Research on Belt Deviation Fault Detection Technology of Belt Conveyors Based on Machine Vision

Abstract

:1. Introduction

2. Theory

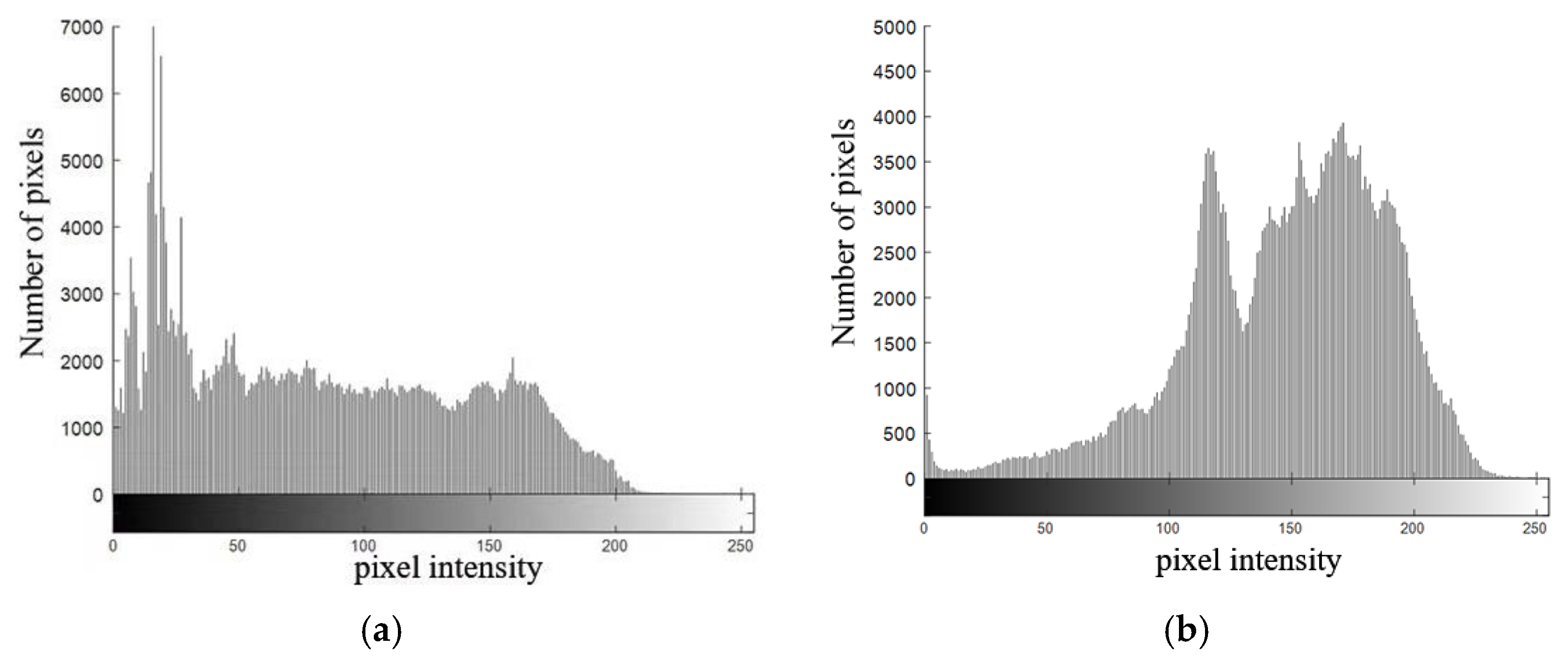

2.1. Image Low-Light Processing

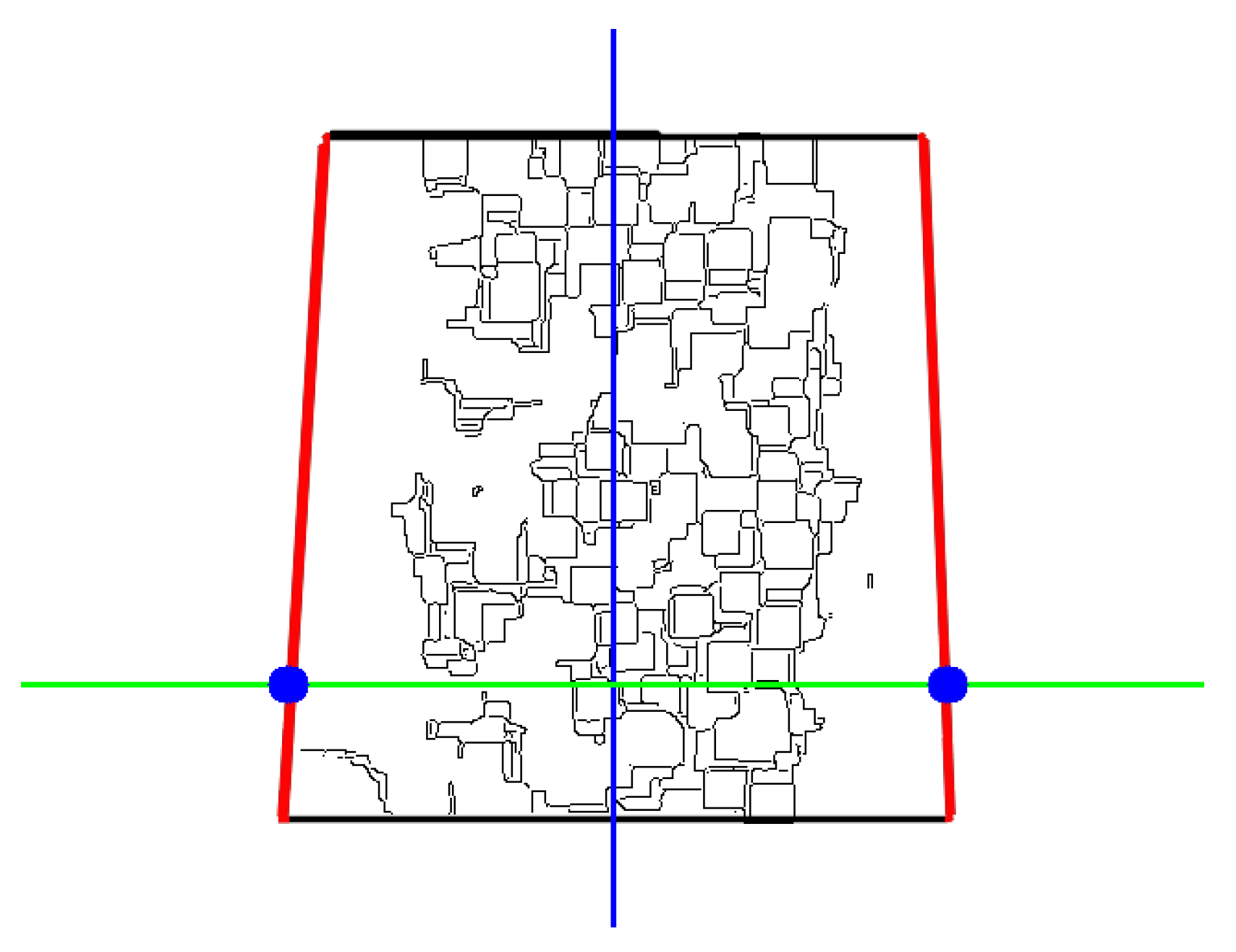

2.2. Belt Edge Feature Extraction

- (1)

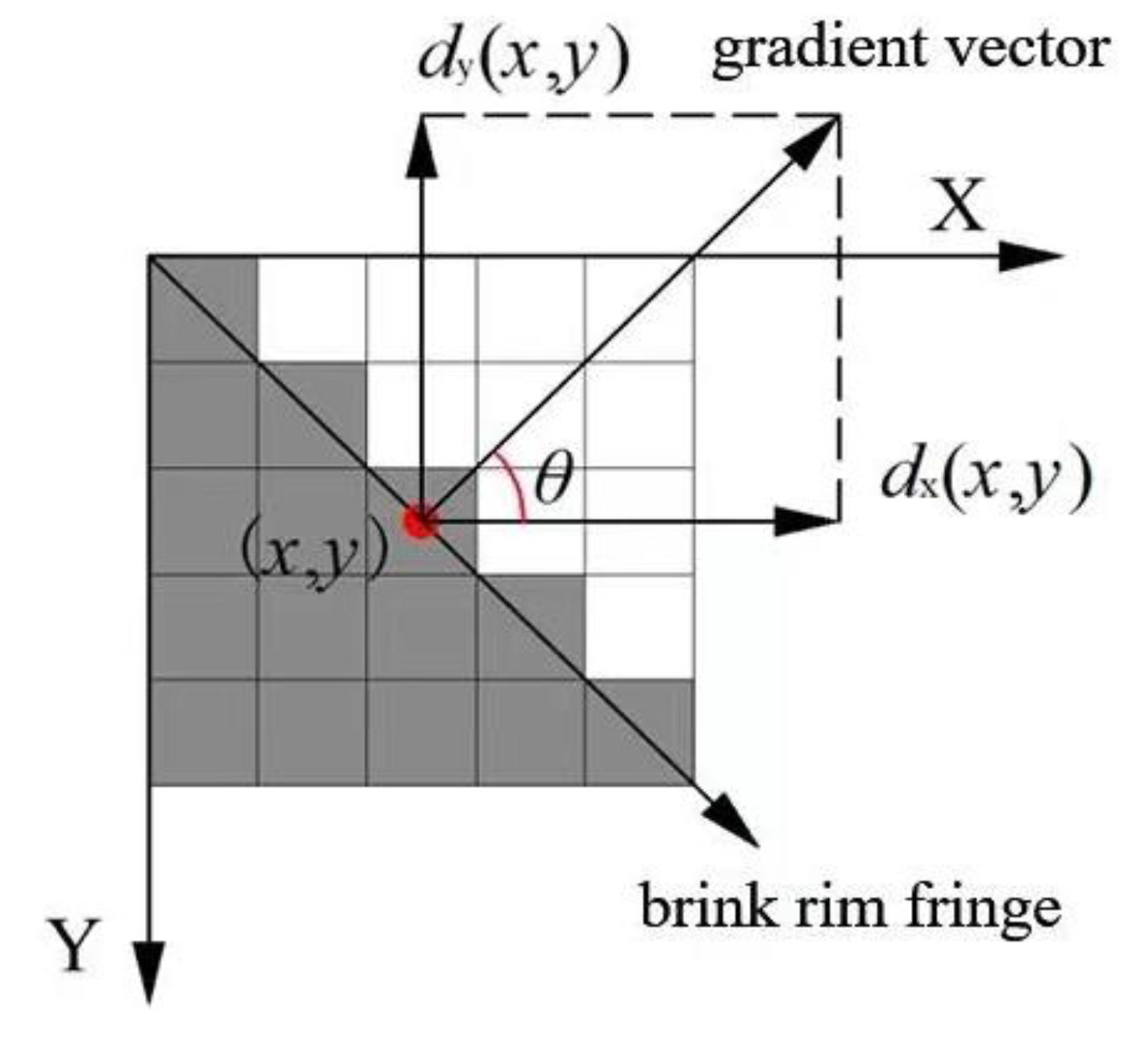

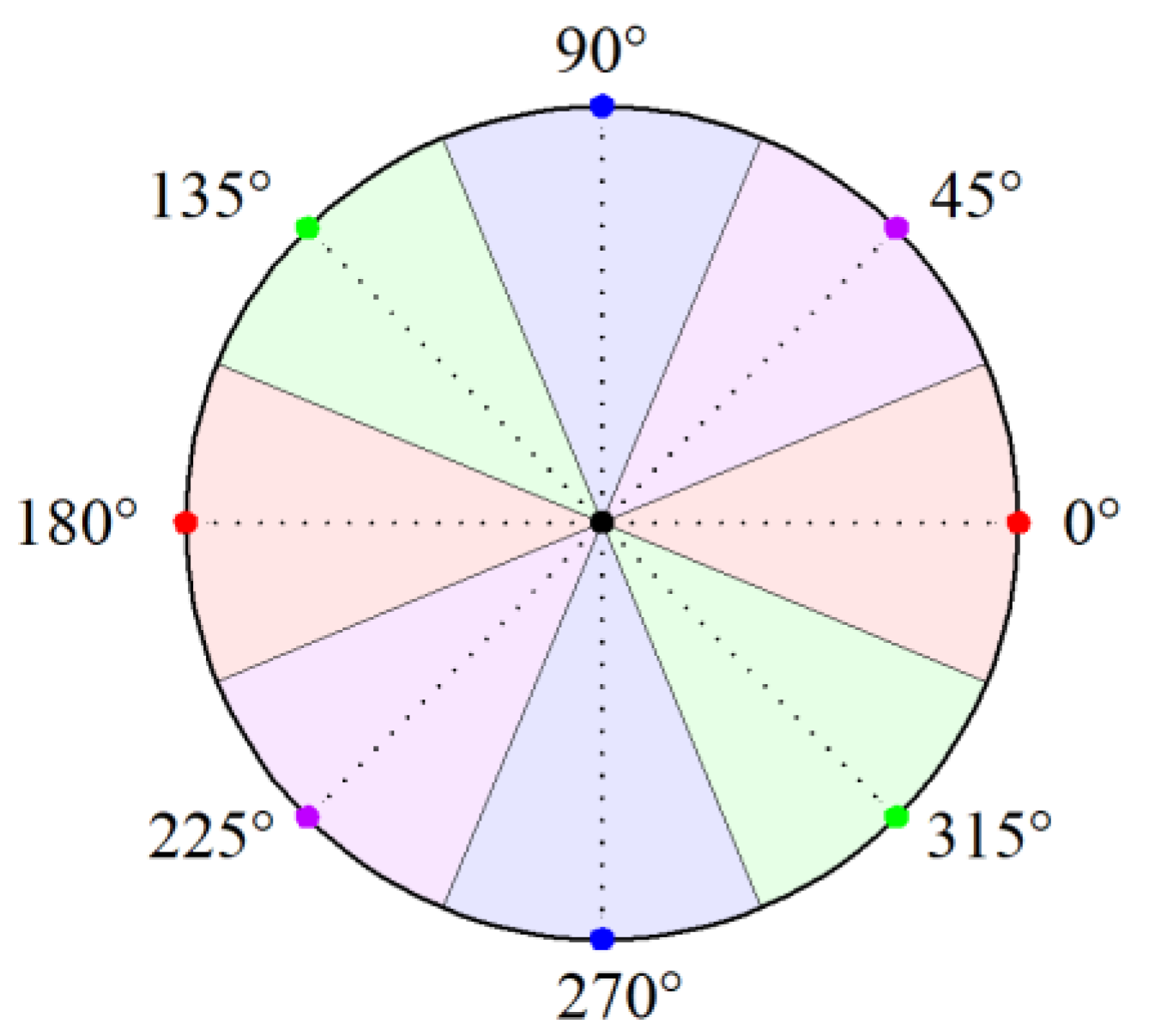

- Canny edge detection

- (2)

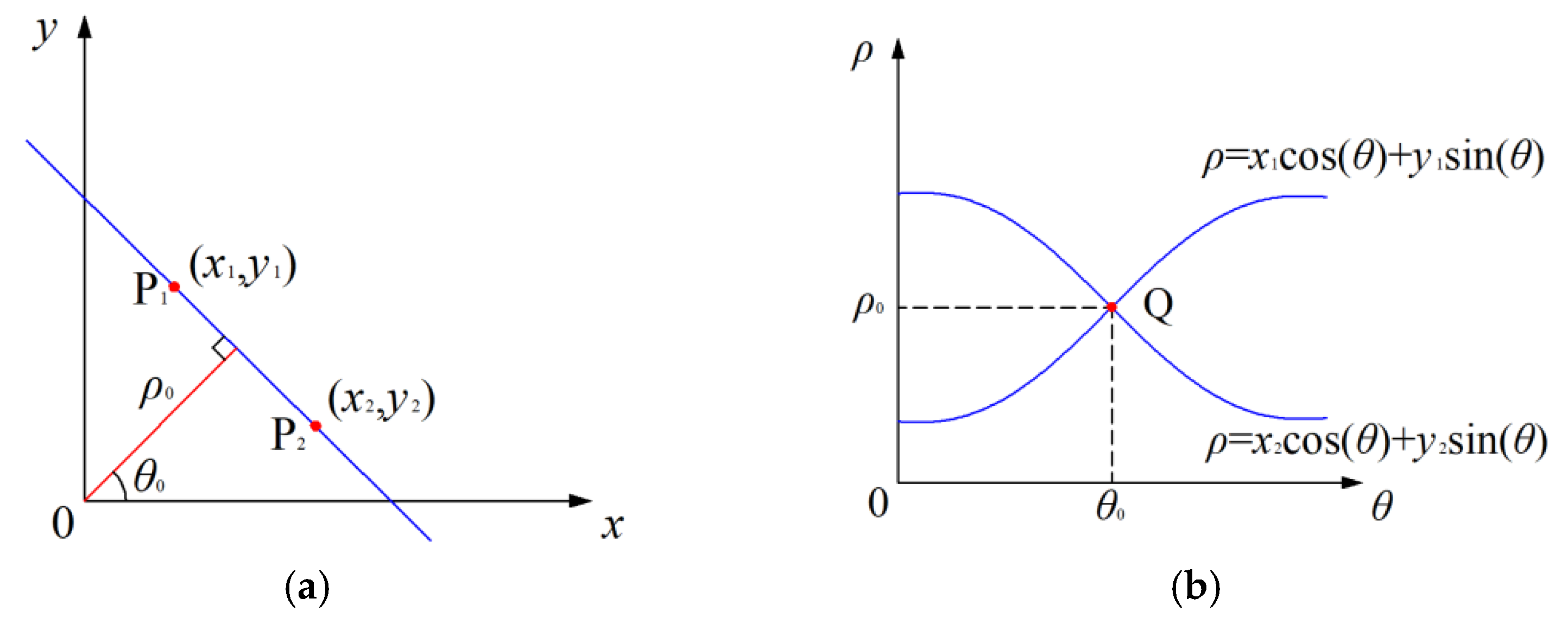

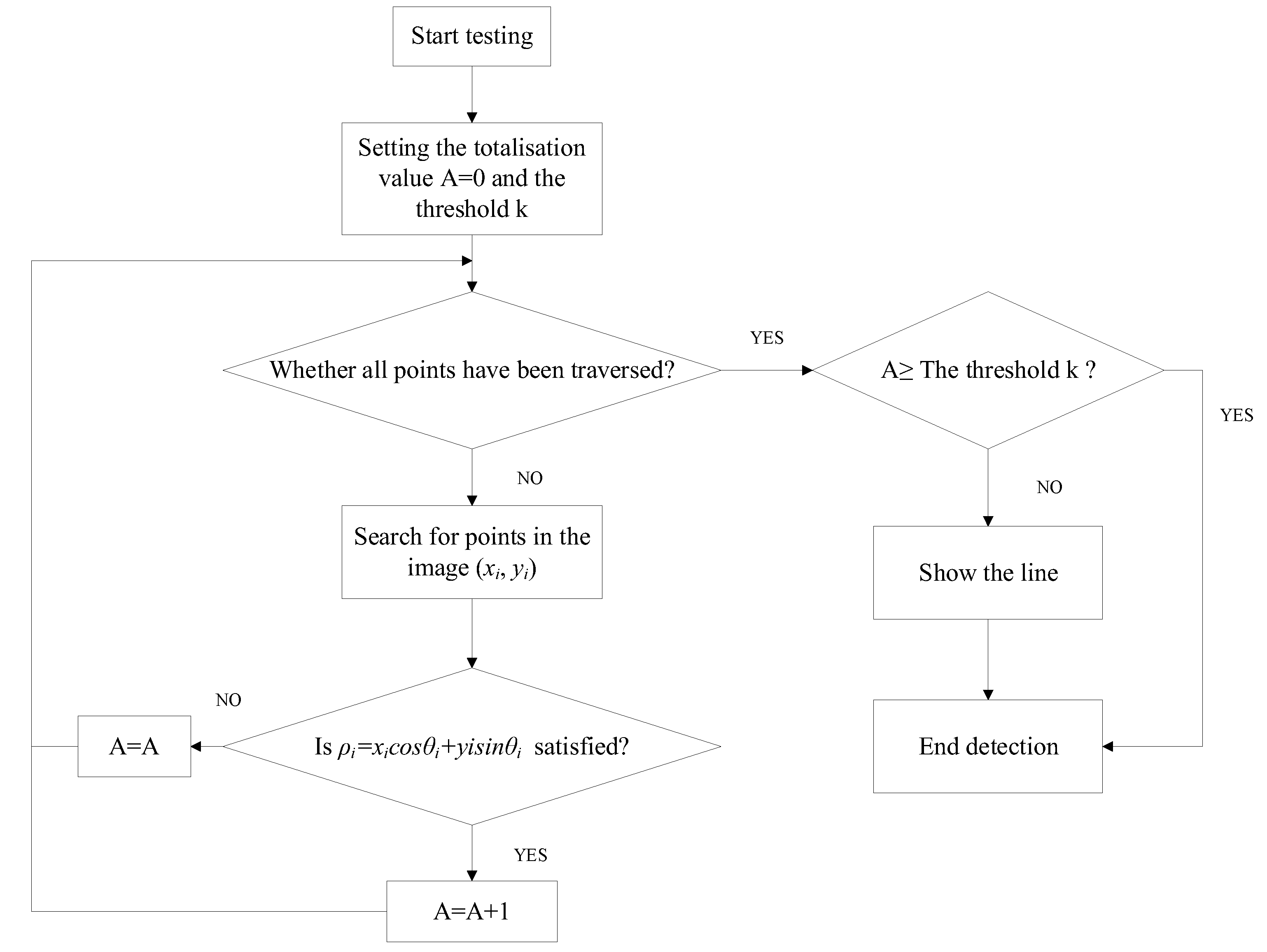

- Hough transform linear detection

- (3)

- Conveyor belt edge feature extraction test

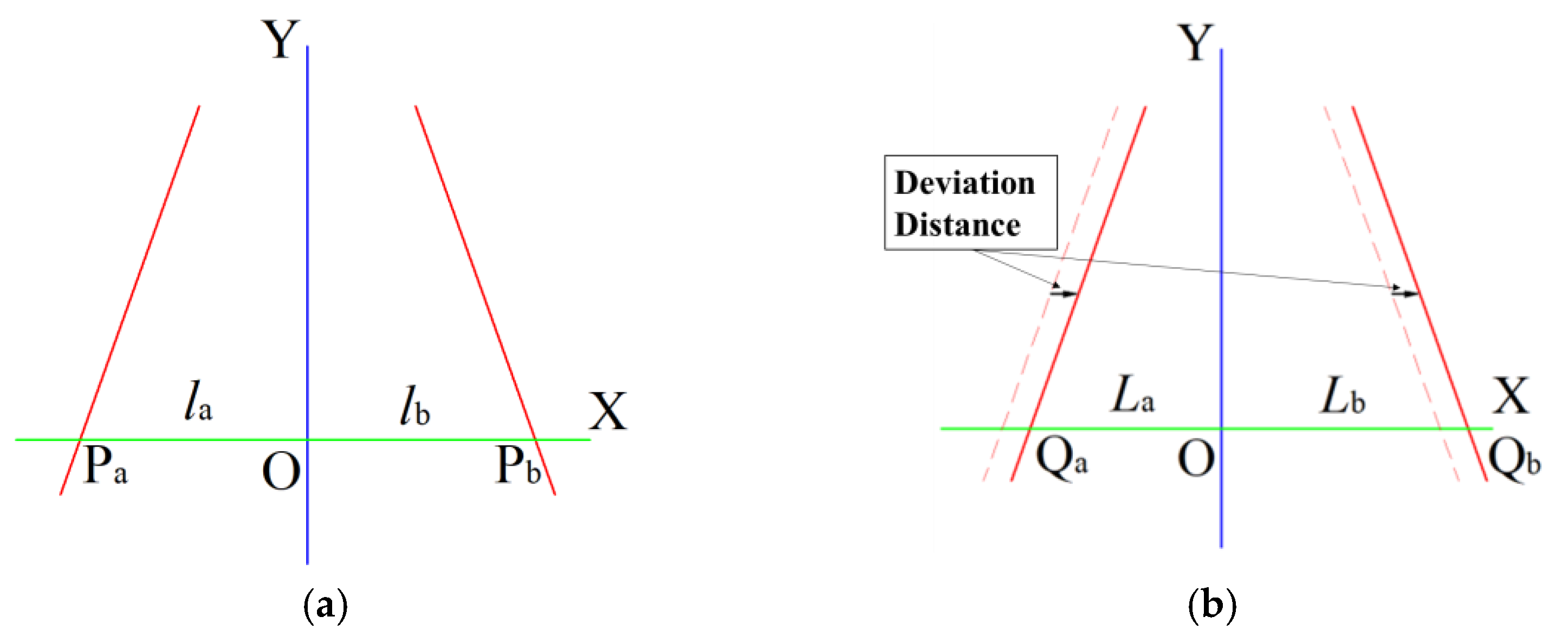

2.3. Feature Identification and Fault Determination

3. Experimental Design

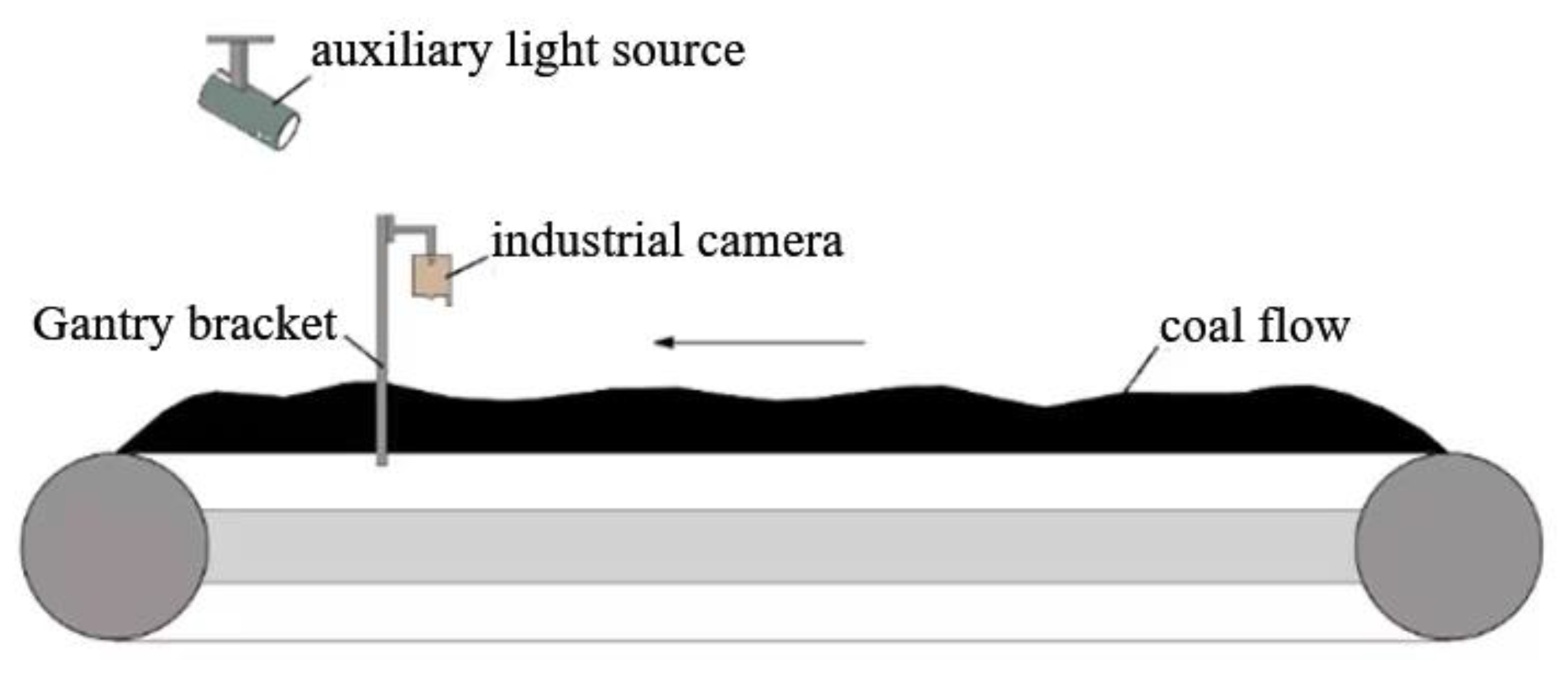

3.1. Experimental Program Design

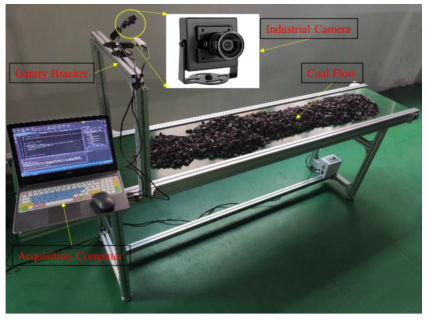

3.2. Experimental Bench Construction

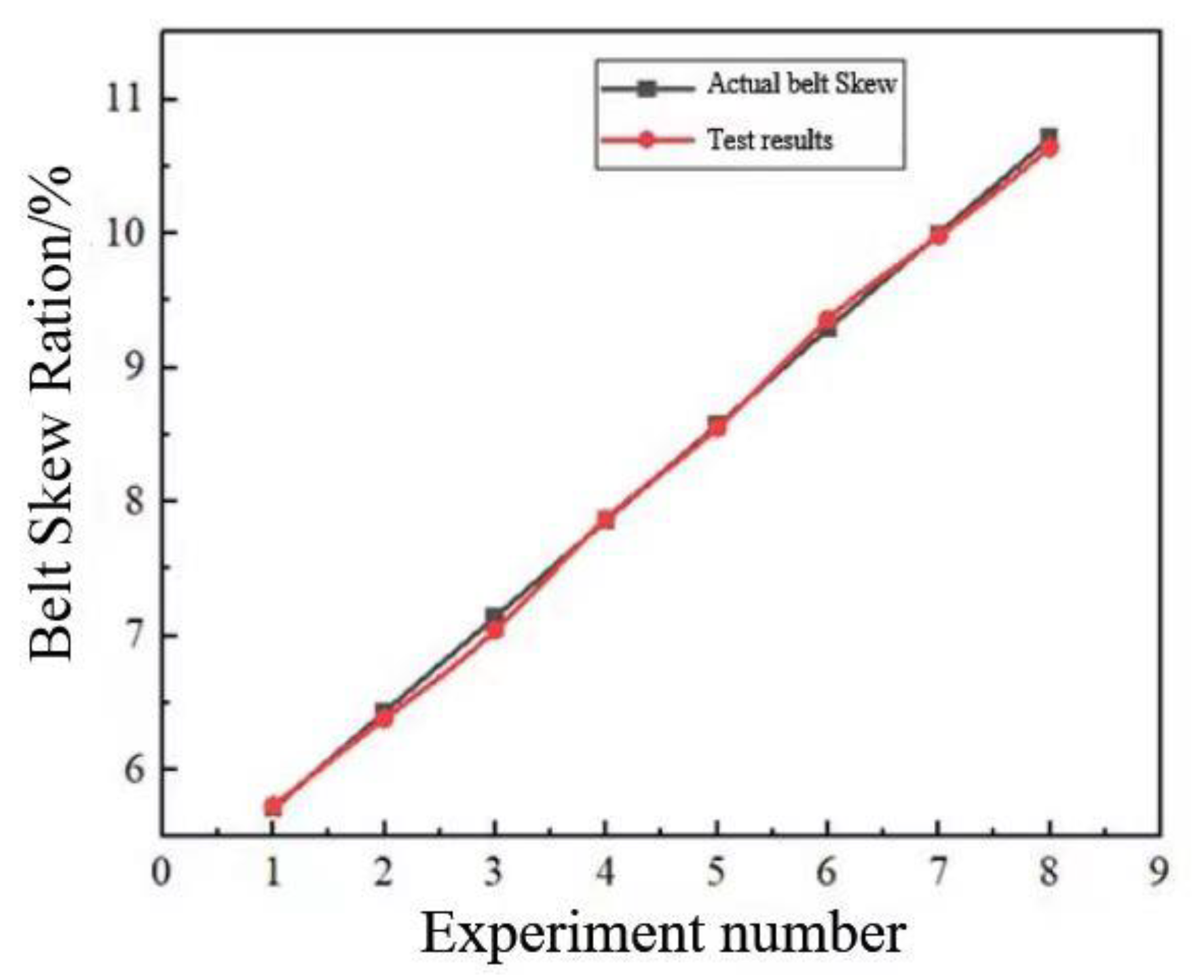

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, W.; Ren, M.; Kang, J.; Zhou, Y.; Yuan, J. Estimating Stranded Coal Assets in China’s Power Sector. Util. Policy 2022, 75, 101352. [Google Scholar] [CrossRef]

- Zhang, X.; Ning, Y.; Lu, C. Evaluation of Coal Supply and Demand Security in China and Associated Obstacle Factors. Sustainability 2022, 14, 10605. [Google Scholar] [CrossRef]

- Zhao, D.; Su, G.; Cheng, G.; Wang, P.; Chen, W.; Yang, Y. Research on Real-Time Perception Method of Key Targets in the Comprehensive Excavation Working Face of Coal Mine. Meas. Sci. Technol. 2023, 35, 015410. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, P.; Wang, E.; Chen, D.; Li, C. Characteristics of Coal Resources in China and Statistical Analysis and Preventive Measures for Coal Mine Accidents. Int. J. Coal Sci. Technol. 2023, 10, 22. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Wu, Y.; Xu, T.; Bhattacharya, S. A Review on in-situ Process Analytical Techniques for the Thermochemical Conversion of Coal and Biomass. Rev. Chem. Eng. 2023, 20230003. [Google Scholar] [CrossRef]

- Lei, M.; Zhang, X.; Dong, Z.; Wan, J.; Zhang, C.; Zhang, G. Locating Anchor Drilling Holes Based on Binocular Vision in Coal Mine Roadways. Mathematics 2023, 11, 4365. [Google Scholar] [CrossRef]

- Pan, R.; Gao, R.; Chao, J.; Jia, H. Thermal Characteristics Analysis of Conveyor Belt during Ignition. Combust. Sci. Technol. 2023, 417–422. [Google Scholar] [CrossRef]

- Wu, L.; Zhang, L.; Chen, L.; Shi, J.; Wan, J. A Lightweight and Multisource Information Fusion Method for Real-Time Monitoring of Lump Coal on Mining Conveyor Belts. Int. J. Intell. Syst. 2023, 2023, 5327122. [Google Scholar] [CrossRef]

- Huang, K.; Li, S.; Cai, F.; Zhou, R. Detection of Large Foreign Objects on Coal Mine Belt Conveyor Based on Improved. Processes 2023, 11, 2469. [Google Scholar] [CrossRef]

- Yang, L.; Deng, C.; Wang, G. Demagnetization Modeling and Characteristic Analysis of Belt Conveyor Permanent Magnet Electric Roller Based on Back Electromotive Force. J. Nanoelectron. Optoelectron. 2021, 16, 957–966. [Google Scholar] [CrossRef]

- Zhang, M.; Shi, H.; Zhang, Y.; Yu, Y.; Zhou, M. Deep Learning-Based Damage Detection of Mining Conveyor Belt. Measurement 2021, 175, 109130. [Google Scholar] [CrossRef]

- Wang, B.; Dou, D.; Shen, N. An Intelligent Belt Wear Fault Diagnosis Method Based on Deep Learning. Int. J. Coal Prep. Util. 2023, 43, 708–725. [Google Scholar] [CrossRef]

- Ji, H.; Hou, Q.; Wu, D. Modified Performance-Enhanced PCA for Incipient Fault Detection of Dynamic Industrial Processes. J. Process Control 2023, 131, 103107. [Google Scholar] [CrossRef]

- The Computer System for Real-Time Working Condition Monitoring and Fault Diagnosis of Steel-Cord Belt Conveyors-All Databases. Available online: https://webofscience.clarivate.cn/wos/alldb/full-record/PQDT:67692980 (accessed on 15 November 2023).

- Wang, T.; Dong, Z.; Liu, J. Research of Mine Conveyor Belt Deviation Detection System Based on Machine Vision. J. Min. Sci. 2021, 57, 703–712. [Google Scholar] [CrossRef]

- Liu, M.; Mei, X.; Sun, D.; Zhang, J.; Chen, Z. An On-Line Detection Method for Conveyor Belt Deviation Faults. Therm. Sci. 2023, 27, 2099–2107. [Google Scholar] [CrossRef]

- Xu, C.; Zeng, X.; Zhang, R.; Wang, K. Detection Method of Edge Position of Belt Conveyor Based on Complex Environment. In Proceedings of the 2021 4th International Conference on Robotics, Control and Automation Engineering (RCAE), Wuhan, China, 4–6 November 2021; IEEE: New York, NY, USA, 2021; pp. 417–422. [Google Scholar]

- Wang, J.; Liu, Q.; Dai, M. Belt Vision Localization Algorithm Based on Machine Vision and Belt Conveyor Deviation Detection. In Proceedings of the 2019 34rd Youth Academic Annual Conference of Chinese Association of Automation (YAC), Jinzhou, China, 6–8 June 2019; IEEE: New York, NY, USA; pp. 269–273. [Google Scholar]

- Zhang, M.; Jiang, K.; Cao, Y.; Li, M.; Hao, N.; Zhang, Y. A Deep Learning-Based Method for Deviation Status Detection in Intelligent Conveyor Belt System. J. Clean. Prod. 2022, 363, 132575. [Google Scholar] [CrossRef]

- Hu, J.; Zhu, J.; Zhou, P. Efficient 3D Measurement of a HDR Surface Based on Adaptive Fringe Projection. Appl. Opt. 2022, 61, 9028. [Google Scholar] [CrossRef]

- Xu, S.; Feng, T.; Xing, F. Three-Dimensional Measurement Method for High Dynamic Range Surfaces Based on Adaptive Fringe Projection. IEEE Trans. Instrum. Meas. 2023, 72, 1–11. [Google Scholar] [CrossRef]

- Qiu, J.; Wang, Z.; Huang, H. High Dynamic Range Image Compression Based on the Multi-Peak S-Shaped Tone Curve. Opt. Express 2023, 31, 9841. [Google Scholar] [CrossRef]

- Singh, P.; Diwakar, M.; Ghosh, D.; Vidyarthi, A.; Gupta, D.; Gupta, P. An Algorithmic Approach towards Remote Sensing Imagery Data Restoration Using Guided Filters in Real-Time Applications. Can. J. Remote Sens. 2023, 49, 2257323. [Google Scholar] [CrossRef]

- Jaiswal, V.; Sharma, V.; Bisen, D. Modified Deep-Convolution Neural Network Model for Flower Images Segmentation and Predictions. Multimed. Tools Appl. 2023, 165303. [Google Scholar] [CrossRef]

- Hong, J.; Dong, Z.; Zhang, X.; Song, N.; Cao, P. A Fast Gradient Iterative Affine Motion Estimation Algorithm Based on Edge Detection for Versatile Video Coding. Electronics 2023, 12, 3414. [Google Scholar] [CrossRef]

- Xia, Z.; Hou, P.; Song, T.; Li, Q. Nonlinear Self-Calibration Method Based on Phase Registration in Phase-Shifting Profilometry. Opt. Laser Technol. 2023, 167, 109745. [Google Scholar] [CrossRef]

| Experiment Number | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

|---|---|---|---|---|---|---|---|---|

| Actual bandwidth/mm | 700 | 700 | 700 | 700 | 700 | 700 | 700 | 700 |

| Actual deviation distance/mm | 0 | 5 | 10 | 15 | 20 | 25 | 30 | 35 |

| Actual bias ratio | 0 | 0.71% | 1.43% | 2.14% | 2.86% | 3.57% | 4.29% | 5.00% |

| The number of bandwidth pixels | 468 | 468 | 470 | 469 | 470 | 468 | 471 | 470 |

| The number of deviation pixels | 2 | 5 | 8 | 11 | 14 | 17 | 21 | 24 |

| Detecting bandwidth bias ratio | 0.43% | 1.07% | 1.70% | 2.35% | 2.98% | 3.63% | 4.46% | 5.11% |

| Detection error | 0.43% | 0.36% | 0.27% | 0.21% | 0.12% | 0.06% | 0.17% | 0.11% |

| Experiment Number | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

|---|---|---|---|---|---|---|---|---|

| Actual bandwidth/mm | 700 | 700 | 700 | 700 | 700 | 700 | 700 | 700 |

| Actual deviation distance/mm | 40 | 45 | 50 | 55 | 60 | 65 | 70 | 75 |

| Actual bias ratio | 5.71% | 6.43% | 7.14% | 7.86% | 8.57% | 9.29% | 10.00% | 10.71% |

| The number of bandwidth pixels | 471 | 470 | 469 | 470 | 468 | 470 | 471 | 470 |

| The number of deviation pixels | 27 | 31 | 33 | 37 | 40 | 42 | 43 | 45 |

| Detecting bandwidth bias ratio | 5.73% | 6.38% | 7.04% | 7.87% | 8.55% | 9.36% | 9.98% | 10.64% |

| Detection error | 0.02% | 0.05% | 0.10% | 0.01% | 0.02% | 0.07% | 0.02% | 0.07% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, X.; Wang, C.; Tian, Z.; Huang, X.; Wang, Q. Research on Belt Deviation Fault Detection Technology of Belt Conveyors Based on Machine Vision. Machines 2023, 11, 1039. https://doi.org/10.3390/machines11121039

Wu X, Wang C, Tian Z, Huang X, Wang Q. Research on Belt Deviation Fault Detection Technology of Belt Conveyors Based on Machine Vision. Machines. 2023; 11(12):1039. https://doi.org/10.3390/machines11121039

Chicago/Turabian StyleWu, Xiangfan, Chusen Wang, Zuzhi Tian, Xiankang Huang, and Qian Wang. 2023. "Research on Belt Deviation Fault Detection Technology of Belt Conveyors Based on Machine Vision" Machines 11, no. 12: 1039. https://doi.org/10.3390/machines11121039

APA StyleWu, X., Wang, C., Tian, Z., Huang, X., & Wang, Q. (2023). Research on Belt Deviation Fault Detection Technology of Belt Conveyors Based on Machine Vision. Machines, 11(12), 1039. https://doi.org/10.3390/machines11121039