Marine Systems and Equipment Prognostics and Health Management: A Systematic Review from Health Condition Monitoring to Maintenance Strategy

Abstract

1. Introduction

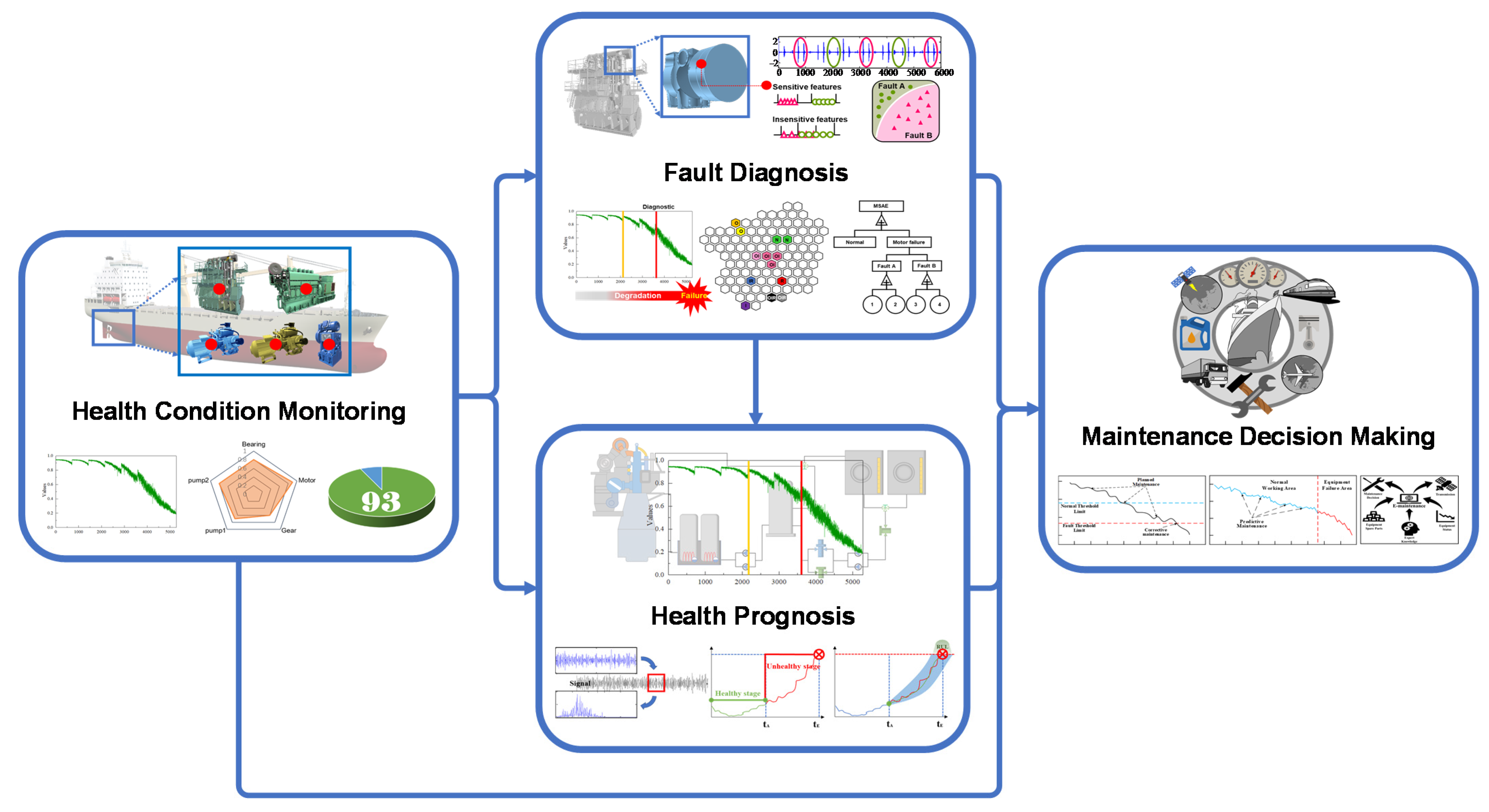

2. Health Condition Monitoring

2.1. Data Acquisition

2.1.1. Data Collection

2.1.2. Data Transmission

- (1)

- Local data transmission

- (2)

- Remote data transmission

2.1.3. Data Storage

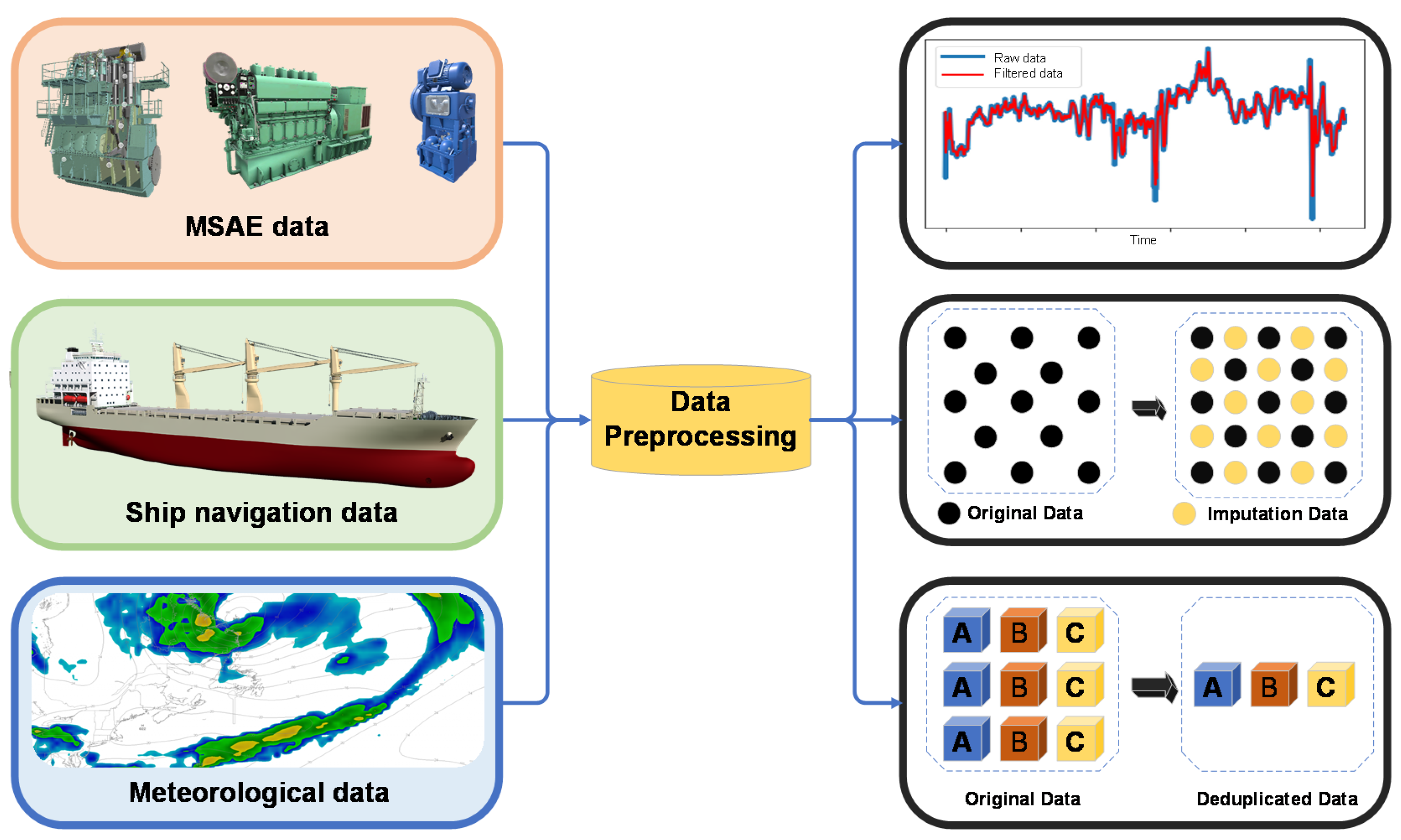

2.2. Data Processing

2.2.1. Data Preprocessing

- (1)

- Data imputation

- (2)

- Outliers detection

- (3)

- Redundant data deletion

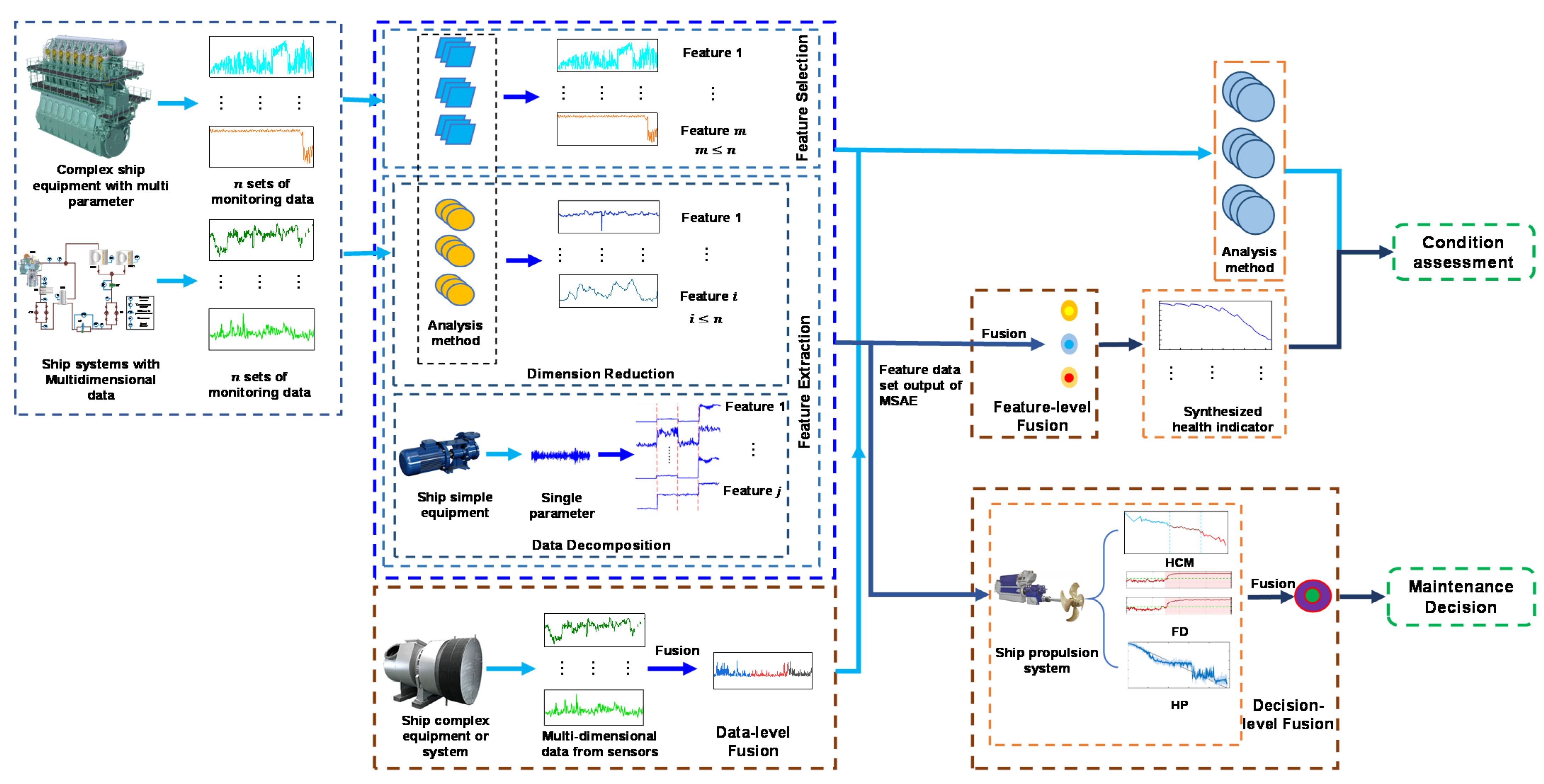

2.2.2. Feature Processing

- (1)

- Feature selection

- (2)

- Feature extraction

2.2.3. Data Fusion

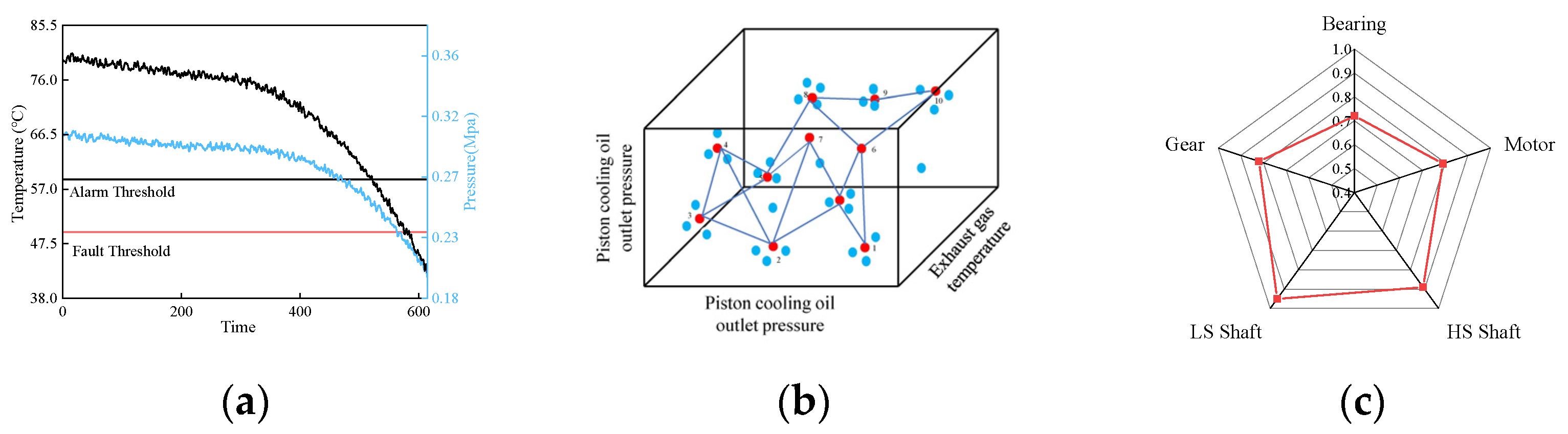

2.3. Condition Monitoring

2.3.1. Categories of Condition Monitoring

- (1)

- Equipment-level condition monitoring

- (2)

- System-level condition monitoring

- (3)

- Visualization tools for condition monitoring

2.3.2. Monitoring System for Ship Application

2.4. Epilog

3. Fault Diagnosis

3.1. FD Methods

3.1.1. Physics Model-Based Method

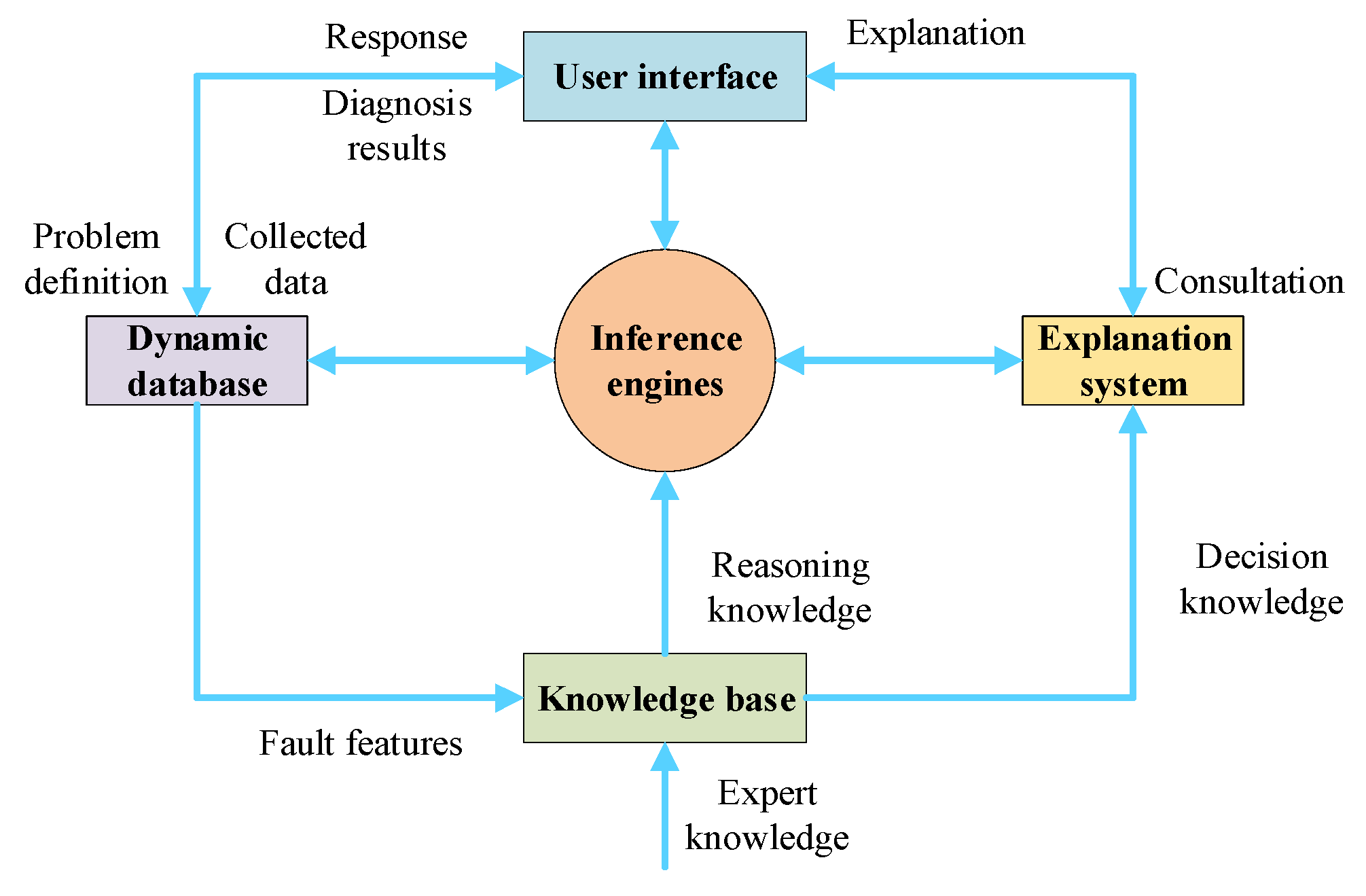

3.1.2. Knowledge-Based Method

3.1.3. Data Driven-Based Method

- (1)

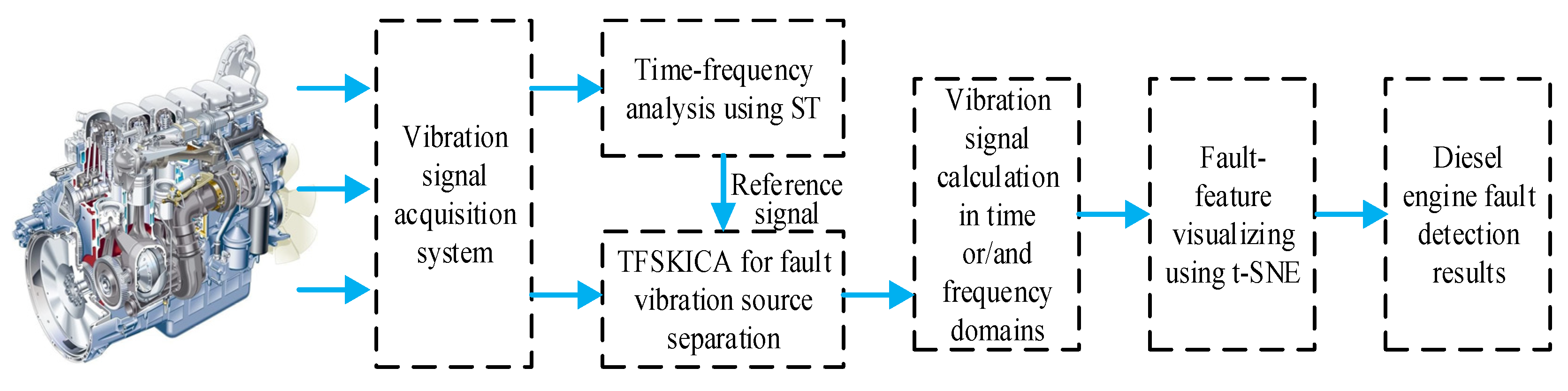

- Signal processing methods

- (2)

- Multivariate statistical analysis

- PCA

- ICA

- (3)

- Traditional Machine learning

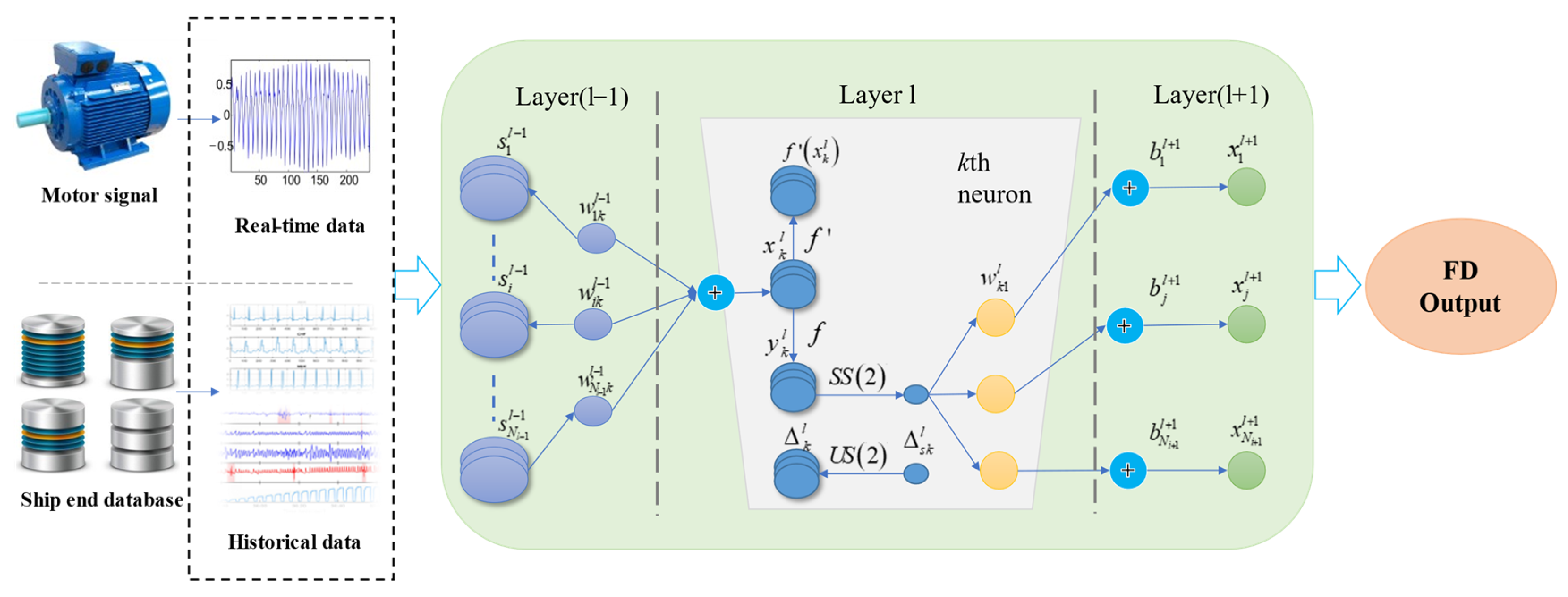

- ANN-based FD model

- SVM-based FD model

3.1.4. Hybrid Approaches

3.2. Current New Fault Diagnosis Algorithm

3.2.1. Intelligent FD Methods Using Deep Learning Theories

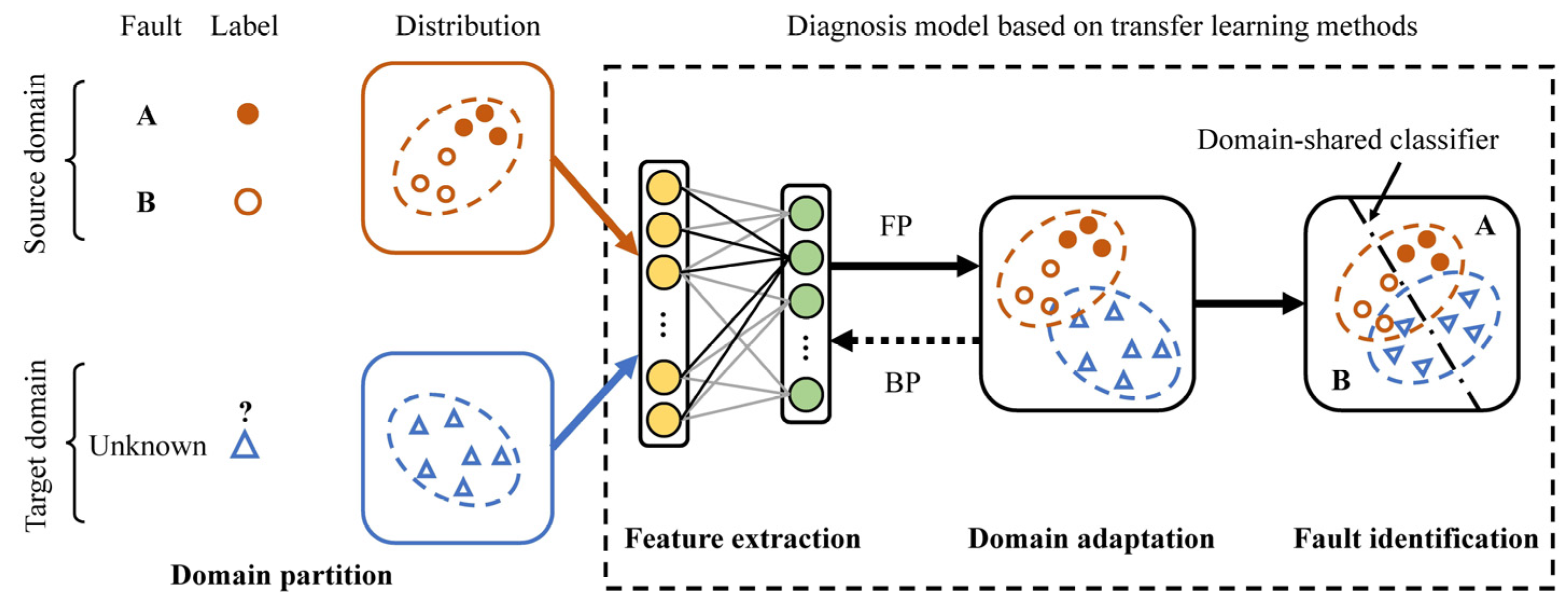

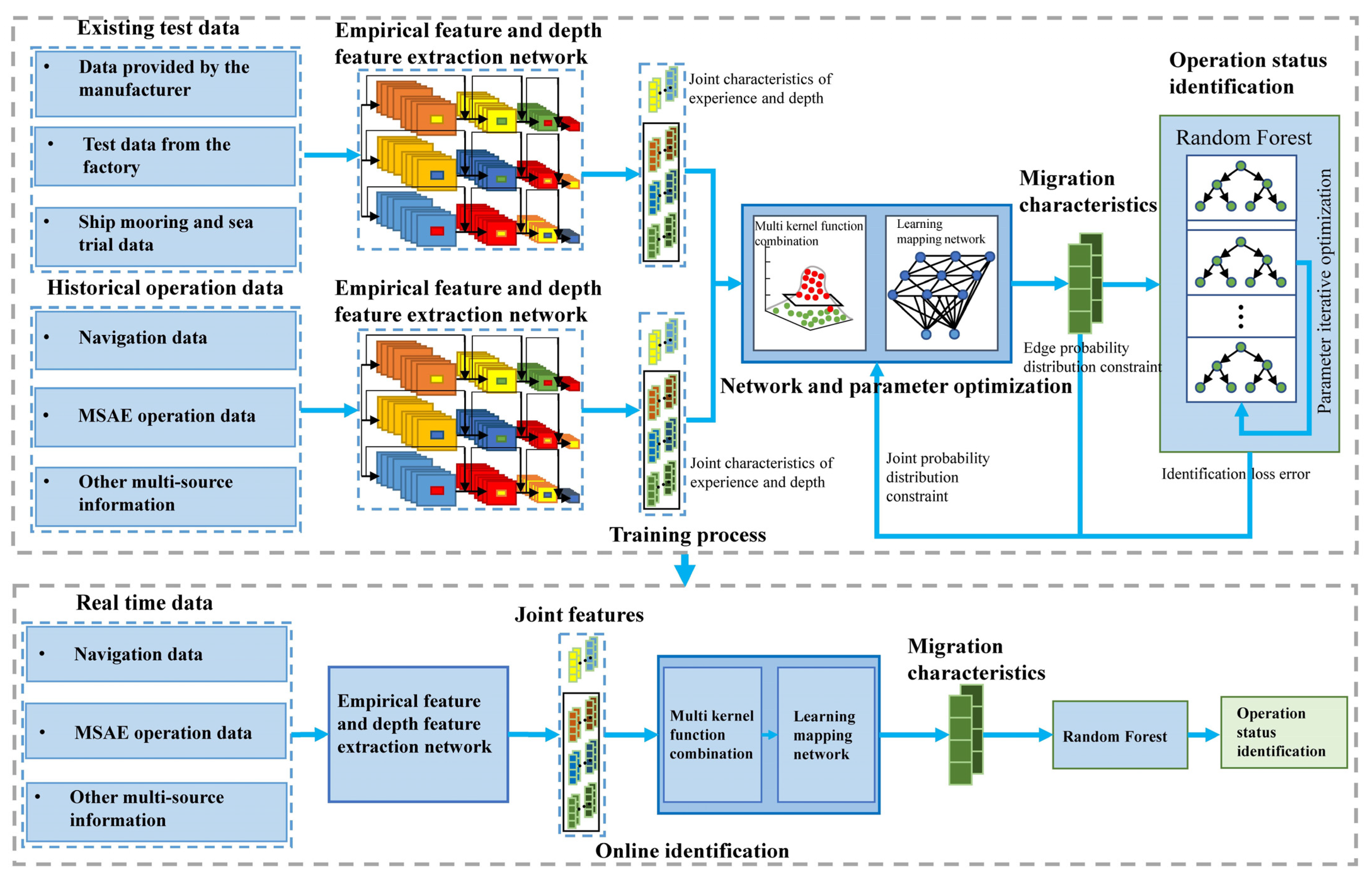

3.2.2. Intelligent FD Methods Using Transfer Learning Theories

- (1)

- The input data

- (2)

- Empirical and depth feature extraction

- (3)

- Feature transfer learning

- (4)

- Fault pattern recognition

3.3. Summary of Application

3.4. Epilog

- Under normal conditions, some MSAEs are not allowed to run to failure as an unexpected failure could result in a breakdown of the ship, maritime traffic accidents, casualties, and environmental pollution. Consequently, failure data in various modes are difficult to be obtained in marine fields.

- Marine machinery, such as main engines, propulsion systems, always works under rough sea conditions. Some external uncertainties from the outside environment (wind, wave, and current) and internal environment (vibration, noise, and electromagnetic) are mixed into the measurement parameters, thus increasing the difficulty of fault pattern recognition.

- Working modes identification is important. The MSAEs work alternately in a variety of working modes. When the modes are different, the optimal value (baseline value) and limits (thresholds) of the same variable will be significantly different, which will increase the difficulty of fault identification.

4. Health Prognostics

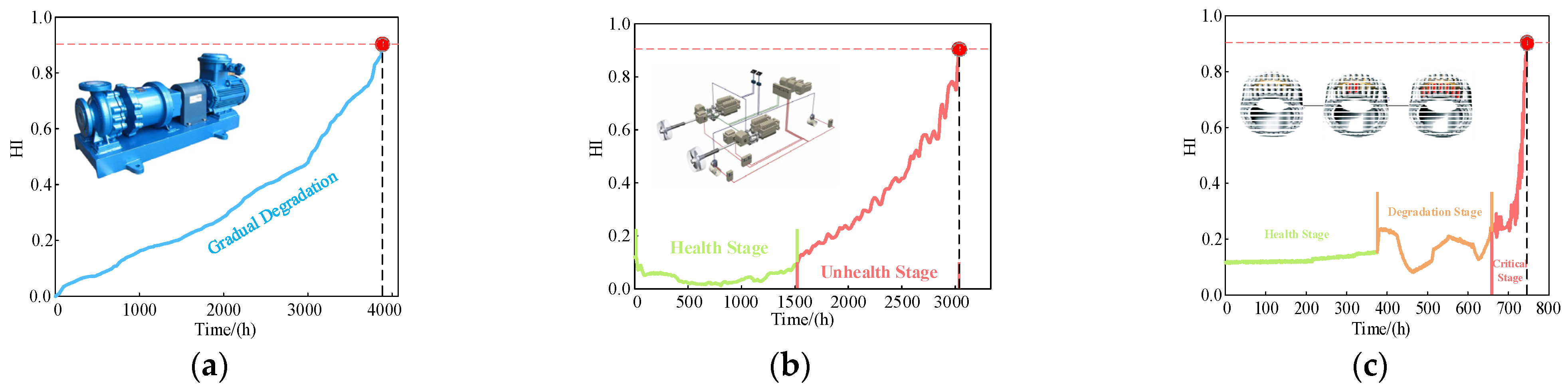

4.1. HI Construction

4.1.1. Single HI

4.1.2. Synthesize HI

4.2. HS Division

4.2.1. Degradation Stage

4.2.2. Time-to-Start and Failure Threshold

- (1)

- Time-to-start (TTS)

- (2)

- Failure threshold

4.3. RUL

4.3.1. Degradation Model

- (1)

- Physical Degradation Models

- (2)

- Empirical Degradation Model

4.3.2. Machine Learning Method

- (1)

- ANN

- (2)

- SVM/RVM

- (3)

- Gaussian process regression (GPR)

4.3.3. Hybrid Failure Prognostics

- (1)

- Degradation Model Fusion

- (2)

- Prognostics Method Fusion

- (3)

- Degradation Model and Prognostics Methods Fusion

4.4. Epilog

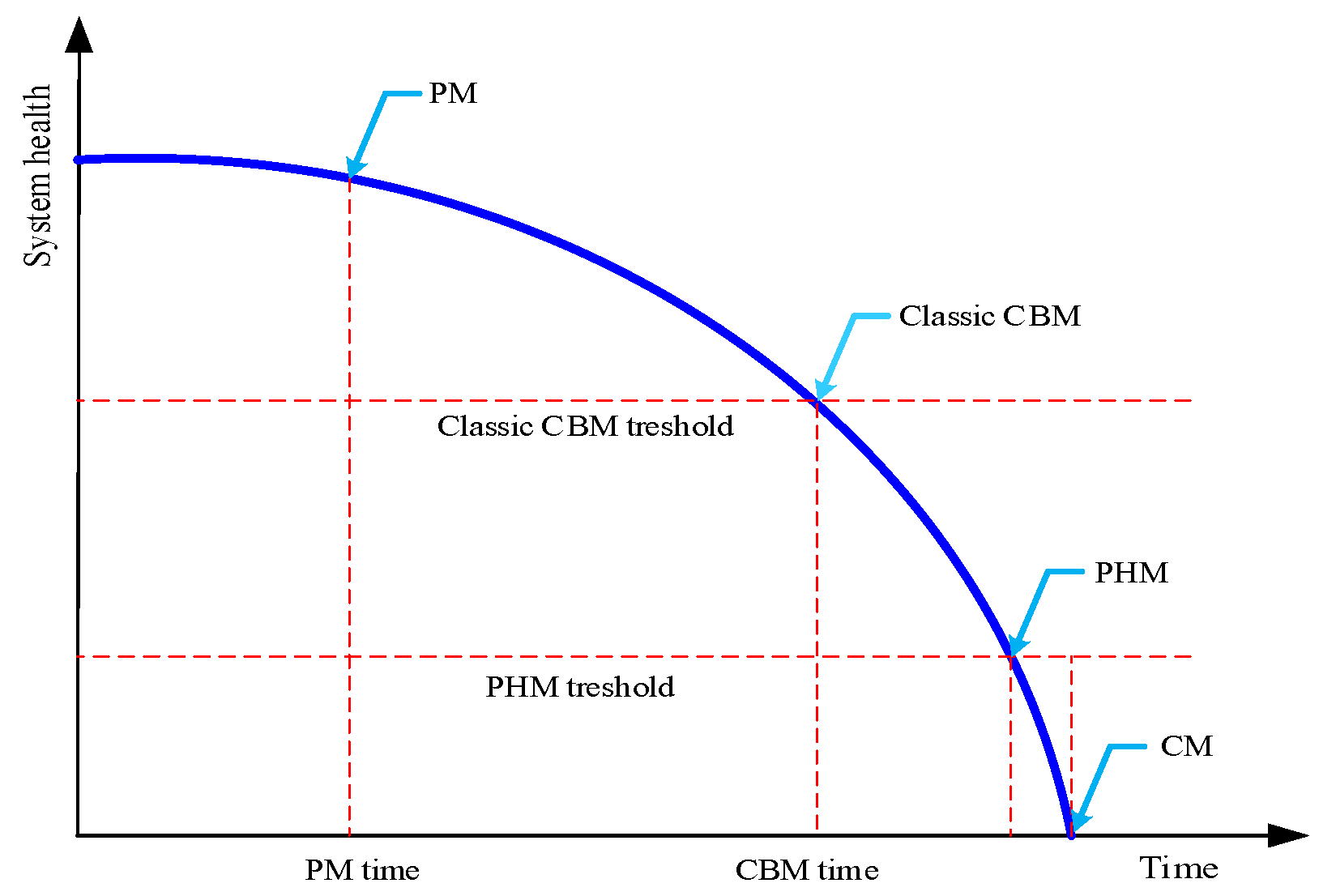

5. Maintenance Decision

- The first generation maintenance method mainly adopts the run to failure maintenance method. That is, the maintenance process is operated until it breaks down. The typical maintenance practices are routine maintenance (RM), (ii) CM [295].

- Second-generation maintenance is mainly preventive maintenance. With the increasing complexity of MSAE, the maintenance cost increases. The maintenance policies adopted are (i) PM, (ii) time-based maintenance (TM).

- The maintenance strategies adopted during the period 1980–2000 are called the third generation maintenance. The typical maintenance character of this period is mainly predictive maintenance. (i) CBM, (ii) reliability centered maintenance (RCM).

- The traditional maintenance methods are transforming to more proactive types, this is the recent generation maintenance. This generation is highly characterized by the inception of risk-based maintenance (RBM) in addition to RCM, Predictive Maintenance, CBM, and CBM+.

5.1. Corrective Maintenance

5.2. Preventive Maintenance

5.3. Predictive Maintenance

5.3.1. CBM

5.3.2. RCM

5.4. Proactive Maintenance

5.4.1. RBM

5.4.2. An E-Maintenance

5.5. Epilog

6. Future Challenges by Intelligent Ship PHM

6.1. Omnidirectional Condition Perception

6.2. DIaK Integrated Coding Technology

6.3. Treatment of Uncertainty Problems

6.4. Proactive Perception

6.5. Engineering Self-Healing and Immune System

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Nian, F. Viewpoints about the prognostic and health management. Chin. J. Sci. Instrum. 2018, 39, 1–14. [Google Scholar]

- Lan, F.; Jiang, Y.; Wang, H.Y. Performance Prediction Method of Prognostics and Health Management of Marine Diesel Engine. In Proceedings of the 2020 3rd International Conference on Applied Mathematics, Modeling and Simulation, Shanghai, China, 20–21 September 2020; IOP Publishing: Bristol, UK, 2020; Volume 1670. [Google Scholar]

- Volponi, A.J.; Brotherton, T.; Luppold, R.; Simon, D.L. Development of an Information Fusion System for Engine Diagnostics and Health Management. In Proceedings of the AIAA 1st Intelligent Systems Technical Conference, Chicago, IL, USA, 20–22 September 2004. [Google Scholar]

- Lee, J.; Wu, F.; Zhao, W.; Ghaffari, M.; Liao, L.; Siegel, D. Prognostics and health management design for rotary machinery systems—Reviews, methodology and applications. Mech. Syst. Signal. Pr. 2014, 42, 314–334. [Google Scholar] [CrossRef]

- Rao, X.; Sheng, C.; Guo, Z.; Yuan, C. A review of online condition monitoring and maintenance strategy for cylinder liner-piston rings of diesel engines. Mech. Syst. Signal Process. 2022, 165, 108385. [Google Scholar] [CrossRef]

- Xie, T.; Wang, T.; He, Q.; Diallo, D.; Claramunt, C. A review of current issues of marine current turbine blade fault detection. Ocean. Eng. 2020, 218, 108194. [Google Scholar] [CrossRef]

- Cipollini, F.; Oneto, L.; Coraddu, A.; Murphy, A.J.; Anguita, D. Condition-based maintenance of naval propulsion systems: Data analysis with minimal feedback. Reliab. Eng. Syst. Saf. 2018, 177, 12–23. [Google Scholar] [CrossRef]

- Kang, Y.J.; Ma, L.; Liu, L.G. Research on Data Security Acquisition System Based on Artificial Intelligence. In Proceedings of the 3rd European-Alliance-for-Innovation (EAI) International Conference on Advanced Hybrid Information Processing (ADHIP), Nanjing, China, 21–22 September 2019; pp. 112–119. [Google Scholar]

- Jeon, M.; Noh, Y.; Shin, Y.; Lim, O.K.; Lee, I.; Cho, D. Prediction of ship fuel consumption by using an artificial neural network. J. Mech. Sci. Technol. 2018, 32, 5785–5796. [Google Scholar] [CrossRef]

- Dong, Y.; Frangopol, D.M.; Sabatino, S. A decision support system for mission-based ship routing considering multiple performance criteria. Reliab. Eng. Syst. Saf. 2016, 150, 190–201. [Google Scholar] [CrossRef]

- Rødseth, Ø.; Perera, L.P.; Mo, B. Big Data in Shipping-Challenges and Opportunities. In Proceedings of the 15th International Conference on Computer Applications and Information Technology in the Maritime Industries (COMPIT 2016), Lecce, Italy, 1 May 2016. [Google Scholar]

- ABS Guidance Notes on Smart Function Implementation. Available online: https://ww2.eagle.org/content/dam/eagle/rules-and-guides/current/other/304-gn-smart-function-implementation-2018/smart-functions-gn-nov18.pdf (accessed on 9 November 2021).

- Asalapuram, V.; Khan, I.; Rao, K. A Novel Architecture for Condition Based Machinery Health Monitoring on Marine Vessels Using Deep Learning and Edge Computing. In Proceedings of the 22nd IEEE International Symposium on Measurement and Control in Robotics (ISMCR)-Robotics for the Benefit of Humanity, University Houston, Clear Lake, Houston, TX, USA, 19–21 September 2019. [Google Scholar]

- Xu, M. Research on CAN Bus Based Ship Automation System and System Design. Shipbuild. China 2012, 53, 185–191. [Google Scholar]

- Shi, B.; Wang, G.; Zhang, H.; Zhang, Y. Strain data acquisition aystem based on ZigBee Wireless Network. Intstrument Tech. Sens. 2020, 444, 79–82. [Google Scholar]

- Liu, Z.K.; Gui, C.Z.; Zhao, G. Ieee Design of New High Availability Ship Platform Monitoring Network Architecture. In Proceedings of the 31st Chinese Control and Decision Conference (CCDC), Nanchang, China, 3–5 June 2019; pp. 2352–2354. [Google Scholar]

- Zhuang, X.Q.; Xu, Y.Q.; Gao, Y.L.; Sun, G.L.; Lin, T.J.; Chan, C.C.K. Remote Data Transmission Technology Based on BeiDou Satellite Navigation Sensor System Onboard Ship. Sens. Mater. 2021, 33, 715–726. [Google Scholar] [CrossRef]

- Yang, Q.; Xie, B.; Jin, Z.; Su, Y.; Huang, X. Interconnection gateway between underwater acoustic sensor networks and VHF communication networks based on embedded technology. Comput. Eng. Sci. 2018, 40, 642–648. [Google Scholar]

- Tsitsilonis, K.-M.; Theotokatos, G. A novel systematic methodology for ship propulsion engines energy management. J. Clean. Prod. 2018, 204, 212–236. [Google Scholar] [CrossRef]

- Lazakis, I.; Gkerekos, C.; Theotokatos, G. Investigating an SVM-driven, one-class approach to estimating ship systems condition. Ships Offshore Struc. 2019, 14, 432–441. [Google Scholar] [CrossRef]

- Cheliotis, M.; Gkerekos, C.; Lazakis, I.; Theotokatos, G. A novel data condition and performance hybrid imputation method for energy efficient operations of marine systems. Ocean Eng. 2019, 188, 106220. [Google Scholar] [CrossRef]

- Qu, F.M.; Liu, J.H.; Ma, Y.J.; Zang, D.; Fu, M.R. A novel wind turbine data imputation method with multiple optimizations based on GANs. Mech. Syst. Signal Process. 2020, 139, 106610. [Google Scholar] [CrossRef]

- Lin, J.; Li, N.H.; Alam, M.A.; Ma, Y.Q. Data-driven missing data imputation in cluster monitoring system based on deep neural network. Appl. Intell. 2020, 50, 860–877. [Google Scholar] [CrossRef]

- Velasco-Gallego, C.; Lazakis, I. Real-time data-driven missing data imputation for short-term sensor data of marine systems. A comparative study. Ocean Eng. 2020, 218, 23. [Google Scholar] [CrossRef]

- Jeon, M.; Noh, Y.; Jeon, K.; Lee, S.; Lee, I. Data gap analysis of ship and maritime data using meta learning. Appl. Soft. Comput. 2021, 101, 14. [Google Scholar] [CrossRef]

- Wang, B.; Mao, Z.Z. Outlier detection based on Gaussian process with application to industrial processes. Appl. Soft. Comput. 2019, 76, 505–516. [Google Scholar] [CrossRef]

- Li, H.; Ma, D.; Yan, Z.; Fu, J.; Zeng, M.; Bao, W. Algorithm of Vehicle’s Data Cleaning and Monitoring. J. Phys. Conf. Ser. 2021, 1828, 012052. [Google Scholar] [CrossRef]

- Huyghues-Beaufond, N.; Tindemans, S.; Falugi, P.; Sun, M.Y.; Strbac, G. Robust and automatic data cleansing method for short-term load forecasting of distribution feeders. Appl. Energy 2020, 261, 17. [Google Scholar] [CrossRef]

- Sun, J.; Wang, F.; Ning, S. Aircraft air conditioning system health state estimation and prediction for predictive maintenance. Chin. J. Aeronaut. 2019, 261, 114405. [Google Scholar] [CrossRef]

- Cai, J.; Luo, J.; Wang, S.; Yang, S. Feature selection in machine learning: A new perspective. Neurocomputing 2018, 300, 70–79. [Google Scholar] [CrossRef]

- Boullosa-Falces, D.; Barrena, J.L.L.; Lopez-Arraiza, A.; Menendez, J.; Solaetxe, M.A.G. Monitoring of fuel oil process of marine diesel engine. Appl. Therm. Eng. 2017, 127, 517–526. [Google Scholar] [CrossRef]

- Ellefsen, A.L.; Han, P.; Cheng, X.; Holmeset, F.T.; Æsøy, V.; Zhang, H. Online Fault Detection in Autonomous Ferries: Using Fault-Type Independent Spectral Anomaly Detection. IEEE Trans. Instrum. Meas. 2020, 69, 8216–8225. [Google Scholar] [CrossRef]

- Tu, F.; Ge, S.S.; Choo, Y.S.; Hang, C.C. Sea state identification based on vessel motion response learning via multi-layer classifiers. Ocean Eng. 2018, 147, 318–332. [Google Scholar] [CrossRef]

- Wei, G.; Luo, Z.; Yu, X. Clustering Research on Ship Fault Phenomena Based on K-means Algorithm. In Proceedings of the 2019 Chinese Control And Decision Conference (CCDC), Nanchang, China, 3–5 June 2019; pp. 4412–4415. [Google Scholar]

- Shi, L.; Zhang, X.; Seielstad, G.; Zhao, C.; He, M. Oil spill detection by MODIS images using fuzzy cluster and texture feature extraction. In Proceedings of the Oil Spill Detection by MODIS Images using Fuzzy Cluster and Texture Feature Extraction, OCEANS 2007-Europe, Aberdeen, UK, 18–21 June 2007; pp. 1–5. [Google Scholar]

- Yan, X.; Xu, X.; Sheng, C.; Yuan, C.; Li, Z. Intelligent wear mode identification system for marine diesel engines based on multi-level belief rule base methodology. Meas. Sci. Technol. 2017, 29, 015110. [Google Scholar] [CrossRef]

- Xie, T.; Li, Z.; Wang, T.; Shi, M.; Wang, Y. An integration fault detection method using stator voltage for marine current turbines. Ocean Eng. 2021, 226, 108808. [Google Scholar] [CrossRef]

- Chen, Y.W.; Lin, C.J. Feature Extraction: Foundations and Applications; Springer: Berlin/Heidelberg, Germany, 2006. [Google Scholar]

- Haddad, R.Z.; Strangas, E.G. On the Accuracy of Fault Detection and Separation in Permanent Magnet Synchronous Machines Using MCSA/MVSA and LDA. IEEE Trans. Energy Convers. 2016, 31, 924–934. [Google Scholar] [CrossRef]

- Zhou, T.T.; Zhu, X.M.; Wu, C.J.; Peng, W.C. Marine propulsion shaft system fault diagnosis method based on partly ensemble empirical mode decomposition and SVM. J. Vibroengineering 2015, 17, 1783–1795. [Google Scholar]

- Yang, K.; Hu, B.; Malekian, R.; Li, Z. An improved control-limit-based principal component analysis method for condition monitoring of marine turbine generators. J. Mar. Eng. Technol. 2019, 19, 249–256. [Google Scholar] [CrossRef]

- Xi, W.; Li, Z.; Tian, Z.; Duan, Z. A feature extraction and visualization method for fault detection of marine diesel engines. Measurement 2018, 116, 429–437. [Google Scholar] [CrossRef]

- Zhang, Z.Z.; Wang, D.J.; Liu, G.Q.; Zhang, Y.L. Fault Diagnosis Method of Ship Fuel System Based on Kernel Principal Component Analysis and Particle Swarm Optimization Support Vector Machine. In Proceedings of the 2020 IEEE 4th Information Technology, Networking, Electronic and Automation Control Conference, Chongqing, China, 12–14 June 2020; pp. 1581–1585. [Google Scholar]

- Li, Z.; Yan, X.; Peng, Z. Intelligent fault diagnosis method for marine diesel engines using instantaneous angular speed. J. Mech. Sci. Technol. 2012, 26, 2413–2423. [Google Scholar] [CrossRef]

- Meng, T.; Jing, X.; Yan, Z.; Pedrycz, W. A survey on machine learning for data fusion. Inf. Fusion 2020, 57, 115–129. [Google Scholar] [CrossRef]

- Zhou, J.; Yang, Y.; Ding, S.X.; Zi, Y.; Wei, M. A Fault Detection and Health Monitoring Scheme for Ship Propulsion Systems Using SVM Technique. IEEE Access 2018, 6, 16207–16215. [Google Scholar] [CrossRef]

- Jiang, H.; Jia, S.; Lai, G. Fault diagnosis of marine main engine based on BP neural network. In Proceedings of the 2009 8th International Conference on Reliability, Maintainability and Safety, Chengdu, China, 20–24 July 2009; pp. 822–825. [Google Scholar]

- Jiang, Y.; Lan, G.; Zhang, Z. Ship engine detection based on wavelet neural network and FPGA image scanning. Alex. Eng. J. 2021, 60, 4287–4297. [Google Scholar] [CrossRef]

- Wang, S.; Wang, J.; Ding, X. An Intelligent Fault Diagnosis Scheme Based On PCA-BP Neural Network for the Marine Diesel Engine. Mater. Sci. Eng. 2020, 782, 032079. [Google Scholar] [CrossRef]

- Xu, X.; Zhao, Z.; Xu, X.; Yang, J.; Chang, L.; Yan, X.; Wang, G. Machine learning-based wear fault diagnosis for marine diesel engine by fusing multiple data-driven models. Knowl-Based Syst. 2020, 190, 105324. [Google Scholar] [CrossRef]

- Bye, R.J.; Almklov, P.G. Normalization of maritime accident data using AIS. Mar. Policy 2019, 109, 103675. [Google Scholar] [CrossRef]

- Zhang, M.; Wang, T.; Tang, T.; Benbouzid, M.; Diallo, D. An imbalance fault detection method based on data normalization and EMD for marine current turbines. ISA Trans. 2017, 68, 302–312. [Google Scholar] [CrossRef]

- Rabatel, G.; Marini, F.; Walczak, B.; Roger, J.-M. VSN: Variable sorting for normalization. J. Chemom. 2020, 34, e3164. [Google Scholar] [CrossRef]

- Singh, D.; Singh, B. Feature wise normalization: An effective way of normalizing data. Pattern Recognit. 2022, 122, 108307. [Google Scholar] [CrossRef]

- Sun, Y.-S.; Ran, X.-R.; Li, Y.-M.; Zhang, G.-C.; Zhang, Y.-h. Thruster fault diagnosis method based on Gaussian particle filter for autonomous underwater vehicles. Int. J. Nav. Archit. Ocean Eng. 2016, 8, 243–251. [Google Scholar] [CrossRef]

- Zhou, X.-Y.; Liu, Z.-J.; Wang, F.-W.; Wu, Z.-L.; Cui, R.-D. Towards applicability evaluation of hazard analysis methods for autonomous ships. Ocean Eng. 2020, 214, 107773. [Google Scholar] [CrossRef]

- Kowalski, J.; Krawczyk, B.; Wozniak, M. Fault diagnosis of marine 4-stroke diesel engines using a one-vs-one extreme learning ensemble. Eng. Appl. Artif. Intell. 2017, 57, 134–141. [Google Scholar] [CrossRef]

- Chandroth, G. Condition monitoring: The case for integrating data from independent sources. Proc. IMarEST-Part A-J. Mar. Eng. Technol. 2004, 2004, 9–16. [Google Scholar] [CrossRef][Green Version]

- Watzenig, D.; Sommer, M.S.; Steiner, G. Engine state monitoring and fault diagnosis of large marine diesel engines. E I Elektrotechnik Und Inf. 2009, 126, 173–179. [Google Scholar] [CrossRef]

- Yan, X.-p.; Sheng, C.; Zhao, J.; Yang, K.; Li, Z. Study of on-line condition monitoring and fault feature extraction for marine diesel engines based on tribological information. P. I. Mech. Eng. O-J. Ris. 2015, 229, 291–300. [Google Scholar] [CrossRef]

- Raptodimos, Y.; Lazakis, I. Using artificial neural network-self-organising map for data clustering of marine engine condition monitoring applications. Ships Offshore Struc. 2018, 13, 649–656. [Google Scholar] [CrossRef]

- Asuquo, M.; Wang, J.; Zhang, L.; Phylip-Jones, G. An integrated risk assessment for maintenance prediction of oil wetted gearbox and bearing in marine and offshore industries using a fuzzy rule base method. Proc. Inst. Mech. Eng. Part M J. Eng. Marit. Environ. 2020, 234, 147509021989952. [Google Scholar] [CrossRef]

- Tan, Y.; Tian, H.; Jiang, R.; Lin, Y.; Zhang, J. A comparative investigation of data-driven approaches based on one-class classifiers for condition monitoring of marine machinery system. Ocean Eng. 2020, 201, 107174. [Google Scholar] [CrossRef]

- Dudojc, B.; Mindykowski, J. New Approach to Analysis of Selected Measurement and Monitoring Systems Solutions in Ship Technology. Sensors 2019, 19, 1775. [Google Scholar] [CrossRef]

- Zhang, Y.W.; Zhang, P.; Zhang, B.S.; Sun, P.T. Health Condition Assessment of Marine Systems Based on an Improved Radar Chart. Math. Probl. Eng. 2020, 2020, 8878908. [Google Scholar] [CrossRef]

- Bai, G.L.; White, M.F. Transient speed analysis and its application to diagnosis of engine cylinder faults. Qld. Univ. Technol. Syst. Integr. Maint. 2000, 6, 81–85. [Google Scholar]

- Azzoni, P. Reconstruction of Indicated Pressure Waveform in a Spark-Ignition Engine From Block Vibration Measurements. J. Dyn. Syst. Meas. Contr. 1997, 119, 614–619. [Google Scholar] [CrossRef]

- Mauer, G.F.; Watts, R.J. Combustion Engine Performance Diagnostics by Kinetic Energy Measurement. J. Eng. Gas Turbines Power 1990, 112, 301–307. [Google Scholar] [CrossRef]

- Lazakis, I.; Ölçer, A. Selection of the best maintenance approach in the maritime industry under fuzzy multiple attributive group decision-making environment. Proc. Inst. Mech. Eng. Part M J. Eng. Marit. Environ. 2015, 230, 297–309. [Google Scholar] [CrossRef]

- Venkatasubramanian, V.; Rengaswamy, R.; Yin, K.; Kavuri, S.N. A review of process fault detection and diagnosis: Part I: Quantitative model-based methods. Comput. Chem. Eng. 2003, 27, 293–311. [Google Scholar] [CrossRef]

- Tidriri, K.; Chatti, N.; Verron, S.; Tiplica, T. Bridging data-driven and model-based approaches for process fault diagnosis and health monitoring: A review of researches and future challenges. Annu. Rev. Control. 2016, 42, 63–81. [Google Scholar] [CrossRef]

- Pedersen, E. Bond Graph Modeling of Marine Vehicle Dynamics. IFAC Proc. Vol. 2012, 45, 415–420. [Google Scholar] [CrossRef]

- Tan, M.; Chen, L.; Jin, J.; Sun, F.; Wu, C. Bond-graph-based fault-diagnosis for a marine condensate–booster–feedwater system. Appl. Energy 2005, 81, 449–458. [Google Scholar] [CrossRef]

- Huang, L.; Cheng, G.; Zhu, G.; Li, D. Development of a bond graph based model library for turbocharged diesel engines. Energy. 2018, 148, 728–743. [Google Scholar] [CrossRef]

- Song, Y.; Zhong, M.; Xue, T.; Ding, S.X.; Li, W. Parity space-based fault isolation using minimum error minimax probability machine. Control Eng. Pract. 2020, 95, 104242. [Google Scholar] [CrossRef]

- Wang, T.; Liu, L.; Zhang, J.; Schaeffer, E.; Wang, Y. A M-EKF fault detection strategy of insulation system for marine current turbine. Mech. Syst. Signal. Pr. 2019, 115, 269–280. [Google Scholar] [CrossRef]

- Kowalczuk, Z.; Bíałaszewski, T. Pareto-Optimal Observers for Ship Propulsion Systems by Evolutionary Computation. IFAC Proc. Vol. 2000, 33, 891–896. [Google Scholar] [CrossRef]

- Chu, Z.; Chen, Y.; Zhu, D.; Zhang, M. Observer-based fault detection for magnetic coupling underwater thrusters with applications in jiaolong HOV. Ocean Eng. 2020, 210, 107570. [Google Scholar] [CrossRef]

- Liu, Z. Adaptive extended state observer based heading control for surface ships associated with sideslip compensation. Appl. Ocean Res. 2021, 110, 102605. [Google Scholar] [CrossRef]

- Lei, Y.; Yang, B.; Jiang, X.; Jia, F.; Li, N.; Nandi, A.K. Applications of machine learning to machine fault diagnosis: A review and roadmap. Mech. Syst. Signal Process. 2020, 138, 106587. [Google Scholar] [CrossRef]

- Xu, X.J.; Yan, X.P.; Sheng, C.X.; Yuan, C.Q.; Xu, D.L.; Yang, J.B. A Belief Rule-Based Expert System for Fault Diagnosis of Marine Diesel Engines. IEEE Trans. Syst. Man. Cybern. 2020, 50, 656–672. [Google Scholar] [CrossRef]

- Yang, B.-S.; Lim, D.-S.; Tan, A.C.C. VIBEX: An expert system for vibration fault diagnosis of rotating machinery using decision tree and decision table. Expert. Syst. Appl. 2005, 28, 735–742. [Google Scholar] [CrossRef]

- Angeli, C. An online expert system for fault diagnosis in hydraulic systems. Expert. Syst 1999, 16, 115–120. [Google Scholar] [CrossRef]

- Ebersbach, S.; Peng, Z. Expert system development for vibration analysis in machine condition monitoring. Expert. Syst. Appl. 2008, 34, 291–299. [Google Scholar] [CrossRef]

- Hein, K.; Xu, Y.; Senthilkumar, Y.; Gary, W.; Gupta, A.K. Rule-based operation task-aware energy management for ship power systems. IET. Gener. Transm. Dis. 2020, 14, 6348–6358. [Google Scholar] [CrossRef]

- Lee, H.J.; Park, D.Y.; Ahn, B.S.; Park, Y.M.; Park, J.K.; Venkata, S.S. A fuzzy expert system for the integrated fault diagnosis. IEEE Trans. Power Deliv. 2000, 15, 833–838. [Google Scholar]

- Wu, J.D.; Wang, Y.H.; Bai, M.S.R. Development of an expert system for fault diagnosis in scooter engine platform using fuzzy-logic inference. Expert. Syst. Appl. 2007, 33, 1063–1075. [Google Scholar] [CrossRef]

- Berredjem, T.; Benidir, M. Bearing faults diagnosis using fuzzy expert system relying on an Improved Range Overlaps and Similarity method. Expert. Syst. Appl. 2018, 108, 134–142. [Google Scholar] [CrossRef]

- Ahmed, S.; Gu, X.-C. Accident-based FMECA study of Marine boiler for risk prioritization using fuzzy expert system. Results Eng. 2020, 6, 100123. [Google Scholar] [CrossRef]

- Shah, J.; Wang, W. An evolving neuro-fuzzy classifier for fault diagnosis of gear systems. ISA Trans. 2021, in press. [Google Scholar] [CrossRef]

- Wu, J.-D.; Chiang, P.-H.; Chang, Y.-W.; Shiao, Y.-J. An expert system for fault diagnosis in internal combustion engines using probability neural network. Expert. Syst. Appl. 2008, 34, 2704–2713. [Google Scholar] [CrossRef]

- Hajnayeb, A.; Khadem, S.E.; Moradi, M.H. Design and implementation of an automatic condition-monitoring expert system for ball-bearing fault detection. Ind. Lubr. Tribol. 2008, 60, 93–100. [Google Scholar] [CrossRef]

- Isermann, R. Model-based fault-detection and diagnosis–status and applications. Annu. Rev. Control 2005, 29, 71–85. [Google Scholar] [CrossRef]

- Dai, X.; Gao, Z. From Model, Signal to Knowledge: A Data-Driven Perspective of Fault Detection and Diagnosis. IEEE Trans. Ind. Inform. 2013, 9, 2226–2238. [Google Scholar] [CrossRef]

- Zhan, Y.L.; Shi, Z.B.; Liu, M.M. IEEE, the application of support vector machines (SVM) to fault diagnosis of marine main engine cylinder cover. In Proceedings of the Iecon 2007: 33rd Annual Conference of the Ieee Industrial Electronics Society, Taipei, Taiwan, 5–8 November 2007; Volume 1–3, pp. 3018–3022. [Google Scholar]

- De Stefano, C.; Ferrigno, L.; Fontanella, F.; Gerevini, L.; Scotto di Freca, A. A novel PCA-based approach for building on-board sensor classifiers for water contaminant detection. Pattern. Recognit. Lett. 2020, 135, 375–381. [Google Scholar] [CrossRef]

- Albarbar, A.; Gu, F.; Ball, A.D. Diesel engine fuel injection monitoring using acoustic measurements and independent component analysis. Measurement. 2010, 43, 1376–1386. [Google Scholar] [CrossRef]

- Li, Z.X.; Yan, X.P.; Guo, Z.W.; Liu, P.; Yuan, C.Q.; Peng, Z.X. A New Intelligent Fusion Method of Multi-Dimensional Sensors and Its Application to Tribo-System Fault Diagnosis of Marine Diesel Engines. Tribol. Lett. 2012, 47, 1–15. [Google Scholar] [CrossRef]

- Jing, Y.B.; Liu, C.W.; Bi, F.R.; Bi, X.Y.; Wang, X.; Shao, K. Diesel Engine Valve Clearance Fault Diagnosis Based on Features Extraction Techniques and FastICA-SVM. Chin. J. Mesh. Eng. 2017, 30, 991–1007. [Google Scholar] [CrossRef]

- Zhong, B.; MacIntyre, J.; He, Y.; Tait, J. High order neural networks for simultaneous diagnosis of multiple faults in rotating machines. Neural. Comput. Appl. 1999, 8, 189–195. [Google Scholar] [CrossRef]

- Yang, B.S.; Han, T.; An, J.L. ART–KOHONEN neural network for fault diagnosis of rotating machinery. Mech. Syst. Signal. Pr. 2004, 18, 645–657. [Google Scholar] [CrossRef]

- Chen, X.; Zhou, J.; Xiao, H.; Wang, E.; Xiao, J.; Zhang, H. Fault diagnosis based on comprehensive geometric characteristic and probability neural network. Appl. Math. Comput. 2014, 230, 542–554. [Google Scholar] [CrossRef]

- Li, Z.; Yan, X.; Yuan, C.; Zhao, J.; Peng, Z. Fault detection and diagnosis of a gearbox in marine propulsion systems using bispectrum analysis and artificial neural networks. J. Mar. Sci. Appl. 2011, 10, 17–24. [Google Scholar] [CrossRef]

- Basurko, O.C.; Uriondo, Z. Condition-Based Maintenance for medium speed diesel engines used in vessels in operation. Appl. Therm. Eng. 2015, 80, 404–412. [Google Scholar] [CrossRef]

- Rapur, J.S.; Tiwari, R. Automation of multi-fault diagnosing of centrifugal pumps using multi-class support vector machine with vibration and motor current signals in frequency domain. J. Braz. Soc. Mech. Sci. Eng. 2018, 40, 278. [Google Scholar] [CrossRef]

- Li, Y.; Xu, M.; Wei, Y.; Huang, W. A new rolling bearing fault diagnosis method based on multiscale permutation entropy and improved support vector machine based binary tree. Measurement 2016, 77, 80–94. [Google Scholar] [CrossRef]

- Li, Y.; Li, G.; Yang, Y.; Liang, X.; Xu, M. A fault diagnosis scheme for planetary gearboxes using adaptive multi-scale morphology filter and modified hierarchical permutation entropy. Mech. Syst. Signal Process. 2018, 105, 319–337. [Google Scholar] [CrossRef]

- Tang, B.; Song, T.; Li, F.; Deng, L. Fault diagnosis for a wind turbine transmission system based on manifold learning and Shannon wavelet support vector machine. Renew. Energy 2014, 62, 1–9. [Google Scholar] [CrossRef]

- Cai, C.T.; Weng, X.Y.; Zhang, C.B. A novel approach for marine diesel engine fault diagnosis. Clust. Comput. 2017, 20, 1691–1702. [Google Scholar] [CrossRef]

- Wei, Y.; Liu, H.L.; Chen, G.X.; Ye, J.W. Fault Diagnosis of Marine Turbocharger System Based on an Unsupervised Algorithm. J. Electr. Eng. Technol. 2020, 15, 1331–1343. [Google Scholar] [CrossRef]

- Leturiondo, U. Hybrid Modelling in Condition Monitoring. Ph.D. Thesis, Luleå University of Technology, Lulea, Sweden, 2016. [Google Scholar]

- Coraddu, A.; Oneto, L.; Ghio, A.; Savio, S.; Anguita, D.; Figari, M. Machine learning approaches for improving condition-based maintenance of naval propulsion plants. P. I. Mech. Eng. M-J. Eng. 2016, 230, 136–153. [Google Scholar] [CrossRef]

- Wang, R.H.; Chen, H.; Guan, C.; Gong, W.F.; Zhang, Z.H. Research on the fault monitoring method of marine diesel engines based on the manifold learning and isolation forest. Appl. Ocean Res. 2021, 112, 102681. [Google Scholar] [CrossRef]

- Li, Z.X.; Yan, X.P.; Guo, Z.W.; Zhang, Y.L.; Yuan, C.Q.; Peng, Z. Condition Monitoring and Fault Diagnosis for Marine Diesel Engines using Information Fusion Techniques. Elektron. Elektr. 2012, 123, 109–112. [Google Scholar] [CrossRef]

- Verma, N.K.; Gupta, V.K.; Sharma, M.; Sevakula, R.K. Ieee, Intelligent Condition Based Monitoring of Rotating Machines using Sparse Auto-encoders. In Proceedings of the 2013 IEEE Conference on prognostics and health management (PHM), Gaithersburg, MD, USA, 24–27 June 2013. [Google Scholar]

- Li, C.; Sanchez, R.V.; Zurita, G.; Cerrada, M.; Cabrera, D. Fault Diagnosis for Rotating Machinery Using Vibration Measurement Deep Statistical Feature Learning. Sensors 2016, 16, 895. [Google Scholar] [CrossRef]

- Ince, T.; Kiranyaz, S.; Eren, L.; Askar, M.; Gabbouj, M. Real-Time Motor Fault Detection by 1-D Convolutional Neural Networks. IEEE Trans. Ind. Electron. 2016, 63, 7067–7075. [Google Scholar] [CrossRef]

- Pan, S.J.; Yang, Q.A. A Survey on Transfer Learning. IEEE Trans. Knowl. Data Eng. 2010, 22, 1345–1359. [Google Scholar] [CrossRef]

- Yang, B.; Lei, Y.; Jia, F.; Xing, S. An intelligent fault diagnosis approach based on transfer learning from laboratory bearings to locomotive bearings. Mech. Syst. Sig. Prrocess. 2019, 122, 692–706. [Google Scholar] [CrossRef]

- Xiong, G.Q.; Ma, W.S.; Zhao, N.Y.; Zhang, J.J.; Jiang, Z.N.; Mao, Z.W. Multi-Type Diesel Engines Operating Condition Recognition Method Based on Stacked Auto-Encoder and Feature Transfer Learning. IEEE Access 2021, 9, 31043–31052. [Google Scholar] [CrossRef]

- Pedersen, T.A.; Pedersen, E. Bond graph modelling of marine power systems. Math. Comput. Modell. Dyn. Syst. 2012, 18, 153–173. [Google Scholar] [CrossRef]

- Huang, L.; Cheng, G.; Zhu, G.Q. Bond Graph Based Modeling and Simulation of Marine Condenser. In Proceedings of the 2018 Eighth International Conference on Instrumentation and Measurement, Computer, Communication and Control, Harbin, China, 19–21 July 2018; Li, J.B., Ed.; pp. 390–394. [Google Scholar]

- Huang, L.; Cheng, G.; Zhu, G.; Chen, Y. Fault isolation and parameter estimation of marine main power plant based on bicausal bond graphs. J. Natl. Univ. Def. Technol. 2019, 41, 176–184. [Google Scholar]

- Benetazzo, F.; Ippoliti, G.; Longhi, S.; Raspa, P. Advanced control for fault-tolerant dynamic positioning of an offshore supply vessel. Ocean Eng. 2015, 106, 472–484. [Google Scholar] [CrossRef]

- Nagy-Kiss, A.M.; Schutz, G.; Ragot, J. Parameter estimation for uncertain systems based on fault diagnosis using Takagi–Sugeno model. ISA Trans. 2015, 56, 65–74. [Google Scholar] [CrossRef] [PubMed]

- Torres, L.; Verde, C.; Vázquez-Hernández, O. Parameter identification of marine risers using Kalman-like observers. Ocean Eng. 2015, 93, 84–97. [Google Scholar] [CrossRef]

- Zhang, Z.; Chen, J. Fault detection and diagnosis based on particle filters combined with interactive multiple-model estimation in dynamic process systems. ISA Trans. 2019, 85, 247–261. [Google Scholar] [CrossRef]

- Zhou, J.; Yang, Y.; Zhao, Z.; Ding, S.X. A fault detection scheme for ship propulsion systems using randomized algorithm techniques. Control Eng. Pract. 2018, 81, 65–72. [Google Scholar] [CrossRef]

- Cui, J.; Yang, R.; Pang, C.; Zhang, Q. Observer-based adaptive robust stabilization of dynamic positioning ship with delay via Hamiltonian method. Ocean Eng. 2021, 222, 108439. [Google Scholar] [CrossRef]

- Lootsma, T.F.; Izadi-Zamanabadi, R.; Nijmeijer, H. Observer-Based FDI for Gain Fault Detection in Ship Propulsion Benchmark- A Geometric Approach1. IFAC Proc. Vol. 2001, 34, 125–130. [Google Scholar] [CrossRef]

- Qiao, L.; Yang, Y. Design of PD Observer-Based Fault-Tolerant Controller for Descriptor Systems: Application to a Ship Propulsion System. In Proceedings of the 2018 37th Chinese Control Conference, Wuhan, China, 25–27 July 2018; Chen, X., Zhao, Q.C., Eds.; pp. 6033–6037. [Google Scholar]

- Zhou, Z.T.; Zhong, M.Y.; Wang, Y.Q. Fault Diagnosis Observer and Fault-Tolerant Control Design for Unmanned Surface Vehicles in Network Environments. IEEE Access 2019, 7, 173694–173702. [Google Scholar] [CrossRef]

- Wang, Y.L.; Han, Q.L. Network-Based Fault Detection Filter and Controller Coordinated Design for Unmanned Surface Vehicles in Network Environments. IEEE Trans. Ind. Inform. 2016, 12, 1753–1765. [Google Scholar] [CrossRef]

- Roy, J. Rule-based expert system for maritime anomaly detection. In Sensors, and Command, Control, Communications, and Intelligence; Carapezza, E.M., Ed.; International Society for Optics and Photonics: Bellingham, WA, USA, 2010; Volume 7666. [Google Scholar]

- Coenen, F.; Smeaton, P. Rule-based algorithms for geographic constraints in a marine knowledge-based system. Knowl-Based Syst. 1991, 4, 157–164. [Google Scholar] [CrossRef]

- Qiao, L.; Yang, Y. Fault-tolerant control for T–S fuzzy systems with sensor faults: Application to a ship propulsion system. J. Franklin Inst. 2018, 355, 4854–4872. [Google Scholar] [CrossRef]

- Marichal, G.N.; Avila, D.; Hernandez, A.; Padron, I.; Castejon, C. Feature Extraction from Indirect Monitoring in Marine Oil Separation Systems. Sensors 2018, 18, 3159. [Google Scholar] [CrossRef]

- Freeman, B.; Tang, Y.; Huang, Y.; VanZwieten, J. Rotor blade imbalance fault detection for variable-speed marine current turbines via generator power signal analysis. Ocean Eng. 2021, 223, 108666. [Google Scholar] [CrossRef]

- Zhan, Y.L.; Shi, Z.B.; Shwe, T.; Wang, X.Z. Fault diagnosis of marine main engine cylinder cover based on vibration signal. In Proceedings of the 2007 International Conference on Machine Learning and Cybernetics, Hong Kong, China, 19–22 August 2007; pp. 1126–1130. [Google Scholar]

- Dayong, N.; Changle, S.; Yongjun, G.; Zengmeng, Z.; Jiaoyi, H. Extraction of fault component from abnormal sound in diesel engines using acoustic signals. Mech. Syst. Signal Process. 2016, 75, 544–555. [Google Scholar] [CrossRef]

- Hu, X.J.; Xi, Z.D.; Li, K.; Cong, B. Ieee, Application of Translation-invariant Multiwavelets Denoising Using Neighboring Coefficients to Fault Diagnosis of Antennas on Vessel. In Proceedings of the 2013 International Conference on Mechatronic Sciences, Electric Engineering and Computer (MEC), Shengyang, China, 20–22 December 2013; pp. 870–873. [Google Scholar]

- Cui, J.C.; Ma, L.J. Fault Diagnosis Feature Extraction of Marine Rolling Bearing Based on MEMD and Pe. J. Coast. Res. 2019, 94, 342–346. [Google Scholar] [CrossRef]

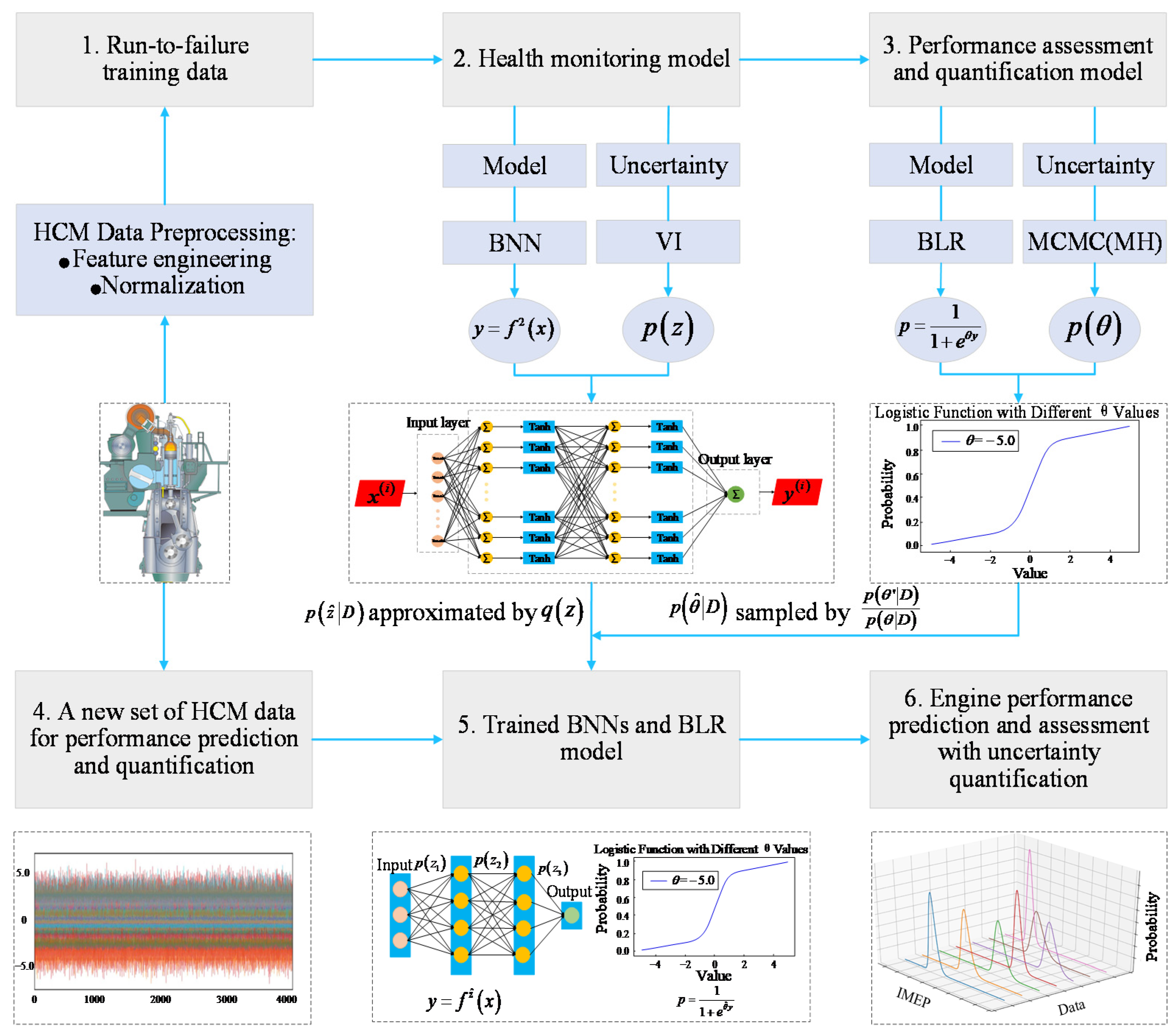

- Wang, R.; Chen, H.; Guan, C. A Bayesian inference-based approach for performance prognostics towards uncertainty quantification and its applications on the marine diesel engine. ISA Trans. 2021, 118, 159–173. [Google Scholar] [CrossRef]

- Peng, X.; Chai, Y.; Man, X. Fault Diagnosis of Marine Diesel Engine Based on PCA-KFCM. Control Eng. China 2012, 19, 311–315. [Google Scholar]

- Zhong, K.; Li, J.B.; Wang, J.; Han, M. Ieee, Fault Detection for Marine Diesel Engine Using Semi-supervised Principal Component Analysis. In Proceedings of the 2019 9th International Conference on Information Science and Technology, Hulunbuir, China, 2–5 August 2019; pp. 146–151. [Google Scholar]

- Fabiani, F.; Grechi, S.; Della Tommasina, S.; Caiti, A. A NLPCA Hybrid Approach for AUV Thrusters Fault Detection and Isolation. In Proceedings of the 2016 3rd Conference on Control and Fault-Tolerant Systems, Barcelona, Spain, 7–9 September 2016; Sarrate, R., Ed.; pp. 111–116. [Google Scholar]

- Pantelelis, N.G.; Kanarachos, A.E.; Gotzias, N. Neural networks and simple models for the fault diagnosis of naval turbochargers. Math. Comput. Simul. 2000, 51, 387–397. [Google Scholar] [CrossRef]

- Cheliotis, M.; Lazakis, I.; Theotokatos, G. Machine learning and data-driven fault detection for ship systems operations. Ocean Eng. 2020, 216, 107968. [Google Scholar] [CrossRef]

- Karagiannidis, P.; Themelis, N. Data-driven modelling of ship propulsion and the effect of data pre-processing on the prediction of ship fuel consumption and speed loss. Ocean Eng. 2021, 222, 108616. [Google Scholar] [CrossRef]

- Sánchez-Herguedas, A.; Mena-Nieto, A.; Rodrigo-Muñoz, F. A new analytical method to optimise the preventive maintenance interval by using a semi-Markov process and z-transform with an application to marine diesel engines. Reliab. Eng. Syst. Saf. 2021, 207, 107394. [Google Scholar] [CrossRef]

- Qin, H.L.; Li, H.J.; Li, Z.X. Intelligent Fault Diagnosis Method for Marine Diesel Engines Based on KICA-Wigner Bispectrum and SVM. Inf.-Tokyo 2011, 14, 975–980. [Google Scholar]

- Sikorska, J.Z.; Hodkiewicz, M.; Ma, L. Prognostic modelling options for remaining useful life estimation by industry. Mech. Syst. Signal Process. 2011, 25, 1803–1836. [Google Scholar] [CrossRef]

- Hu, C.; Youn, B.D.; Wang, P.; Taek Yoon, J. Ensemble of data-driven prognostic algorithms for robust prediction of remaining useful life. Reliab. Eng. Syst. Saf. 2012, 103, 120–135. [Google Scholar] [CrossRef]

- Lei, Y.; Li, N.; Guo, L.; Li, N.; Yan, T.; Lin, J. Machinery health prognostics: A systematic review from data acquisition to RUL prediction. Mech. Syst. Signal Process. 2018, 104, 799–834. [Google Scholar] [CrossRef]

- Camci, F.; Medjaher, K.; Zerhouni, N.; Nectoux, P. Feature Evaluation for Effective Bearing Prognostics. Qual. Reliab. Eng. Int. 2013, 29, 477–486. [Google Scholar] [CrossRef]

- Brotherton, T.; Grabill, P.; Wroblewski, D.; Friend, R.; Sotomayer, B.; Berry, J. A testbed for data fusion for engine diagnostics and prognostics. In Proceedings of the Proceedings, IEEE Aerospace Conference, Big Sky, MT, USA, 9–16 March 2002; p. 6. [Google Scholar]

- Saxena, A.; Goebel, K.; Simon, D.; Eklund, N. Damage propagation modeling for aircraft engine run-to-failure simulation. In Proceedings of the 2008 International Conference on Prognostics and Health Management, Denver, CO, USA, 6–9 October 2008; pp. 1–9. [Google Scholar]

- Song, C.; Liu, K.; Zhang, X. Integration of Data-Level Fusion Model and Kernel Methods for Degradation Modeling and Prognostic Analysis. IEEE Trans. Reliab. 2018, 67, 640–650. [Google Scholar] [CrossRef]

- Wang, P.; Youn, B.D.; Hu, C. A generic probabilistic framework for structural health prognostics and uncertainty management. Mech. Syst. Signal Process. 2012, 28, 622–637. [Google Scholar] [CrossRef]

- Zhu, J.; Nostrand, T.; Spiegel, C.; Morton, B. Survey of condition indicators for condition monitoring systems. In PHM 2014-Proceedings of the Annual Conference of the Prognostics and Health Management Society; Renewable NRG Systems Hinesburg United States: Hinesburg, VT, USA, 2014; pp. 635–647. [Google Scholar]

- Malhi, A.; Yan, R.; Gao, R.X. Prognosis of Defect Propagation Based on Recurrent Neural Networks. IEEE Trans. Instrum. Meas. 2011, 60, 703–711. [Google Scholar] [CrossRef]

- Huang, Z.; Xu, Z.; Ke, X.; Wang, W.; Sun, Y. Remaining useful life prediction for an adaptive skew-Wiener process model. Mech. Syst. Signal Process. 2017, 87, 294–306. [Google Scholar] [CrossRef]

- Zhang, Z.; Si, X.; Hu, C. An Age- and State-Dependent Nonlinear Prognostic Model for Degrading Systems. IEEE Trans. Reliab. 2015, 64, 1214–1228. [Google Scholar] [CrossRef]

- Tran, V.; Pham, H.; Yang, B.-S.; Nguyen, T. Machine performance degradation assessment and remaining useful life prediction using proportional hazard model and support vector machine. Mech. Syst. Signal Process. 2012, 32, 320–330. [Google Scholar] [CrossRef]

- Liao, H.; Tian, Z. A framework for predicting the remaining useful life of a single unit under time-varying operating conditions. IIE Trans. 2013, 45, 964–980. [Google Scholar] [CrossRef]

- Hu, L.; Hu, N.-Q.; Fan, B.; Gu, F.-S.; Zhang, X.-Y. Modeling the Relationship between Vibration Features and Condition Parameters Using Relevance Vector Machines for Health Monitoring of Rolling Element Bearings under Varying Operation Conditions. Math. Prob. Eng. 2015, 2015, 123730. [Google Scholar] [CrossRef]

- Gašperin, M.; Juričić, Đ.; Boškoski, P.; Vižintin, J. Model-based prognostics of gear health using stochastic dynamical models. Mech. Syst. Signal Process. 2011, 25, 537–548. [Google Scholar] [CrossRef]

- Elwany, A.H.; Gebraeel, N.Z. Sensor-driven prognostic models for equipment replacement and spare parts inventory. IIE Trans. 2008, 40, 629–639. [Google Scholar] [CrossRef]

- Hu, J.; Tse, P.W. A Relevance Vector Machine-Based Approach with Application to Oil Sand Pump Prognostics. Sensors 2013, 13, 12663–12686. [Google Scholar] [CrossRef] [PubMed]

- Hanachi, H.; Liu, J.; Banerjee, A.; Chen, Y.; Koul, A. A Physics-Based Modeling Approach for Performance Monitoring in Gas Turbine Engines. IEEE Trans. Reliab. 2015, 64, 197–205. [Google Scholar] [CrossRef]

- Guo, J.; Li, Z.; Pecht, M. A Bayesian approach for Li-Ion battery capacity fade modeling and cycles to failure prognostics. J. Power Sources 2015, 281, 173–184. [Google Scholar] [CrossRef]

- Li, Z.; Deng, Y.; Mastrangelo, C. Model selection for degradation-based Bayesian reliability analysis. J. Manuf. Syst. 2015, 37, 72–82. [Google Scholar] [CrossRef]

- Wen, P.; Zhao, S.; Chen, S.; Li, Y. A generalized remaining useful life prediction method for complex systems based on composite health indicator. Reliab. Eng. Syst. Saf. 2021, 205, 107241. [Google Scholar] [CrossRef]

- Baraldi, P.; Bonfanti, G.; Zio, E. Differential evolution-based multi-objective optimization for the definition of a health indicator for fault diagnostics and prognostics. Mech. Syst. Signal Process. 2018, 102, 382–400. [Google Scholar] [CrossRef]

- Loukopoulos, P.; Zolkiewski, G.; Bennett, I.; Sampath, S.; Pilidis, P.; Li, X.; Mba, D. Abrupt fault remaining useful life estimation using measurements from a reciprocating compressor valve failure. Mech. Syst. Signal Process. 2019, 121, 359–372. [Google Scholar] [CrossRef]

- Zhou, H.; Huang, J.; Lu, F. Reduced kernel recursive least squares algorithm for aero-engine degradation prediction. Mech. Syst. Signal Process. 2017, 95, 446–467. [Google Scholar] [CrossRef]

- Liao, L. Discovering Prognostic Features Using Genetic Programming in Remaining Useful Life Prediction. IEEE Trans. Ind. Electron. 2014, 61, 2464–2472. [Google Scholar] [CrossRef]

- Yan, H.; Liu, K.; Zhang, X.; Shi, J. Multiple Sensor Data Fusion for Degradation Modeling and Prognostics Under Multiple Operational Conditions. IEEE Trans. Reliab. 2016, 65, 1416–1426. [Google Scholar] [CrossRef]

- Liu, Q.; Wang, H.-P. A case study on multisensor data fusion for imbalance diagnosis of rotating machinery. Al Edam 2001, 15, 203–210. [Google Scholar] [CrossRef]

- Liu, K.; Gebraeel, N.; Shi, J. A Data-Level Fusion Model for Developing Composite Health Indices for Degradation Modeling and Prognostic Analysis. IEEE Trans. Autom. Sci. Eng. 2013, 10, 652–664. [Google Scholar] [CrossRef]

- Liu, K.; Huang, S. Integration of data fusion methodology and degradation modeling process to improve prognostics. IEEE Trans. Autom. Sci. Eng. 2016, 13, 344–354. [Google Scholar] [CrossRef]

- Liu, K.; Chehade, A.; Song, C. Optimize the Signal Quality of the Composite Health Index via Data Fusion for Degradation Modeling and Prognostic Analysis. IEEE Trans. Autom. Sci. Eng. 2017, 14, 1504–1514. [Google Scholar] [CrossRef]

- Zhang, D.C.; Stewart, E.; Ye, J.Q.; Entezami, M.; Roberts, C. Roller Bearing Degradation Assessment Based on a Deep MLP Convolution Neural Network Considering Outlier Regions. IEEE Trans. Instrum. Meas. 2020, 69, 2996–3004. [Google Scholar] [CrossRef]

- Hong, S.; Zhou, Z.; Zio, E.; Hong, K. Condition assessment for the performance degradation of bearing based on a combinatorial feature extraction method. Digit. Signal Process. 2014, 27, 159–166. [Google Scholar] [CrossRef]

- Rai, A.; Upadhyay, S.H. An integrated approach to bearing prognostics based on EEMD-multi feature extraction, Gaussian mixture models and Jensen-Rényi divergence. Appl. Soft Comput. 2018, 71, 36–50. [Google Scholar] [CrossRef]

- Yu, W.; Kim, I.I.Y.; Mechefske, C. Remaining useful life estimation using a bidirectional recurrent neural network based autoencoder scheme. Mech. Syst. Signal Process. 2019, 129, 764–780. [Google Scholar] [CrossRef]

- Nguyen, K.T.P.; Medjaher, K. An automated health indicator construction methodology for prognostics based on multi-criteria optimization. ISA Trans. 2021, 113, 81–96. [Google Scholar] [CrossRef] [PubMed]

- Wang, W. A model to predict the residual life of rolling element bearings given monitored condition information to date. IMA J. Manag. Math. 2002, 13, 3–16. [Google Scholar] [CrossRef]

- Wang, Y.; Peng, Y.; Zi, Y.; Jin, X.; Tsui, K. A Two-Stage Data-Driven-Based Prognostic Approach for Bearing Degradation Problem. IEEE Trans. Ind. Inform. 2016, 12, 924–932. [Google Scholar] [CrossRef]

- Qian, Y.; Yan, R.; Hu, S. Bearing Degradation Evaluation Using Recurrence Quantification Analysis and Kalman Filter. IEEE Trans. Instrum. Meas. 2014, 63, 2599–2610. [Google Scholar] [CrossRef]

- Georgoulas, G.; Loutas, T.; Stylios, C.D.; Kostopoulos, V. Bearing fault detection based on hybrid ensemble detector and empirical mode decomposition. Mech. Syst. Signal Process. 2013, 41, 510–525. [Google Scholar] [CrossRef]

- Kimotho, J.; Sondermann-Woelke, C.; Meyer, T.; Sextro, W. Machinery Prognostic Method Based on Multi-Class Support Vector Machines and Hybrid Differential Evolution Particle Swarm Optimization. Chem. Eng. Trans. 2013, 33, 619–624. [Google Scholar]

- Sutrisno, E.; Oh, H.; Vasan, A.S.S.; Pecht, M. Estimation of remaining useful life of ball bearings using data driven methodologies. In Proceedings of the 2012 IEEE Conference on Prognostics and Health Management, Denver, CO, USA, 18–21 June 2012; pp. 1–7. [Google Scholar]

- Hu, Y.; Li, H.; Liao, X.; Song, E.; Liu, H.; Chen, Z. A probability evaluation method of early deterioration condition for the critical components of wind turbine generator systems. Mech. Syst. Signal Process. 2016, 76–77, 729–741. [Google Scholar] [CrossRef]

- Hong, S.; Zhou, Z.; Zio, E.; Wang, W. An adaptive method for health trend prediction of rotating bearings. Digit. Signal Process. 2014, 35, 117–123. [Google Scholar] [CrossRef]

- Ramasso, E.; Rombaut, M.; Zerhouni, N. Joint Prediction of Continuous and Discrete States in Time-Series Based on Belief Functions. IEEE Trans. Syst. Man Cybern. Part B Cybern. 2012, 43, 37–50. [Google Scholar] [CrossRef]

- Javed, K.; Gouriveau, R.; Zerhouni, N. A New Multivariate Approach for Prognostics Based on Extreme Learning Machine and Fuzzy Clustering. IEEE Trans. Cybern. 2015, 45, 2626–2639. [Google Scholar] [CrossRef]

- Scanlon, P.; Kavanagh, D.F.; Boland, F.M. Residual Life Prediction of Rotating Machines Using Acoustic Noise Signals. IEEE Trans. Instrum. Meas. 2013, 62, 95–108. [Google Scholar] [CrossRef]

- Tamilselvan, P.; Wang, Y.; Wang, P. Deep Belief Network based state classification for structural health diagnosis. In Proceedings of the 2012 IEEE Aerospace Conference, Big Sky, MT, USA, 3–10 March 2012; pp. 1–11. [Google Scholar]

- Guo, L.; Gao, H.; Huang, H.; He, X.; Li, S. Multifeatures Fusion and Nonlinear Dimension Reduction for Intelligent Bearing Condition Monitoring. Shock. Vib. 2016, 2016, 4632562. [Google Scholar] [CrossRef]

- Soualhi, A.; Medjaher, K.; Zerhouni, N. Bearing Health Monitoring Based on Hilbert–Huang Transform, Support Vector Machine, and Regression. IEEE Trans. Instrum. Meas. 2015, 64, 52–62. [Google Scholar] [CrossRef]

- Zurita, D.; Carino, J.A.; Delgado, M.; Ortega, J.A. Distributed neuro-fuzzy feature forecasting approach for condition monitoring. In Proceedings of the 2014 IEEE Emerging Technology and Factory Automation (ETFA), Barcelona, Spain, 16–19 September 2014; pp. 1–8. [Google Scholar]

- Kim, H.-E.; Tan, A.C.C.; Mathew, J.; Choi, B.-K. Bearing fault prognosis based on health state probability estimation. Expert Syst. Appl. 2012, 39, 5200–5213. [Google Scholar] [CrossRef]

- Zhang, B.; Sconyers, C.; Byington, C.; Patrick, R.; Orchard, M.E.; Vachtsevanos, G. A Probabilistic Fault Detection Approach: Application to Bearing Fault Detection. IEEE Trans. Ind. Electron. 2011, 58, 2011–2018. [Google Scholar] [CrossRef]

- Yang, B.; Liu, R.; Zio, E. Remaining Useful Life Prediction Based on a Double-Convolutional Neural Network Architecture. IEEE Trans. Ind. Electron. 2019, 66, 9521–9530. [Google Scholar] [CrossRef]

- Chen, S.; Li, X.; Zhang, H.; Chen, G.; Du, X. Vision-based displacement test method for high-rise building shaking table test. J. Vibroeng. 2015, 17, 4057–4068. [Google Scholar]

- Yu, J. Bearing performance degradation assessment using locality preserving projections and Gaussian mixture models. Mech. Syst. Signal Process. 2011, 25, 2573–2588. [Google Scholar] [CrossRef]

- Li, R.; He, D. Rotational Machine Health Monitoring and Fault Detection Using EMD-Based Acoustic Emission Feature Quantification. IEEE Trans. Instrum. Meas. 2012, 61, 990–1001. [Google Scholar] [CrossRef]

- Shakya, P.; Kulkarni, M.S.; Darpe, A.K. A novel methodology for online detection of bearing health status for naturally progressing defect. J. Sound Vib. 2014, 333, 5614–5629. [Google Scholar] [CrossRef]

- Alkaya, A.; Eker, İ. Variance sensitive adaptive threshold-based PCA method for fault detection with experimental application. ISA Trans. 2011, 50, 287–302. [Google Scholar] [CrossRef]

- Gebraeel, N. Sensory-Updated Residual Life Distributions for Components With Exponential Degradation Patterns. IEEE Trans. Autom. Sci. Eng. 2006, 3, 382–393. [Google Scholar] [CrossRef]

- Abbas, M.; Shafiee, M. An overview of maintenance management strategies for corroded steel structures in extreme marine environments. Mar. Struct. 2020, 71, 102718. [Google Scholar] [CrossRef]

- Tang, W.S.; Roman, D.; Dickie, R.; Robu, V.; Flynn, D. Prognostics and Health Management for the Optimization of Marine Hybrid Energy Systems. Energies 2020, 13, 4676. [Google Scholar] [CrossRef]

- Lei, Y.; Li, N.; Lin, J. A New Method Based on Stochastic Process Models for Machine Remaining Useful Life Prediction. IEEE Trans. Instrum. Meas. 2016, 65, 2671–2684. [Google Scholar] [CrossRef]

- Zhao, X.; Nakagawa, T.; Zuo, M.J. Optimal Replacement Last With Continuous and Discrete Policies. IEEE Trans. Reliab. 2014, 63, 868–880. [Google Scholar] [CrossRef]

- Cui, L.; Du, S.; Hawkes, A.G. A study on a single-unit repairable system with state aggregations. IIE Trans. 2012, 44, 1022–1032. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, W.; Hu, C.; Si, X.-S.; Zhang, W. A Prognostic-Information-Based Order-Replacement Policy for a Non-Repairable Critical System in Service. IEEE Trans. Reliab. 2014, 64, 721–735. [Google Scholar] [CrossRef]

- Abou, S.C. Fuzzy-logic-based network for complex systems risk assessment: Application to ship performance analysis. Accid. Anal. Prev. 2012, 45, 305–316. [Google Scholar] [CrossRef] [PubMed]

- Moghaddass, R.; Zuo, M.J. An integrated framework for online diagnostic and prognostic health monitoring using a multistate deterioration process. Reliab. Eng. Syst. Saf. 2014, 124, 92–104. [Google Scholar] [CrossRef]

- Jardine, A.K.S.; Lin, D.; Banjevic, D. A review on machinery diagnostics and prognostics implementing condition-based maintenance. Mech. Syst. Signal Process. 2006, 20, 1483–1510. [Google Scholar] [CrossRef]

- Zio, E. Prognostics and Health Management of Industrial Equipment. In Diagnostics and Prognostics of Engineering Systems: Methods and Techniques; Seifedine, K., Ed.; IGI Global: Hershey, PA, USA, 2013; pp. 333–356. [Google Scholar]

- Wang, T.; Jianbo, Y.; Siegel, D.; Lee, J. A similarity-based prognostics approach for Remaining Useful Life estimation of engineered systems. In Proceedings of the 2008 International Conference on Prognostics and Health Management, Denver, CO, USA, 6–9 October 2008; pp. 1–6. [Google Scholar]

- Medjaher, K.; Tobon-Mejia, D.A.; Zerhouni, N. Remaining Useful Life Estimation of Critical Components With Application to Bearings. IEEE Trans. Reliab. 2012, 61, 292–302. [Google Scholar] [CrossRef]

- Shafiee, M.; Animah, I. Life extension decision making of safety critical systems: An overview. J. Loss Prevent. Proc. 2017, 47, 174–188. [Google Scholar] [CrossRef]

- Okoh, C.; Roy, R.; Mehnen, J.; Redding, L. Overview of Remaining Useful Life Prediction Techniques in Through-life Engineering Services. Procedia CIRP 2014, 16, 158–163. [Google Scholar] [CrossRef]

- Man, J.; Zhou, Q. Prediction of hard failures with stochastic degradation signals using Wiener process and proportional hazards model. Comput. Ind. Eng. 2018, 125, 480–489. [Google Scholar] [CrossRef]

- Zhao, M.; Tang, B.; Tan, Q. Bearing remaining useful life estimation based on time–frequency representation and supervised dimensionality reduction. Measurement 2016, 86, 41–55. [Google Scholar] [CrossRef]

- Li, Y.; Kurfess, T.R.; Liang, S.Y. Stochastic prognostics for rolling element bearings. Mech. Syst. Signal Process. 2000, 14, 747–762. [Google Scholar] [CrossRef]

- Li, C.J.; Lee, H. Gear fatigue crack prognosis using embedded model, gear dynamic model and fracture mechanics. Mech. Syst. Signal Process. 2005, 19, 836–846. [Google Scholar] [CrossRef]

- Da Igle, M.; Kai, G. Multiple damage progression paths in model-based prognostics. In Proceedings of the Aerospace Conference, Big Sky, MT, USA, 5–12 March 2011. [Google Scholar]

- Oppenheimer, C.; Loparo, K. Physically based diagnosis and prognosis of cracked rotor shafts. In Proceedings of SPIE-The International Society for Optical Engineering; International Society for Optics and Photonics: Hinesburg, VT, USA, 2002. [Google Scholar]

- Liu, Y.; Hu, X.; Zhang, W. Remaining useful life prediction based on health index similarity. Reliab. Eng. Syst. Saf. 2019, 185, 502–510. [Google Scholar] [CrossRef]

- Javed, K.; Gouriveau, R.; Zerhouni, N. State of the art and taxonomy of prognostics approaches, trends of prognostics applications and open issues towards maturity at different technology readiness levels. Mech. Syst. Signal Process. 2017, 94, 214–236. [Google Scholar] [CrossRef]

- Pan, Y.; Hong, R.; Chen, J.; Singh, J.; Jia, X. Performance degradation assessment of a wind turbine gearbox based on multi-sensor data fusion. Mech. Mach. Theory 2019, 137, 509–526. [Google Scholar] [CrossRef]

- Hu, Y.; Li, H.; Shi, P.; Chai, Z.; Wang, K.; Xie, X.; Chen, Z. A prediction method for the real-time remaining useful life of wind turbine bearings based on the Wiener process. Renew. Energy 2018, 127, 452–460. [Google Scholar] [CrossRef]

- Dong, Q.; Zheng, J.-F.; Hu, C.-H.; Li, B.; Han-Xiao, M. Remaining useful life prognostic method based on two-stage adaptive wiener process. Acta Autom. Sin. 2021, 47, 539–553. [Google Scholar]

- Si, X.-S.; Wang, W.; Hu, C.-H.; Zhou, D.-H. Remaining useful life estimation—A review on the statistical data driven approaches. Eur. J. Oper. Res. 2011, 213, 1–14. [Google Scholar] [CrossRef]

- Xing, Y.; Ma, E.W.M.; Tsui, K.-L.; Pecht, M. An ensemble model for predicting the remaining useful performance of lithium-ion batteries. Microelectron. Reliab. 2013, 53, 811–820. [Google Scholar] [CrossRef]

- Ahmad, W.; Khan, S.A.; Islam, M.M.M.; Kim, J.-M. A reliable technique for remaining useful life estimation of rolling element bearings using dynamic regression models. Reliab. Eng. Syst. Saf. 2019, 184, 67–76. [Google Scholar] [CrossRef]

- Gebraeel, N.; Lawley, M.; Li, R.; Ryan, J. Residual-life distribution from component degradation signals: A Bayesian approach. Iie Trans. 2005, 37, 543–557. [Google Scholar] [CrossRef]

- Ben Ali, J.; Chebel-Morello, B.; Saidi, L.; Malinowski, S.; Fnaiech, F. Accurate bearing remaining useful life prediction based on Weibull distribution and artificial neural network. Mech. Syst. Signal Process. 2015, 56, 150–172. [Google Scholar] [CrossRef]

- Kumar, D.; Klefsjö, B. Proportional hazards model: A review. Reliab. Eng. Syst. Saf. 1994, 44, 177–188. [Google Scholar] [CrossRef]

- Si, X.-S.; Wang, W.; Hu, C.-H.; Chen, M.-Y.; Zhou, D.-H. A Wiener-process-based degradation model with a recursive filter algorithm for remaining useful life estimation. Mech. Syst. Signal Process. 2013, 35, 219–237. [Google Scholar] [CrossRef]

- Qin, A.; Zhang, Q.; Hu, Q.; Sun, G.; He, J.; Lin, S. Remaining Useful Life Prediction for Rotating Machinery Based on Optimal Degradation Indicator. Shock. Vib. 2017, 2017, 6754968. [Google Scholar] [CrossRef]

- Wang, X. Wiener processes with random effects for degradation data. J. Multivar. Anal. 2010, 101, 340–351. [Google Scholar] [CrossRef]

- Ye, Z.; Wang, Y.; Tsui, K.; Pecht, M. Degradation Data Analysis Using Wiener Processes With Measurement Errors. IEEE Trans. Reliab. 2013, 62, 772–780. [Google Scholar] [CrossRef]

- van Noortwijk, J.M. A survey of the application of gamma processes in maintenance. Reliab. Eng. Syst. Saf. 2009, 94, 2–21. [Google Scholar] [CrossRef]

- Lawless, J.; Crowder, M. Covariates and Random Effects in a Gamma Process Model with Application to Degradation and Failure. Lifetime Data Anal. 2004, 10, 213–227. [Google Scholar] [CrossRef]

- Ye, Z.-S.; Chen, N. The Inverse Gaussian Process as a Degradation Model. Technometrics 2014, 56, 302–311. [Google Scholar] [CrossRef]

- Wang, X.; Xu, D. An Inverse Gaussian Process Model for Degradation Data. Technometrics 2010, 52, 188–197. [Google Scholar] [CrossRef]

- Wen, X.; Wang, Z.; Fu, H.; Wu, Q.; Liu, C. BLUEs and Reliability Analysis for General Censored Data Subject to Inverse Gaussian Distribution. IEEE Trans. Reliab. 2019, 68, 1257–1271. [Google Scholar] [CrossRef]

- Geramifard, O.; Xu, J.-X.; Zhou, J.-H.; Li, X. A Physically Segmented Hidden Markov Model Approach for Continuous Tool Condition Monitoring: Diagnostics and Prognostics. IEEE Trans. Ind. Inf. 2012, 8, 964–973. [Google Scholar] [CrossRef]

- Yu, J.; Liang, S.; Tang, D.; Liu, H. A weighted hidden Markov model approach for continuous-state tool wear monitoring and tool life prediction. Int. J. Adv. Manuf. Technol. 2017, 91, 201–211. [Google Scholar] [CrossRef]

- Loutas, T.; Eleftheroglou, N.; Georgoulas, G.; Loukopoulos, P.; Mba, D.; Bennett, I. Valve Failure Prognostics in Reciprocating Compressors Utilizing Temperature Measurements, PCA-Based Data Fusion, and Probabilistic Algorithms. IEEE Trans. Ind. Electron. 2019, 67, 5022–5029. [Google Scholar] [CrossRef]

- Peng, Y.; Dong, M. A prognosis method using age-dependent hidden semi-Markov model for equipment health prediction. Mech. Syst. Signal Process. 2011, 25, 237–252. [Google Scholar] [CrossRef]

- Dong, M.; He, D. Hidden semi-Markov model-based methodology for multi-sensor equipment health diagnosis and prognosis. Eur. J. Oper. Res. 2007, 178, 858–878. [Google Scholar] [CrossRef]

- Dong, M.; He, D. A segmental hidden semi-Markov model (HSMM)-based diagnostics and prognostics framework and methodology. Mech. Syst. Signal Process. 2007, 21, 2248–2266. [Google Scholar] [CrossRef]

- Dong, M.; He, D.; Banerjee, P.; Keller, J. Equipment health diagnosis and prognosis using hidden semi-Markov models. Int. J. Adv. Manuf. Technol. 2006, 30, 738–749. [Google Scholar] [CrossRef]

- Kan, M.S.; Tan, A.C.C.; Mathew, J. A review on prognostic techniques for non-stationary and non-linear rotating systems. Mech. Syst. Signal Process. 2015, 62–63, 1–20. [Google Scholar] [CrossRef]

- Si, X. An Adaptive Prognostic Approach via Nonlinear Degradation Modeling: Application to Battery Data. IEEE Trans. Ind. Electron. 2015, 62, 5082–5096. [Google Scholar] [CrossRef]

- Liu, D.; Luo, Y.; Liu, J.; Peng, Y.; Guo, L.; Pecht, M. Lithium-ion battery remaining useful life estimation based on fusion nonlinear degradation AR model and RPF algorithm. Neural Comput. Appl. 2014, 25, 557–572. [Google Scholar] [CrossRef]

- Zio, E.; Peloni, G. Particle filtering prognostic estimation of the remaining useful life of nonlinear components. Reliab. Eng. Syst. Saf. 2011, 96, 403–409. [Google Scholar] [CrossRef]

- Tian, Z. An artificial neural network approach for remaining useful life prediction of equipments subject to condition monitoring. In Proceedings of the 2009 8th International Conference on Reliability, Maintainability and Safety, Chengdu, China, 20–24 July 2009; pp. 143–148. [Google Scholar]

- Gebraeel, N.; Lawley, M.; Liu, R.; Parmeshwaran, V. Residual life predictions from vibration-based degradation signals: A neural network approach. IEEE Trans. Ind. Electron. 2004, 51, 694–700. [Google Scholar] [CrossRef]

- Mahamad, A.K.; Saon, S.; Hiyama, T. Predicting remaining useful life of rotating machinery based artificial neural network. Comput. Math. Appl. 2010, 60, 1078–1087. [Google Scholar] [CrossRef]

- Vachtsevanos, G.; Wang, P. Fault prognosis using dynamic wavelet neural networks. In Proceedings of the 2001 IEEE Autotestcon Proceedings. IEEE Systems Readiness Technology Conference (Cat. No.01CH37237), Valley Forge, PA, USA, 20–23 August 2001; pp. 857–870. [Google Scholar]

- Cui, X.J.; Yang, C.L.; Serrano, J.R.; Shi, M.W. A performance degradation evaluation method for a turbocharger in a diesel engine. R. Soc. Open Sci. 2018, 5, 181093. [Google Scholar] [CrossRef]

- Zhang, Y.; Xiong, R.; He, H.; Pecht, M.G. Long Short-Term Memory Recurrent Neural Network for Remaining Useful Life Prediction of Lithium-Ion Batteries. IEEE Trans. Veh. Technol. 2018, 67, 5695–5705. [Google Scholar] [CrossRef]

- Sun, C.; Ma, M.; Zhao, Z.; Tian, S.; Yan, R.; Chen, X. Deep Transfer Learning Based on Sparse Autoencoder for Remaining Useful Life Prediction of Tool in Manufacturing. IEEE Trans. Ind. Inform. 2019, 15, 2416–2425. [Google Scholar] [CrossRef]

- Dong, S.; Luo, T. Bearing degradation process prediction based on the PCA and optimized LS-SVM model. Measurement 2013, 46, 3143–3152. [Google Scholar] [CrossRef]

- Carino, J.A.; Zurita, D.; De Lgado, M.; Ortega, J.A.; Romero-Troncoso, R.J. Remaining useful life estimation of ball bearings by means of monotonic score calibration. In Proceedings of the IEEE International Conference on Industrial Technology, Seville, Spain, 17–19 March 2015; pp. 1752–1758. [Google Scholar]

- Manjurul Islam, M.M.; Prosvirin, A.E.; Kim, J.-M. Data-driven prognostic scheme for rolling-element bearings using a new health index and variants of least-square support vector machines. Mech. Syst. Signal Process. 2021, 160, 107853. [Google Scholar] [CrossRef]

- Benkedjouh, T.; Medjaher, K.; Zerhouni, N.; Rechak, S. Remaining useful life estimation based on nonlinear feature reduction and support vector regression. Eng. Appl. Artif. Intell. 2013, 26, 1751–1760. [Google Scholar] [CrossRef]

- Tipping, M.E. Bayesian Inference: An Introduction to Principles and Practice in Machine Learning. In Advanced Lectures on Machine Learning, Ml Summer Schools, Canberra, Australia, February, Tübingen, Germany, August, Revised Lectures; Springer: Berlin/Heidelberg, Germany, 2003. [Google Scholar]

- Widodo, A.; Yang, B.-S. Application of relevance vector machine and survival probability to machine degradation assessment. Expert Syst. Appl. 2011, 38, 2592–2599. [Google Scholar] [CrossRef]

- Boškoski, P.; Gašperin, M.; Petelin, D.; Juričić, Đ. Bearing fault prognostics using Rényi entropy based features and Gaussian process models. Mech. Syst. Signal Process. 2015, 52–53, 327–337. [Google Scholar] [CrossRef]

- Yu, J. State of health prediction of lithium-ion batteries: Multiscale logic regression and Gaussian process regression ensemble. Reliab. Eng. Syst. Saf. 2018, 174, 82–95. [Google Scholar] [CrossRef]

- Wang, Z.; Ma, J.; Zhang, L. State-of-Health Estimation for Lithium-Ion Batteries Based on the Multi-Island Genetic Algorithm and the Gaussian Process Regression. IEEE Access 2017, 5, 21286–21295. [Google Scholar] [CrossRef]

- Kong, D.; Chen, Y.; Li, N. Gaussian process regression for tool wear prediction. Mech. Syst. Signal Process. 2018, 104, 556–574. [Google Scholar] [CrossRef]

- Liu, D.; Pang, J.; Zhou, J.; Peng, Y.; Pecht, M. Prognostics for state of health estimation of lithium-ion batteries based on combination Gaussian process functional regression. Microelectron. Reliab. 2013, 53, 832–839. [Google Scholar] [CrossRef]

- An, D.; Kim, N.H.; Choi, J.-H. Practical options for selecting data-driven or physics-based prognostics algorithms with reviews. Reliab. Eng. Syst. Saf. 2015, 133, 223–236. [Google Scholar] [CrossRef]

- Chen, Z.; Cao, S.; Mao, Z. Remaining Useful Life Estimation of Aircraft Engines Using a Modified Similarity and Supporting Vector Machine (SVM) Approach. Energies 2017, 11, 28. [Google Scholar] [CrossRef]

- Lu, Y.; Christou, A. Prognostics of IGBT modules based on the approach of particle filtering. Microelectron. Reliab. 2019, 92, 96–105. [Google Scholar] [CrossRef]

- Peng, W.; Li, Y.-F.; Yang, Y.-J.; Huang, H.-Z.; Zuo, M.J. Inverse Gaussian process models for degradation analysis: A Bayesian perspective. Reliab. Eng. Syst. Saf. 2014, 130, 175–189. [Google Scholar] [CrossRef]

- Wang, P.; Tang, Y.; Bae, S.J.; Xu, A. Bayesian Approach for Two-Phase Degradation Data Based on Change-Point Wiener Process With Measurement Errors. IEEE Trans. Reliab. 2018, 67, 688–700. [Google Scholar] [CrossRef]

- Yan, B.; Ma, X.; Huang, G.; Zhao, Y. Two-stage physics-based Wiener process models for online RUL prediction in field vibration data. Mech. Syst. Signal Process. 2021, 152, 107378. [Google Scholar] [CrossRef]

- Ma, G.; Zhang, Y.; Cheng, C.; Zhou, B.; Hu, P.; Yuan, Y. Remaining useful life prediction of lithium-ion batteries based on false nearest neighbors and a hybrid neural network. Appl. Energy 2019, 253, 113626. [Google Scholar] [CrossRef]

- Wei, Z.; Tao, T.; ZhuoShu, D.; Zio, E. A dynamic particle filter-support vector regression method for reliability prediction. Reliab. Eng. Syst. Saf. 2013, 119, 109–116. [Google Scholar] [CrossRef]

- Niu, G.; Yang, B.-S. Intelligent condition monitoring and prognostics system based on data-fusion strategy. Expert Syst. Appl. 2010, 37, 8831–8840. [Google Scholar] [CrossRef]

- Ding, Y.; Jia, M.; Miao, Q.; Huang, P. Remaining useful life estimation using deep metric transfer learning for kernel regression. Reliab. Eng. Syst. Saf. 2021, 212, 107583. [Google Scholar] [CrossRef]

- Yu, J. Machine health prognostics using the Bayesian-inference-based probabilistic indication and high-order particle filtering framework. J. Sound Vib. 2015, 358, 97–110. [Google Scholar] [CrossRef]

- Zhicai, Z.; Dongfeng, L.; Xinfa, S. Research on combination of data-driven and probability-based prognostics techniques for equipments. In Proceedings of the 2014 Prognostics and System Health Management Conference (PHM-2014 Hunan), Zhangjiajie, China, 24–27 August 2014; pp. 323–326. [Google Scholar]

- Byington, C.S.; Watson, M.J.; Sheldon, J.S.; Swerdon, G.M. Shaft coupling model-based prognostics enhanced by vibration diagnostics. OR Insight 2009, 51, 420–425. [Google Scholar] [CrossRef]

- Shafiee, M. Maintenance strategy selection problem: An MCDM overview. J. Qual. Maint. Eng. 2015, 21, 378–402. [Google Scholar] [CrossRef]

- Arunraj, N.S.; Maiti, J. Risk-based maintenance—Techniques and applications. J. Hazard. Mater. 2007, 142, 653–661. [Google Scholar] [CrossRef]

- Blache, K.M.; Shrivastava, A.B. Reliability and Maintainability of Machinery and Equipment for Effective Maintenance; SAE Technical Paper 930569; SAE International: Warrendale, PA, USA, 1993; Volume 1. [Google Scholar]

- Pickthorne, M. International safety management code. Uporedno Pomor. Pravo = Comp. Marit. Law 1994, 38, 149–152. [Google Scholar]

- Lazakis, I.; Raptodimos, Y.; Varelas, T. Predicting ship machinery system condition through analytical reliability tools and artificial neural networks. Ocean Eng. 2018, 152, 404–415. [Google Scholar] [CrossRef]

- Selvik, J.; Scarf, P.; Aven, T. An extended methodology for risk based inspection planning. Reliab. Theory Appl. 2011, 6, 115–126. [Google Scholar]

- Anantharaman, M. Using Reliability Block Diagrams and Fault Tree circuits, to develop a Condition Based Maintenance Model for a Vessel’s Main Propulsion System and Related Subsystems. TransNav Int. J. Mar. Navig. Saf. Sea Transp. 2013, 7, 409–413. [Google Scholar] [CrossRef][Green Version]

- Cullum, J.; Binns, J.; Lonsdale, M.; Abbassi, R.; Garaniya, V. Risk-Based Maintenance Scheduling with application to naval vessels and ships. Ocean Eng. 2018, 148, 476–485. [Google Scholar] [CrossRef]

- Mulford, E.; Carrasquilla, J.; Moreno, G. Proactive Maintenance in the Azimuth Marine Propulsion: SCHOTTEL Condition Monitoring Solutions. In Proceedings of the VI International Ship Design & Naval Engineering Congress (CIDIN) and XXVI Pan-American Congress of Naval Engineering, Maritime Transportation and Port Engineering (COPINAVAL), Cartagena, Colombia, 13–15 March 2019; pp. 413–423. [Google Scholar]

- Potter, A.; Al-Kaabi, H.; Naim, M. Aircraft maintenance, repair and overhaul. In The Global Commercial Aviation Industry; Taylor & Francis Group: Oxford, UK, 2015; pp. 170–189. [Google Scholar]

- Igba, J.; Alemzadeh, K.; Anyanwu-Ebo, I.; Gibbons, P.; Friis, J. A Systems Approach Towards Reliability-Centred Maintenance (RCM) of Wind Turbines. Procedia. Comput. Sci. 2013, 16, 814–823. [Google Scholar] [CrossRef]

- Yssaad, B.; Khiat, M.; Chaker, A. Reliability centered maintenance optimization for power distribution systems. Int. J. Electr. Power Energy Syst. 2014, 55, 108–115. [Google Scholar] [CrossRef]

- Yssaad, B.; Abene, A. Rational Reliability Centered Maintenance Optimization for power distribution systems. Int. J. Electr. Power Energy Syst. 2015, 73, 350–360. [Google Scholar] [CrossRef]

- Mkandawire, B.O.B.; Ijumba, N.; Saha, A. Transformer risk modelling by stochastic augmentation of reliability-centred maintenance. Electr. Power Syst. Res. 2015, 119, 471–477. [Google Scholar] [CrossRef]

- Jian, G.; Li, Z.; Wolf, J. Reliability centered preventive maintenance optimization for aircraft indicators. In Proceedings of the 2016 Annual Reliability and Maintainability Symposium (RAMS), Tucson, AZ, USA, 25–28 January 2016. [Google Scholar]

- Cotaina, N.; Matos, F.; Chabrol, J.; Djeapragache, D.; Prete, P.; Carretero, J.; García, F.; Pérez, M.; Peña, J.; Pérez, J. Study of existing reliability centered maintenance (rcm) approaches used in different industries. Nav. Eng. J. 2000, 110, 89–97. [Google Scholar]

- Lazakis, I.; Turan, O.; Aksu, S.; Incecik, A. Increasing ship operational reliability through the implementation of a holistic maintenance management strategy. Ships Offshore Struc. 2011, 6, 175. [Google Scholar] [CrossRef]

- Conachey, R.M. ABS Technical Papers 2005 Development of Machinery Survey Requirements Based on Reliability-Centered Maintenance. 2014. Available online: https://citeseerx.ist.psu.edu/viewdoc/download?doi=10.1.1.432.8321&rep=rep1&type=pdf (accessed on 10 November 2021).

- Eriksen, S.; Utne, I.B.; Lützen, M. An RCM approach for assessing reliability challenges and maintenance needs of unmanned cargo ships. Reliab. Eng. Syst. Saf. 2021, 210, 107550. [Google Scholar] [CrossRef]

- Baliwangi, L.; Ishida, K.; Arima, H.; Artana, K.B. Optimizing Ship Machinery Maintenance Scheduling Through Risk Analysis and Life Cycle Cost Analysis. In Proceedings of the International Conference on Offshore Mechanics & Arctic Engineering, Hamburg, Germany, 4–9 June 2006; Volume 3, pp. 127–134. [Google Scholar]

- Diamantoulaki, I.; Angelides, D.C.J.S.S. Risk-based maintenance scheduling using monitoring data for moored floating breakwaters. Struct. Saf. 2013, 41, 107–118. [Google Scholar] [CrossRef]

- Dong, Y.; Frangopol, D.M. Risk-informed life-cycle optimum inspection and maintenance of ship structures considering corrosion and fatigue. Ocean Eng. 2015, 101, 161–171. [Google Scholar] [CrossRef]

- Handani, D.W.; Ishida, K.; Nishimura, S.; Hariyanto, S. Ieee, System Dynamics Simulation for Constructing Maintenance Management of Ship Machinery. In Proceedings of the 2011 IEEE International Conference on Industrial Engineering and Engineering Management, Singapore, Singapore, 6–9 December 2011; pp. 1549–1553. [Google Scholar]

- Giorgio, M.; Guida, M.; Pulcini, G. A condition-based maintenance policy for deteriorating units. An application to the cylinder liners of marine engine. Appl. Stoch. Model. Bus. 2015, 31, 339–348. [Google Scholar] [CrossRef]

- Iung, B.; Levrat, E.; Marquez, A.C.; Erbe, H. Conceptual framework for e-Maintenance: Illustration by e-Maintenance technologies and platforms. Annu. Rev. Control 2009, 33, 220–229. [Google Scholar] [CrossRef]

- Muller, A.; Marquez, A.C.; Iung, B. On the concept of e-maintenance: Review and current research. Reliab. Eng. Syst. Saf. 2008, 93, 1165–1187. [Google Scholar] [CrossRef]

- He, K.; Jia, M.; Liu, C.; Zhao, Z. Sensor layout optimization by integrating Bayesian approach to diagnose multi-station assembly processes. Measurement 2019, 146, 230–240. [Google Scholar] [CrossRef]

- Li, J.; Li, H.; Wang, F.; Cheng, A.S.K.; Yang, X.; Wang, H. Proactive analysis of construction equipment operators’ hazard perception error based on cognitive modeling and a dynamic Bayesian network. Reliab. Eng. Syst. Saf. 2021, 205, 107203. [Google Scholar] [CrossRef]

| Technical Processes | Constitution | Description |

|---|---|---|

| HCM |

| HCM is to use various monitoring data, information, and knowledge to realize the monitoring and assessment of MSAE health conditions. |

| ||

| ||

| FD |

| FD exhibits an important role in demonstrating the relationship between the HCM information to the health condition. |

| ||

| ||

| HP |

| HP aims to predict the RUL of machinery based on the historical and ongoing degradation trends observed from HCM information. |

| ||

| ||

| MD |

| MD is to consider the coordination of health and safety of assets from a management perspective in the whole life cycle. |

| ||

| ||

|

| Communication Technology | Communication Features | Scope of Application |

|---|---|---|

| Universal mobile communication network. | Low communication cost and large network bandwidth; small coverage and low network security. | Suitable for inland rivers and offshore ships. |

| Automatic identification system (AIS) | Can directly realize the speed measurement navigation function of ship positioning and monitoring and carry out information broadcasting; high service cost, seriously affected by electromagnetic environment interference, communication distance is limited. | Suitable for inland rivers and offshore ships. |

| Maritime satellite | Can provide data link for ocean-going ships; high cost, low communication bandwidth, maximum speed is only 492 Kbps. | Suitable for global navigation ships. |

| Spread spectrum communication technology | Strong concealment and good anti-interference performance; the system uses a wide frequency band and has a limited data transmission rate and distance. | Suitable for inland rivers and offshore ships. |

| GPS | Accurate positioning and strong anti-interference ability. | Only applicable to ship positioning, unable toachieve communication. |

| BDS | All-weather, all-day, high-precision positioning; short message communication has low cost and high | Suitable for global navigation ships. |

| Methodologies | References | Marine Objects | |

|---|---|---|---|

| Physics model-based method | Bond graph | (Tan et al., Huang et al., Pedersen and Pedersen, Huang et al., Huang et al.) [73,74,121,122,123] | Feedwater system Condenser Power system Diesel engine |

| Parity space | (Benetazzo et al.) [124] | Dynamic positioning system | |

| Parameter estimation | (Wang et al., Nagy-Kiss et al., Torres et al. Zhang and Chen, Zhou, et al.) [76,125,126,127,128] | Raisers Current turbine Prolusion system | |

| Observers | (Chu et al., Cui et al., Lootsma et al., Qiao and Yang, Wang and Han, Zhou et al.) [78,129,130,131,132,133] | Underwater thruster Propulsion system Unmanned surface vehicle | |

| Knowledge-based methods | Rule-based reasoning | (Xu et al., Hein et al., Roy, Coenen and Smeaton.) [81,85,134,135] | Power system Diesel engine |

| Fuzzy logic-based reasoning | (Berredjem and Benidir, Ahmed and Gu, Shah and Wang, Qiao and Yang.) [88,89,90,136] | Boiler Prolusion system Bearing | |

| Neural network-based reasoning | (Wu et al.) [91] | Diesel engine | |