Developing Digital Observer of Angular Gaps in Rolling Stand Mechatronic System

Abstract

1. Introduction

2. Problem Formulation

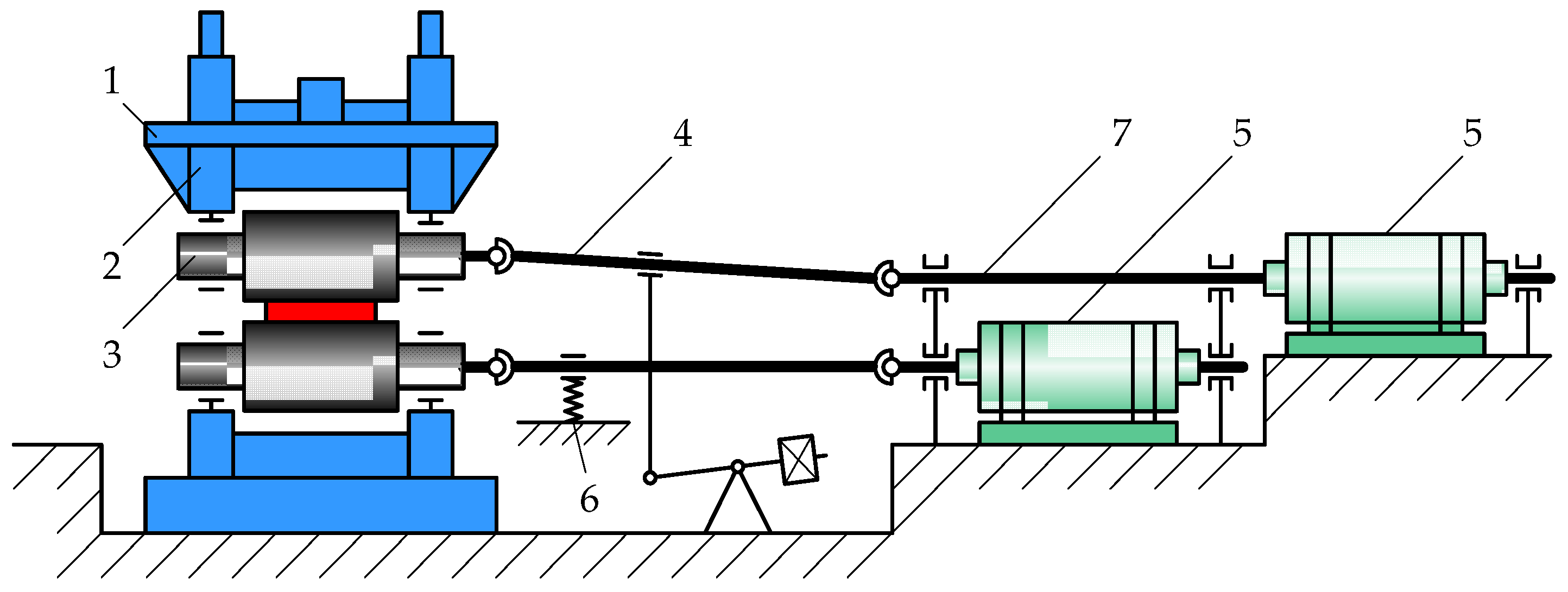

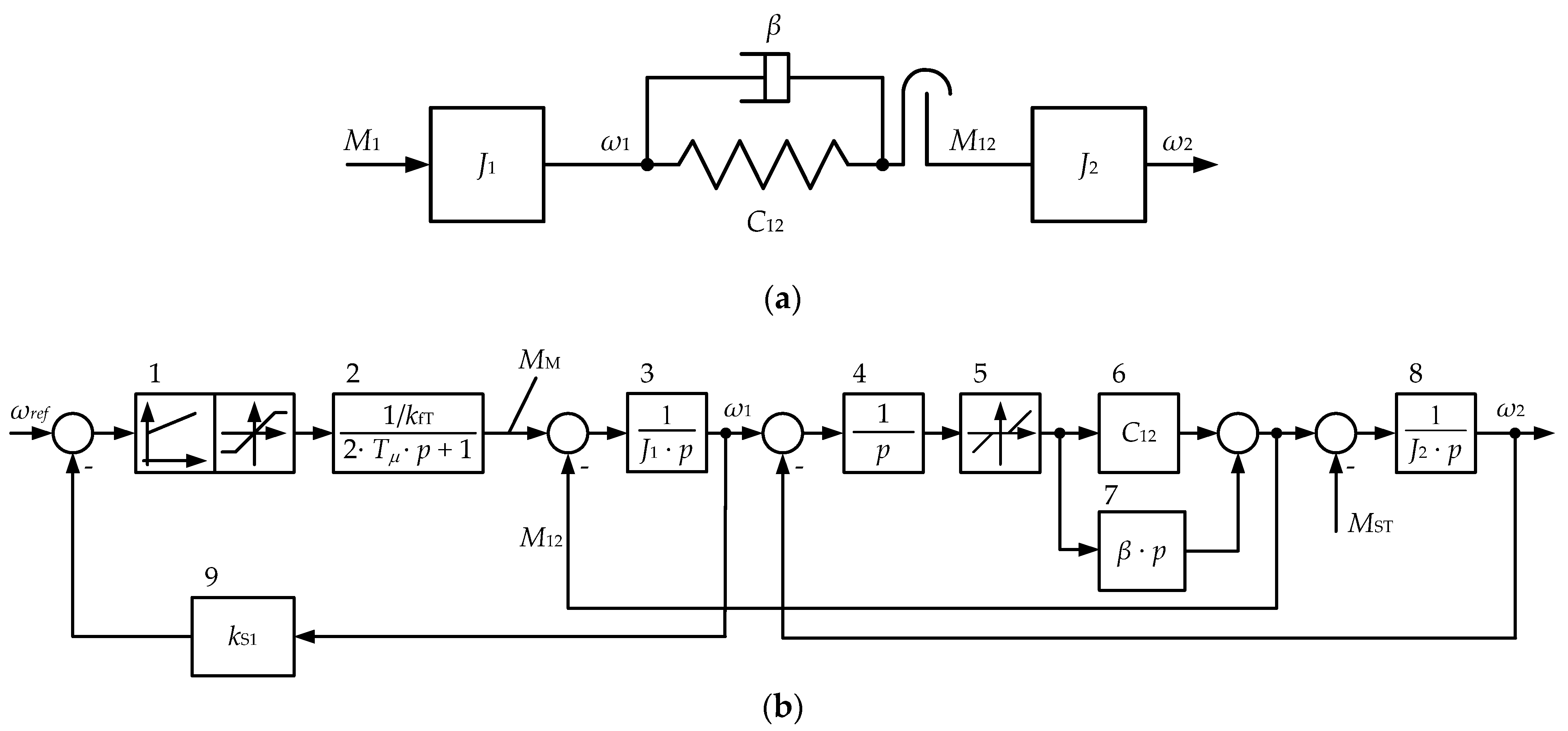

2.1. Specifications of Dual-Mass Electromechanical Systems of the Mill Stand 5000

2.2. Spindle Design

2.3. Experimental Justification of Preliminary Acceleration

- -

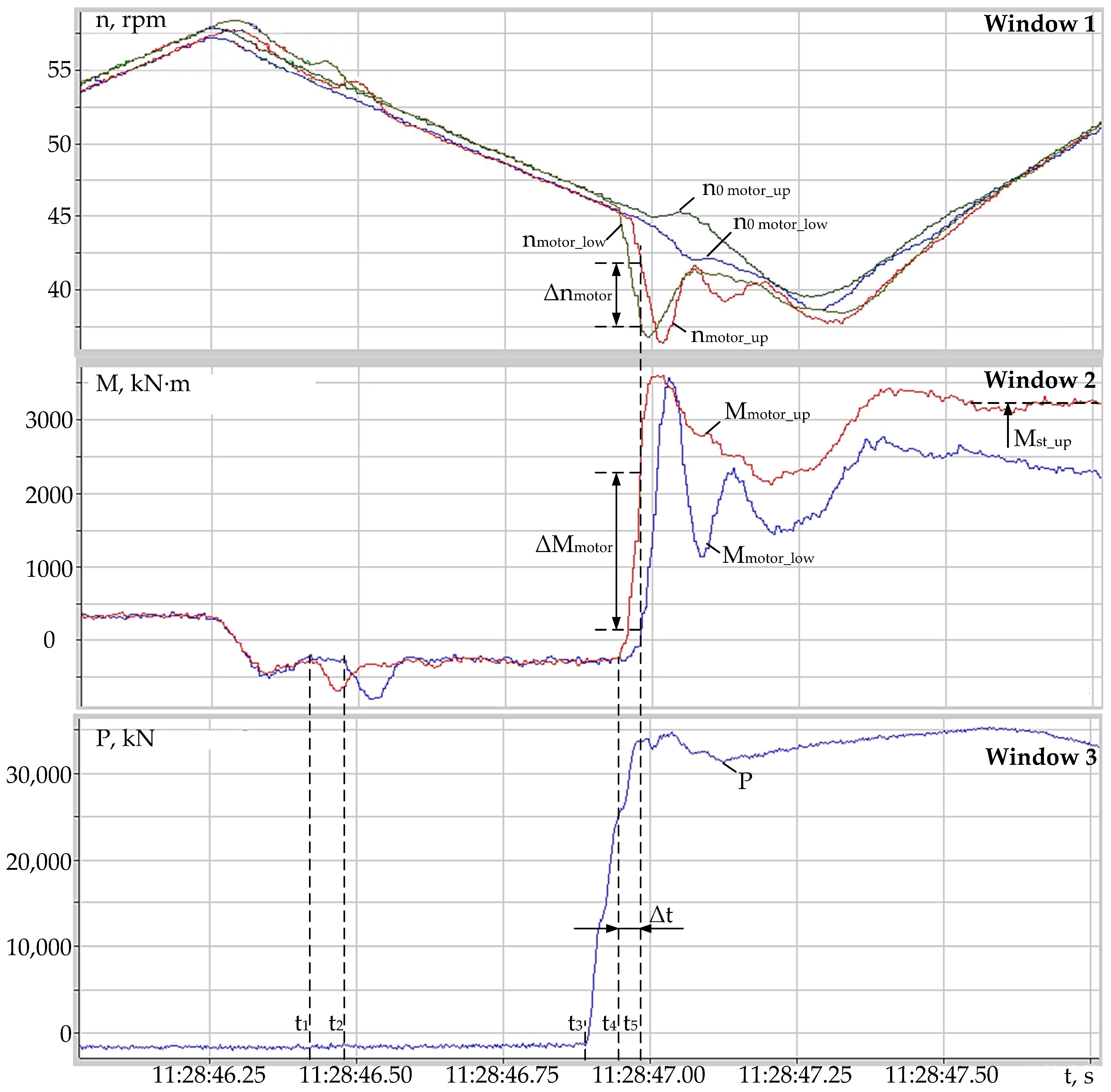

- For open-gap biting (Figure 4a), the impact torque amplitude exceeds the steady-state torque by 1.9 times (maximum Mmax = 3250 kN∙m, steady-state Mst = 1750 kN∙m);

- -

- -

3. Materials and Methods

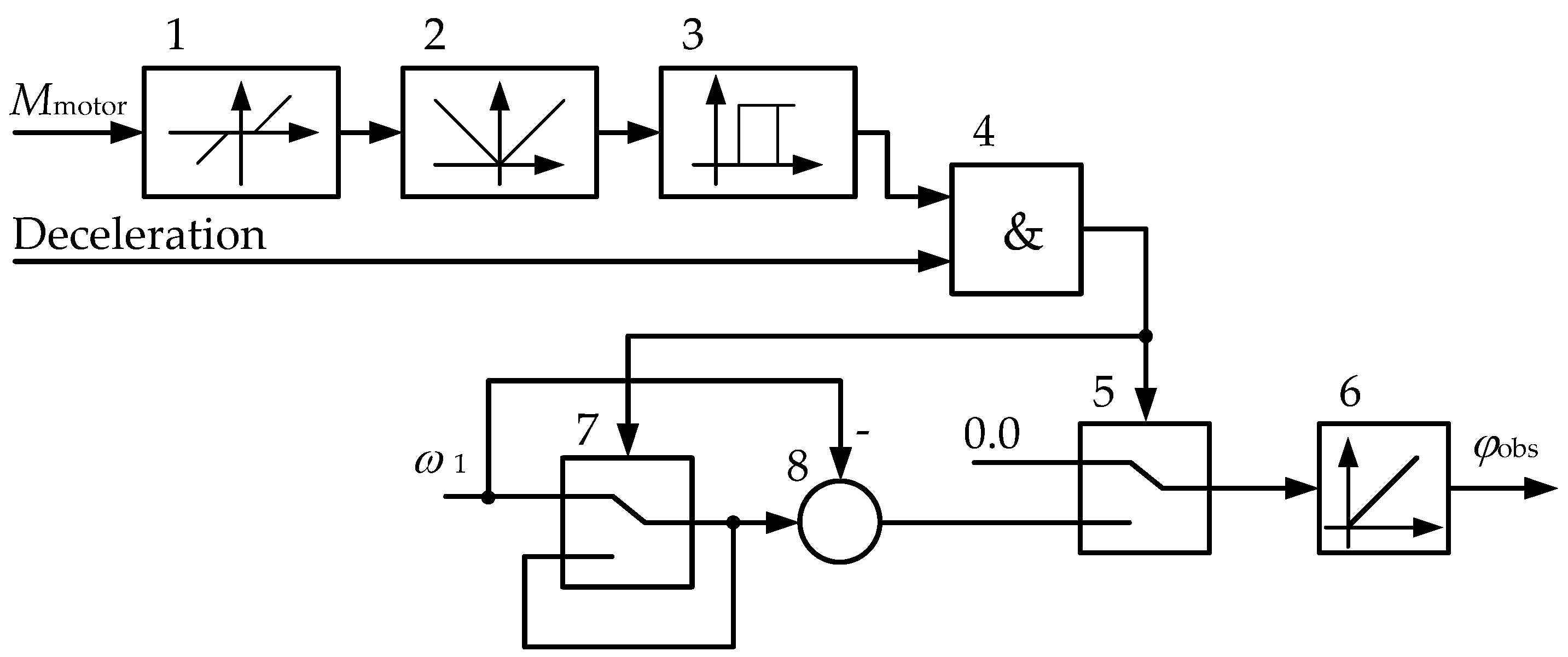

3.1. The Angular Gap Indirect Determination Procedure

- -

- Indirect angular gap definition by integrating the speed over the open-gap interval;

- -

- Fixing the change in the rotation direction (acceleration sign) and active gap closing instant with no metal in the rolls to estimate the interval boundaries.

3.2. Developing an Observer

3.3. Simulation and Experimental Studies

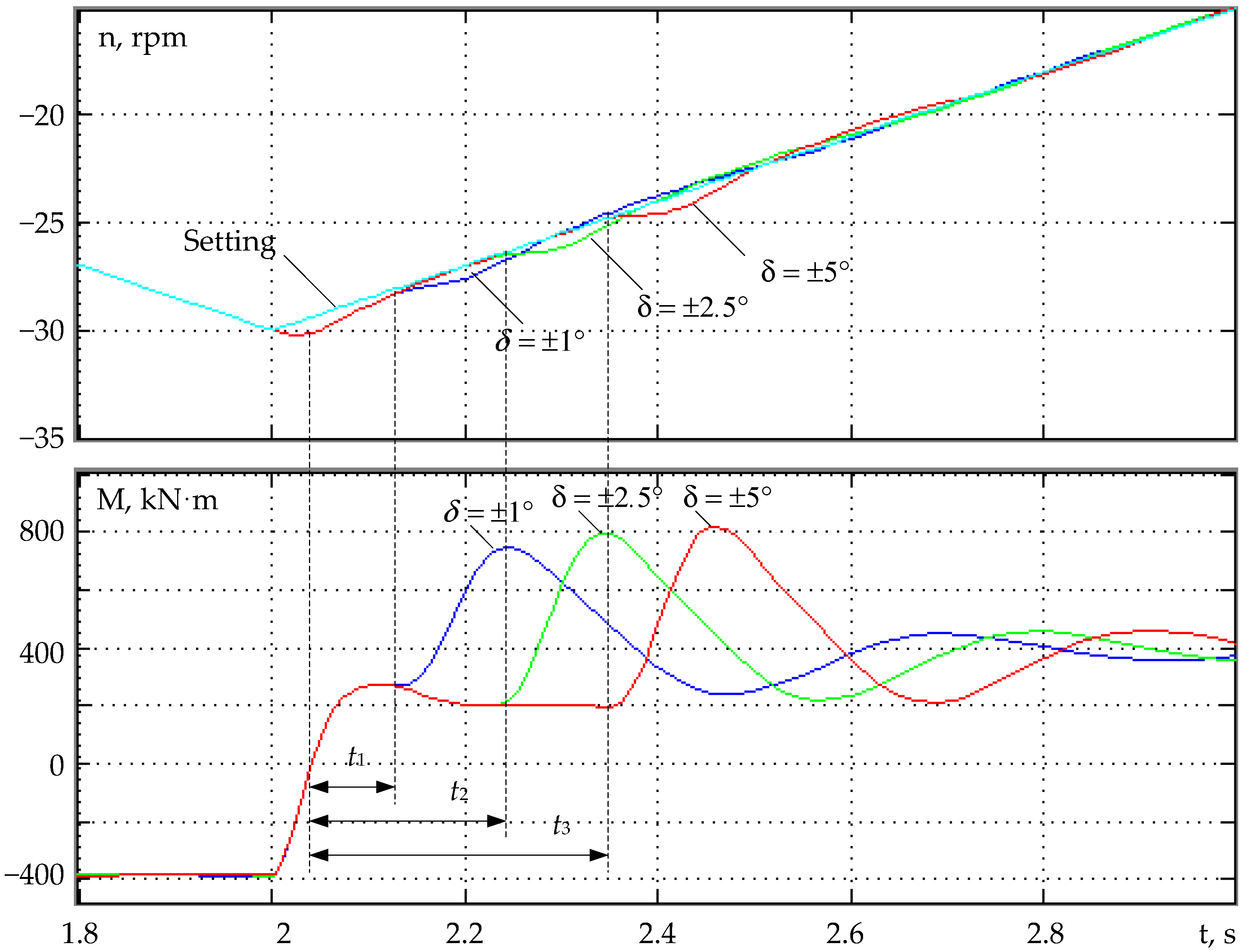

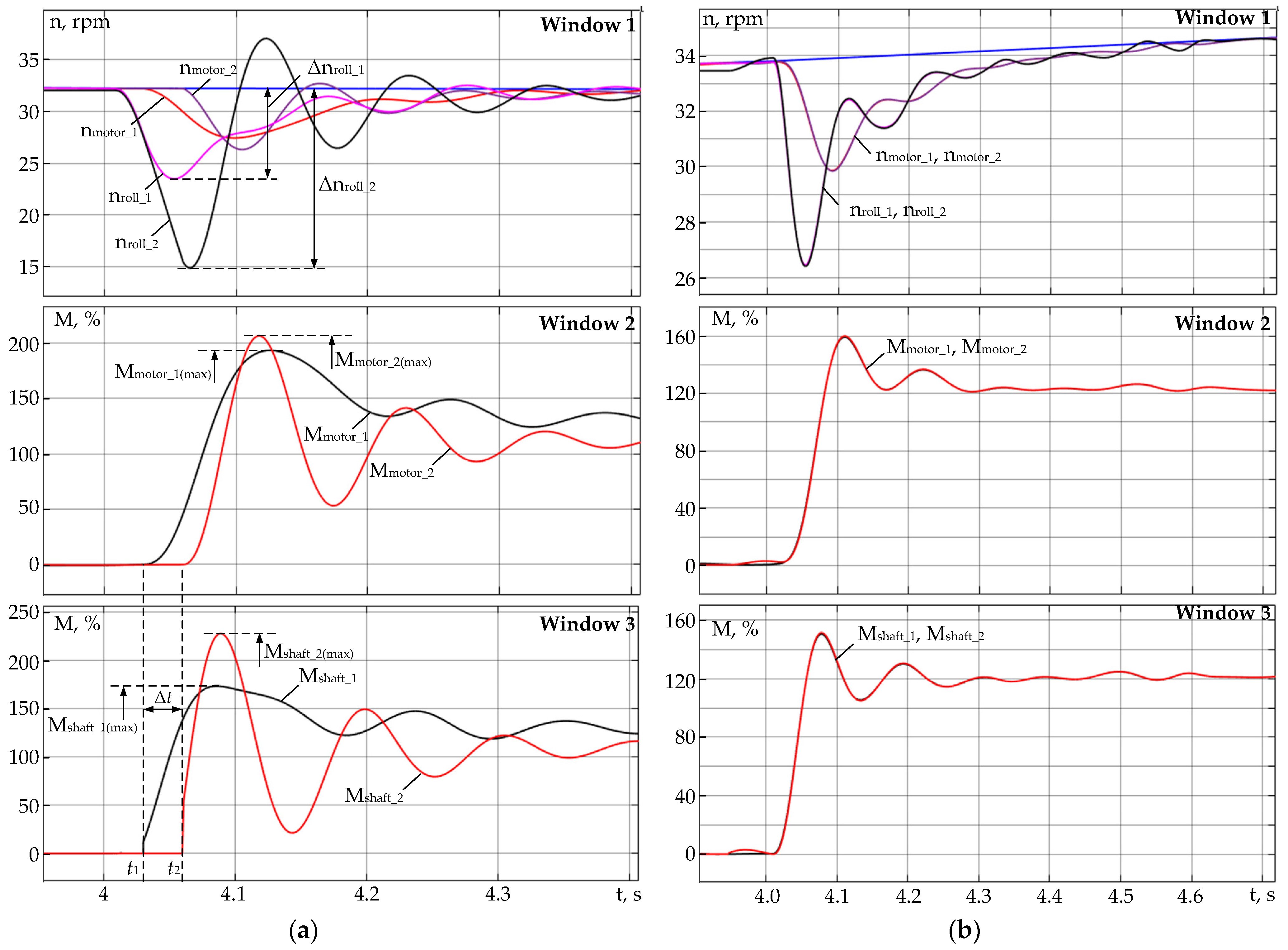

- The Mmotor_1 (max) and Mmotor_2 (max) motor torque amplitudes (window 2, Figure 10a) differ by 9.5%. The Mshaft_1 (max) and Mshaft_2 (max) spindle elastic torque amplitudes (window 3) differ by 27%. This indicates a significant impact of gaps on the transients of these parameters under the same biting conditions (for the upper and lower rolls, these conditions are the same);

- The t1 and t2 upper and lower spindle gaps closing instants also differ. Under the same biting conditions, a spindle with a larger play is loaded later. With the specified gaps, the time difference Δt is 25 ms;

- In the electromechanical system with a large angular gap, longer damping elastic torque oscillations with a larger amplitude occur. The dynamic deviations of the second mass (roll) speed Δnroll_2 exceed those of the first mass speed Δnroll_1;

- In Figure 10b, curves of the UMD and LMD torque transients at closed gaps match. It can be argued that the system is linearized since the non-linearity introduced by the gaps disappears.

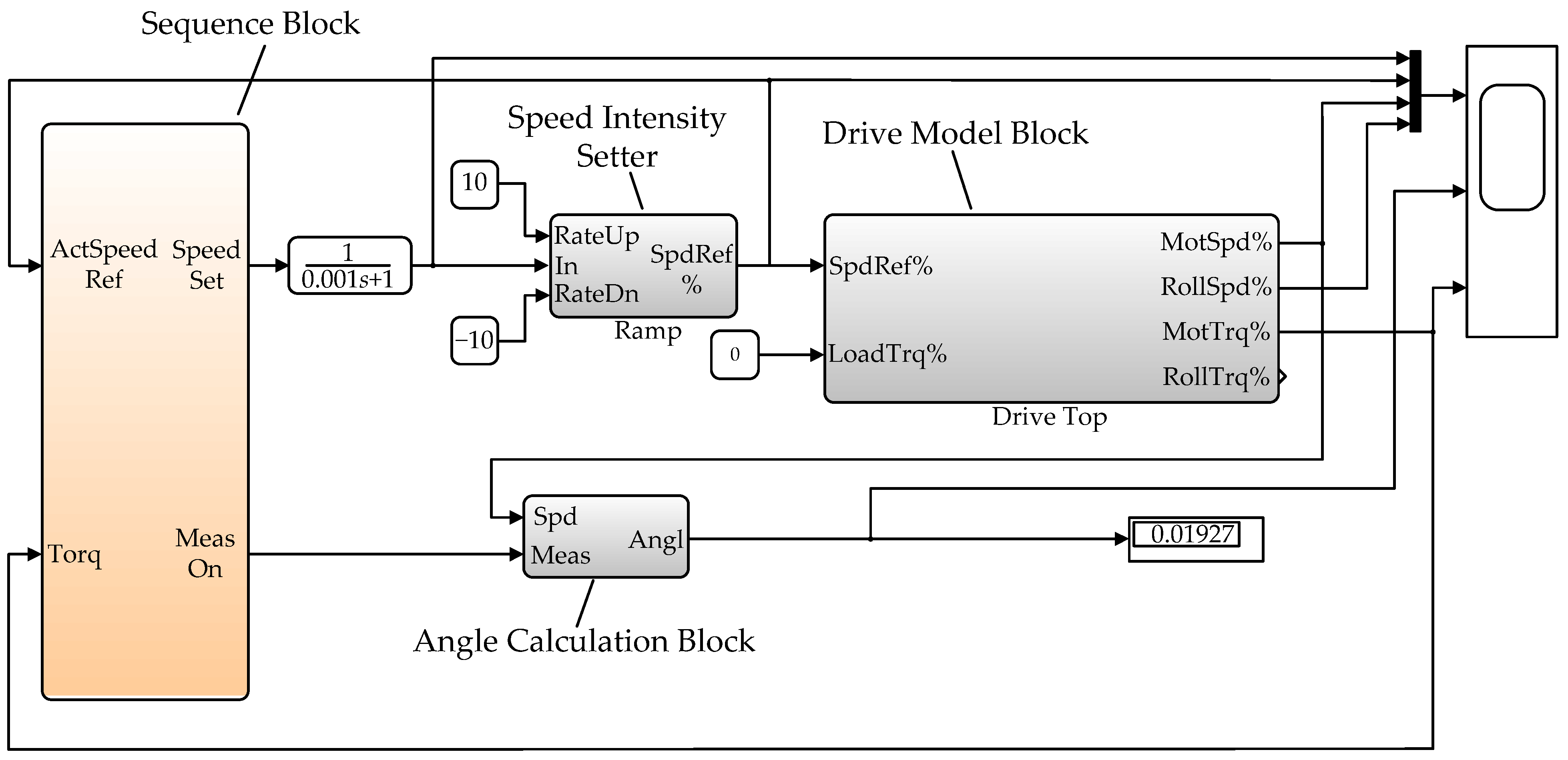

4. Implementation

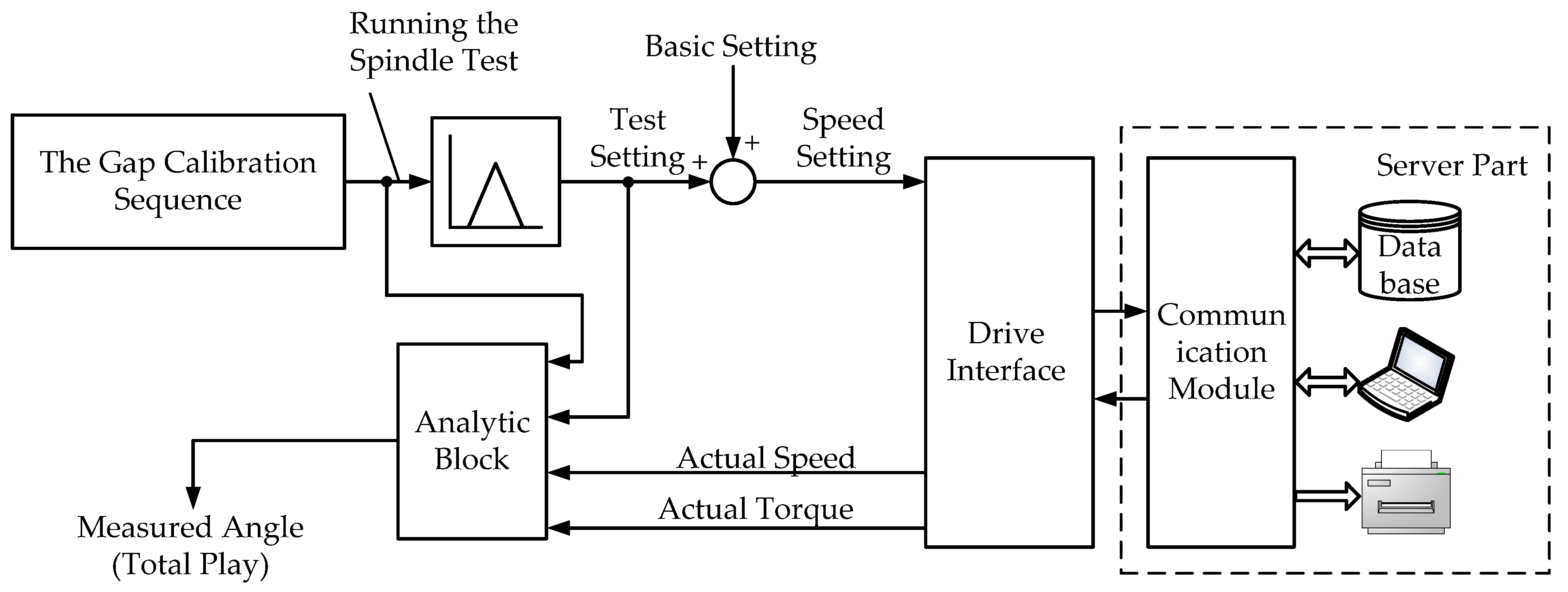

- Programming and adapting the gap measurement algorithm using a simulator (virtual model), the scheme of which is shown in Figure 7;

- Transfer of the debugged program to the industrial controller software. These actions provide virtual commissioning, reducing the observer configuration time. Such an approach is expedient since the angular gap is difficult to measure and impossible to change under the operating mill conditions. The virtual input allows for any changes in the monitoring algorithm;

- Experimental approval or correction of the calculated drive acceleration, ensuring guaranteed closing of the maximum gap;

- Experimental setting of the dead zone in block 1, Figure 6, allowing for a reliable determination of the opening time instant;

- Introducing the algorithms developed into the calibration program.

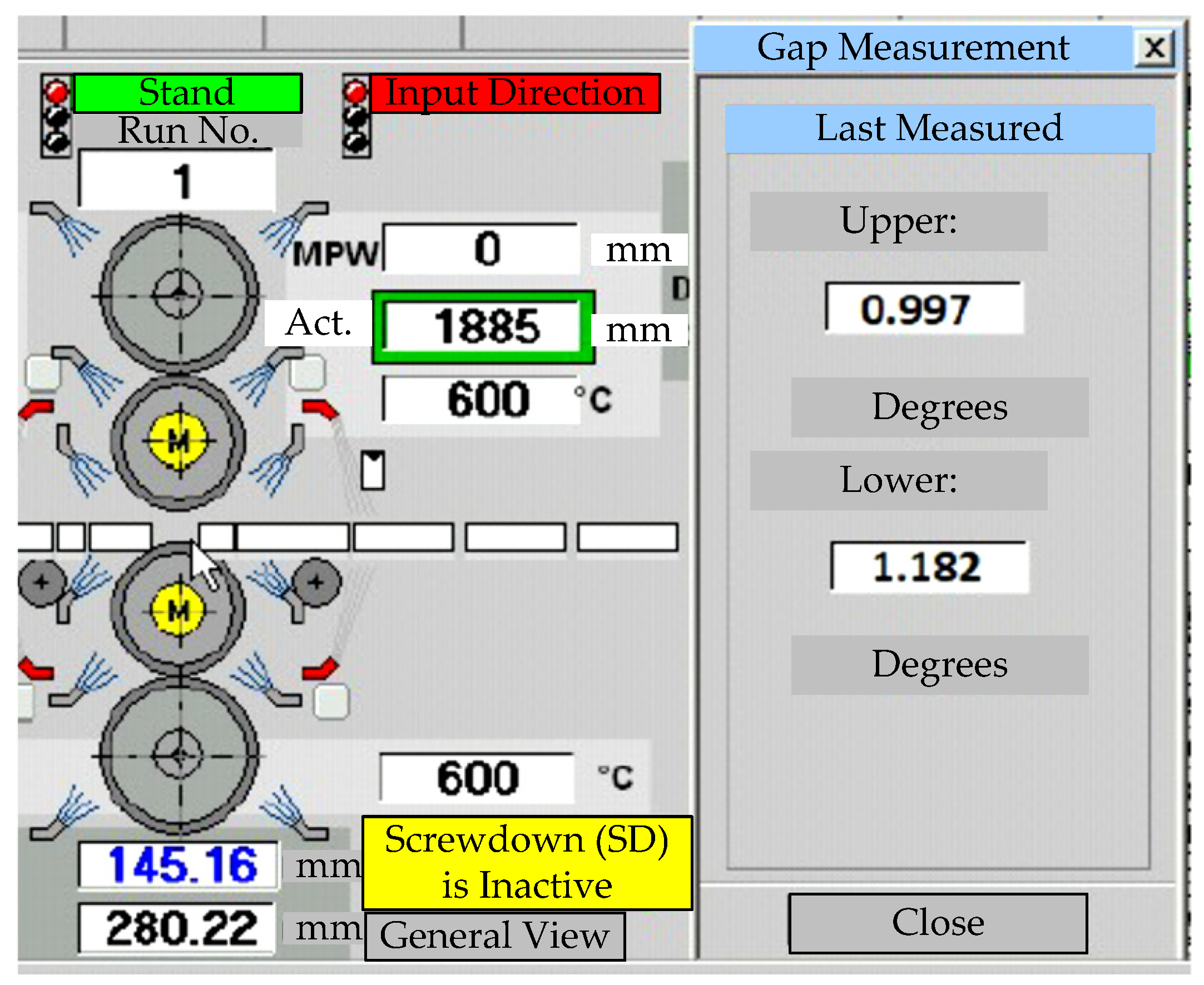

- Visualizing the spindle joint serviceability data. A drop-down window is provided on the operator’s display to warn about developing an emergency. The view of such a window on the Mill 5000 stand control station display is given in Figure 12;

- Building empirical dependences of the spindle joint wear on the angular gap. They should be obtained by statistically processing experimental data with a large volume of measurements. Dependencies will provide sufficient accuracy since the joint wear is of a long-term nature.

- 3.

- Developing tailored software to determine the wear dynamics and forecast the spindle joint state is expedient. They should provide a mathematical processing of diagnostic parameter trends. Building trends requires the accumulation of large data volumes. This predetermines the expediency of creating a customized database.

5. Conclusions

- Setting the drive speed to provide the gap closing when the shaft rotates in one direction, and then opening and repeatedly closing when the shaft rotates in the opposite direction. To achieve this, the speed tachogram should have a triangular shape with equal deceleration and acceleration rates;

- The motor electromagnetic torque monitoring to determine the gap closing and opening instants when testing the tachogram;

- Recording the speed signal over the open-gap time interval. Calculating the angular gap as a speed integral over this interval. For the linear time dependence of speed ensured by the triangular tachogram, integration can be replaced by multiplying the speed and time increments.

- -

- A reduction of the emergency mill downtime;

- -

- A reduction of the cost of eliminating the consequences of accidents, and replacing and restoring equipment;

- -

- An extension of the service life of electrical and mechanical equipment.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- El-Thalji, I. Predictive maintenance (PdM) analysis matrix: A tool to determine technical specifications for PdM ready-equipment. IOP Conf. Ser. Mater. Sci. Eng. 2019, 700, 012033. [Google Scholar] [CrossRef]

- A Survey of Predictive Maintenance: Systems, Purposes and Approaches. Available online: https://www.researchgate.net/publication/337971929_A_Survey_of_Predictive_Maintenance_Systems_Purposes_and_Approaches (accessed on 25 January 2022).

- Krot, P.; Prykhodko, I.; Raznosilin, V.; Zimroz, R. Model Based Monitoring of Dynamic Loads and Remaining Useful Life Prediction in Rolling Mills and Heavy Machinery. In Advances in Asset Management and Condition Monitoring. Smart Innovation, Systems and Technologies; Ball, A., Gelman, L., Rao, B., Eds.; Springer: Cham, Switzerland, 2020; Volume 166, pp. 399–416. [Google Scholar] [CrossRef]

- Management Problems of Rolling Mills Equipment Technical Operation. Fundamental and Applied Problems of Ferrous Metallurgy. Available online: http://dspace.nbuv.gov.ua/bitstream/handle/123456789/21509/38-Krot.pdf?sequence=1 (accessed on 25 January 2022).

- Nordin, M.; Gutman, P.-O. Controlling mechanical systems with backlash—A survey. Automatica 2002, 38, 1633–1649. [Google Scholar] [CrossRef]

- Karandaev, A.S.; Gasiyarov, V.R.; Maklakova, E.A.; Loginov, B.M.; Khramshina, E.A. Method limiting dynamic loads of electromechanical systems of plate mill stand. In Proceedings of the IEEE Conference of Russian Young Researchers in Electrical and Electronic Engineering (EIConRus), Moscow and St. Petersburg, Russia, 29 January–1 February 2018; pp. 651–656. [Google Scholar] [CrossRef]

- Radionov, A.A.; Gasiyarov, V.R.; Karandaev, A.S.; Khramshin, V.R. Use of automated electric drives for limiting dynamic loads in shaft lines of roll mill stands. J. Eng. 2019, 2019, 3578–3581. [Google Scholar] [CrossRef]

- Ohlert, J.; Sprock, A.; Sudau, P. Digitalization in hot and cold rolling mills. Mat. Sci. Forum 2016, 854, 215–224. [Google Scholar] [CrossRef]

- Lei, Y.; Li, N.; Guo, L.; Li, N.; Yan, T.; Lin, J. Machinery health prognostics: A systematic review from data acquisition to RUL prediction. Mech. Syst. Signal Process. 2018, 104, 799–834. [Google Scholar] [CrossRef]

- Bachschmid, N.; Pennacchi, P.; Vania, A. Identification of multiple faults in rotor systems. J. Sound Vibr. 2003, 254, 327–366. [Google Scholar] [CrossRef]

- Tinga, T.; Loendersloot, R. Physical model-based prognostics and health monitoring to enable predictive maintenance. In Predictive Maintenance in Dynamic Systems: Advanced Methods, Decision Support Tools and Real-World Applications; Lughofer, E., Sayed-Mouchaweh, M., Eds.; Springer: Cham, Switzerland, 2019; pp. 313–353. [Google Scholar] [CrossRef]

- Mapelli, F.; Ruspini, E.; Sabbioni, E.; Tarsitano, D. A state observer for speed regulation in rolling mill drives. In Structural Dynamics, Volume 3. Conference Proceedings of the Society for Experimental Mechanics Series; Proulx, T., Ed.; Springer: New York, NY, USA, 2011; pp. 1193–1205. [Google Scholar] [CrossRef]

- Zhang, R.; Chen, Z.; Yang, Y.; Tong, C. Torsional vibration suppression control in the main drive system of rolling mill by state feedback speed controller based on extended state observer. In Proceedings of the IEEE International Conference on Control and Automation, Guangzhou, China, 30 May–1 June 2007; p. 4376745. [Google Scholar] [CrossRef]

- Xu, Y.; Chao-nan, T. Nonlinear Modeling and Global Sliding Mode Control of Main Drive System Torsional Vibration in Cold Rollling Mill. In Proceedings of the V International Conference on Intelligent Computation Technology and Automation, Zhangjiajie, China, 12–14 January 2012. [Google Scholar] [CrossRef]

- Fan, X.; Zang, Y.; Jin, K. Rolling process and its influence analysis on hot continuous rolling mill vibration. Appl. Phys. A 2016, 122, 1008. [Google Scholar] [CrossRef]

- Qian, C.; Zhang, L.; Hua, C. Adaptive Torsional Vibration Control of the Nonlinear Rolling Mill Main Drive System with Performance Constraints and Sensor Errors. Int. J. Control Autom. Syst. 2021, 19, 1264–1272. [Google Scholar] [CrossRef]

- Peng, Y.; Cui, J.; Sun, J.; Zhang, M. Torsional Vibration for Rolling Mill with the Drive System Shaft Axis Deviations. Arab. J. Sci. Eng. 2021, 46, 12165–12177. [Google Scholar] [CrossRef]

- Peng, R.; Zhang, X.; Shi, P. Vertical–Horizontal Coupling Vibration of Hot Rolling Mill Rolls under Multi-Piecewise Nonlinear Constraints. Metals 2021, 11, 170. [Google Scholar] [CrossRef]

- Fan, X.B.; Zhao, B.; Jiang, Y.; Fan, B.X. Review on main drive torsional vibration and roller coupling vibration of rolling mill. Recent Pat. Eng. 2020, 14, 1872–2121. [Google Scholar] [CrossRef]

- Butler, D.H.E.; Churches, M.A.; Anbe, Y.; Naitoh, H. Compensation of a digitally controlled static power converter for the damping of rolling mill torsional vibration. IEEE Trans. Ind. Appl. 1992, 28, 427–433. [Google Scholar] [CrossRef]

- Han, D.; Shi, P.; Xia, K. Nonlinear Torsional Vibration Dynamics Behaviors of Rolling Mill’s Multi-DOF Main Drive System under Parametric Excitation. J. Appl. Math. 2014, 2014, 202686. [Google Scholar] [CrossRef]

- Fan, X.; Zang, Y.; Sun, Y.; Wang, P. Impact Analysis of Roller System Stability for Four-High Mill Horizontal Vibration. Shock. Vib. 2016, 2016, 5693584. [Google Scholar] [CrossRef]

- Krot, P.V. Hot rolling mill drive train dynamics: Torsional vibration control and backlash diagnostics. Millenn. Steel China 2009, Annual Issue, 91–95. Available online: https://www.researchgate.net/publication/202044159_Hot_rolling_mill_drive_train_dynamics_torsional_vibration_control_and_backlashes_diagnostics (accessed on 25 January 2022).

- Krot, P.V. Nonlinear Vibrations and Backlashes Diagnostics in the Rolling Mills Drive Trains. In Proceedings of the 6th EUROMECH Nonlinear Dynamics Conference (ENOC 2008), Institute of Problems in Mechanical Engineering RAS, St. Petersburg, Russia, 30 June–4 July 2008; pp. 360–365. [Google Scholar] [CrossRef]

- Krot, P.V. Transient torsional vibrations control in the geared drive trains of the hot rolling mills. In Proceedings of the IEEE Multi-conference on Systems and Control, St. Petersburg, Russia, 8–10 July 2009; pp. 1368–1373. [Google Scholar] [CrossRef]

- Junquera, A.M.V.; González, J.G.; Balsera, J.M.V.; Montequín, V.R. A Wire Rod Rolling Mill Digital Twin for the Simulation of the Rolls Replacement Process. Proceedings 2020, 63, 13. [Google Scholar] [CrossRef]

- Riches, P. Rolling into the future, long rolling control system utilizing the changing trends in technology and digitalization. In Proceedings of the Technical Contribution to the 21° Seminário de Automação e TI, São Paulo, Brazil, 2–6 October 2017; p. 30728. [Google Scholar] [CrossRef]

- Kritzinger, W.; Karner, M.; Traar, G.; Jan, H.J.; Sihn, W. Digital Twin in manufacturing: A categorical literature review and classification. IFAC-PapersOnLine 2018, 51, 1016–1022. [Google Scholar] [CrossRef]

- Fuller, A.; Fan, Z.; Day, C.; Barlow, C. Digital Twin: Enabling Technologies, Challenges and Open Research. IEEE Access 2020, 8, 108952–108971. [Google Scholar] [CrossRef]

- Bouheraoua, M.; Wang, J.; Atallah, K. Influence of Control Structures and Load Parameters on Performance of a Pseudo Direct Drive. Machines 2014, 2, 158–175. [Google Scholar] [CrossRef]

- Radionov, A.A.; Karandaev, A.S.; Gasiyarov, V.R.; Loginov, B.M.; Gartlib, E.A. Development of an Automatic Elastic Torque Control System Based on a Two-Mass Electric Drive Coordinate Observer. Machines 2021, 9, 305. [Google Scholar] [CrossRef]

- Kolganov, A.R.; Lebedev, S.K.; Gnezdov, N.E. Electromechanotronic Systems. Modern Techniques for Control, Implementation, and Application; Infra-Engineering: Moscow, Russia; Vologda, Russia, 2019. [Google Scholar]

- Lebedev, S.K.; Kolganov, A.R. Commercial Manipulator Motion Control; Lenin Ivanovo State Power Engineering University: Ivanovo, Russia, 2018. [Google Scholar]

- Szabat, K.; Orlowska-Kowalska, T.; Dybkowski, M. Indirect adaptive control of induction motor drive system with an elastic coupling. IEEE Trans. Ind. Electron. 2009, 56, 4038–4042. [Google Scholar] [CrossRef]

- Szabat, K.; Orlowska-Kowalska, T. Control of the Drive System with Stiff and Elastic Couplings Using Adaptive Neuro-Fuzzy Approach. IEEE Trans. Ind. Electron. 2007, 54, 228–240. [Google Scholar] [CrossRef]

- Muszynski, R.; Deskur, J. Damping of Torsional Vibrations in High-Dynamic Industrial Drives. IEEE Trans. Ind. Electron. 2010, 57, 544–552. [Google Scholar] [CrossRef]

- Thomsen, S.; Hoffmann, N.; Fuchs, F.W. PI Control, PI-Based State Space Control, and Model-Based Predictive Control for Drive Systems With Elastically Coupled Loads—A Comparative Study. IEEE Trans. Ind. Electron. 2011, 58, 3647–3657. [Google Scholar] [CrossRef]

- Moghadam, F.K.; Nejad, A.R. Online condition monitoring of floating wind turbines drivetrain by means of digital twin. Mech. Syst. Signal Processing 2022, 162, 108087. [Google Scholar] [CrossRef]

- Falekas, G.; Karlis, A. Digital Twin in Electrical Machine Control and Predictive Maintenance: State-of-the-Art and Future Prospects. Energies 2021, 14, 5933. [Google Scholar] [CrossRef]

- Johansen, S.S.; Nejad, A.R. On Digital Twin Condition Monitoring Approach for Drivetrains in Marine Applications. In Proceedings of the ASME 38th International Conference on Ocean, Offshore and Arctic Engineering (OMAE), Glasgow, Scotland, UK, 9–14 June 2019; p. 95152. [Google Scholar] [CrossRef]

- Krot, P.V.; Prikhodko, I.Y. Rolling Mill Active Torsional Oscillation and Vibration Control. Machine Vibrations. In Measurement, Reduction, Protection: Scientific, Technical and Industrial Coll. of Papers. Iss. 3; Donetsk: DonSTU, Ukraine, 2009; pp. 44–60. [Google Scholar]

- Sieklucki, G. Optimization of Observers in a Two-Mass System—Dual LQ Problem. In Proceedings of the International Symposium on Electrical Machines (SME), Andrychow, Poland, 10–13 June 2018; p. 8442808. [Google Scholar] [CrossRef]

- Gasiyarov, V.R.; Khramshin, V.R.; Voronin, S.S.; Lisovskaya, T.A.; Gasiyarova, O.A. Dynamic Torque Limitation Principle in the Main Line of a Mill Stand: Explanation and Rationale for Use. Machines 2019, 7, 76. [Google Scholar] [CrossRef]

- Khramshin, V.R.; Karandaev, A.S.; Gasiyarov, V.R.; Zinchenko, M.A.; Loginov, B.M. Limiting Dynamic Loads in the Main Line of a Rolling Mill through an Automated Drive. In Proceedings of the International Russian Automation Conference (RusAu-toCon), Sochi, Russia, 6–12 September 2020; pp. 1122–1126. [Google Scholar] [CrossRef]

- Khramshin, V.R.; Gasiyarov, V.R.; Karandaev, A.S.; Baskov, S.N.; Loginov, B.M. Constraining the Dynamic Torque of a Rolling Mill Stand Drive. Bull. South Ural. State Univ. Ser. Power Eng. 2018, 18, 101–111. [Google Scholar] [CrossRef]

- Radionov, A.A.; Gasiyarov, V.R.; Karandaev, A.S.; Usatiy, D.Y.; Khramshin, V.R. Dynamic Load Limitation in Electromechanical Systems of the Rolling Mill Stand during Biting. In Proceedings of the IEEE 11th International Conference on Mechanical and Intelligent Manufacturing Technologies (ICMIMT), Cape Town, South Africa, 20–22 January 2020. [Google Scholar] [CrossRef]

- Radionov, A.A.; Karandaev, A.S.; Loginov, B.M.; Gasiyarova, O.A. Conceptual Areas of Creating Digital Twins of the Rolling Production Unit Electrical Systems. Russ. Electromech. 2021, 64, 54–68. [Google Scholar] [CrossRef]

- Barbieri, G.; Bertuzzi, A.; Capriotti, A.; Ragazzini, L.; Gutierrez, D.; Negri, E.; Fumagalli, L. A virtual commissioning based methodology to integrate digital twins into manufacturing systems. Prod. Eng. 2021, 15, 397–412. [Google Scholar] [CrossRef]

- Rauch, L.; Pietrzyk, M. Digital twins as a modern approach to design of industrial processes. J. Mach. Eng. 2019, 19, 86–97. [Google Scholar] [CrossRef]

- Rauch, L.; Bzowski, K.; Kuziak, R.; Uranga, P.; Gutierrez, I.; Isasti, N.; Jacolot, R.; Kitowski, J.; Pietrzyk, M. Computer-Integrated Platform for Automatic, Flexible, and Optimal Multivariable Design of a Hot Strip Rolling Technology Using Advanced Multiphase Steels. Metals 2019, 9, 737. [Google Scholar] [CrossRef]

- Wagg, D.J.; Worden, K.; Barthorpe, R.J.; Gardner, P. Digital twins: State-of-the-art future directions for modelling and simulation in engineering dynamics applications. ASCE—ASME J. Risk Uncertain. Eng. Syst. Part B. Mech. Eng. 2020, 6, 030901. [Google Scholar] [CrossRef]

- Gasiyarov, V.R. A Way to Limit the Dynamic Loads of the Plate Mill Stand Mechatronic Systems. Bull. South Ural. State Univ. Ser. Mach. Build. 2019, 19, 5–18. [Google Scholar] [CrossRef][Green Version]

- Karandaev, A.S.; Gasiyarov, V.R.; Radionov, A.A.; Loginov, B.M. Development of Digital Models of Interconnected Electrical Profiles for Rolling–Drawing Wire Mills. Machines 2021, 9, 54. [Google Scholar] [CrossRef]

- Radionov, A.A.; Gasiyarov, V.R.; Karandaev, A.S.; Loginov, B.M.; Khramshin, V.R. Advancement of Roll-Gap Control to Curb the Camber in Heavy-Plate Rolling Mills. Appl. Sci. 2021, 11, 8865. [Google Scholar] [CrossRef]

- Radionov, A.A.; Gasiyarov, V.R.; Baskov, S.N.; Karandaev, A.S.; Khramshin, V.R. Mathematical Modeling of Mechatronics System “Hydraulic Screwdown Mechanism-Electric Drive of Rolling Mill Stand”. IOP Conf. Ser. Mater. Sci. Eng. 2018, 361, 012020. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, D. Dynamic characteristics of a rolling mill drive system with backlash in rolling slippage. J. Mater. Processing Technol. 2000, 97, 69–73. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, D. Method of judging the self-excited vibration of rolling main drive system in rolling slippage. J. Sound Vib. 1998, 215, 1135–1143. [Google Scholar] [CrossRef]

- Chongyi, G.; Jianxiong, L.; Guojun, D. Comparative research of nonlinear torsional vibration in the drive system with clearances. In Proceedings of the 54th Annual Conference of the Society of Instrument and Control Engineers of Japan (SICE), Hangzhou, China, 28–30 July 2015; pp. 1003–1006. [Google Scholar] [CrossRef]

- Kuznetsov, B.I.; Nikitina, T.B.; Bovdui, I.V.; Voloshko, A.V.; Vinichenko, E.V. Mathematical Model of Independent Main Electric Drives of Rolling Mills with Synchronous Motors Considering Their Linkage Through the Metal Rolled. Tekhnichna Elektrodin. 2010, 2, 207–212. [Google Scholar]

- Kuznetsov, B.I.; Bovdui, I.V.; Voloshko, A.V.; Vinichenko, E.V. Mathematical Model of the Rolling Mill Main Drives Considering Their Linkage Through the Metal Rolled as a Robust Control System Object. Bull. Natl. Tech. Univ. KhPI 2009, 44, 56–61. [Google Scholar]

| Parameter | Symbol | Dimensions | Value |

|---|---|---|---|

| Moment of inertia of the first moving mass (the motor) | J1 | kg∙m2 | 125,000 |

| Moment of inertia of the second moving mass (the roll) | J2 | kg∙m2 | 114,571 |

| Elastic coupling rigidity | c12 | N∙m/rad | 5,934,842 |

| Eigenfrequency of elastic oscillations | ω12 | rad/s | 9.96 |

| Electric drive acceleration | ε0 | rad/s2 | 1–3 |

| Transmission gap | δ | Rad | 0.017–0.085 (1–5°) |

| Mean elastic torque | M12 | MN∙m | 1.9 |

| Damping ratio | β | - | 2.817 |

| Attenuation decrement | ξ | - | 0.172 |

| Speed controller gain | ksc | - | 19.5 |

| Speed controller time constant | Tsc | S | 0.0041 |

| Parameter | Oscillogram Value | |||||

|---|---|---|---|---|---|---|

| Open Angular Play | Early Play Locking | |||||

| Motor Torque | Mst | Mmax | ktorque | Mst | Mmax | ktorque |

| kN∙m | unit | kN∙m | unit | |||

| 1750 | 3250 | 1.9 | 1750 | 2850 | 1.6 | |

| Motor Speed | ncap | nmin | Δ | ncap | nmin | Δ |

| rps | % | rps | % | |||

| 0.82 | 0.71 | 13.4 | 0.76 | 0.69 | 9.2 | |

| Parameter | Dynamic Torque Deviations in Figure 10a | ||

|---|---|---|---|

| Motor Torque | Mmotor_1 (max) | Mmotor_2 (max) | ΔMmotor (max), % |

| 190 | 210 | 9.5 | |

| Spindle Torque | Mshaft_1 (max) | Mshaft_2 (max) | ΔMshaft (max), % |

| 169 | 232 | 27 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gasiyarova, O.A.; Karandaev, A.S.; Erdakov, I.N.; Loginov, B.M.; Khramshin, V.R. Developing Digital Observer of Angular Gaps in Rolling Stand Mechatronic System. Machines 2022, 10, 141. https://doi.org/10.3390/machines10020141

Gasiyarova OA, Karandaev AS, Erdakov IN, Loginov BM, Khramshin VR. Developing Digital Observer of Angular Gaps in Rolling Stand Mechatronic System. Machines. 2022; 10(2):141. https://doi.org/10.3390/machines10020141

Chicago/Turabian StyleGasiyarova, Olga A., Alexander S. Karandaev, Ivan N. Erdakov, Boris M. Loginov, and Vadim R. Khramshin. 2022. "Developing Digital Observer of Angular Gaps in Rolling Stand Mechatronic System" Machines 10, no. 2: 141. https://doi.org/10.3390/machines10020141

APA StyleGasiyarova, O. A., Karandaev, A. S., Erdakov, I. N., Loginov, B. M., & Khramshin, V. R. (2022). Developing Digital Observer of Angular Gaps in Rolling Stand Mechatronic System. Machines, 10(2), 141. https://doi.org/10.3390/machines10020141