Abstract

Background: Exploring the impact of combining Industry 4.0 technologies and Lean Manufacturing tools on organizational performance has been a popular topic in recent years. Design/Methodology/Approach: We propose a novel Smart and Sustainable Manufacturing System (SSMS) to provide management insights related to social impact, economic performance, and environmental impact. Some tools called Dynamic Lean 4.0 tools, such as Sustainable Value Steam Mapping (VSM), Extended Single Minute Exchange of Die (SMED), and Digital Poka-Yoke, are presented as outputs of synergistic relationships that optimize production processes. Originality/Research gap: There are few studies on the application of SSMS. This work presents a case study, aiming to fill this gap. A case study of vacuum degassing equipment fabrication is presented to demonstrate the improvement of utilizing the Define-Measure-Analyze-Improve-Control (DMAIC) method with Digital Poka-Yoke. Key statistical results: The implementation of this project increased the process capability index, Cpk, from 1.278 to 2. Practical Implications: It was concluded that the company successfully implemented a smart and sustainable manufacturing system, and created a safer working environment and new job opportunities, while increasing production yield from 99.44% to 100%, improving worker utilization, and directly saving NT$68,000. Limitations of the investigation: This paper is the use of a single case study. More applications of Dynamic Lean 4.0 tools in SSMS should be explored.

1. Introduction

Lean Manufacturing (LM) refers to a set of management techniques and principles designed to eliminate waste and simplify activities that add value to products from a customer perspective. By optimizing process steps and eliminating waste, only useful value is added at each production stage. LM principles are now applied across industries, and these tools are recognized worldwide as a successful operational framework for reducing waste, increasing productivity, and continuously improving organizations [1]. Due to LM, waste and costs are minimized, thereby increasing productivity and profit [2]. From an economic point of view, LM reduces waste, which in turn increases market share and profits [3]. In terms of social impact, LM improves occupational health and safety, thereby improving the quality of life in society [4]. The LM concept has been shown to be critical to achieving sustainability in any organization [5]. On the environmental front, LM can lead to lower levels of pollutants and slower resource consumption due to improved products and reduced storage materials. Lean culture has shown a significant impact on the sustainability performance of different industries, including plastics manufacturing, and lean culture has a moderating effect [6]. Several industries have benefited from the implementation of LM and resulted in better organizational performance [7,8,9].

Industry 4.0 offers organizations the opportunity to improve their current manufacturing operations and practices to a more advanced level by leveraging emerging technologies. As the global market continues to evolve, manufacturing systems become smarter, more flexible, digital, agile, and are able to keep pace with market volatility [10]. Industry 4.0 drives smart manufacturing, enabling manufactures to maximize output from existing production capacities and develop next generation production capabilities necessary to compete in the digital economy. Manufacturers around the world are experiencing dramatic changes by leveraging Industry 4.0 technologies, such as cloud computing, big data analytics, robotics, and the Internet of Things (IoT). Industry 4.0 technologies have a significant impact on the sustainability performance of the manufacturing industry as they produce better machines, enhanced communications, improved working conditions, and product quality [11]. IoT, sensors, and big data can enhance the environmental, social, and economic aspects of the Brazilian plastics industry [12]. Through digitalization, Industry 4.0 technologies can reduce production and transportation costs and lead times, thereby increasing customer satisfaction and organization’s profits [13]. With respect to the environmental aspect, data sharing among supply chain stakeholders, and the availability of real-time data facilitate the efficient allocation of raw materials, water, energy, and labor time, thereby reducing resource consumption and waste generation [14]. As a social concept, Industry 4.0 offers people with new technologies to improve motivation and morale by providing safe working conditions [15].

The importance of combining LM and Industry 4.0 has become as a hot topic [16]. Integrating LM into Industry 4.0 requires more research, although it is considered an enabler of Industry 4.0 or a pre-requisite for its introduction [17]. A systematic review of the literature found that they have many symbioses and synergies [18]. Organizations are expected to benefit greatly from Industry 4.0 technologies and LM together. Their combination can also reduce waste and cost in areas where LM alone is not feasible [19]. Additionally, Industry 4.0 technologies are more expensive to implement without LM principles, so further integration of them is expected to reduce implementation costs. Although these two factors are important in different manufacturing industries, few studies have examined their relationship [20]. Furthermore, there are few real case studies on LM and Industry 4.0 applications and their impact on organizational performance [21]. Organizations can benefit from new innovative and automated manufacturing techniques, namely lean digital transformation [22].

The work involved in LM and Industry 4.0 can be divided into two categories: (i) conceptual and theoretical discussions [11]; and (ii) application-oriented use case study [23]. This paper covers both categories. First, there is a lack of research on the combined impact of Industry 4.0 and LM principles on corporate performance. In this regard, the novelty of this study lies in the in-depth exploration of possible relationships between Industry 4.0 technologies and useful LM tools. We propose a Smart and Sustainable Manufacturing System (SSMS) with Dynamic Lean 4.0 tools as the outputs of synergistic relationships for optimized production processes. Second, as a validation of the proposed framework and integrated tools, a case study of vacuum degassing equipment fabrication is presented. The need to improve process capability and production yield became the background for the selection of the case study. The rest of the paper is organized as follows: the related work on lean tools, followed by Industry 4.0 technologies. In Section 3, we describe a SSMS framework and some Dynamic Lean 4.0 tools. Section 4 presents the implementation of the proposed method for a real case study. The final section draws the conclusion.

2. Related Work

2.1. Lean Manufacturing Tools

LM aims at producing products and services at the lowest cost and as fast as required by the customer. Various lean tools effectively eliminate the organization’s waste. In the context of Industry 4.0, Value Stream Mapping (VSM) 4.0 is recently developed as collaborative value stream tool for lean management. By utilizing VSM 4.0, companies can map flow components and process boundaries, and plan full-scale implementation digitally [24]. Single Minute Exchange of Die (SMED) describes the activities necessary to prepare a production line for manufacturing a product, while setup time refers to the time spent between the end of a previous process and the beginning of the next process [25]. Poka-Yoke devices prevent errors from occurring or make them apparent [26]. The Poka-Yoke system can be used to identify any errors, prevent them from moving to the next process, and manage the identification of the causes of any errors occurring [27].

2.2. Industry 4.0 Technologies

Industry 4.0 refers to a new stage of industrialization in which companies can achieve greater industrial performance by integrating vertical and horizontal manufacturing processes. A key feature of Industry 4.0 is to enable regular machines to become self-aware and self-learning so they can perform better and monitor their maintenance more efficiently. Industry 4.0 mainly focuses on real-time monitoring of data, tracking the status and location of products, and controlling production processes [28]. A number of digital technologies have become enablers of Industry 4.0. The use of autonomous robots allows for more precise execution of autonomous production methods and operations where the work of human workers is limited [29]. In the context of Industry 4.0, simulation reaches the next frontier, known as the digital twin, which is a virtual representation of a physical object using digital data. To create higher quality products, digital simulation tools can enable faster, more flexible and efficient processes by integrating with production systems. Using sensory data in digital simulation can improve the efficiency of production planning and execution by increasing the credibility of production system [30]. IoT includes the dynamic management of complex systems through the real-time interaction of people, machines, objects, and information and communication technology systems. The growth of cyber-physical systems within Industry 4.0 means that a cybersecurity market is emerging [31]. A key component of Industry 4.0 is additive manufacturing, as it reduces the complexity of manufacturing and saves time and money. This allows rapid prototyping and highly decentralized production processes [32]. In a digitalized and easily comprehensible manner, Augmented Reality (AR) provides remote maintenance support through numerous applications for technical knowledge dissemination [33]. An important aspect of Industry 4.0 is the application of big data, which can examine enormous quantities of information to discover hidden patterns and correlations [34].

3. Smart and Sustainable Manufacturing System

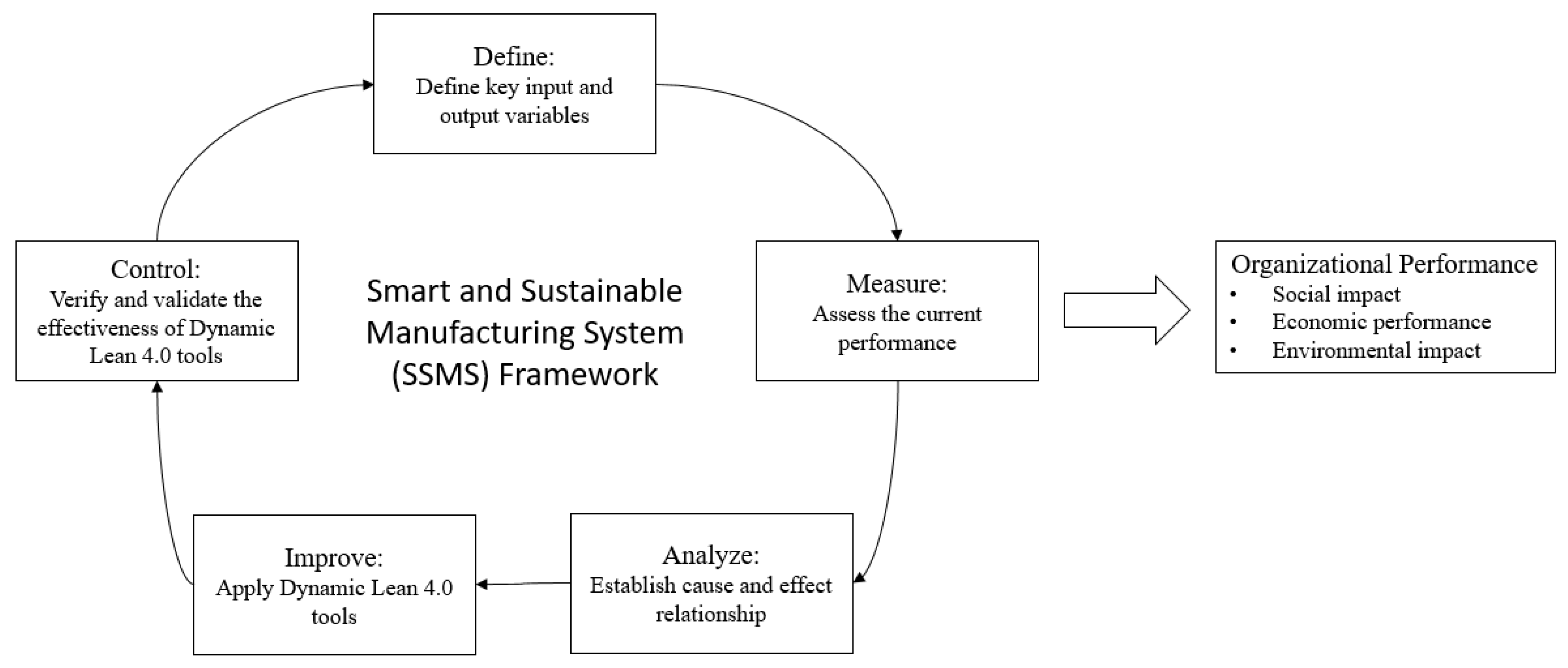

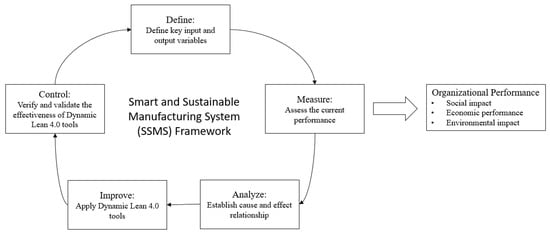

This section presents a novel SSMS framework and provides managerial insights about organizational performance with social impact, economic performance, and environmental impact. The SSMS framework adopted the concept of the Define-Measure-Analyze-Improve-Control (DMAIC) methodology and some tools called Dynamic Lean 4.0 tools as the outputs of synergistic relationships for optimized production processes.

3.1. SSMS Framework

In the Industry 4.0 digital environment, smart factories play an important role in machines and devices can automate and optimize processes. Real-time data and connections between machines support automated and analytical manufacturing. By combining powerful, in-depth and accurate analytics, manufacturers will be able to unlock new possibilities and business advantages by leveraging the autonomous smart manufacturing capabilities of Industry 4.0.

From an economic point of view, smart factories have a direct impact on production, services, and final products. The concept of the smart factory involves the use of smart devices, such as smart machines, robots and workpieces, that communicate in a continuous manner during the production process. Integrated production optimizes operations through self-organization and adaptation, resulting in smart products that can be easily tracked using Radio-Frequency Identification (RFID) tags. In addition, smart production ensures customer satisfaction by producing high-quality products, custom designs, and short production lead times and lead times.

From a societal perspective, smart factories affect a wide range of issues, including the job market, worker safety, and labor laws. Using the smart factory model, the company is able to automate and optimize its operations. With the development of smart devices, certain tasks and functions are being replaced by smart devices, thereby changing the job market and reducing the number of low-skilled workers. Additionally, as smart devices become more commonplace, more skilled workers are required to operate them. When factories become smart factories, workers will face another job hazard. Therefore, it is important to improve worker safety at work and ensure compliance with human rights while reducing workplace risks.

Sustainable manufacturing is the responsibility of the manufacturer, both in terms of operations and product design. As a result of industrial operations, it is clear that industry contributes to the overuse of the earth’s resources. In addition, pollution, excessive waste, and improper disposal can lead to further environmental damage. When the industry is under pressure to reduce its environmental footprint, ignoring environmental concerns represents a huge risk. As climate change and environmental concerns increase, the need for sustainable manufacturing will increase. Manufacturers must make meaningful changes to meet local and government needs. As a result of these changes, people are turning to smart factories, and digital transformation is becoming more common.

Creating value in manufacturing is enabled by smart and sustainable operations that reduce waste and improve the environment. Enabling lean techniques in Industry 4.0 helps organizations achieve more smart and sustainable operations with data-driven decision making and optimizing manufacturing and operations, as depicted in Figure 1.

Figure 1.

Smart and sustainable manufacturing system framework.

3.2. DMAIC Methodology on SSMS Framework

A standard improvement model, such as DMAIC, is very helpful for deploying improvements in a company because it provides an improvement roadmap. Project definition leads to the identification of key process characteristics and the benchmarking of these characteristics during the measure and analyze phase. In the improve phase, a process is transformed for better performance, while in the control phase, gains are monitored and maintained. Therefore, we propose a DMAIC model based on SSMS framework and Dynamic Lean 4.0 tools to improve organizational performance. The DMAIC model consists of the following basic elements and key tools.

During the define phase, the goal is to identify opportunities for the project and verify or confirm their viability. The project must have a significant impact on both the customer and the business. Potential uses of the project require consent from stakeholders and downstream customers. The define phase can also be aided by graphical aids, such as process maps and SIPOC diagrams. A flowchart describes an overview of a company’s approach to meeting customer requirements. The SIPOC diagram consists of Supplier, Input, Process, Output, and Customer, and is used to refine the project scope and boundaries. It can help visualize and understand the essential elements of a process: Supplier—an entity that provides any information, material, or item processes in a process. Input—information or material provided. Process—the steps required to transform an input into an output. Output—the product or service that is sent to the customer, considering the critical quality attributes. Customer—the next step or end customer of the business.

The measure phase evaluates and understands the current process state. It involves gathering information on quality, cost, and timeliness from various sources. In order to be able to analyze and understand current process performance in relation to key metrics, sufficient data is required. Observational studies are often necessary to collect current data. Process data can be collected over a period of time using continuous data collection or sampling methods. The collected data is used to determine the baseline performance of the current process. A run chart can be used to display observed data in chronological order. In addition, the capability of the process should be assessed. This can be done using process capability analysis, such as Process Capability Ratio (PCR), to measure the actual capability of the process.

Data collected during the measure phase is used in the analyze phase to begin to identify causal relationships in the process and understand the different sources of variability. Specifically, the analyze phase aims to identify potential causes of defects, quality issues, customer issues, cycle time, and throughput issues, waste, and inefficiencies leading to the project. Various tools are available during the analyze phase, such as Five Whys and Quality Function Development (QFD). Five Whys is a problem-solving approach that explores the underlying cause-and-effect relationships of a particular problem. QFD is a structured method for defining customer requirements and translating design specifications or product control characteristics in the form of a planning matrix. The House of Quality (HOQ) matrix involves collecting and analyzing the voice of customer to define the relationship between customer needs and product or company capabilities.

The improve phase should identify specific opportunities and root causes for improvement. As part of the improve phase, improvement strategies are developed and tested in practice. At this phase, think creatively about what can be changed and how the performance of the process can be improved to achieve the desired effect. Digital transformation is essential for manufacturers to evolve into smart and sustainable businesses. We introduce some novel tools such as an integration of lean tools and Industry 4.0 technologies, called Dynamic Lean 4.0, including Sustainable VSM, Extended SMED, and Digital Poka-Yoke. The three steps to apply Dynamic Lean 4.0 tools are as follows:

Step 1: Technology roadmaps describe related technologies to help organizations plan and implement technology development. In addition, it can be used as a forecasting tool for technical trends. By analyzing the current state of technology, customer needs, and expected market entry strategies, technology roadmaps can be used to identify alternative technologies, competitors, and market entry opportunities. Additionally, it can help understand how organizational goals, organizational technology resources, and rapidly changing market conditions relate to each other.

Step 2: Technology classification is conducted by evaluating the technology’s main functions. Due to advances in operations and information technology, a well-established sequence of layers has been established. There are four levels, including sensors, manufacturing data acquisition, monitoring and control, and operations management.

Step 3: As shown in Table 1, the application of Dynamic Lean 4.0 tools is expected to help manufacturers solve certain problems. By separating the elements of production that are actively involved in the manufacturing process from those that are passive, Lean 4.0 tools can evolve into an intelligent and adaptable Industry 4.0 production system. An active asset system can be viewed as a dynamic, manageable resource system for digital control, real-time tracking, and processes transparency. Manufacturing cells are transformed into Lean-Industry 4.0 by updating specific active physical components, corresponding digital components and activating Lean 4.0 tools. It allows Lean 4.0 tools to interact with manufacturing cloud databases, customize according to manufacturing scenarios, integrate with applications, or implement different algorithms. The transition from lean to smart, adaptable Industry 4.0 production systems makes Lean 4.0 tools dynamic, flexible and intelligent. Ejsmont et al. [35] pointed out several Industry 4.0 technologies such as digital twin, big data, IoT and how they interact with lean tools. However, not all authors agree on which are the main Industry 4.0 technologies affecting lean [36]. Langlotz et al. [37] emphasized that these digital technologies, when properly integrated into a lean environment, can improve processes of a pulled nature to increase efficiency. Thus, Dynamic Lean 4.0 tools perform the interaction of Industry 4.0 technologies with lean tools. Sustainable VSM enables the management and control of the daily operations of the production line facilitate the integration of the entire value stream in the organization chain and its related dependents. Digital Poka-Yoke uses digital data from digital technologies to facilitate error-proofing processes by integrating employees and Industry 4.0. Combining advanced technology and lean tools, smart and autonomous production systems are possible, and are in line with the dynamic demands of the global economy. Companies will benefit from lower production costs, improved regulatory compliance, and long-term resilience, while better connections to target customers will yield better growth opportunities.

Table 1.

Dynamic Lean 4.0 tools and its function.

The goal of the control phase is to complete all remaining work on the project, ensuring that the benefits of the project contribute to the tracking of the process and subsequent improvements. Before and after data on key process indicators should be provided and a validation check after project completion is recommended. Data needs to be collected to compare and demonstrate that improvements achieve better results. Preliminary results must remain stable to continue to have a positive financial impact. Keeping a good list of items is essential to keep the process improving.

4. Case Study

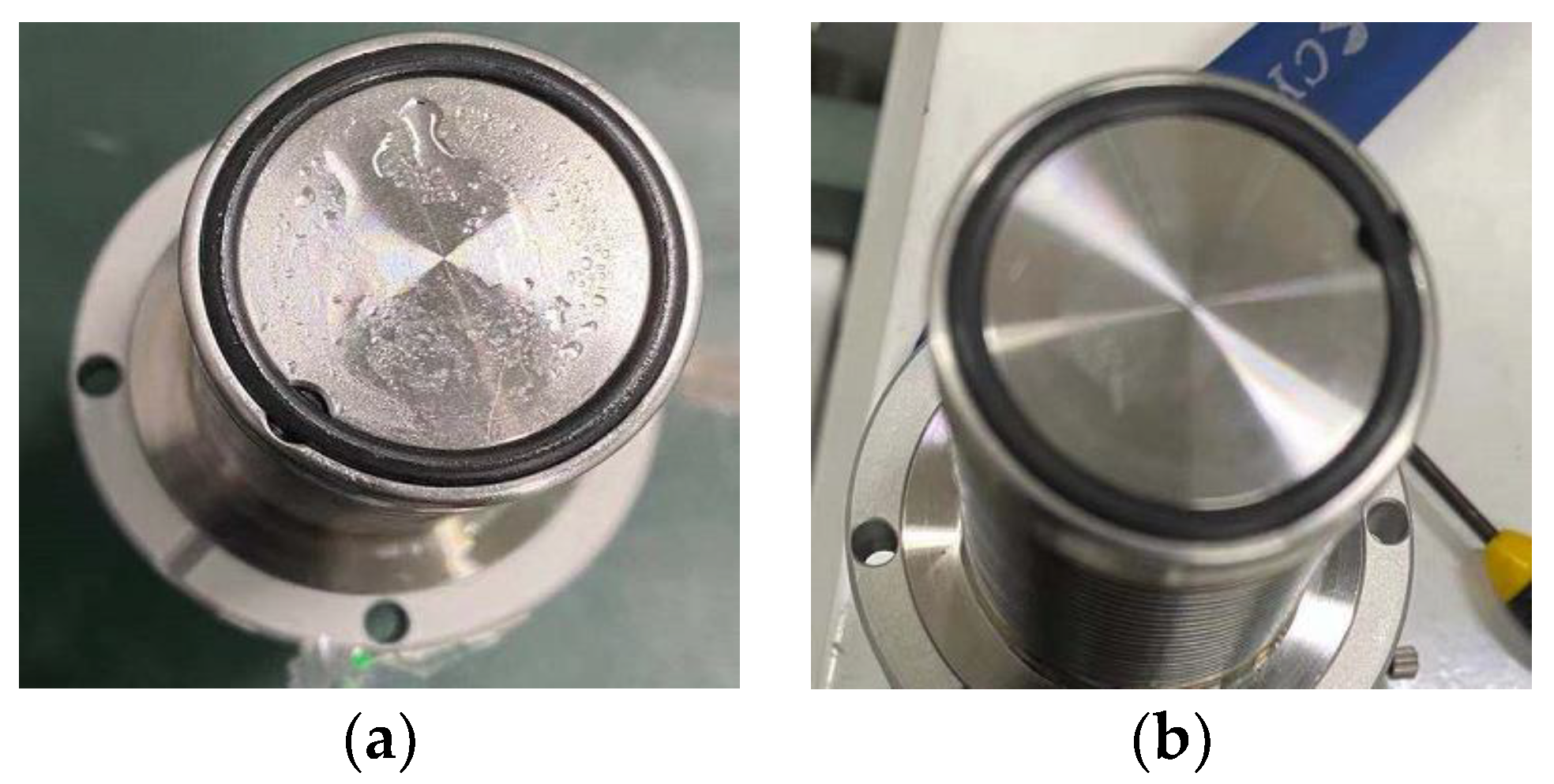

The case company, called Company-T, is located in Taiwan. The company manufactures vacuum degassing equipment (see Figure 2), where its key function is to support in several systems, such as vacuum, ice water, hydraulic, air pressure, and electrical system. This company faces a problem that the storage volume in this equipment does not reach the target, therefore causing an anomaly status. The tube with fault label judged by the machine will be removed, and the storage volume value will be abnormal. A clear roadmap can be achieved through the use of the DMAIC process, which provides a useful framework for running selected projects. An explanation of the DMAIC method for problem solving and the importance of achieving SSMS is provided in this case study. The following explains how DMAIC works in this case study.

Figure 2.

Vacuum degassing equipment.

4.1. Define

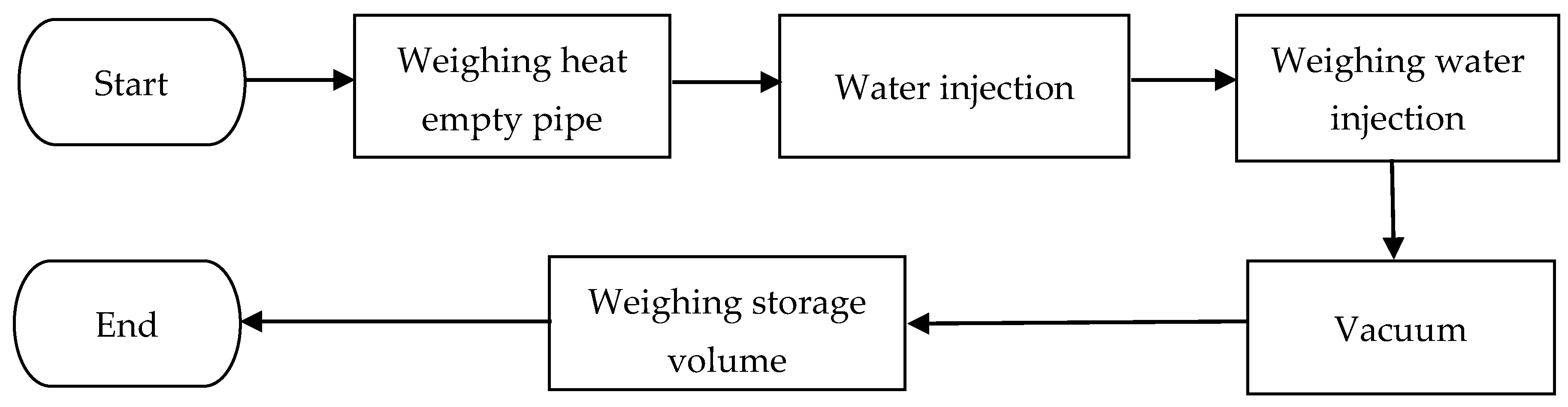

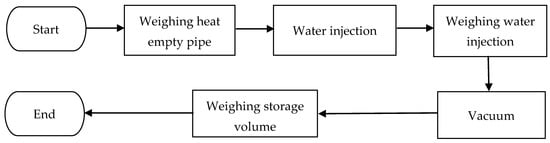

During the define phase, product design and development process issues are identified. Subsequently, the results of product construction and trial operation were reviewed. As part of this process improvement project, the project team used SIPOC-related activities (see Table 2) to identify all relevant elements. It helps define a complex project that may not have a good scope and provides additional detail. The operation process of heat pipe water injection is shown in Figure 3.

Table 2.

SIPOC diagram.

Figure 3.

Heat pipe water injection process.

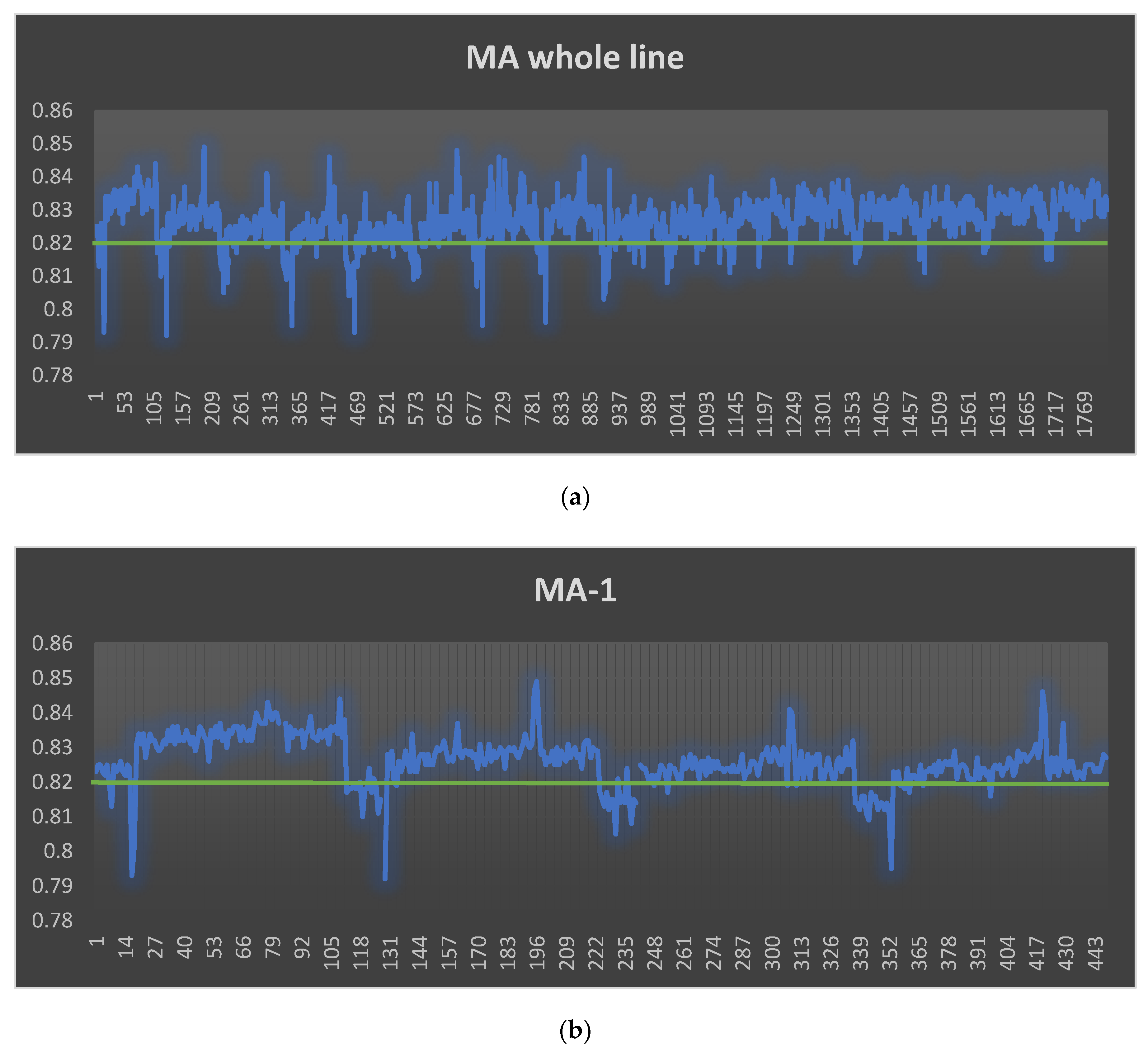

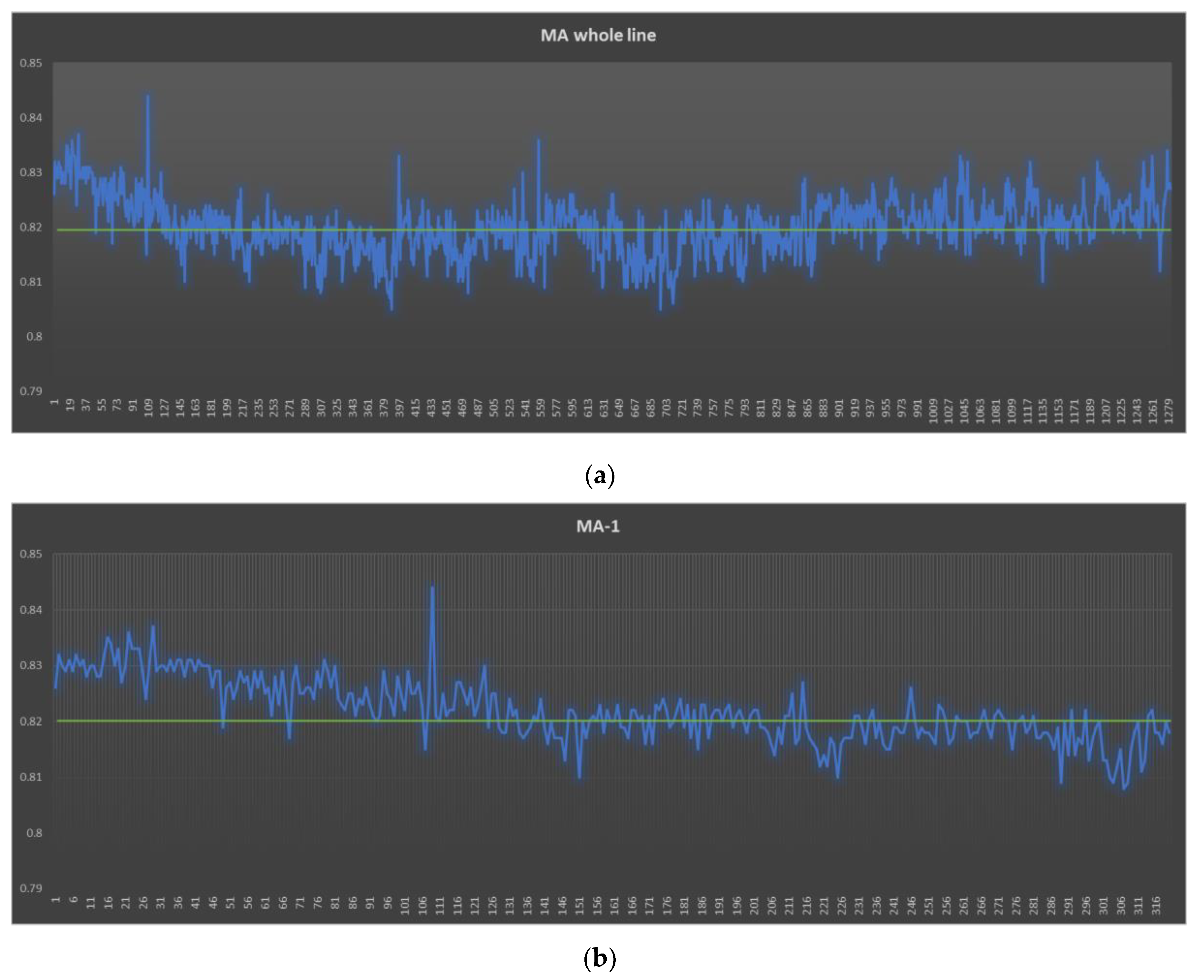

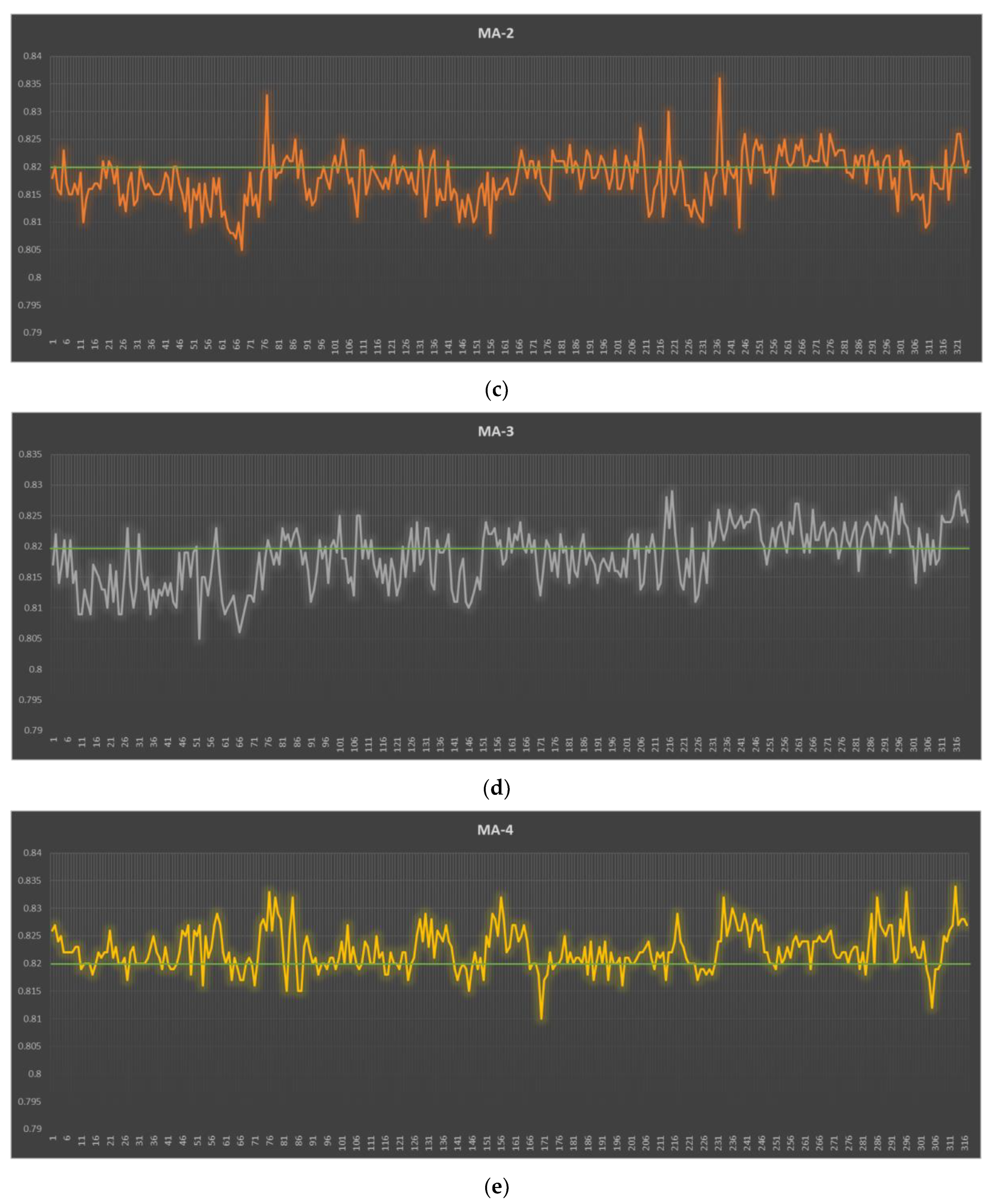

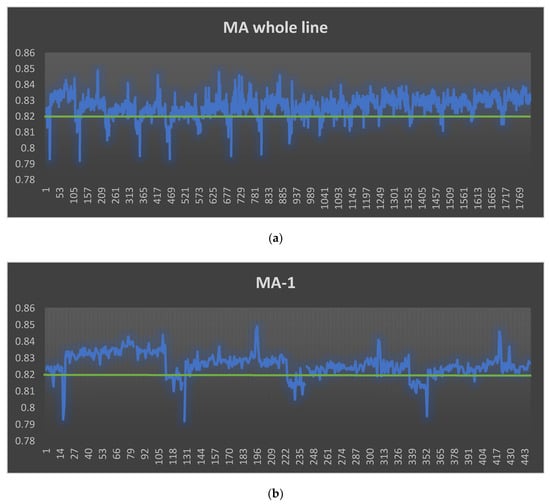

4.2. Measure

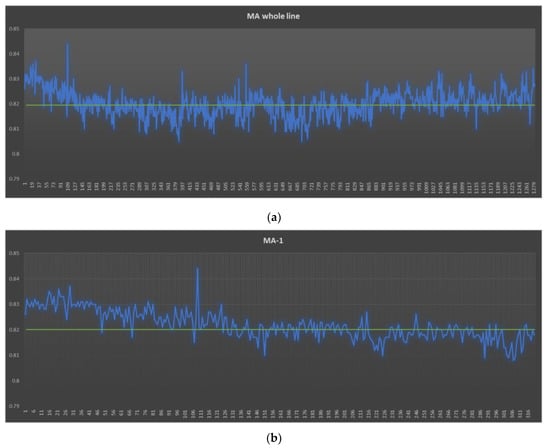

At this phase, customer specifications are confirmed and current performance is assessed. A total of 1810 samples were collected, and the production yield was 99.44%. Table 3 provides the initial state of the machine. It showed that the short-term capability PCR-Cpk of MA whole line was 1.278. Therefore, the current process capability is not that good compared to the guideline for minimum value, which is 1.33. Note: Cpk = min{(Process mean − LSL)/3s, (USL-process mean)/3s}, LSL = lower specification limit, and USL = upper specification limit. The storage data for each machine is shown in Figure 4. It shows that the amount of storage is significantly from the target value of 0.82. Therefore, it is impossible to meet the customer’s specification requirements for production.

Table 3.

The performance of initial state of the machine.

Figure 4.

Initial state-run chart of storage volume on machines (a) MA whole line, (b) MA-1, (c) MA-2, (d) MA-3, and (e) MA-4.

4.3. Analyze

At this phase, the specifications and product characteristics are analyzed. The two steps involved in the phase are as follows:

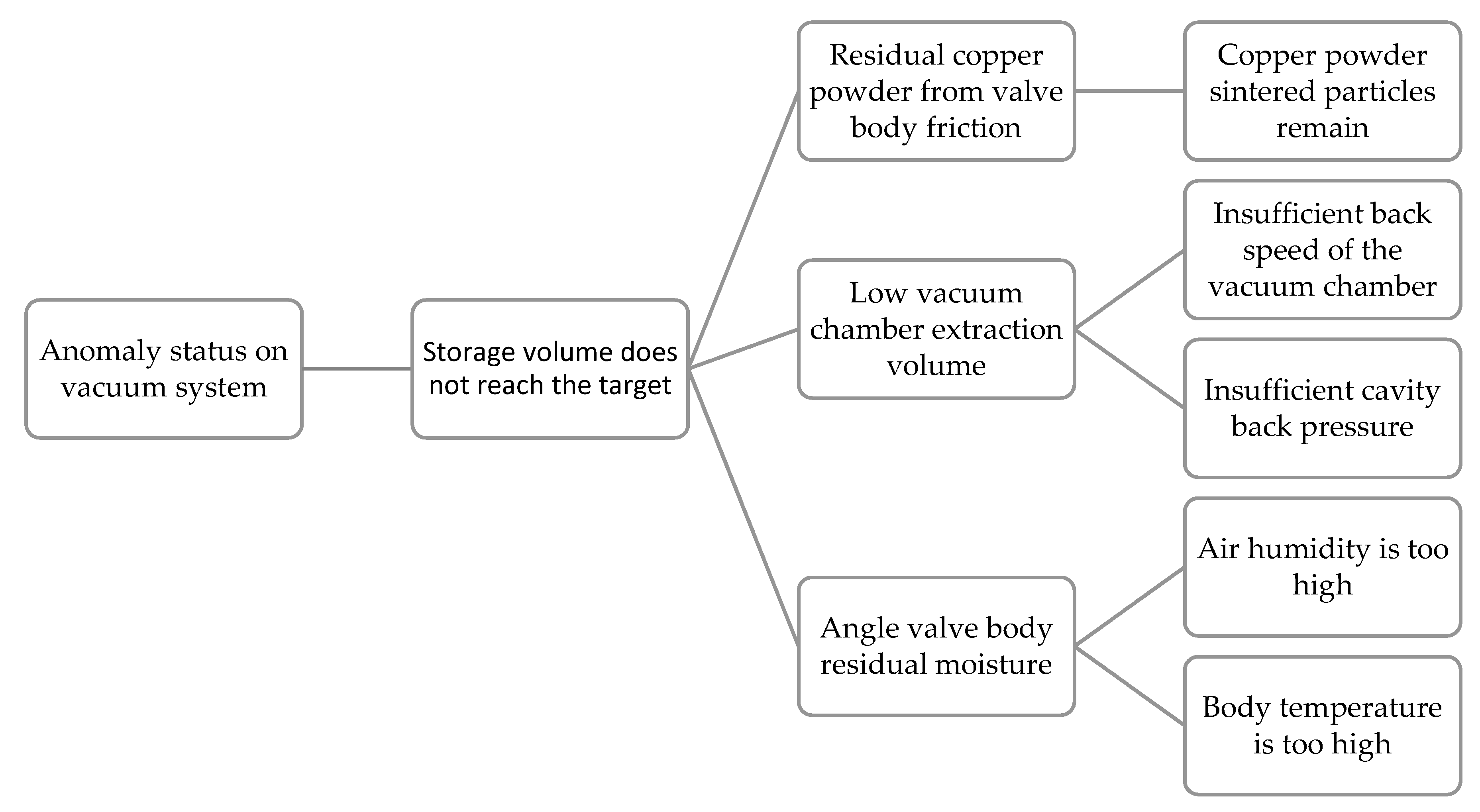

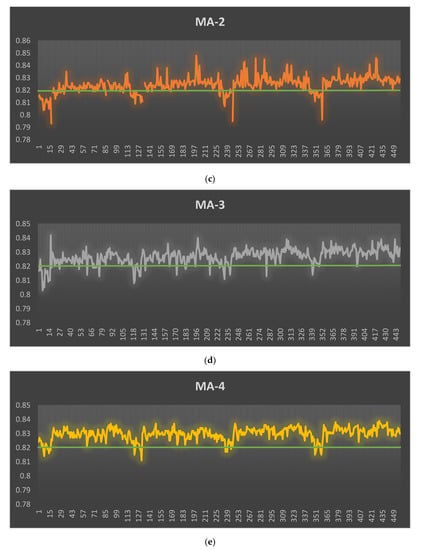

Step 1: Identify root cause—The root cause of the vacuum system abnormal problem is determined by using the Five Whys tool, as shown in Figure 5.

Figure 5.

The root cause identification using the Five Whys tool.

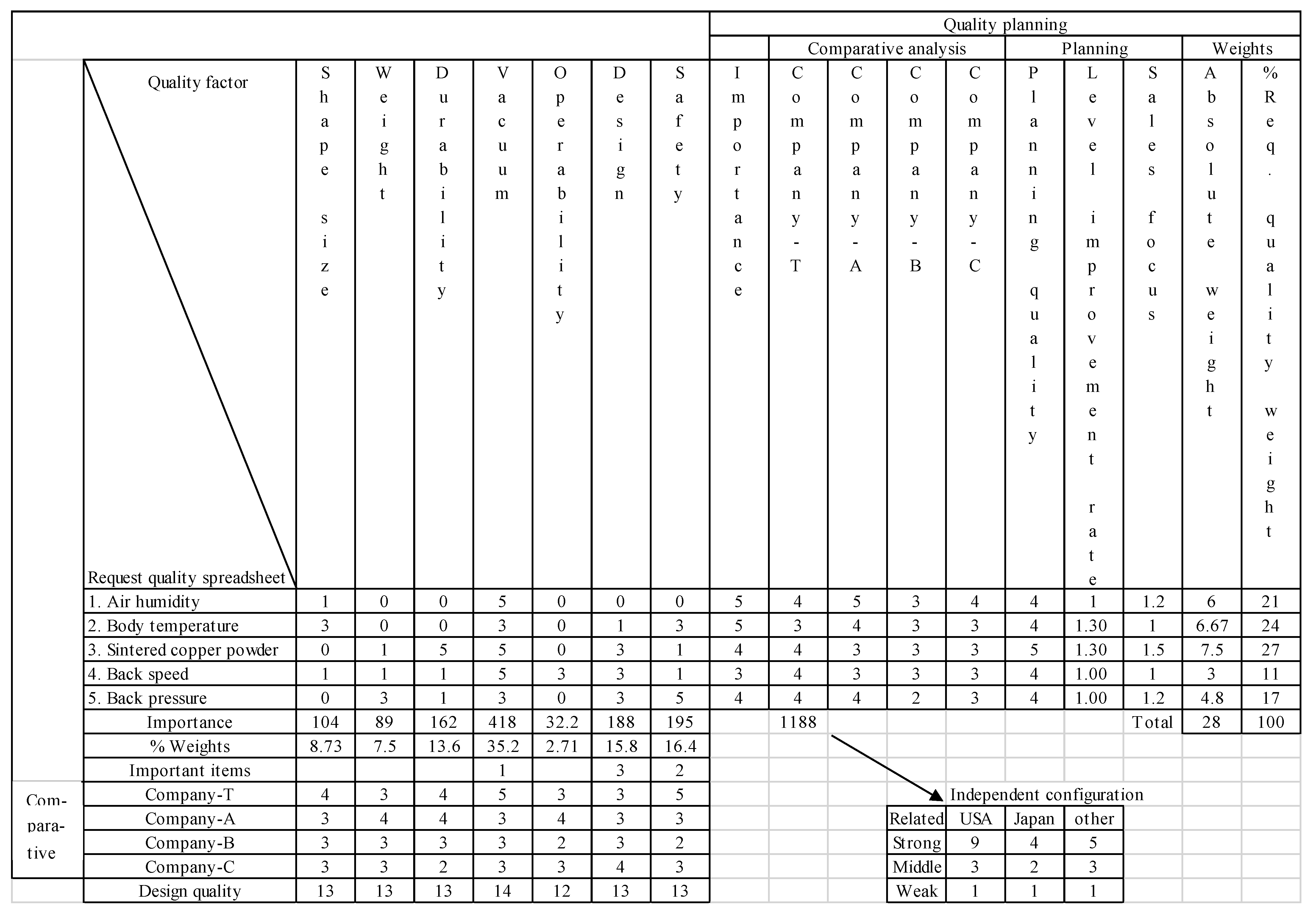

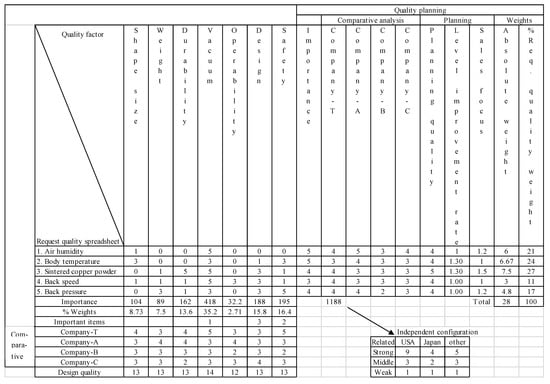

Step 2: Planning process—QFD is used to define and translate customer requirements into specific plans to produce a product that meets the voice of the customer. As shown in Figure 6, a summary of customer requirements is described in the house of quality matrix. Among the design factors, vacuum has the largest weight at 35.2%.

Figure 6.

House of quality matrix.

4.4. Improve

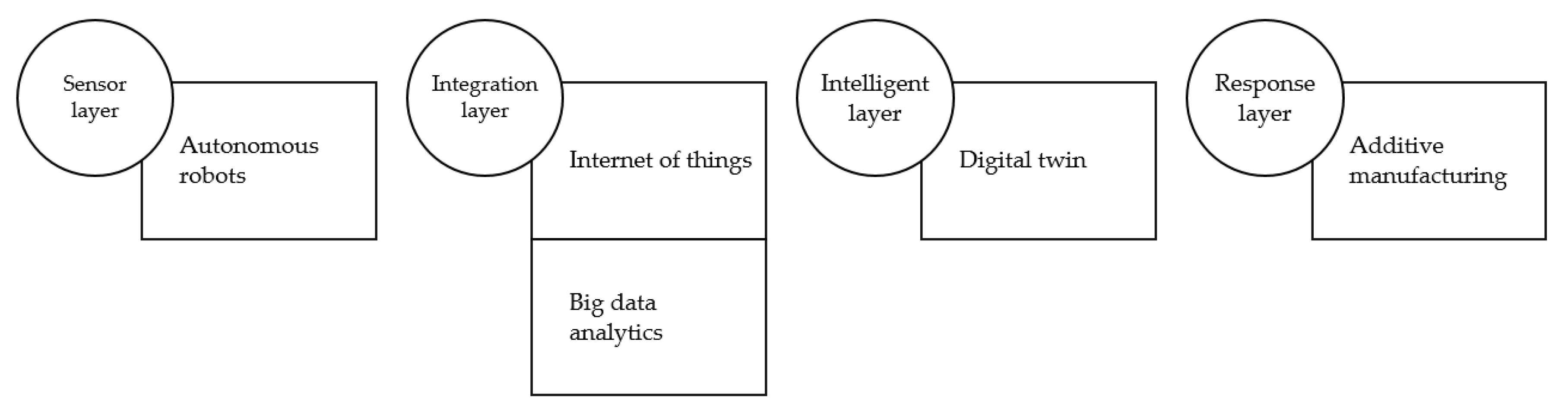

During the improve phase, we applied a Dynamic Lean 4.0 tools called Digital Poka-Yoke to improve the process performance. The three steps involved in the phase are as follows:

Step 1: Technology roadmap, which is based on the root causes and customer needs identified during the analysis phase, we identified five Industry 4.0 technologies that are a foolproof match. The five technologies are autonomous robotics, digital twins, IoT, big data analytics, and additive manufacturing to reduce process variation.

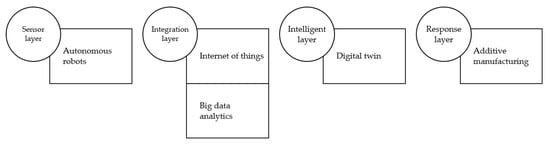

Step 2: Technology classification, which is based on technical relevance to Poka-Yoke. The technology architecture is divided into four layers: sensor, integration, intelligence, and response (see Figure 7). At the sensor layer, physical and environmental data are monitored locally. Once the sensor layer collects data, it is passed to the integration layer for processing. The intelligence layer uses data analytics and algorithms to make predictions based on aggregated information. The response layer then develops various applications and services on top of the other three layers.

Figure 7.

Technology architecture and classification.

Step 3: Digital Poka-Yoke application—Autonomous robots make a significant contribution to increasing productivity and streamlining processes by integrating automated intelligent systems into transportation and handling operations. They facilitate continuous flow and improve operator performance through standardized processes. The role of worker just input the material to the machine, then the robots do all the process operations until vacuum degassing equipment can run well. Using high-volume, interconnected, or even integrated robots with sensors to ensure job safety can eliminate human error through advanced automation that eliminates the need for human intervention. This means the worker has no longer exist on the production floor.

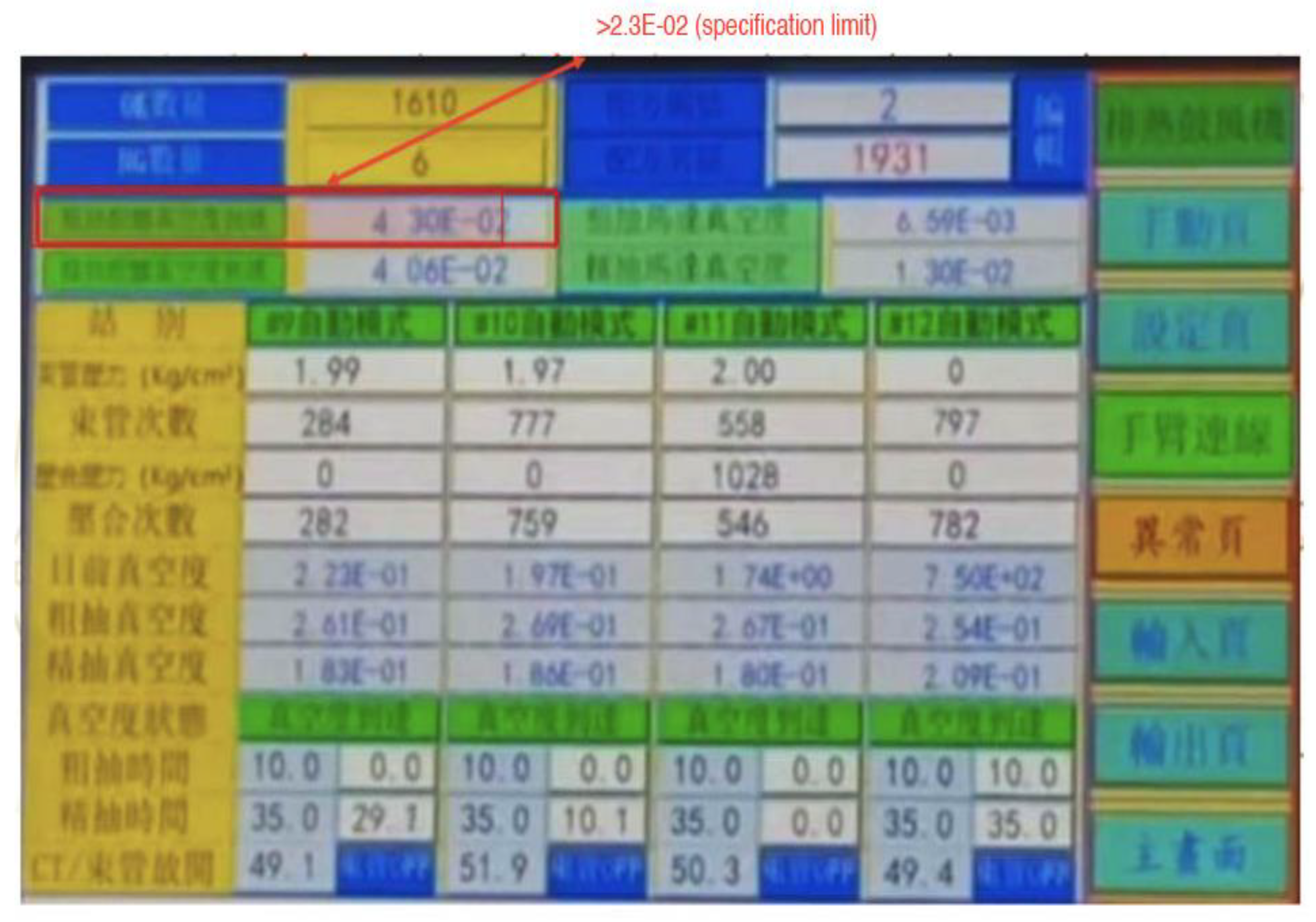

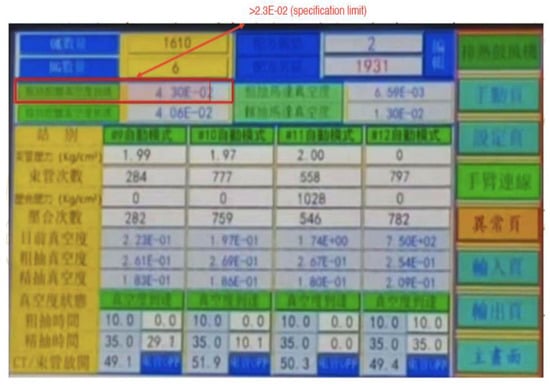

In the context of current applications of Digital Poka-Yoke, this company realizes a manufacturing production system based on digital twins. An innovative concept of digital twin is introduced into equipment fault diagnosis and trend prediction as a means of improving fault identification accuracy and increasing manufacturing intelligence. Production quality can be effectively improved and production efficiency can be increased through the application of the digital twin to error-proofing management. An integrated manufacturing workshop management and control system with digital twin technology and IT is designed to optimize manufacturing equipment monitoring so that errors do not occur in production. In addition to the digital twin, data transmission and workshop data collection are used to predict equipment faults. Real-time machine status data is captured by a factory-level digital twin model that enables virtual and real-time interaction feedback. In spite of the fact that error-proofing sensors have been existed, IoT advancements have made them easier to install and maintain. With the advent of IoT, error-proofing relies less on manual mechanisms and more on IoT-enabled sensors interconnected across all devices in the shop floor (see Figure 8). In Figure 8, it indicates that the current process is out of control because the metric is greater than the specification limit. An IoT-enabled sensor can send this false alarm information automatically. Initially, the machine runs under the operator’s control. By applying Digital Poka-Yoke, the machine no longer needs to be manually controlled by the operator. The operator does not need to wait and pay attention to the machine status. On the other hand, the operator can do other added-value work to improve utilization. If the measured value is greater than the nominal value, the machine will automatically stop and an alarm will be issued to inform the operator. After that, the operator will check and eliminate the anomaly. Using IoT, error-proofing devices can be controlled immediately. With such immediacy, error-proofing devices are less likely to be bypassed. As the company next improvement in the future, sensors will be able to be adjusted remotely from any location at any time. Through the integration of sensors directly into processes, error detection has been greatly improved. Flexible manufacturing involves Digital Poka-Yoke devices based on specific product versions. Sensors provide true data to the control system or offer remote programming capabilities. Traceability is also integrated into the system, so they know exactly what version of the product is being manufactured. By using digital and wireless industrial communication network, sensors can capture and process enriched data. The data then is used to increase productivity, optimize efficiency and minimize errors in automated processes.

Figure 8.

Sensor connected with internet of things technology on the machine interface.

An autonomous inspection has also been implemented in this company. This helps worker to do the monitoring, and in case there is a problem happened, the machine can be shut down automatically. Additive manufacturing process involves the creation of solid three-dimensional objects based on digital models. This company has developed various 3D printing technologies, which the common feature is to create layers by layers of a physical model. Making mistake-proof fixtures for the visually impaired is an innovative application of 3D printing technologies. A Digital Poka-Yoke and 3D printing system is used for blind-friendly fixtures that ensure the correct positioning of the assembly components. As a result, a person with visual impairments is now able to perform jobs that before were not available to them. Additionally, it improves the capability of autonomous inspection.

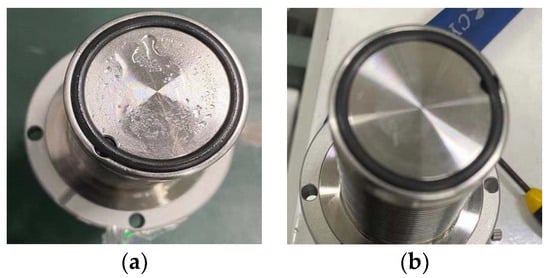

Figure 9 depicts the results of before and after the improvement of the water vapor residue in vacuum degassing equipment using Digital Poka-Yoke.

Figure 9.

Comparison image (a) before and (b) after the improvement of the water vapor residue.

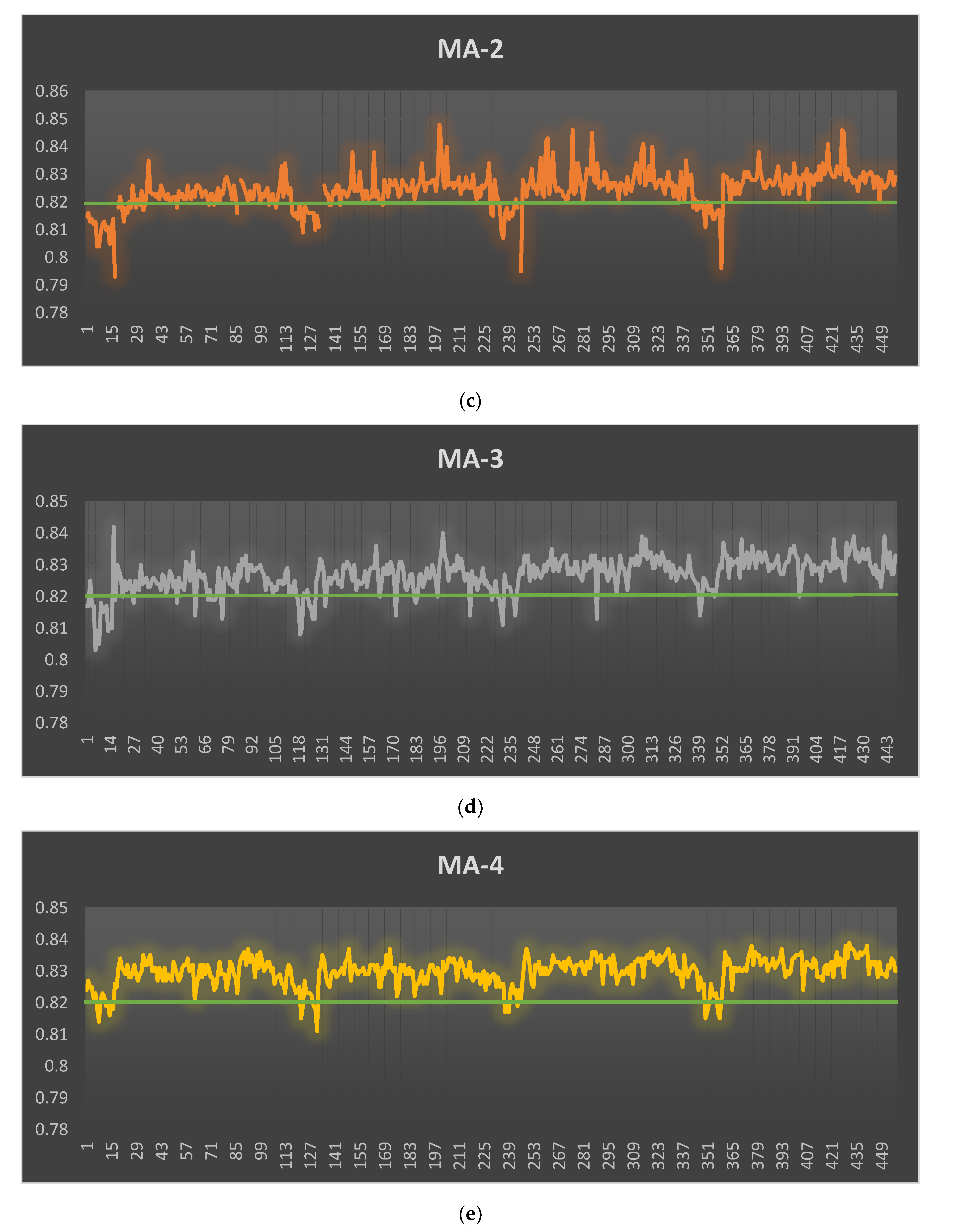

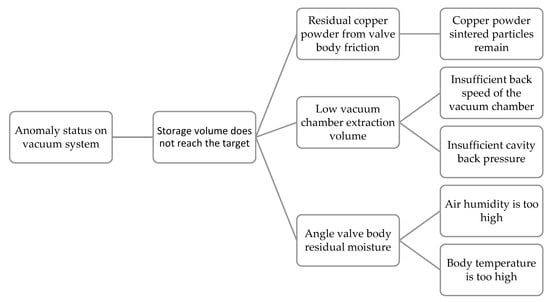

4.5. Control

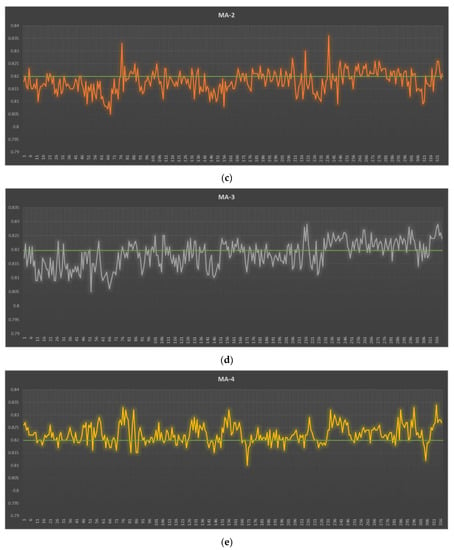

During the control phase, the process capability index for new data is measured. After applying Digital Poka-Yoke, project team members collect up-to-date samples to identify new process capabilities and monitor improvements. A total of 1282 samples were collected, and the production yield was 100%. As shown in Figure 10, the process average improved significantly and moved closer to the specification target. The process proven to have a higher capability to meet customer specifications. The results of the analysis showed that the process average of the MA line decreased from 0.827 to 0.820. In addition, the process variation is also significantly reduced, especially for the MA-3 line, from 0.007 to 0.004. Consequently, PCR-Cpk was enhanced for all MA lines (whole and 1–4 lines) and was greater than the recommended minimum value of 1.33 (see Table 4). This means improved processes to meet customer requirements.

Figure 10.

Improved state-run chart of storage volume on machines (a) MA whole line, (b) MA-1, (c) MA-2, (d) MA-3, and (e) MA-4.

Table 4.

Improved condition.

Furthermore, the adaptation of the Digital Poka-Yoke tool realizes this company achieve the SSMS that can be seen from three aspects. In relation to social impact, the working environment become safer with the presence of autonomous robots. The worker’s load has decreased due to autonomous inspection. Additionally, the company has successfully created new job opportunity for visually impaired and involved them into work through the aid of additive manufacturing technology. From the economic perspective, the production yield rate has improved from 99.44% to 100% with the existence of IoT-enabled error-proofing devices. The direct savings of the project amounted to NT$68,000, mainly due to the high worker utilization rate and less rework process. Thus, it leads to high efficiency and increase profitability of this company. Lastly, the high level of operational efficiency has successfully reduced the excessive of material waste. This means that the Company-T contributes to the environmental sustainability.

5. Contribution and Practical Implications

This study offers valuable insights for scholars and practitioners. Similar to Antony et al.’s [16] studies on the integration of Lean Six Sigma and Industry 4.0, this paper discusses the development of lean principles in the digital environment of Industry 4.0 for the interest of researchers. More research is needed to understand the relationship of LM to Industry 4.0 technologies [17]. Therefore, this study aims to introduce a possible integration between several lean tools and emerging technologies, called Dynamic Lean 4.0 tools.

Although their relationship is still in its infancy, the literature review [18] found a synergistic need for each other. Cost competitiveness [19] and waste reduction [20] are expected to be the result of Industry 4.0 combined with lean. Furthermore, the impact of LM and Industry 4.0 on organizational performance is rarely investigated in real case studies [21]. Therefore, this paper fills the gap by introducing an SSMS framework that employs the concept of DMAIC methodology for continuous improvement of social impact, economic performance and environmental impact. It is worth noting that DMAIC provides an improvement roadmap. We modified the improvement phase by applying Dynamic Lean 4.0 tools and verify their effectiveness on organizational performance during the Control phase.

From a practical standpoint, this study provides valuable insights for all managers and leaders to better understand the application of lean tools in Industry 4.0. LM have been prominent manufacturing paradigms over the past decades, with the respective aim of reducing waste to achieve low cost in production processes. Industry 4.0 is transforming traditional manufacturing systems into smart ones. The current competitive market requires manufacturing companies to improve cost-efficiency with the application of Industry 4.0 technologies. LM implementation integrated with Industry 4.0 adoption leads to high operational performance improvement. Therefore, we introduce some novel tools, called Sustainable VSM, Extended SMED, and Digital Poka-Yoke, as extensions to popular lean tools combined with proper Industry 4.0 technologies. A case study is presented to verify the effectiveness of Digital Poka-Yoke tool. As a result, this novel tool successfully improves the process capability and production yield, resulting in a smart and sustainable manufacturing system.

6. Conclusions

This work aims to explore the possible relationship between Industry 4.0 technologies and useful LM tools on business performance. We propose a novel SSMS framework and some tools called Dynamic Lean 4.0 tools as an output of synergistic relationships to optimize production processes. In-depth exploration through project planning has been conducted to provide management insights into organizational performance and social, economic, and environmental impact.

In addition, this paper fills a gap in the literature on the combined impact of Industry 4.0 and LM principles on corporate performance, and the case study validating these impacts. A conceptual and theoretical discussion about LM and Industry 4.0 has been refined in this study to meet the research needs discussed in [11]. An application-oriented use case study is also presented to satisfy the shortfall of work described in [23]. Therefore, this study provides further advantages for researchers and practitioners.

We have demonstrated the improved effect of using the DMAIC method with Digital Poka-Yoke in the fabrication of vacuum degassing equipment. This project improvement program helped company-T successfully eliminate wasteful variations and improve business performance, increasing the process capability index, Cpk, from 1.278 Cpk to 2 Cpk and increasing the production yield from 99.44% to 100%. The direct savings of the project amounted to NTD 68,000, mainly due to the higher worker utilization rate. Additionally, safer working environments, new job opportunities, and excessive material waste are all improved to implement smart and sustainable manufacturing systems.

This paper is limited by the use of a single case study. More applications of Dynamic Lean 4.0 tools in SSMS should be explored. Future research may include implementing other Dynamic Lean 4.0 tools, such as Sustainable VSM and Extended SMED for SSMS framework. However, our approach provides a general learning perspective. A means of continuous improvement is demonstrated through the effective application of the DMAIC process. Therefore, this paper can serve as a unique roadmap for practitioners and academia to improve process capability to meet customer specifications, especially to improve social, economic, and environmental performance.

Author Contributions

Conceptualization, B.R. and F.-K.W.; methodology, B.R., F.-K.W. and Y.-P.C.; software, B.R.; validation, F.-K.W. and R.-H.Y.; resources, F.-K.W. and R.-H.Y.; data curation, Y.-P.C.; writing—original draft preparation, B.R. and F.-K.W.; writing—review and editing, F.-K.W. and R.-H.Y.; visualization, B.R. and Y.-P.C.; supervision, F.-K.W. and R.-H.Y.; project administration, F.-K.W. and R.-H.Y. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Santos, A.C.O.; da Silva, C.E.S.; Braga, R.A.D.S.; Corrêa, J.É.; de Almeida, F.A. Customer value in lean product development: Conceptual model for incremental innovations. Syst. Eng. 2020, 23, 281–293. [Google Scholar] [CrossRef]

- McDermott, O.; Antony, J.; Sony, M.; Healy, T. Critical Failure Factors for Continuous Improvement Methodologies in the Irish MedTech Industry. TQM J. 2022, 34, 18–38. [Google Scholar] [CrossRef]

- Ratnayake, R.C.; Chaudry, O. Maintaining sustainable performance in operating petroleum assets via a lean-six-sigma approach: A case study from engineering support services. Int. J. Lean Six Sigma 2017, 8, 33–52. [Google Scholar] [CrossRef]

- De Souza, J.P.E.; Alves, J.M. Lean-integrated management system: A model for sustainability improvement. J. Clean. Prod. 2018, 172, 2667–2682. [Google Scholar] [CrossRef]

- Mathiyazhagan, K.; Gnanavelbabu, A.; Kumar, N.; Agarwal, V. A framework for implementing sustainable lean manufacturing in the electrical and electronics component manufacturing industry: An emerging economies country perspective. J. Clean. Prod. 2022, 334, 130169. [Google Scholar] [CrossRef]

- Iranmanesh, M.; Zailani, S.; Hyun, S.S.; Ali, M.H.; Kim, K. Impact of lean manufacturing practices on firms’ sustainable performance: Lean culture as a moderator. Sustainability 2019, 11, 1112. [Google Scholar] [CrossRef]

- Maware, C.; Adetunji, O. Lean manufacturing implementation in Zimbabwean industries: Impact on operational performance. Int. J. Eng. Bus. Manag. 2019, 11, 1–12. [Google Scholar] [CrossRef]

- Byrne, B.; McDermott, O.; Noonan, J. Applying lean six sigma methodology to a pharmaceutical manufacturing facility: A case study. Processes 2021, 9, 550. [Google Scholar] [CrossRef]

- Trakulsunti, Y.; Antony, J.; Edgeman, R.; Cudney, B.; Dempsey, M.; Brennan, A. Reducing pharmacy medication errors using lean six sigma: A Thai hospital case study. Total Qual. Manag. Bus. Excell. 2022, 33, 664–682. [Google Scholar] [CrossRef]

- Zhong, R.Y.; Xu, X.; Klotz, E.; Newman, S.T. Intelligent manufacturing in the context of industry 4.0: A review. Engineering 2017, 3, 616–630. [Google Scholar] [CrossRef]

- Jamwal, A.; Agrawal, R.; Sharma, M.; Giallanza, A. Industry 4.0 technologies for manufacturing sustainability: A systematic review and future research directions. Appl. Sci. 2021, 11, 5725. [Google Scholar] [CrossRef]

- Nara, E.O.B.; da Costa, M.B.; Baierle, I.C.; Schaefer, J.L.; Benitez, G.; do Santos, L.M.A.L.; Benitez, L.B. Expected impact of industry 4.0 technologies on sustainable development: A study in the context of Brazil’s plastic industry. Sustain. Prod. Consum. 2021, 25, 102–122. [Google Scholar] [CrossRef]

- Sony, M.; Antony, J.; Mc Dermott, O.; Garza-Reyes, J.A. An empirical examination of benefits, challenges, and critical success factors of industry 4.0 in manufacturing and service sector. Technol. Soc. 2021, 67, 101754. [Google Scholar] [CrossRef]

- De Sousa Jabbour, A.B.L.; Jabbour, C.J.C.; Foropon, C.; Godinho Filho, M. When titans meet—Can industry 4.0 revolutionise the environmentally-sustainable manufacturing wave? the role of critical success factors. Technol. Forecast. Soc. Chang. 2018, 132, 18–25. [Google Scholar] [CrossRef]

- Kamble, S.S.; Gunasekaran, A.; Sharma, R. Analysis of the driving and dependence power of barriers to adopt industry 4.0 in Indian manufacturing industry. Comput. Ind. 2018, 101, 107–119. [Google Scholar] [CrossRef]

- Antony, J.; McDermott, O.; Powell, D.; Sony, M. The evolution and future of lean six sigma 4.0. TQM J. 2022. ahead-of-print. [Google Scholar] [CrossRef]

- Buer, S.-V.; Semini, M.; Strandhagen, J.O.; Sgarbossa, F. The complementary effect of lean manufacturing and digitalisation on operational performance. Int. J. Prod. Res. 2021, 59, 1976–1992. [Google Scholar] [CrossRef]

- Felsberger, A.; Qaiser, F.H.; Choudhary, A.; Reiner, G. The impact of Industry 4.0 on the reconciliation of dynamic capabilities: Evidence from the European manufacturing industries. Prod. Plan. Control 2022, 33, 277–300. [Google Scholar] [CrossRef]

- Ding, B.; Hernandez, X.; Jane, N. Combining lean and agile manufacturing competitive advantages through Industry 4.0 technologies: An integrative approach. Prod. Plan. Control 2023. [Google Scholar] [CrossRef]

- Tortorella, G.L.; Fettermann, D.C. Implementation of Industry 4.0 and lean production in Brazilian manufacturing companies. Int. J. Prod. Res. 2018, 56, 2975–2987. [Google Scholar] [CrossRef]

- Vlachos, I.P.; Pascazzi, R.M.; Zobolas, G.; Repoussis, P.; Giannakis, M. Lean manufacturing systems in the area of industry 4.0: A lean automation plan of AGVs/IoT integration. Prod. Plan. Control 2023. [Google Scholar] [CrossRef]

- Calabrese, A.; Dora, M.; Ghiron, N.L.; Tiburzi, L. Industry’s 4.0 transformation process: How to start, where to aim, what to be aware of. Prod. Plan. Control 2022, 33, 492–512. [Google Scholar] [CrossRef]

- Ciano, M.P.; Dallasega, P.; Orzes, G.; Rossi, T. One-to-one relationships between Industry 4.0 technologies and lean production techniques: A multiple case study. Int. J. Prod. Res. 2021, 59, 1386–1410. [Google Scholar] [CrossRef]

- Wang, F.-K.; Rahardjo, B.; Rovira, P.R. Lean six sigma with value stream mapping in industry 4.0 for human-centered workstation design. Sustainability 2022, 14, 11020. [Google Scholar] [CrossRef]

- Ribeiro, M.A.S.; Santos, A.C.O.; de Amorim, G.D.F.; de Oliveira, C.H.; da Silva Braga, R.A.; Netto, R.S. Analysis of the implementation of the single minute exchange of die methodology in an agroindustry through action research. Machines 2022, 10, 287. [Google Scholar] [CrossRef]

- Sundaramali, G.; Shankar, S.A.; Kummar, M.M. Non-conformity recovery and safe disposal by Poka Yoke and hallmarking in a piston unit. Int. J. Product. Qual. Manag. 2018, 24, 460–474. [Google Scholar] [CrossRef]

- Haddud, A.; Khare, A. Digitalizing supply chains potential benefits and impact on lean operations. Int. J. Lean Six Sigma 2020, 11, 731–765. [Google Scholar] [CrossRef]

- Borowski, P.F. Digitization, digital twins, blockchain, and industry 4.0 as elements of management process in enterprises in the energy sector. Energies 2021, 14, 1885. [Google Scholar] [CrossRef]

- Vaidya, S.; Ambad, P.; Bhosle, S. Industry 4.0—A glimpse. Procedia Manuf. 2018, 20, 233–238. [Google Scholar] [CrossRef]

- Guerra-Zubiaga, D.; Kuts, V.; Mahmood, K.; Bondar, A.; Nasajpour-Esfahani, N.; Otto, T. An approach to develop a digital twin for industry 4.0 systems: Manufacturing automation case studies. Int. J. Comput. Integr. Manuf. 2021, 34, 933–949. [Google Scholar] [CrossRef]

- Ing, T.S.; Lee, T.C.; Chan, S.W.; Alipal, J.; Hamid, N.A. An overview of the rising challenges in implementing industry 4.0. Int. J. Supply Chain. Manag. 2019, 8, 1181–1188. [Google Scholar]

- Horst, D.J.; Duvoisin, C.A.; de Almeida Vieira, R. Additive manufacturing at industry 4.0: A review. Int. J. Eng. Tech. Res. 2018, 8, 3–8. [Google Scholar]

- Mourtzis, D.; Vlachou, E.; Zogopoulos, V.; Fotini, X. Integrated production and maintenance scheduling through machine monitoring and augmented reality: An industry 4.0 approach. In IFIP International Conference on Advances in Production Management Systems; Springer: Cham, Switzerland, 2017; pp. 354–362. [Google Scholar]

- Park, J.; Bae, H. Big data and AI for process innovation in the industry 4.0 era. Appl. Sci. 2022, 12, 6346. [Google Scholar] [CrossRef]

- Ejsmont, K.; Gladysz, B.; Corti, D.; Castaño, F.; Mohammed, W.M.; Lastra, J.L.M. Towards ‘lean industry 4.0’—Current trends and future perspectives. Cogent Bus. Manag. 2020, 7, 1781995. [Google Scholar] [CrossRef]

- Gallo, T.; Cagnetti, C.; Silvestri, C.; Ruggieri, A. Industry 4.0 tools in lean production: A systematic literature review. Procedia Comput. Sci. 2021, 180, 394–403. [Google Scholar] [CrossRef]

- Langlotz, P.; Siedler, C.; Aurich, J.C. Unification of lean production and industry 4.0. Procedia CIRP 2021, 99, 15–20. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).