Time Series Prediction for Energy Consumption of Computer Numerical Control Axes Using Hybrid Machine Learning Models

Abstract

:1. Introduction

2. State of the Art

- How can one predict HF energy-related time series for machine tool axes for general paths, based on the NC code?

- What accuracies can be achieved?

- What are the requirements and limits of the model and how can they be addressed?

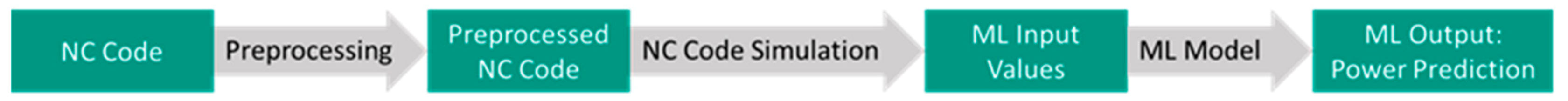

3. Approach

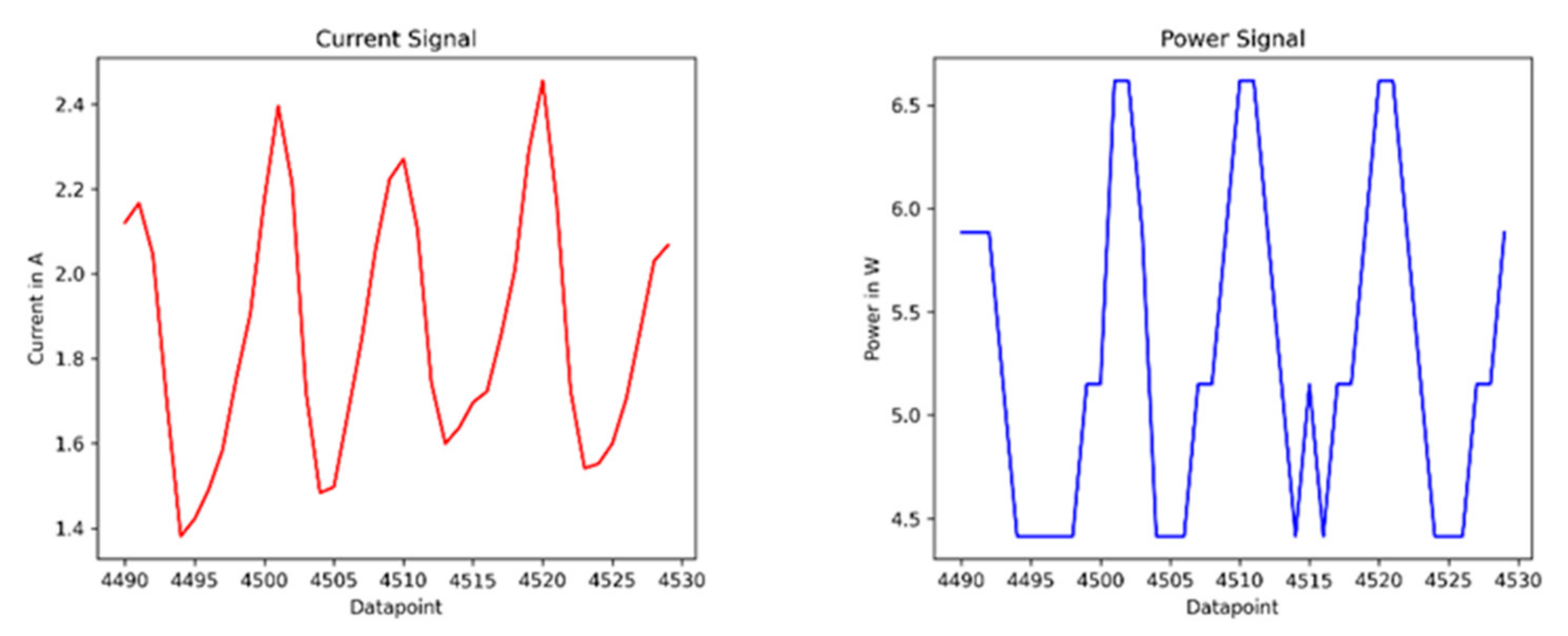

4. Datasets

5. Hybrid Model for HF Time Series Prediction

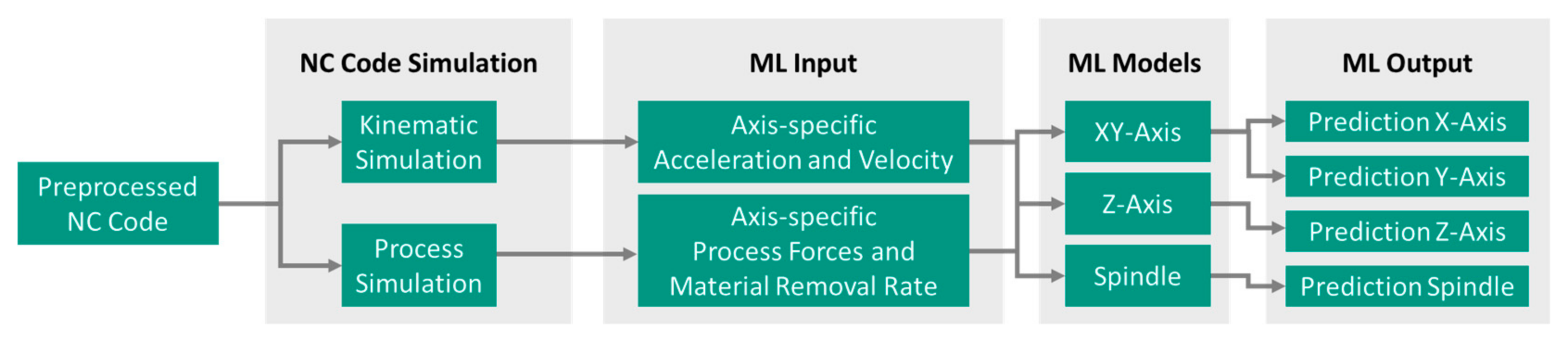

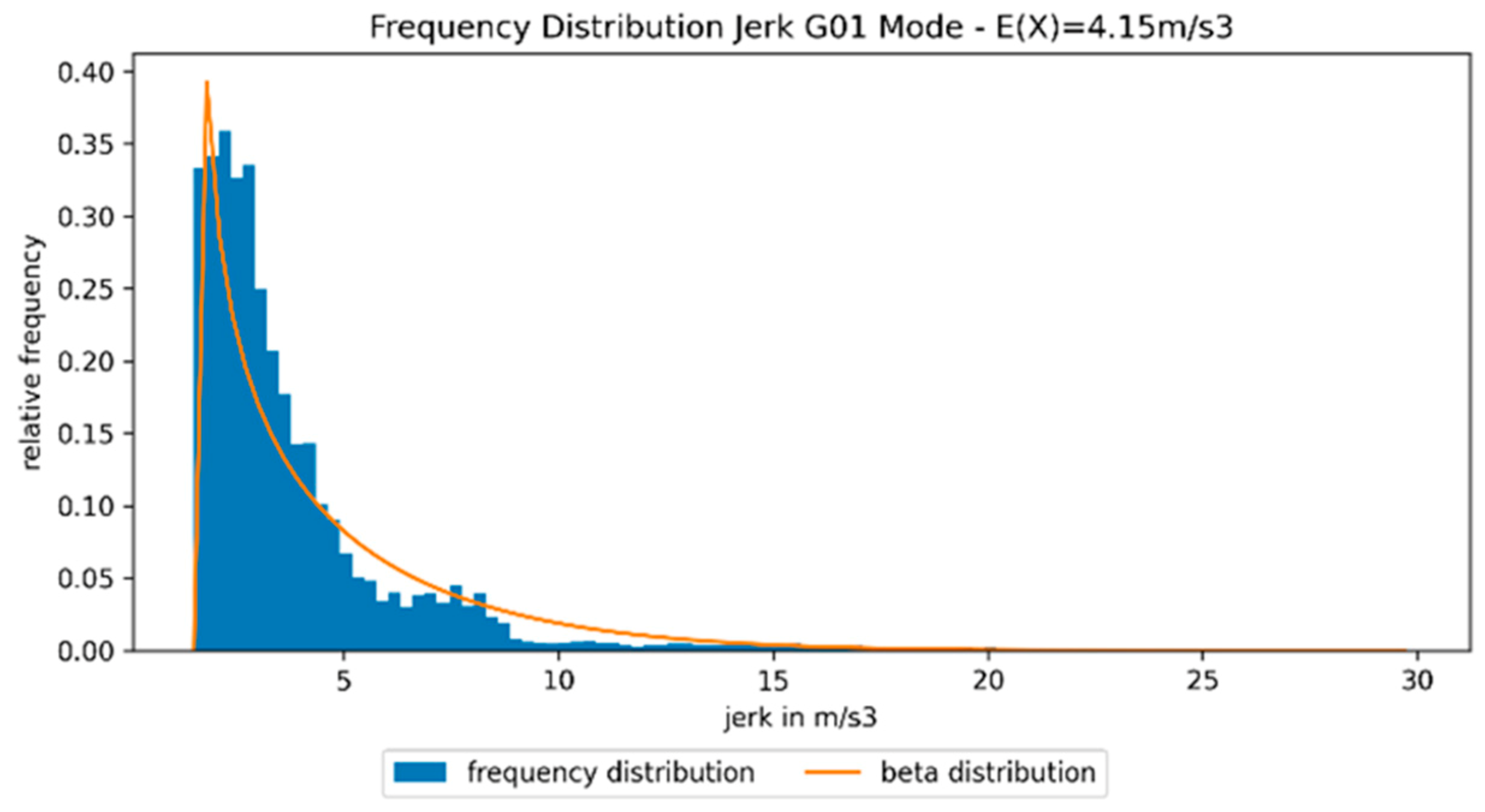

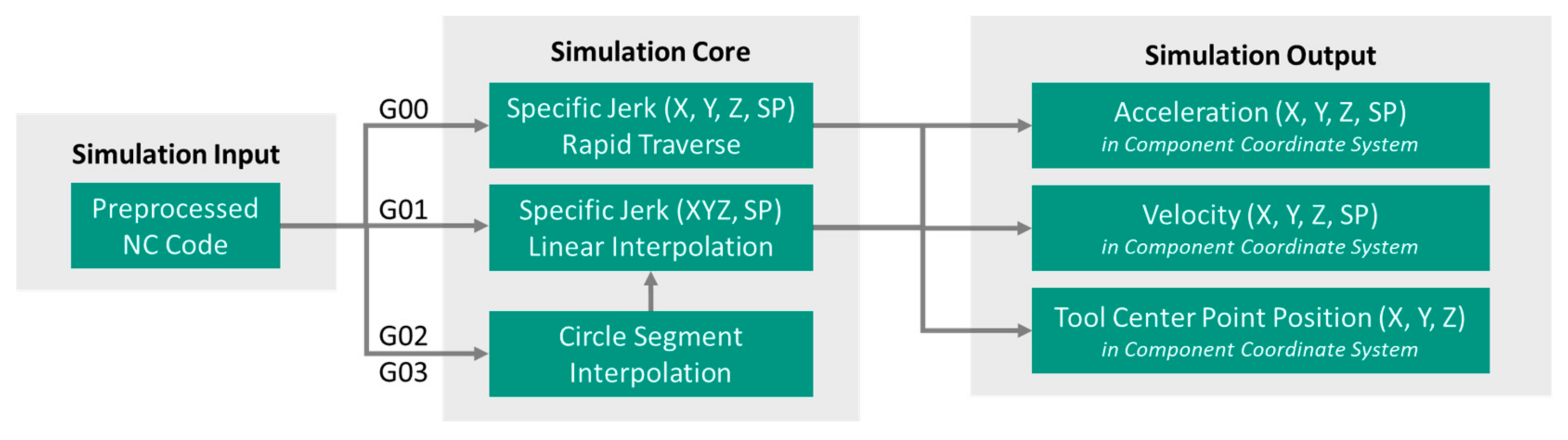

5.1. Kinematic Simulation

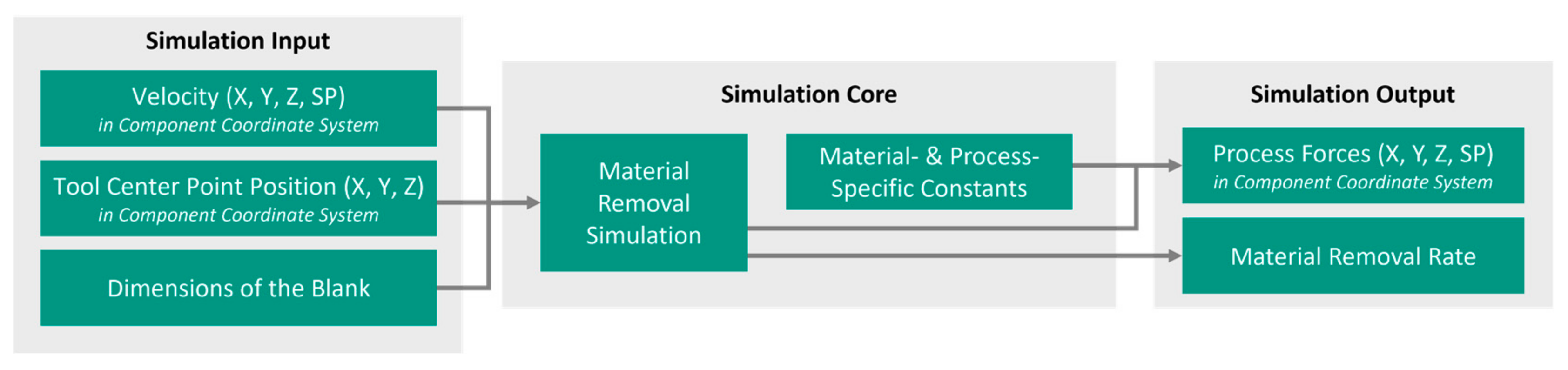

5.2. Process Simulation

5.3. ML Input

5.4. ML Model

5.5. ML Output

6. Validation

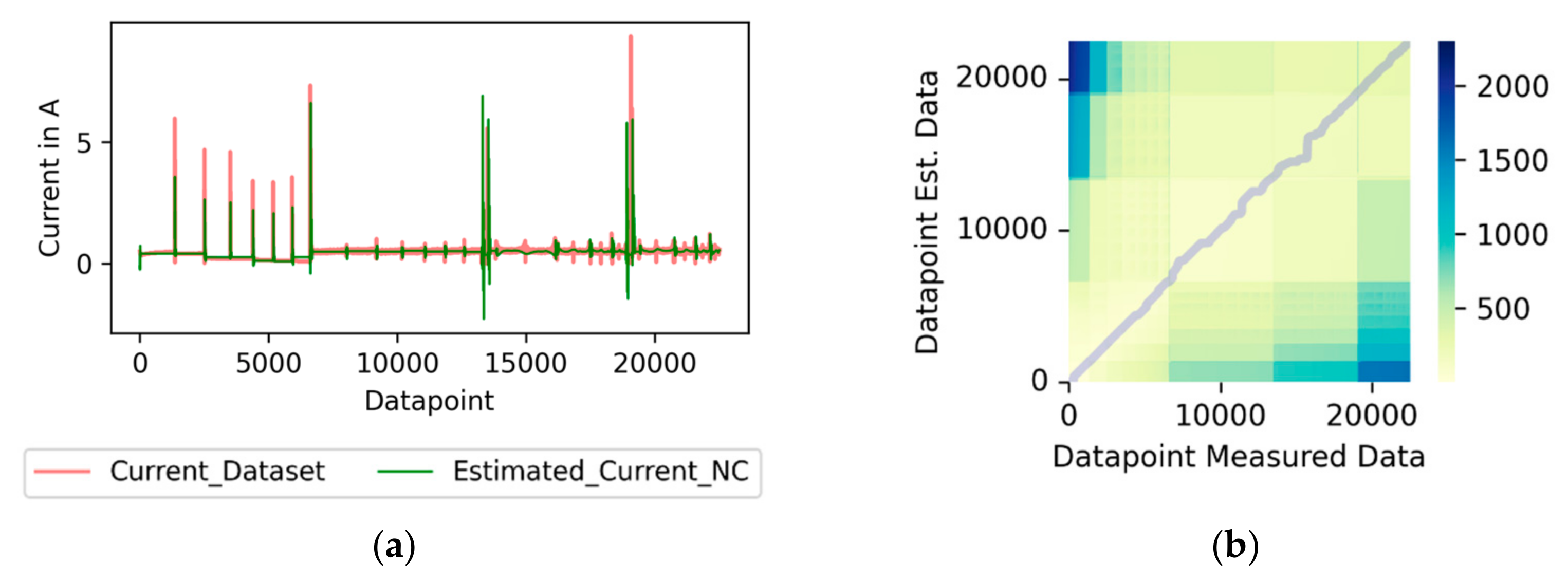

6.1. Experiment 1: Training on Part One and Two Aircut Data—Validation on Unseen Data of Part One

6.2. Experiment 2: Training on Part One Aluminum/Steel Aircut Data—Validation on Part One Steel/Aluminum Data (Exp. a/b)

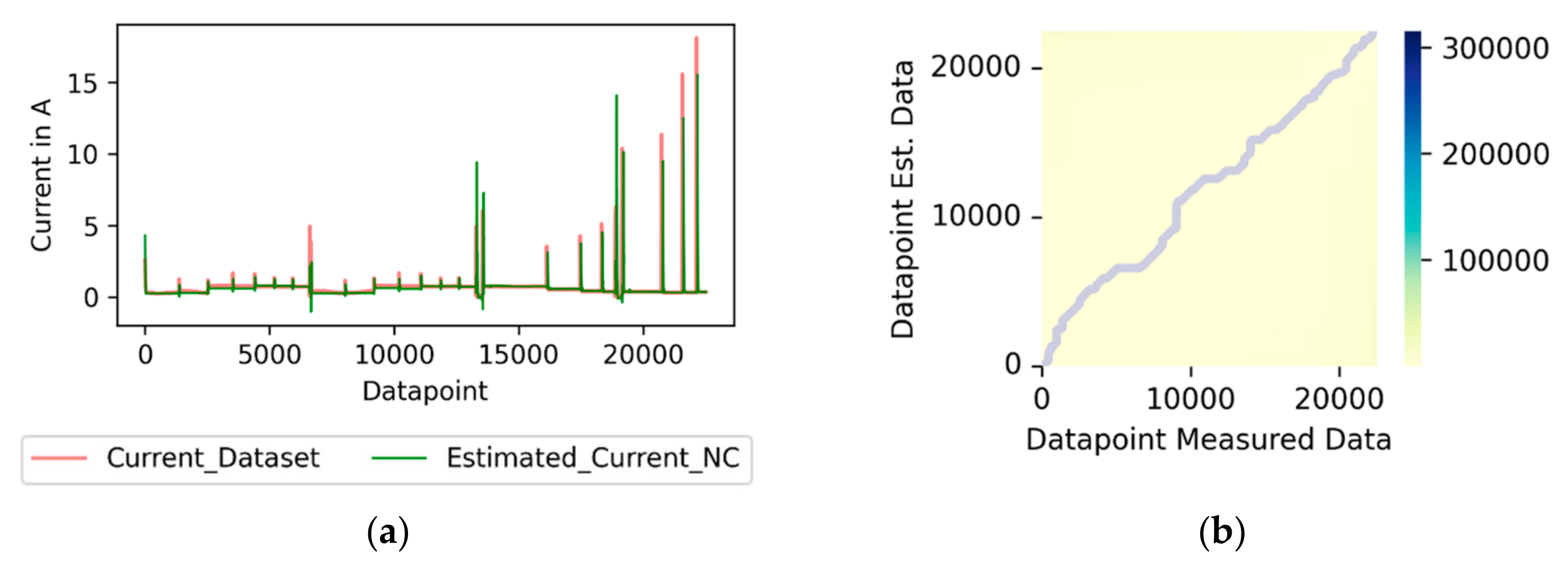

6.3. Experiment 3: Training on Part One Aircut Data—Validation on Part Two Data

6.4. Experiment 4: Training on Part One and Two Aircut Data—Validation on Unseen Data of Part Two

6.5. Experiment 5: Training on Part One and Two Process Data—Validation on Unseen Data of Part One

6.6. Experiment 6: Training on Part One and Two Process Data—Validation on Unseen Data of Part One

6.7. Experiment 7: Training on Part One and Two Process and Aircut Data—Validation on Unseen Part One Data

6.8. Experiment 8: Training on Part One and Two Process and Aircut Data without Part Two Steel/Aluminum Data—Validation on Part Two Aluminum/Steel Data (Exp. a/b)

7. Results

8. Discussion

9. Conclusions and Further Work

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Bhatia, P.; Ranganathan, J.; World Business Council for Sustainable Development (WBCSD). The Greenhouse Gas Protocol. 2004. Available online: https://www.wri.org/research/greenhouse-gas-protocol-0 (accessed on 7 September 2023).

- Schlagenhauf, T.; Netzer, M.; Fleischer, J. OEE+: Ein Vorschlag zur zeitgemäßen Erweiterung der OEE um Nachhaltigkeitsaspekte= A proposal for the contemporary extension of the OEE to include sustainability aspects. WT Werkstattstech. 2022, 112, 481. [Google Scholar]

- BDEW. (15 February 2023). Industriestrompreise* (Inklusive Stromsteuer) in Deutschland in den Jahren 1998 bis 2023 (In Euro-Cent pro Kilowattstunde) [Graph]. Available online: https://de.statista.com/statistik/daten/studie/252029/umfrage/industriestrompreise-inkl-stromsteuer-in-deutschland/ (accessed on 7 September 2023).

- Denkena, B.; Abele, E.; Brecher, C.; Dittrich, M.A.; Kara, S.; Mori, M. Energy efficient machine tools. CIRP Ann. 2020, 69, 646–667. [Google Scholar] [CrossRef]

- Borgia, S.; Pellegrinelli, S.; Bianchi, G.; Leonesio, M. A reduced model for energy consumption analysis in milling. Procedia CIRP 2014, 17, 529–534. [Google Scholar] [CrossRef]

- Pavanaskar, S.; McMains, S. Machine specific energy consumption analysis for CNC-milling toolpaths. In Proceedings of the International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Boston, MA, USA, 2–5 August 2015; American Society of Mechanical Engineers: New York, NY, USA, 2015; Volume 57045, p. V01AT02A018. [Google Scholar]

- Edem, I.F.; Mativenga, P.T. Impact of feed axis on electrical energy demand in mechanical machining processes. J. Clean. Prod. 2016, 137, 230–240. [Google Scholar] [CrossRef]

- Edem, I.F.; Mativenga, P.T. Energy demand reduction in milling based on component and toolpath orientations. Procedia Manuf. 2017, 7, 253–261. [Google Scholar] [CrossRef]

- Edem, I.F.; Mativenga, P.T. Modelling of energy demand from computer numerical control (CNC) toolpaths. J. Clean. Prod. 2017, 157, 310–321. [Google Scholar] [CrossRef]

- Edem, I.F. Energy Modelling for Machine Tool Axis and Toolpaths; The University of Manchester: Manchester, UK, 2017. [Google Scholar]

- Altıntaş, R.S.; Kahya, M.; Ünver, H.Ö. Modelling and optimization of energy consumption for feature based milling. Int. J. Adv. Manuf. Technol. 2016, 86, 3345–3363. [Google Scholar] [CrossRef]

- Zhang, C.; Zhou, Z.; Tian, G.; Xie, Y.; Lin, W.; Huang, Z. Energy consumption modeling and prediction of the milling process: A multistage perspective. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2018, 232, 1973–1985. [Google Scholar] [CrossRef]

- Ma, F.; Zhang, H.; Cao, H.; Hon, K.K.B. An energy consumption optimization strategy for CNC milling. Int. J. Adv. Manuf. Technol. 2017, 90, 1715–1726. [Google Scholar] [CrossRef]

- Imani Asrai, R.; Newman, S.T.; Nassehi, A. A mechanistic model of energy consumption in milling. Int. J. Prod. Res. 2018, 56, 642–659. [Google Scholar] [CrossRef]

- Lv, L.; Deng, Z.; Yan, C.; Liu, T.; Wan, L.; Gu, Q. Modelling and analysis for processing energy consumption of mechanism and data integrated machine tool. Int. J. Prod. Res. 2020, 58, 7078–7093. [Google Scholar] [CrossRef]

- Pawar, S.S.; Bera, T.C.; Sangwan, K.S. Modelling of energy consumption for milling of circular geometry. Procedia CIRP 2021, 98, 470–475. [Google Scholar] [CrossRef]

- Yu, S.; Zhao, G.; Li, C.; Xu, S.; Zheng, Z. Prediction models for energy consumption and surface quality in stainless steel milling. Int. J. Adv. Manuf. Technol. 2021, 117, 3777–3792. [Google Scholar] [CrossRef]

- Brillinger, M.; Wuwer, M.; Hadi, M.A.; Haas, F. Energy prediction for CNC machining with machine learning. CIRP J. Manuf. Sci. Technol. 2021, 35, 715–723. [Google Scholar] [CrossRef]

- Cao, J.; Xia, X.; Wang, L.; Zhang, Z.; Liu, X. A Novel CNC Milling Energy Consumption Prediction Method Based on Program Parsing and Parallel Neural Network. Sustainability 2021, 13, 13918. [Google Scholar] [CrossRef]

- Pawar, S.S.; Bera, T.C.; Sangwan, K.S. Energy consumption modelling in milling of variable curved geometry. Int. J. Adv. Manuf. Technol. 2022, 120, 1967–1987. [Google Scholar] [CrossRef]

- Duc, L.A.; Trinh, N.D. A new study for prediction and optimisation of energy consumption during high-speed milling. Int. J. Comput. Integr. Manuf. 2022, 35, 1352–1377. [Google Scholar] [CrossRef]

- Ströbel, R.; Probst, Y.; Fleischer, J. Training and Validation Dataset of Milling Processes for Time Series Prediction; Institut für Produktionstechnik (WBK): Karlsruhe, Germany, 2023. [Google Scholar] [CrossRef]

- Ströbel, R.; Probst, Y.; Hutt, L.; Fleischer, J. Software-Defined Workpiece Positioning for Resource-Optimized Machine Tool Utilization. J. Mach. Eng. 2023, 23, 71–84. [Google Scholar] [CrossRef]

- Diaz, N.; Redelsheimer, E.; Dornfeld, D. Energy Consumption Characterization and Reduction Strategies for Milling Machine Tool Use. In Glocalized Solutions for Sustainability in Manufacturing; Hesselbach, J., Herrmann, C., Eds.; Springer: Berlin/Heidelberg, Germany, 2011. [Google Scholar]

- Shannon, C.E. Communication in the presence of noise. Proc. IRE 1949, 37, 10–21. [Google Scholar] [CrossRef]

- Paszke, A.; Gross, S.; Massa, F.; Lerer, A.; Bradbury, J.; Chanan, G.; Killeen, T.; Lin, Z.; Gimelshein, N.; Antiga, L.; et al. PyTorch: An Imperative Style, High-Performance Deep Learning Library. In Advances in Neural Information Processing Systems 32; Curran Associates, Inc.: Red Hook, NY, USA, 2019; pp. 8024–8035. Available online: http://papers.neurips.cc/paper/9015-pytorch-an-imperative-style-high-performance-deep-learning-library.pdf (accessed on 7 September 2023).

- Meert, W.; Hendrickx, K.; Van Craenendonck, T.; Robberechts, P.; Blockeel, H.; Davis, J. DTAIDistance (v2.3.10). Zenodo. 2020. Available online: https://zenodo.org/records/7158824 (accessed on 7 September 2023).

- Salvador, S.; Chan, P. FastDTW: Toward accurate dynamic time warping in linear time and space. Intell. Data Anal. 2007, 11, 561–580. [Google Scholar] [CrossRef]

| Experiment | Measure | X-Axis | Y-Axis | Z-Axis | Spindle | All Axes |

|---|---|---|---|---|---|---|

| 1a | Total Deviation | 0.2% | −1.09% | 0.09% | −8.83% | −0.96% |

| DTW-Distance | 69.9 × 10−3 | 64.81 × 10−3 | 66.96 × 10−3 | 93.14 × 10−3 | 294.91 × 10−3 | |

| 1b | Total Deviation | 2.06% | 3.74% | 0.99% | −9.51% | 0.19% |

| DTW-Distance | 60.22 × 10−3 | 71.18 × 10−3 | 59.97 × 10−3 | 38.49 × 10−3 | 229.86 × 10−3 | |

| 2a | Total Deviation | −1.59% | −2.77% | 2.25% | −7.66% | 0.44% |

| DTW-Distance | 61.79 × 10−3 | 76.17 × 10−3 | 86.26 × 10−3 | 65.76 × 10−3 | 289.98 × 10−3 | |

| 2b | Total Deviation | −1.01% | 1.64% | 1.32% | −10.46% | −0.09% |

| DTW-Distance | 67.36 × 10−3 | 70.93 × 10−3 | 62.4 × 10−3 | 59.85 × 10−3 | 260.54 × 10−3 | |

| 3a | Total Deviation | 33.29% | 16.66% | 8.32% | −34.79% | 7.05% |

| DTW-Distance | 238.97 × 10−3 | 197.62 × 10−3 | 384.75 × 10−3 | 170.34 × 10−3 | 991.68 × 10−3 | |

| 3b | Total Deviation | 32.46% | 33.89% | 3.63% | −14.9% | 7.38% |

| DTW-Distance | 152.35 × 10−3 | 275.81 × 10−3 | 335.37 × 10−3 | 211.69 × 10−3 | 975.21 × 10−3 | |

| 4a | Total Deviation | 16.64% | 6.62% | −2.95% | −14.79% | −1.45% |

| DTW-Distance | 130.86 × 10−3 | 157.92 × 10−3 | 341.87 × 10−3 | 233.78 × 10−3 | 864.43 × 10−3 | |

| 4b | Total Deviation | 15.31% | 6.05% | −4.57% | −7.86% | −2.02% |

| DTW-Distance | 110.69 × 10−3 | 167.95 × 10−3 | 377.53 × 10−3 | 205.03 × 10−3 | 861.21 × 10−3 | |

| 5a | Total Deviation | 0.15% | −3.55% | −2.21% | −21.55% | −8.11% |

| DTW-Distance | 324.85 × 10−3 | 259.92 × 10−3 | 223.54 × 10−3 | 558.08 × 10−3 | 1366.39 × 10−3 | |

| 5b | Total Deviation | 43.87% | 44.17% | 1.45% | 78.76% | 22.95% |

| DTW-Distance | 323.84 × 10−3 | 321.22 × 10−3 | 226.71 × 10−3 | 1154.33 × 10−3 | 2026.10 × 10−3 | |

| 6a | Total Deviation | −1.6% | −5.05% | −3.33% | −24.67% | −9.95% |

| DTW-Distance | 322.65 × 10−3 | 270.90 × 10−3 | 337.00 × 10−3 | 619.26 × 10−3 | 1549.81 × 10−3 | |

| 6b | Total Deviation | 43.45% | 43.83% | 1.81% | 69.35% | 21.45% |

| DTW-Distance | 289.60 × 10−3 | 311.32 × 10−3 | 214.04 × 10−3 | 1119.97 × 10−3 | 1934.93 × 10−3 | |

| 7a | Total Deviation | −19.47% | −14.68% | −2.77% | −40.49% | −17.54% |

| DTW-Distance | 395.03 × 10−3 | 388.46 × 10−3 | 293.08 × 10−3 | 1174.27 × 10−3 | 2250.84 × 10−3 | |

| 7b | Total Deviation | 11.48% | 36.73% | −0.11% | 40.26% | 11.45% |

| DTW-Distance | 168.99 × 10−3 | 270.81 × 10−3 | 145.81 × 10−3 | 599.64 × 10−3 | 1185.25 × 10−3 | |

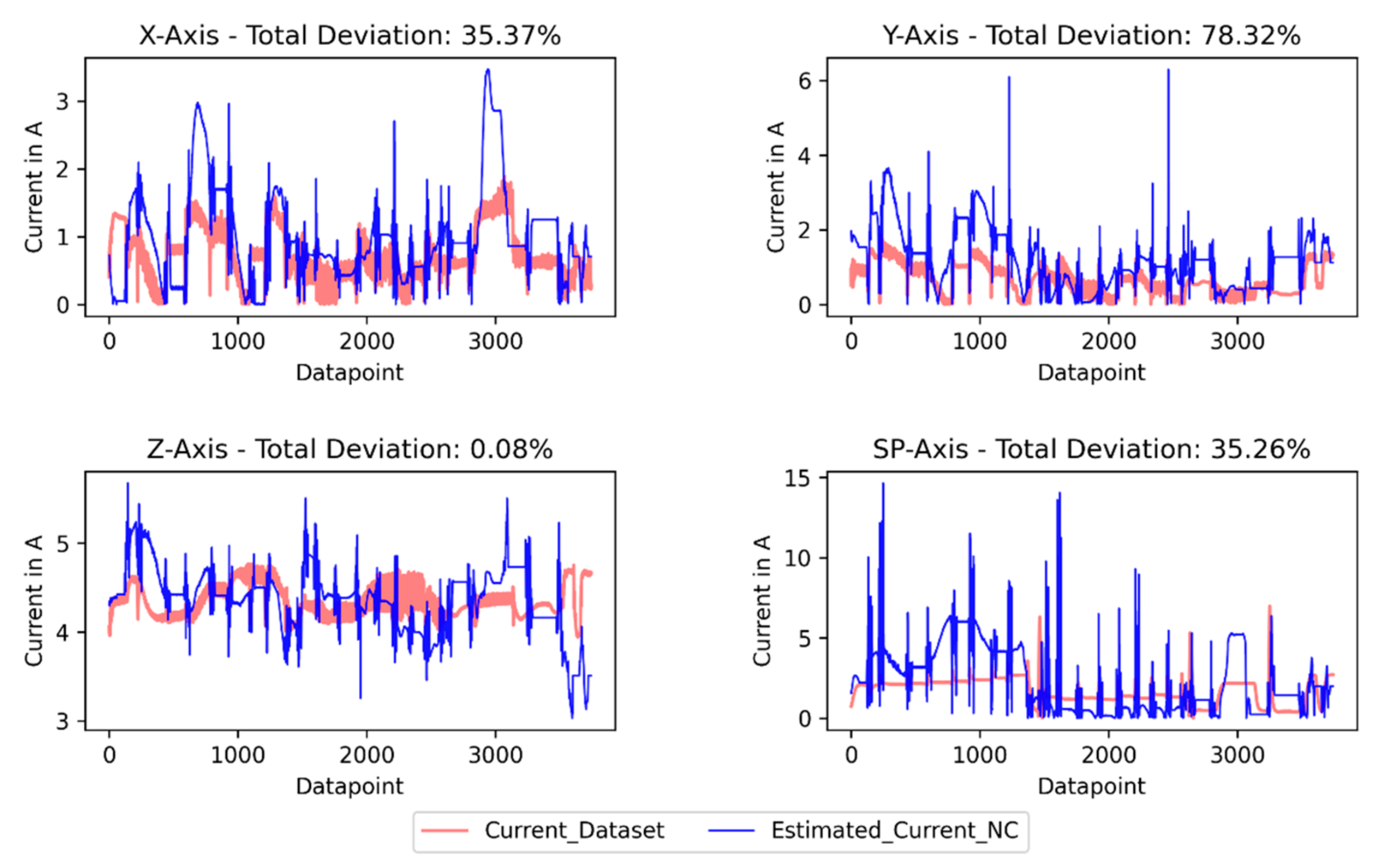

| 8a | Total Deviation | 35.37% | 78.32% | 0.08% | 35.26% | 18.49% |

| DTW-Distance | 356.31 × 10−3 | 382.32 × 10−3 | 203.73 × 10−3 | 897.44 × 10−3 | 1839.8 × 10−3 | |

| 8b | Total Deviation | 68.44% | 106.61% | 2.34% | 169.98% | 41.45% |

| DTW-Distance | 349.48 × 10−3 | 624.84 × 10−3 | 176.59 × 10−3 | 787.27 × 10−3 | 1938.19 × 10−3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ströbel, R.; Probst, Y.; Deucker, S.; Fleischer, J. Time Series Prediction for Energy Consumption of Computer Numerical Control Axes Using Hybrid Machine Learning Models. Machines 2023, 11, 1015. https://doi.org/10.3390/machines11111015

Ströbel R, Probst Y, Deucker S, Fleischer J. Time Series Prediction for Energy Consumption of Computer Numerical Control Axes Using Hybrid Machine Learning Models. Machines. 2023; 11(11):1015. https://doi.org/10.3390/machines11111015

Chicago/Turabian StyleStröbel, Robin, Yannik Probst, Samuel Deucker, and Jürgen Fleischer. 2023. "Time Series Prediction for Energy Consumption of Computer Numerical Control Axes Using Hybrid Machine Learning Models" Machines 11, no. 11: 1015. https://doi.org/10.3390/machines11111015

APA StyleStröbel, R., Probst, Y., Deucker, S., & Fleischer, J. (2023). Time Series Prediction for Energy Consumption of Computer Numerical Control Axes Using Hybrid Machine Learning Models. Machines, 11(11), 1015. https://doi.org/10.3390/machines11111015