Magnetic Anchoring Considerations for Retractors Supporting Manual and Robot-Assisted Minimally Invasive Surgery †

Abstract

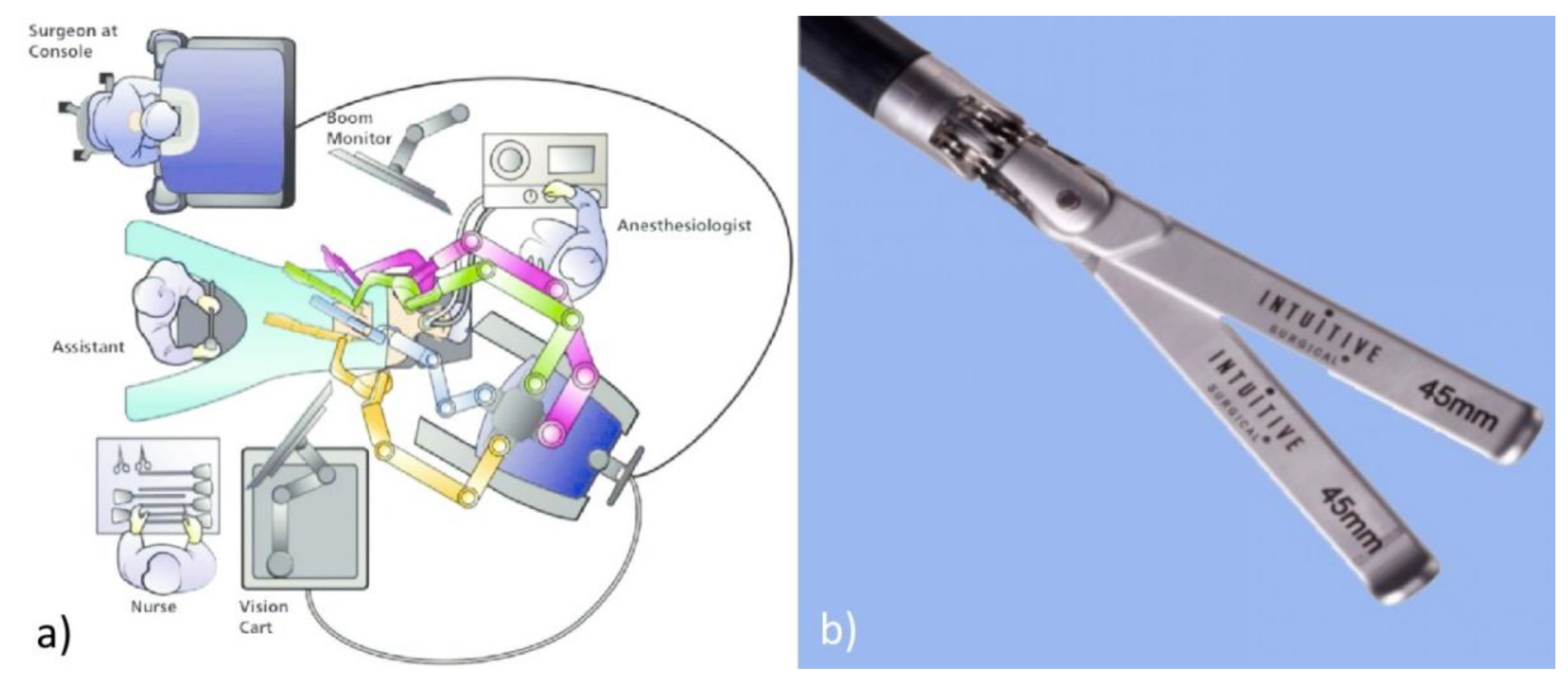

1. Introduction

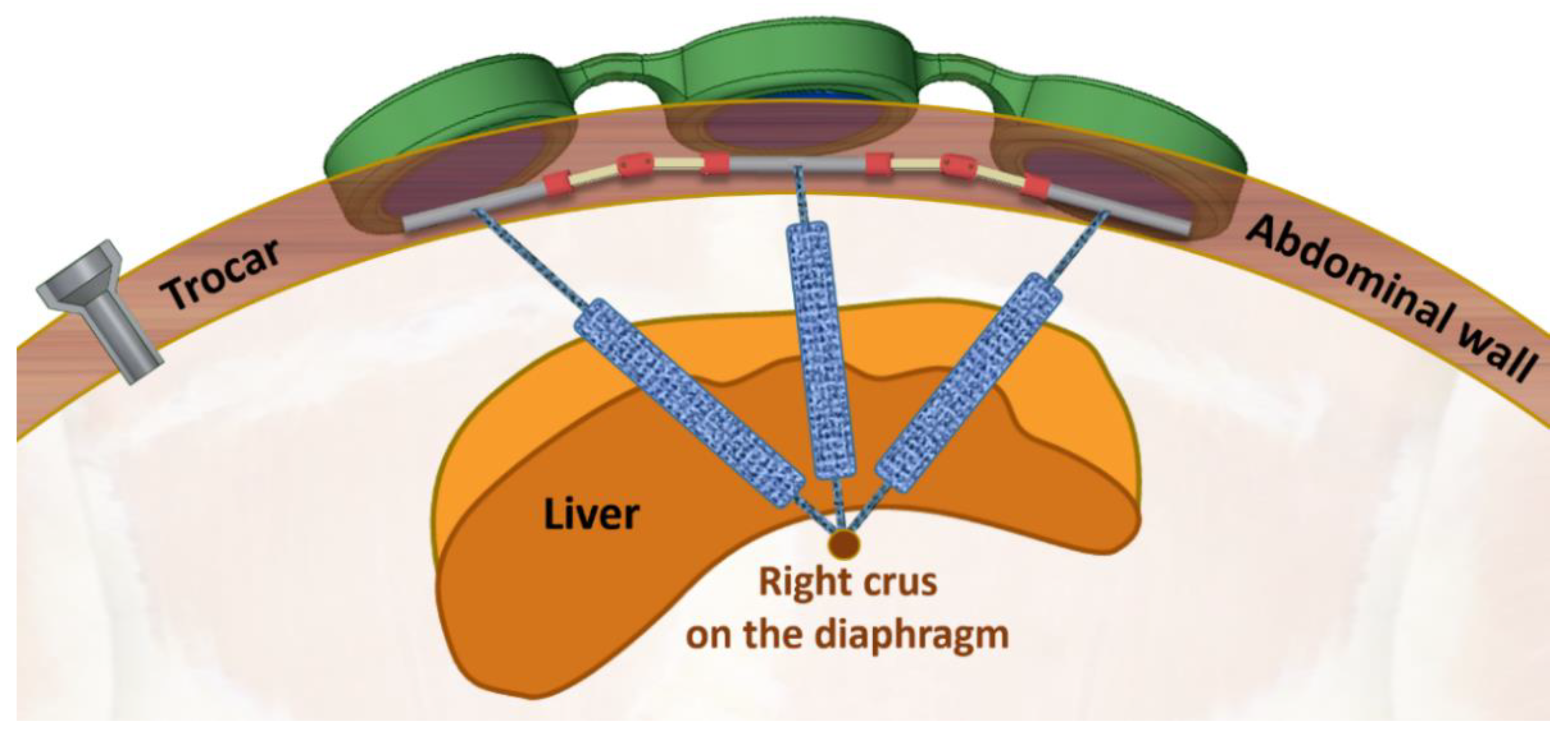

2. Motivation

3. Methods

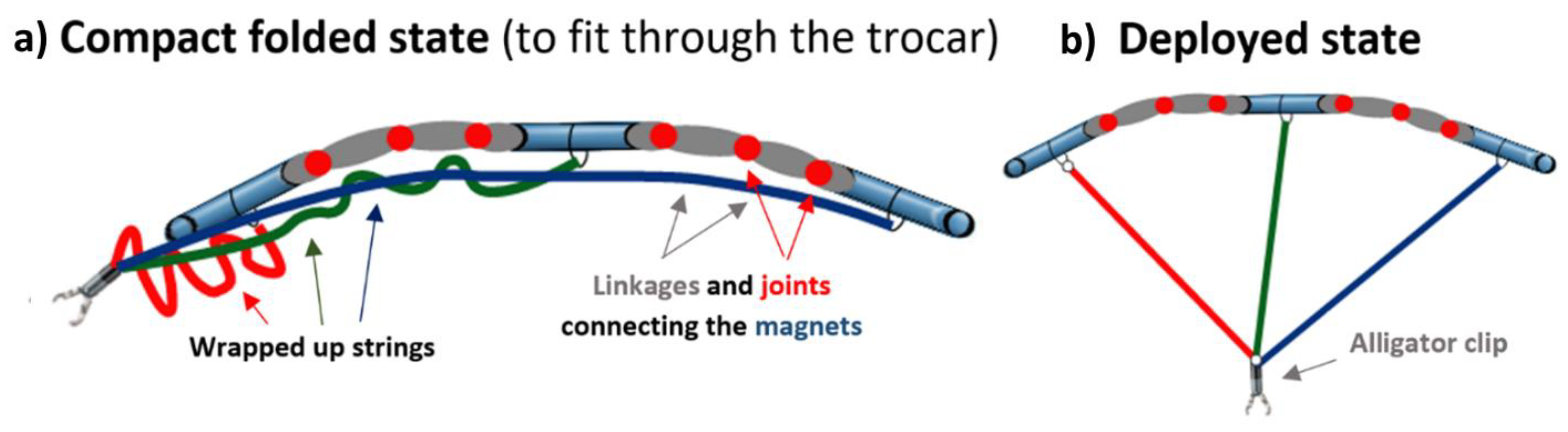

3.1. Basic Functional Requirements

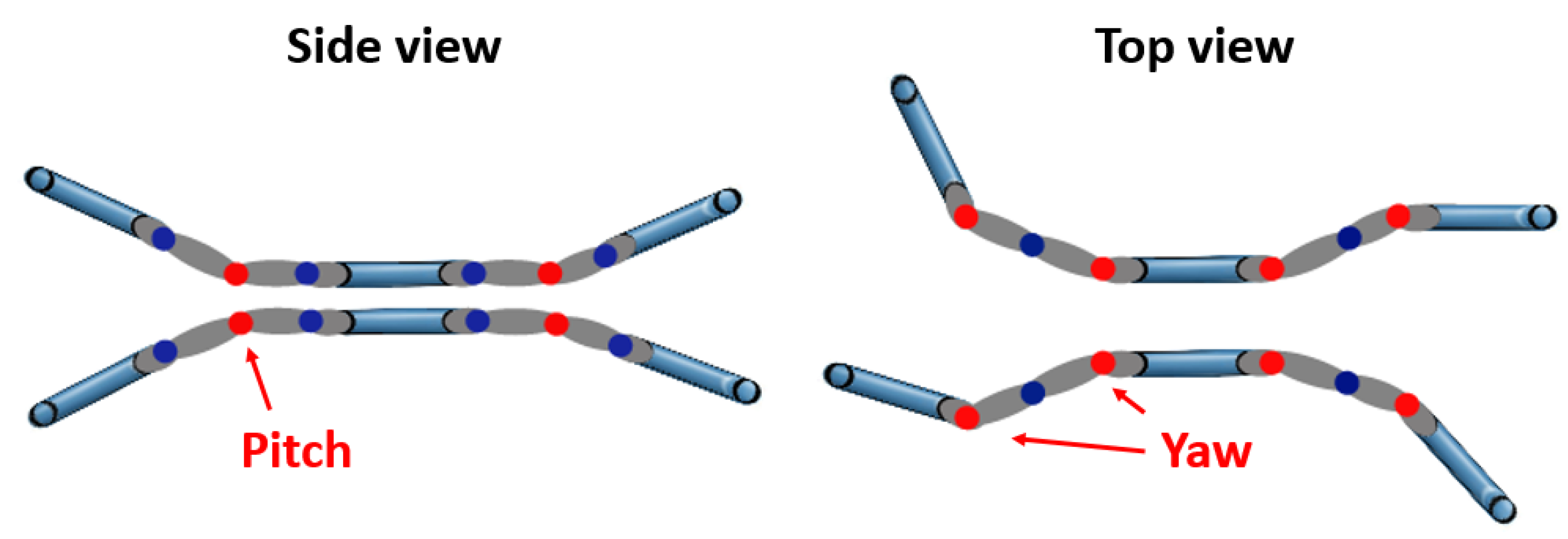

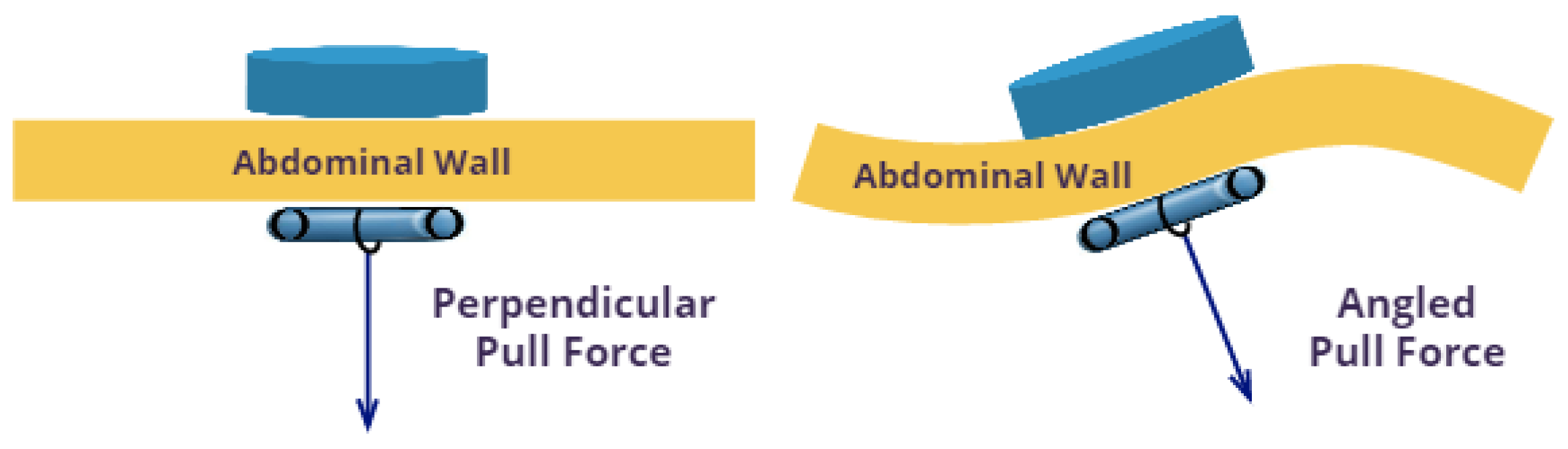

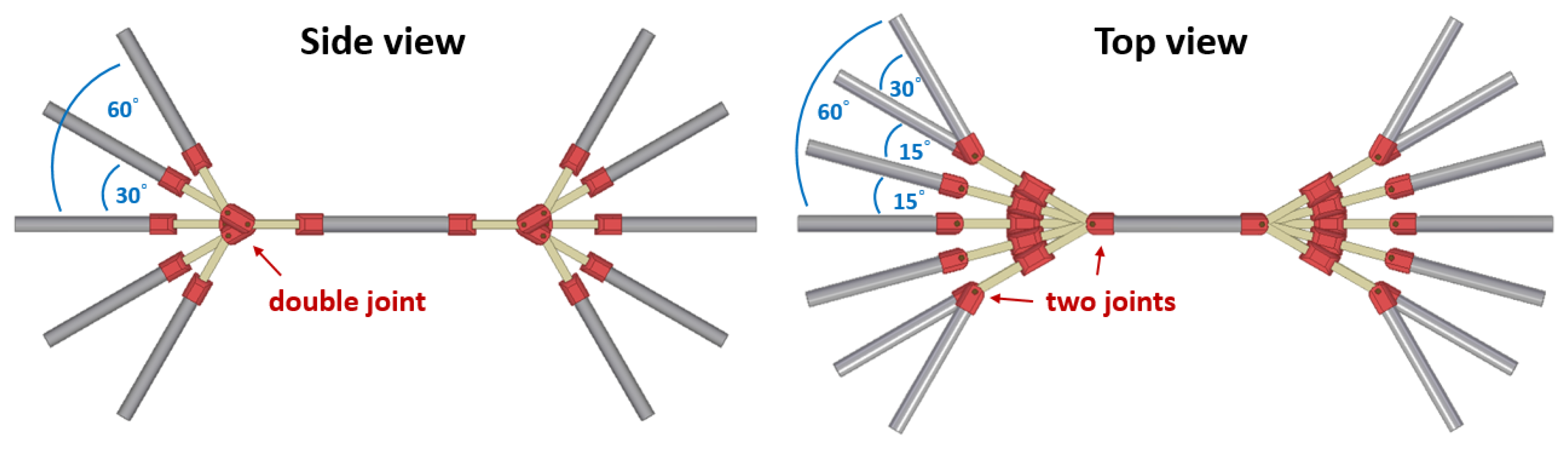

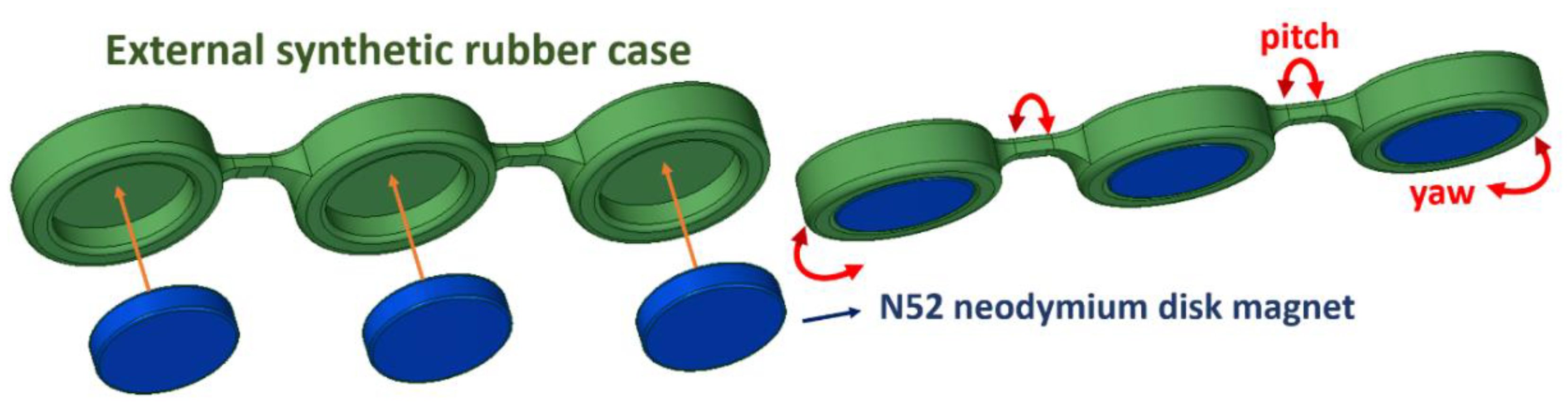

3.2. Design Considerations

3.3. Optimized Magnetic Anchoring

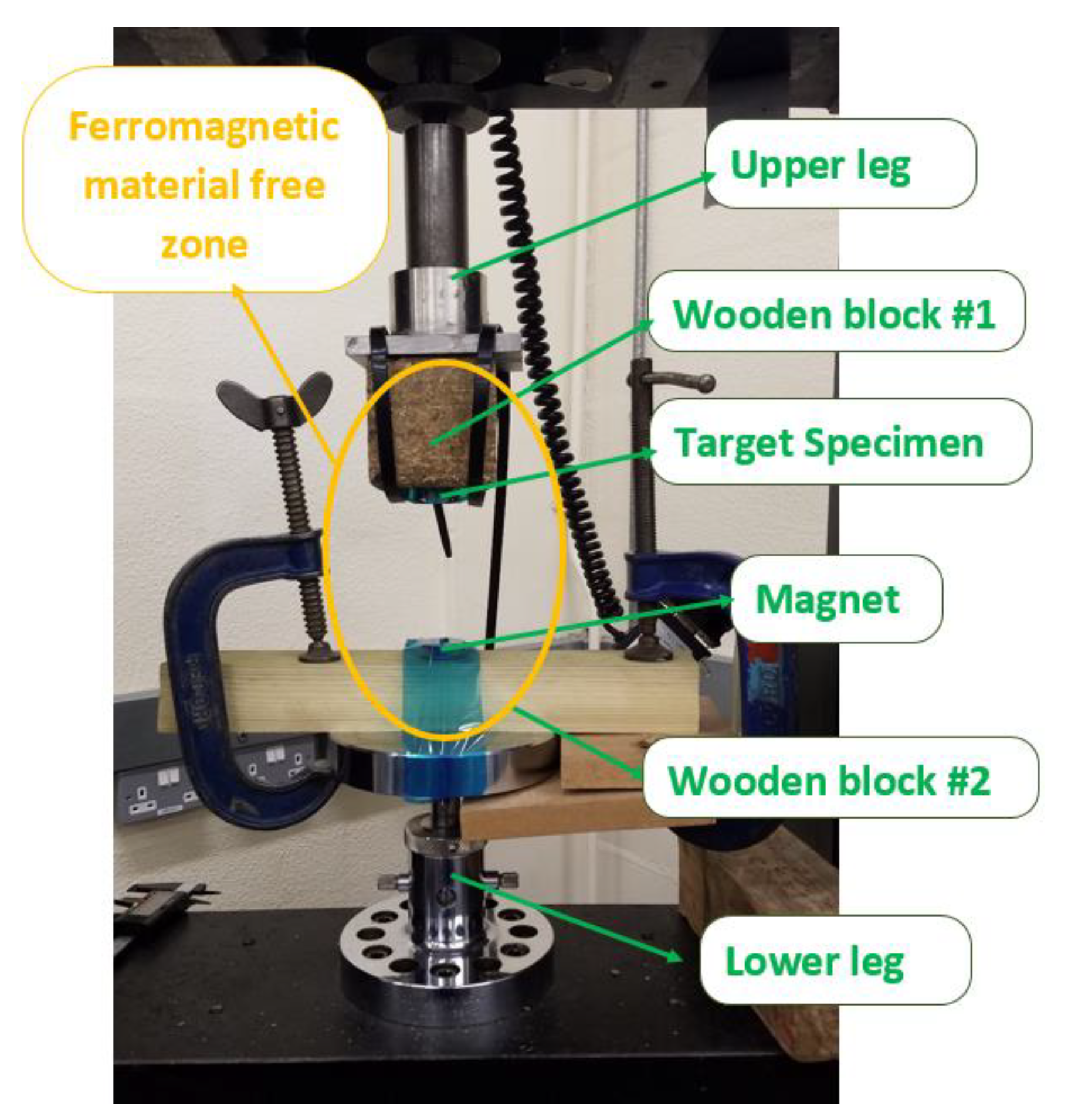

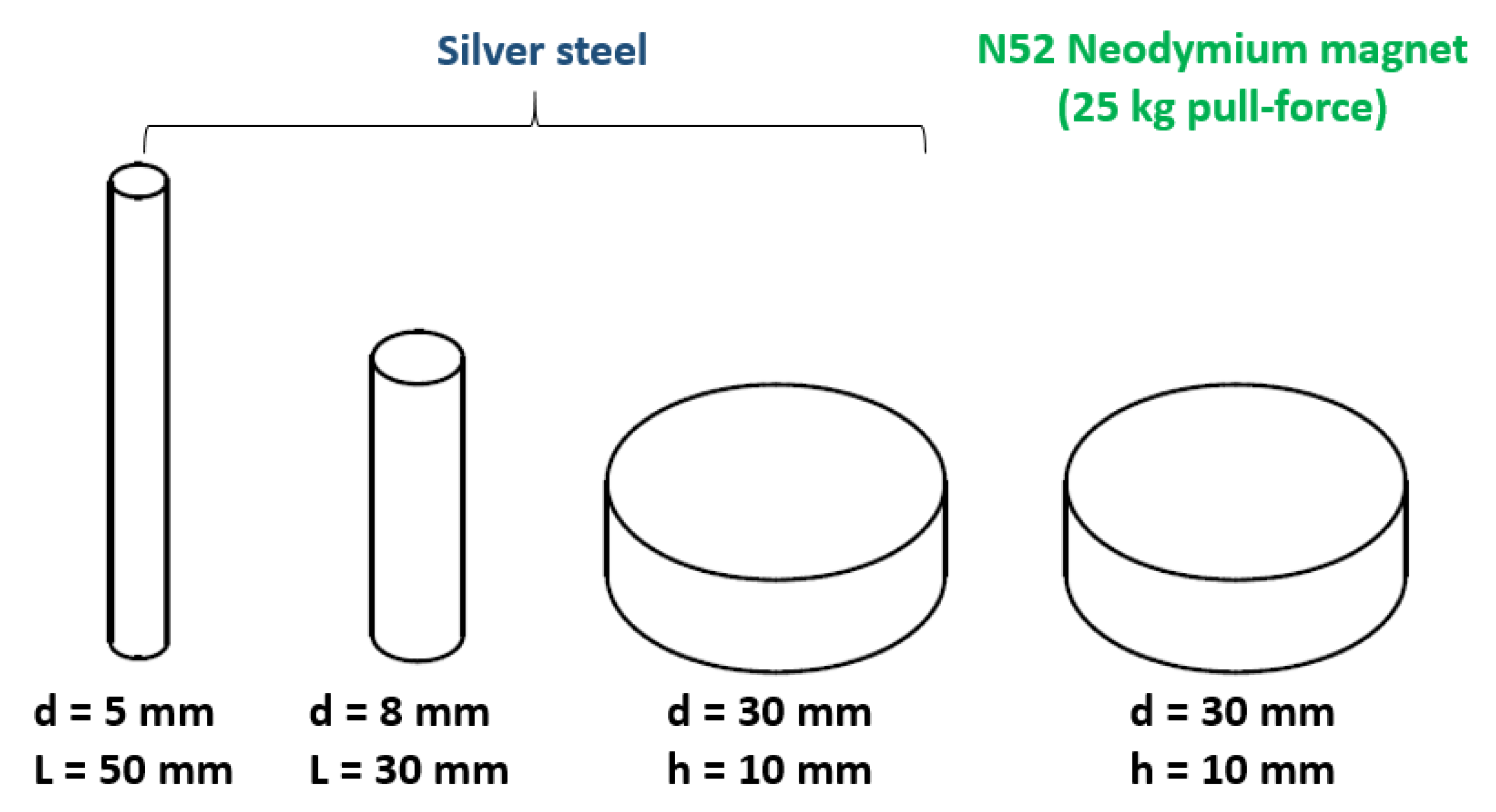

4. Experimental Methods and Numeric Outcomes

4.1. Experimental Equipment

4.2. Experimental Methods and Results

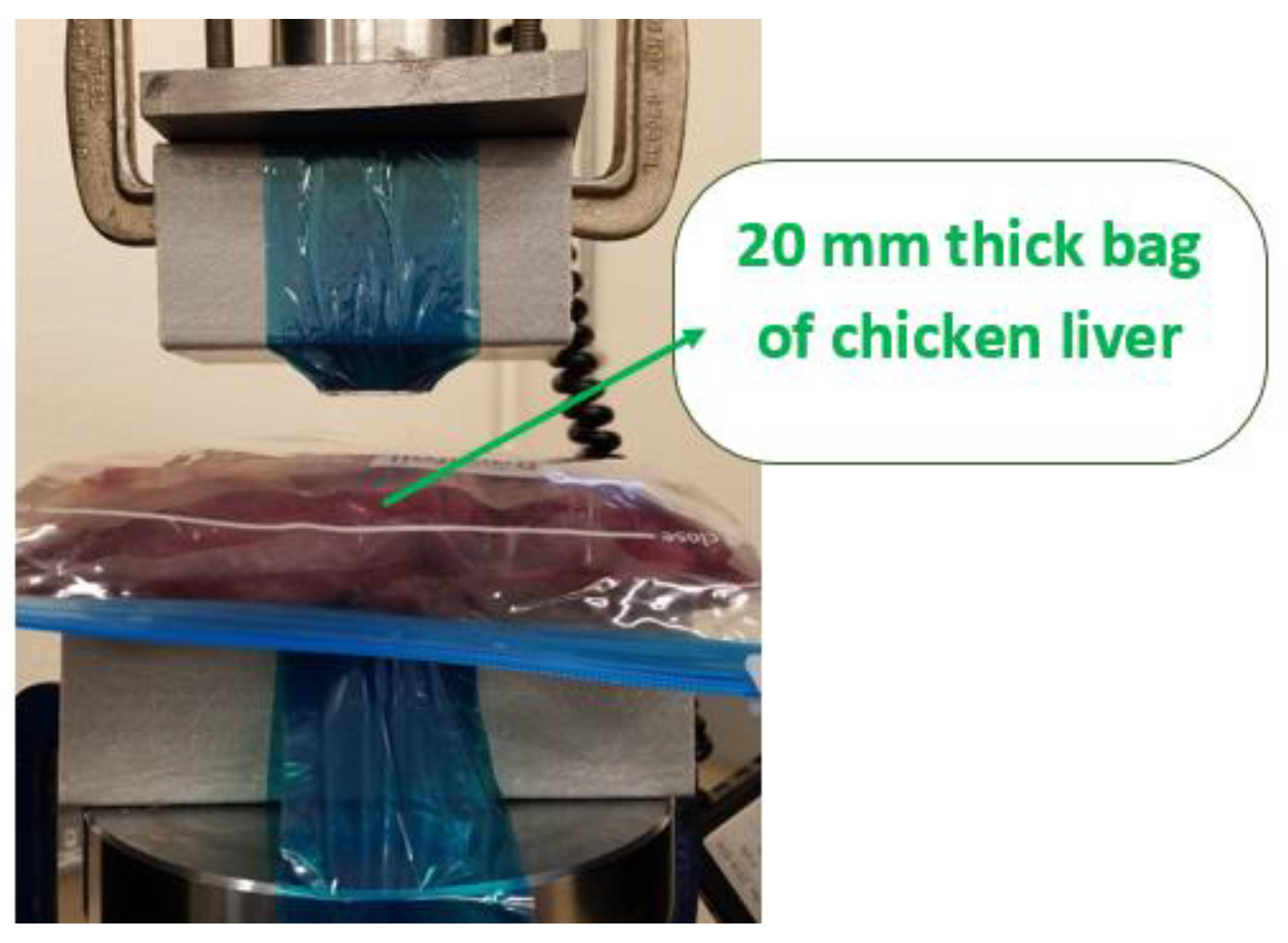

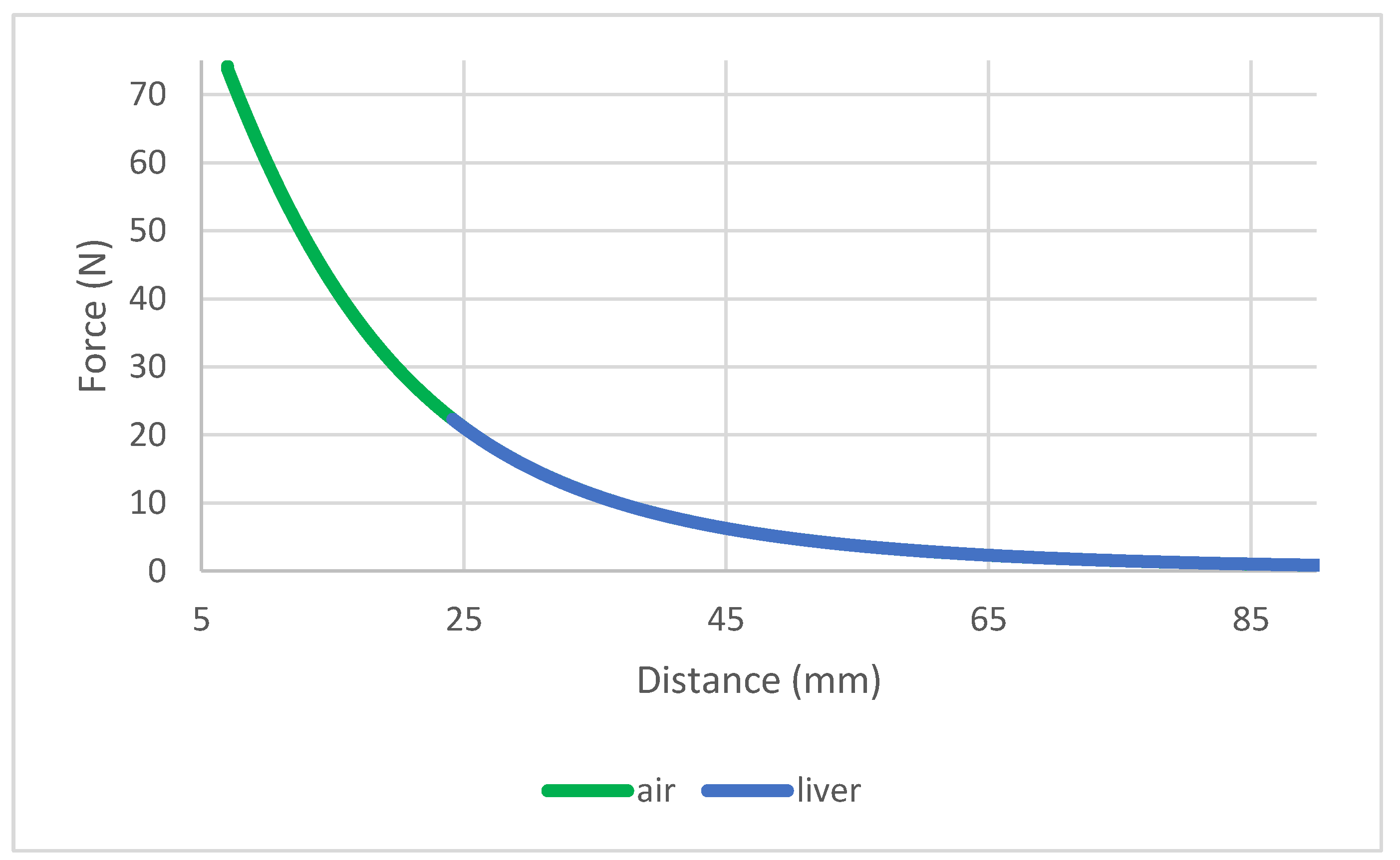

4.2.1. Experiment Series 1

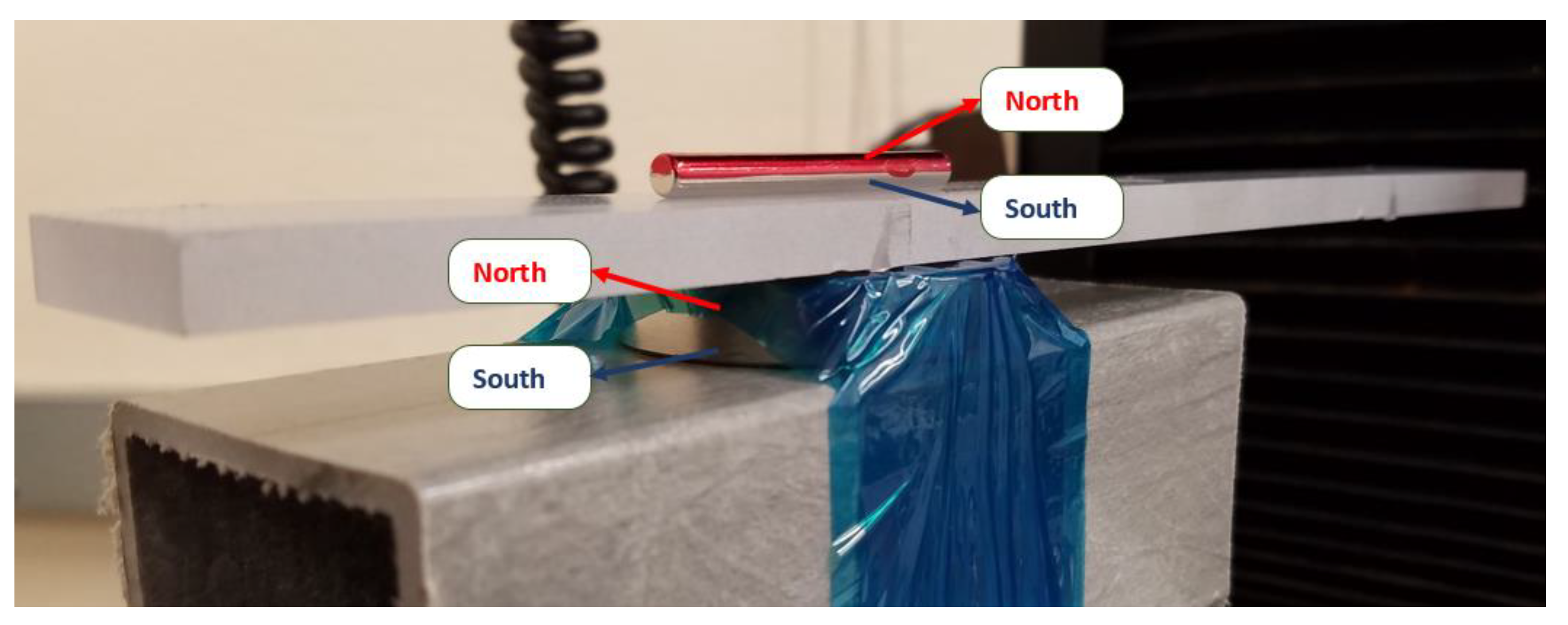

4.2.2. Experiment Series 2

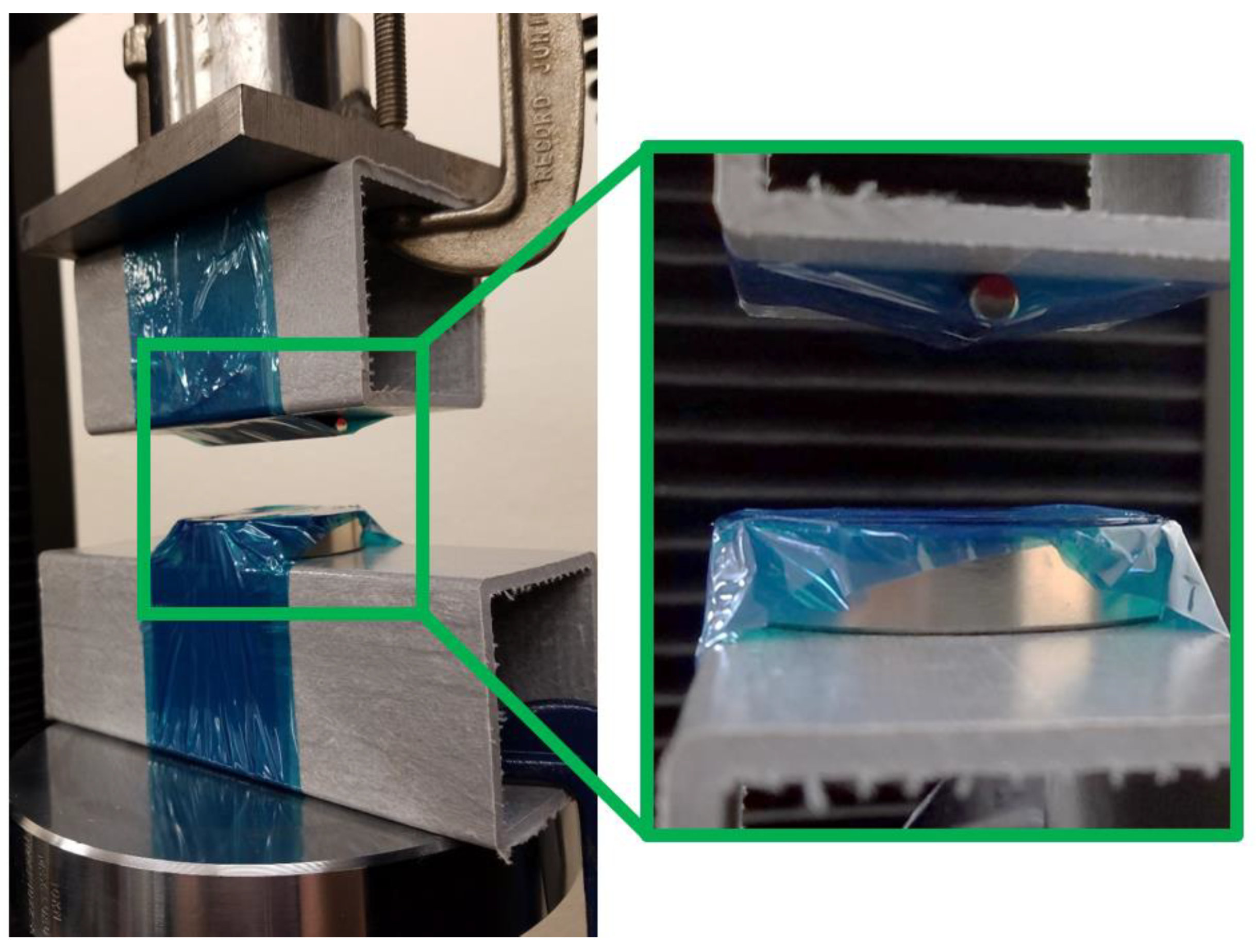

4.2.3. Experiment Series 3

4.2.4. Experiment Series 4

4.3. Discussion of Experimental Results

5. Detailed Designs of the Magnetic Actuator Concept

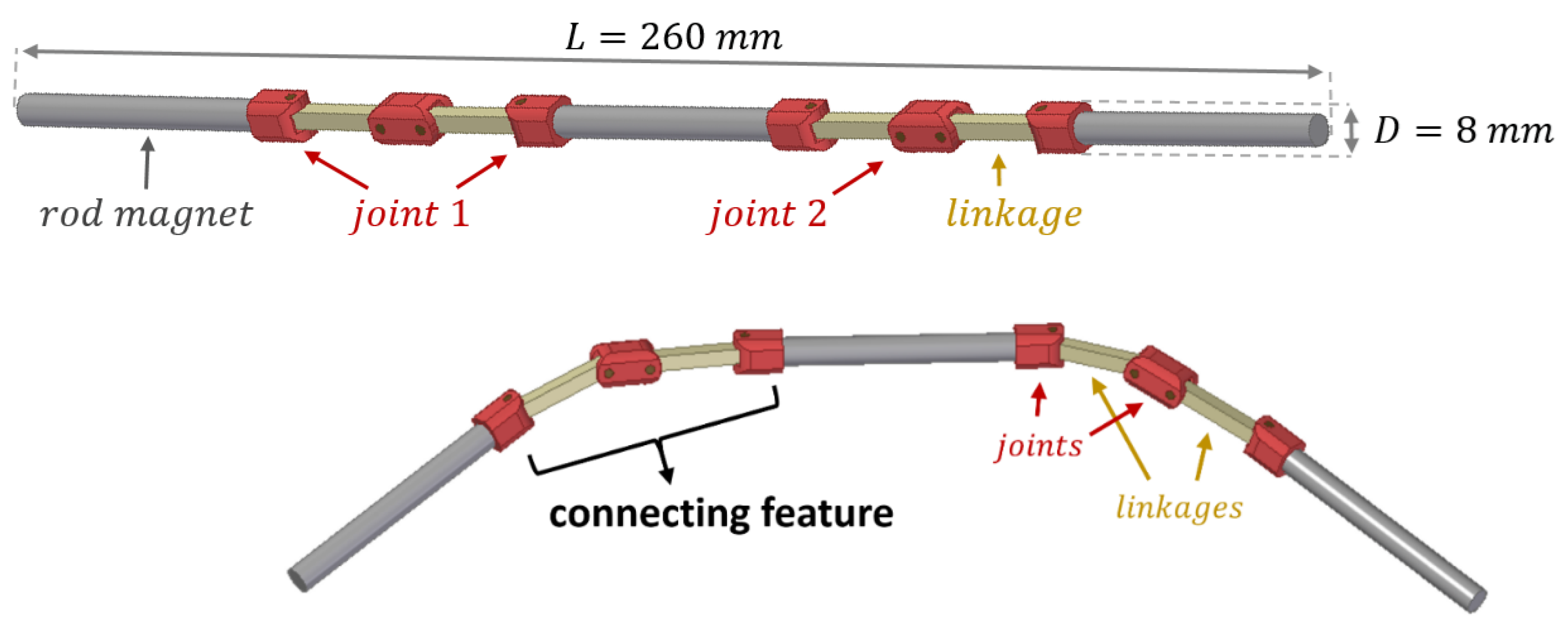

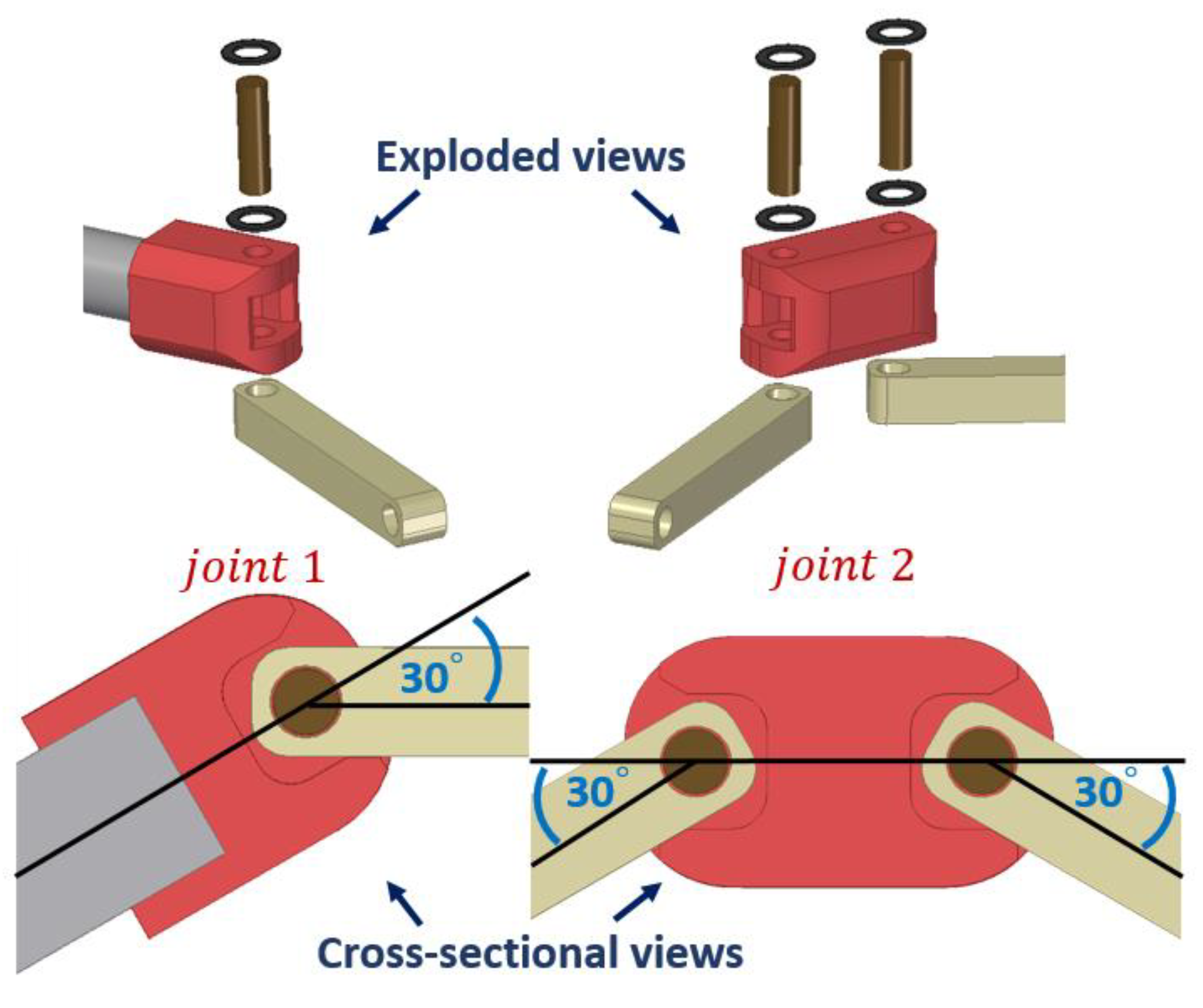

5.1. Structural Design

5.2. Material Considerations

6. Discussion

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Haidegger, T.; Speidel, S.; Stoyanov, D.; Satava, R.M. Robot-Assisted Minimally Invasive Surgery—Surgical Robotics in the Data Age. Proc. IEEE 2022, 110, 835–846. [Google Scholar] [CrossRef]

- Fichtinger, G.; Troccaz, J.; Haidegger, T. Image-Guided Interventional Robotics: Lost in Translation? Proc. IEEE 2022, 110, 932–950. [Google Scholar] [CrossRef]

- Lajkó, G.; Elek, R.N.; Haidegger, T. Endoscopic Image-Based Skill Assessment in Robot-Assisted Minimally Invasive Surgery. Sensors 2021, 21, 5412. [Google Scholar] [CrossRef] [PubMed]

- Shadrin, G.K.; Alontseva, D.L.; Kussaiyn-Murat, A.T.; Kadyroldina, O.B.; Ospanov, H.; Tamás, H. Application of Compensation Algorithms to Control the Movement of a Robot Manipulator. Acta Polytech. Hung. 2020, 17, 191–214. [Google Scholar] [CrossRef]

- Prestes, E.; Houghtaling, M.A.; Goncalves, P.J.; Fabiano, N.; Ulgen, O.; Fiorini, S.R.; Murahwi, Z.; Olszewska, J.I.; Haidegger, T. The First Global Ontological Standard for Ethically Driven Robotics and Automation Systems [Standards]. IEEE Robot. Autom. Mag. 2021, 28, 120–124. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, L.; Tang, B.; Frank, T.; Brown, S.; Cuschieri, A. Retraction by surface ferromagnetisation of target tissues: Preliminary studies on feasibility of magnetic retraction for endoscopic surgery. Surg. Endosc. 2007, 22, 1838–1844. [Google Scholar] [CrossRef]

- Simaan, N.; Yasin, R.M.; Wang, L. Medical Technologies and Challenges of Robot-Assisted Minimally Invasive Intervention and Diagnostics. arXiv 2018, arXiv:1807.03731. [Google Scholar] [CrossRef]

- Park, S.; Bergs, R.A.; Eberhart, R.; Baker, L.; Fernandez, R.; Cadeddu, J.A. Trocar-less instrumentation for laparoscopy: Magnetic positioning of intra-abdominal camera and retractor. Ann. Surg. 2007, 245, 379. [Google Scholar] [CrossRef]

- Steinberg, R.; Johnson, B.A.; Meskawi, M.; Gettman, M.T.; Cadeddu, J.A. Magnet-Assisted Robotic Prostatectomy Using the da Vinci SP Robot: An Initial Case Series. J. Endourol. 2019, 33, 829–834. [Google Scholar] [CrossRef]

- Davis, M.; Davalos, G.; Ortega, C.; Chen, S.; Schimpke, S.; Jain-Spangler, K.; Yoo, J.; Seymour, K.; Sudan, R.; Portenier, D.; et al. Magnetic Liver Retraction: An Incision-Less Approach for Less Invasive Bariatric Surgery. Obes. Surg. 2019, 29, 1068–1073. [Google Scholar] [CrossRef]

- O’Shea, C.; Kelliher, D.; Andrews, E.; O’Ríordáin, M.; O’Shea, M.; Power, T.; Cantillon-Murphy, P. Design, Development and Evaluation of an Inflatable Retractor for Atraumatic Retraction in Laparoscopic Colectomy. Ann. Biomed. Eng. 2014, 42, 1942–1951. [Google Scholar] [CrossRef]

- Nigicser, I.; Oldfield, M.; Haidegger, T. Stability and Retraction Force Verification of a New Retractor Design for Minimally Invasive Surgery. In Proceedings of the 2021 IEEE 25th International Conference on Intelligent Engineering Systems (INES), Budapest, Hungary, 7–9 July 2021; pp. 183–188. [Google Scholar]

- Bandari, N.; Dargahi, J.; Packirisamy, M. Tactile Sensors for Minimally Invasive Surgery: A Review of the State-of-the-Art, Applications, and Perspectives. IEEE Access 2019, 8, 7682–7708. [Google Scholar] [CrossRef]

- Chen, C.-C.; Yeh, P.-C.; Cheng, C.-C.; Lin, C.-K.; Wong, T.-H.; Chenga, Y.-C.; Hsu, W.; Chung, T.-K. Magnetic Targeting Systems for Endo-Bronchoscope Diagnosis and Intramedullary-Nail Surgery: A Review. IEEE Sens. J. 2021, 21, 12545–12562. [Google Scholar] [CrossRef]

- Giaccone, A.; Solli, P.; Bertolaccini, L. Magnetic anchoring guidance system in video-assisted thoracic surgery. J. Vis. Surg. 2017, 2, 17. [Google Scholar] [CrossRef][Green Version]

- Takács, A.; Rudas, I.J.; Haidegger, T. Surface deformation and reaction force estimation of liver tissue based on a novel nonlinear mass–spring–damper viscoelastic model. Med. Biol. Eng. Comput. 2015, 54, 1553–1562. [Google Scholar] [CrossRef]

- Nagy, T.D.; Takács, M.; Rudas, I.J.; Haidegger, T. Surgical subtask automation—Soft tissue retraction. In Proceedings of the 2018 IEEE 16th World Symposium on Applied Machine Intelligence and Informatics (SAMI), Kosice and Herlany, Slovakia, 7–10 February 2018; pp. 55–60. [Google Scholar]

- Haidegger, T. Autonomy for Surgical Robots: Concepts and Paradigms. IEEE Trans. Med. Robot. Bionics 2019, 1, 65–76. [Google Scholar] [CrossRef]

- Fulla, J.; Small, A.; Kaplan-Marans, E.; Palese, M. Magnetic-Assisted Robotic and Laparoscopic Renal Surgery: Initial Clinical Experience with the Levita Magnetic Surgical System. J. Endourol. 2020, 34, 1242–1246. [Google Scholar] [CrossRef]

- Tortora, G.; Ranzani, T.; De Falco, I.; Dario, P.; Menciassi, A. A Miniature Robot for Retraction Tasks under Vision Assistance in Minimally Invasive Surgery. Robotics 2014, 3, 70–82. [Google Scholar] [CrossRef]

- Shah, D.; Alderson, A.; Corden, J.; Satyadas, T.; Augustine, T. In Vivo Measurement of Surface Pressures and Retraction Distances Applied on Abdominal Organs During Surgery. Surg. Innov. 2018, 25, 50–56. [Google Scholar] [CrossRef]

- Sucandy, I.; Nadzam, G.; Duffy, A.J.; Roberts, K.E. Two-Port Laparoscopic Cholecystectomy: 18 Patients Human Experience Using the Dynamic Laparoscopic NovaTract Retractor. J. Laparoendosc. Adv. Surg. Tech. 2016, 26, 625–629. [Google Scholar] [CrossRef]

- Genser, L.; Torcivia, A.; Saget, A.; Vaillant, J.-C.; Siksik, J.-M. Minimal Invasive Internal Liver Retractor in Conventional and Trans-umbilical Single-Incision Laparoscopic Sleeve Gastrectomy: Video Report. Obes. Surg. 2016, 26, 704–705. [Google Scholar] [CrossRef]

- Kim, H.J.; Gong, E.J.; Bang, C.S.; Lee, J.J.; Suk, K.T.; Baik, G.H. Computer-Aided Diagnosis of Gastrointestinal Protruded Lesions Using Wireless Capsule Endoscopy: A Systematic Review and Diagnostic Test Accuracy Meta-Analysis. J. Pers. Med. 2022, 12, 644. [Google Scholar] [CrossRef]

- Xu, Y.; Chen, R.; Zhang, P.; Chen, L.; Luo, B.; Li, Y.; Xiao, X.; Dong, W. A review of magnetic sensor-based positioning techniques for capsule endoscopy. ISPRS Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2022, 26, 219–226. [Google Scholar] [CrossRef]

- Bencsik, M.; Bowtell, R.; Bowley, R. Electric fields induced in the human body by time-varying magnetic field gradients in MRI: Numerical calculations and correlation analysis. Phys. Med. Biol. 2007, 52, 2337–2353. [Google Scholar] [CrossRef]

- Tongyoo, A.; Chatthamrak, P.; Sriussadaporn, E.; Limpavitayaporn, P.; Mingmalairak, C. Risk assessment of abdominal wall thickness measured on pre-operative computerized tomography for incisional surgical site infection after abdominal surgery. J. Med. Assoc. Thai 2015, 98, 677-83. [Google Scholar]

- Jiles, D. Introduction to Magnetism and Magnetic Materials; CRC Press: Boca Raton, FL, USA, 2015. [Google Scholar]

- Henkel Corporation. Retaining Compound Design Guide. 2013. Available online: http://dm.henkel-dam.com/is/content/henkel/RetainingDesignGuidepdf. (accessed on 11 June 2022).

- Ismail, H.; Pasbakhsh, P.; Fauzi, M.A.; Bakar, A.A. Morphological, thermal and tensile properties of halloysite nanotubes filled ethylene propylene diene monomer (EPDM) nanocomposites. Polym. Test. 2008, 27, 841–850. [Google Scholar] [CrossRef]

- Perrin, F.M.; Fletcher, F.A. Laparoscopic abdominal surgery. Contin. Educ. Anaesth. Crit. Care Pain 2004, 4, 107–110. [Google Scholar] [CrossRef]

- Bohm, L.L.; Enderle, H.F.; Fleifßner, M. High-density polyethylene pipe resins. Adv. Mater. 1992, 4, 234–238. [Google Scholar] [CrossRef]

- Javidi, M.; Javadpour, S.; Bahrololoom, M.; Ma, J. Electrophoretic deposition of natural hydroxyapatite on medical grade 316L stainless steel. Mater. Sci. Eng. C 2008, 28, 1509–1515. [Google Scholar] [CrossRef]

- Cavallo, A.; Brancadoro, M.; Tognarelli, S.; Menciassi, A. A Soft Retraction System for Surgery Based on Ferromagnetic Materials and Granular Jamming. Soft Robot. 2019, 6, 161–173. [Google Scholar] [CrossRef]

- Sajid, M.S.; Bokhari, S.A.; Mallick, A.S.; Cheek, E.; Baig, M.K. Laparoscopic versus open repair of incisional/ventral hernia: A meta-analysis. Am. J. Surg. 2009, 197, 64–72. [Google Scholar] [CrossRef]

- Palanivelu, P.; Patil, K.P.; Parthasarathi, R.; Viswambharan, J.K.; Senthilnathan, P.; Palanivelu, C. Review of various liver retraction techniques in single incision laparoscopic surgery for the exposure of hiatus. J. Minimal Access Surg. 2015, 11, 198. [Google Scholar] [CrossRef]

- Attanasio, A.; Scaglioni, B.; Leonetti, M.; Frangi, A.F.; Cross, W.; Biyani, C.S.; Valdastri, P. Autonomous Tissue Retraction in Robotic Assisted Minimally Invasive Surgery—A Feasibility Study. IEEE Robot. Autom. Lett. 2020, 5, 6528–6535. [Google Scholar] [CrossRef]

- Khamis, A.; Meng, J.; Wang, J.; Azar, A.T.; Prestes, E.; Li, H.; Hameed, I.A.; Takács, A.; Rudas, I.J.; Haidegger, T. Robotics and Intelligent Systems Against a Pandemic. Acta Polytech. Hung. 2021, 18, 13–35. [Google Scholar] [CrossRef]

- Chinzei, K. Safety of surgical robots and IEC 80601-2-77: The first international standard for surgical robots. Acta Polytech. Hung. 2019, 16, 171–184. [Google Scholar]

- Barattini, P.; Federico, V.; Virk, G.S.; Haidegger, T. (Eds.) Human-Robot Interaction: Safety, Standardization, and Benchmarking; CRC Press: Boca Raton, FL, USA, 2019. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nigicser, I.; Oldfield, M.; Haidegger, T. Magnetic Anchoring Considerations for Retractors Supporting Manual and Robot-Assisted Minimally Invasive Surgery. Machines 2022, 10, 745. https://doi.org/10.3390/machines10090745

Nigicser I, Oldfield M, Haidegger T. Magnetic Anchoring Considerations for Retractors Supporting Manual and Robot-Assisted Minimally Invasive Surgery. Machines. 2022; 10(9):745. https://doi.org/10.3390/machines10090745

Chicago/Turabian StyleNigicser, Illés, Matthew Oldfield, and Tamás Haidegger. 2022. "Magnetic Anchoring Considerations for Retractors Supporting Manual and Robot-Assisted Minimally Invasive Surgery" Machines 10, no. 9: 745. https://doi.org/10.3390/machines10090745

APA StyleNigicser, I., Oldfield, M., & Haidegger, T. (2022). Magnetic Anchoring Considerations for Retractors Supporting Manual and Robot-Assisted Minimally Invasive Surgery. Machines, 10(9), 745. https://doi.org/10.3390/machines10090745