An Improved Deadbeat Current Controller of PMSM Based on Bilinear Discretization

Abstract

:1. Introduction

2. Discretization Mathematical Model of PMSM

2.1. Dynamic Equations of Stator Currents in PMSM

2.2. Conventional Discretization Method

2.3. Comparison of Discretization Method

- Forward Euler Discretization formula

- Bilinear transformation method.

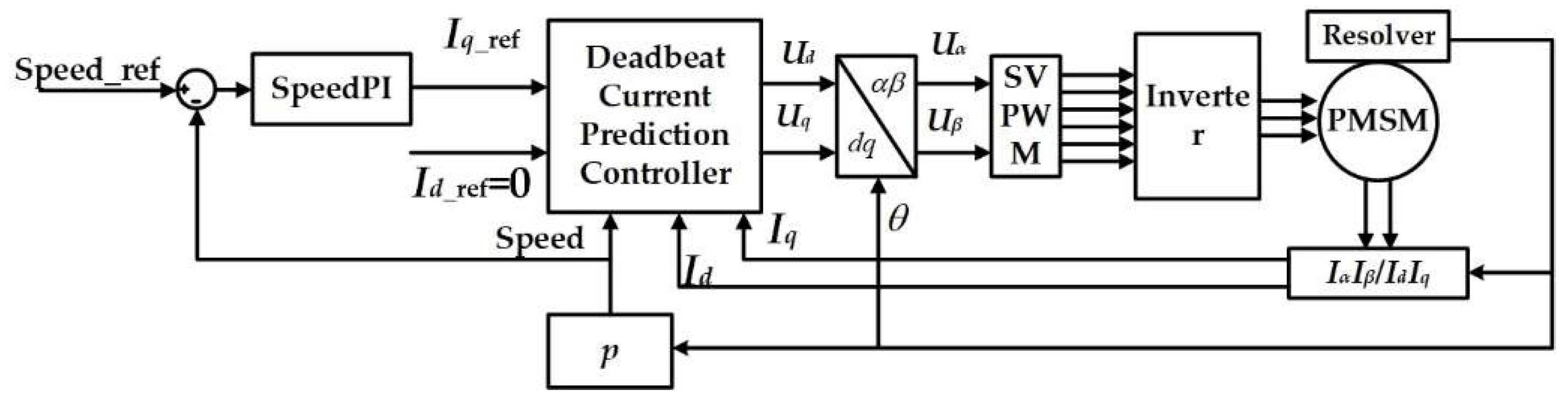

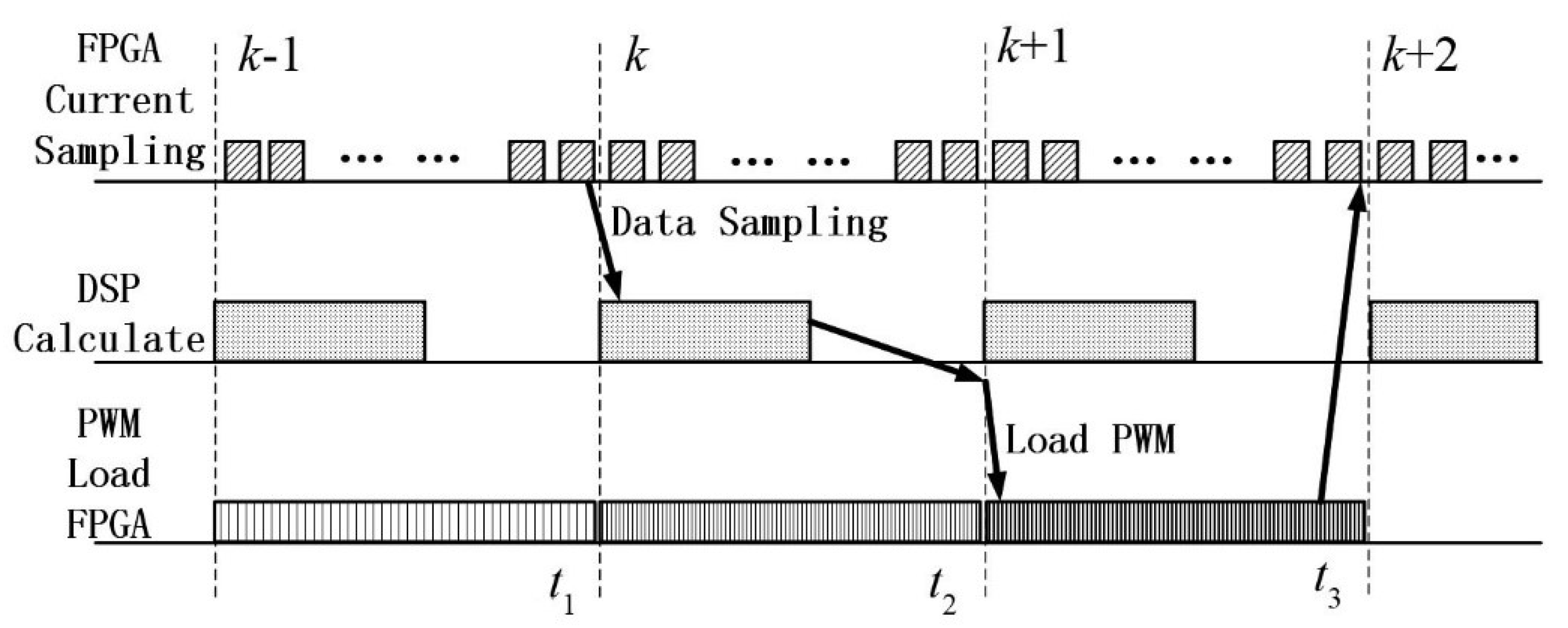

3. Deadbeat Current Predictive Control Algorithm of PMSM in the Digital Platform

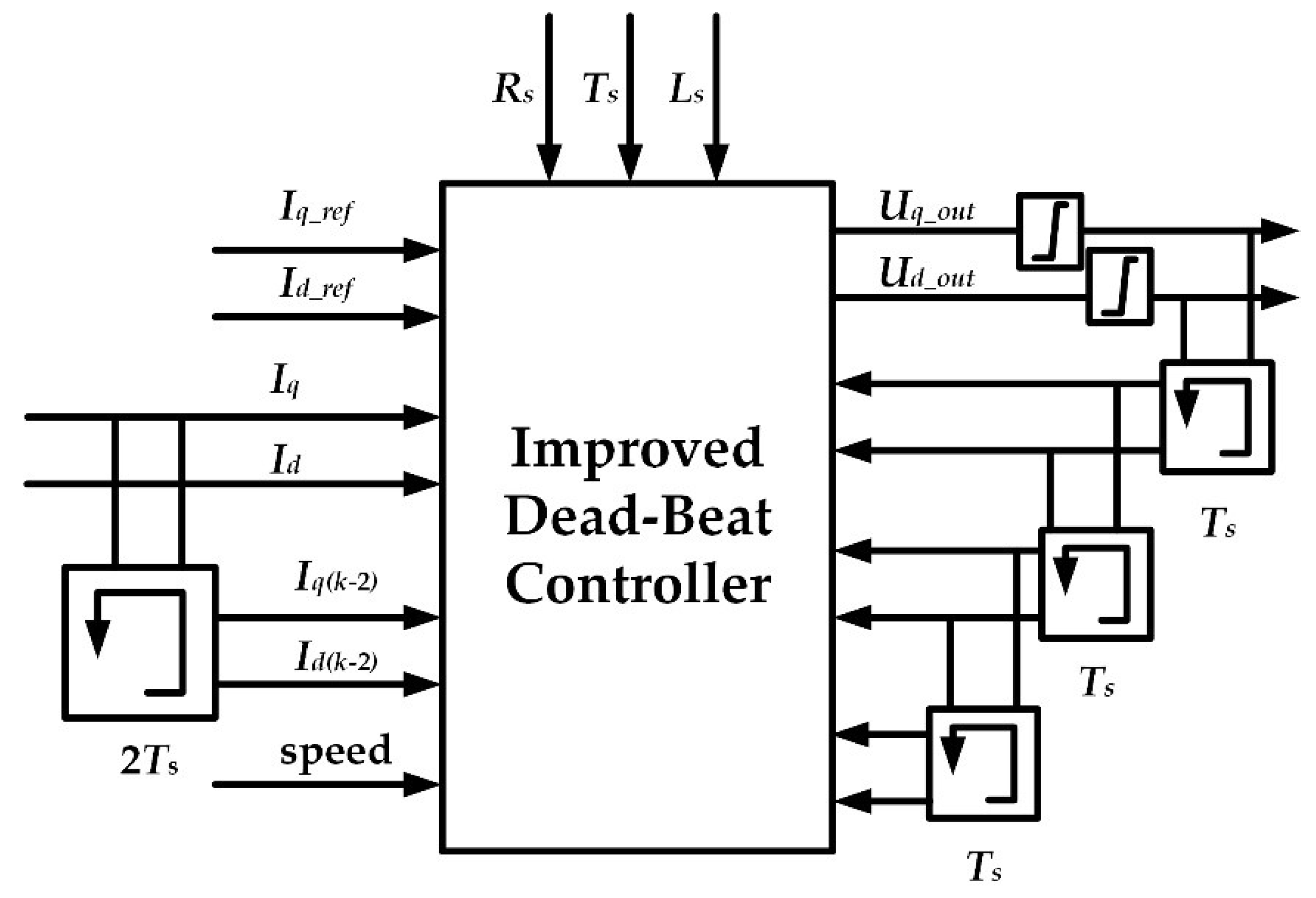

4. Bilinear Discretization Predictive Current Controller

4.1. Proposed Predictive Current Controller

4.2. Stability Analysis of Control Algorithm

- L0 > L

- L0 < L

5. Simulation and Experiment Validation

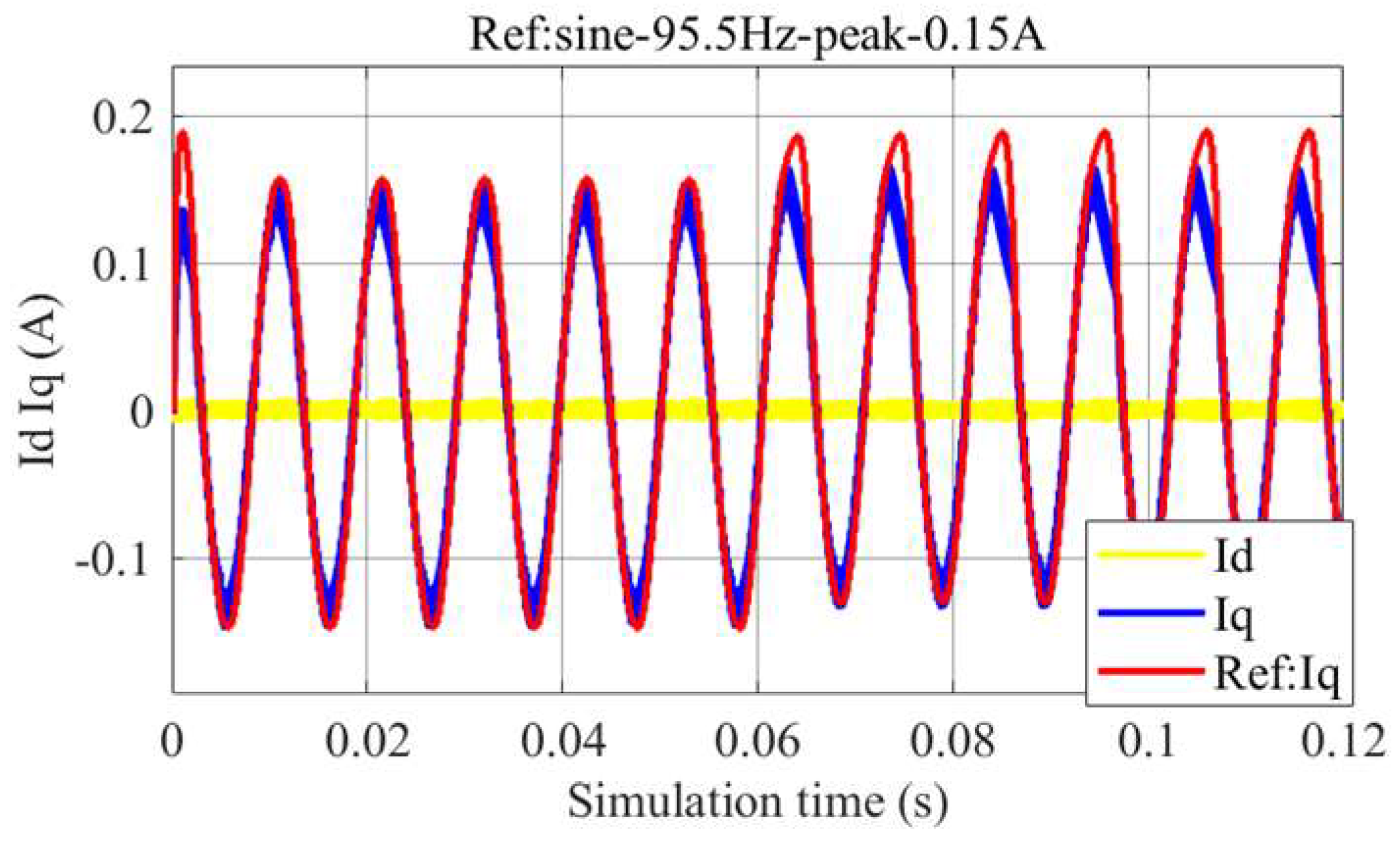

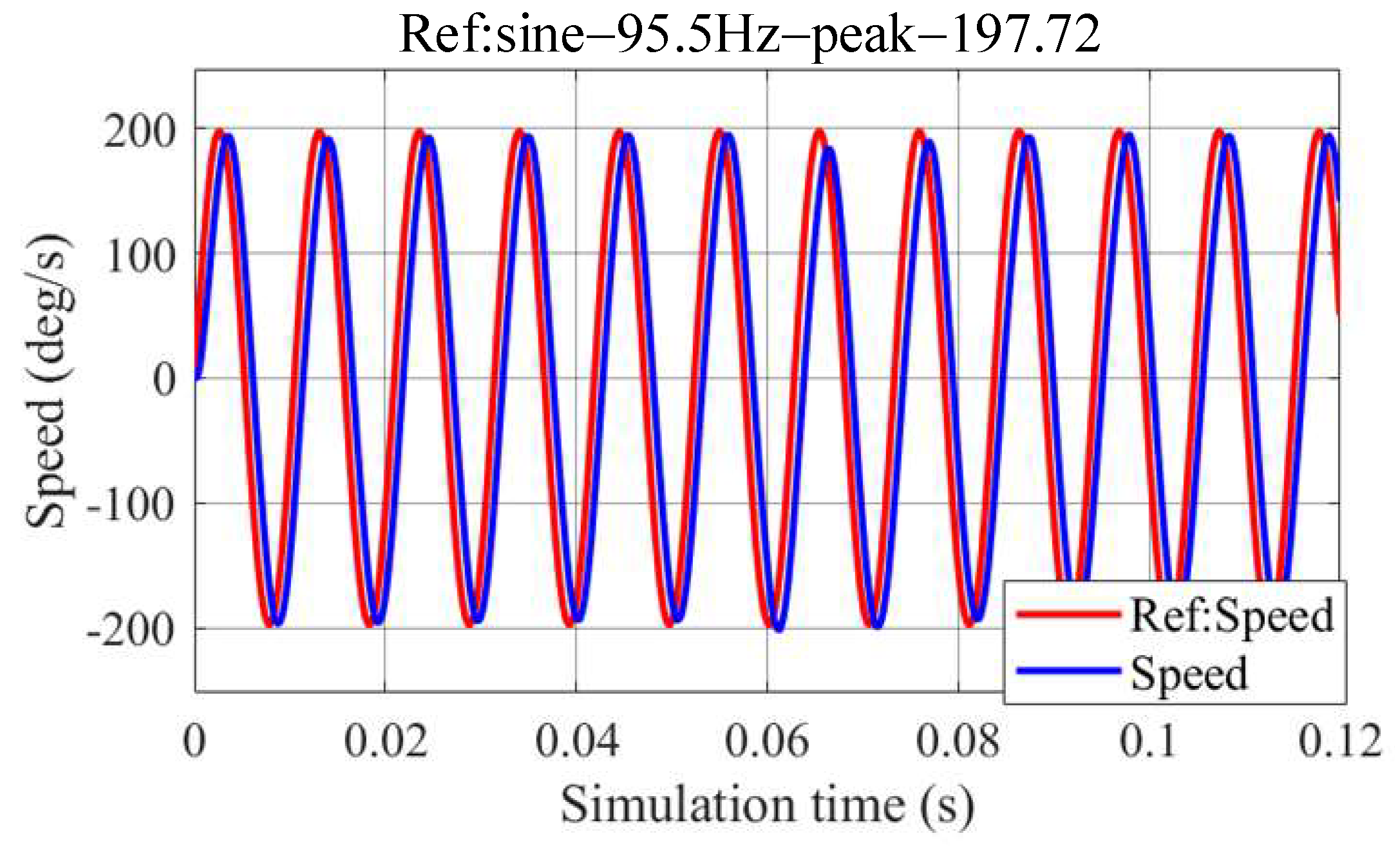

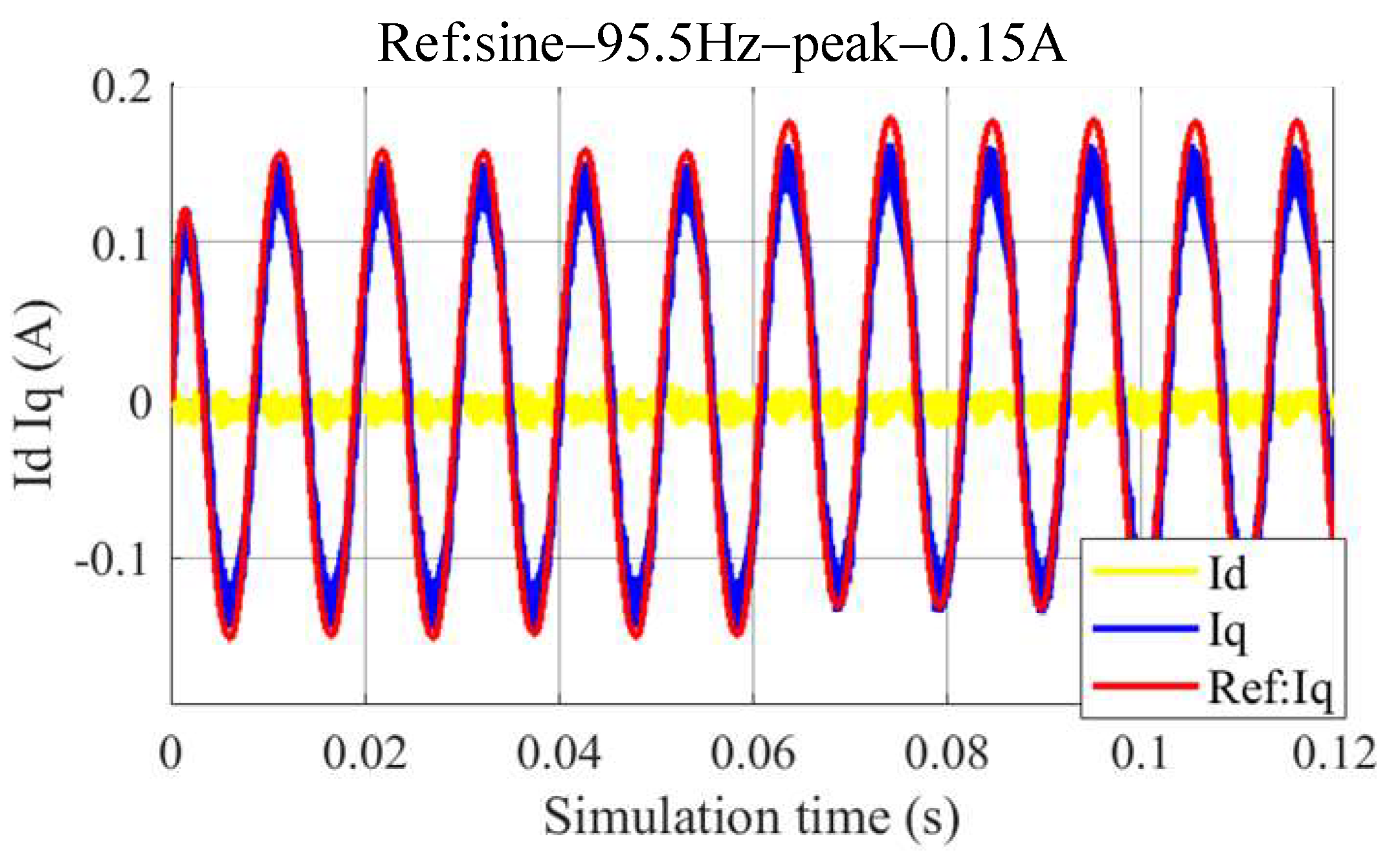

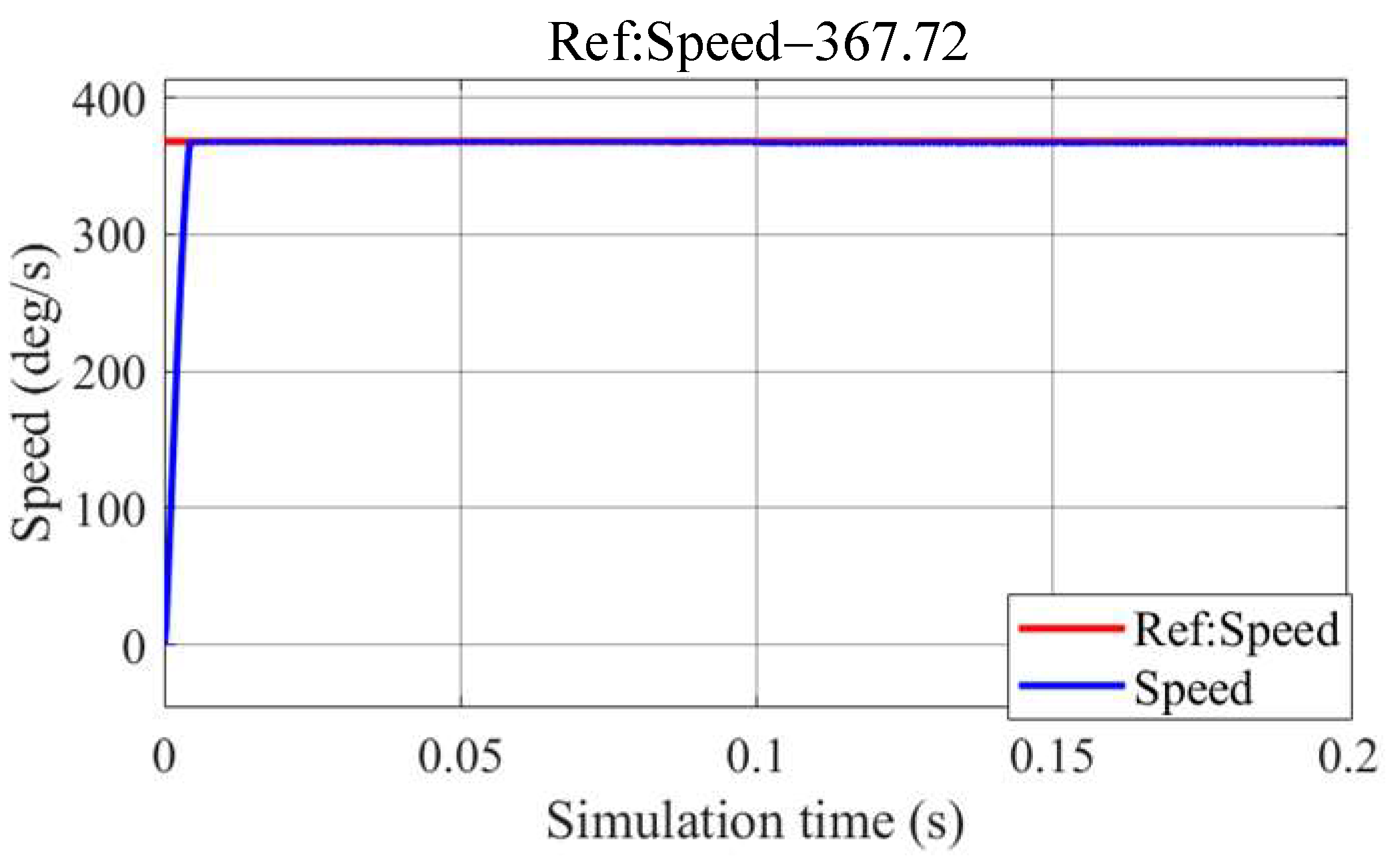

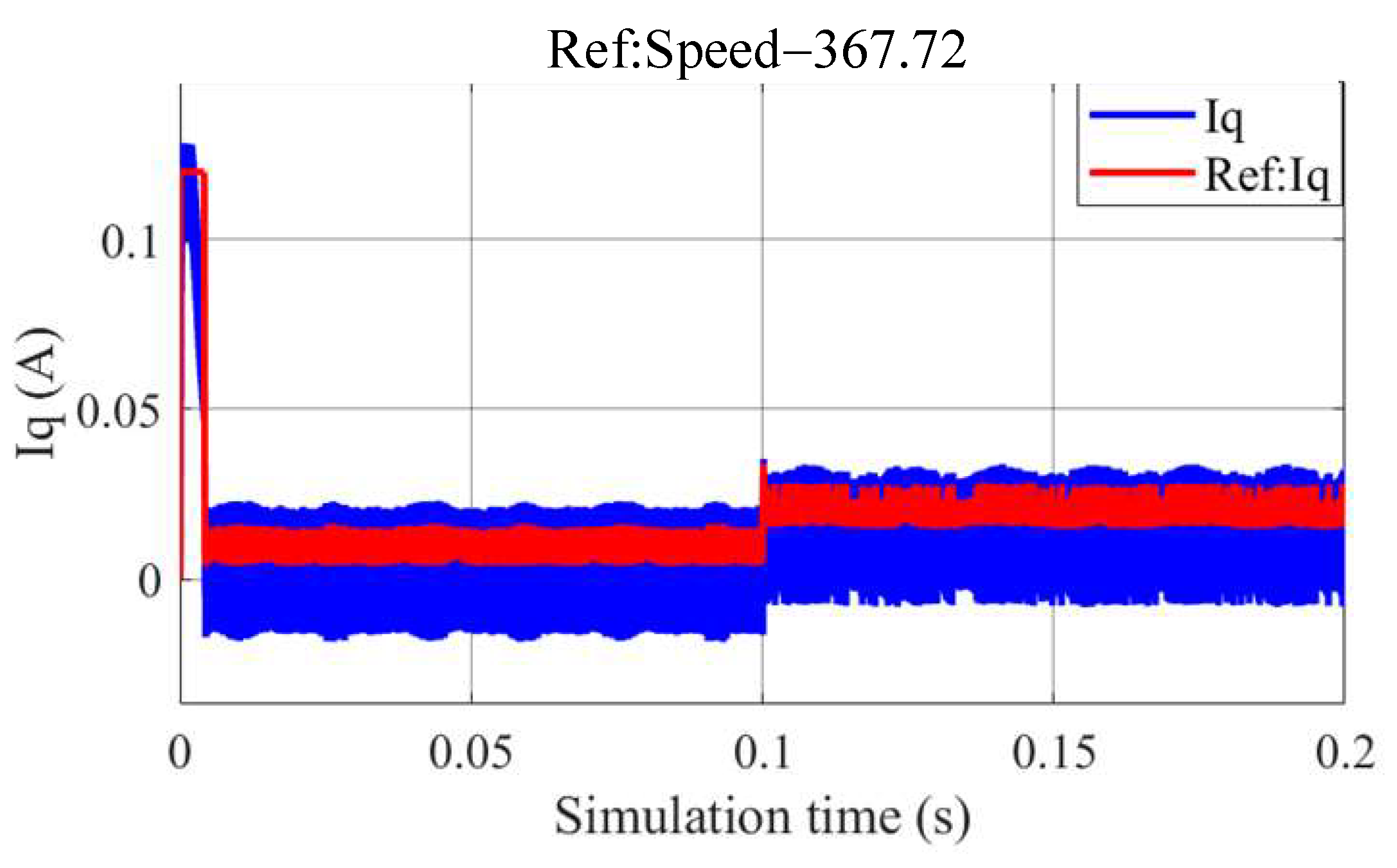

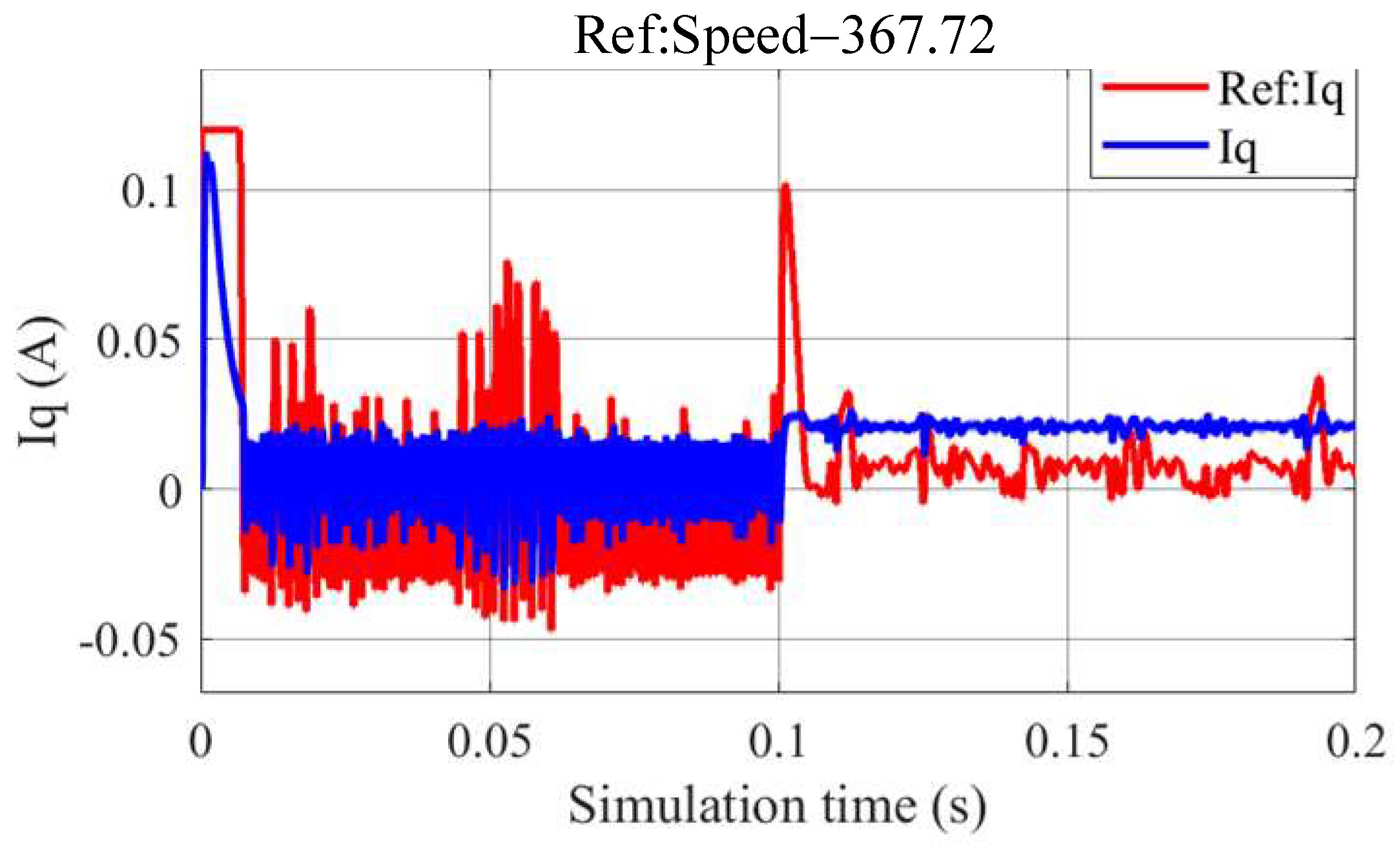

5.1. Simulation

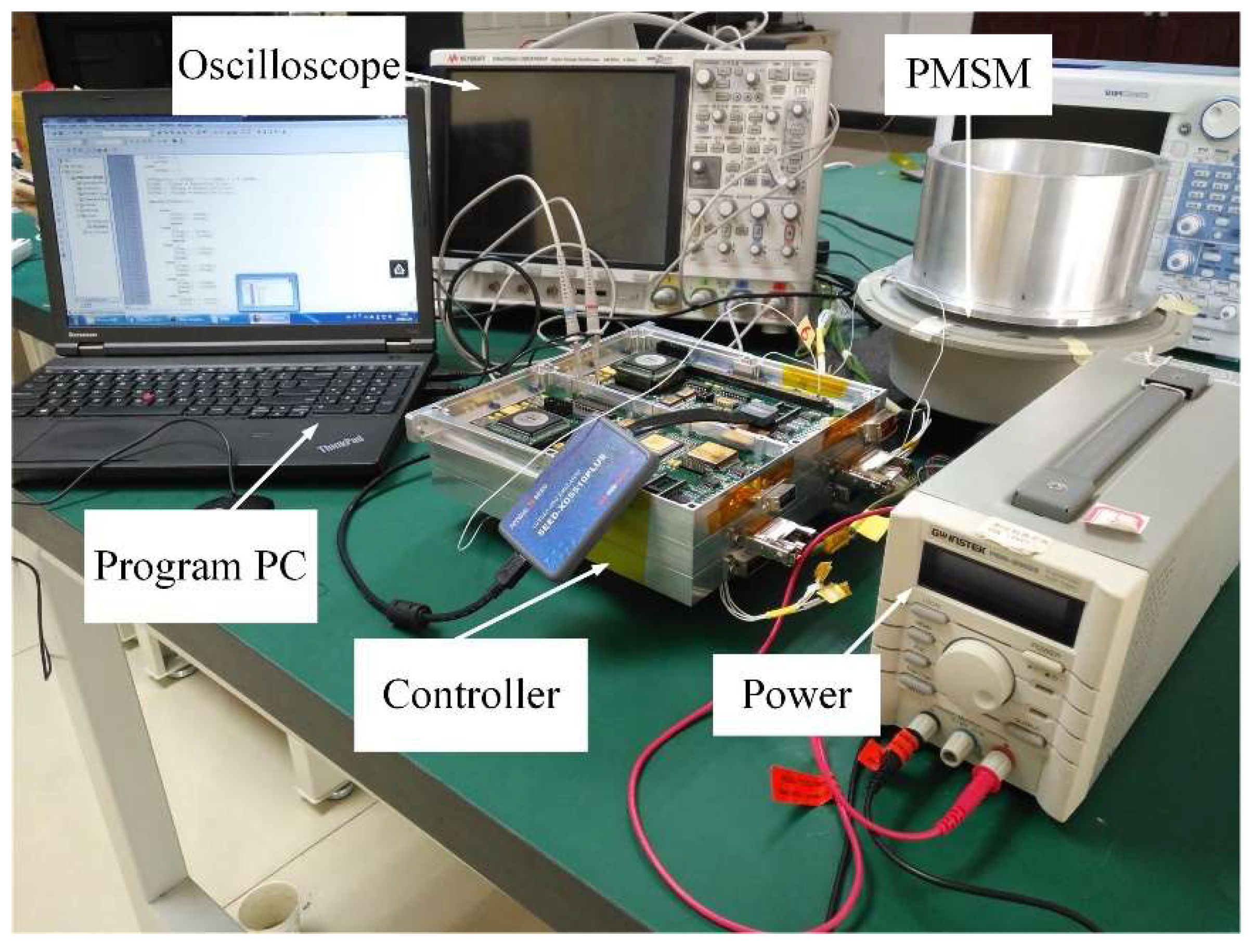

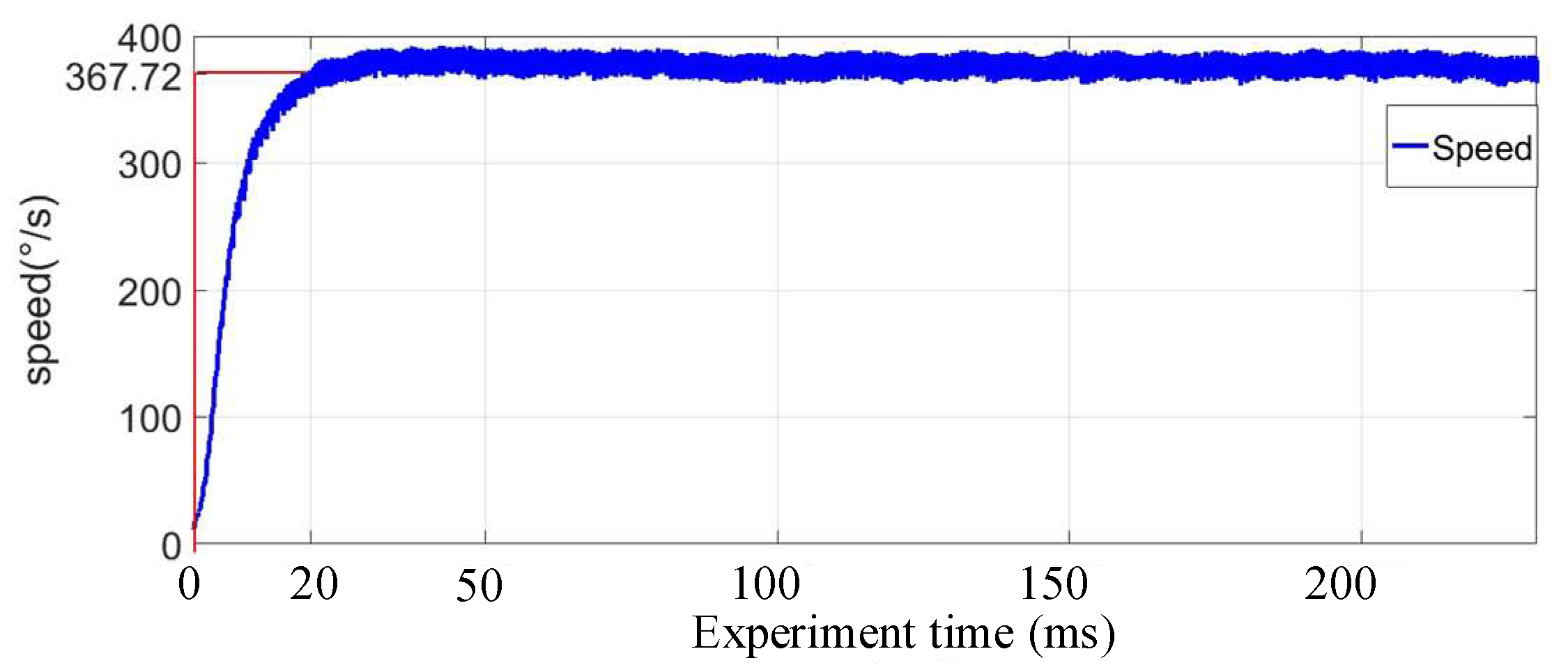

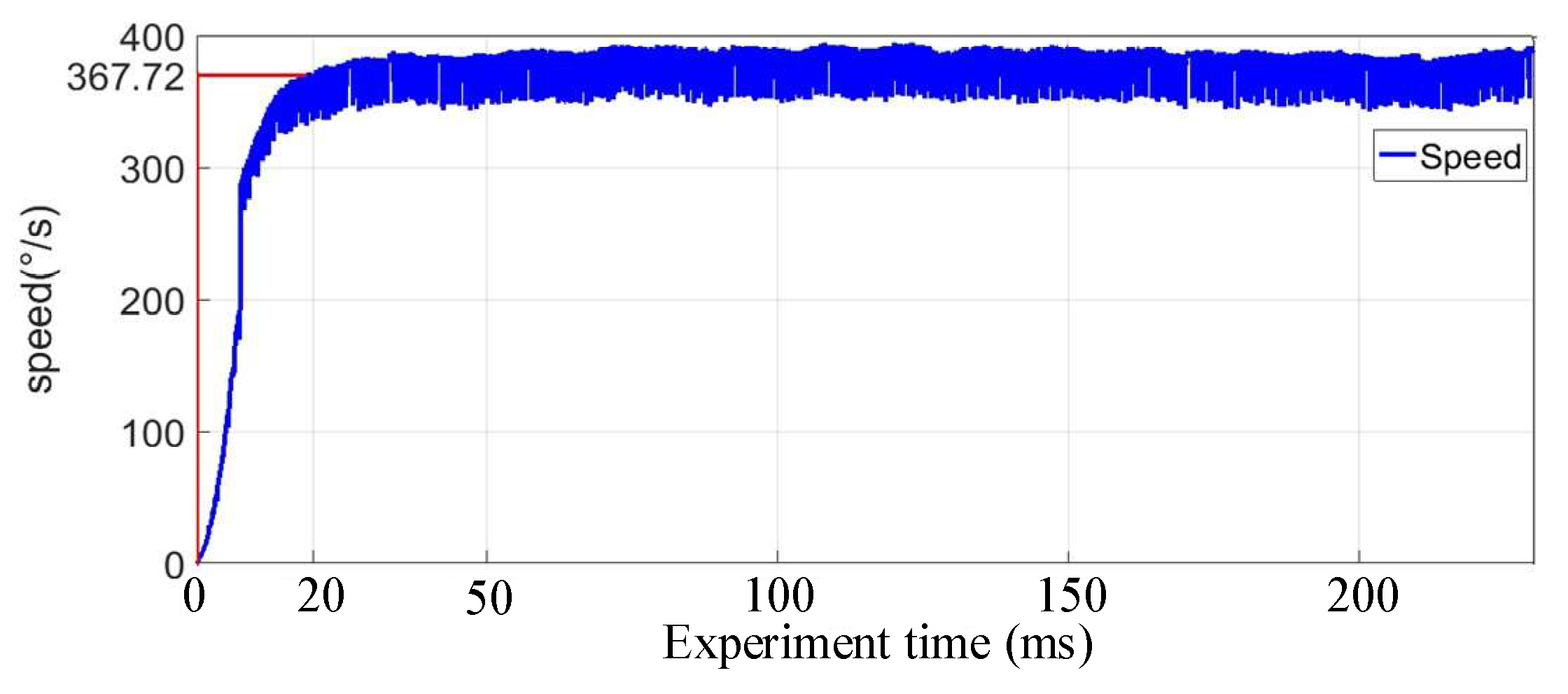

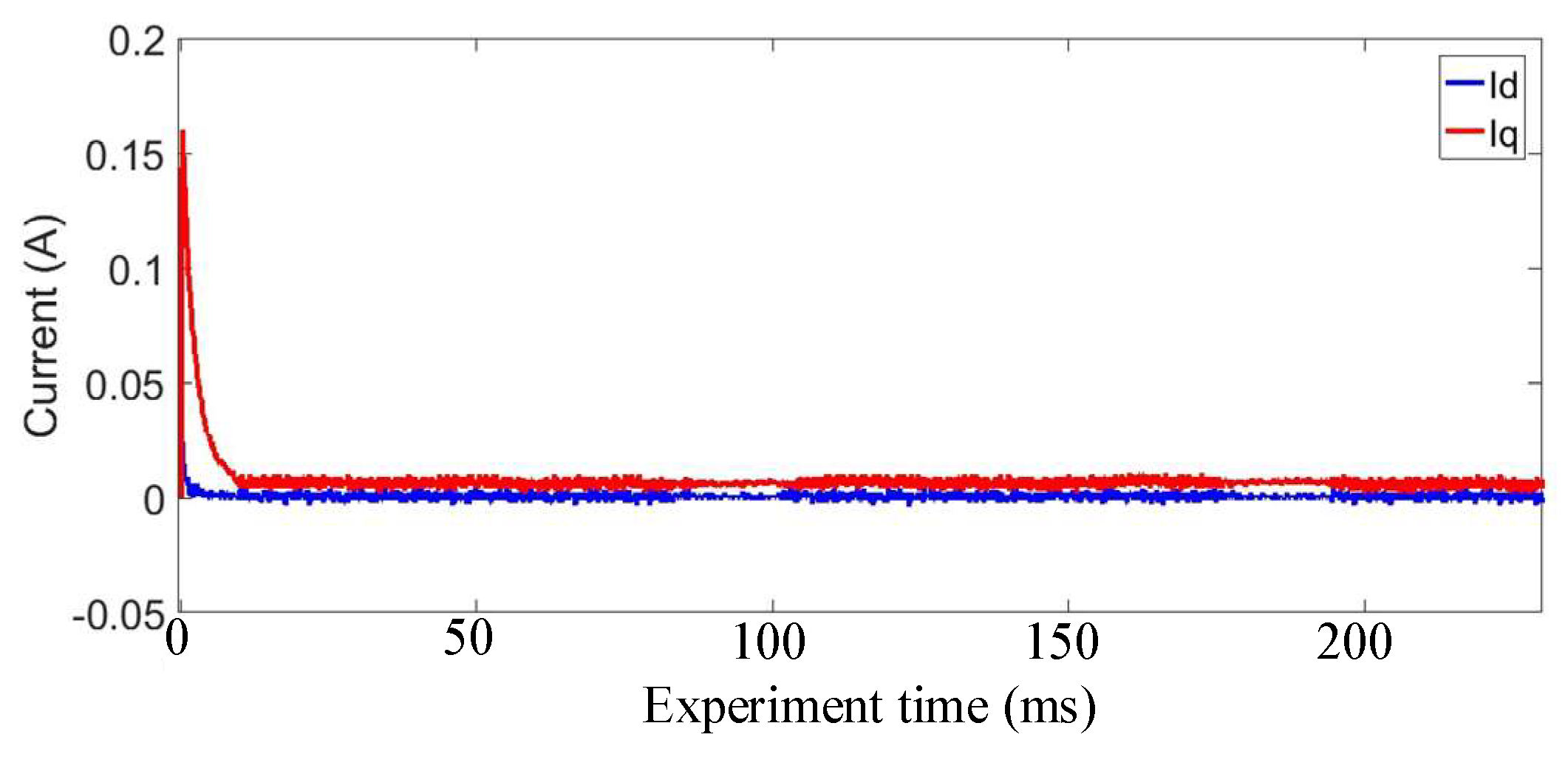

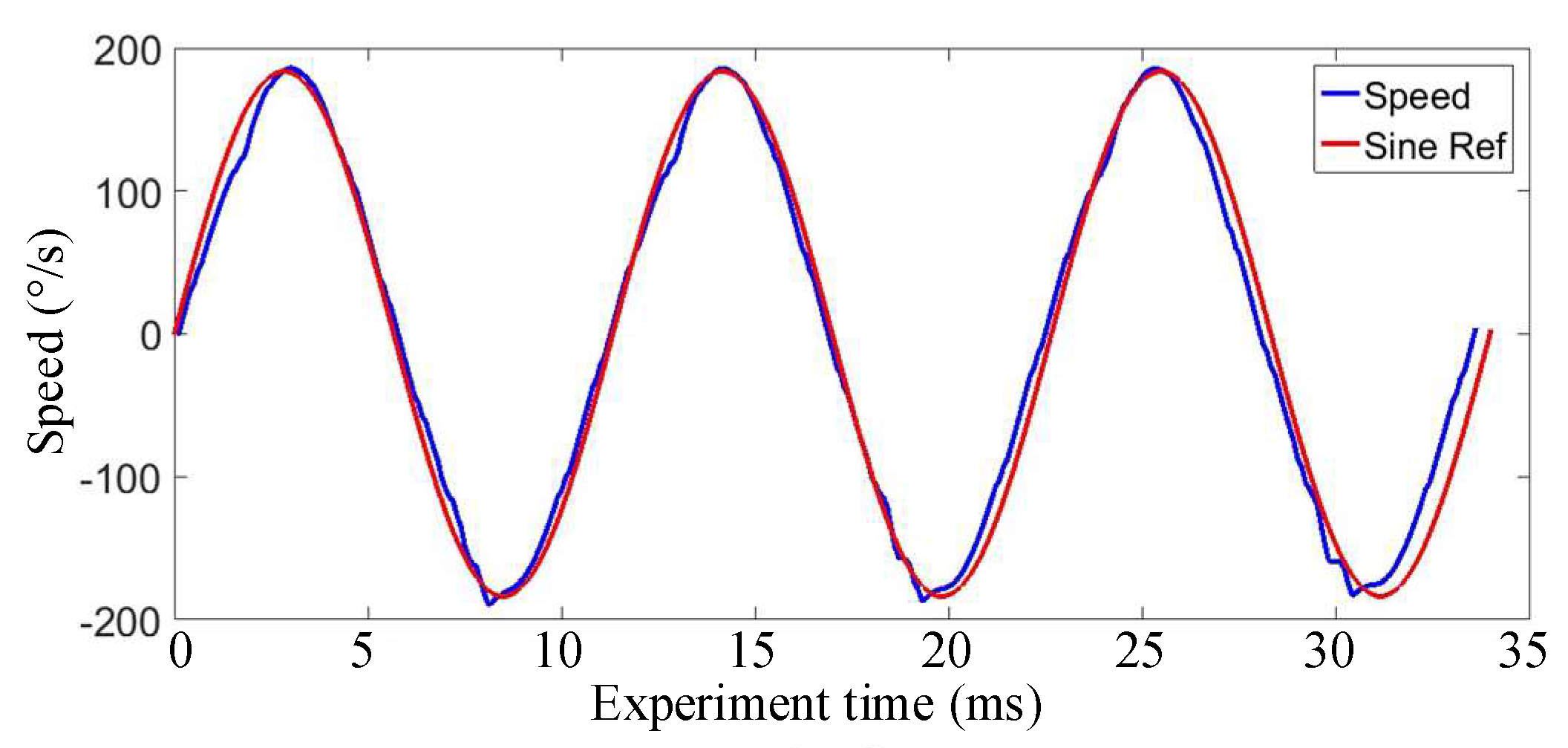

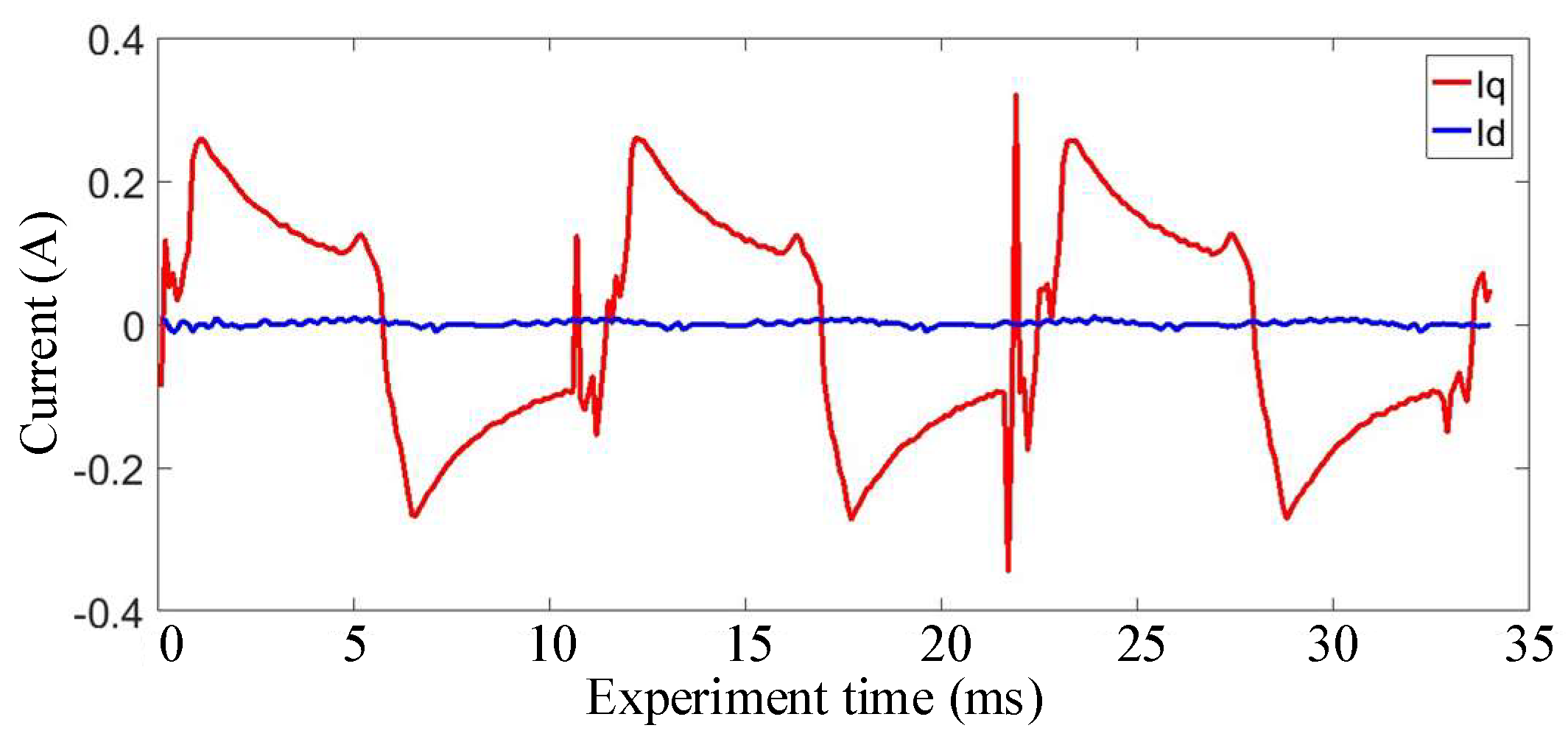

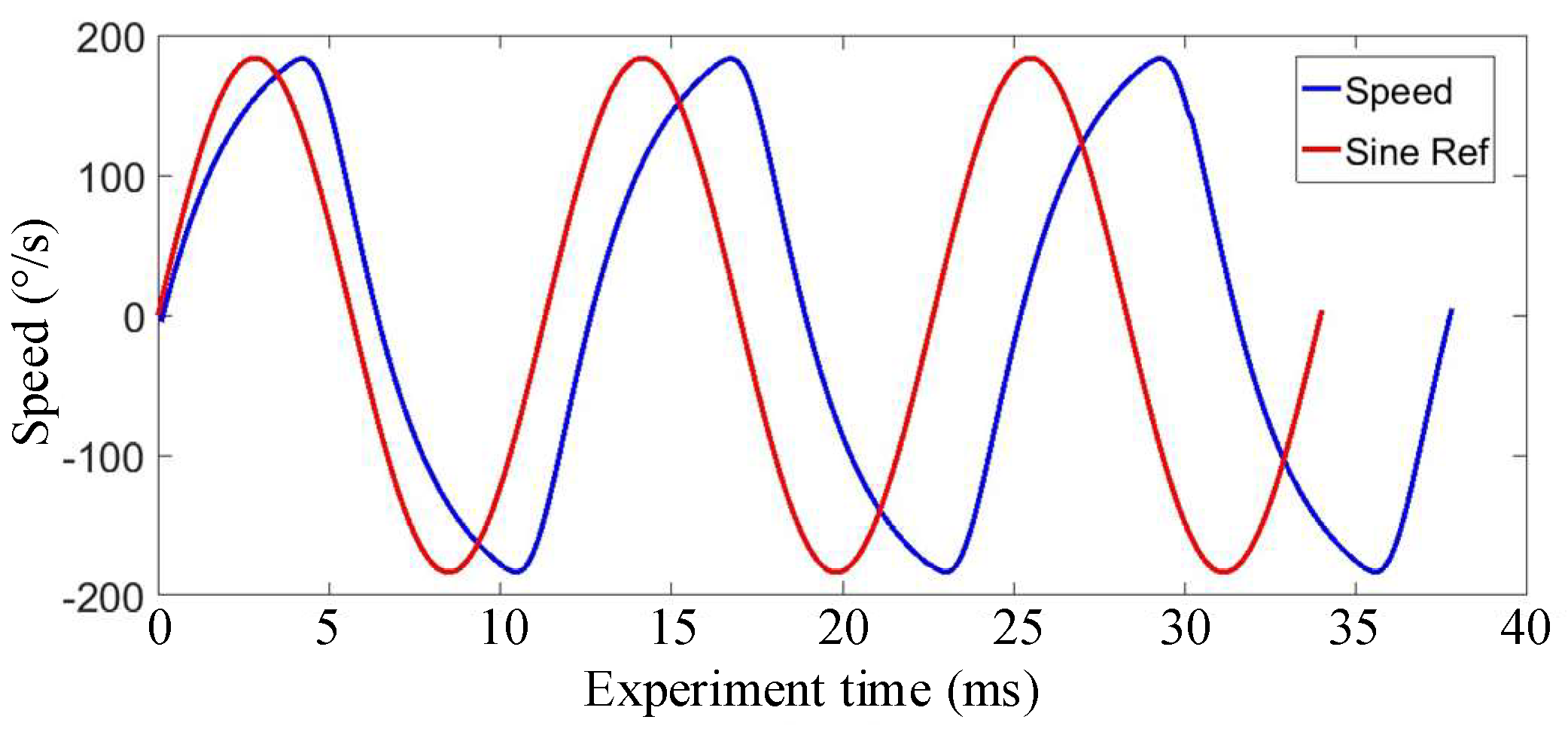

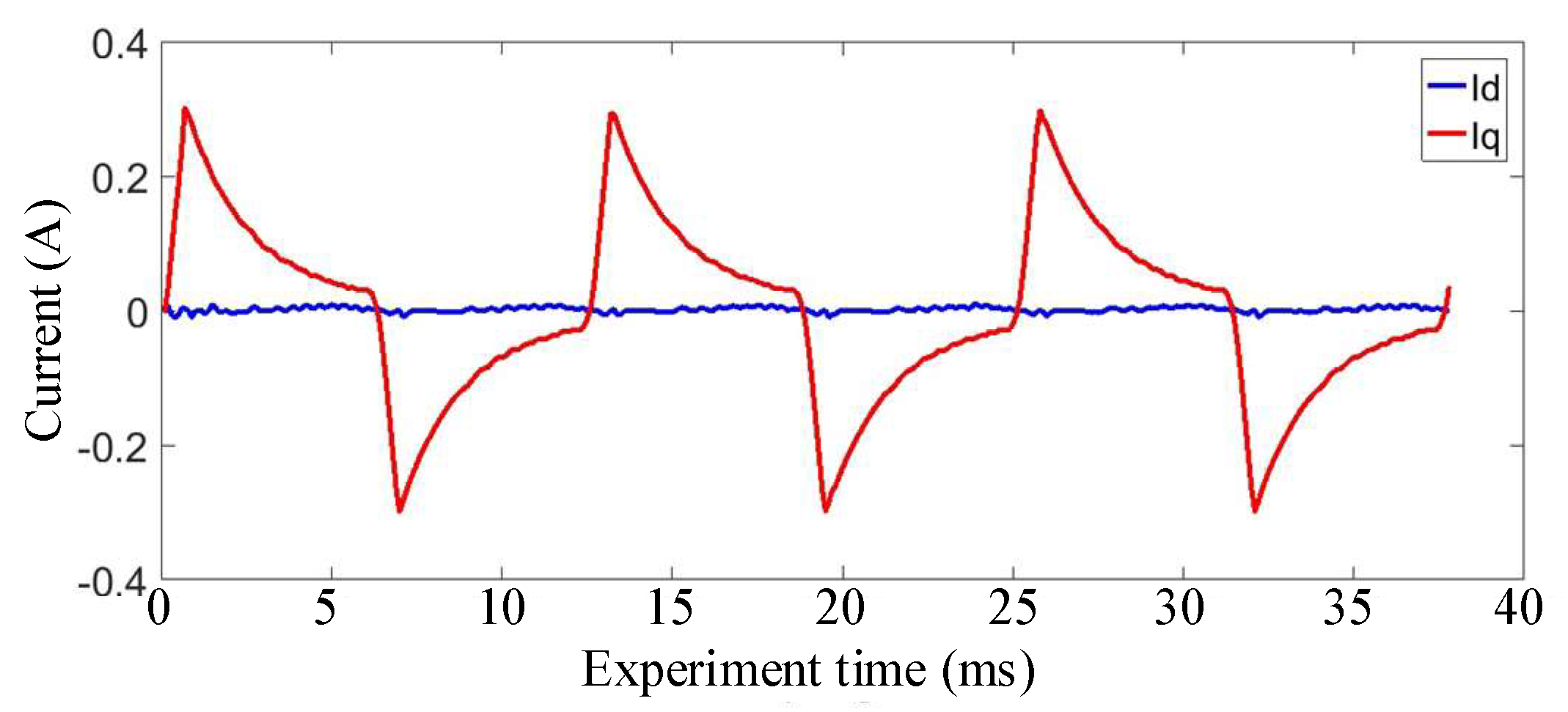

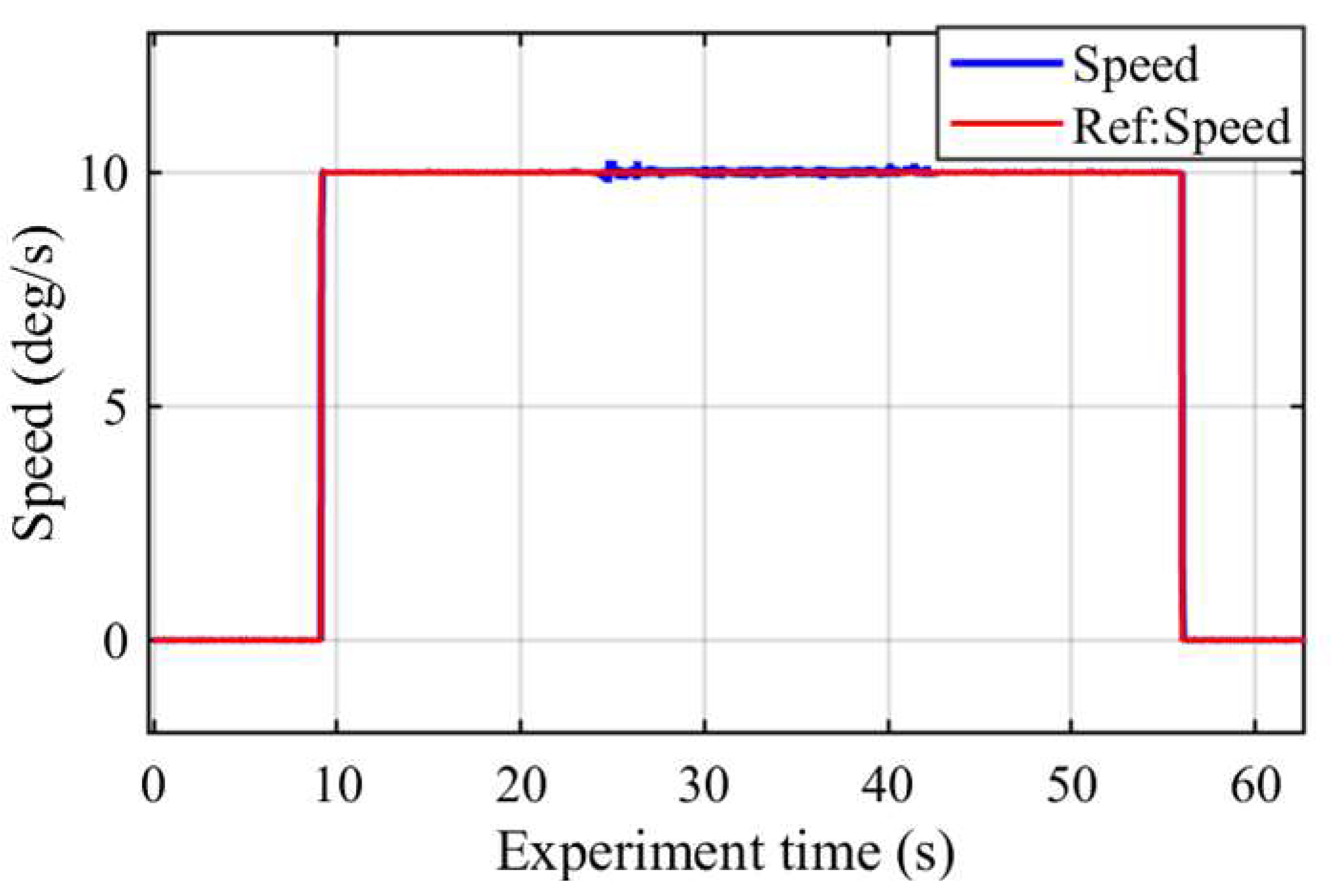

5.2. Experiments

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kwon, Y.; Kim, S.; Sul, S. Six-step operation of PMSM with instantaneous current control. IEEE Trans. Ind. Appl. 2014, 50, 2614–2625. [Google Scholar] [CrossRef]

- Hezzi, A.; Ben Elghali, S.; Bensalem, Y.; Zhou, Z.; Benbouzid, M.; Abdelkrim, M.N. ADRC-based robust and resilient control of a 5-phase PMSM driven electric vehicle. Machines 2020, 8, 17. [Google Scholar] [CrossRef]

- Wang, C.; Chen, M.; Hu, B.; Yan, L.; Yu, Y.; Zou, J.; Guo, Y.; Li, G. Design of high reliability gimbal servo system of control moment gyroscope. In Proceedings of the 2019 IEEE 2nd International Conference on Information Systems and Computer Aided Education (ICISCAE), Dalian, China, 23–30 September 2019; pp. 442–445. [Google Scholar]

- Mao, H.; Yang, X.; Chen, Z.; Wang, Z. A hysteresis current controller for single-phase three-level voltage source inverters. IEEE Trans. Power Electron. 2012, 27, 3330–3339. [Google Scholar] [CrossRef]

- Dey, A.; Rajeevan, P.P.; Ramchand, R.; Mathew, K.; Gopakumar, K. A space-vector-based hysteresis current controller for a general n-level inverter-fed drive with nearly constant switching frequency control. IEEE Trans. Ind. Electron. 2013, 60, 1989–1998. [Google Scholar] [CrossRef]

- Lee, J.S.; Lorenz, R.D. Deadbeat direct torque and flux control of IPMSM drives using a minimum time ramp trajectory method at voltage and current limits. IEEE Trans. Ind. Appl. 2012, 50, 3795–3804. [Google Scholar] [CrossRef]

- Gabbi, T.S.; Grundling, H.A.; Vieira, R.P. Current controller for sensorless PMSM drive using combined sliding mode strategy and disturbance observer. In Proceedings of the 41st Annual Conference of the IEEE Industrial Electronics Society, Yokohama, Japan, 9–12 November 2015; pp. 3773–3778. [Google Scholar]

- Hou, Q.; Ding, S.; Yu, X. Composite super-twisting sliding mode control design for PMSM speed regulation problem based on a novel disturbance observer. IEEE Trans. Energy Convers. 2020, 36, 2591–2599. [Google Scholar] [CrossRef]

- Kazmierkowski, M.P.; Malesani, L. Current control techniques for three-phase voltage-source PWM converters: A survey. IEEE Trans. Ind. Electron. 1998, 45, 691–703. [Google Scholar] [CrossRef]

- Rowan, T.M.; Kerkman, R.J. A new synchronous current regulator and an analysis of current-regulated PWM inverters. IEEE Trans. Ind. Appl. 1986, 22, 678–690. [Google Scholar] [CrossRef]

- Song, W.; Ma, J.; Zhou, L.; Feng, X. Deadbeat predictive power control of single-phase three-level neutral-point-clamped converters using space-vector modulation for electric railway traction. IEEE Trans. Power Electron. 2016, 31, 721–731. [Google Scholar] [CrossRef]

- Liu, Q.; Chang, X. Position IP control of a permanent magnet synchronous motor based on fuzzy neural network. In Proceedings of the 2018 Chinese Control And Decision Conference (CCDC), Shenyang, China, 9–11 June 2018; pp. 1081–1086. [Google Scholar]

- Moon, H.T.; Kim, H.S.; Youn, M.J. A discrete-time predictive current control for PMSM. IEEE Trans. Power Electron. 2003, 18, 464–472. [Google Scholar] [CrossRef]

- Morel, F.; Lin-Shi, X.; Retif, J.-M.; Allard, B.; Buttay, C. A comparative study of predictive current control schemes for a permanent-magnet synchronous machine drive. IEEE Trans. Ind. Electron. 2009, 56, 2715–2728. [Google Scholar] [CrossRef] [Green Version]

- Liu, H.; Li, S. Speed control for PMSM servo system using predictive functional control and extended state observer. IEEE Trans. Ind. Electron. 2012, 59, 1171–1183. [Google Scholar] [CrossRef]

- Preindl, M.; Schaltz, E. Sensorless model predictive direct current control using novel second-order PLL observer for PMSM drive systems. IEEE Trans. Ind. Electron. 2011, 58, 4087–4095. [Google Scholar] [CrossRef]

- Xie, W.; Wang, X.C.; Wang, F.X.; Xu, W.; Kennel, R.M.; Gerling, D.; Lorenz, R.D. Finite control set-model predictive torque control with a deadbeat solution for PMSM drives. IEEE Trans. Ind. Electron. 2015, 62, 5402–5410. [Google Scholar] [CrossRef]

- Zhang, X.G.; Hou, B.S.; Mei, Y. Deadbeat predictive current control of permanent magnet synchronous motors with stator current and disturbance observer. IEEE Trans. Power Electron. 2017, 32, 3818–3834. [Google Scholar] [CrossRef]

- Tong, L.; Zou, X.D.; Feng, S.S.; Chen, Y.; Kang, Y.; Huang, Q.J.; Huang, Y.R. An SRF-PLL-based sensorless vector control using the predictive deadbeat algorithm for the direct-driven permanent magnet synchronous generator. IEEE Trans. Power Electron. 2014, 29, 2837–2849. [Google Scholar] [CrossRef]

- Malesani, L.; Mattavelli, P.; Buso, S. Robust dead-beat current control for PWM rectifiers and active filters. IEEE Trans. Ind. Appl. 1999, 35, 613–620. [Google Scholar] [CrossRef]

- Cortes, P.; Rodriguez, J.; Silva, C.; Flores, A. Delay compensation in model predictive current control of a three-phase inverter. IEEE Trans. Ind. Electron. 2012, 59, 1323–1325. [Google Scholar] [CrossRef]

- Moreno, J.; Huerta, J.; Gil, R.; Gonzalez, S. A robust predictive current control for three-phase grid-connected inverters. IEEE Trans. Ind. Electron. 2009, 56, 1993–2004. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhu, J.; Xu, W. Analysis of one step delay in direct torque control of permanent magnet synchronous motor and its remedies. In Proceedings of the 2010 International Conference on Electrical Machines and Systems, Incheon, Korea, 10–13 October 2010; pp. 792–797. [Google Scholar]

- Barros, J.D.; Silva, J.F.A.; Jesus, E.G.A. Fast predictive optimal control of NPC multilevel converters. IEEE Trans. Ind. Electron. 2013, 60, 619–627. [Google Scholar] [CrossRef]

- Shi, Y.; Sun, K.; Huang, L.; Li, Y. Online identification of permanent magnet flux based on extended Kalman filter for IPMSM drive with position sensorless control. IEEE Trans. Ind. Electron. 2012, 59, 4169–4178. [Google Scholar] [CrossRef]

| Parameter | Unit | Value |

|---|---|---|

| Stator resistance R | Ω | 48.9 |

| Inductance Ld = Lq | H | 14 × 10−3 |

| Number of poles p | 10 | |

| Inertial J | kg·m2 | 9.717 × 10−5 |

| Torque constant | N*m/A_peak | 1.4213 |

| Simulation Parameter | Value |

|---|---|

| 28 V | |

| Triangular Carrier Frequency | 10 kHz |

| Triangular Carrier Output | [0 1250 0] |

| Simulation Solver | Runge-Kutta |

| Rated Speed | 367.72 deg/s |

| Step Size | 10−7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, L.; Chen, Z.; Wang, H.; Li, L.; Mao, X.; Li, Z.; Zhang, J.; Wu, D. An Improved Deadbeat Current Controller of PMSM Based on Bilinear Discretization. Machines 2022, 10, 79. https://doi.org/10.3390/machines10020079

Zhao L, Chen Z, Wang H, Li L, Mao X, Li Z, Zhang J, Wu D. An Improved Deadbeat Current Controller of PMSM Based on Bilinear Discretization. Machines. 2022; 10(2):79. https://doi.org/10.3390/machines10020079

Chicago/Turabian StyleZhao, Lei, Zhen Chen, Haoyu Wang, Li Li, Xuefei Mao, Zhen Li, Jiyang Zhang, and Dengyun Wu. 2022. "An Improved Deadbeat Current Controller of PMSM Based on Bilinear Discretization" Machines 10, no. 2: 79. https://doi.org/10.3390/machines10020079

APA StyleZhao, L., Chen, Z., Wang, H., Li, L., Mao, X., Li, Z., Zhang, J., & Wu, D. (2022). An Improved Deadbeat Current Controller of PMSM Based on Bilinear Discretization. Machines, 10(2), 79. https://doi.org/10.3390/machines10020079