Dimensional Optimization of a Modular Robot Manipulator

Abstract

:1. Introduction

2. Kinematic Analysis of Manipulator

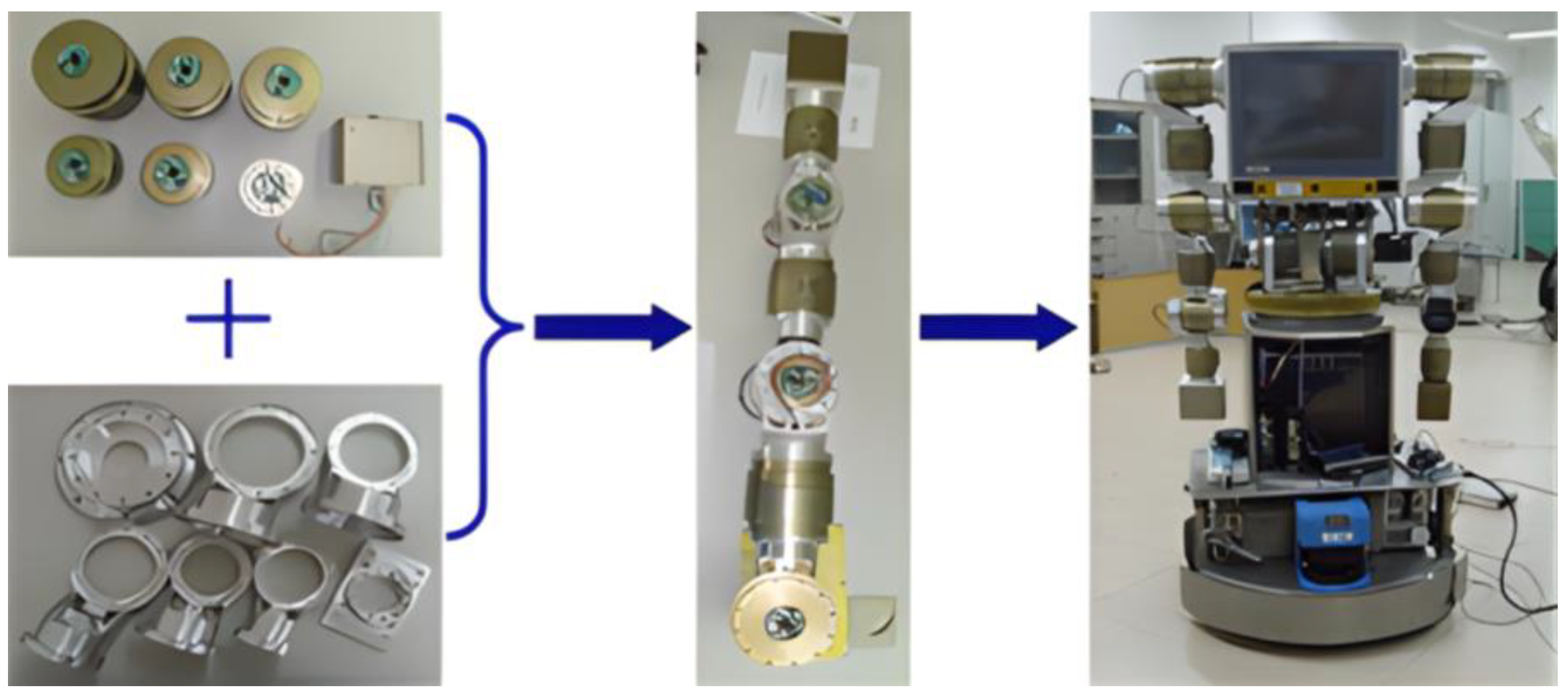

2.1. Manipulator Model

2.2. Kinematics Analysis

2.3. Jacobian Matrix

3. Discrete Coefficient of Local and Global Index and Condition Numbers

3.1. Condition Number Index

3.2. SLI Index

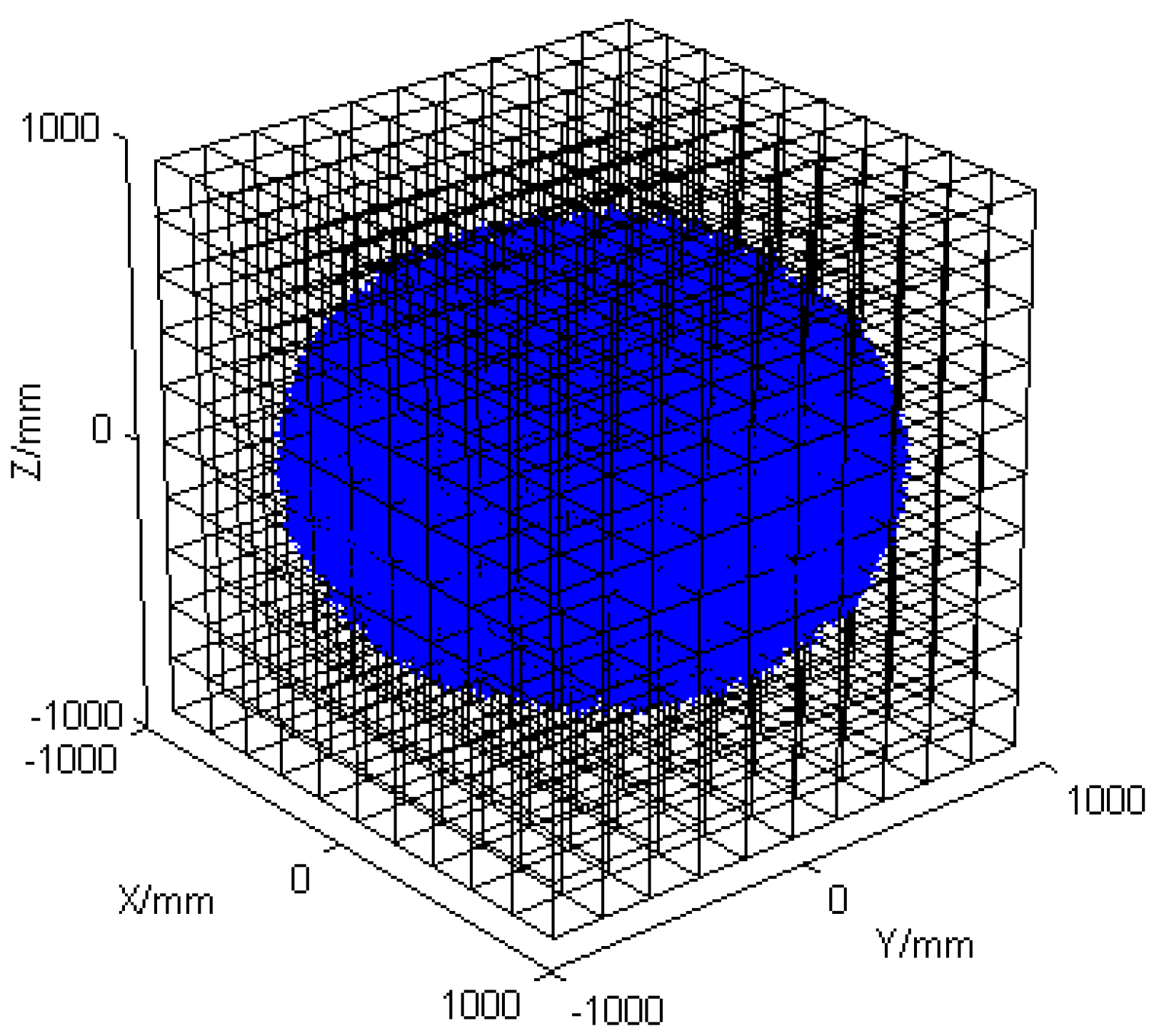

- In the MATLAB software environment of version 2021, the Robotics toolbox was used to build the model of the manipulator. The position coordinates of the end of the manipulator were obtained based on the Monte Carlo method and using the kinematics equation of the manipulator. Then the MATLAB visualization function was applied to display the position coordinates of these points by tracing them. The extent of the workspace point cloud and the projected limits of the workspace on each axis were obtained.

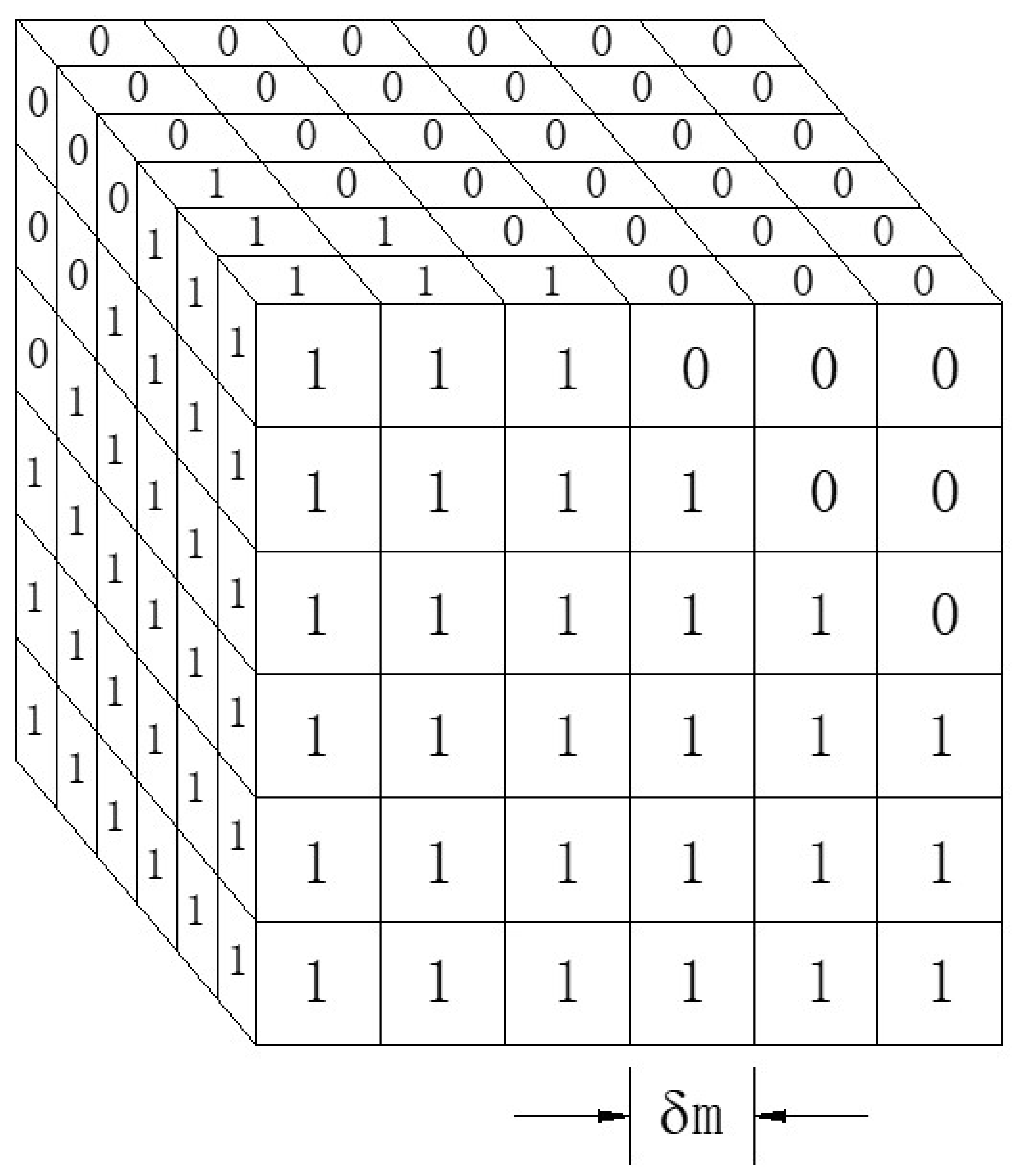

- A cube was formed by the maximum value of the limit of each coordinate axis in (1) as the edge length. The cube was used to envelop the manipulator to reach the workspace. The side length of the cube was divided into m parts, and the length of each section was . The cube was divided into several small cubes, and each small cube had a value of . The small cube could represent the end position of the manipulator and could be described with a 3D matrix [20]. Due to factors such as calculation time, the edge length of a small cube was taken as 2 mm in this paper. The reachable workspace point cloud and grid discretization processing are shown in Figure 3.

- The data of the end position of the manipulator were converted into a cube cell, which could be described by a 3D matrix. When the cube cell contained at least one position coordinate value, the 3D matrix that described the cell of the cube was assigned to 1, and the rest was assigned to 0. Its principle is shown in Figure 4.

- Finally, the workspace volume of the manipulator could be obtained by adding up the number of cube cells assigned to 1.

3.3. GCI

3.4. Discrete Coefficient of the Condition Number

4. Experiment Design

Orthogonal Experiment Design and Experiment Results

5. Experiment Results Processing

5.1. Experiment Results

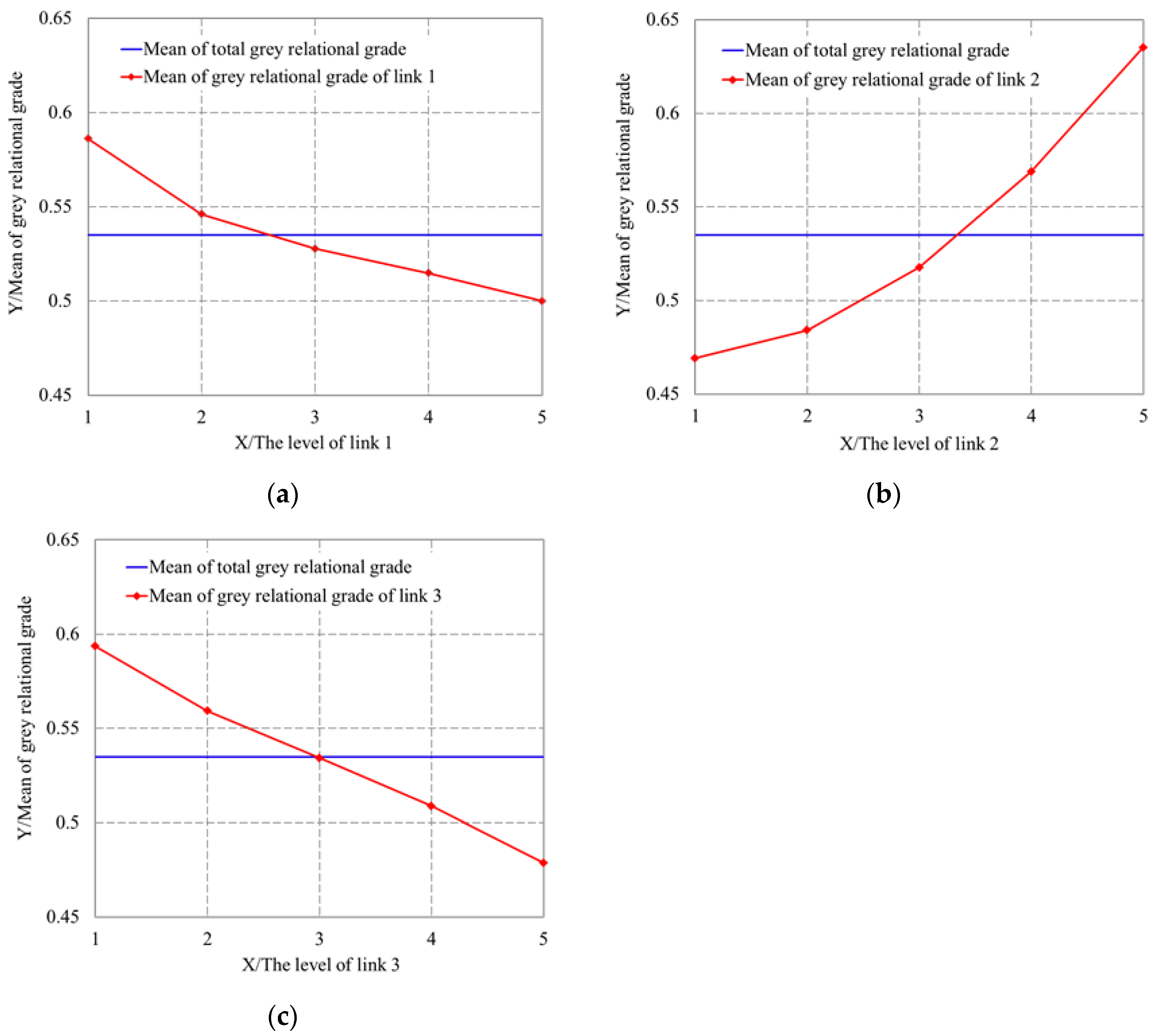

5.2. Grey Correlation Analysis of Experiment Results

6. Optimization Result Analysis

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| degree of freedom | |

| structural length index | |

| global manipulability index | |

| global conditioning index | |

| modified dynamic conditioning index | |

| local sensitivity Index | |

| position vector | |

| rotation matrix | |

| orthogonal array | |

| Latin hypercube design | |

| discrete coefficient | |

| the number of nodes in the manipulator workspace |

References

- Gao, W.; Wang, H.; Jiang, Y.; Pan, X. Research on the Calibration for a Modular Robot. J. Mech. Eng. 2014, 50, 33–40. [Google Scholar] [CrossRef]

- Patel, S.; Sobh, T. Manipulator Performance Measures—A Comprehensive Literature Survey. J. Intell. Robot. Syst. 2015, 77, 547–570. [Google Scholar] [CrossRef]

- Xu, Q.; Zhan, Q.; Tian, X. Link Lengths Optimization Based on Multiple Performance Indexes of Anthropomorphic Manipulators. IEEE Access 2021, 9, 20089–20099. [Google Scholar] [CrossRef]

- Zhao, K.; Fu, Y.; Niu, G.; Pan, B. Mechanical Design and Dimensional Optimization of Minimally Invasive Celiac Surgical Robot. J. Huazhong Univ. Sci. Technol. 2013, 41, 324–328. [Google Scholar]

- Hwang, S.; Kim, H.; Choi, Y.; Shin, K.; Han, C. Design Optimization Method for 7 DOF Robot Manipulator Using Performance Indices. Int. J. Precis. Eng. Manuf. 2017, 18, 293–299. [Google Scholar] [CrossRef]

- Kim, H.-G.; Shin, K.-S.; Hwang, S.-W.; Han, C.-S. Link Length Determination Method for the Reduction of the Performance Deviation of the Manipulator: Extension of the Valid Workspace. Int. J. Precis. Eng. 2014, 15, 1831–1838. [Google Scholar] [CrossRef]

- Mohd Zaman, M.H.; Ibrahim, M.F.; Moubark, A. Dimensional Optimization of 4-DOF Robot Manipulator Using Artificial Bee Colony Algorithm. In Proceedings of the 2021 International Conference on Electrical Engineering and Informatics (ICEEI), Kuala Terengganu, Malaysia, 12–13 October 2021; pp. 1–4. [Google Scholar]

- Zhang, P.; Yao, Z.; Du, Z. Global Performance Index System for Kinematic Optimization of Robotic Mechanism. J. Mech. Design. 2014, 136, 031001. [Google Scholar] [CrossRef]

- Gao, L.Y.; Hou, Y.Y.; Wu, W.G. A modular design method of lightweight robot manipulators. Mach. Des. Manuf. 2014, 1, 154–156. [Google Scholar]

- Ma, R.; Dong, W.; Du, Z.; Li, G. Mechanical Design and Dexterity Optimization for Hybrid Active-Passive Minimally Invasive Surgical Manipulator. Robot 2013, 35, 81–89. [Google Scholar] [CrossRef]

- Brahmia, A.; Kelaiaia, R.; Company, O.; Chemori, A. Sensitivity Analysis of Manipulators Using a Novel Dimensionless Index. Rob. Auton. Syst. 2022, 150, 104021. [Google Scholar] [CrossRef]

- Gosselin, C.M.; Angeles, J. A Global Performance Index for the Kinematic Optimization of Robotic Manipulators. J. Mech. Design. 1991, 113, 220–226. [Google Scholar] [CrossRef]

- Yoshikawa, T. Manipulability of Robotic Mechanisms. Int. J. Rob. Res. 1985, 4, 3–9. [Google Scholar] [CrossRef]

- Lim, H.; Hwang, S.; Shin, K.; Han, C. Design Optimization of the Robot Manipulator Based on Global Performance Indices Using the Grey-Based Taguchi Method. IFAC Proc. Vol. 2010, 43, 285–292. [Google Scholar] [CrossRef]

- Liu, Y.; Yi, W.; Feng, Z.; Yao, J.; Zhao, Y. Design and Motion Planning of a 7-DOF Assembly Robot with Heavy Load in Spacecraft Module. Robot. Comput. Integr. Manuf. 2024, 86, 102645. [Google Scholar] [CrossRef]

- Siciliano, B.; Sciavicco, L.; Villani, L.; Oriolo, G. Robotics Modelling, Planning and Control; Springer: London, UK, 2010. [Google Scholar]

- Salisbury, J.K.; Craig, J.J. Articulated Hands: Force Control and Kinematic Issues. Int. J. Robot. Res. 1982, 1, 4–17. [Google Scholar] [CrossRef]

- Stejskal, T.; Svetlík, J.; Ondočko, Š. Mapping Robot Singularities through the Monte Carlo Method. Appl. Sci. 2022, 12, 8330. [Google Scholar] [CrossRef]

- Alciatore, D.G.; Ng, C.-C.D. Determining Manipulator Workspace Boundaries Using the Monte Carlo Method and Least Squares Segmentation. In Proceedings of the 1994 ASME Design Technical Conferences, Minneapolis, MN, USA, 11–14 September 1994; Part 1 (of 3). Volume 72, pp. 141–146. [Google Scholar]

- Guan, Y.; Yokoi, K.; Zhang, X. Numerical Methods for Reachable Space Generation of Humanoid Robots. Int. J. Rob. Res. 2008, 27, 935–950. [Google Scholar] [CrossRef]

- Puglisi, L.J.; Saltaren, R.J.; Moreno, H.A.; Cardenas, P.F.; Garcia, C.; Aracil, R. Dimensional Synthesis of a Spherical Parallel Manipulator Based on the Evaluation of Global Performance Indexes. Rob. Auton. Syst. 2012, 60, 1037–1045. [Google Scholar] [CrossRef]

- Le Guiban, K.; Rimmel, A.; Weisser, M.-A.; Tomasik, J. Completion of Partial Latin Hypercube Designs: NP-Completeness and Inapproximability. Theor. Comput. Sci. 2018, 715, 1–20. [Google Scholar] [CrossRef]

- Gray, C.T. Introduction to Quality Engineering: Designing Quality into Products and Processes. Qual. Reliab. Eng. Int. 1988, 4, 198. [Google Scholar] [CrossRef]

- Lim, H.; Hwang, S.; Shin, K.; Han, C. The Application of the Grey-Based Taguchi Method to Optimize the Global Performances of the Robot Manipulator. In Proceedings of the 2010 IEEE/RSJ International Conference on Intelligent Robots and Systems, Taipei, Taiwan, 8–22 October 2010; pp. 3868–3874. [Google Scholar]

- Deng, D.; Li, T.; Huang, Z.; Jiang, H.; Yang, S.; Zhang, Y. Multi-Response Optimization of Laser Cladding for TiC Particle Reinforced Fe Matrix Composite Based on Taguchi Method and Grey Relational Analysis. Opt. Laser. Technol. 2022, 153, 108259. [Google Scholar] [CrossRef]

- Pan, L.K.; Wang, C.C.; Wei, S.L.; Sher, H.F. Optimizing Multiple Quality Characteristics via Taguchi Method-Based Grey Analysis. J. Mater. Process. Technol. 2007, 182, 107–116. [Google Scholar] [CrossRef]

- Li, X.; Gu, Y.; Wu, L.; Sun, Q.; Song, T. Time and Energy Optimal Trajectory Planning of Wheeled Mobile Dual-Arm Robot Based on Tip-Over Stability Constraint. Appl. Sci. 2023, 13, 3780. [Google Scholar] [CrossRef]

- Fi, R.A. Statistical Methods for Research Workers, 11th ed.; Blackwell Scientific Publications: Hoboken, NJ, USA, 1950; pp. 457–492. [Google Scholar]

| Joints | Range of Joints | ||||

|---|---|---|---|---|---|

| 1 | 0 | 0 | 0 | −180~180 | |

| 2 | −90 | 0 | −180~180 | ||

| 3 | 90 | 0 | 0 | −120~120 | |

| 4 | −90 | 0 | −180~180 | ||

| 5 | 90 | 0 | 0 | −120~120 | |

| 6 | −90 | 0 | −180~120 |

| Link Number | Level 1 (m) | Level 2 (m) | Level 3 (m) | Level 4 (m) | Level 5 (m) |

|---|---|---|---|---|---|

| Link 1 | 0.2624 | 0.2952 | 0.328 | 0.3608 | 0.3936 |

| Link 2 | 0.2212 | 0.2489 | 0.2765 | 0.3042 | 0.3318 |

| Link 3 | 0.2690 | 0.3026 | 0.3362 | 0.3698 | 0.4034 |

| Group | Link 1 | Link 2 | Link 3 | Cv | SLI | GCI |

|---|---|---|---|---|---|---|

| 1 | 1 (0.2624) | 1 (0.2212) | 1 (0.2690) | 94.4889 | 0.6856 | 0.0234 |

| 2 | 1 (0.2624) | 2 (0.2489) | 2 (0.3026) | 94.5672 | 0.6787 | 0.0249 |

| 3 | 1 (0.2624) | 3 (0.2765) | 3 (0.3362) | 94.6512 | 0.6732 | 0.0261 |

| 4 | 1 (0.2624) | 4 (0.3042) | 4 (0.3698) | 94.7399 | 0.6686 | 0.0269 |

| 5 | 1 (0.2624) | 5 (0.3318) | 5 (0.4034) | 94.8308 | 0.6648 | 0.0275 |

| 6 | 2 (0.2952) | 1 (0.2212) | 2 (0.3026) | 94.5650 | 0.6889 | 0.0237 |

| 7 | 2 (0.2952) | 2 (0.2489) | 3 (0.3362) | 94.6504 | 0.6821 | 0.0254 |

| 8 | 2 (0.2952) | 3 (0.2765) | 4 (0.3698) | 94.7402 | 0.6765 | 0.0267 |

| 9 | 2 (0.2952) | 4 (0.3042) | 5 (0.4034) | 94.8322 | 0.6719 | 0.0277 |

| 10 | 2 (0.2952) | 5 (0.3318) | 1 (0.2690) | 94.5770 | 0.6805 | 0.0310 |

| 11 | 3 (0.3280) | 1 (0.2212) | 3 (0.3362) | 94.6509 | 0.6918 | 0.0238 |

| 12 | 3 (0.3280) | 2 (0.2489) | 4 (0.3698) | 94.7416 | 0.6850 | 0.0256 |

| 13 | 3 (0.3280) | 3 (0.2765) | 5 (0.4034) | 94.8339 | 0.6795 | 0.0270 |

| 14 | 3 (0.3280) | 4 (0.3042) | 1 (0.2690) | 94.5784 | 0.6899 | 0.0307 |

| 15 | 3 (0.3280) | 5 (0.3318) | 2 (0.3026) | 94.6657 | 0.6835 | 0.0318 |

| 16 | 4 (0.3608) | 1 (0.2212) | 4 (0.3698) | 94.7435 | 0.6943 | 0.0237 |

| 17 | 4 (0.3608) | 2 (0.2489) | 5 (0.4034) | 94.8364 | 0.6877 | 0.0256 |

| 18 | 4 (0.3608) | 3 (0.2765) | 1 (0.2690) | 94.5808 | 0.7002 | 0.0294 |

| 19 | 4 (0.3608) | 4 (0.3042) | 2 (0.3026) | 94.6687 | 0.6925 | 0.0310 |

| 20 | 4 (0.3608) | 5 (0.3318) | 3 (0.3362) | 94.7621 | 0.6862 | 0.0323 |

| 21 | 5 (0.3936) | 1 (0.2212) | 5 (0.4034) | 94.8389 | 0.6966 | 0.0236 |

| 22 | 5 (0.3936) | 2 (0.2489) | 1 (0.2690) | 94.5838 | 0.7120 | 0.0276 |

| 23 | 5 (0.3936) | 3 (0.2765) | 2 (0.3026) | 94.6720 | 0.7023 | 0.0295 |

| 24 | 5 (0.3936) | 4 (0.3042) | 3 (0.3362) | 94.7658 | 0.6948 | 0.0311 |

| 25 | 5 (0.3936) | 5 (0.3318) | 4 (0.3698) | 94.8463 | 0.6886 | 0.0324 |

| Group | Normalization Data | Grey Relational Coefficient | ||||

|---|---|---|---|---|---|---|

| Cv | SLI | GCI | Cv | SLI | GCI | |

| 1 | 1.0000 | 0.5593 | 0.0000 | 1.0000 | 0.5315 | 0.3333 |

| 2 | 0.7809 | 0.7055 | 0.1667 | 0.6953 | 0.6293 | 0.3750 |

| 3 | 0.5459 | 0.8220 | 0.3000 | 0.5241 | 0.7375 | 0.4167 |

| 4 | 0.2977 | 0.9195 | 0.3889 | 0.4159 | 0.8613 | 0.4500 |

| 5 | 0.0434 | 1.0000 | 0.4556 | 0.3433 | 1.0000 | 0.4787 |

| 6 | 0.7871 | 0.4894 | 0.0333 | 0.7014 | 0.4948 | 0.3409 |

| 7 | 0.5481 | 0.6335 | 0.2222 | 0.5253 | 0.5770 | 0.3913 |

| 8 | 0.2969 | 0.7521 | 0.3667 | 0.4156 | 0.6685 | 0.4412 |

| 9 | 0.0395 | 0.8496 | 0.4778 | 0.3423 | 0.7688 | 0.4891 |

| 10 | 0.7535 | 0.6674 | 0.8444 | 0.6698 | 0.6005 | 0.7627 |

| 11 | 0.5467 | 0.4280 | 0.0444 | 0.5245 | 0.4664 | 0.3435 |

| 12 | 0.2929 | 0.5720 | 0.2444 | 0.4142 | 0.5388 | 0.3982 |

| 13 | 0.0347 | 0.6886 | 0.4000 | 0.3412 | 0.6162 | 0.4545 |

| 14 | 0.7496 | 0.4682 | 0.8111 | 0.6663 | 0.4846 | 0.7258 |

| 15 | 0.5053 | 0.6038 | 0.9333 | 0.5027 | 0.5579 | 0.8823 |

| 16 | 0.2876 | 0.3750 | 0.0333 | 0.4124 | 0.4444 | 0.3409 |

| 17 | 0.0277 | 0.5148 | 0.2444 | 0.3396 | 0.5075 | 0.3982 |

| 18 | 0.7429 | 0.2500 | 0.6667 | 0.6604 | 0.4000 | 0.6000 |

| 19 | 0.4969 | 0.4131 | 0.8444 | 0.4985 | 0.4600 | 0.7627 |

| 20 | 0.2356 | 0.5466 | 0.9889 | 0.3954 | 0.5244 | 0.9783 |

| 21 | 0.0207 | 0.3263 | 0.0222 | 0.3380 | 0.4260 | 0.3383 |

| 22 | 0.7345 | 0.0000 | 0.4667 | 0.6532 | 0.3333 | 0.4839 |

| 23 | 0.4877 | 0.2055 | 0.6778 | 0.4939 | 0.3862 | 0.6081 |

| 24 | 0.2252 | 0.3644 | 0.8556 | 0.3922 | 0.4403 | 0.7759 |

| 25 | 0.0000 | 0.4958 | 1.0000 | 0.3333 | 0.4979 | 1.0000 |

| Group | Relational Grade | Order |

|---|---|---|

| 1 | 0.6216 | 5 |

| 2 | 0.5665 | 10 |

| 3 | 0.5594 | 11 |

| 4 | 0.5757 | 8 |

| 5 | 0.6073 | 7 |

| 6 | 0.5124 | 15 |

| 7 | 0.4979 | 17 |

| 8 | 0.5084 | 16 |

| 9 | 0.5334 | 14 |

| 10 | 0.6777 | 1 |

| 11 | 0.4448 | 22 |

| 12 | 0.4504 | 21 |

| 13 | 0.4706 | 20 |

| 14 | 0.6256 | 4 |

| 15 | 0.6476 | 2 |

| 16 | 0.3992 | 24 |

| 17 | 0.4151 | 23 |

| 18 | 0.5535 | 12 |

| 19 | 0.5737 | 9 |

| 20 | 0.6327 | 3 |

| 21 | 0.3674 | 25 |

| 22 | 0.4901 | 19 |

| 23 | 0.4961 | 18 |

| 24 | 0.5361 | 13 |

| 25 | 0.6104 | 6 |

| Link Number | Level 1 | Level 2 | Level 3 | Level 4 | Level 5 |

|---|---|---|---|---|---|

| Link 1 | 0.5861 | 0.5460 | 0.5278 | 0.5148 | 0.5000 |

| Link 2 | 0.4691 | 0.4840 | 0.5176 | 0.5689 | 0.6351 |

| Link 3 | 0.5935 | 0.5593 | 0.5342 | 0.5088 | 0.4788 |

| Before Optimization (m) | After Optimization (m) | |

|---|---|---|

| Link 1 | 0.3280 | 0.2624 |

| Link 2 | 0.2765 | 0.3318 |

| Link 3 | 0.3362 | 0.2690 |

| Length of the arm | 0.9407 | 0.8632 |

| Index | Before Optimization | After Optimization | Percentage of Promotion (%) |

|---|---|---|---|

| Cv | 94.6895 | 94.5554 | 1.40 |

| SLI | 0.6856 | 0.6742 | 1.66 |

| GCI | 0.0280 | 0.0293 | 4.64 |

| Link Parameter | Deviation Squared Sum | DOF | Mean Square Error | F Value | Square Sum Proportion |

|---|---|---|---|---|---|

| Link 1 | 0.0394 | 4 | 0.0099 | 58.7040 | 25.32% |

| Link 2 | 0.0921 | 4 | 0.0230 | 137.2161 | 59.19% |

| Link 3 | 0.0221 | 4 | 0.0055 | 32.8637 | 14.2% |

| Error | 0.0020 | 12 | [ ] | [ ] | 1.29% |

| Sum total | 0.1556 | 24 | [ ] | [ ] | 100% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Qiu, X.; Lin, F.; Fei, S.; Song, T. Dimensional Optimization of a Modular Robot Manipulator. Machines 2023, 11, 1074. https://doi.org/10.3390/machines11121074

Li X, Qiu X, Lin F, Fei S, Song T. Dimensional Optimization of a Modular Robot Manipulator. Machines. 2023; 11(12):1074. https://doi.org/10.3390/machines11121074

Chicago/Turabian StyleLi, Xianhua, Xun Qiu, Fengtao Lin, Sixian Fei, and Tao Song. 2023. "Dimensional Optimization of a Modular Robot Manipulator" Machines 11, no. 12: 1074. https://doi.org/10.3390/machines11121074

APA StyleLi, X., Qiu, X., Lin, F., Fei, S., & Song, T. (2023). Dimensional Optimization of a Modular Robot Manipulator. Machines, 11(12), 1074. https://doi.org/10.3390/machines11121074