1. Introduction

Engine variable valve timing technology (VVT) has come a long way over the past few decades. Many VVT actuators based on the camshaft were applied in engines [

1,

2]. However, there are also some deficiencies of camshaft-based VVT actuators. Generally, for camshaft-driven actuators, only engine valve timing is variable, and the variable range is very small [

2,

3]. With the development of sensors, microelectronics and manufacture, some camless variable valve actuators (CVVAs) were developed [

4,

5]. For CVVAs, engine valves are driven by independent actuators (electro-hydraulic [

6], electro-pneumatic [

7], electromagnetic [

8], motor [

9], etc.). Thus, the engine valve timing, velocity and valve lift are variable. With CVVAs, engine valve lifts are no longer limited by valve cams, and flexible valve lifts are tracked easily. Therefore, engine performance can be improved significantly [

7,

8,

10].

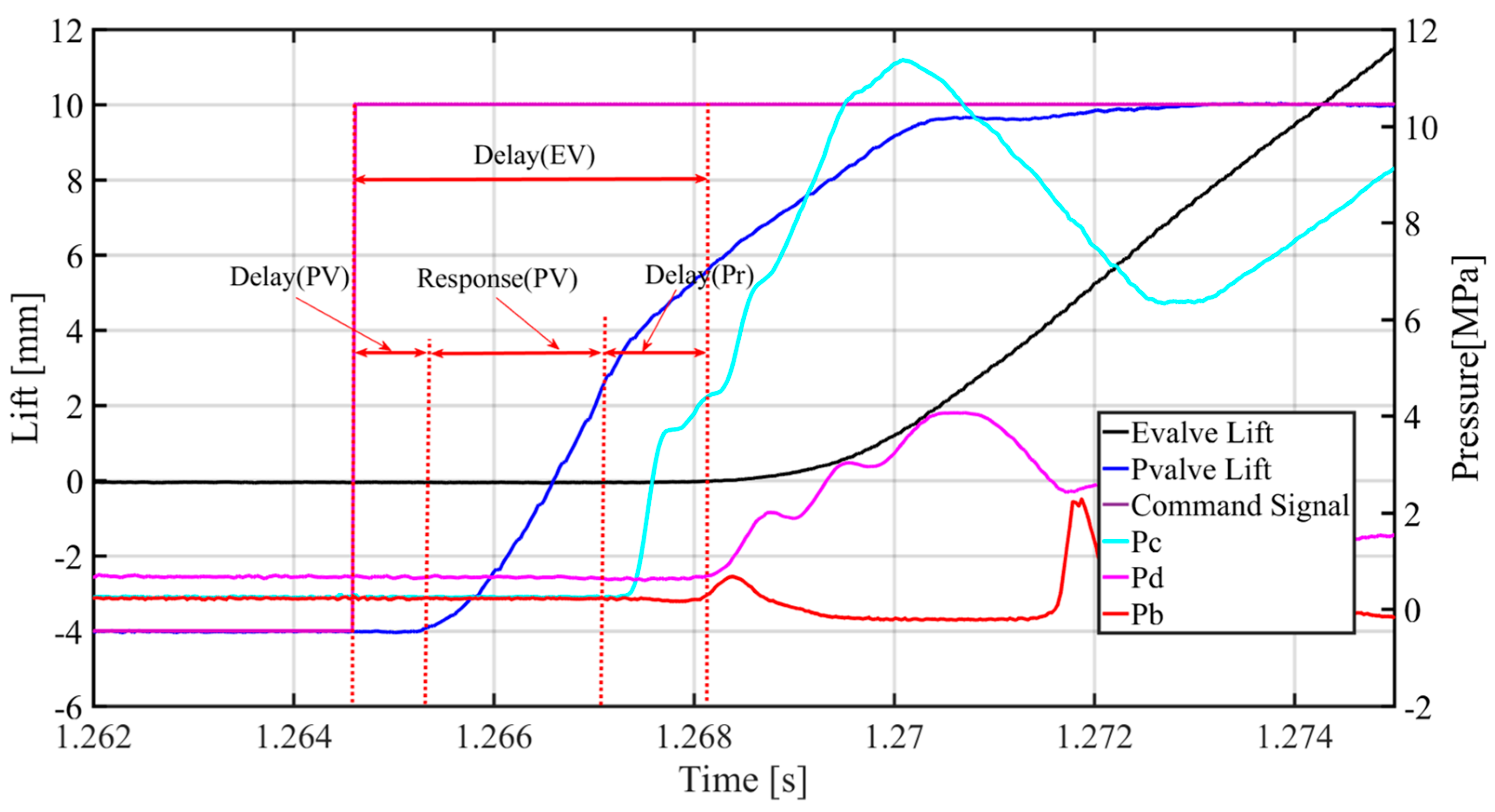

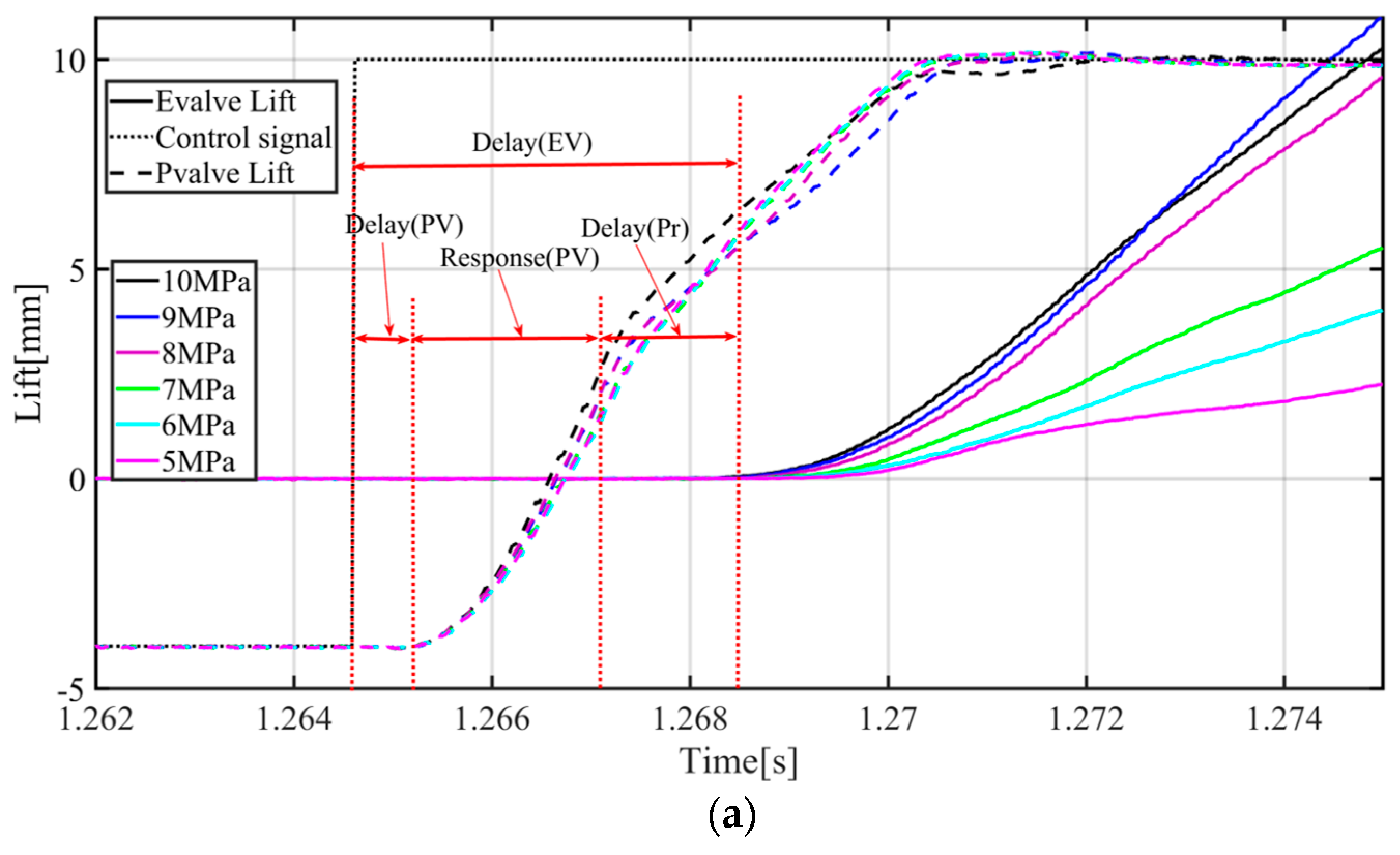

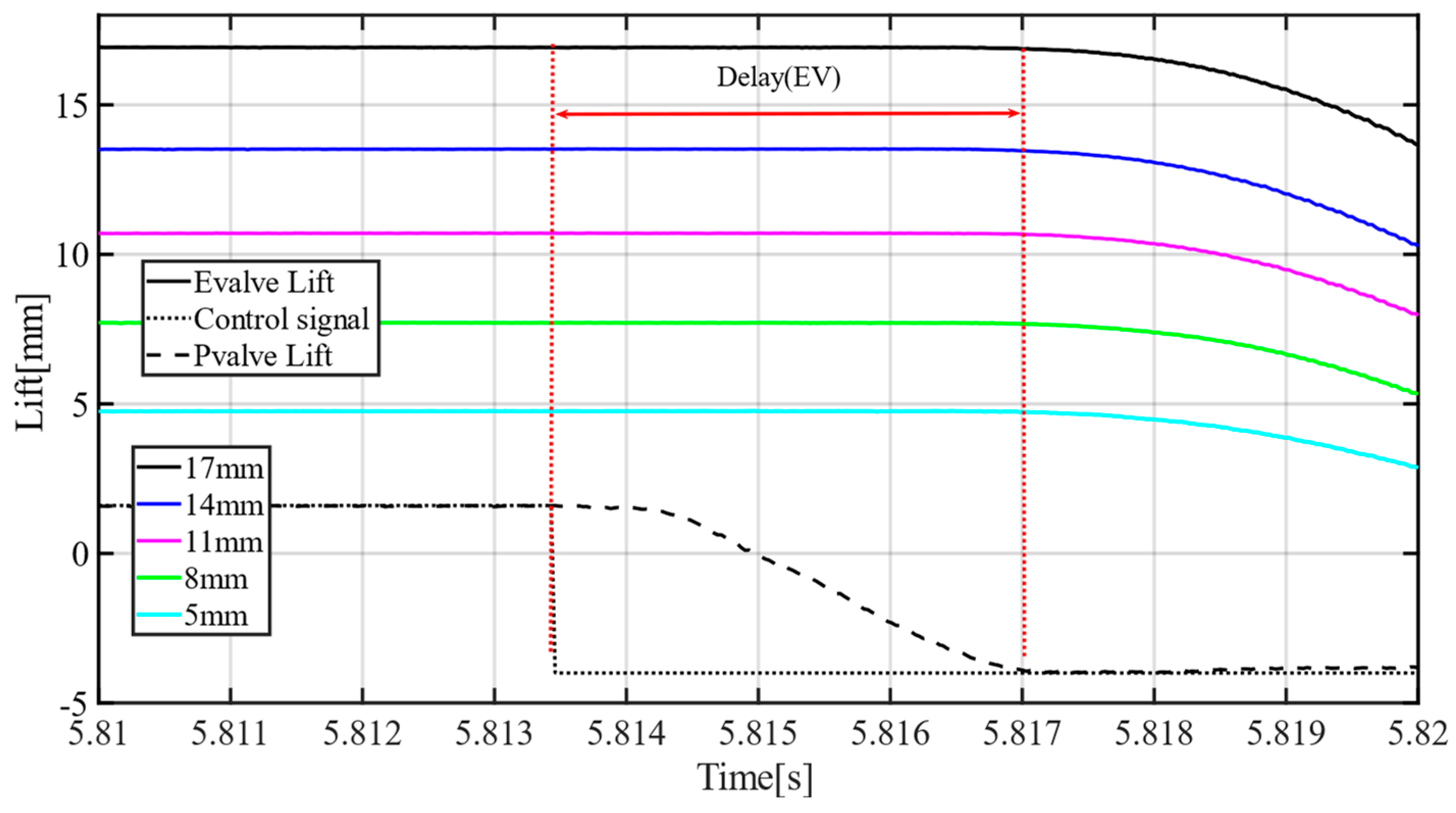

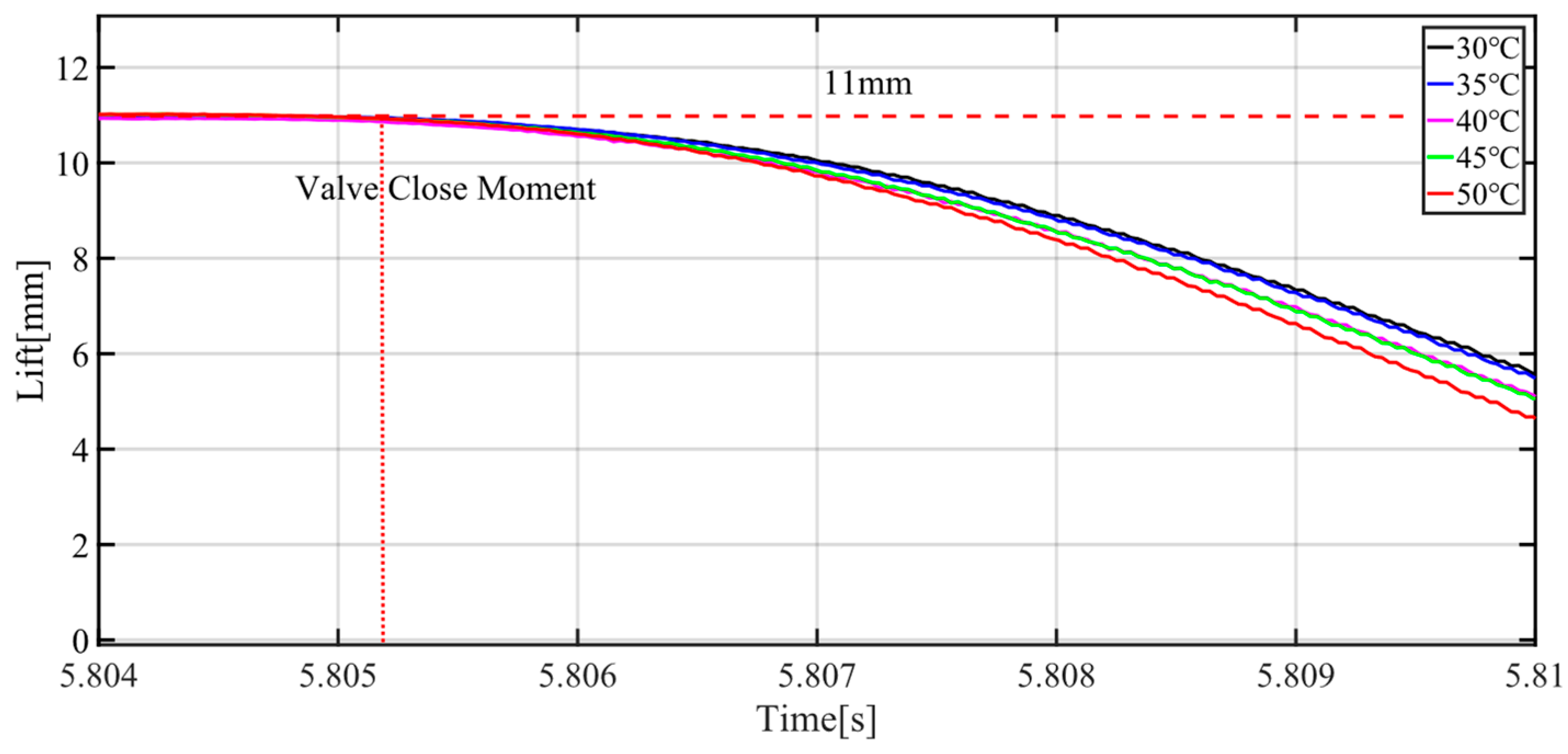

For medium- and high-speed diesel engines, the valve spring stiffness and lifts are greater than those for gasoline engines. Therefore, hydraulic variable valve actuators (HVVAs) which can provide greater driven force and valve lift are the best solutions. Studies showed engine valve timing moment has a great influence on engine performance [

11,

12]. However, the engine valve response delay is caused by many factors, such as control valve delay, control valve dead-zone, actuator friction force and valve spring pre-tightening. Given the complex valve response delay of HVVAs, ensuring the accurate engine valve timing moment is one of the most important challenges [

11,

13]. This paper focuses on the engine valve response delay analysis and its compensation with HVVAs.

The time delay of hydraulic systems has a great effect on system control performance and stability [

14]. To compensate system delay, some advanced strategies have been developed. The Smith predictor has been widely used in pure delay systems. In [

15], a Smith predictor was used in a fluid temperature control system. In [

16], a Smith predictor was used to compensate time delay of hardware-in-the-loop testing of an electro-hydraulic fuel control unit for a turbojet engine. In [

17], an adaptive Smith-predictor controller was proposed to deal with variable process dynamics. The Smith predictor has improved system control performance for constant system delay. The IAE and IAC can be reduced by 24.3% and 57.38%, respectively. However, for complex nonlinear variable delay, the Smith predictor is not suitable. To solve complex delay, many delay observers have been developed. In [

18], the delay estimation was applied to a pump-controlled electro-hydraulic actuator, and the tracking error could be reduced from ±1 mm to ±0.4 mm. In [

19], a relatively large time delay for the VTOL aircraft in the outputs was tested in a numerical simulation, and the simulation results showed the effectiveness of the proposed observer. In [

20], Sadath and Vyasarayani proposed a method of converting the delay integrodifferential equations into a system of ordinary differential equations. In [

21], the framework of the Lyapunov–Krasovskii functional was extended to deal with the problem of exponential stabilization for a class of linear parabolic DPSs with time-varying delay and a spatiotemporal control input. Despite the progress of delay observers, model-based delay observers are generally difficult to accurately model for time-varying nonlinear delay systems, which prevents the realization of delay observers in complex nonlinear systems. To solve the time delay of time-varying nonlinear delay systems, this paper proposed a data-based delay observer, which is used in the repeat tracking events.

To compensate system delay, the delay observers are synthesized into many advanced controllers, such as sliding model control, adaptive control and backstepping control. In [

22], the delay observer was synthesized into a sliding mode controller. In [

23], Lu proposed a receding horizon control (RHC) algorithm for a class of time delay systems; it estimates system state delays online and produces the stabilizable control input for state-delay estimation errors. In [

24], the unknown time delays which exist in each system state were compensated in the backstepping process with the novel Lyapunov–Krasovkii functional and appropriate control gain function. For a hydraulic system, in addition to system delay, there are many nonlinear factors to consider, such as actuator leakage, nonlinear friction and hydraulic valve dead-zone. Backstepping control, which can compensate most nonlinear factors during recursive steps, is one of the most popular solutions for dealing with nonlinear systems [

25,

26]. In [

25], compared with the PD controller, the mean positioning accuracy (MPA), absolute positioning accuracy (APA), weighted position accuracy (WPA), saturation index (SAT), robustness index (RI) and composite index (CI) were all reduced.

The paper focuses on the engine valve lift tracking control based on the electro-hydraulic actuator. To compensate the engine valve response delay, a data-based delay observer is designed. In addition, the proportional valve dead-zone, system uncertainties and system friction force are synthesized into a backstepping controller.

For engine valve response delay compensation, the paper has the following technical novelties:

- (1)

The engine valve response delay for camless hydraulic valve actuators is analyzed in detail, and a date-based delay observer is designed.

- (2)

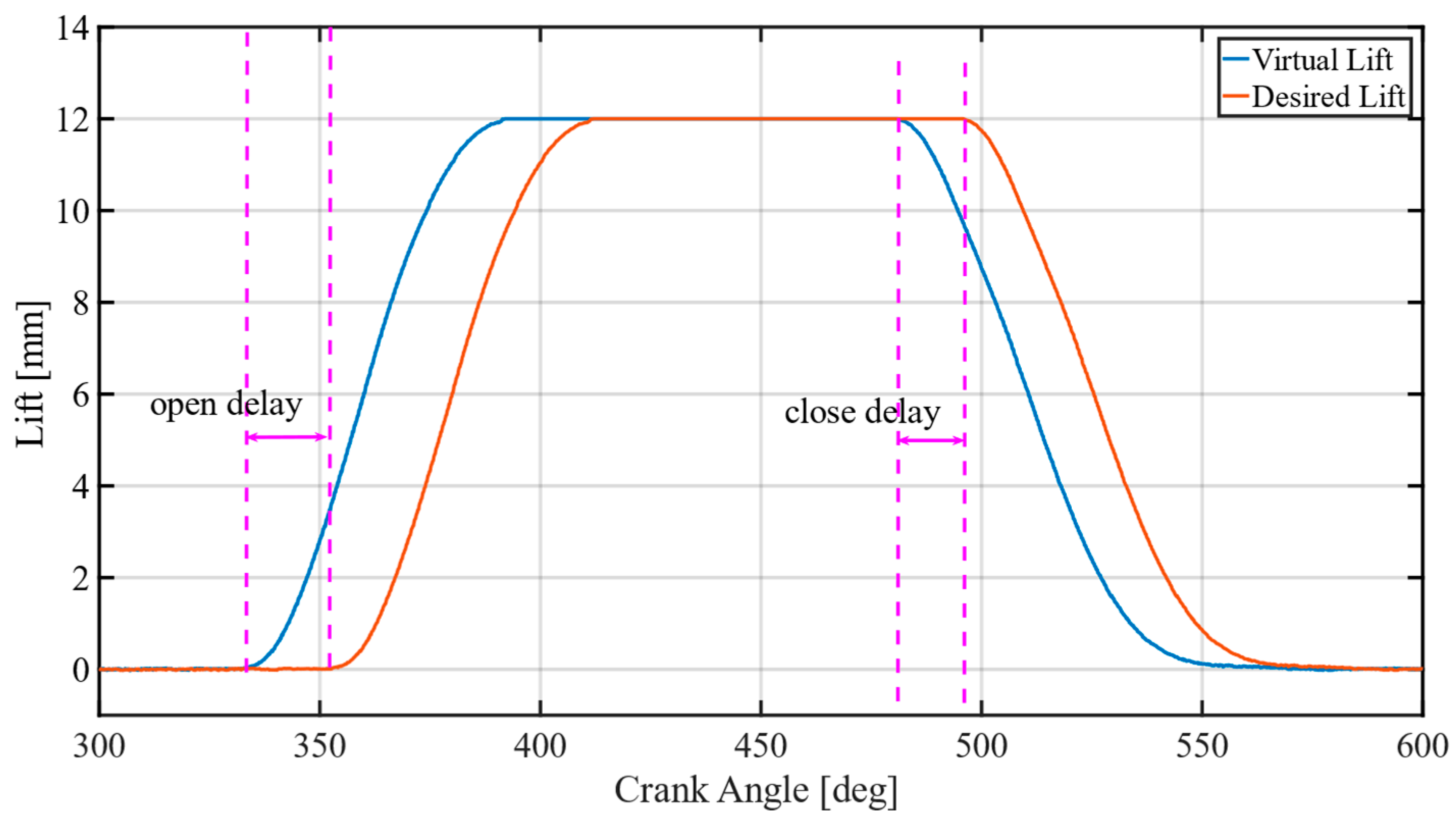

A delay compensation strategy which builds the virtual desired valve lift is proposed, and a backstepping controller with a virtual engine valve lift is designed. The virtual desired lift is used to calculate the input signal based on the system model, and the actual desired valve lift is used to calculate tracking errors.

The paper is organized as follows: The HVVA system and the engine valve response delay analysis are shown in

Section 2. A delay compensation strategy is proposed in

Section 3. The control-oriented system model is given in

Section 3. A backstepping controller with delay compensation is developed in

Section 4.

Section 5 reveals experiment comparisons between the P controller and the controller proposed in this paper. Finally, some conclusions are given in

Section 6.

4. Controller Design and Stability Analysis

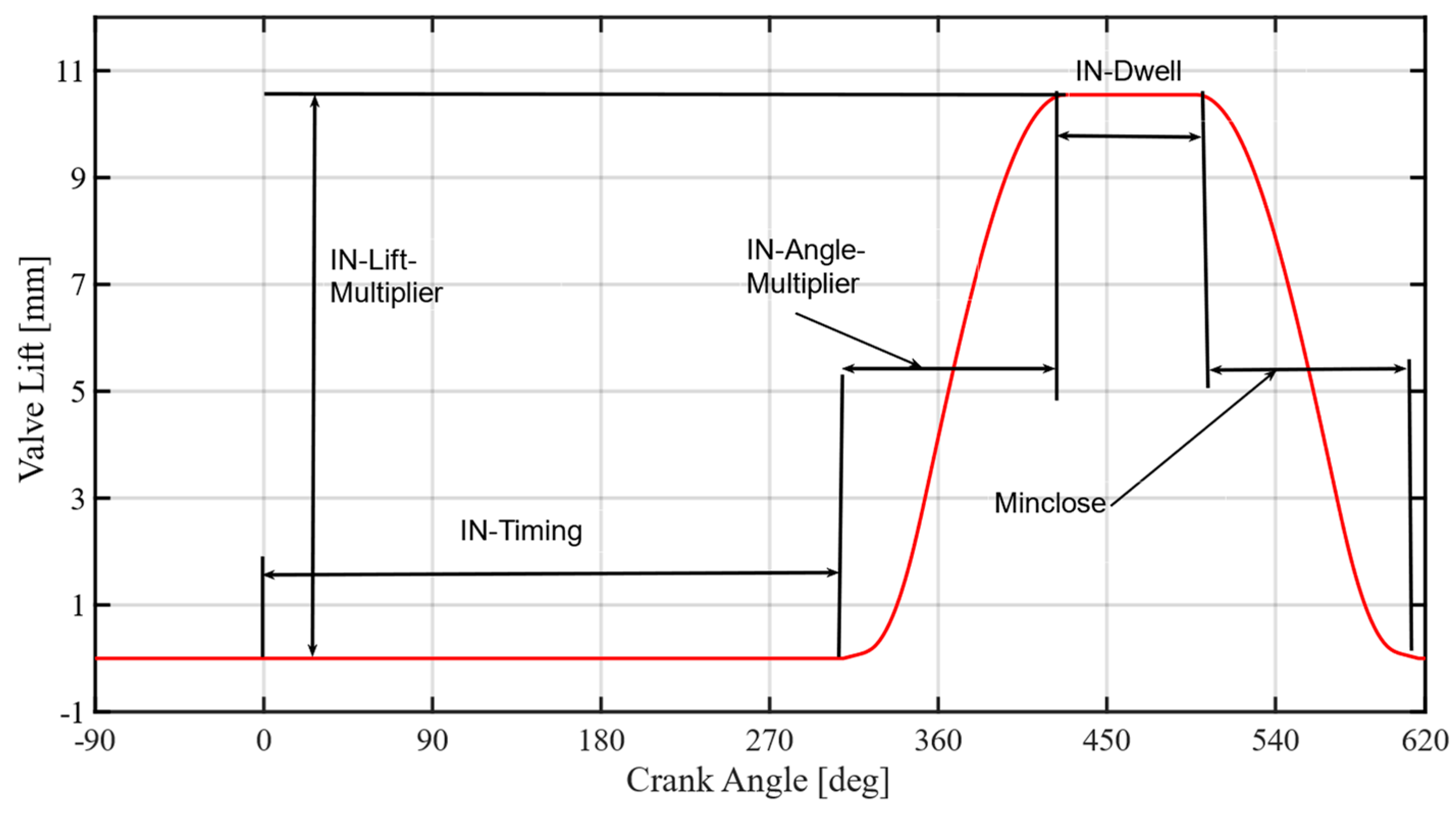

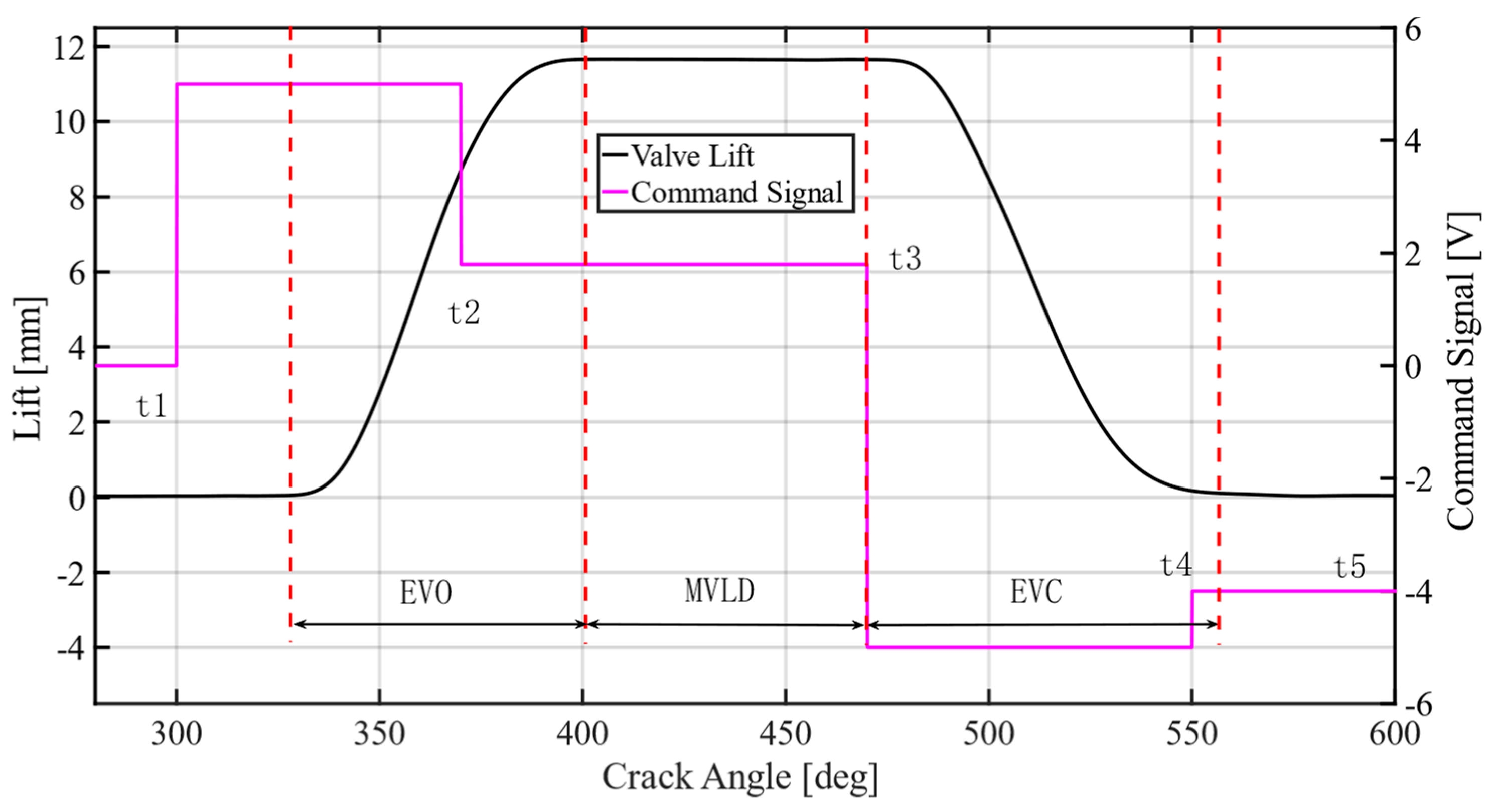

As shown in

Figure 11, the motion of the engine valve can be decoupled into three stages: engine valve open stage (EVO), maximum valve lift dwell stage (MVLD) and engine valve close stage (EVC).

Based on (6)–(17), the system state variables are defined as:

The system model (6)–(17) is converted to state-space form:

For an engine valve application, only engine valve lift (

) can be measured directly. Therefore, a state observer is necessary. To compensate system uncertainties,

is extended to

. The extended state observer can be designed:

The following is defined:

where

is the observer gain matrix. In this paper,

. Observer error is

. It is easy to prove that the characteristic polynomial of the state observer satisfies the Hurwitz law. Thus, the observer is stable.

4.1. Controller Design

Based on the system model, a backstepping controller based on the delay compensation strategy can be designed.

Step 1: Define the engine valve lift tracking error and engine valve velocity tracking error:

where

is the desired valve lift,

is the virtual desired engine valve lift,

is the virtual valve velocity and

is the positive feedback gain of

.

For the engine valve lift tracking event, engine valve lift error

will converge to zero if engine valve velocity error

converges zero. Differentiating (7),

Take

as the virtual input of (25); the engine valve lift error converges to zero upon the design of a control function

that converges to

. Define

;

can be calculated by:

where

is a feedforward controller based on the system model and desired input,

is linear feedback to

,

is used to compensate the unmatched uncertainty,

and

are positive feedback gain,

is the maximum estimation error of friction force and

is the maximum unmatched uncertainty.

In (26),

is used to suppress the uncertainties, and it should satisfy:

Step 2: Similar to Step 1, if

converges to zero,

and

will also converge to zero. The time difference of

can be calculated by:

Treat valve opening

as virtual input of (34), and it can be calculated by:

Similarly, in (36),

is used to suppress the uncertainties, and it should satisfy:

Step 3: Dead-zone compensation.

For a proportional valve, the dead zone is not negligible. Based on the obtained valve opening in Step 2, the proportional valve command signal can be calculated by a smooth dead-zone inverse function shown in (44)–(46). The dead-zone inverse has been proposed in [

31], and the experiments in [

32] verified the effectiveness. The parameters of the dead-zone inverse shown in

Table 4 were calibrated by experiments.

4.2. Stability Analysis

Define a positive semi-definite

function as

The time derivative of

is:

Apply (30) and (40) to (48); thus,

where

,

.

As shown in (52), the controller is stable.

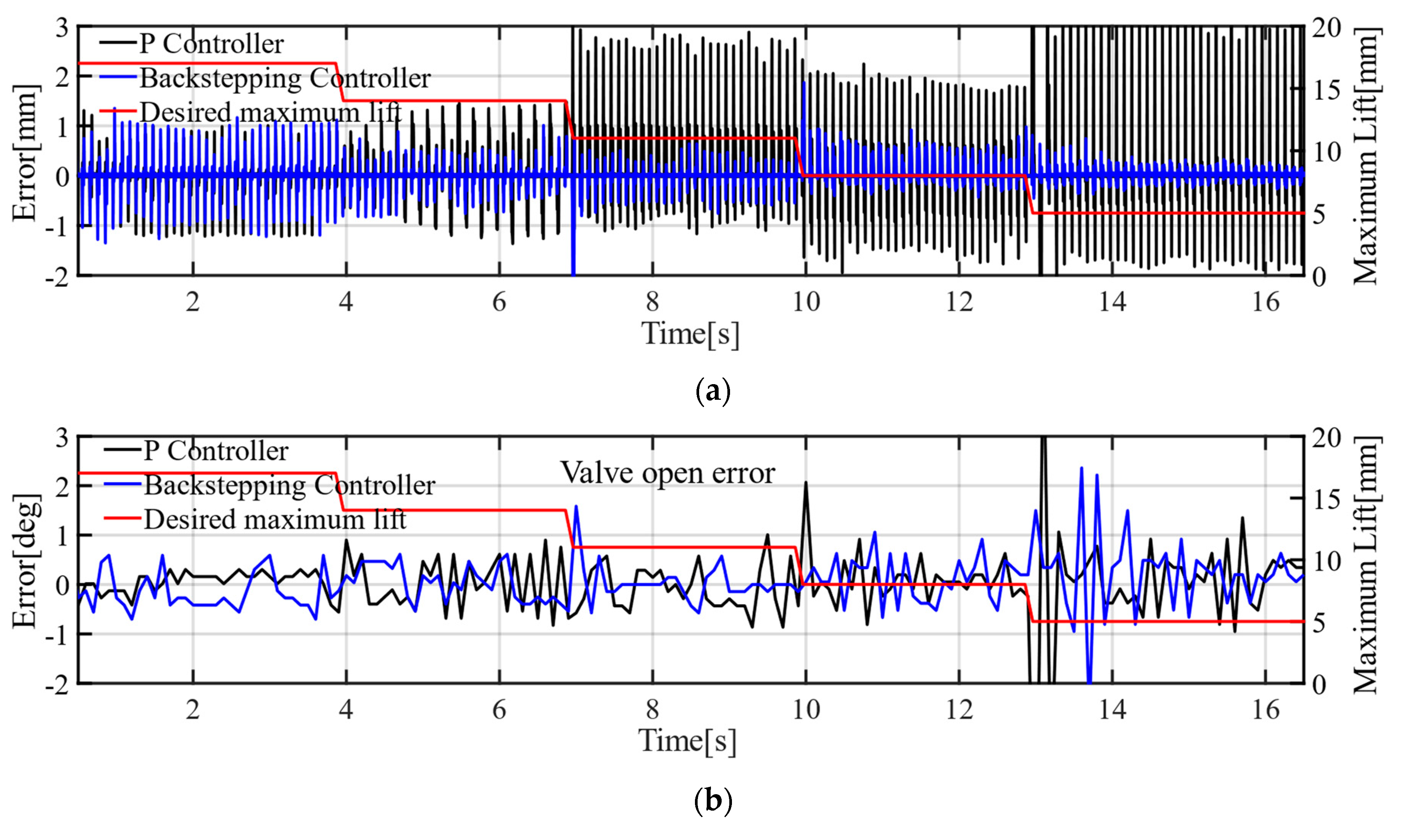

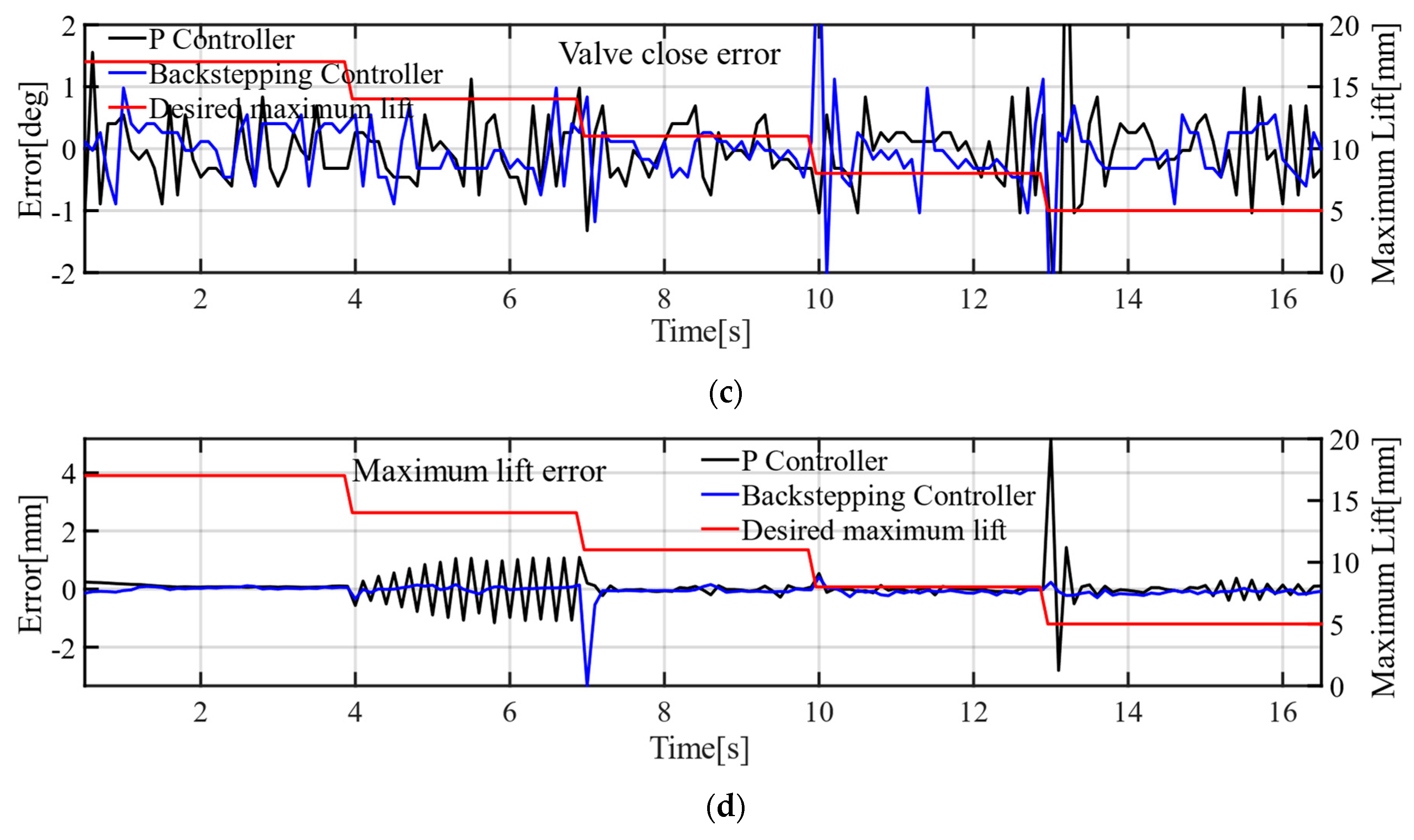

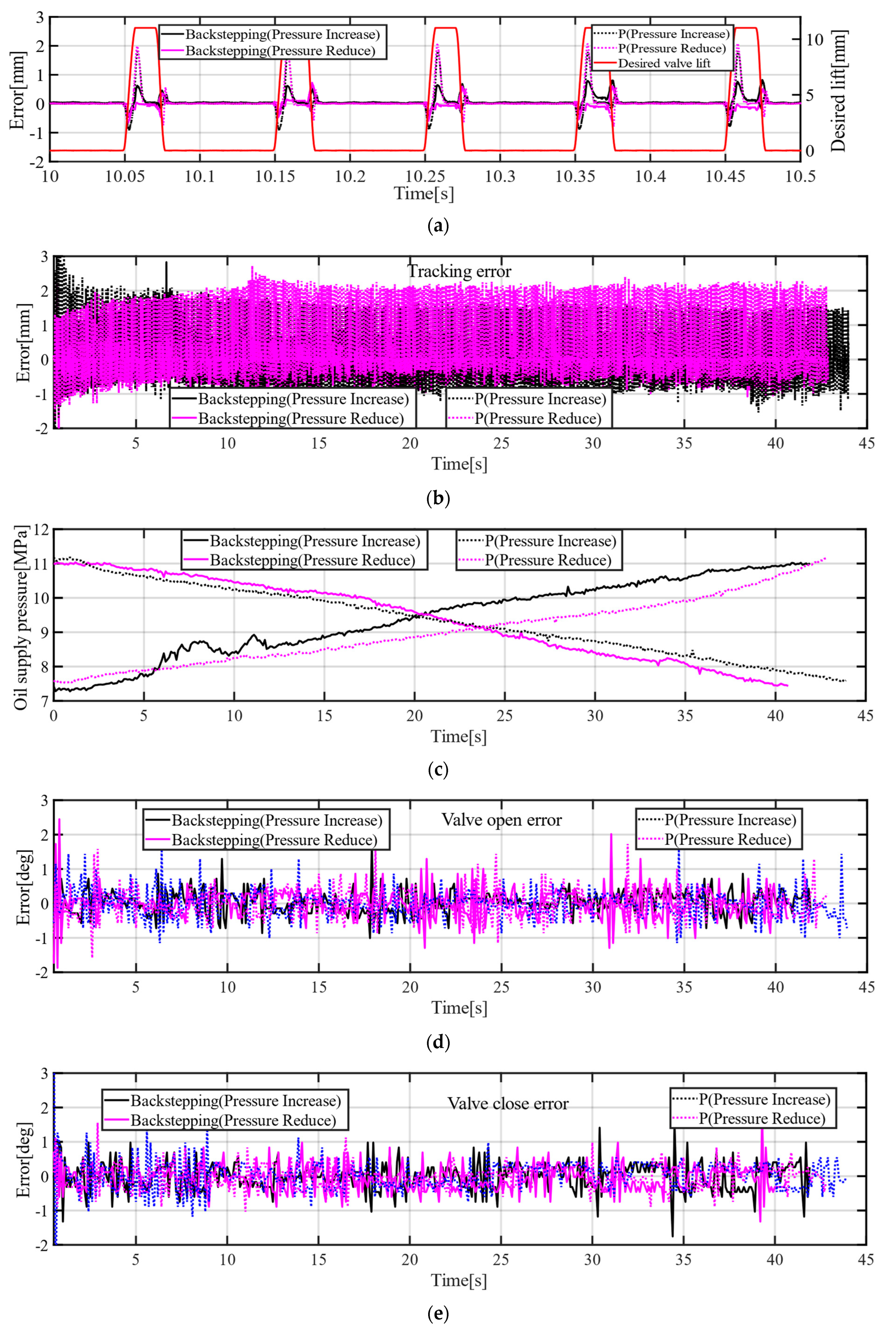

6. Conclusions

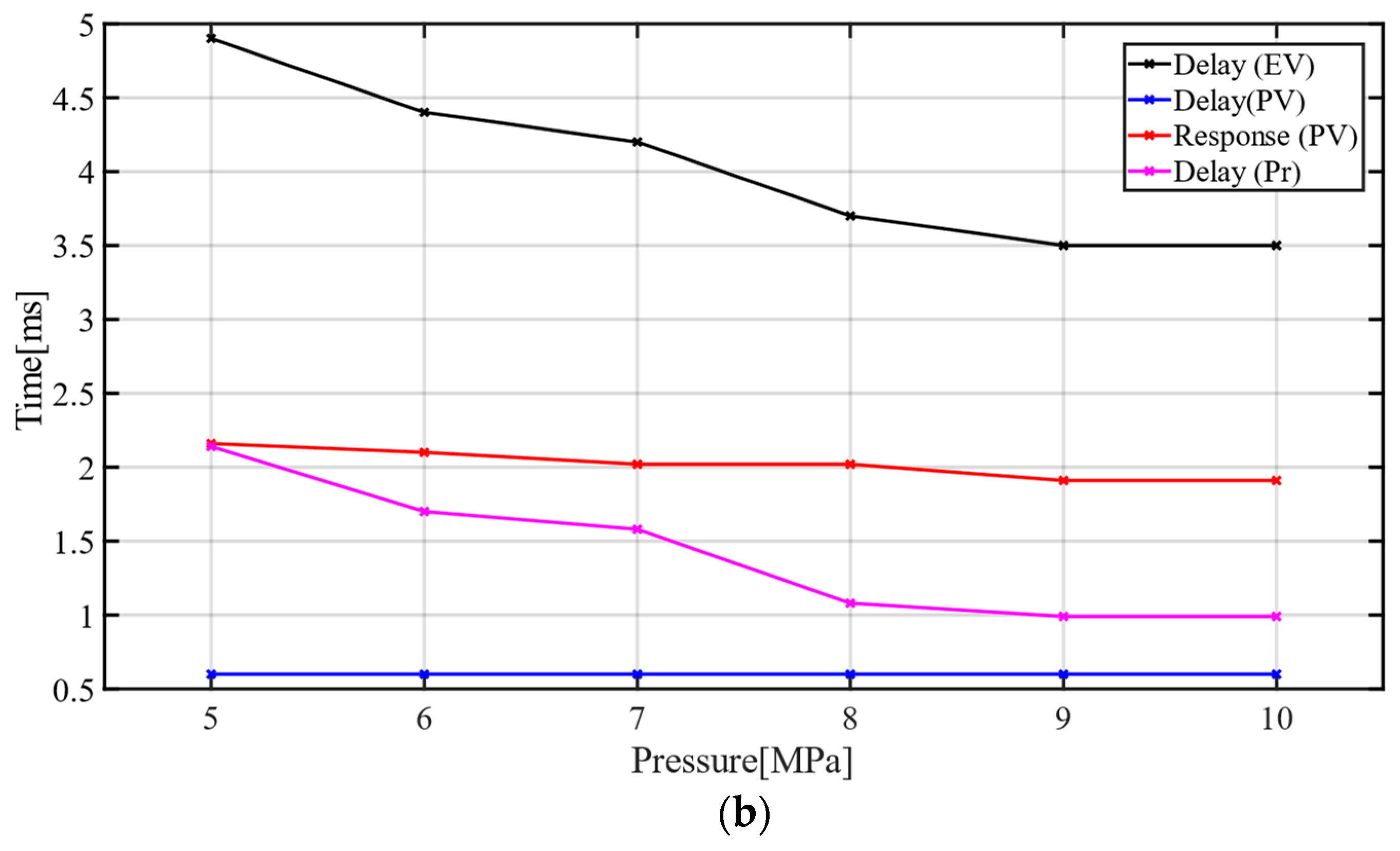

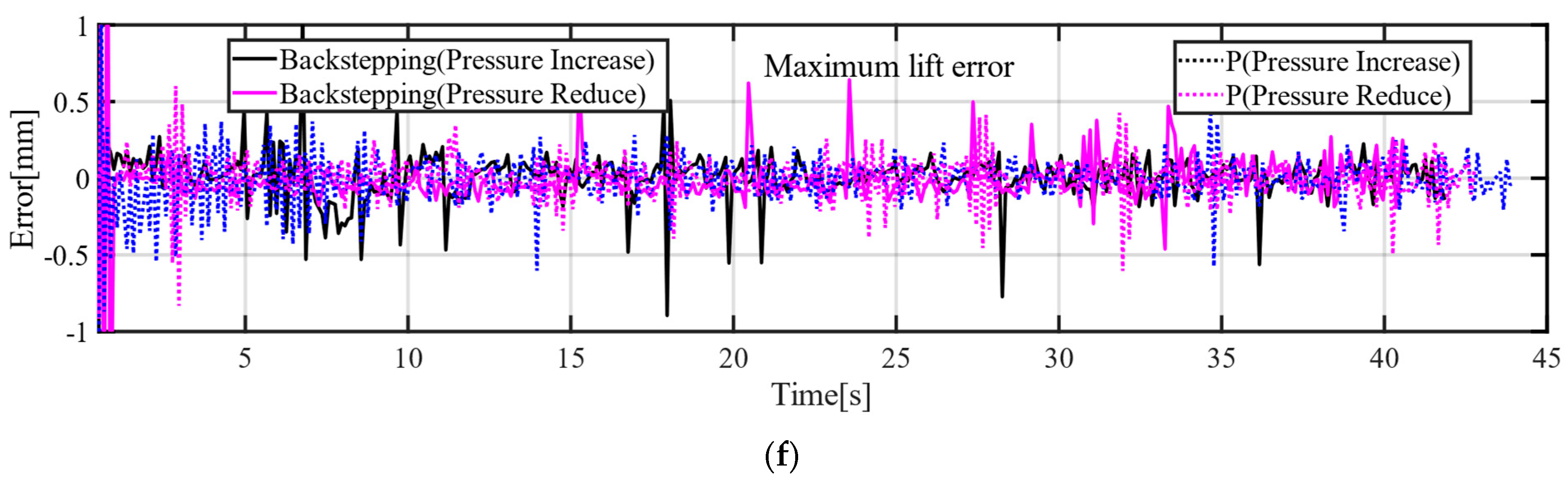

The paper focuses on the electro-hydraulic engine valve response delay analysis and compensation. The experiment results show that the engine valve response delay is affected by proportional valve response delay, proportional valve response time, maximum static friction force, etc. Complicated delay characteristics make it difficult to build a model-based delay observer. Therefore, the paper proposed a data-based delay observer to estimate engine valve response delay. The experiment results show that the oil supply pressure has an obvious influence on engine valve response delay. Therefore, the engine valve response delay is predicted by the previous five engine cycles and oil pressure fluctuations in this paper. Based on the engine valve delay observer, a delay compensation strategy which builds the virtual desired valve lift is proposed. Finally, a backstepping controller with a virtual engine valve lift is designed. The virtual desired lift is used to calculate the input signal based on the system model, and the actual desired valve lift is used to calculate tracking errors. In addition, the controller synthesizes the proportional dead-zone and uncertainties. The engine valve lift tracking experiments show that engine valve open error, valve close error and maximum valve lift can be reduced significantly both at stable conditions and transient conditions with the proposed controller. The experiment results show that the valve open error is not more than 0.39 °CA, and the valve close error is not more than 0.44 °CA at stable conditions. With transient maximum valve lift, the average open time error is reduced by 23.56%, the average close time error is reduced by 16.88% and the average maximum valve lift error is reduced by 65.67%. With transient oil supply pressure, the average valve close error can be reduced by 31.04% and the average maximum valve lift error can be reduced by 65.63%. With different temperature, the valve open error can be reduced by 18.33%, the valve close error can be reduced by 4% and the maximum valve lift error can be reduced by 48.33%. In this paper, system uncertainties are suppressed by the robust term of the controller. However, for actual engine tests, there are many uncertainties such as transient cylinder pressure and engine vibration. In the future, engine bench experiments are necessary to verify the effectiveness of the controller proposed in this paper.