Abstract

Chalk lines are used to print layouts in construction sites to indicate the location of attaching or cutting objects; printing depends on the skills of workers and is suitable for small-scale work. Moreover, this type of work requires a precise measurement process, which is time-consuming, to avoid errors. Thus, discrepancies between blueprints and construction site layouts can occur if construction plans and management are not uniformly aligned. To improve the traditional floor-layout-printing technique on construction sites, this study introduces a manually operated mecanum-wheeled mobile robot in the preliminary stage, i.e., before the development of a full-fledged automated system. This manually operated robot helps determine the technologies required for robotic automation. In the development process, layout-printing technology is classified into a marking toolkit, control system that can be manually operated, and mobile driver. To improve layout-printing quality, this study adopted a mecanum-wheeled design to improve mobility. In this study, applied tests are required to consider the site environment for automatically marking floor layout prints. To determine the applicability of the developed technology, this study conducted a field applicability experiment with a pen-type marking module and laser-type toolkit. The experiment confirmed that layout printing based on environmental changes on the construction site can be manually performed using the mobile robot system. To automatically mark floor-layout-printing work, it is necessary to consider the floor characteristics on the construction site. In addition, this experiment shows that the newly applied laser toolkit technology can be applied to layout printing within 12 mm from the floor. To apply this mechanism to a mobile robot that can automate layout printing, it is necessary to technically enhance the optimization of marking quality, e.g., floor separation distance and marking thickness.

1. Introduction

Several studies have taken advantage of the Fourth Industrial Revolution to develop applications that leverage automated systems to effectively handle meticulous and time-consuming processes [1], e.g., the layout-printing work performed at construction sites. This process involves floor-marking using chalk boxes, chalk, and string to indicate reference points where columns and walls should be erected [2].

The precision level of conventional layout-printing techniques varies based on the skills of on-site workers, e.g., carpenters [3]. Moreover, discrepancies between the on-site layout and blueprint have been cited as one of the main factors deteriorating construction quality [4].

Layout-printing workers on construction sites use chalk lines to indicate the location of attaching or cutting objects. Other measuring devices, e.g., measuring tape, are used to measure the length (Figure 1) [5]. Moreover, in the marking process, workers hold both ends of the chalk line and check blueprints; this process is labor-intensive [6,7].

Figure 1.

Printing tool used and layout-printing work performed on construction sites: (a) layout-printing tool; (b) layout-printing work.

This traditional technique, which is highly dependent on the skills of workers, is only suitable for small-scale work [8]. Moreover, this type of work requires a lengthy process [9] for accurate measurement and, thus, often leads to errors [10]. Therefore, in a few construction sites, where construction plans and management are not uniformly aligned, discrepancies between the construction site layout and blueprint may occur [11].

To improve the traditional floor-layout-printing technique on construction sites, this study introduces a manually operated mecanum-wheeled mobile robot in the preliminary stage before the development of a full-fledged automated system [12]. This manually operated robot helps determine technologies required for full-scale automation [13,14].

In the development process, layout-printing technology is classified into a marking toolkit, control system that can be manually operated, and mobile driver [15]. To improve layout-printing quality, this study adopted a mecanum wheel design to improve mobility.

The development process described in this study is to determine whether layout printing can be manually implemented on the construction site using the mobile robot system in different environments [16]. To this end, this study conducted the following three analyses:

- -

- Analysis of the marking toolkit module for layout printing;

- -

- Analysis of the laser-type toolkit considering the floor environment on the construction site;

- -

- Analysis of mobile robots and systems that can be manually operated before the automation stage.

In this study, applied tests are required to consider the site environment for automatically marking floor layout prints [17]. This study conducted the following two experiments to determine the applicability of the developed technology:

- -

- Layout printing applicability test of the marking toolkit module;

- -

- Field applicability test of the laser-type toolkit.

These experiments are intended to examine the possibility of marking the pen type and determine the environmental applicability of the developed technology by conducting a concrete floor experiment. In addition, a laser toolkit has been used for the application of new marking technology. This technology has been experimentally evaluated to confirm that layout printing can be used on the construction site floor.

2. Material: Development of a Mobile Robot That Prints Construction Layouts

2.1. Development of Marking Modules for Layout Printing

Industrial markers are used on materials with irregular surfaces and weak adhesion, e.g., glass, plastics, concrete, and wood [18]. In particular, these markers can be used on wet, oily, and rough surfaces and rapidly dry with minimal smudging [19]. Therefore, in this study, a modular design was developed using an industrial non-toxic ink-based pointed marker as the marking tool.

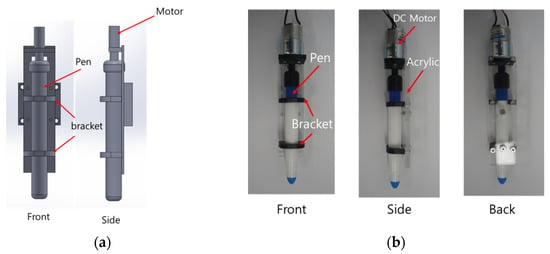

Rotating the top part of the pen causes the marker to protrude (Figure 2). Considering marker wear, a pen-type marking toolkit was designed that adjusts the length of the pen tip and allows for continuous marking on the floor.

Figure 2.

Development of a pen-type module for the marking toolkit: (a) Solidworks design; (b) marking toolkit.

A single pen-type module was developed in which the pen was fixed to the acrylic backside using semicircle-shaped brackets. To minimize the pen movement, the brackets were fixed with bolts.

The cap was designed for low-cost twist-up pens with different colors and water-based functions. The cap was equipped with a DC motor that adjusted the length of the pen tip based on rotation.

In addition, considering floor surface characteristics, this study developed a toolkit on which a laser module could be mounted. It includes the same brackets as the pen-type toolkit and can be readily attached to and detached from the robot.

This study developed toolkits with a flexible modular design that can accommodate different modules depending on the marking surface. A manually operated mecanum-wheeled mobile robot was developed to perform a fundamental test of the toolkits. Section 2.2 describes a manually operated mobile robot that can accommodate the developed toolkits.

2.2. Manually Operated Mobile Robot

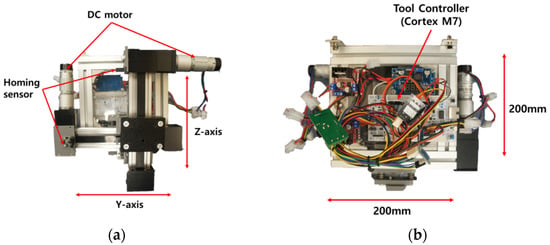

This study developed a system that enables the movement of the developed toolkits along the y and z axes (Figure 3). The system exhibits a modular design and can be readily attached to and detached from the mobile robot. A tool controller (Cortex M7) can be mounted on its rear side to control the movement along the y and z axes. It was developed as an all-in-one device for efficient modular expansion and proper and timely maintenance and repair in case of failure [20].

Figure 3.

Toolkit control mechanism: (a) front; (b) back.

Furthermore, for marking efficiency, this study developed a mechanism to maintain the toolkit along the z-axis depending on the surface. In combination with linear rails, brackets were developed that allowed movements along the y and z axes (horizontal and vertical); interrupt sensors can be mounted on the brackets.

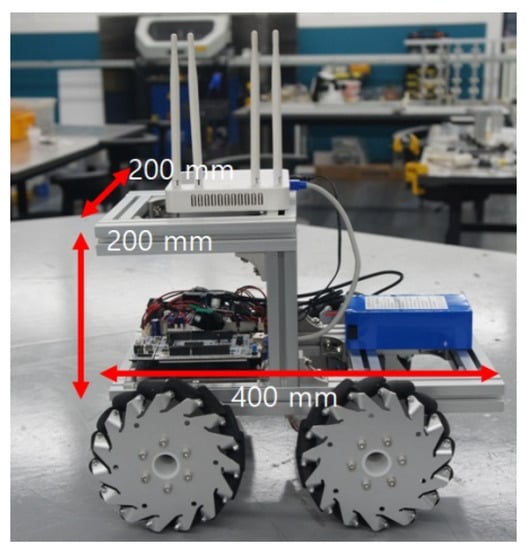

Considering the working environment on construction sites, the mecanum-wheeled mobile robot was developed to move the toolkits instead of using a regular mobile robot (Figure 4). The omnidirectional design of the mecanum wheel allows the robot to move in any direction (forward, backward, diagonal, and U-turns), even in narrow spaces [21].

Figure 4.

Mecanum wheel.

The dimension of the mecanum-wheeled mobile robot was 200 × 400 × 200 mm3 (width × depth × height), with a wheel size of 147 mm. The robot was equipped with a cargo space to accommodate batteries or laptops.

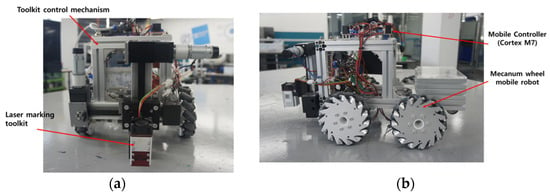

As shown in Figure 5, the toolkit control mechanism was integrated into the mecanum-wheeled mobile robot. The toolkit control mechanism was assembled so that it could print while moving along the y and z axes. The mobile robot was developed to move along the x-axis and print on the surface following the shape of the line.

Figure 5.

Toolkit control mechanism assembly on the mecanum-wheeled mobile robot: (a) front view; (b) side view.

Section 2.3 describes the overall toolkit system designed to operate the developed hardware tool, toolkit controller, and mecanum-wheeled mobile robot.

2.3. System Design

The overall system culminated in the design of a mobile robot that can be manually operated. The robot was equipped with a flexible voltage system (input voltage of 0–24 V and output voltages of 12 and 9 V) to accommodate multiple toolkits. Moreover, it included two C-motors, which allowed the toolkit control mechanism to maneuver along the y and z axes; the motors were mounted on the robot for hardware-independent movement.

The robot was designed to allow the individual movement of pen-type and laser-type toolkits. Moreover, it allows two pens in a double-pen toolkit to move independently.

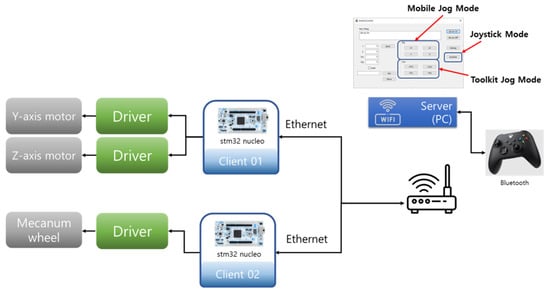

To operate the toolkit and mobile robot and implement the toolkit control mechanism, the freeRTOS operating system for microcontroller units (MCU) (Cortex M7) was embedded in each driver to perform real-time operations (Figure 6). A homing sensor, motor control, and ethernet connection were installed to ensure the real-time operation of each function. To analyze movements and work functions required for printing, systems were developed for manual operation instead of automation to help users proactively learn and propose suggestions for positive changes.

Figure 6.

Composition of the overall system.

To facilitate layout-printing experiments, a Bluetooth joystick was used for manual operation. This joystick, which is linked to a Windows-based user program, can control the movement of the toolkit mounted on the multilayer mechanism part and the operation of the mobile robot.

As shown in Figure 6, a Microsoft Foundation Class (MFC)-based server was built, so that the controller of each driver could connect to a corresponding client for joystick-based operations. To analyze the layout printing quality, depending on the surface conditions, a joystick-based operation was deployed to simulate manual inspection [22].

Section 3 describes the actual experiments in which the manually operated mecanum-wheeled mobile robot printed on a piece of paper and concrete floor, while alternately employing the pen-type and laser-type toolkits.

3. Tests and Results: Experiments for Manual Operation Considering Field Applicability with the Toolkits

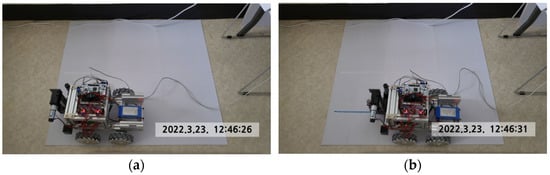

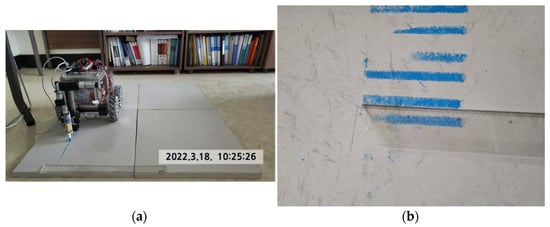

Two experiments were conducted using the developed marking toolkits under different surface conditions: a B4 sheet of paper placed on the floor and a markable concrete panel. Figure 7 shows the printing results of the mobile robot equipped with a toolkit controller on which the blue pen-type marking toolkit was mounted, moving along the x-axis based on joystick operations. The results confirmed that the robot printed a blue line on the B4 paper. The distance from the floor surface affected the thickness and accuracy of the marking.

Figure 7.

Pen-type toolkit testing on paper: (a) before the test; (b) after the test.

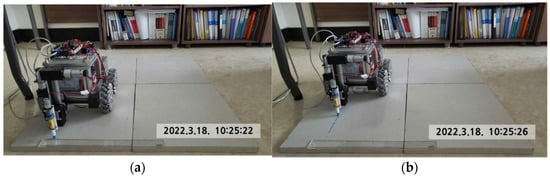

After the paper test, a concrete panel was constructed and used as a test bed for the functional analysis of layout printing. This test bed was used to build an environment that mimicked an actual construction site for simulation.

The same pen-type toolkit was used to test the concrete panel. As shown in Figure 8, the robot functioned properly on the concrete floor and printed accurately.

Figure 8.

Pen-type toolkit test on the concrete panel: (a) before the test; (b) after the test.

After marking using the pen-type toolkit, the pen type was replaced with a laser toolkit, and a functional test was conducted on the concrete panel (Figure 9).

Figure 9.

Laser-type toolkit test on concrete panel: (a) before the test; (b) after the test.

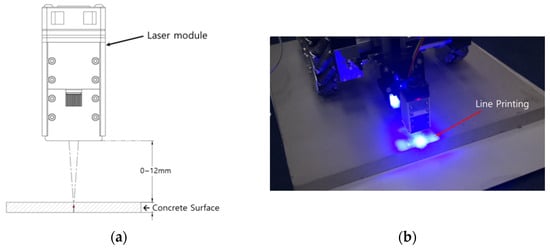

The test indicated that the laser toolkit could only print when it was positioned approximately 12 mm from the concrete floor surface (Figure 10). This study hypothesized that using a laser can cause safety problems; however, it posed a negligible risk to the surrounding environments.

Figure 10.

Development of a laser-type module for the marking toolkit: (a) laser-type marking toolkit concept; (b) laser-type marking toolkit testing.

Using the manually operated mobile robot, performance tests were conducted for the marking toolkits, and functional tests were performed for the robot to explore the possibility of using automated technology on real construction sites.

4. Discussion and Findings

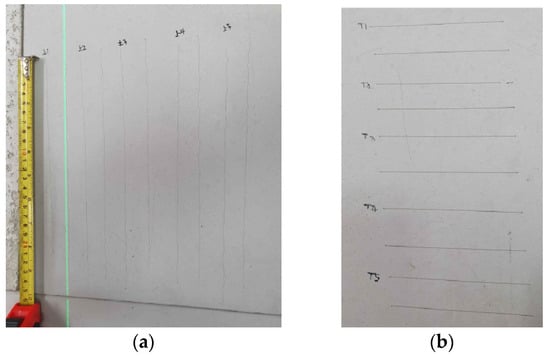

In this study, the test on the concrete panel confirmed marking with a traditional marking-type tool, i.e., a pen-type tool. As shown in Figure 11, the functional test was smoothly conducted on the concrete floor, and line marking was accurately displayed in the marking test. However, the marker at the end of the pen could not evenly print because the concrete floor surface was uneven.

Figure 11.

Pen-type toolkit experiment on concrete plane: (a) pen-type toolkit printing test; (b) pen-type toolkit printing test results.

To solve experimental problems, this study developed a system capable of moving along the y and z axes to improve the scalability of layout-printing automation and printing quality. In the case of the y-axis, layout printing on the construction site may require printing of line 2 (double line) instead of line 1. In this case, when the multilayer marking tool is used [15], the y-axis may be required to be separated from the direction of the motion of the mobile. Thus, as explained above, this study developed a mechanism unit capable of moving along the y-axis considering the scalability of such automation. The y-axis will supplement the role and scenario in the layout printing process.

In the case of the z-axis, during the experiment, it is necessary to examine a phenomenon in which printing does not appear evenly because the floor surface of the construction site is not flat. This scenario affects the environment of the concrete floor depending on the characteristics of the construction site. With regard to the scalability of layout printing, this study considered the z-axis separation distance, which needs to be reviewed, for the development of the proposed instrument. In the future, this study will conduct an optimization test for separation using sensors.

The experimental apparatus in this study was replaced with the laser-type toolkit after checking whether it was marked as the fan-type on a concrete panel. The experiment was conducted with a functional test on the concrete floor.

As shown in Figure 12, the layout-printing test results indicate that printing is difficult using a 30-W laser module, despite the focus adjustment, depending on the distance between the laser and concrete panel. However, when a 40-W laser module is used and the focus is adjusted to within 12 mm from the concrete panel, it becomes possible to print on the concrete panel. As illustrated in Figure 12, the robot functions properly on the surface of the concrete floor and prints accurately. In particular, the laser-type toolkit can print on a concrete panel with a thickness similar to that of layout printing performed on actual construction sites.

Figure 12.

Test results of a laser-type toolkit printing test involving (a) a smooth concrete panel; (b) a rough concrete panel.

5. Conclusions

This study introduced a manually operated toolkit robot to simplify the layout-marking process on construction sites. In the functional tests, researchers manually operated the developed marking toolkits and confirmed their ability to mark on a B4 sheet of paper and concrete panel. In particular, the laser-type marking toolkit prints demonstrated thickness similar to that of the layout prints of actual construction sites.

The pen-type toolkit developed in this study can be used on construction sites. Functionally, it can be readily applied to robotic work environments.

However, this study needs to examine one problem during experiments, i.e., prints do not appear evenly because the floor surface of the construction site is not flat. Moreover, this case affects the characteristics of the concrete floor surface depending on the environment of the construction site. This study considered the z-axis separation distance for the development of an instrument considering the scalability of layout printing. Future studies intend to perform a test to set an optimal separation distance using sensors, e.g., end-effecters.

The laser-type toolkit functioned properly within 12 mm of the floor surface. Although the laser-type toolkit exhibited no significant problems, equipment safety needs to be considered. Moreover, correlation analyses, along with a series of tests on worker visibility, are required to investigate various conditions, e.g., distance and sintering temperature, to optimize marking thickness.

The authors suggest that experiments aimed at improving marking-position accuracy and marking quality should be conducted in future studies to incorporate full-scale layout-printing automation in mobile robots. Moreover, additional features, e.g., obstacle avoidance, foreign-body removal, and marking quality confirmation, should be considered to help mobile robots effectively cope with construction-related constraints and achieve high-quality layout printing.

Author Contributions

E.S.P. and A.Y.L. were responsible for the design and development of the system. E.S.P., A.Y.L. and H.C.S. were responsible for design information and concepts. E.S.P. and H.C.S. were responsible for data interpretation. E.S.P. wrote the first draft of the article. E.S.P. were responsible for funding acquisition. A.Y.L. and H.C.S. were responsible for supervision. All authors have read and agreed to the published version of the manuscript.

Funding

This work is supported by the Korea Agency for Infrastructure Technology Advancement(KAIA) grant funded by the Ministry of Land, Infrastructure and Transport (Grant 22CTAP-C163606-02).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Kim, K.P.; Freda, R.; Nguyen, T.H.D. Building information modeling feasibility study for building surveying. Sustainability 2020, 12, 4791. [Google Scholar] [CrossRef]

- Tanaka, K.; Kajitani, M.; Kanamori, C.; Itoh, H.; Abe, Y.; Tanaka, Y. Development of Marking Robot Working at Building. Autom. Robot. Constr. 1995, 12, 235–242. [Google Scholar]

- Sestras, P. Methodological and On-site Applied Construction Layout Plan with Batter Boards Stake-Out Methods Comparison: A Case Study of Romania. Appl. Sci. 2021, 11, 4331. [Google Scholar] [CrossRef]

- Sakamoto, S.; Kano, N.; Igarashi, T.; Kishimoto, H.; Fujii, H.; Oosawa, Y.; Minami, K.; Ishida, K. Laser Marking System Based on 3D CAD Model. In Proceedings of the 28th International Symposium on Automation and Robotics in Construction, Seoul, Korea, 29 June–2 July 2011; pp. 64–69. [Google Scholar]

- Tsuruta, T.; Miura, K.; Miyaguchi, M. Mobile Robot for Marking Free Access Floors at Construction Sites. Autom. Constr. 2019, 107, 102912. [Google Scholar] [CrossRef]

- Inoue, F.; Ohmoto, E. Development of High Accuracy Position Marking System Applying Mark Robot in Construction Site. In Proceedings of the 50th Annual SICE Conference, Tokyo, Japan, 13–18 September 2011; pp. 2413–2417. [Google Scholar]

- Hossain, M.A.; Zhumabekova, A.; Paul, S.C.; Kim, J.R. A review of 3D printing in construction and its impact on the labor market. Sustainability 2020, 12, 8492. [Google Scholar] [CrossRef]

- Jensfelt, F.; Gullstrand, G.; Förell, E. A mobile robot system for automatic floor marking. J. Field Robot. 2006, 23, 441–459. [Google Scholar] [CrossRef]

- Zhao, J.; Hu, Y.; Tian, M. Pose Estimation of Excavator Manipulator Based on Monocular Vision Marker System. Sensors 2021, 21, 4478. [Google Scholar] [CrossRef] [PubMed]

- Se, S.; Lowe, D.G.; Little, J. Mobile Robot Localization and Mapping with Uncertainty Using Scale Invariant Visual Landmarks. Int. J. Robot. Res. 2002, 21, 735–758. [Google Scholar] [CrossRef]

- Kitahara, T.; Satoub, K.; Onoderac, J. Marking Robot in Cooperation with Three-Dimensional Measuring Instruments. In Proceedings of the 35th International Symposium on Automation and Robotics in Construction, Berlin, Germany, 20–25 July 2018; pp. 292–299. [Google Scholar]

- Chalhoub, J.; Ayer, S. Exploring the performance of an augmented reality application for construction layout tasks. Multimed. Tools Appl. 2019, 78, 35075–35098. [Google Scholar] [CrossRef]

- Balzan, A.; Aparicio, C.; Trabucco, D. Robotics in Construction: State-of-Art of On-site Advanced Devices. Int. J. High-Rise Build. 2020, 9, 95–104. [Google Scholar]

- Yuan, X.; Yuan, X.; Wang, X. Path Planning for Mobile Robot Based on Improved Bat Algorithm. Sensors 2021, 21, 4389. [Google Scholar] [CrossRef] [PubMed]

- Park, E.S.; Seo, H.C.; Lee, A.Y. Development of a Multi-layer Marking Toolkit for Layout Printing Automation at Construction Sites. Sensors 2022, 22, 4822. [Google Scholar] [CrossRef] [PubMed]

- Roy, D.; Chowdhury, A.; Maitra, M.; Bhattacharya, S. Geometric Region-Based Swarm Robotics Path Planning in an Unknown Occluded Environment. IEEE Trans. Ind. Electron. 2020, 68, 6053–6063. [Google Scholar] [CrossRef]

- Cao, J.; Pu, G.; Yan, H.; Huang, G.; Guo, Q.; Shi, S.; Yang, M. Coding Technology of Building Space Marking Position. Artificial Intelligence for Communications and Networks; Springer: Cham, Switzerland, 2021; pp. 571–587. [Google Scholar]

- Peel, H.; Luo, S.; Cohn, A.G.; Fuentes, R. Localisation of a mobile robot for bridge bearing inspection. Autom. Constr. 2018, 94, 244–256. [Google Scholar] [CrossRef]

- Tsuruta, T.; Miura, K.; Miyaguchi, M. Improvement of Automated Mobile Marking Robot System Using Reflectorless Three-Dimensional Measuring Instrument. In Proceedings of the 35th International Symposium on Automation and Robotics in Construction, Berlin, Germany, 20–25 July 2018; pp. 756–763. [Google Scholar]

- Calderon, W.T.; Roberts, D.; Golparvar-Fard, M. Synthesizing Pose Sequences from 3D Assets for Vision-Based Activity Analysis. J. Comput. Civ. Eng. 2021, 35, 04020052. [Google Scholar] [CrossRef]

- Liang, C.J.; Lundeen, K.M.; McGee, W.; Menassa, C.C.; Lee, S.; Kamat, V.R. A Vision-Based Marker-Less Pose Estimation System for Articulated Construction Robots. Autom. Constr. 2019, 104, 80–94. [Google Scholar] [CrossRef]

- Xu, W.; Huang, S.; Han, D.; Zhang, Z.; Gao, Y.; Feng, P.; Zhang, D. Toward Automated Construction: The Design-To-Printing Workflow for a Robotic In-situ 3D Printed House. Case Stud. Constr. Mater. 2022, 17, e01442. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).