General Cutting Load Model for Workload Simulation in Spindle Reliability Test

Abstract

:1. Introduction

2. Establishment of Cutting Load Model Based on Rat Decomposition

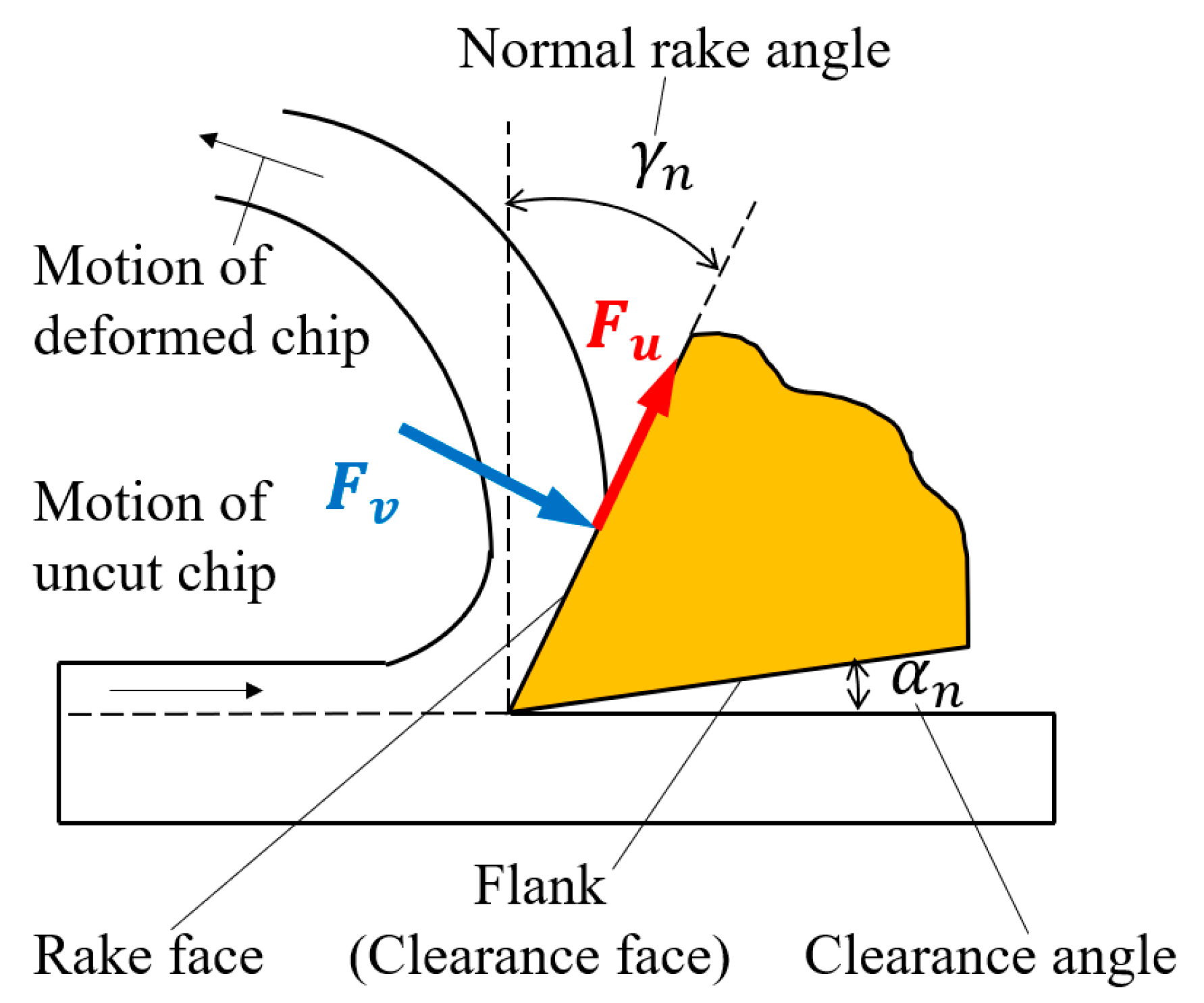

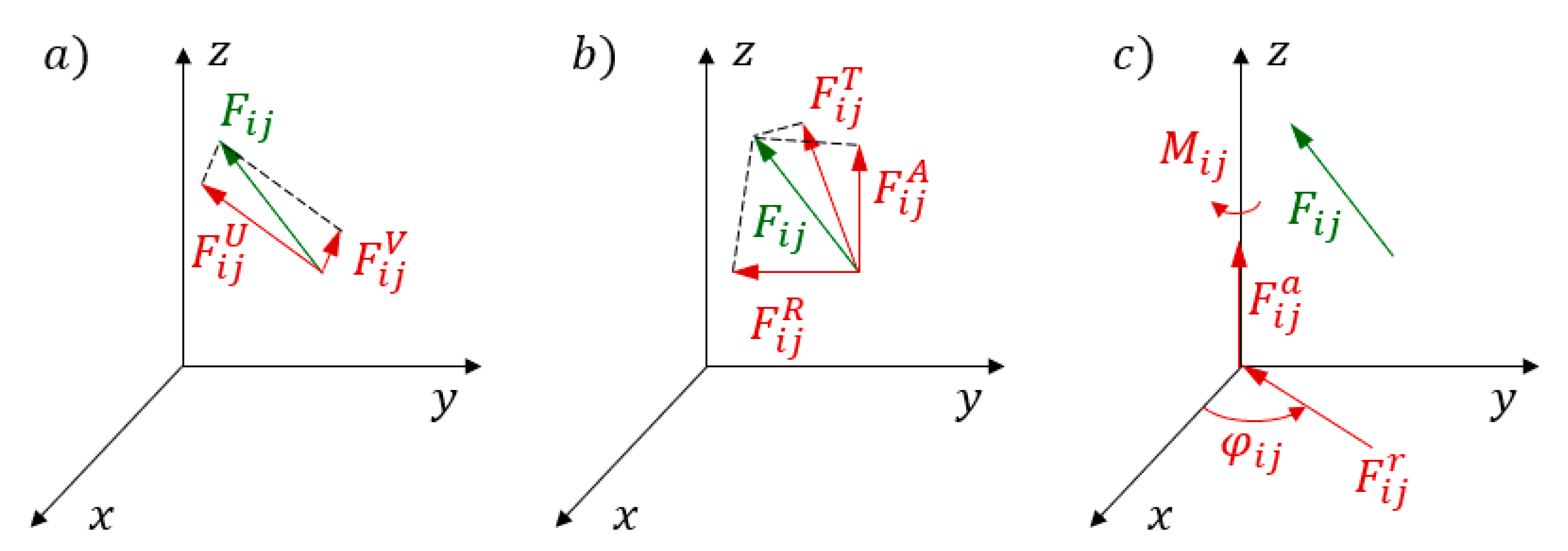

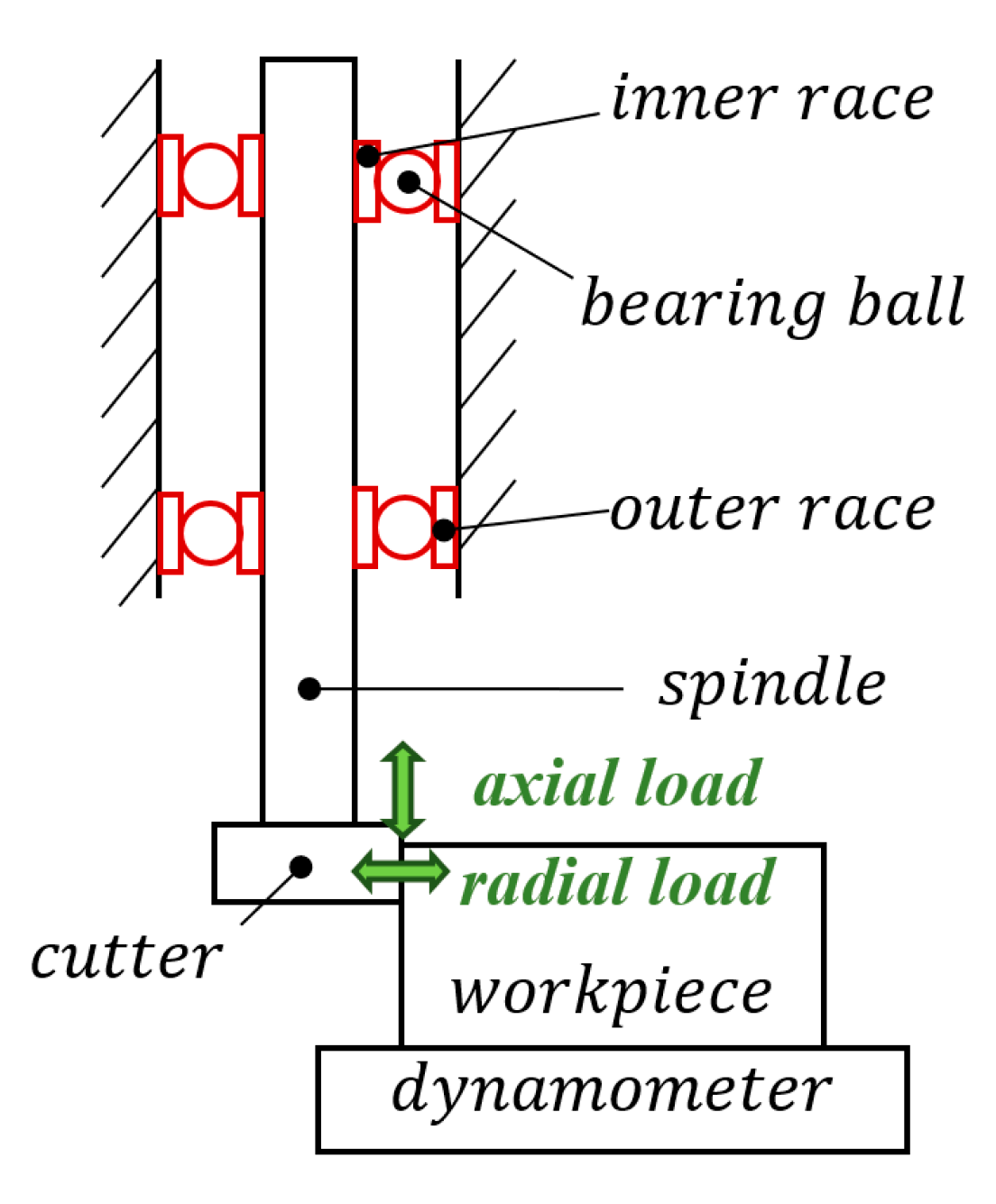

2.1. Establishment of Micro-Element Model

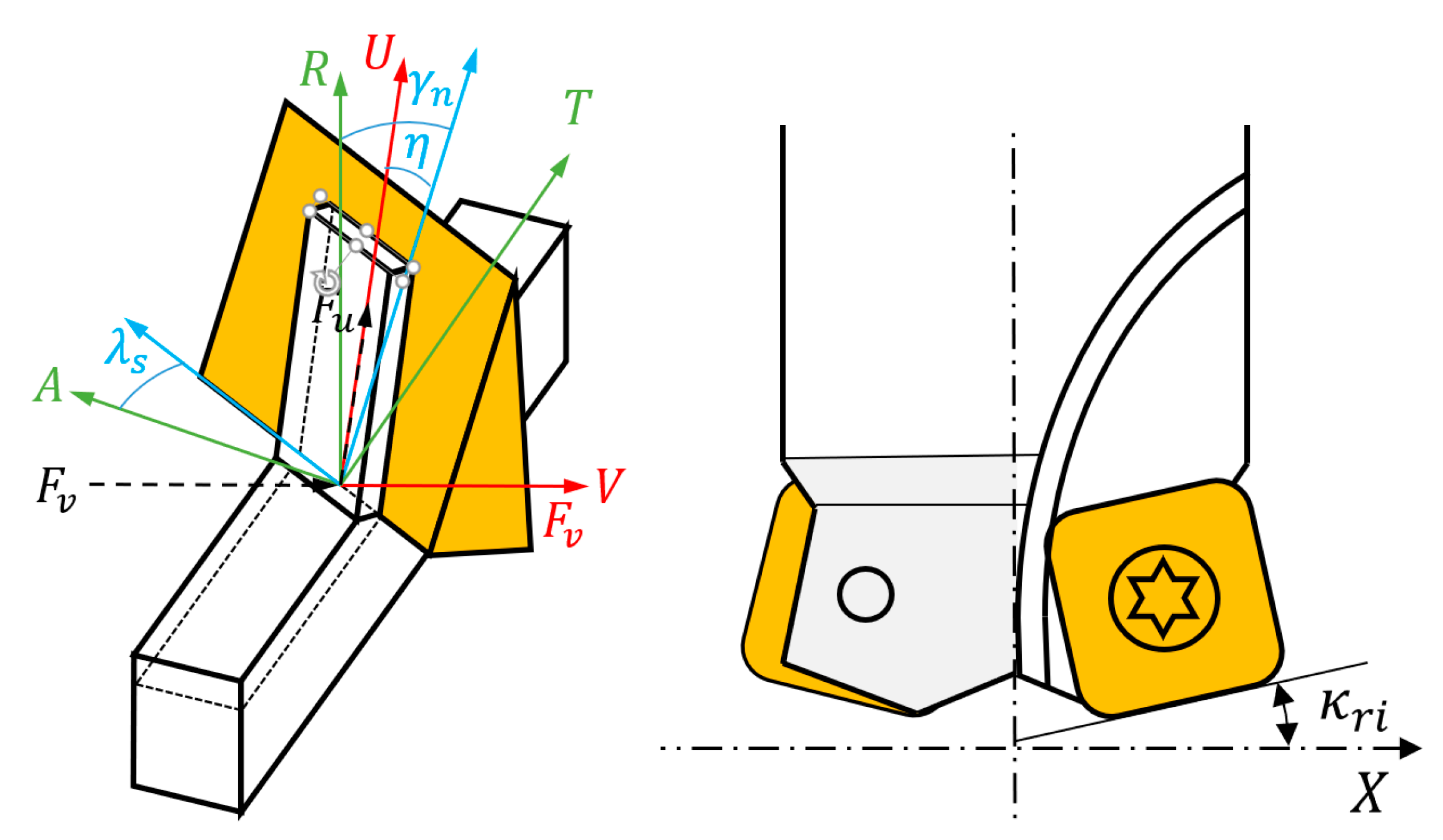

2.2. Establishment of Micro-Element Load Model under RAT Decomposition

2.3. Establishment of the General Cutting Load Model of Spindle

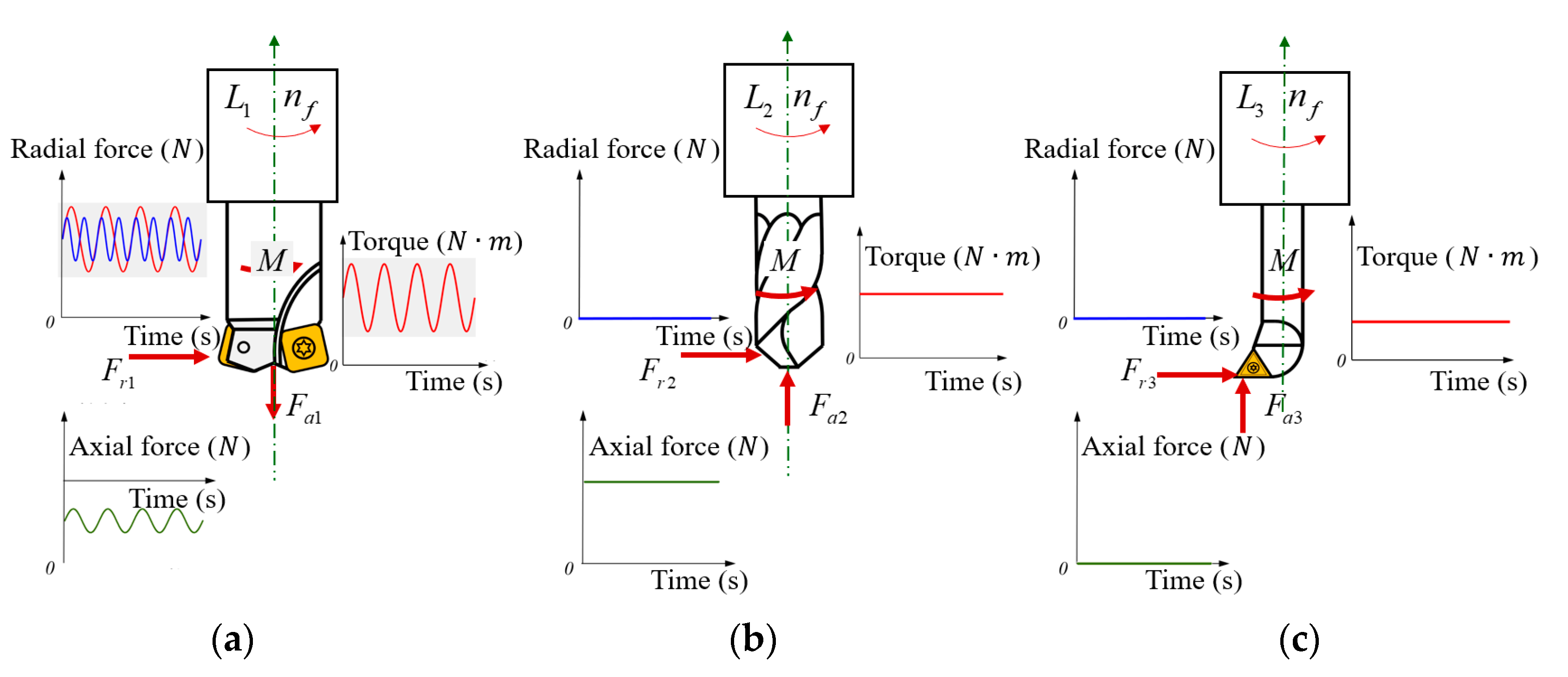

2.3.1. Cutting Load Model under Milling Operation

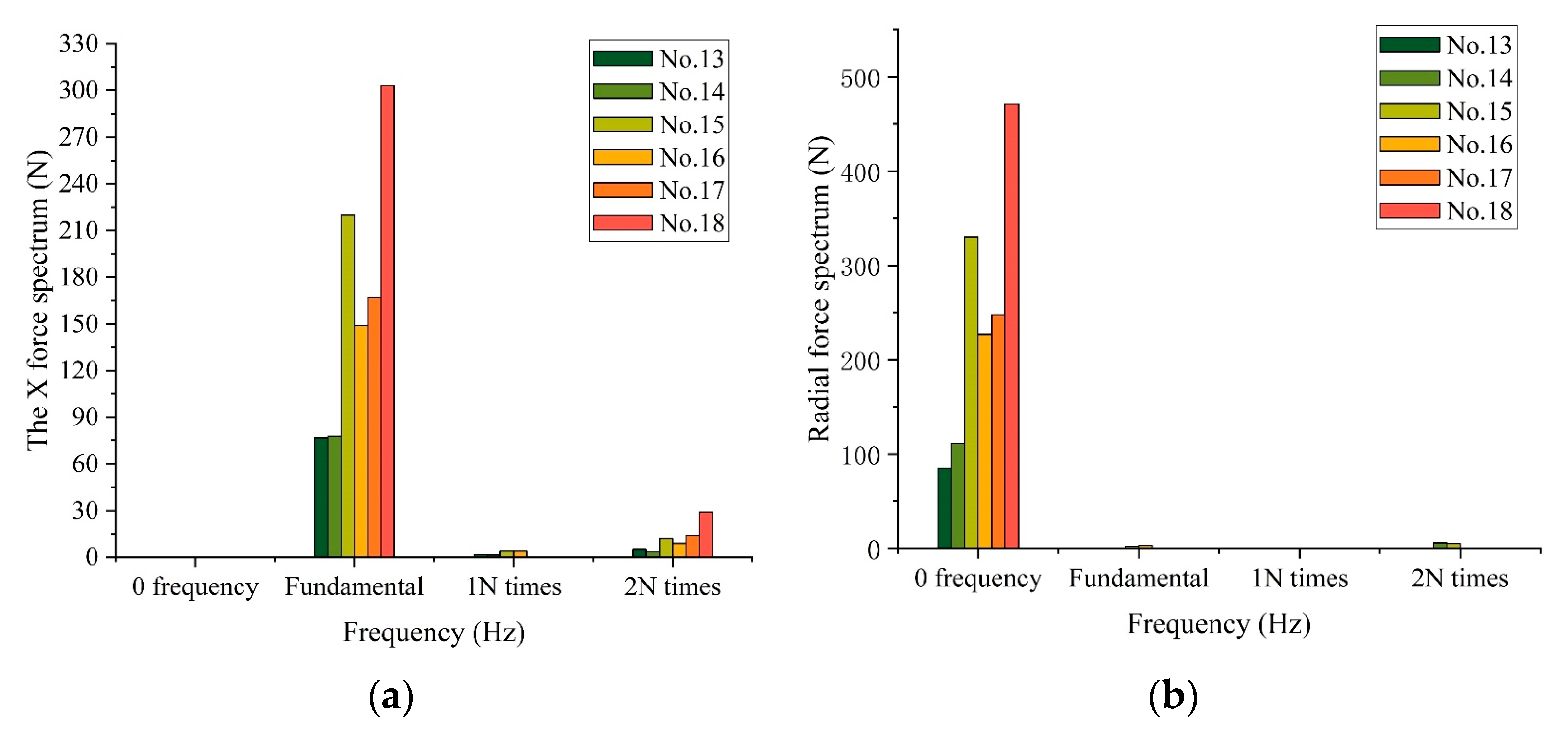

2.3.2. Cutting Load Model under Drilling Operation

2.3.3. Cutting Load Model under Boring Operation

- Milling:

- Drilling:

- Single point boring:

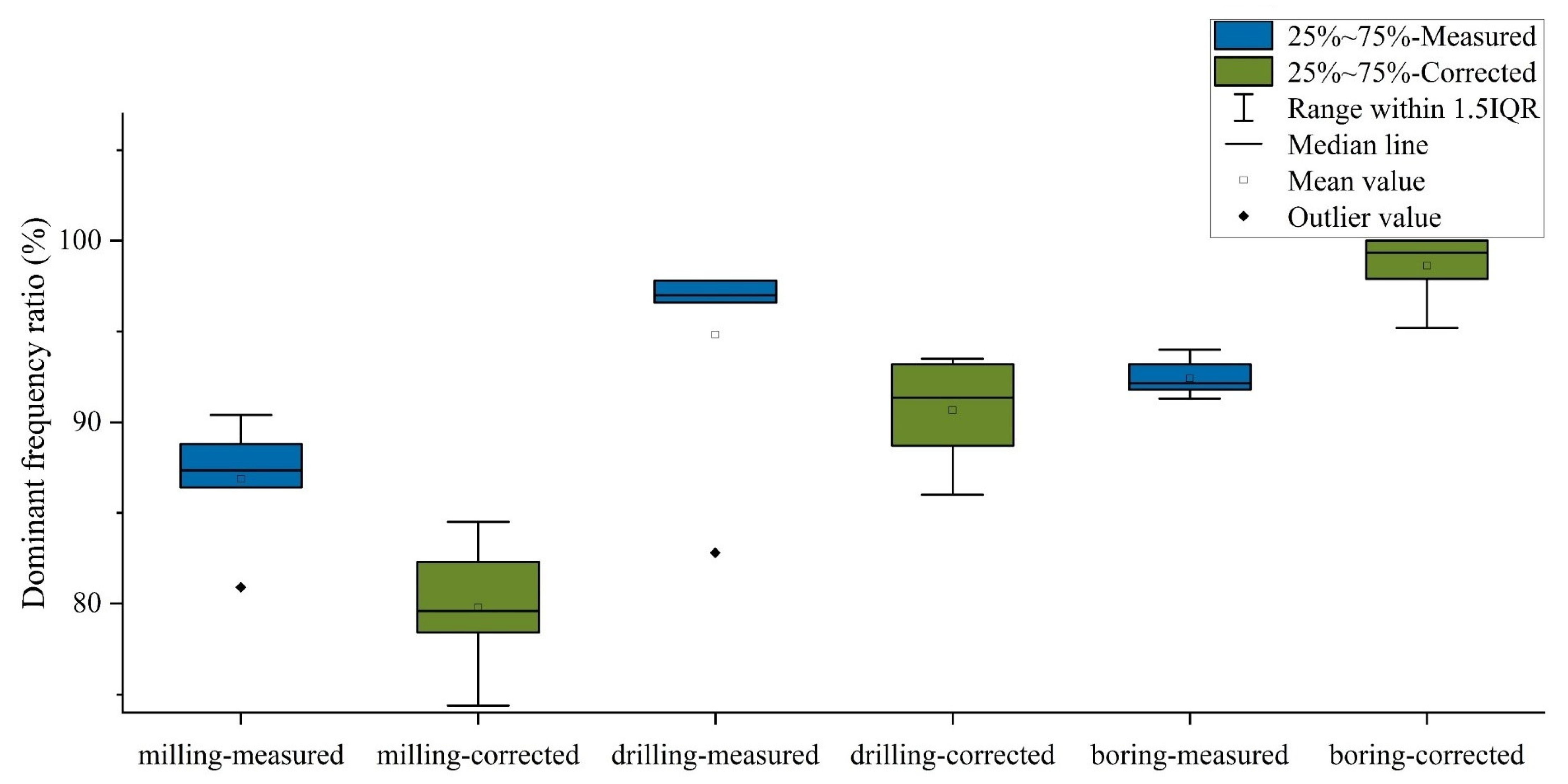

3. Correction and Verification of General Cutting Load Model of the Spindle

3.1. Correction of General Cutting Load Model for Spindle

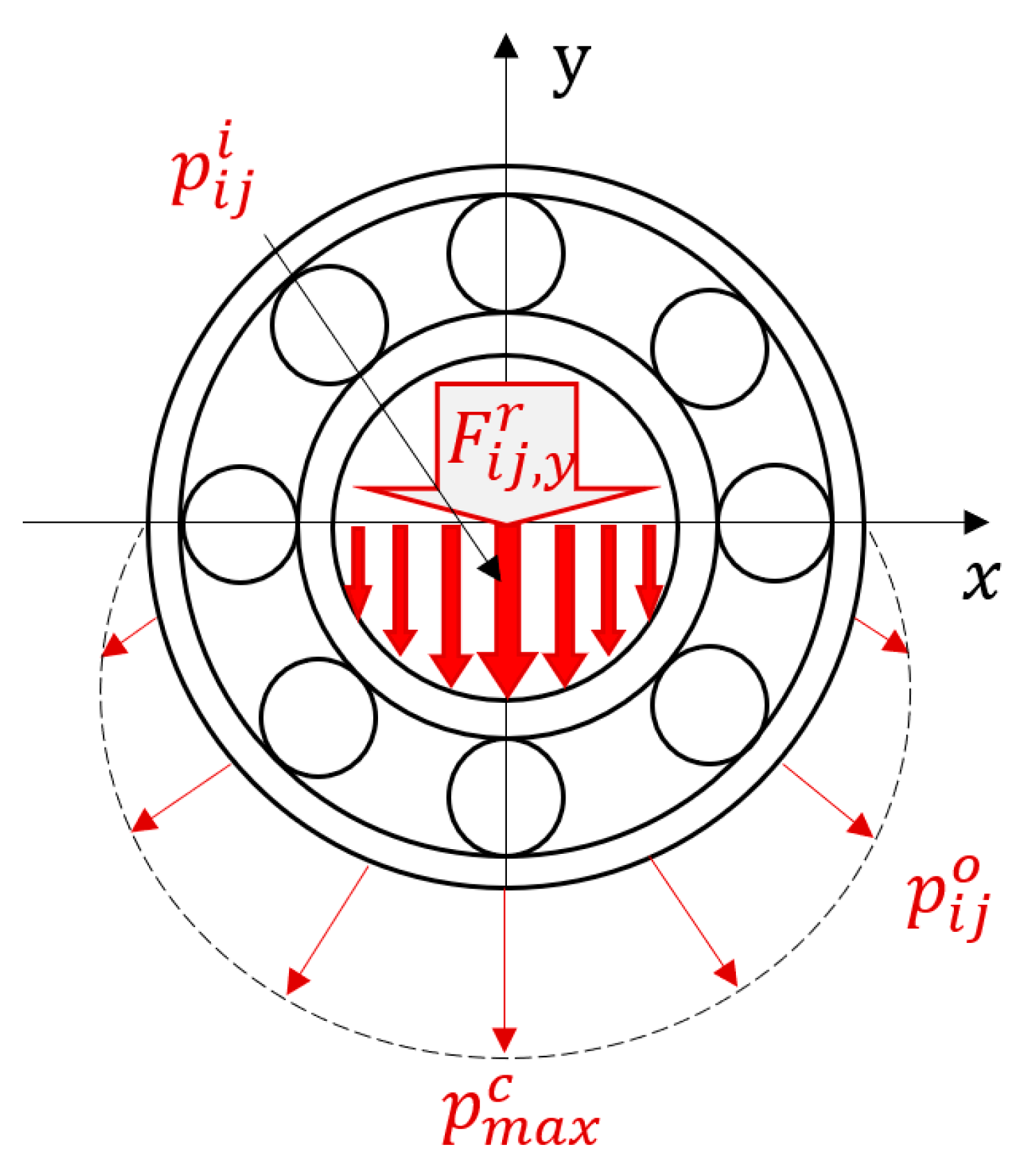

3.1.1. Fatigue Life Analysis of Spindle Bearing

3.1.2. Correction of the Cutting Load Model

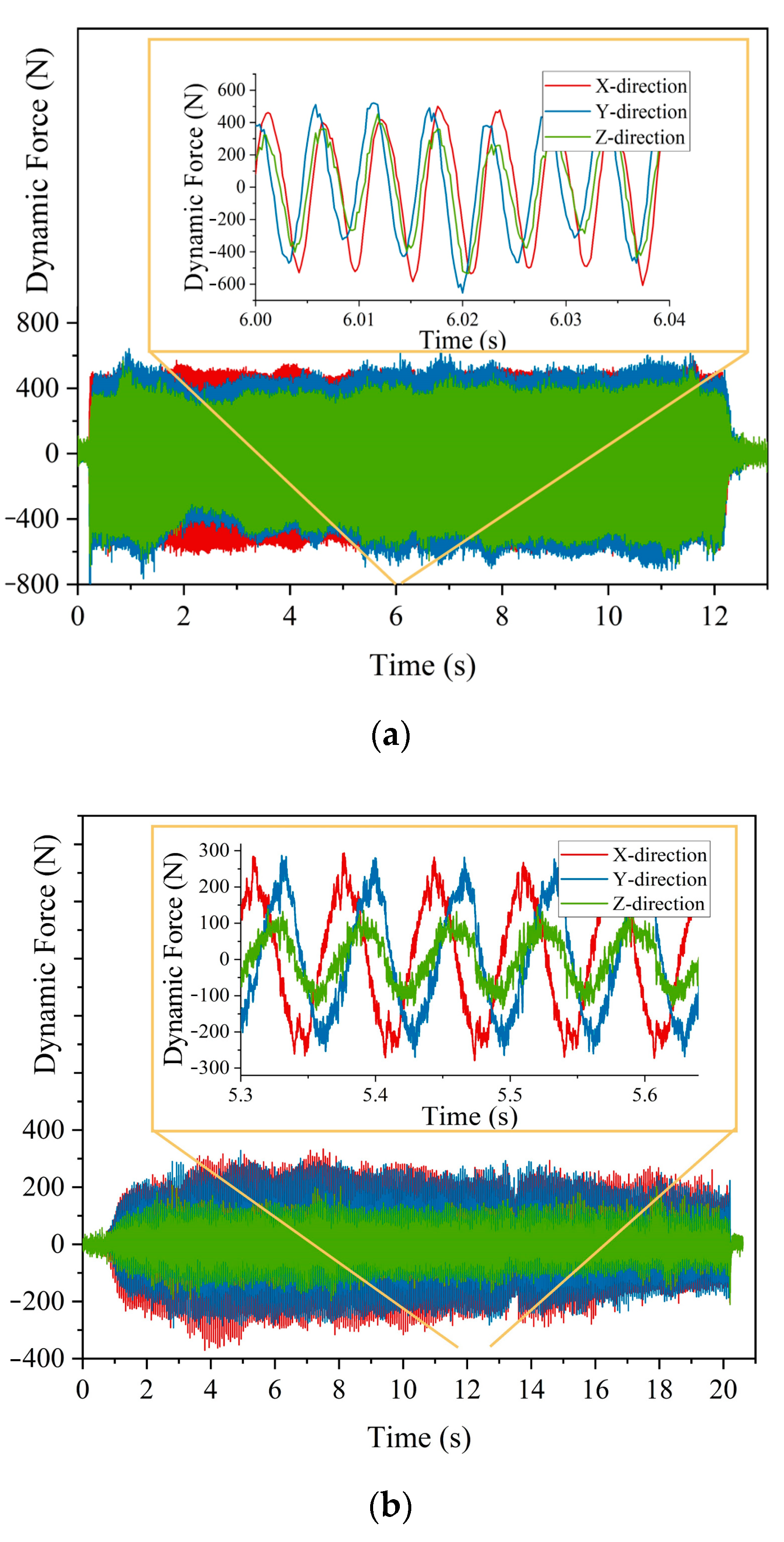

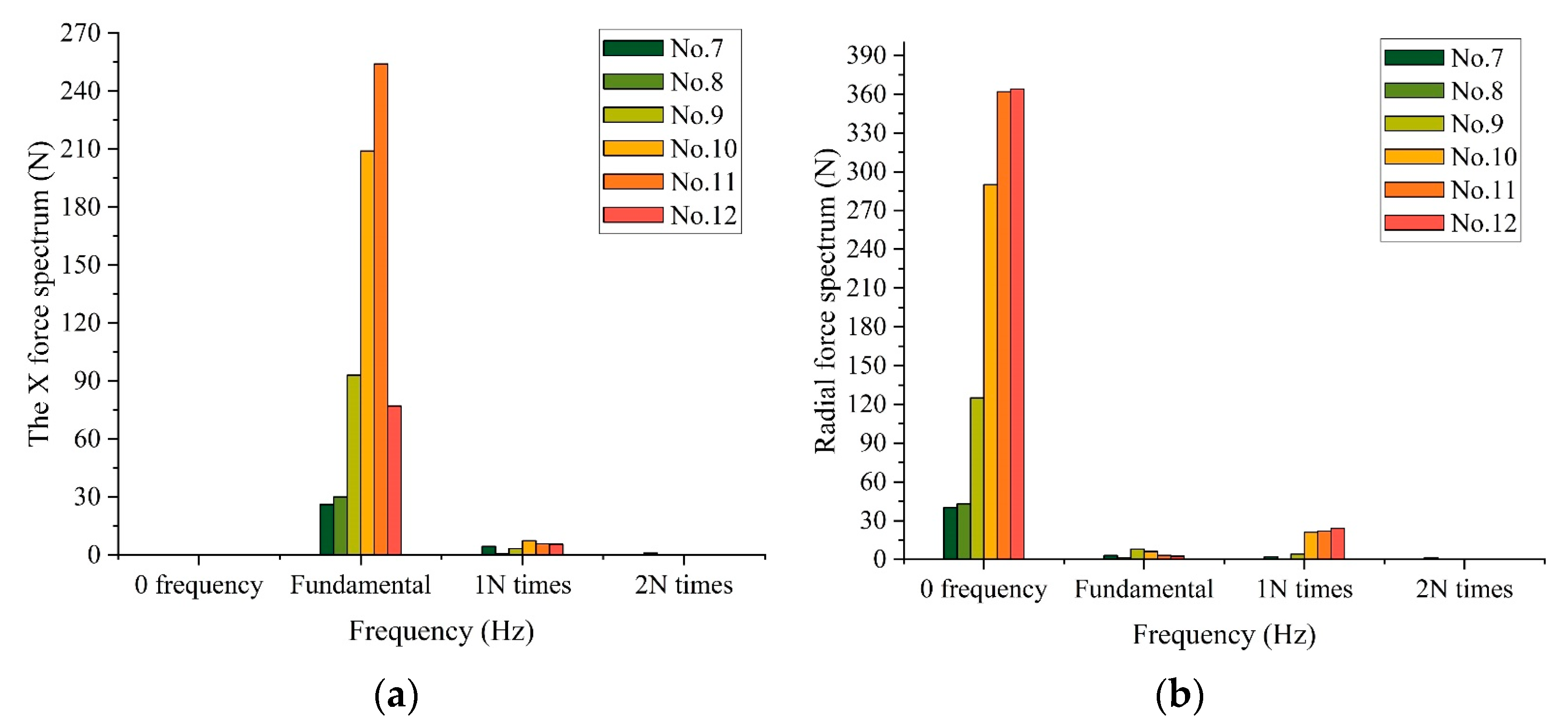

3.2. Verification of General Cutting Model of Spindle

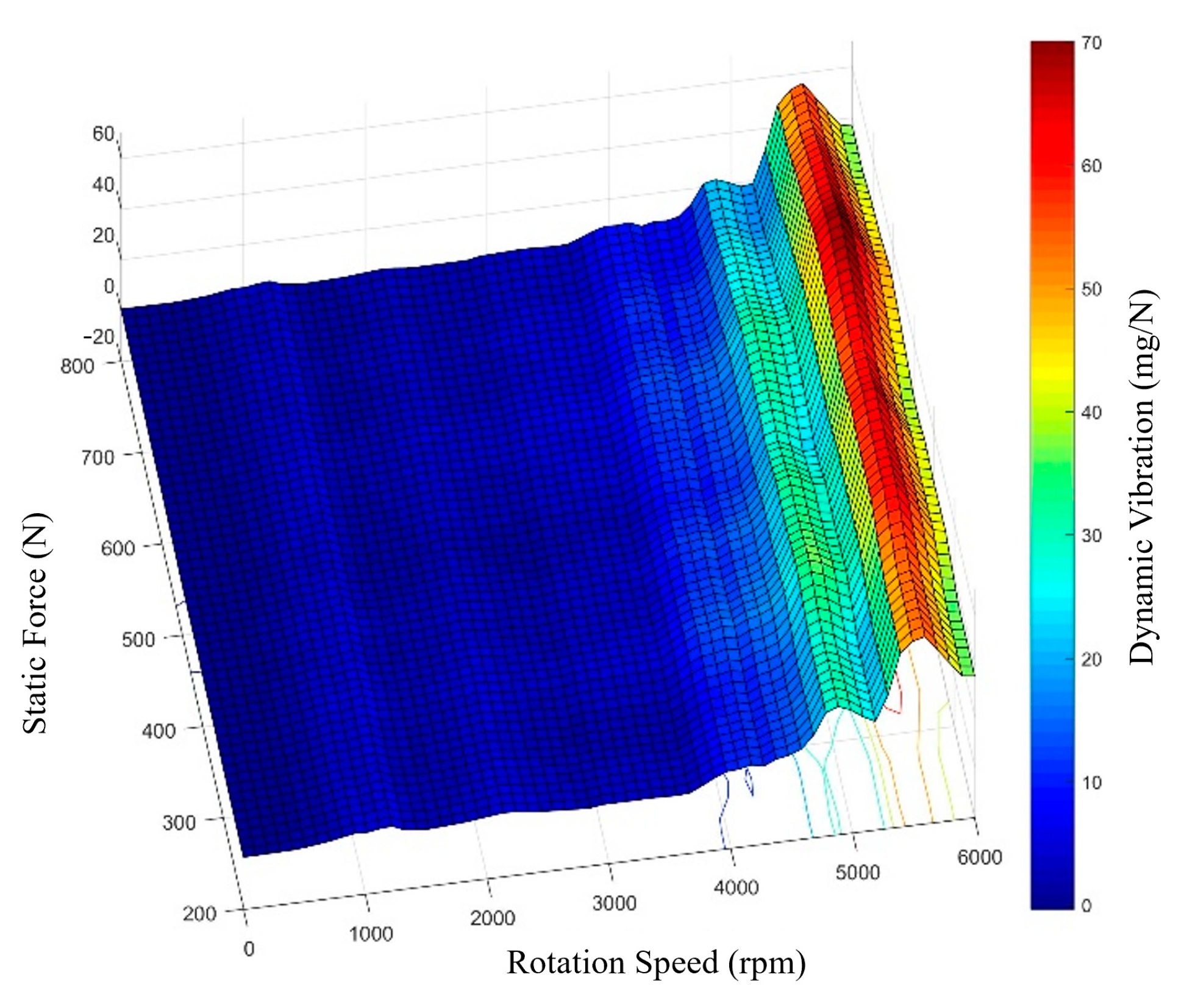

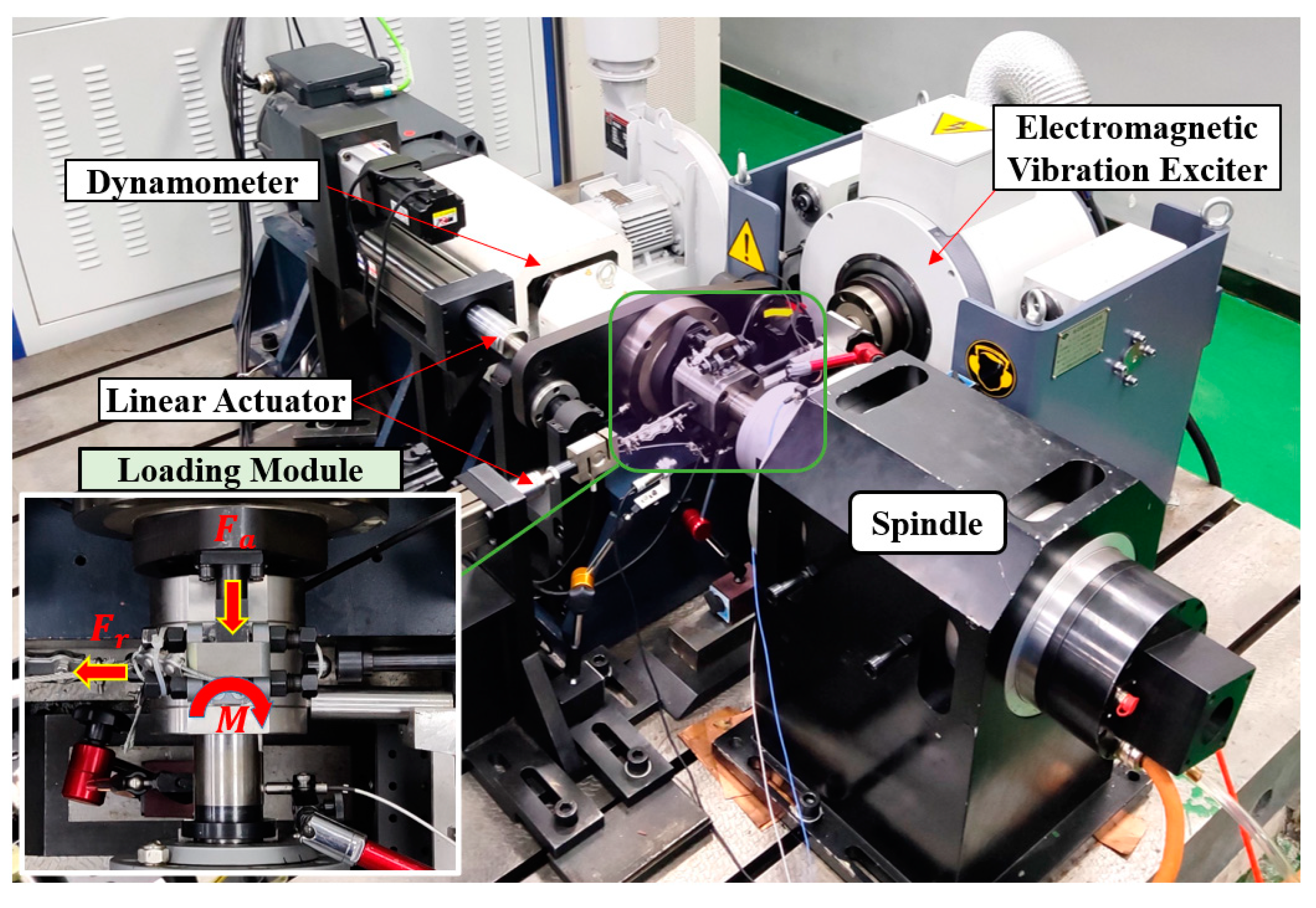

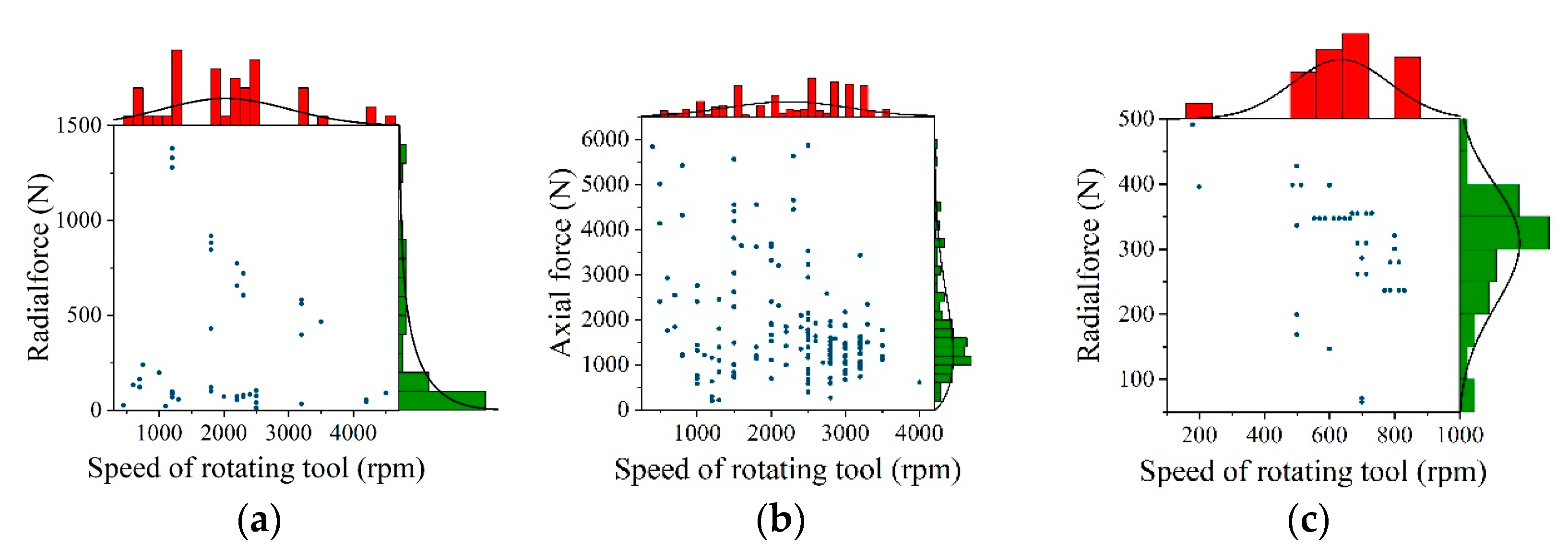

4. Application of General Cutting Load Model for Spindle

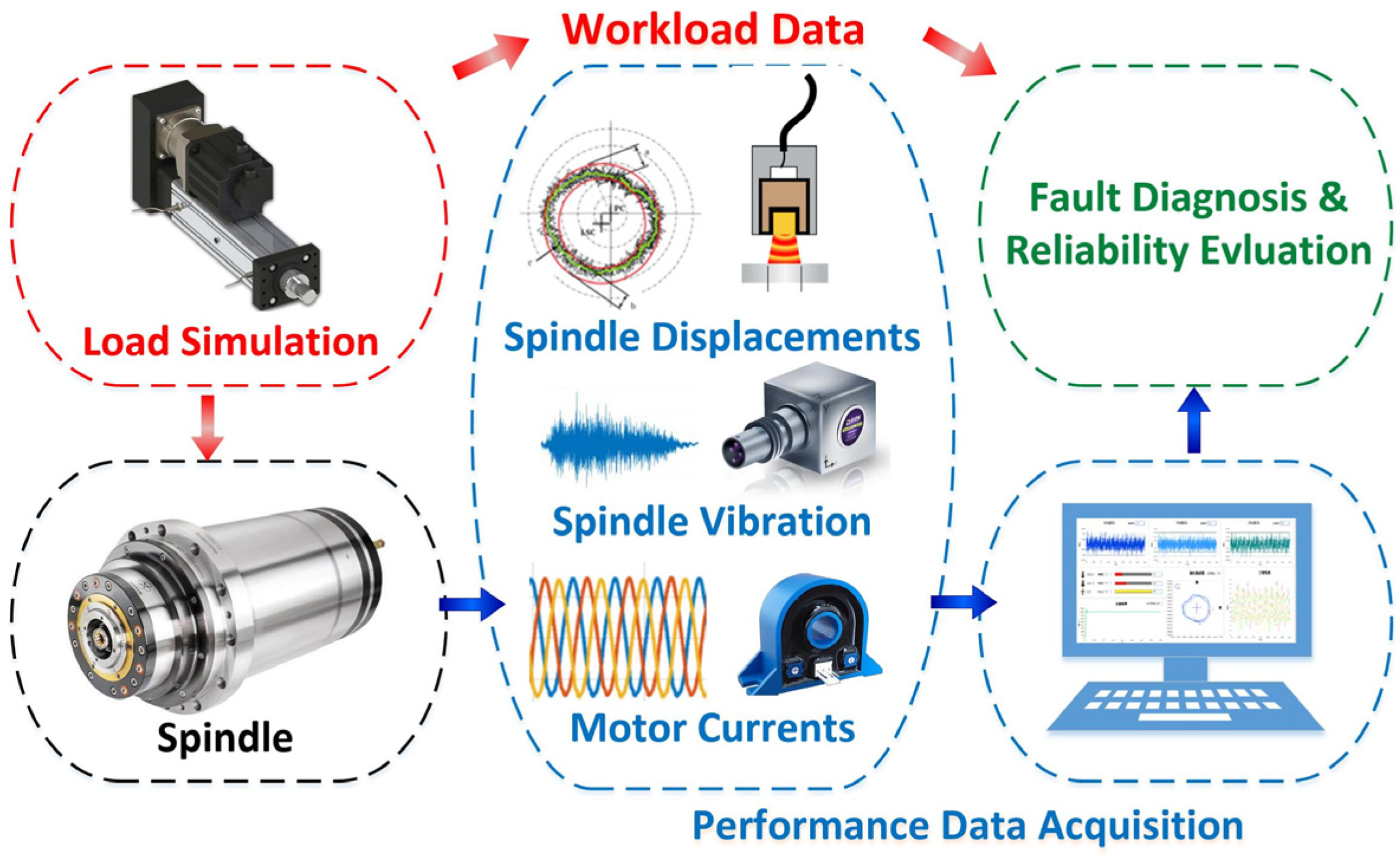

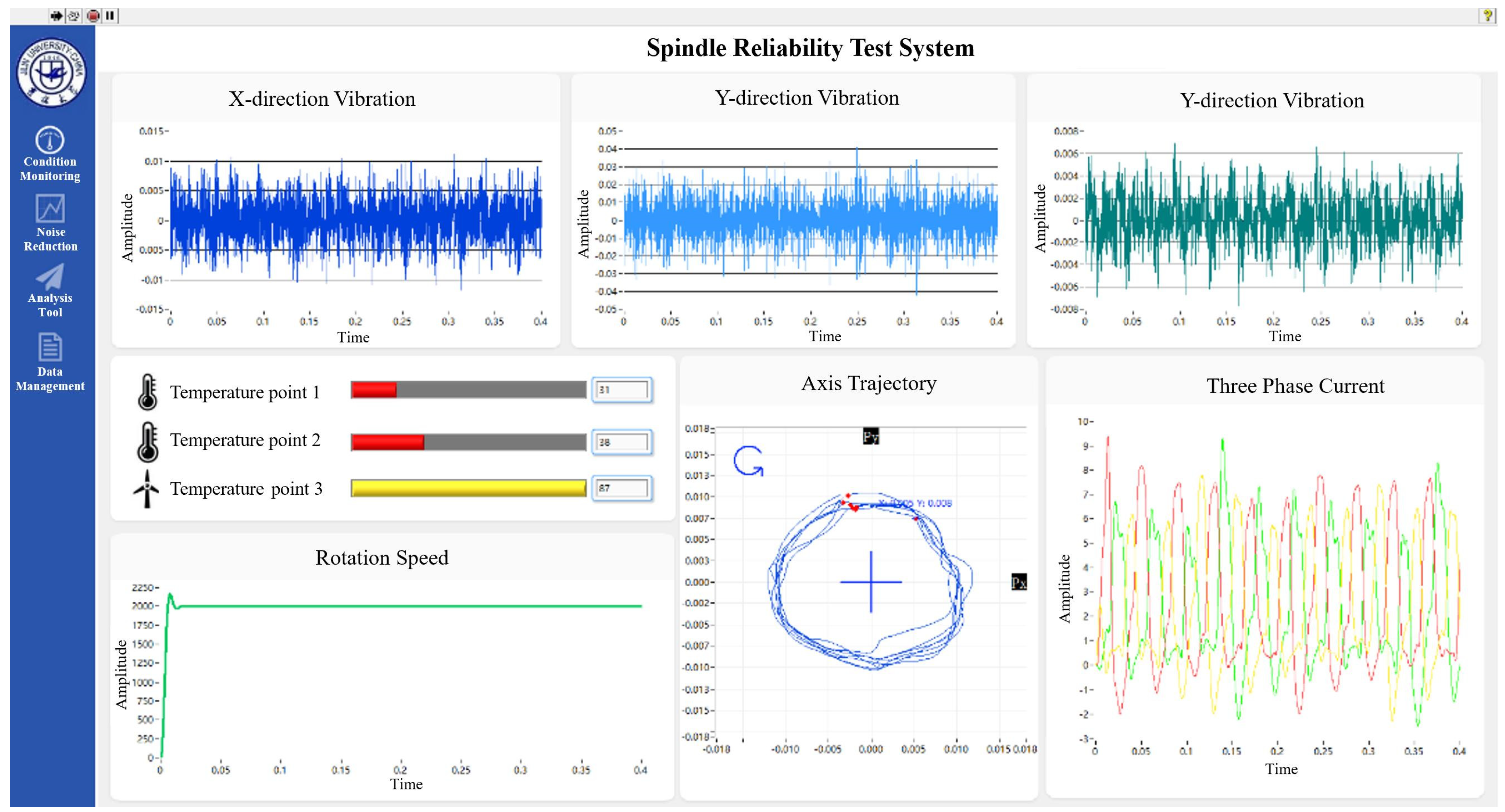

4.1. Design of Reliability Test-Bed for Testing and Leveling of Spindle

4.2. Reliability Test of Spindle

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, Y.; Zhang, X.; Ran, Y.; Zhang, G. Reliability modeling and analysis for CNC machine tool based on meta-action. Qual. Reliab. Eng. Int. 2021, 37, 1451–1467. [Google Scholar] [CrossRef]

- Wang, Y.; Jia, Y.; Qiu, J.; Shen, G. Load spectra of CNC machine tools. Qual. Reliab. Eng. Int. 2000, 16, 229–234. [Google Scholar] [CrossRef]

- Ehmann, K.F.; Kapoor, S.G.; Devor, R.E.; Lazoglu, I. Machining Process Modeling: A Review. J. Manuf. Sci. Eng. 1997, 119, 655–663. [Google Scholar] [CrossRef]

- Liu, X.W.; Cheng, K.; Webb, D.; Luo, X.C. Improved Dynamic Cutting Force Model in Peripheral Milling. Part I: Theoretical Model and Simulation. Int. J. Adv. Manuf. Technol. 2002, 20, 631–638. [Google Scholar] [CrossRef]

- Roukema, J.C.; Altintas, Y. Kinematic Model of Dynamic Drilling Process. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, Anaheim, CA, USA, 13–19 November 2004; pp. 955–963. [Google Scholar] [CrossRef]

- Yussefian, N.Z.; Moetakef-Imani, B.; El-Mounayri, H. The prediction of cutting force for boring process. Int. J. Mach. Tools Manuf. 2008, 48, 1387–1394. [Google Scholar] [CrossRef]

- Williams, J.A. Mechanics of Machining: An Analytical Approach to Assessing Machinability; Halsted Press: Chichester, UK, 1989. [Google Scholar] [CrossRef] [Green Version]

- Tapoglou, N. Development of Cutting Force Model and Process Maps for Power Skiving Using CAD-Based Modelling. Machines 2021, 9, 95. [Google Scholar] [CrossRef]

- van Luttervelt, C.A.; Childs, T.; Jawahir, I.; Klocke, F.; Venuvinod, P.; Altintas, Y.; Armarego, E.; Dornfeld, D.; Grabec, I.; Leopold, J.; et al. Present Situation and Future Trends in Modelling of Machining Operations Progress Report of the CIRP Working Group ‘Modelling of Machining Operations’. CIRP Ann. Manuf. Technol. 1998, 47, 587–626. [Google Scholar] [CrossRef]

- Adetoro, O.B.; Wen, P.H. Prediction of mechanistic cutting force coefficients using ALE formulation. Int. J. Adv. Manuf. Technol. 2010, 46, 79–90. [Google Scholar] [CrossRef]

- Huang, C.Y.; Wang, J. Mechanistic Modeling of Process Damping in Peripheral Milling. J. Manuf. Sci. Eng. 2007, 129, 397–406. [Google Scholar] [CrossRef]

- Kaymakci, M.; Kilic, Z.M.; Altintas, Y. Unified cutting force model for turning, boring, drilling and milling operations. Int. J. Mach. Tools Manuf. 2012, 54–55, 34–45. [Google Scholar] [CrossRef]

- Altintas, Y.; Kilic, Z.M. Generalized dynamic model of metal cutting operations. CIRP Ann. Manuf. Technol. 2013, 62, 47–50. [Google Scholar] [CrossRef]

- Kilic, Z.M.; Altintas, Y. Generalized mechanics and dynamics of metal cutting operations for unified simulations. Int. J. Mach. Tools Manuf. 2016, 104, 1–13. [Google Scholar] [CrossRef]

- Guo, J.; Dan, W.; Chen, W.; Fan, R. Multi-Axis Loading Device for Reliability Tests of Machine Tools. IEEE/ASME Trans. Mechatron. 2018, 23, 1930–1940. [Google Scholar] [CrossRef]

- Ding, Z.; Yang, Z.; Chen, C.; Chen, W.; Chen, H.; Liu, Z. Improved sliding mode dynamic matrix control strategy: Application on spindle loading and precision measuring device based on piezoelectric actuator. Mech. Syst. Signal Process. 2021, 167, 108543. [Google Scholar] [CrossRef]

- Chen, W.; Yang, Z.; Chen, C.; Luo, W. Load-Dependent Rotating Performance of Motorized Spindles: Measurement and Evaluation using Multi-Zones Error Map. IEEE Access 2019, 7, 180482–180490. [Google Scholar] [CrossRef]

- Kilic, Z.M.; Altintas, Y. Generalized modelling of cutting tool geometries for unified process simulation. Int. J. Mach. Tools Manuf. 2016, 104, 14–25. [Google Scholar] [CrossRef]

- Lamikiz, A.; de Lacalle, L.L.; Sánchez, J.; Salgado, M. Cutting force estimation in sculptured surface milling. Int. J. Mach. Tools Manuf. 2004, 44, 1511–1526. [Google Scholar] [CrossRef]

- Keer, L.M.; Bryant, M.D. A Pitting Model for Rolling Contact Fatigue. J. Lubr. Technol. 1983, 105, 198. [Google Scholar] [CrossRef]

| Machining Process | ||||||||

|---|---|---|---|---|---|---|---|---|

| No. | Operation | Tool Type | Tool Material | Tooth Number | Cutter Diameter (mm) | Spindle Speed (r/min) | Depth of Cut (mm) | Feed Speed (mm/min) |

| 1 | Milling | Helical End Mills | Alloy tool steel | 2 | 8 | 900 | 3 | 200 |

| 2 | Helical End Mills | Alloy tool steel | 2 | 8 | 1800 | 3 | 100 | |

| 3 | Helical End Mills | Alloy tool steel | 2 | 8 | 1800 | 6 | 100 | |

| 4 | Helical End Mills | Alloy tool steel | 2 | 8 | 2700 | 6 | 200 | |

| 5 | Helical End Mills | Cemented carbide | 4 | 8 | 900 | 6 | 100 | |

| 6 | Helical End Mills | Cemented carbide | 4 | 10 | 2700 | 3 | 200 | |

| 7 | Drilling | Twist drill | Alloy tool steel | 2 | 8 | 1800 | - | 120 |

| 8 | Twist drill | Alloy tool steel | 2 | 8 | 2700 | - | 30 | |

| 9 | Twist drill | Alloy tool steel | 2 | 16 | 1800 | - | 120 | |

| 10 | Twist drill | Alloy tool steel | 2 | 16 | 900 | - | 60 | |

| 11 | Twist drill | Alloy tool steel | 2 | 16 | 1800 | - | 60 | |

| 12 | Twist drill | Alloy tool steel | 2 | 16 | 2700 | - | 120 | |

| 13 | Boring | Rough boring | High-speed steel | 1 | 22 | 360 | 0.9 | 20 |

| 14 | Rough boring | High-speed steel | 1 | 26 | 540 | 0.9 | 20 | |

| 15 | Rough boring | High-speed steel | 1 | 34 | 540 | 1.5 | 60 | |

| 16 | Rough boring | High-speed steel | 1 | 40 | 360 | 1.2 | 40 | |

| 17 | Rough boring | High-speed steel | 1 | 46 | 180 | 1.2 | 40 | |

| 18 | Rough boring | High-speed steel | 1 | 52 | 180 | 1.5 | 60 | |

| Power | Maximum Speed | Rated Torque | Voltage | Lubrication | Cooling | Radial Runout | Axial Movement |

|---|---|---|---|---|---|---|---|

| 11 kW | 12,000 rpm | 35N·m | 380 V | Grease | Water cooling | ≤0.004 mm | ≤0.002 mm |

| Structural Parameters | Value |

|---|---|

| Inner diameter of bearing d/mm | 60 |

| Outer diameter of bearing D/mm | 95 |

| Rolling element diameter Db/mm | 9.525 |

| Bearing pitch diameter dm/mm | 77.5 |

| Radius of locus of inner raceway groove Curvature centers ri/mm | 4.95 |

| Outer diameter of inner ring da/mm | 67.5 |

| Radius of locus of outer raceway groove Curvature centers re/mm | 4.95 |

| Initial contact angle, ° | 15 |

| Number of balls Z | 18 |

| Block No. | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

|---|---|---|---|---|---|---|---|---|

| Static radial force | 2175 | 2067 | 1806 | 1216 | 1124 | 986 | 1494 | 339 |

| dynamic radial force | 1720 | 1617 | 1428 | 922 | 935 | 642 | 27 | 209 |

| axial force | −450 | −428 | −386 | −285 | −205 | −120 | −247 | −24.50 |

| torque | 35.30 | 33.60 | 29.40 | 17.60 | 6.10 | 4.20 | 2.10 | 1.10 |

| the speed of rotating tool | 600 | 600 | 600 | 1200 | 2200 | 1800 | 2200 | 3500 |

| Uncorrected loading frequency | 40 | 40 | 40 | 80 | 110 | 120 | 147 | 233 |

| Corrected loading frequency of the ball | 10.40 | 10.40 | 10.40 | 20.80 | 28.60 | 31.20 | 38.22 | 60.58 |

| Corrected loading frequency of the bearing outer race | 40 | 40 | 40 | 80 | 110 | 120 | 147 | 233 |

| Corrected loading frequency of the bearing inner race | 4 | 4 | 4 | 4 | 3 | 4 | 4 | 4 |

| Loading time | 0.50 | 1.10 | 0.83 | 2.30 | 21.95 | 11.41 | 41.48 | 80.45 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kong, L.; Chen, W.; Luo, W.; Chen, C.; Yang, Z. General Cutting Load Model for Workload Simulation in Spindle Reliability Test. Machines 2022, 10, 144. https://doi.org/10.3390/machines10020144

Kong L, Chen W, Luo W, Chen C, Yang Z. General Cutting Load Model for Workload Simulation in Spindle Reliability Test. Machines. 2022; 10(2):144. https://doi.org/10.3390/machines10020144

Chicago/Turabian StyleKong, Lingda, Weizheng Chen, Wei Luo, Chuanhai Chen, and Zhaojun Yang. 2022. "General Cutting Load Model for Workload Simulation in Spindle Reliability Test" Machines 10, no. 2: 144. https://doi.org/10.3390/machines10020144

APA StyleKong, L., Chen, W., Luo, W., Chen, C., & Yang, Z. (2022). General Cutting Load Model for Workload Simulation in Spindle Reliability Test. Machines, 10(2), 144. https://doi.org/10.3390/machines10020144