Multipoint Feeding Strategy of Aluminum Reduction Cell Based on Distributed Subspace Predictive Control

Abstract

:1. Introduction

- (1)

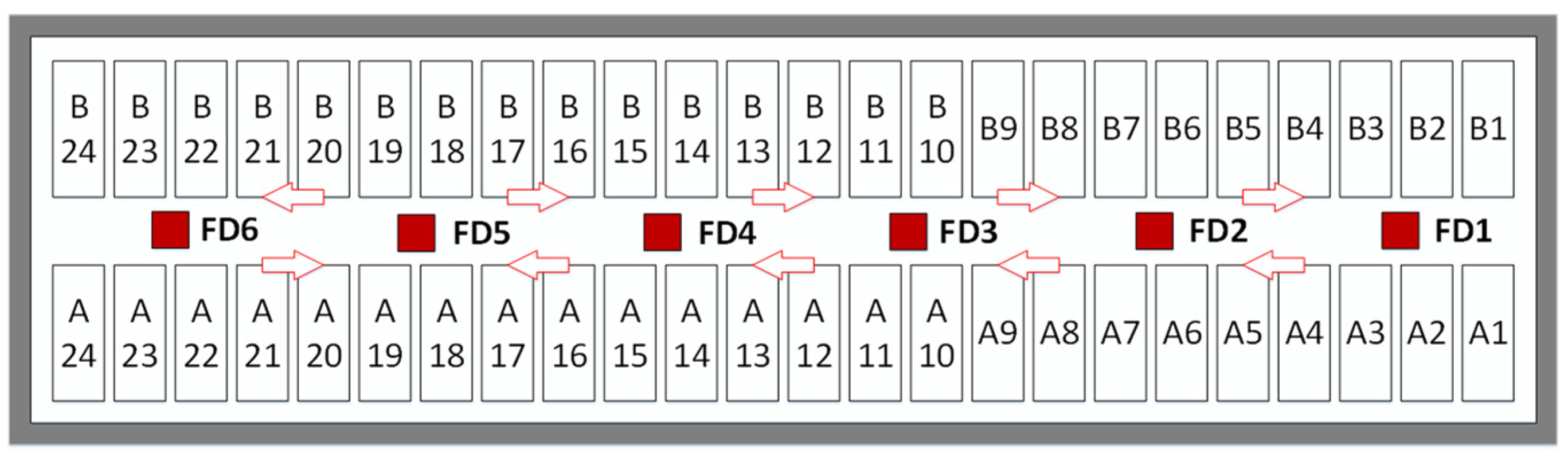

- The large aluminum reduction cell is divided into several subsystems according to the position of the feeder. Compared with the work in [14,15], the difference is that this paper considers the influence of each feeding port caused by the flow of the electrolyte between subsystems on the alumina concentration near other feeding ports.

- (2)

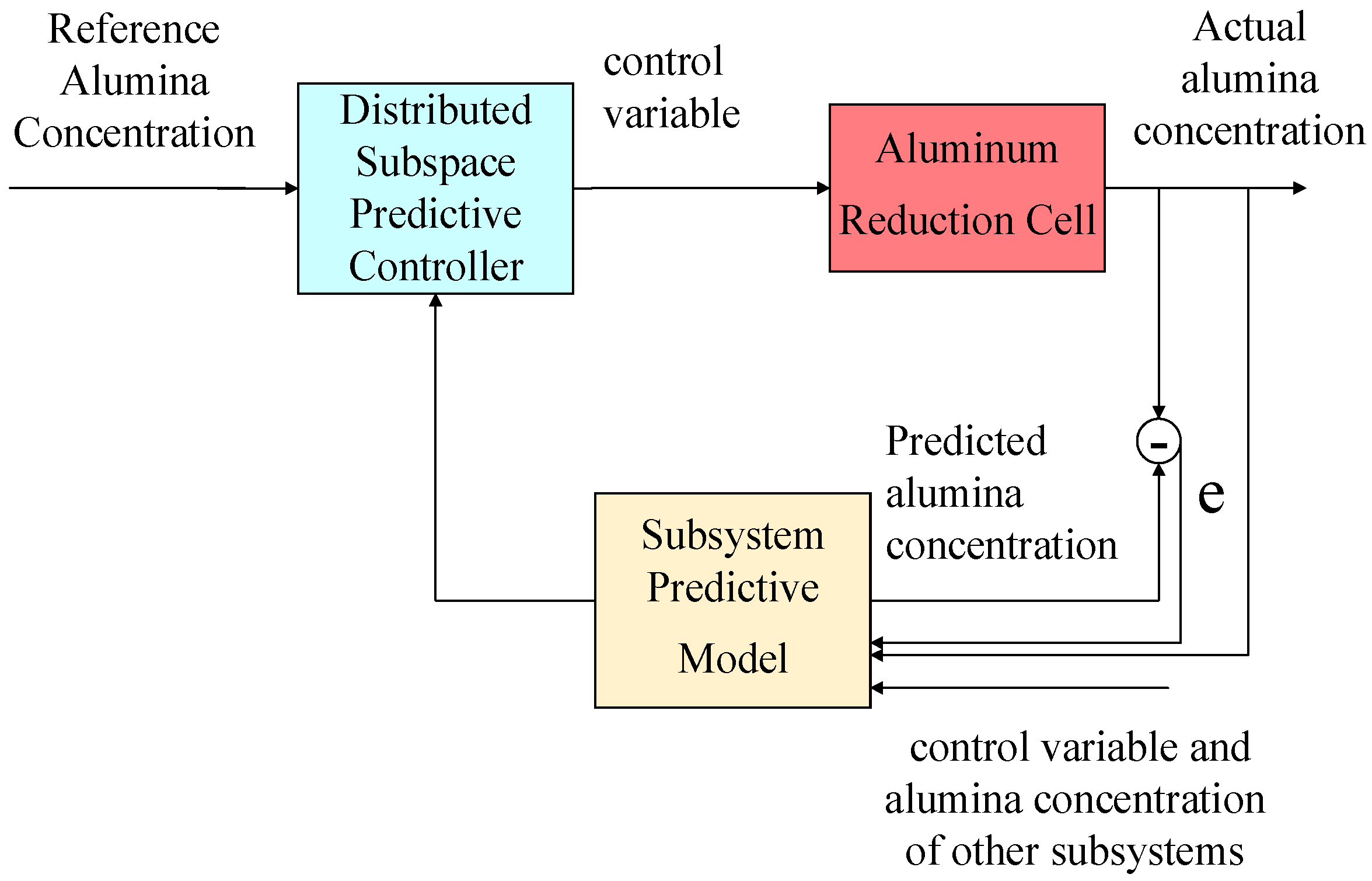

- Inspired by the work of [22], this paper designs the controller by establishing a prediction model between the feed rate and alumina concentration in each subsystem, and the input and output information can be exchanged between each subsystem through the network.

- (3)

- Compared with the traditional timing grouping feeding strategy, a new distributed control feeding strategy is designed in this paper, so that each feeding device is controlled by an independent controller. Each feeder works in coordination with the influence of other subsystems’ feeding, realizing on-demand distributed feeding, and improving the control performance of each subsystem [23].

2. Design of Distributed Feeding Control Scheme for Aluminum Electrolysis

3. Distributed Subspace Predictive Control

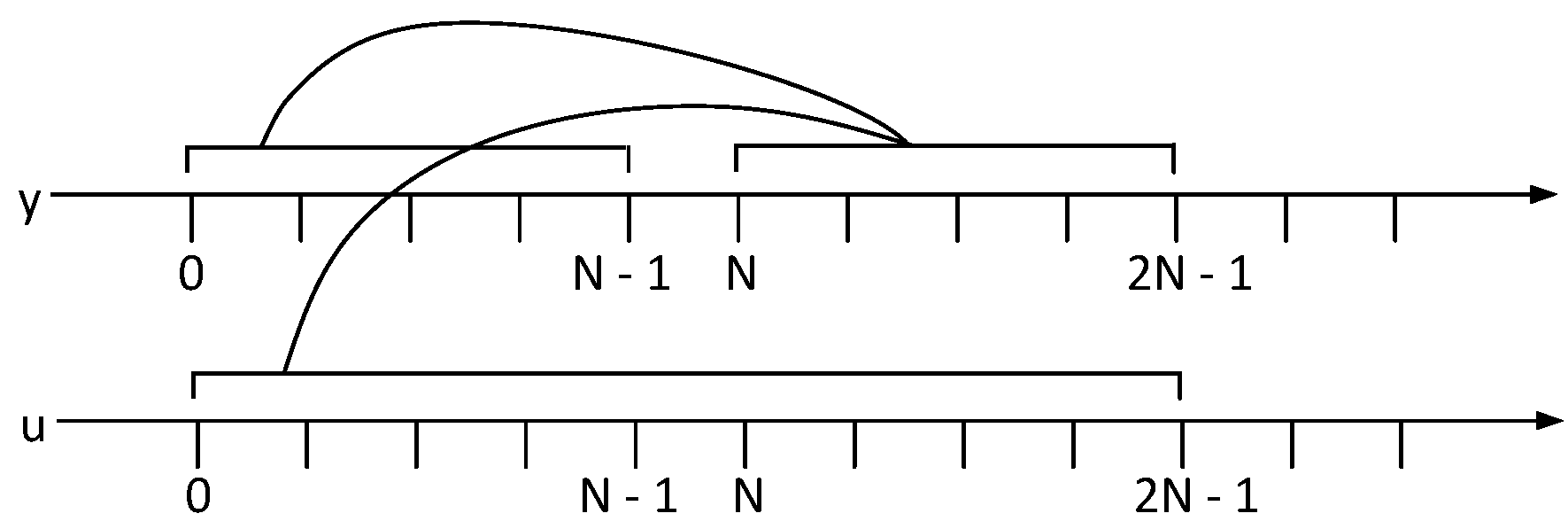

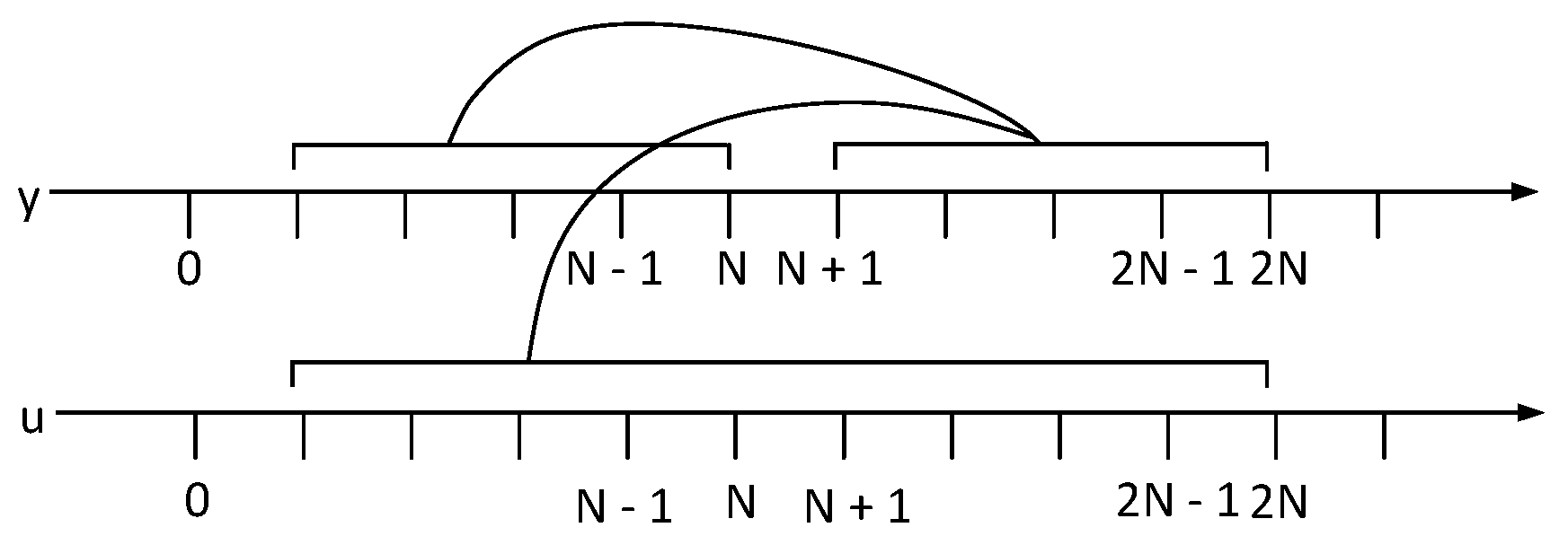

3.1. Data-Driven Distributed Prediction Model

3.2. Design of Distributed Predictive Controller for Aluminum Reduction Cell System

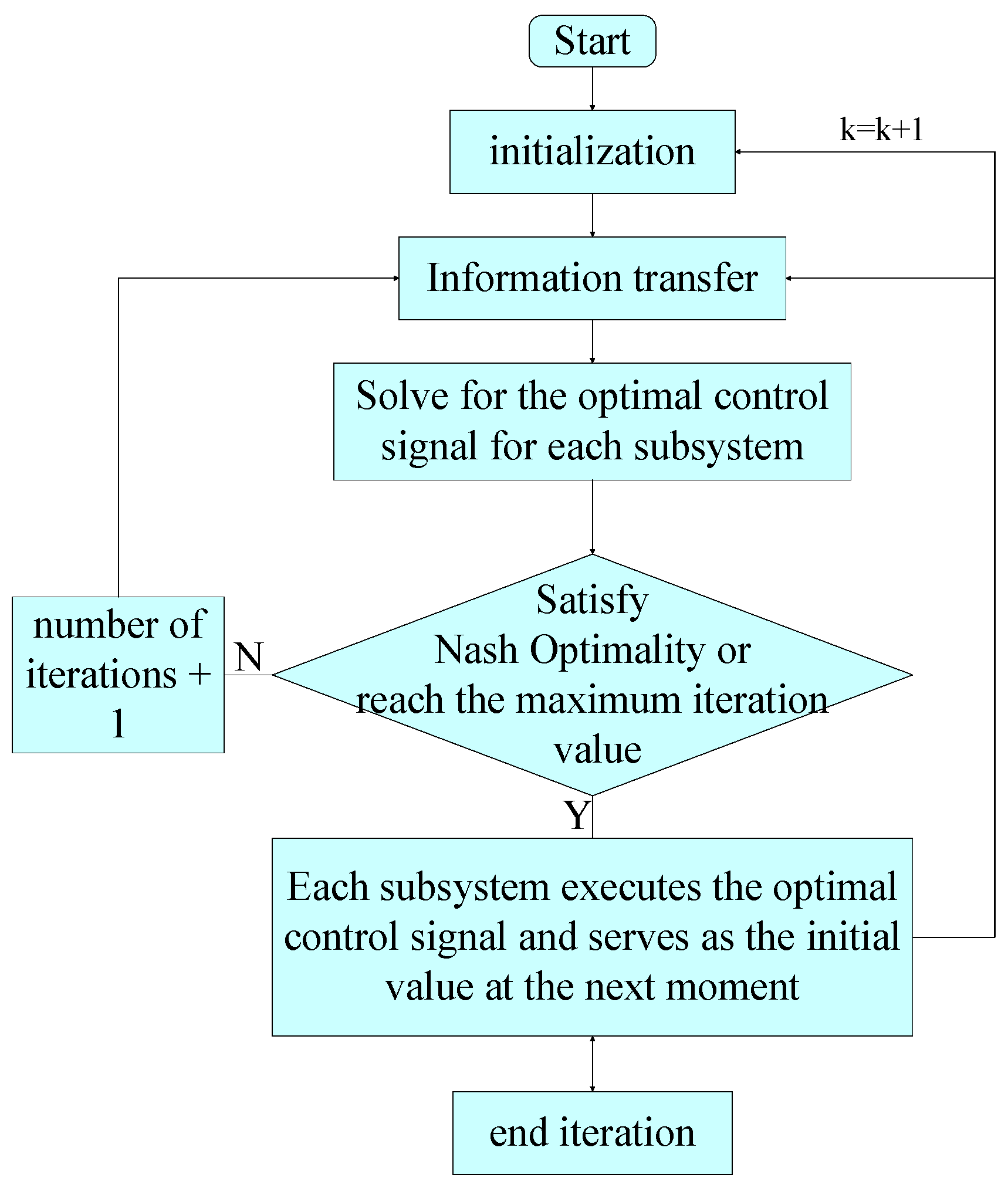

3.3. Determination of Parameters of Aluminum Reduction Cell Prediction Model and Design of Data-Driven Distributed Predictive Control Algorithm

- Step 1 At the k sampling time, take the initial value of the control input variable of each subsystem and pass the initial value to other subsystems, so that the iteration ordinal l = 0;

- Step 2 Use the last iteration value calculate the value of iteration l + 1 for the ith subsystem;

- Step 3 Pass the calculation result to other subsystems through the network;

- Step 4 If the Nash optimality is satisfied for all subsystems or the maximum number of iterations is reached, the iteration is ended, otherwise, return to the second step;

- Step 5 Each subsystem executes the optimal control signal and uses it as the initial value at the next moment;

- Step 6 End the calculation of this sampling time, and wait for the next sampling time k + 1.

4. Simulation Experiments

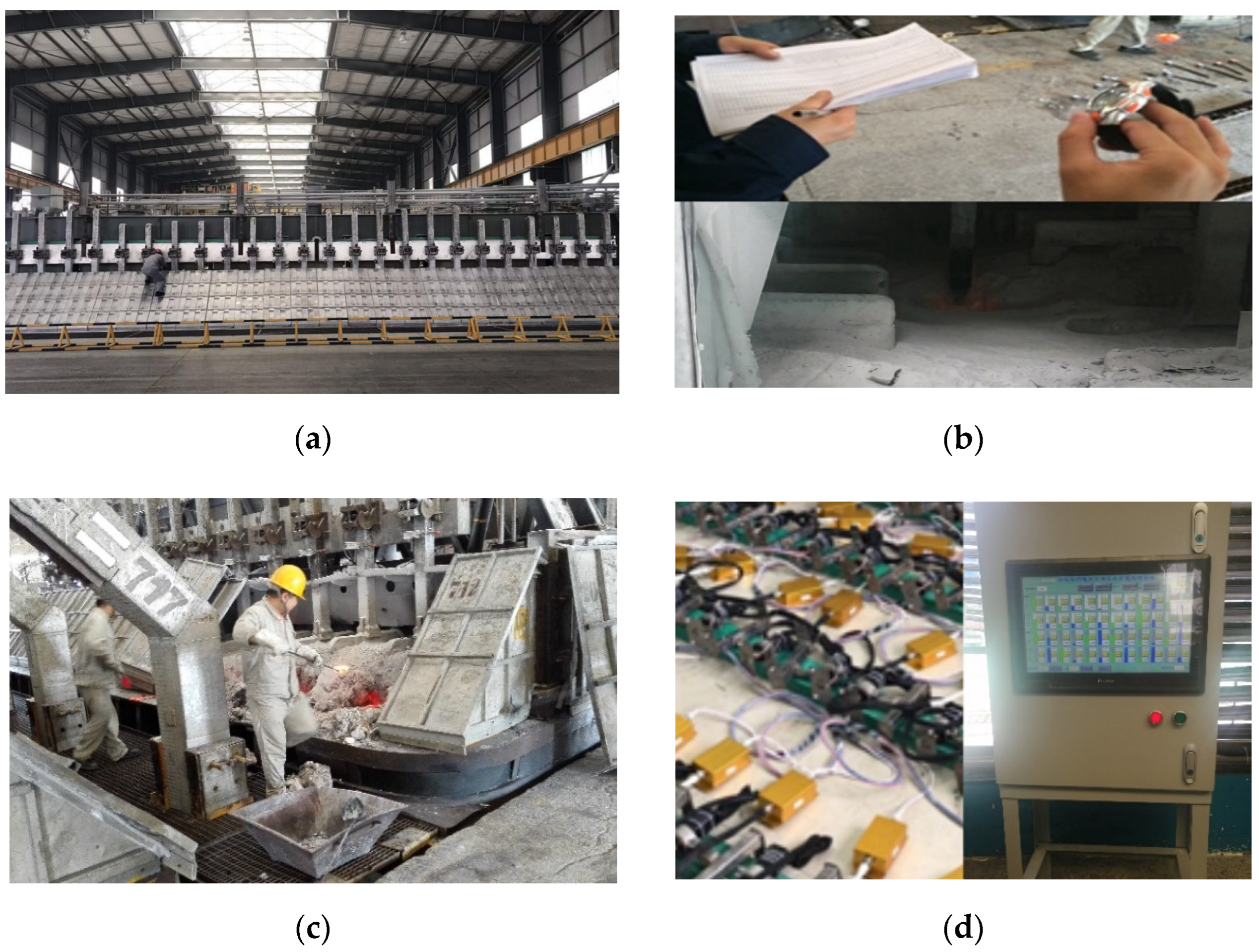

4.1. Data Acquisition

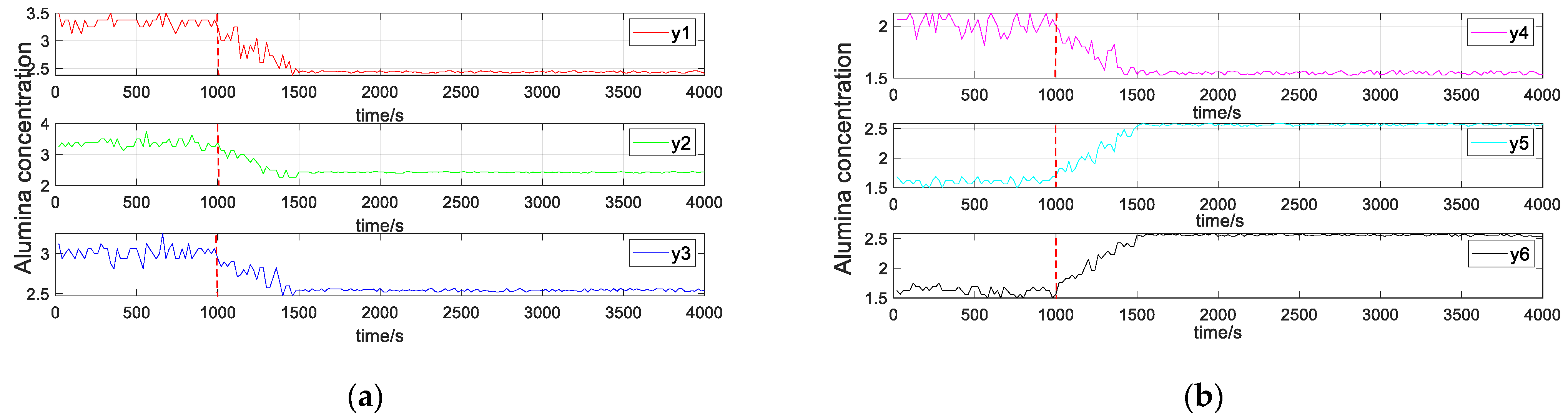

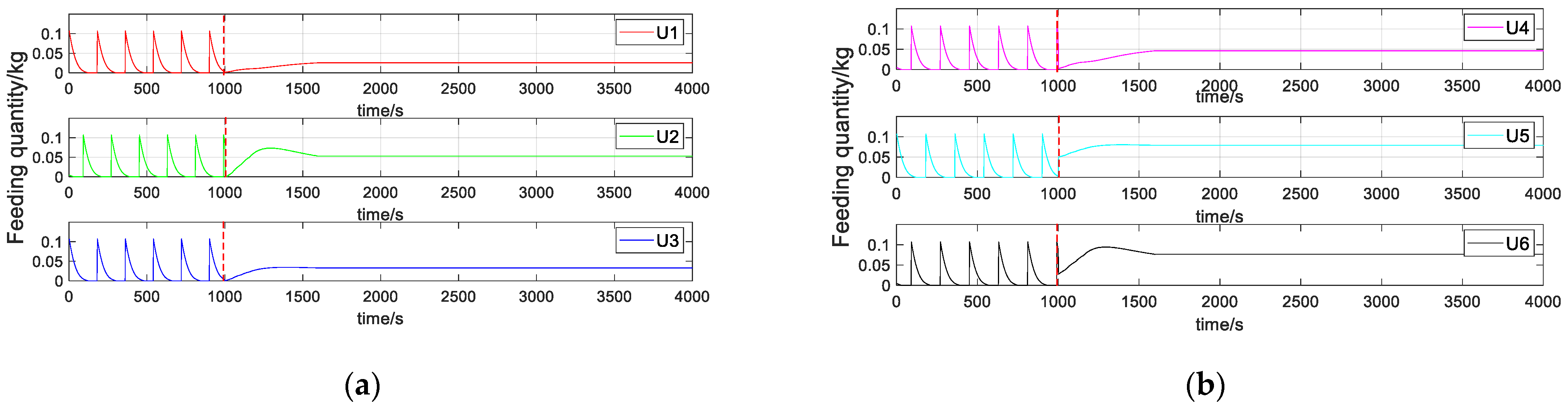

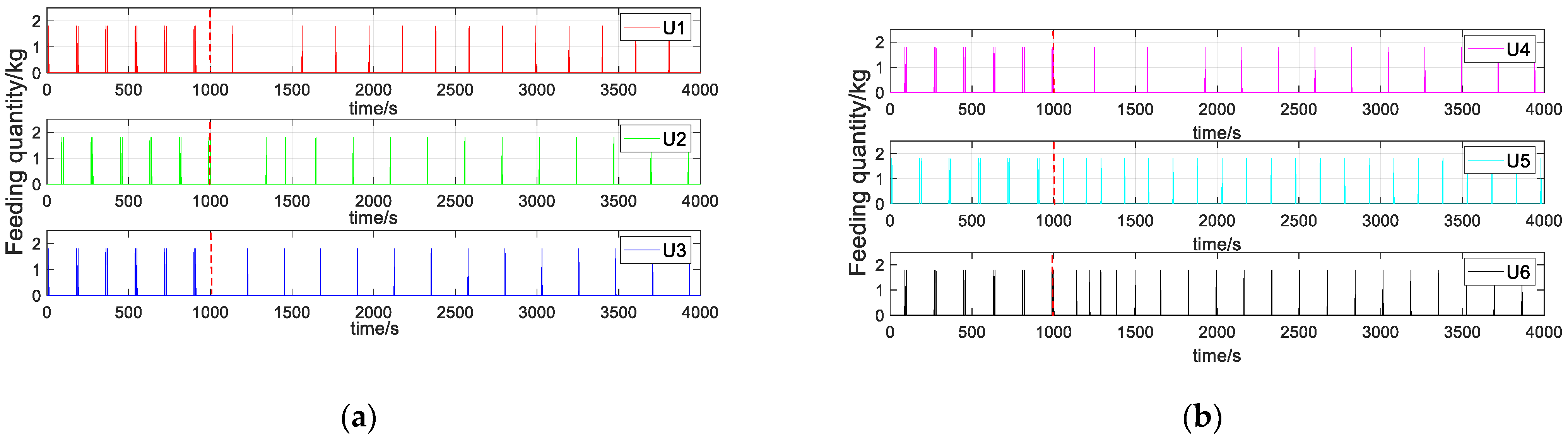

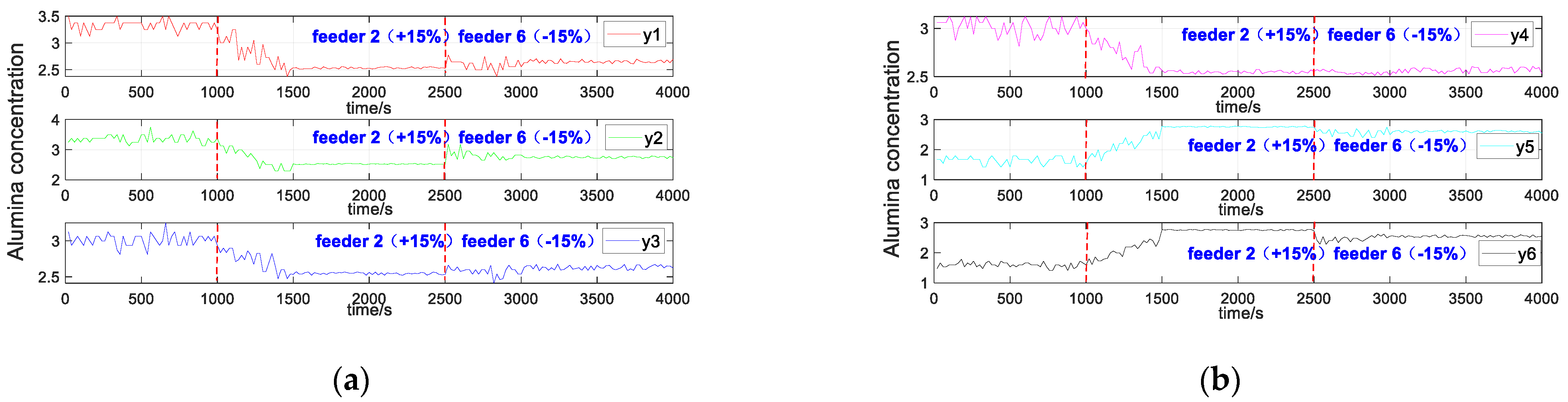

4.2. Control Effect without Any Interference

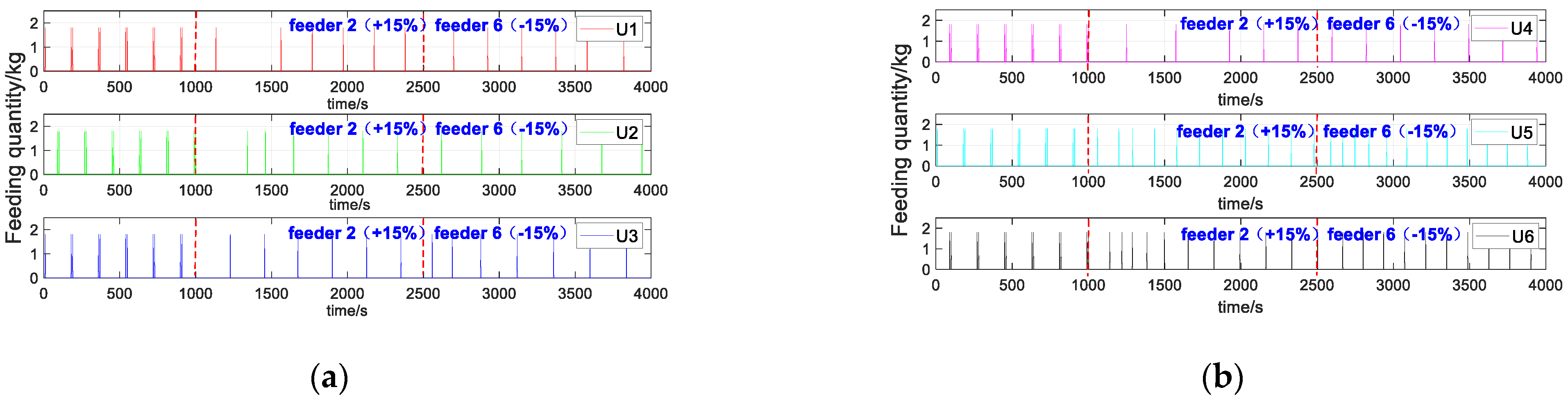

4.3. The Control Effect when the Feeding Amount of the Feeder Is Inconsistent with the Actual Set Value

5. Conclusions

- (1)

- Each feeding device is controlled by an independent controller, and the distributed control method which combines the advantages of centralized and decentralized control is adopted, overcoming their shortcomings.

- (2)

- The mutual influence between the various subsystems and the influence of sudden interference are considered. For example, when the feeding amount is inaccurate, the controller can also control the concentration of alumina well to ensure the stability of the reduction cell.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, Z.Y.; Yang, S.; Zou, Z.; Li, J. Research progress of on-line detection for spatial distribution information in large-amperage aluminum reduction cells. Light Met. 2019, 9, 22–30. [Google Scholar]

- Bai, W.B. Discussion on the control of alumina concentration during aluminum electrolysis under complex electrolyte system. Sci. Technol. Innov. 2018, 36, 53–54. [Google Scholar]

- Wang, Z.W.; Gao, B.L.; Hu, X.W.; Lu, Y.; Li, Y.; Shi, Z.N.; Yu, J.Y. Some Issues in Scale Aluminum Electrolysis Cell. In Proceedings of the 15th session of the 15th China Association for Science and Technology Annual Conference: National Seminar on Aluminum Metallurgy Technology Proceedings of the Conference, Guiyang, China, 25–27 May 2013. [Google Scholar]

- Wu, Z.W.; Ouyang, X.Y. Production practice of accuracy feeding control for aluminum reduction pots. Light Met. 2017, 8, 26–29. [Google Scholar]

- Li, X.; Liu, M.Z. Effect of adjusting feeding Interval on technical parameters of aluminum electrolysis. Light Met. 2011, S1, 228–230. [Google Scholar]

- Lv, Z.M. Basic characteristics and control requirements of stable production mode of large aluminum reduction cell. Alum. Magnes. Commun. 2012, 3, 24–26. [Google Scholar]

- Zeng, S.P.; Zhang, Q.P.; Zhao, G.X. Fuzzy control for the alumina concentration in aluminum cells. Metall. Autom. 2001, 5, 9–11. [Google Scholar]

- Kong, J.Y.; Li, G.F.; Xiong, H.G.; Jiang, G.Z.; Yang, J.T.; Wang, X.D.; Hou, Y. Research on Soft-sensing Modeling Methods and its Application in Industrial Production. Mach. Tool Hydraul. 2007, 6, 149–151. [Google Scholar]

- Yin, H.M.; Wang, M.L.; Fan, J.J. High Speed Milling Cutting Temperature Soft Measurement Modeling and Algorithm Implementation Based on PSO Algorithm. Mach. Des. Res. 2016, 32, 128–131. [Google Scholar]

- Cui, J.R.; Li, W.H.; Su, G.C.; Cao, B.; Huang, R.Y.; Yang, X.; Li, Q. Research progress of distributed all-element model of large-amperage aluminum pots for intelligent manufacturing. Light Met. 2021, 11, 30–38. [Google Scholar]

- Cui, J.R.; Zhang, N.; Yang, X. Soft sensing of alumina concentration in aluminum electrolysis industry based on deep belief network. In Proceedings of the 2020 Chinese Automation Congress (CAC), Shanghai, China, 6–8 November 2020. [Google Scholar]

- Zhang, Y.; Yang, X.; Shardt, Y.A.W.; Cui, J.; Tong, C. A KPI-based probabilistic soft sensor development approach that maximizes the coefficient of determination. Sensors 2018, 18, 3058. [Google Scholar] [CrossRef] [Green Version]

- Yang, X.; Zhang, Y.; Shardt, Y.A.W.; Li, X.; Cui, J.; Tong, C. A KPI-based soft sensor development approach incorporating infrequent, variable time delayed measurements. IEEE Trans. Control Syst. Technol. 2019, 28, 2523–2531. [Google Scholar]

- Li, J.J.; Feng, D.D. Intelligent feeding control strategy based on aluminum concentration identification in aluminum electrolysis. Light Met. 2019, 2, 31–36. [Google Scholar]

- Huang, H.; Wei, Y. Research on Intelligent Control of aluminum reduction cell Based on Data Drive. Electron. Manuf. 2015, 1, 32. [Google Scholar]

- Shi, J.; Yao, Y.; Skyllas-Kazacos, M.; Welch, B.J. Multivariable Feeding Control of Aluminum Reduction Process Using Individual Anode Current Measurement. IFAC Pap. Online 2020, 53, 11907–11912. [Google Scholar] [CrossRef]

- Kaszás, C.; Kiss, L.; Poncsák, S.; Guérard, S.; Bilodeau, J.-F. Spreading of Alumina and Raft Formation on the Surface of Cryolitic Bath. In Proceedings of the 146th TMS Annual Meeting and Exhibition/Conference on Light Metals, San Diego, CA, USA, 26 February–2 March 2017. [Google Scholar]

- Zhan, S.Q.; Li, M.; Zhou, J.-M.; Yang, J.-H.; Zhou, Y.-W. CFD simulation of effect of anode configuration on gas-liquid flow and alumina transport process in an aluminum reduction cell. J. Cent. South Univ. 2015, 22, 2482–2492. [Google Scholar] [CrossRef]

- Kovács, A.; Breward, C.; Einarsrud, K.; Halvorsen, S.A.; Nordgård-Hansen, E.; Manger, E.; Münch, A.; Oliver, J.M. A heat and mass transfer problem for the dissolution of an alumina particle in a cryolite bath. Int. J. Heat Mass Transf. 2020, 162, 120232. [Google Scholar] [CrossRef]

- Gylver, S.E.; Omdahl, N.H.; Prytz, A.K.; Meyer, A.J.; Lossius, L.P.; Einarsrud, K.E. Alumina feeding and raft formation: Raft collection and process parameters. In Proceedings of the Light Metals Symposium at the 148th TMS Annual Meeting, San Antonio, TX, USA, 10–12 March 2019. [Google Scholar]

- Einarsrud, K.E.; Eick, I.; Wei, B.; Feng, Y.; Hua, J.; Witt, P.J. Towards a coupled multi-scale, multi-physics simulation framework for aluminium electrolysis. Appl. Math. Model. 2015, 44, 3–24. [Google Scholar] [CrossRef] [Green Version]

- Wang, R.G.; Bao, J.; Yao, Y.C. A data-centric predictive control approach for nonlinear chemical processes. Chem. Eng. Res. Des. 2018, 142, 154–164. [Google Scholar] [CrossRef]

- Xi, L.; Sun, M.M.; Chen, S.S.; Zhu, J.Z.; Sun, Q.Y.; Liu, Z.J. Multi-region cooperative control method for distributed grid. Electr. Mach. Control 2021, 25, 75–86. [Google Scholar]

- Wang, Z.B.; Li, C.M.; He, W.Y. Control of alumina concentration in aluminum electrolysis production. Des. Nonferrous Met. 2018, 45, 101–103. [Google Scholar]

- Yang, X.; Gao, J.J.; Huang, B. Data-driven design of fault detection and isolation method for distributed homogeneous systems. J. Frankl. Inst. 2021, 358, 4929–4949. [Google Scholar] [CrossRef]

- Yang, X.; Gao, J.J.; Li, L.L.; Luo, H.; Ding, S.X.; Peng, K.X. Data-driven design of fault-tolerant control systems based on recursive stable image representation. Automatica 2020, 122, 109246. [Google Scholar] [CrossRef]

- Han, P.; Liu, M.; Jia, H. Data Driven Pre Tuning Adaptive Subspace Model Predictive Control. J. Syst. Simul. 2018, 30, 332–340. [Google Scholar]

- Wu, X.; Shen, J. Subspace identification and predictive control of boiler-turbine coordination system. J. Southeast Univ. Nat. Sci. Ed. 2012, 42, 281–286. [Google Scholar]

- Dong, T.T.; Li, L.J.; Xiong, L.; Xu, O.G. Distributed Predictive Control Based on Associated Subsystems. Control Eng. 2015, 22, 1201–1206. [Google Scholar]

- Chen, J.M.; Yang, F.W. Communication-Based Data-Driven Distributed Predictive Control. J. East China Univ. Sci. Technol. Nat. Sci. Ed. 2014, 40, 113–119. [Google Scholar]

- Chen, Q.; Li, S.Y.; Xi, Y.G. Distributed Predictive Control Based on Plant-Wide Optimality. J. Shanghai Jiao Tong Univ. 2005, 03, 349–352. [Google Scholar]

- Yao, Y.; Cheung, C.-Y.; Bao, J.; Skyllas-Kazacos, M.; Welch, B.J.; Akhmetov, S. Estimation of spatial alumina concentration in an aluminum reduction cell using a multilevel state observer. AIChE J. 2017, 63, 2806–2818. [Google Scholar] [CrossRef]

- Yao, Y.; Cheung, C.Y.; Bao, J.; Skyllas-Kazacos, M. Monitoring Local Alumina Dissolution in Aluminum Reduction Cells Using State Estimation. Light Met. 2015, 2015, 577–581. [Google Scholar]

- Wahab, N.A.; Katebi, R.; Balderud, J.; Rahmat, M.F. Data-driven adaptive model-based predictive control with application in wastewater systems. IET Control Theory Appl. 2011, 5, 803–812. [Google Scholar] [CrossRef] [Green Version]

- Alexander, M.K. Why are enzymes less active in organic solvents than in water? Trends Biotechnol. 1997, 15, 97–101. [Google Scholar]

| Subsystem | MSE without Interference | MSE with Interference |

|---|---|---|

| Subsystem 1 | 0.0309 | 0.0387 |

| Subsystem 2 | 0.0306 | 0.0667 |

| Subsystem 3 | 0.0140 | 0.0203 |

| Subsystem 4 | 0.0156 | 0.0161 |

| Subsystem 5 | 0.0414 | 0.0475 |

| Subsystem 6 | 0.0421 | 0.0633 |

| Subsystem 1 | 0.0309 | 0.0387 |

| Average | 0.0291 | 0.0421 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cui, J.; Wang, P.; Li, X.; Huang, R.; Li, Q.; Cao, B.; Lu, H. Multipoint Feeding Strategy of Aluminum Reduction Cell Based on Distributed Subspace Predictive Control. Machines 2022, 10, 220. https://doi.org/10.3390/machines10030220

Cui J, Wang P, Li X, Huang R, Li Q, Cao B, Lu H. Multipoint Feeding Strategy of Aluminum Reduction Cell Based on Distributed Subspace Predictive Control. Machines. 2022; 10(3):220. https://doi.org/10.3390/machines10030220

Chicago/Turabian StyleCui, Jiarui, Peining Wang, Xiangquan Li, Ruoyu Huang, Qing Li, Bin Cao, and Hui Lu. 2022. "Multipoint Feeding Strategy of Aluminum Reduction Cell Based on Distributed Subspace Predictive Control" Machines 10, no. 3: 220. https://doi.org/10.3390/machines10030220

APA StyleCui, J., Wang, P., Li, X., Huang, R., Li, Q., Cao, B., & Lu, H. (2022). Multipoint Feeding Strategy of Aluminum Reduction Cell Based on Distributed Subspace Predictive Control. Machines, 10(3), 220. https://doi.org/10.3390/machines10030220