statistical and AI-based; however, the expert system methods, which involve rule- or case-based reasoning, can also infiltrate the data-driven approach, since their application is only on available data [

13,

35,

39,

40]. In [

41,

42,

43,

44], this was proven by using machine-learning intelligent classification algorithms to classify a dataset used in data driven models. Specifically, ref. [

45] evaluated the performance of three kinds of damage samples. Namely, the inner ring damage, outer ring damage, and the healthy condition of the mechanical equipment (bearing). These artificial damages were injected manually by three different methods: electric discharge machining, drilling, and manual electric engraving. These samples were obtained from data collected for real bearing damage samples caused by accelerated lifetime tests using scientific test rigs [

46]. The experiments conducted using the dataset demonstrated an intelligent fault-diagnosis method based on training that utilized one feature extractor and one classifier for classification accuracy.

However, one gain associated with the data-driven model approach for diagnosis is the important use of machine learning techniques. These are of two types: supervised learning, which trains a model on known input and output data so that it can predict future outputs; and unsupervised learning, which finds hidden patterns or intrinsic structures in input data [

22,

34]. These correlate with system-observed measurements for a health state and solve regression and classification problems [

35,

44].

Considering healthy or faulty scenarios, values are assigned for the probability of a system or component being healthy or faulty (statistical analysis). These techniques have been proven to be successful in isolating both component and sensor faults. Apart from this, other AI with variations in algorithms used in data-driven model approaches for diagnosis exist [

46,

47]. Examples of these include, neural networks, artificial neural networks (probabilistic and dynamic), principal component analysis (or different dimensionality reduction algorithms), non-linear principal component analysis, and the partial least squares. These and many others are not explicitly discussed in this paper. However, their fundamental characteristics and their main objectives fall into the methods described under data-driven models.

For an improved diagnosis using data-driven methods, specifically, more feature extractors concerning features and the training of more classifiers for fault pattern recognition will enhance fault diagnosis capability, since separate classifiers are trained for feature extractor algorithms than for fault pattern recognition. Real-life conditions can sometimes be hard to mimic; therefore, a combination of both mathematical and data-driven models to form a hybrid model for analysis has been shown to be more useful [

20,

35,

48].

It is worthy to note that the mathematical models of model-based fault diagnostic approaches comprise statistical models or physical models to account for system conditions, diagnostics, and the tracking of degradation. Usually in a physical-model-based diagnostic approach, the simulation is based on the identification of potential failure mechanisms and failure modes for the physical system; that is, the effect by which a failure is observed to occur in the system. One research study conducted [

11] used a model to monitor physically meaningful parameters that offer excellent early fault-detection capabilities even when the system operation meets or exceeds the minimum requirements. This was because small parameter shifts exist which potentially indicate the early stages of fault progression [

38]. These can still be detected or traced. Therefore, if health classifications are performed using these physical parameters, multiple competitive failure modes can be monitored [

11,

41].

The challenge here is that some attributes of the physics-based models are constructed using first principles or mathematical laws. They are also combined with phenomenological closure models (e.g., constitutive models such as friction models, damping models, boundary conditions, and joints), whose parameters have a clear physical interpretation. This makes it difficult to build high-fidelity, time-consuming computational models of complex engineering systems for diagnostic analysis. Therefore, combinations of models can be made to achieve better results. If models are homogeneously combined, they remain the same as the parent models. For instance, combining either two physics models or two data-driven models will still produce physics or data-driven models respectively; however, in combination, they can produce more accurate results or achieve a faster response [

13,

35,

49,

50,

51]. Hybrid models are produced for heterogeneous combinations. They are a combination of physics-based and data-driven models for diagnosis approaches. In one research study, ref. [

46] authors tested a methodology on two engineering datasets—one for crack growth and the other for filter-clogging—to prove the efficacy of a hybrid model. The performance of the methodology showed that hybrid models improve accuracy, robustness, and applicability, especially in the case of where minimal data are available. Hence, because data-driven models employ historical data to construct a statistical or AI-based model aimed at capturing the degradation process, they involve a large amount of failure degradation data, which may be difficult to obtain. On the other hand, physics or mathematical models require expertise in the application field and tend to be computationally excessive to apply. The hybrid model tends to be better in analysing the forecast of failure degradation in a system.

In summary, IVHM activities have, for many years now, focused on a wide range of diagnostic methods. These have been proposed for either the system or component level. Currently, the most rapidly emerging concept within the diagnostic community is that of system-level diagnostics. This is targeted at accurately detecting faults and establishing the timely replacement of the faulty components to effectively restore the system to a healthy state. System-level diagnostics is of great value for faults that are complex in nature. These faults have a prominent impact at system-level functionality. A prominent outcome of systems-level diagnostics is that it enables a comprehensive understanding of the overall system’s fault modes, causes, and effects. These are used as feedback to improve the design life cycle of new products, offering robust diagnostics capability. This underscores the relevance of IVHM diagnostic tools for different model-based approaches. However, machine learning and AI should comprise the key tools to be employed for robust fault-diagnosis approaches.

4.2. Diagnostics

Diagnosis is defined in this paper as the practice of identifying the nature of a problem (fault) through the examination of its symptoms, conditions, and signs. It is an act that recognizes attributes or characteristics which signify a malfunction or failure in a system or components due to the presence of faults. Hence, diagnostic methodologies are the techniques or methods of identifying or creating conditions for distinctive symptoms and characteristics. These would distinguish healthy and degraded scenarios in a component or system. Ongoing research shows many ways by which diagnostics are carried out [

16]. Some techniques depend on imaging or image tests, others rely on pulse signals, while many depend on parametric conditions, such as temperature, pressure, volume, power, speed, voltage, and current [

19]. Hence, diagnostics would depend on the data or sensor set that is employed to generate the data. These come with procedures associated with the different diagnostics tools used. Model-based methods use a physics model of the system or component under examination to conduct the analysis. Physical parameters calculated by the model are compared with system observations and, by using various techniques, faults can be detected, and their root cause can be isolated. Model-based methods can be further separated into two major categories. One category is found in an approach developed by the Control Engineering community: fault detection and isolation (FDI) [

52]. Another category, which is also relevant, is an approach developed by the diagnostic AI community. Both approaches depend on the knowledge of how the physics models of the systems are created or formed.

Diagnostics in aircraft systems transform raw sensor data into useful information regarding the present condition of aircraft systems and their components for the purpose of addressing likely causes of failure. It is reasoned that diagnostics, prognostics, and the mitigation of systems are applications of different knowledge-based reasoning in the IVHM approach to solving system problems.

Diagnostics for Mechanical and Hydraulic FCAS

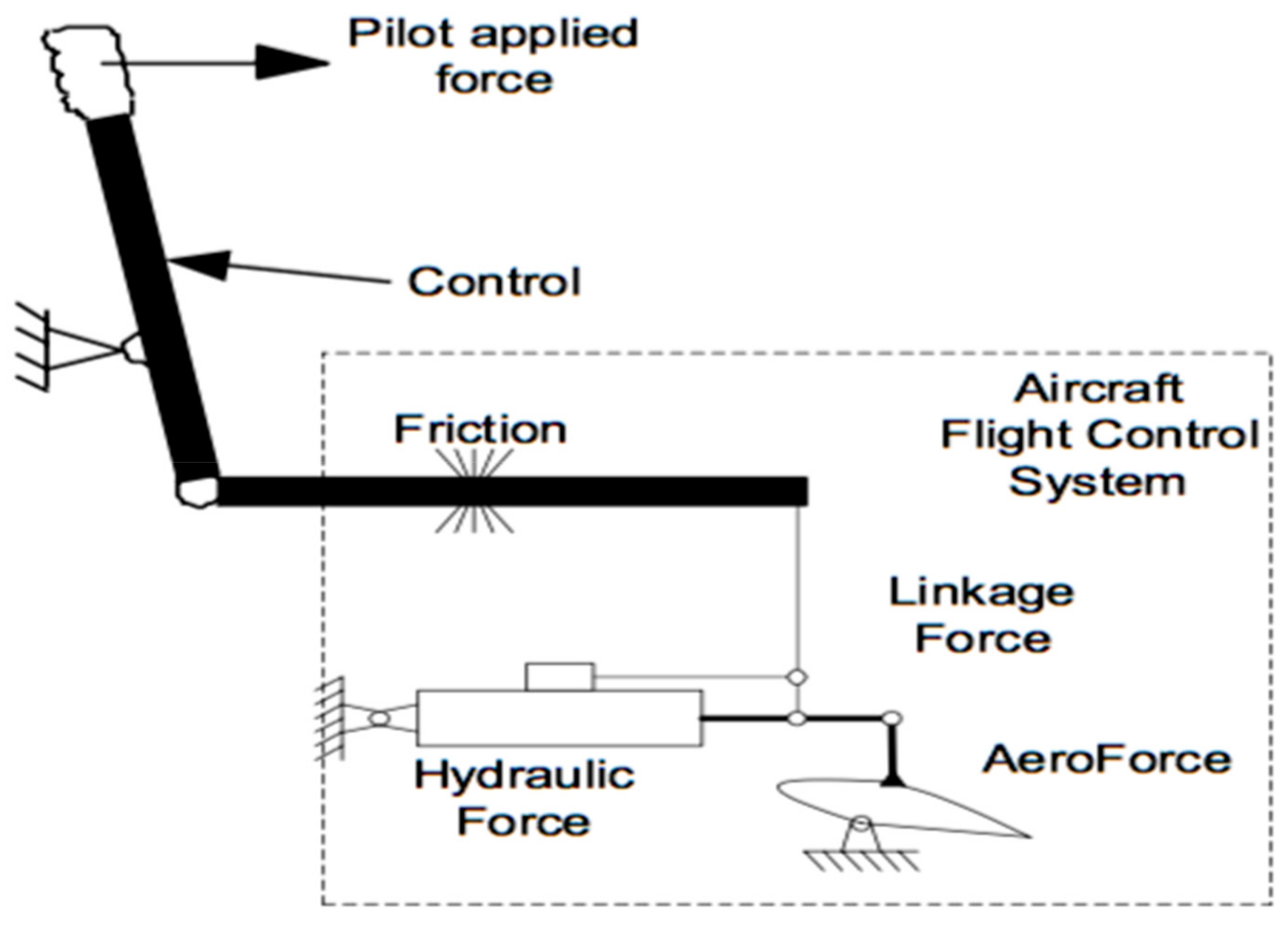

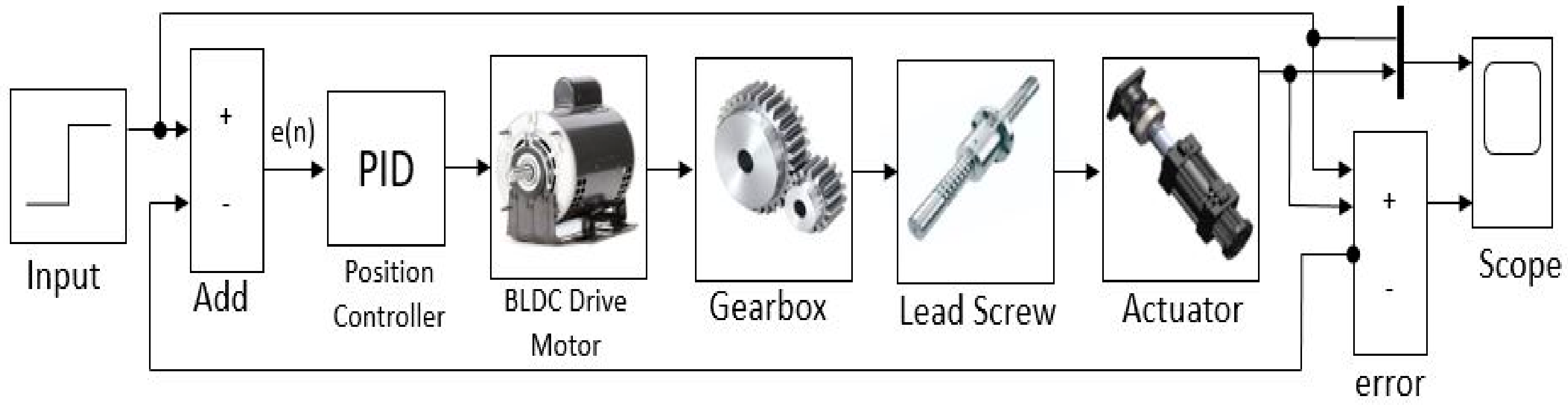

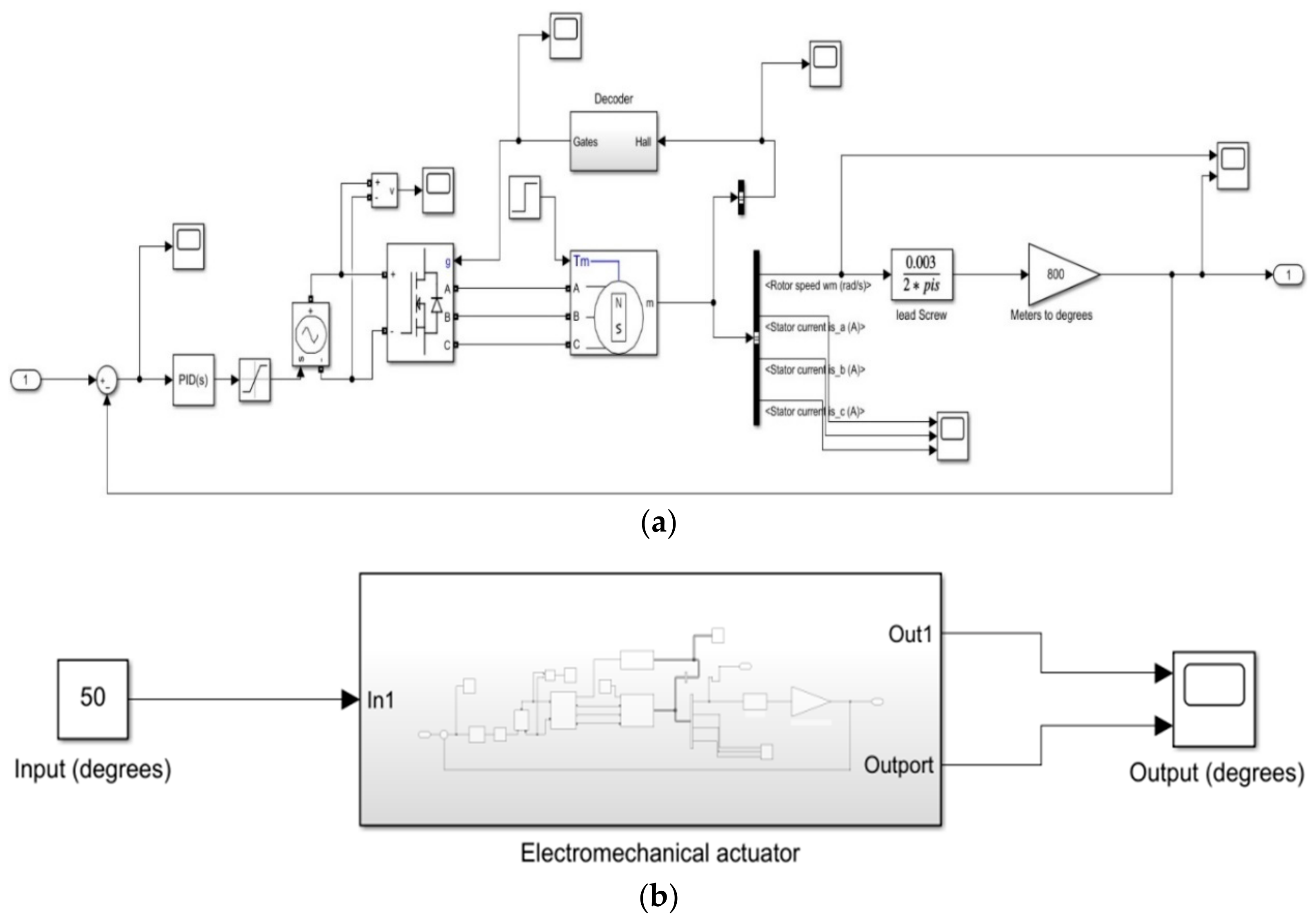

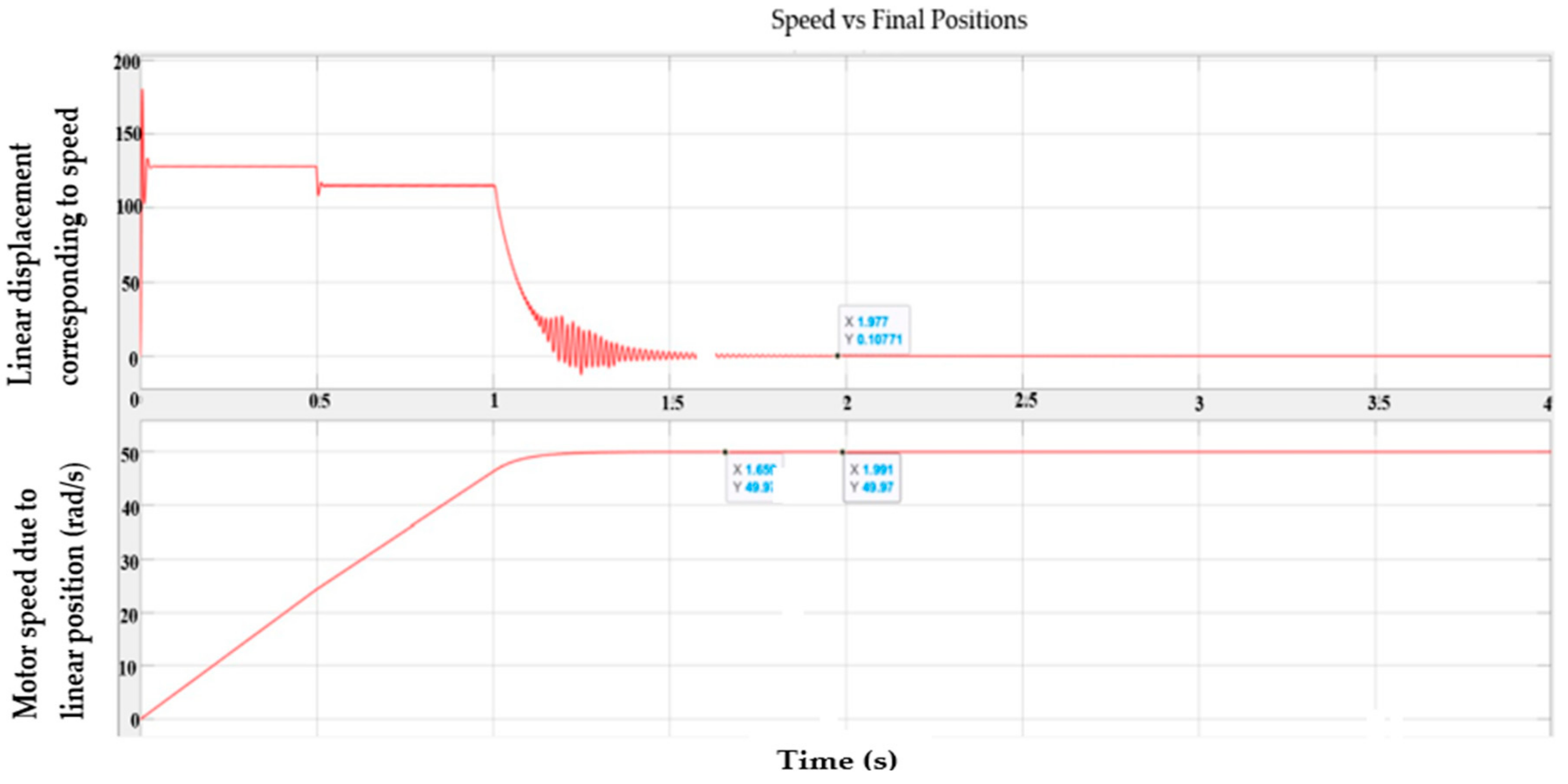

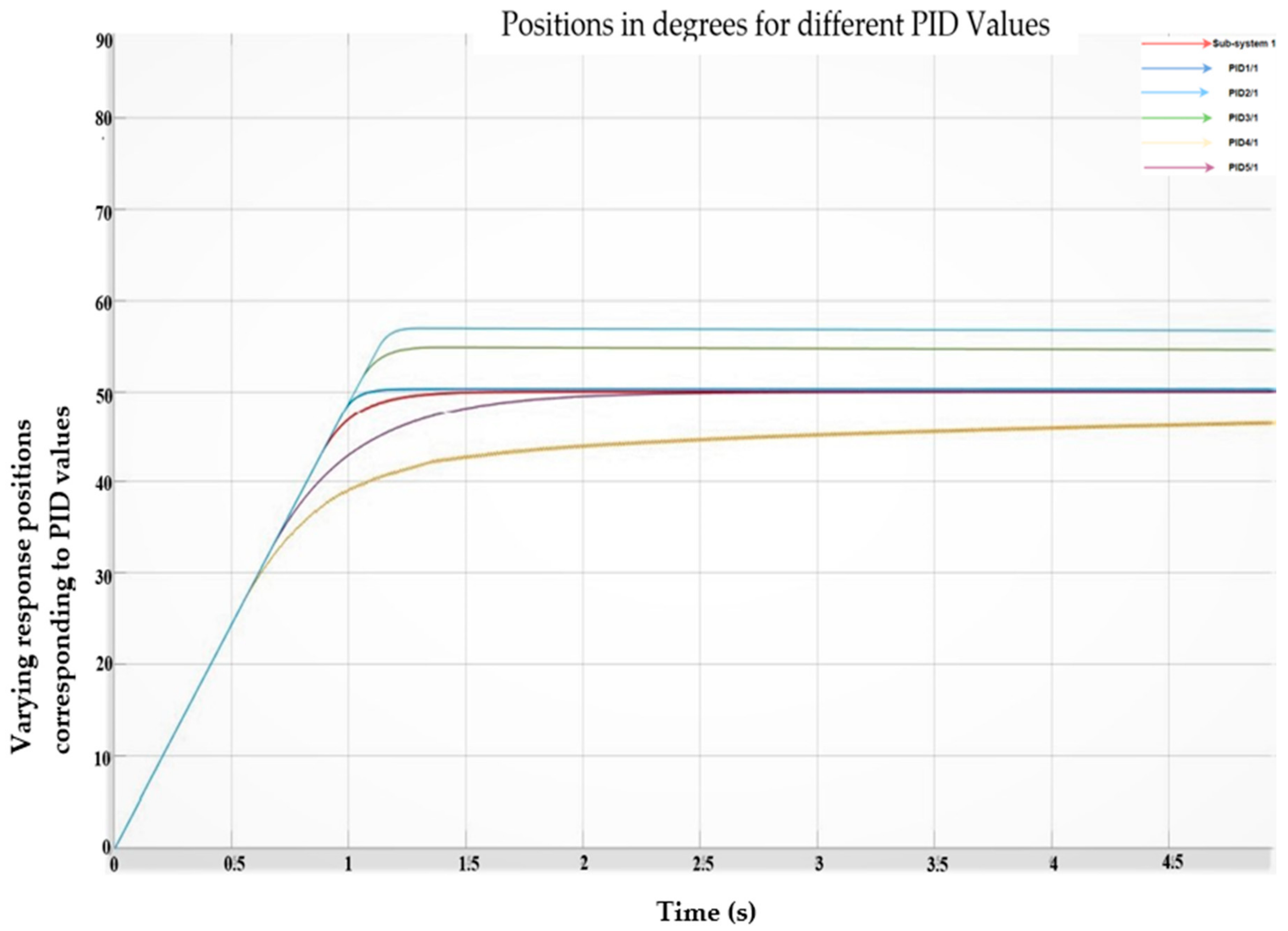

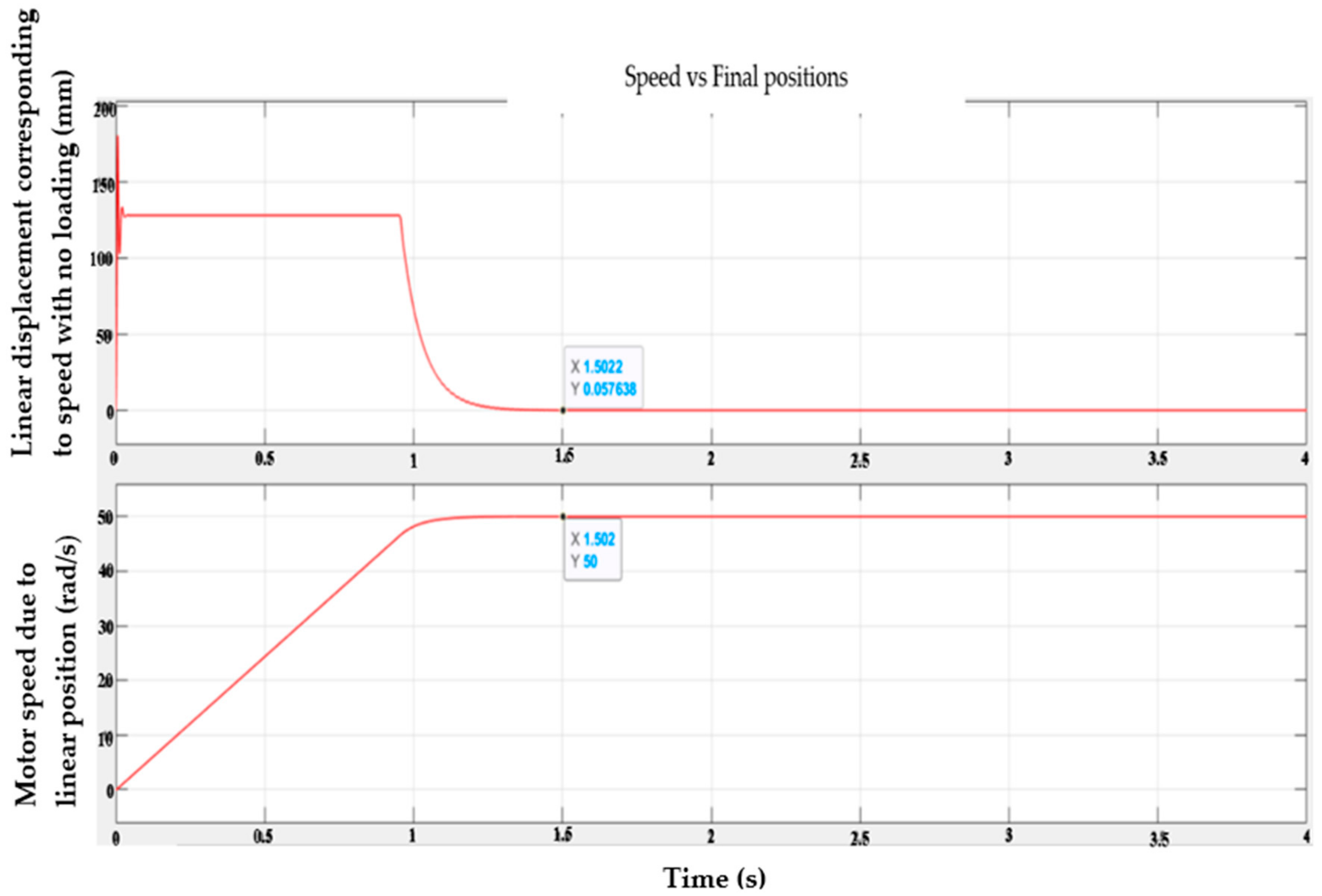

Diagnostic work on an electromechanical actuation system has been carried out, using robust modelling for actuator fault detection and failure prediction, following a model-based approach [

11,

42,

43,

53]. The physical modelling of the system and identified parameters, such as command signals, friction, damping coefficient, and step change in actuator position, were used to develop a model with responses that were focused on the bearing friction. These advanced parameters were used to create the simulation model, the techniques, and a suitable algorithm to predict the time-to-failure for each failure mode in the system [

18,

20,

21,

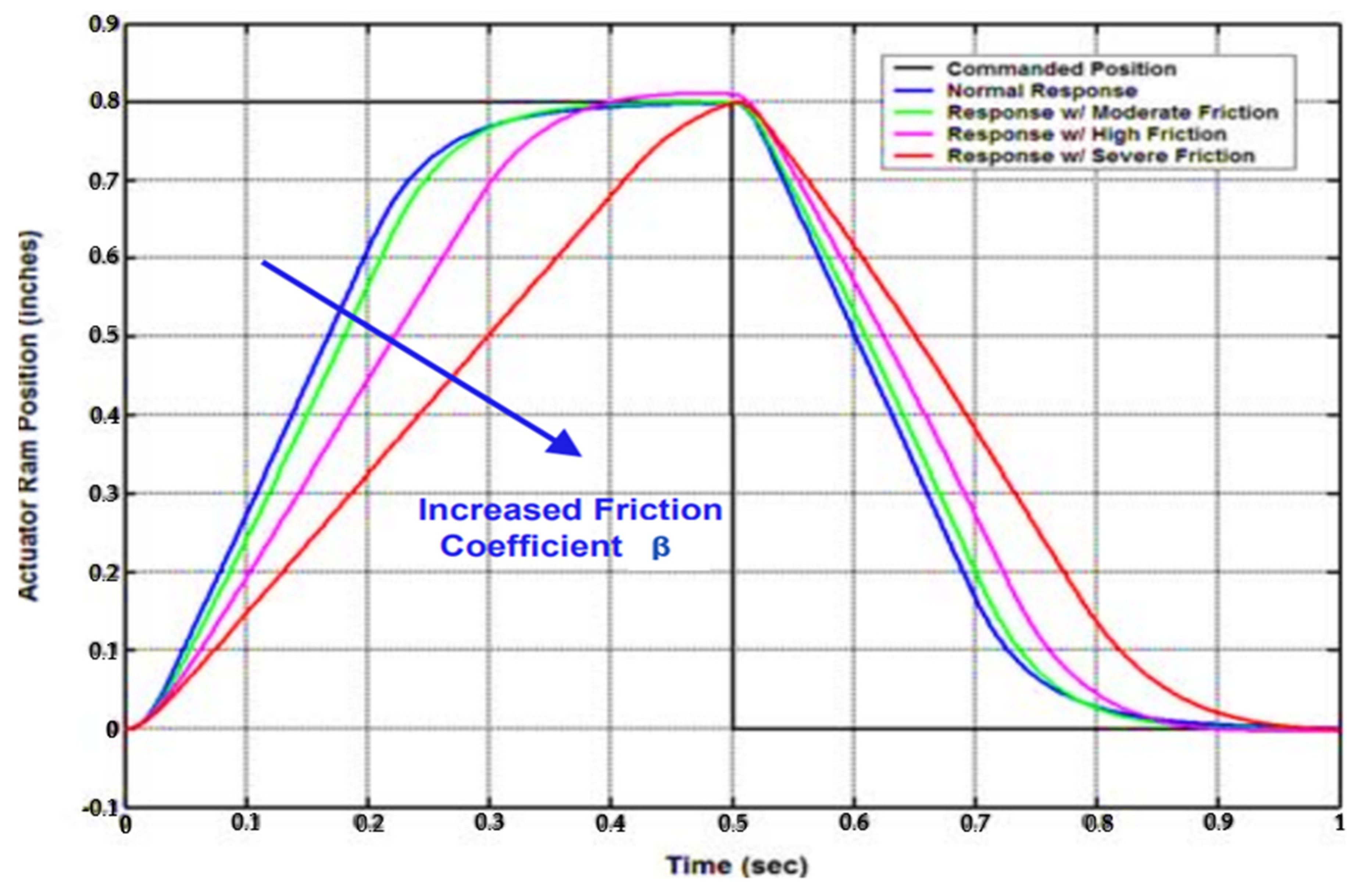

22]. The simulation of bearing failure was created using a single model parameter, such as the friction coefficient, and the results were compared with the normal system response, as shown in

Figure 11.

In

Figure 11, the normal operation of the actuator is shown in blue for a known value of friction coefficient and depicts the actual response when provided with the step input command in black. The green, pink, and red curves show the responses due to changing values of the friction coefficient due to degradation in terms of moderate, high, and severe quantities, respectively. It is an approach to condition-based maintenance which provides an early detection of developing faults. However, the algorithm operated only on flight-control command or response data. The approach employs a mathematical, dynamic model of the actuation system that was directly tied to the physical processes associated with the health of the components—in this case, the actuator and its bearing. According to [

47,

50,

51], this resulted in an intelligent monitoring system that often works well under any load profile, including steady-state and transient performance. It also works with unanticipated conditions of loading and operational regimes, as the only selected parametric factor is friction. However, what if the selected parametric factors were more than one? This would mean that the model configuration would change along with its mathematical derivations. Consequently, more analyses would be involved to address the contributions of the sensor sets from the additional parameters.

The approach was corroborated in [

23,

35,

54], which agreed on using a model, whose physical meaningful parameters are monitored, to offer excellent early fault-detection capabilities. Such that, a set of values for these parameters are taken as dataset values, under which normal operating conditions are defined. A temporal variation of extreme values from these datasets is obtained by measuring the sensor outputs of two sensors, with the actuator responses due to command inputs. If these two sets of values are represented by plotted points whose

x-coordinates represent their minimum values and

y-coordinates represents their maximum values within a time response, the plot forms a cell.

For different conditions of operation and changing values of parameters chosen for measurement, the different measurement values from the sensors can be observed and plotted. Cells produced in this way have multiple values with corresponding points—especially in a time-varying field such as actuator response—creating a span in a space so that a point represents the extreme values at one time-step. For analysis, a cell’s scalar variation over time is characterized as residues so that the area over which corresponding points spread in the span space provides a good measure. This means that the wider these points spread, the higher the cell’s temporal variation is. This is called the parity space for the actuator system response.

The residuals that are created come from pairing all the functional relationships between components at a specific time step or over a specific time range that is observed between the inputs and outputs of a system. It represents the divergence between the expected behaviour and the observed sensor outputs when degradation affects components. A quantitative measure of the achievable level of the residuals implies the presence of fault attributes.

However, parity space must be optimized to narrow the divergence for actuator fault detection and isolation. It is observed that there are small parameter shifts when the system performance falls short of the requirements. These indicate the stages of fault progression. Thus, if these are detected and tracked, health classification and prognostics can be performed using the values of the physical parameters measured and a suitably designed algorithm.

The approach may be applicable to the isolation of the most advanced failure mode, but it can also be used to identify the fastest progressing ones. These could be failure modes that ultimately have the shortest time-to-failure. For this reason, if multiple, competitive failure modes are monitored, it could be difficult to separate and identify them distinctively.

In [

20], a model-based fault-detection and diagnostic method was applied using input and output signals to dynamic-process models. These methods agreed with [

21,

30,

45,

55], not only on parameter estimation and parity space equations, but also on state observers. In this case, signal-modelling approaches were developed that generated several symptoms indicating the difference between the nominal and faulty status for a mechanical system. Model-based methods of fault-detection were developed by using input and output signals and the application of dynamic-process models. The signal approaches were processed to generate several symptoms indicating the difference between nominal and faulty statuses. Based on different symptoms, fault diagnostic procedures were followed, in which the different symptoms observed determine the fault by applying classification or inference methods.

These approaches, involving model-based techniques, are complex and time-consuming because the knowledge of the basic attributes, such as the model parameters (both old and current) if such a system is already in used, is not necessarily available. The control model itself, the diagnostic classifiers for fault identifications, and scalars all must be known for all the components of the model.

The diagnostic methods currently available are mainly for different components and systems in the aircraft. In each of the methods, the knowledge and techniques applied depend on engineering and computer skills, especially in manipulating data attributes to determine healthy and faulty systems. One of these components’ diagnostics analysis [

31] used a layered clustering algorithm to propose the diagnosis of multiple faults in a hydraulic system, but with emphasis on an aircraft hydraulic pump. These faults occur simultaneously; thus, the failure analyses of these types of faults are carried out based on diagnostic sensors designed according to the faults’ risk priority numbers and the characteristics of different fault-feature-extraction methods. If most serious failures are distinguished with the individual signal processing, the clustering diagnosis algorithm will be based on the statistical average presence of the fault features calculated from vibration signals.

However, if the different faults follow different probability distributions, when compared to the fast Fourier transform-based signal processing diagnosis method, the faults will require pattern recognition. A combination of the signal-processing method and a classification algorithm can diagnose the multiple faults, occurring synchronously, with a higher precision and reliability. According to [

45,

56], two of the most typical classifiers for pattern recognition are an artificial neural network (ANN), an intelligent algorithm with an input layer, hidden layer and output layer. Another is a support vector machine (SVM), a computational learning method for the classification of small samples. These are machine learning (ML) algorithms, but the construction and training of both the SVM and ANN, respectively, are dependent on the experience of the user. For the SVM, a supervised ML algorithm that can be used for both classification or regression challenges, ref. [

30] stated that the usage of the SVM for fault diagnosis of a hydraulic system is complex and deficient because training an SVM for large-scale samples is hard to achieve. Secondly, SVM is not ideal for a multi-classification problem.

However, in data-driven models of HPFCASs, there are large numbers of samples required and with an increase in system components, fault propagation together with degree of damage; the number of fault modes will significantly increase.

If the systems are made up of other subsystems, the faults generated by these subsystems, also add up to the diagnostic analysis. More knowledge, skills, and techniques in algorithm development are required.

Thus, in the current diagnosis method, emphasis is placed on consolidating on the knowledge of past efforts by involving the typical model approaches of physics/mathematical, data-driven, and hybrid. Also, to leverage on the intelligent techniques employed through signal processing, vibration analysis, and the use of algorithms such as fuzzy logic, neural networks, ANN, and SVM [

57]. These are now building blocks for the use of AI and ML in modern diagnosis. Although, several machine-learning- and deep-learning-based modules are used to explore good results in fault detection and diagnosis, nevertheless, users and human experts must be knowledgeable in understanding the insights of the modules.

Another reason is related to the lack of availability of labelled historical data; this deficiency, makes the use of supervised models unfeasible. For example, ref. [

46] used explainable AI to investigate faults in rotating machinery (mechanical) using feature extraction, fault detection, and fault diagnosis. This still involved signal processing for vibration features in the time and frequency domains for extraction. Additionally, the verification of a fault presence in an unsupervised manner is based on algorithms used to detect anomalies. The explanation to interpret models through unsupervised classification and root cause analysis was intensive. These effectively showed different mechanical faults in the three datasets generated and used for the research work.

However, in most cases, AI algorithms for fault diagnosis, such as the= k-nearest neighbour approach (k-NN), which is defined as an instance-based learning algorithm is on the principle that the instances within a dataset will, generally, exist near other instances; that is, with similar properties for a given training set of classified instances [

58]. For Naive Bayes classifier, classification method based on Bayes’ Theorem, and the conditional independence assumption for a given training set, SVM and ANN, all these four have become popular due to their robustness and adaptation capabilities. Also, they do not require full prior physical knowledge (which may be difficult to obtain in practice) and are among the various algorithms applied most in fault diagnoses. Although they are used to classify faults, they are usually intended to be trained with labelled data (supervised training) and examples of conditions under which faults may occur. These are not always available or known in the industry. In addition, most AI technologies still require large volumes of data labelled for both normal and fault conditions, dramatically limiting their industry application. This is motivated by recent advances in deep learning.

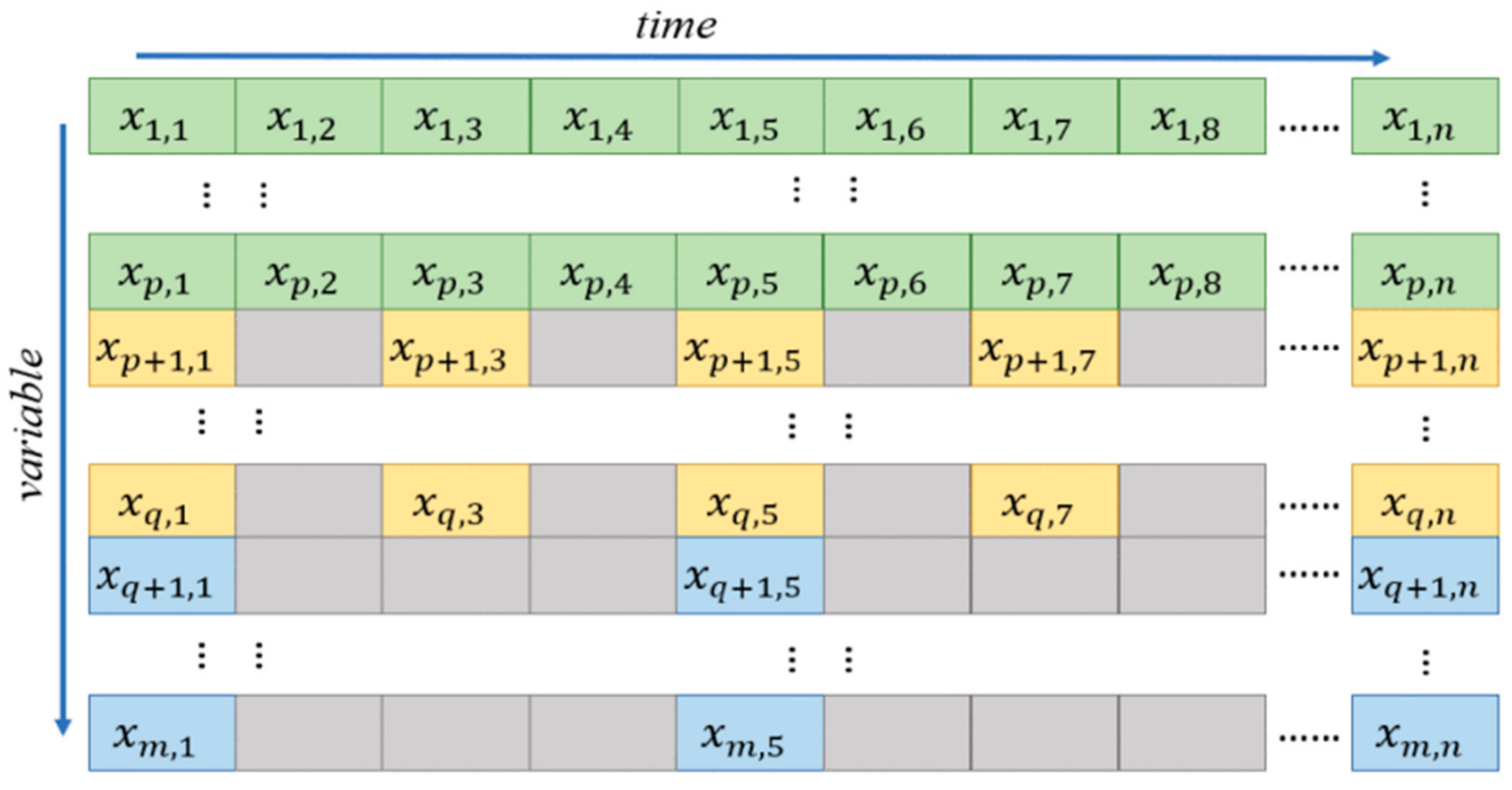

In the evaluation of hydraulic system diagnosis as a class of typical, complex, nonlinear systems, ref. [

59] proposed a deep learning model with multirate data samples to extract features from multirate sampling data automatically without expertise. It was demonstrated that high diagnostic and fault-pattern recognition accuracy could be achieved even when the imbalance degree of the sample data was large.

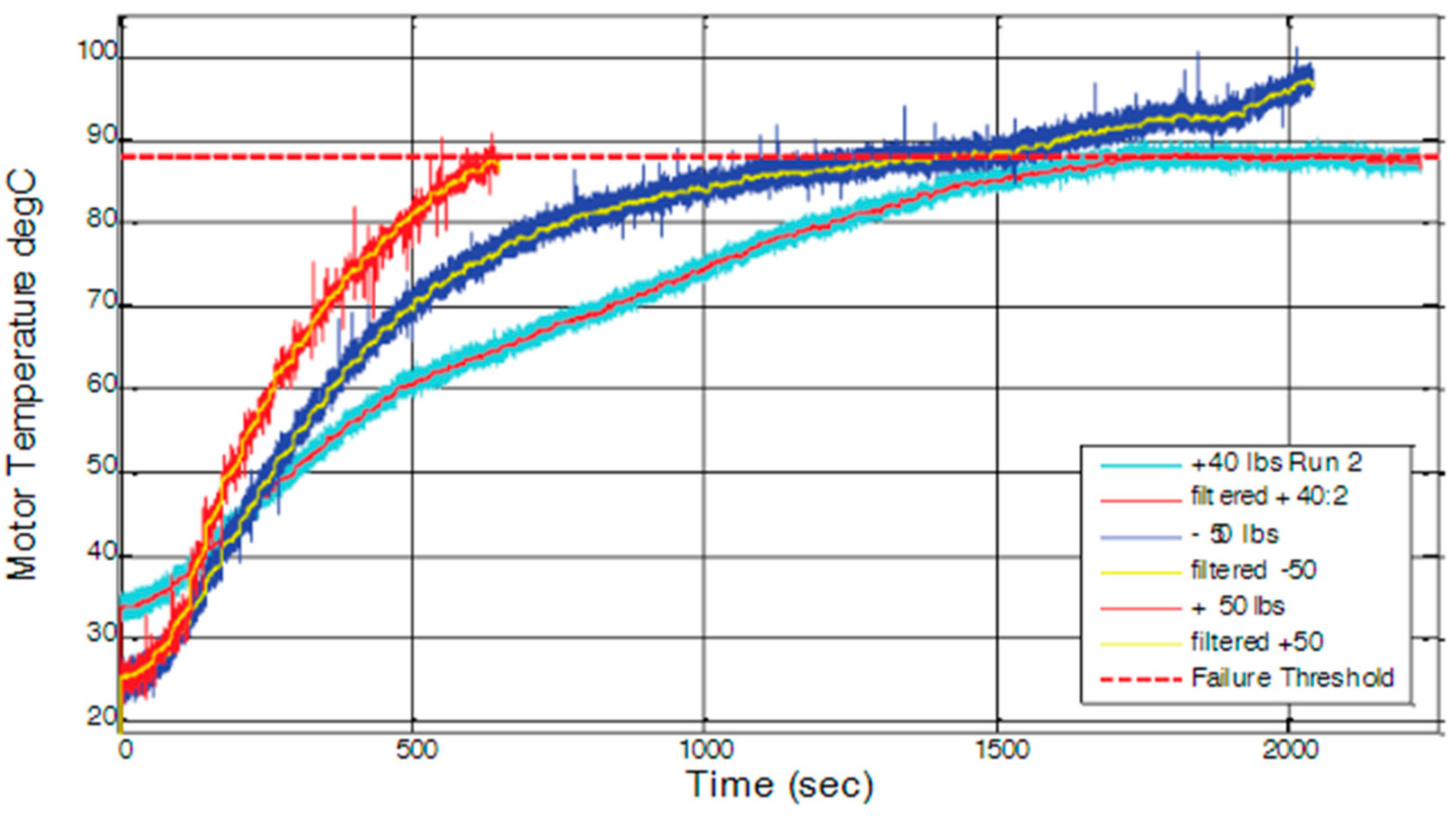

Figure 12 shows a representation of a multirate data sample structure in which grey squares represent uncollected data. The multirate data samples have the characteristics of inadequacy, consistency, and information asymmetry. Inadequacy reflects in the missing values of the variables with a low sampling rate, which are represented by the grey squares in

Figure 12. Consistency refers to the variables at each sampling rate which are uniform and complete, as can be seen in the green squares. Information asymmetry indicates that variables with different sampling rates contain disproportionate information. In a functional process, high-sampling-rate variables are usually mostly process variables which do contain limited process information, whereas low-sampling-rate variables are more quality-related variables; hence, they contain more valuable information. Therefore, in an analysis, down-sampling methods subsample variables with higher sampling rates so that all variables obey the same sampling rate. On the other hand, up-sampling methods use high-sampling-rate variables to predict the missing values of the low-sampling-rate variables.

Generally, the fault diagnosis of hydraulic systems is still challenging because data samples collected from the hydraulic system are always in different sampling rates, and the coupling relationship between the components, brings difficulties to accurate data acquisition. In addition to hydraulic systems having features of multiple sampling rates, different components of hydraulic systems may fail individually or simultaneously, and it will be more difficult to diagnose multiple components. The effect, components have on the health status of systems can be described in two ways. Therefore, the diagnosis of a system is better achieved, as suggested by researchers, if the two ways are considered. In one of the ways, ref. [

60] in his work on the diagnosis of ECS, stated that focusing on the degradation of components would mask component-level analysis. Hence, the necessary and best way to identify the health status of a system is for a system-level diagnosis to be performed. In this way, the effects of more than one fault affecting the system at the same time can be investigated. This is regarded as the second way.

Of course, earlier diagnostic tools such as the Bayesian network, expert knowledge, or other techniques were used on maintenance data to demonstrate this approach. For many diagnostics capabilities, this brand of AI, in its simplest form as first principles, was adopted, and a set of multiple neural networks were trained to recognize different faults in systems. The conclusion reached was that if each set of neural networks is trained to recognize the fault occurring in each component, or the health status, a degraded component will be known. This helps the system-level diagnosis, which is at multiple levels. Again, these approaches would depend on how good classifiers are generated and trained for the different faults observed from the components. The authors demonstrated this by proposing a diagnostic methodology which was used and applied to two systems: the environmental control system and the auxiliary power unit of an aircraft [

60]. A dedicated classifier was assigned for each examined component and the training strategy for multiple scenarios (considering multiple component faults simultaneously) that could occur in a system. The authors concluded that the classifiers identified non-linearities in the training data very accurately, and therefore defined correct decision boundaries to be taken. A limitation of this approach was in the sparse data availability for classification; severity needs to be established for different components with same fault signature or contributions to the fault scenario [

61]. Therefore, the classification of large number of components is difficult to manage. Additionally, for a system such as the HPFCAS, which has some of its system faults as dynamic faults, ways in which the proposed methodology could be used are still not yet implemented, as the examples of fault modes that were considered were not dynamic.

Therefore, by separating a HPFCAS into subsystems and applying the hybrid model approach with AI and ML techniques, a robust diagnosis to address the degradation in the system will be achieved.

4.4. Opportunities

The diagnosis and health monitoring of complex systems is an ongoing study. Efforts made by the diagnostic community to achieve success have been considerable, but more efforts are still required.

In hydraulic systems, most diagnosis methods proposed or used are based on the individual components. There is a huge gap in examining the entire system because, apart from the component faults, multiple faults occur in the system and their origins cannot be traced to any single component easily.

Diagnostic methods used for individual components may vary from one component fault to the other, which necessitates the use of different algorithms for multiple faults. How can these known faults in the system be organized to fall under a comprehensive diagnosis?

With the different techniques and the advancement of learning, it is hoped that the diagnosis of complex systems, such as hydraulic systems, with their nonlinear nature and concealment of fault characteristics, will be addressed using different modern techniques of fault detection and isolation.

The diagnostic methods available for aircraft FCASs were reviewed, and it was found that there are multiple faults that affect the system. If the system can be broken down into smaller subsystem units, more robust diagnostic capabilities will be achieved.

Hence, a strong knowledge of AI and its applications will provide good opportunities for research in these areas. By separating a system into subsystems and applying hybrid model approaches, AI technology promises to provide a robust diagnosis for the system. Lastly, having known the diagnosis of the individual subsystems, it will be possible to create a digital twin of the FCAS which can be utilized for the real-time diagnosis of the entire system.