Study on the Preparation and Performance of Self-Regressive Fixed Abrasive Chemical Mechanical Polishing Pad

Abstract

:1. Introduction

2. Preparation of the SR-FAPP

3. Study on the Physical and Mechanical Properties of the SR-FAPP

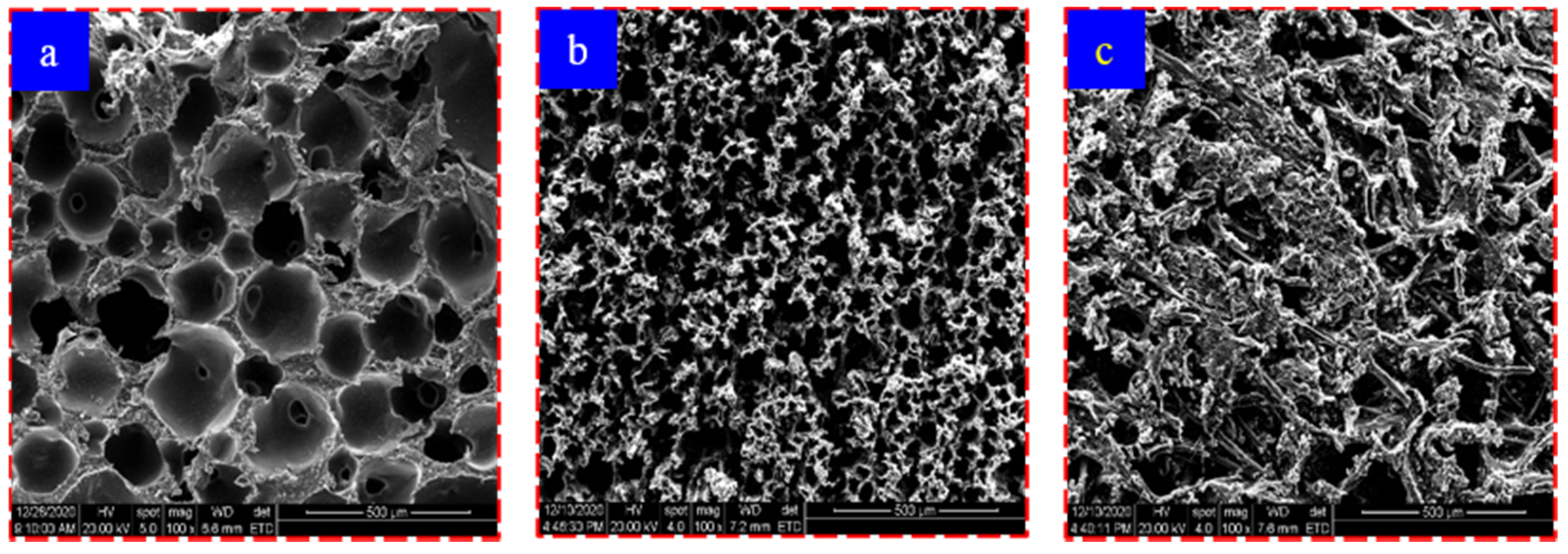

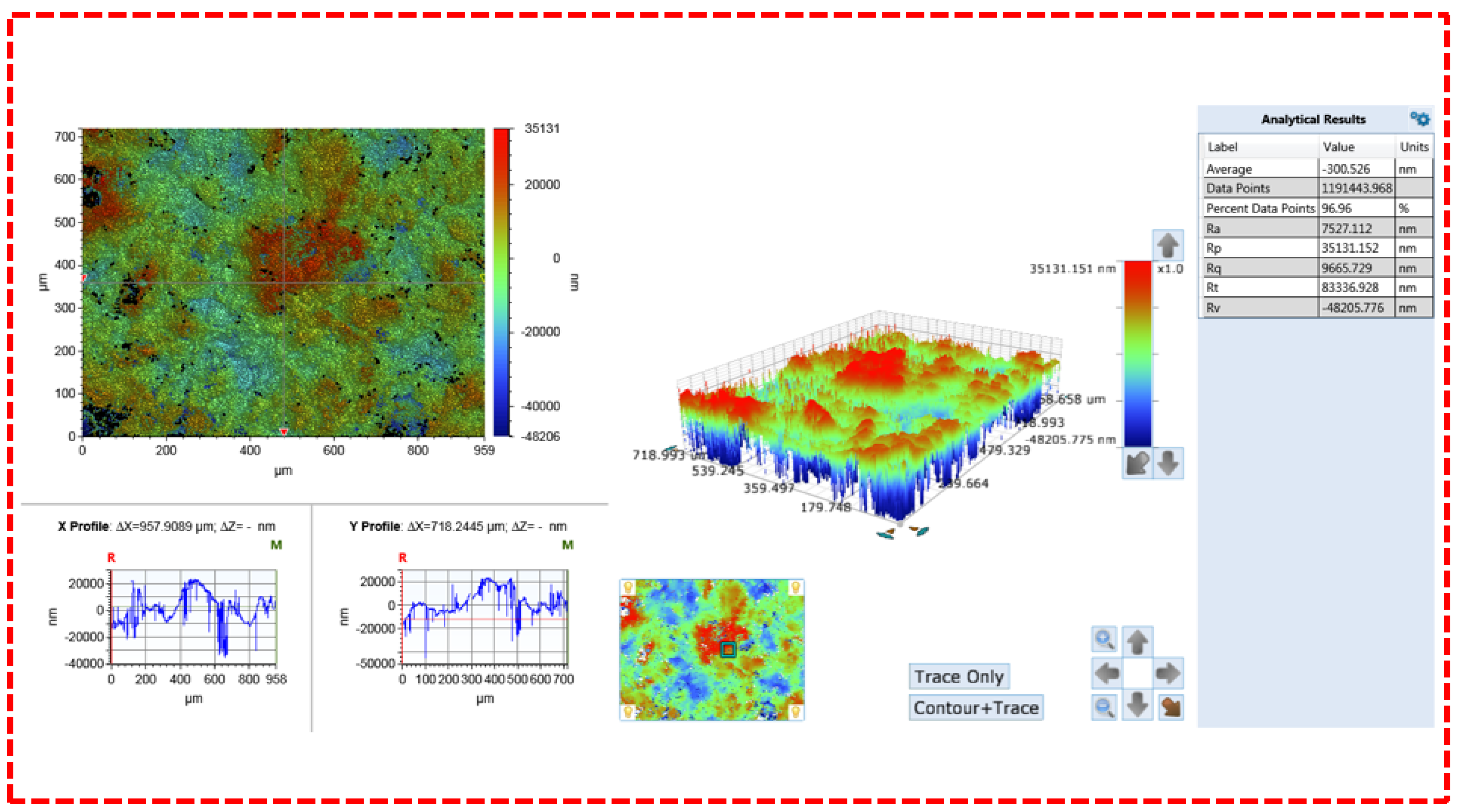

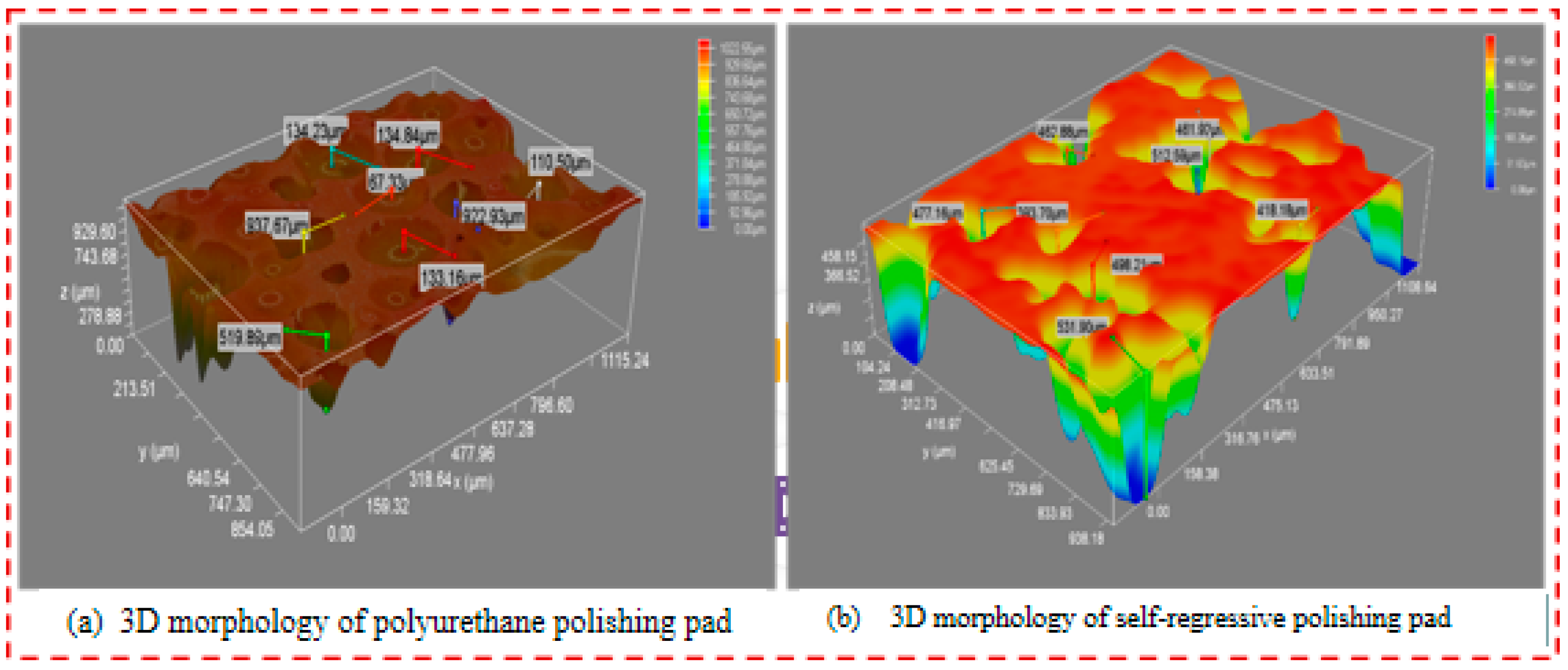

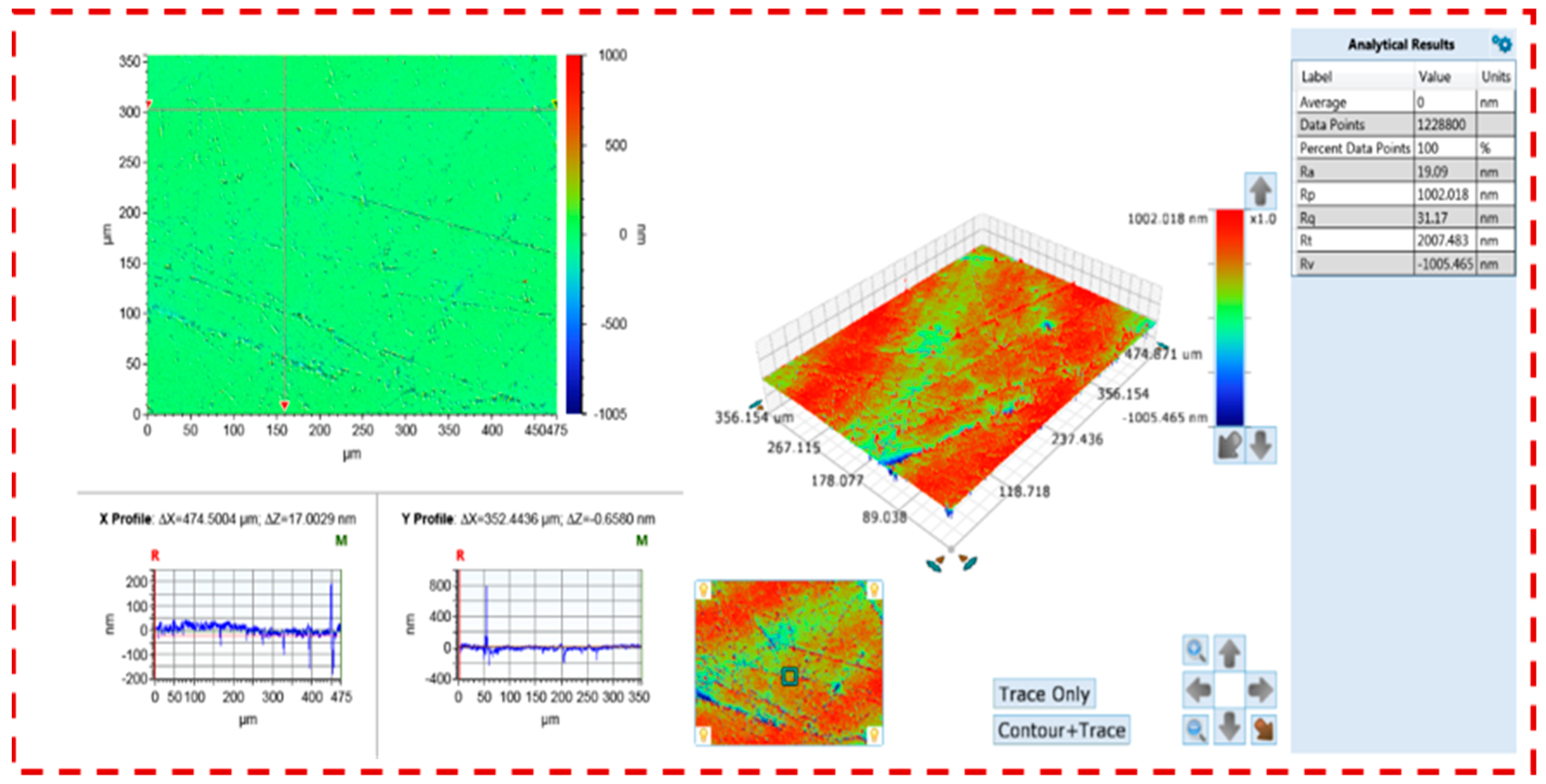

3.1. Study on the Surface Structure of the SR-FAPP

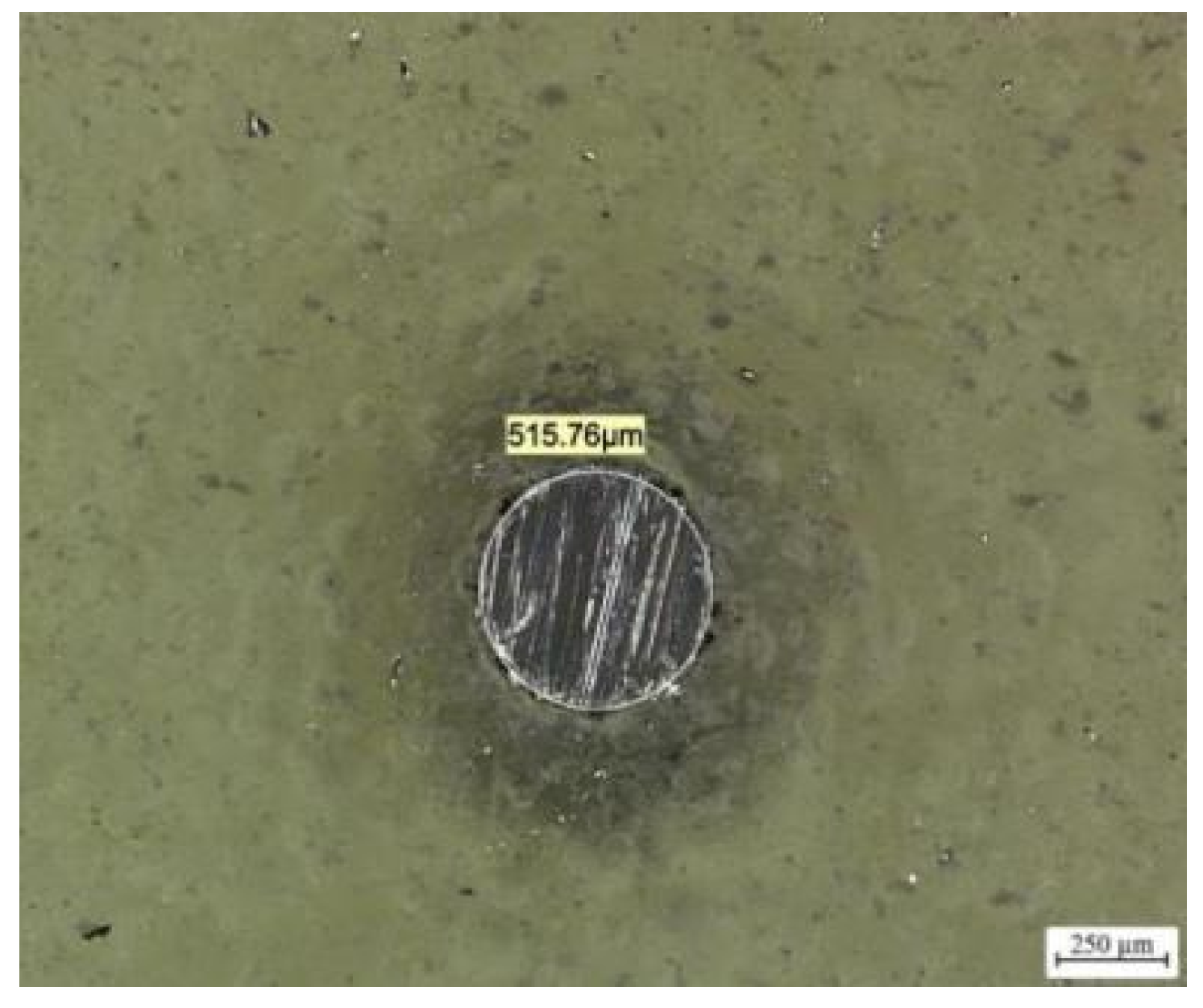

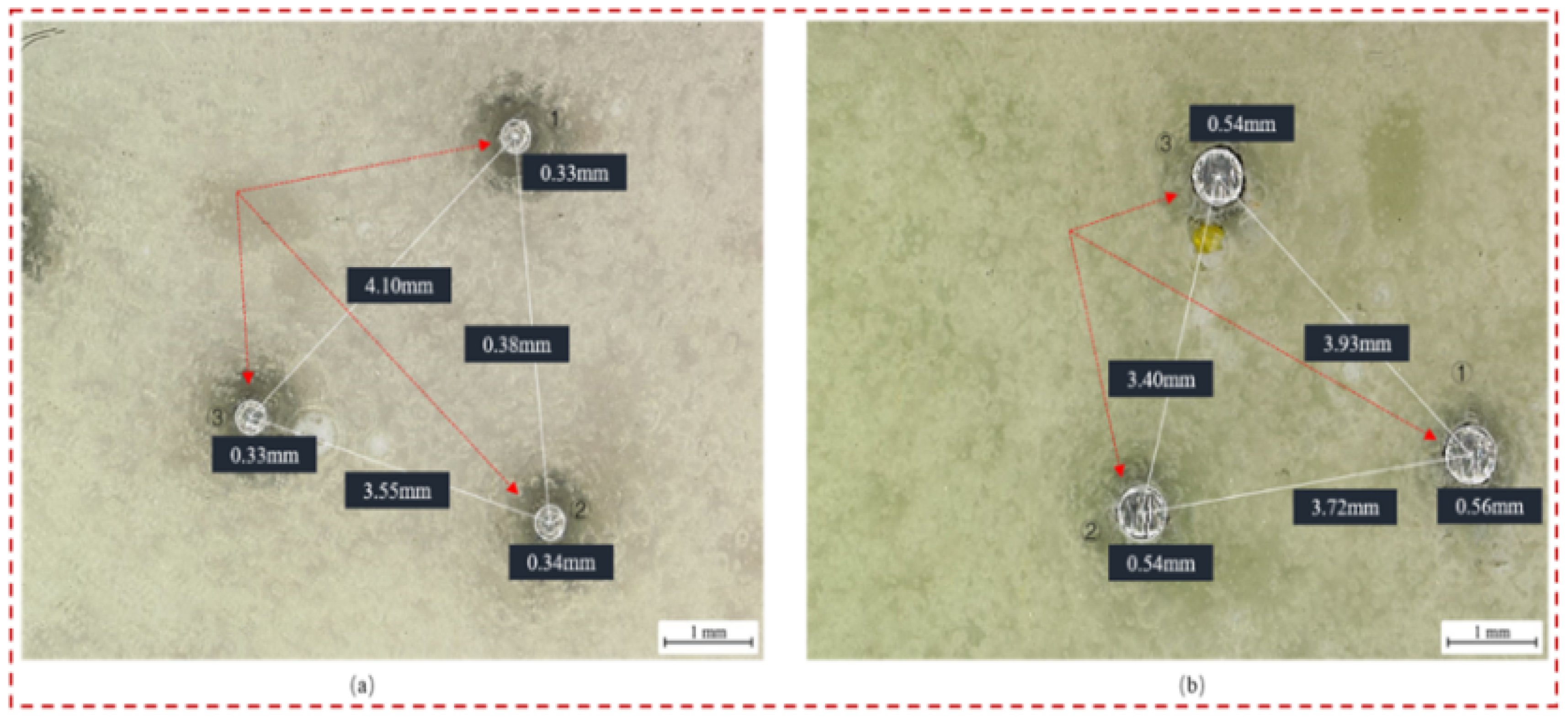

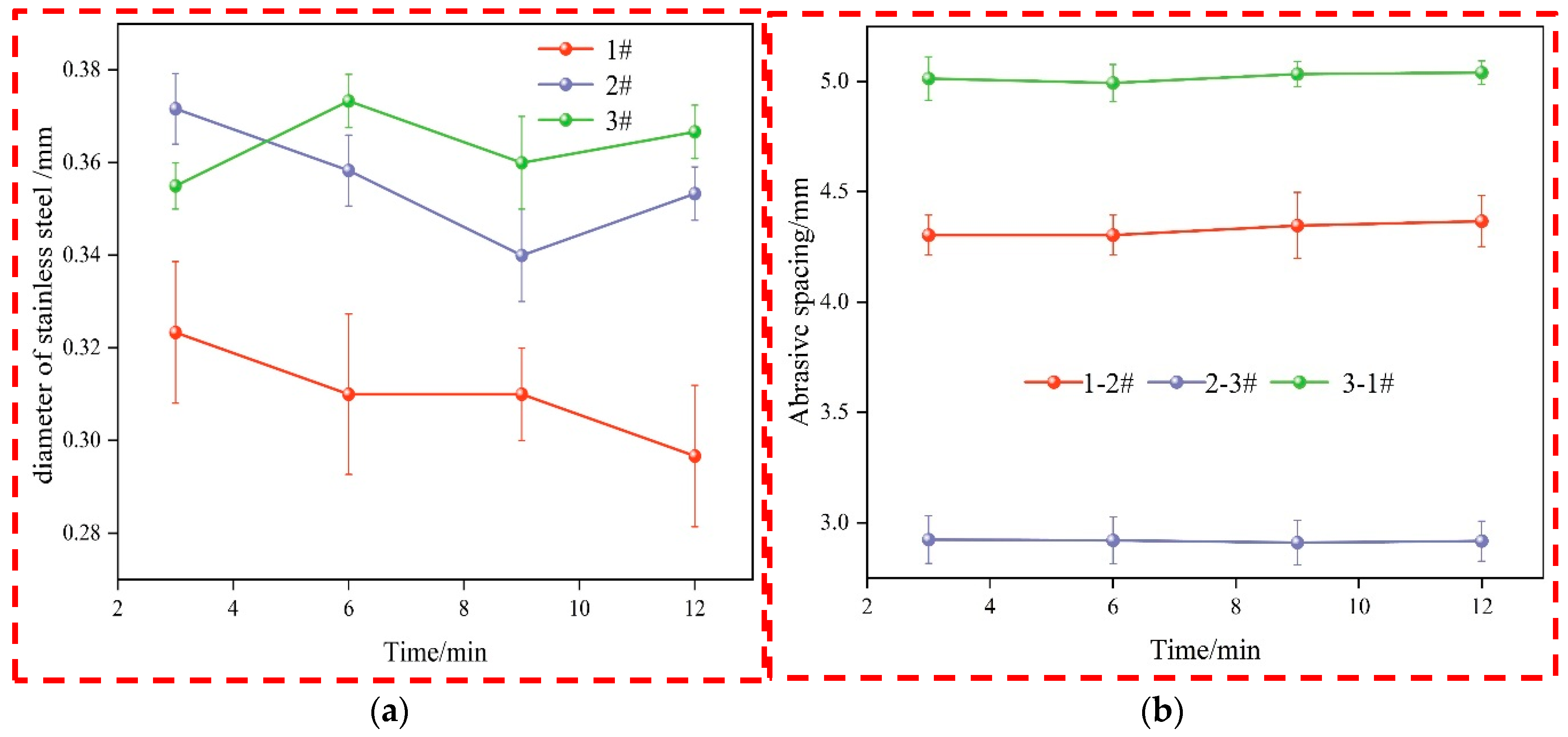

3.2. Study on the Gripping Force of the Self-Repressive Fixed Abrasive Polishing Pad Substrate to Abrasive Particles

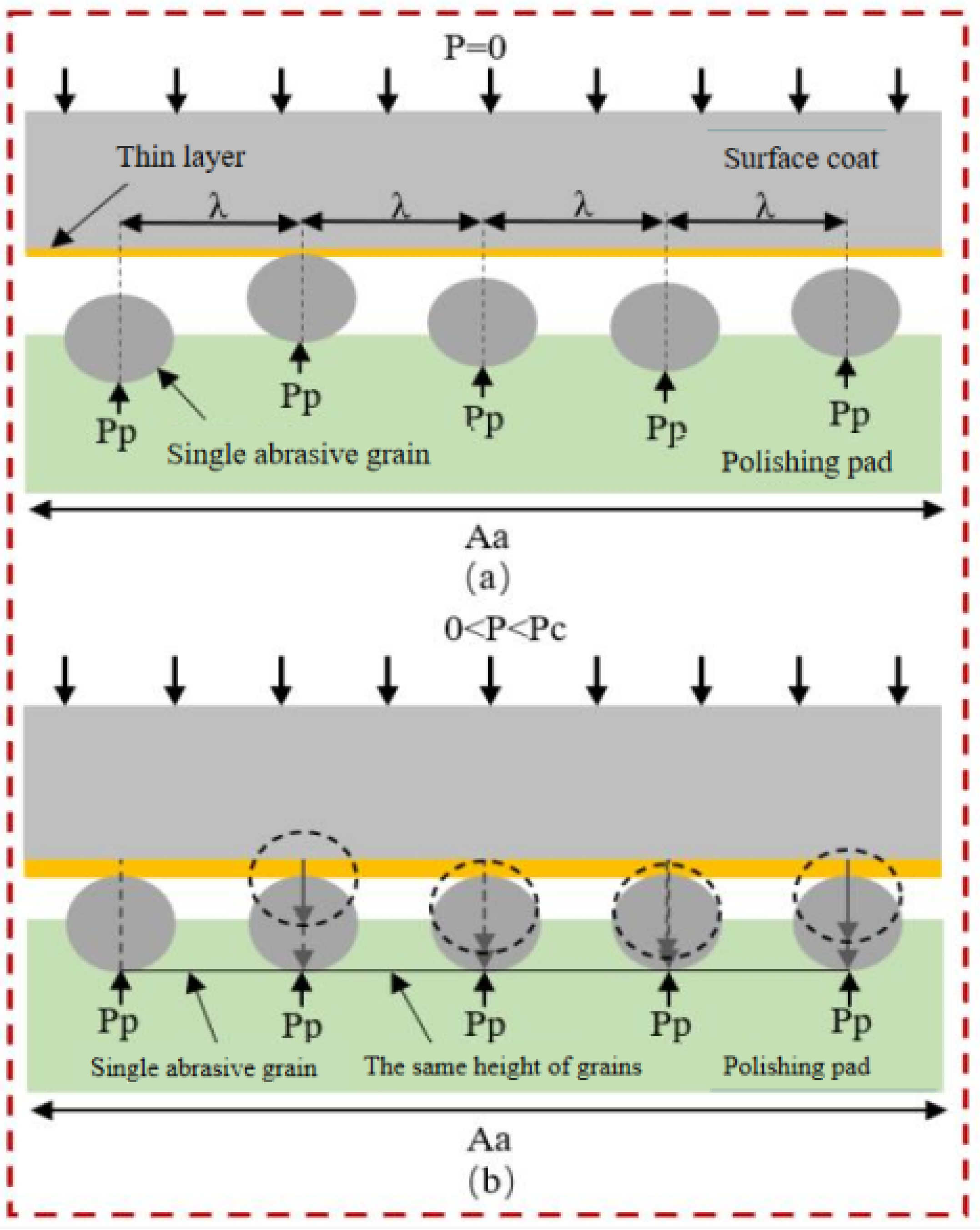

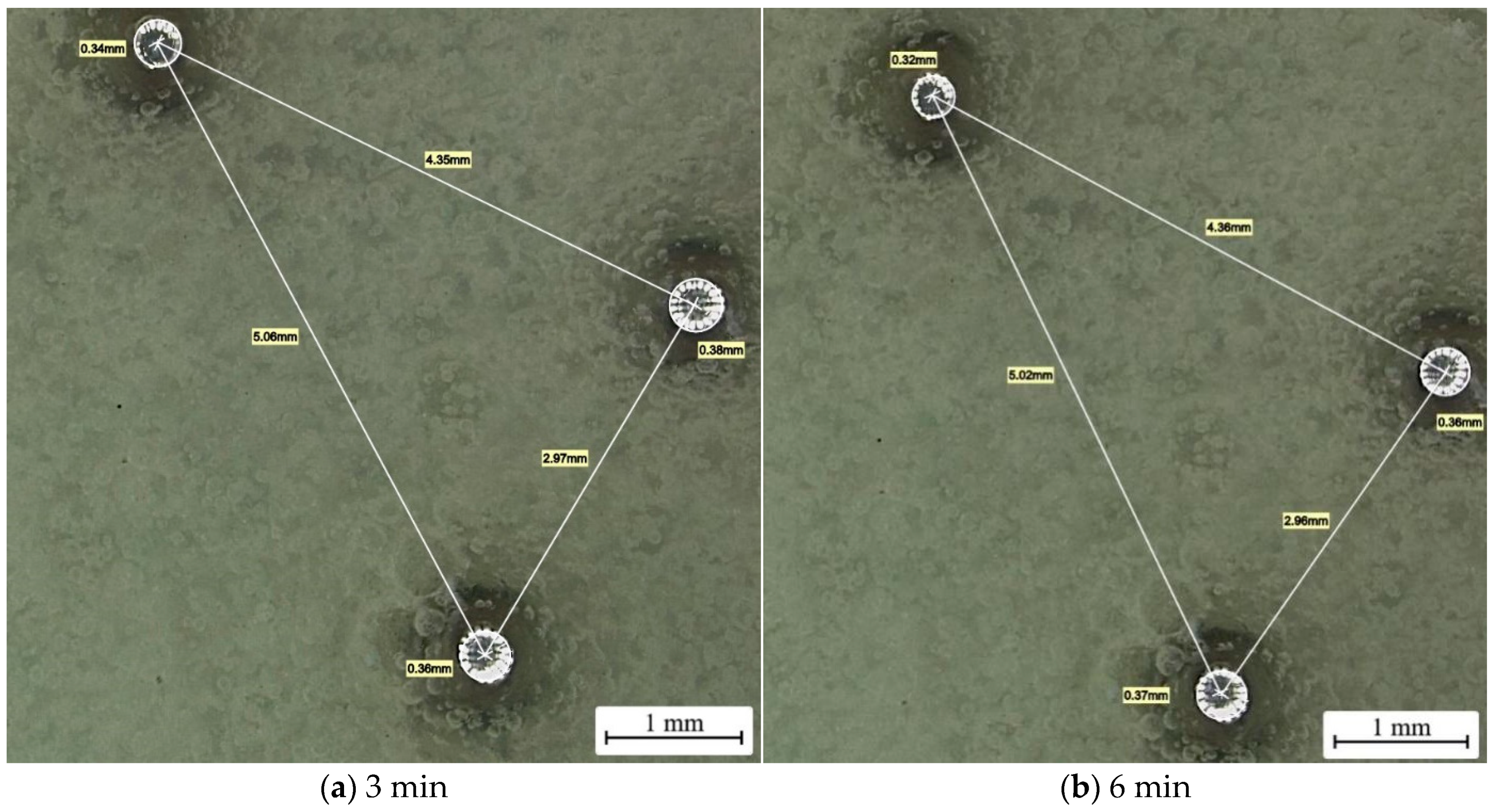

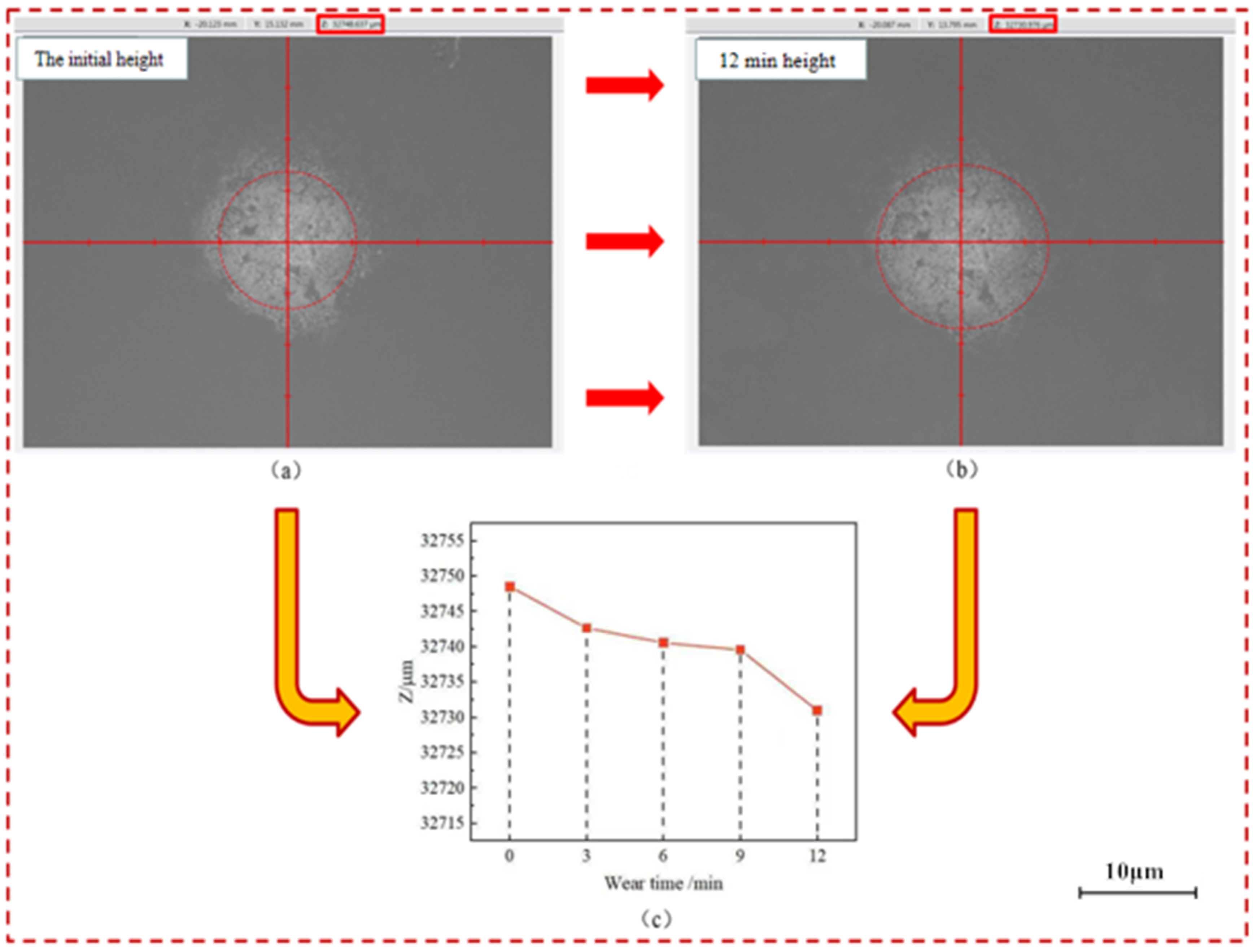

3.3. Study on the Yielding Threshold of the Self-Regressive Fixed Abrasive Polishing Pad

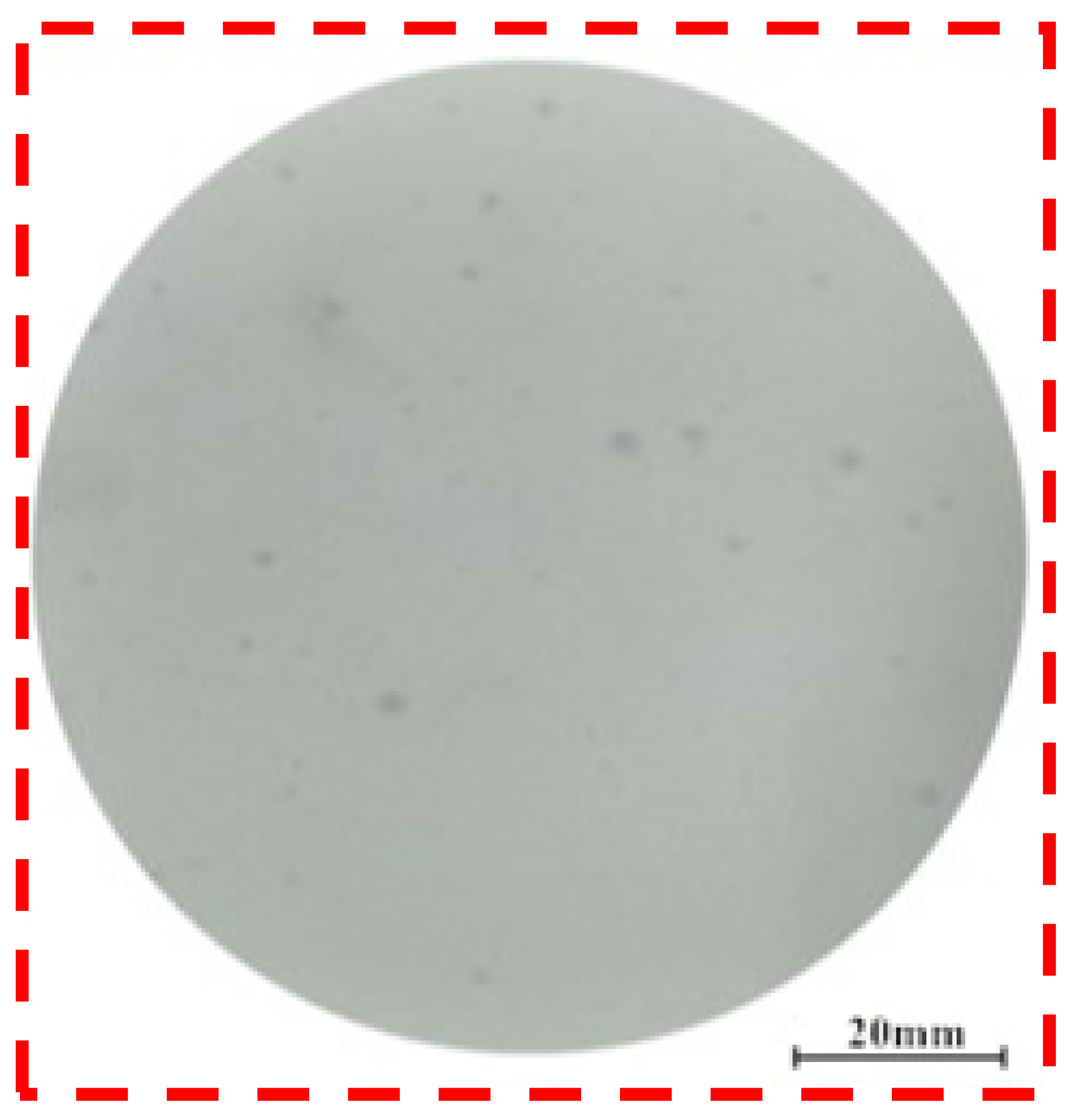

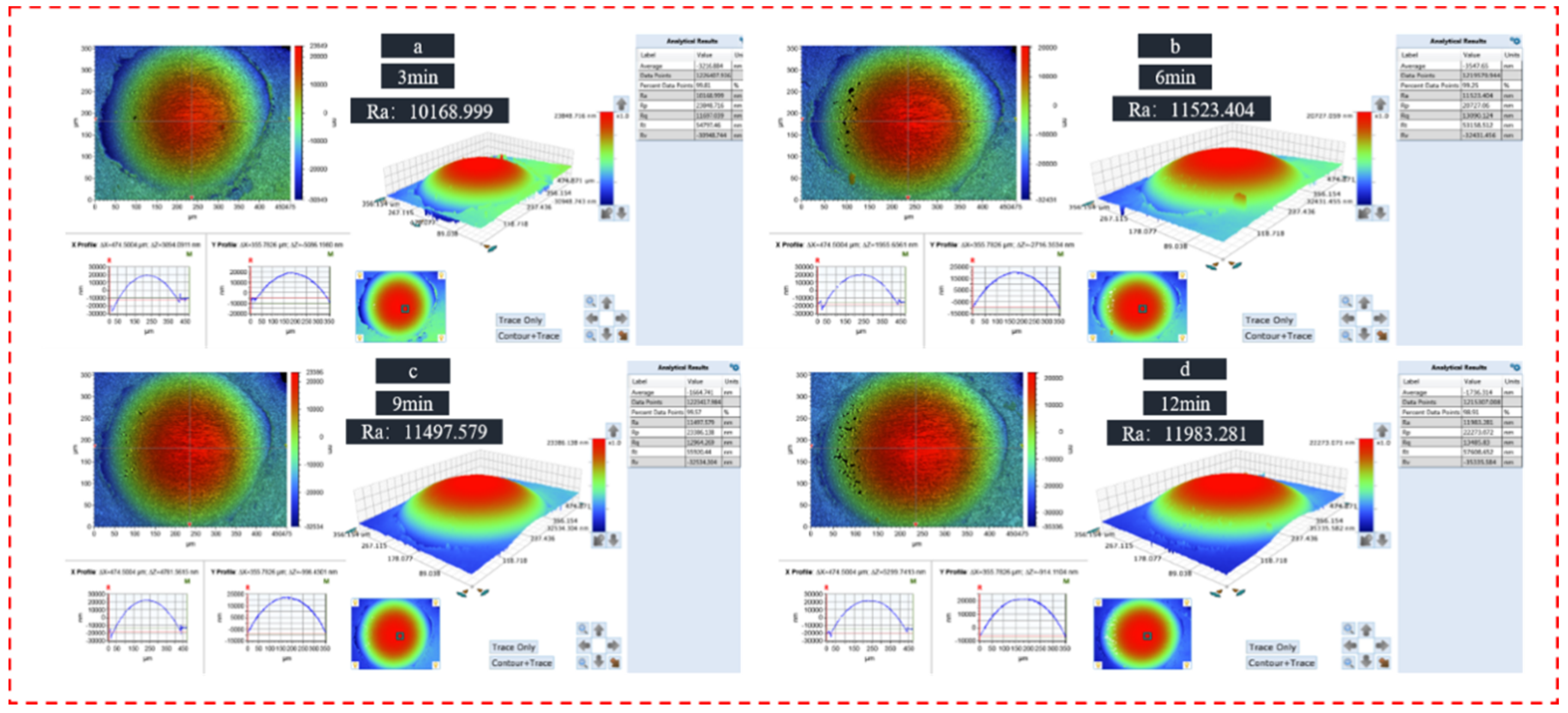

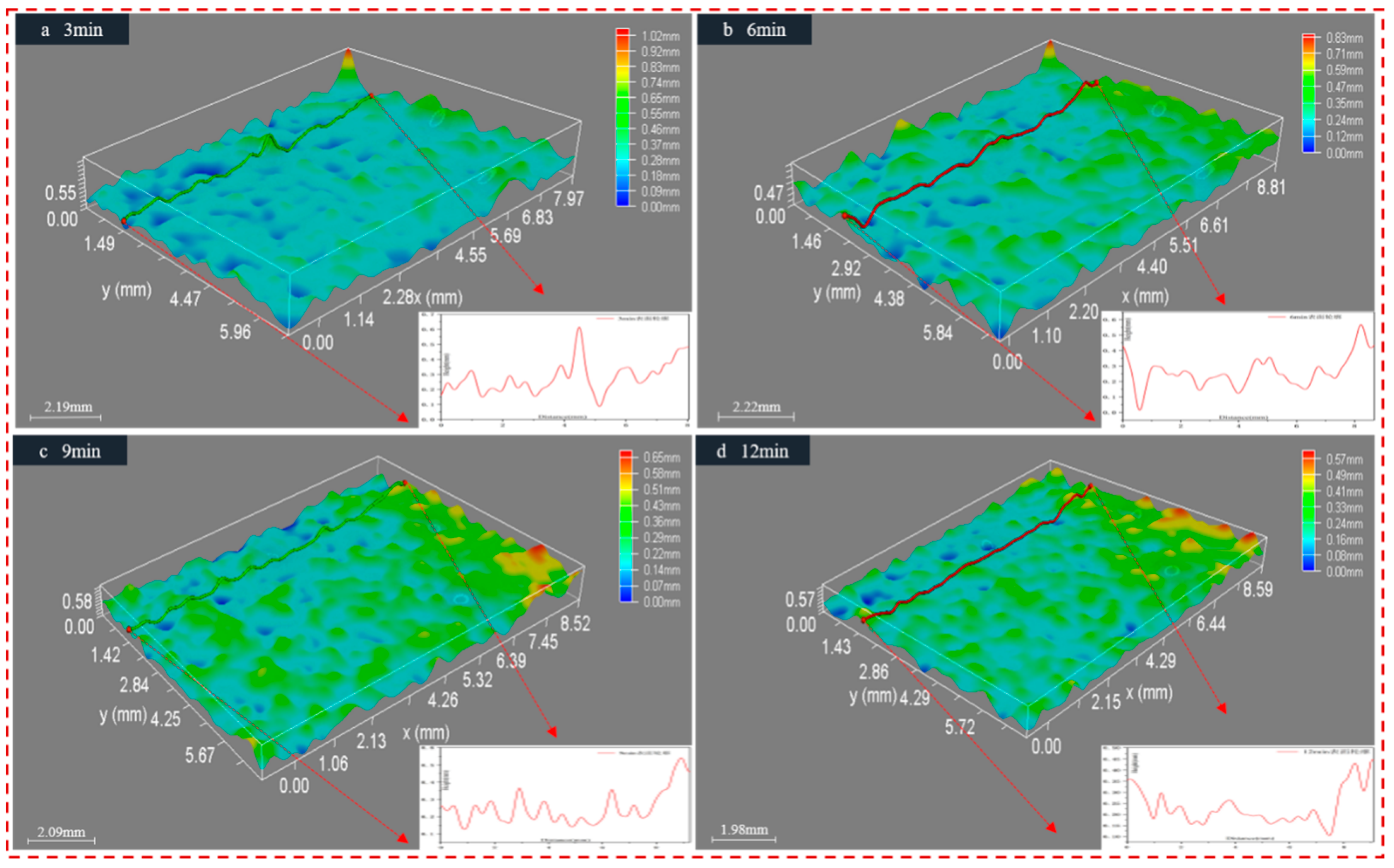

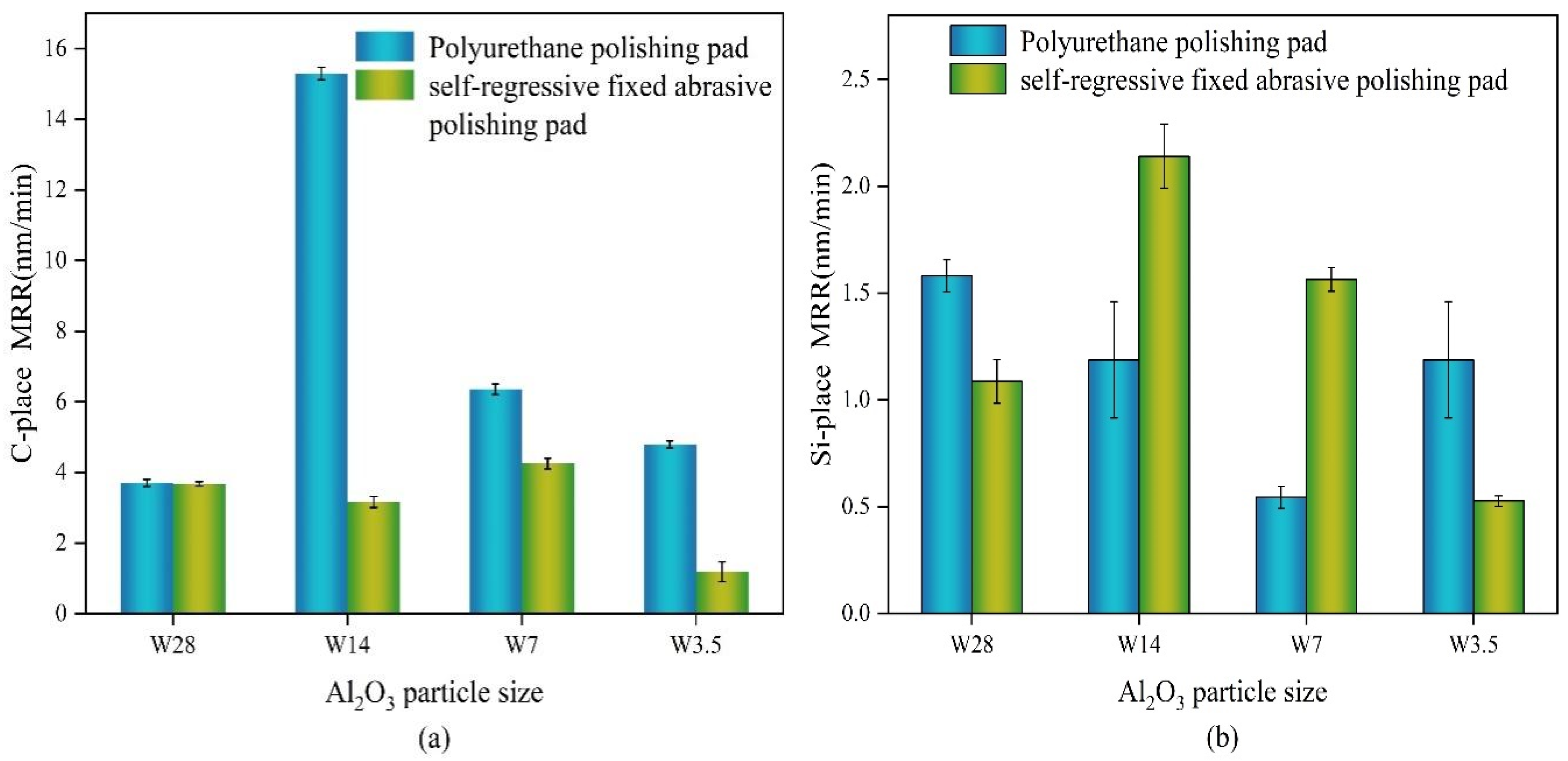

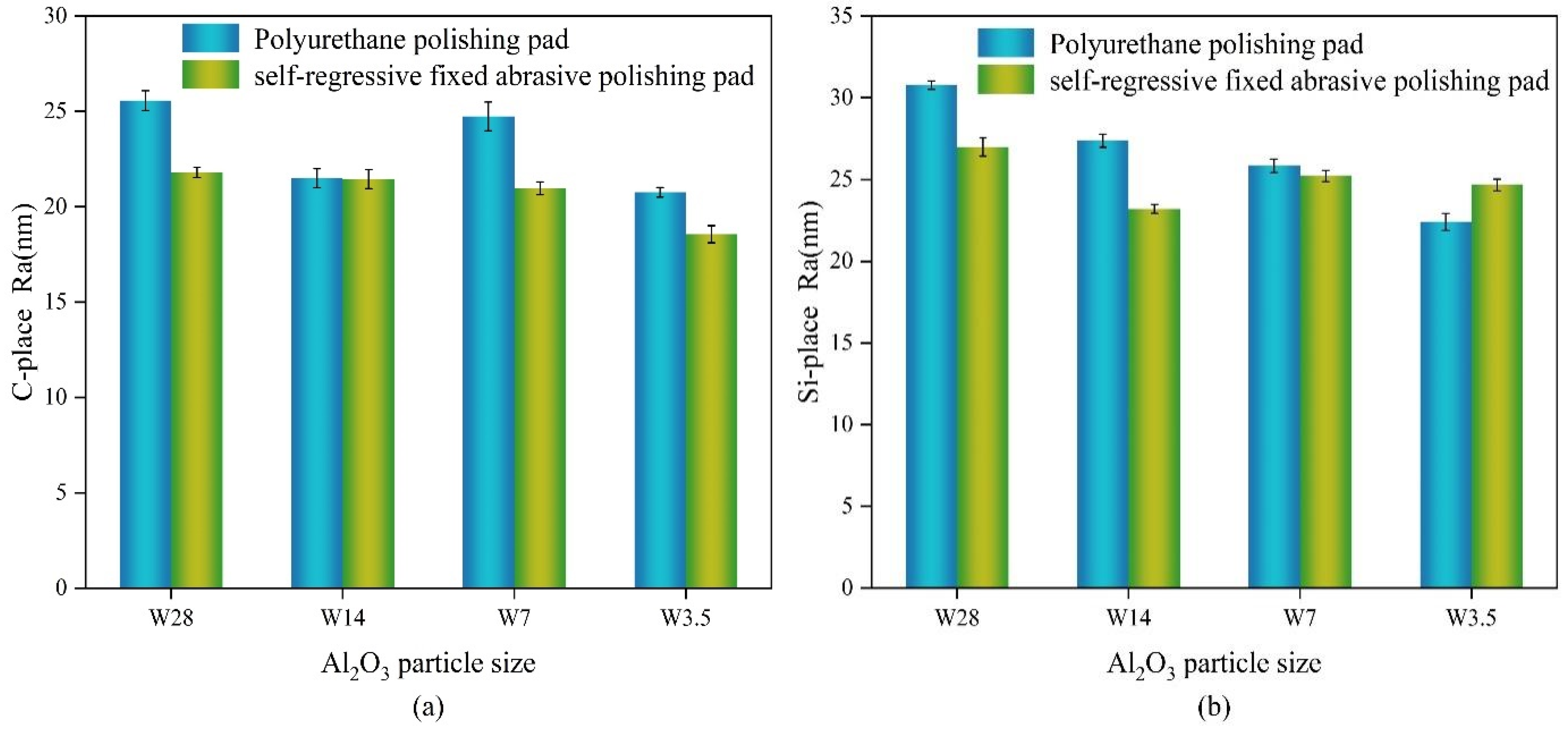

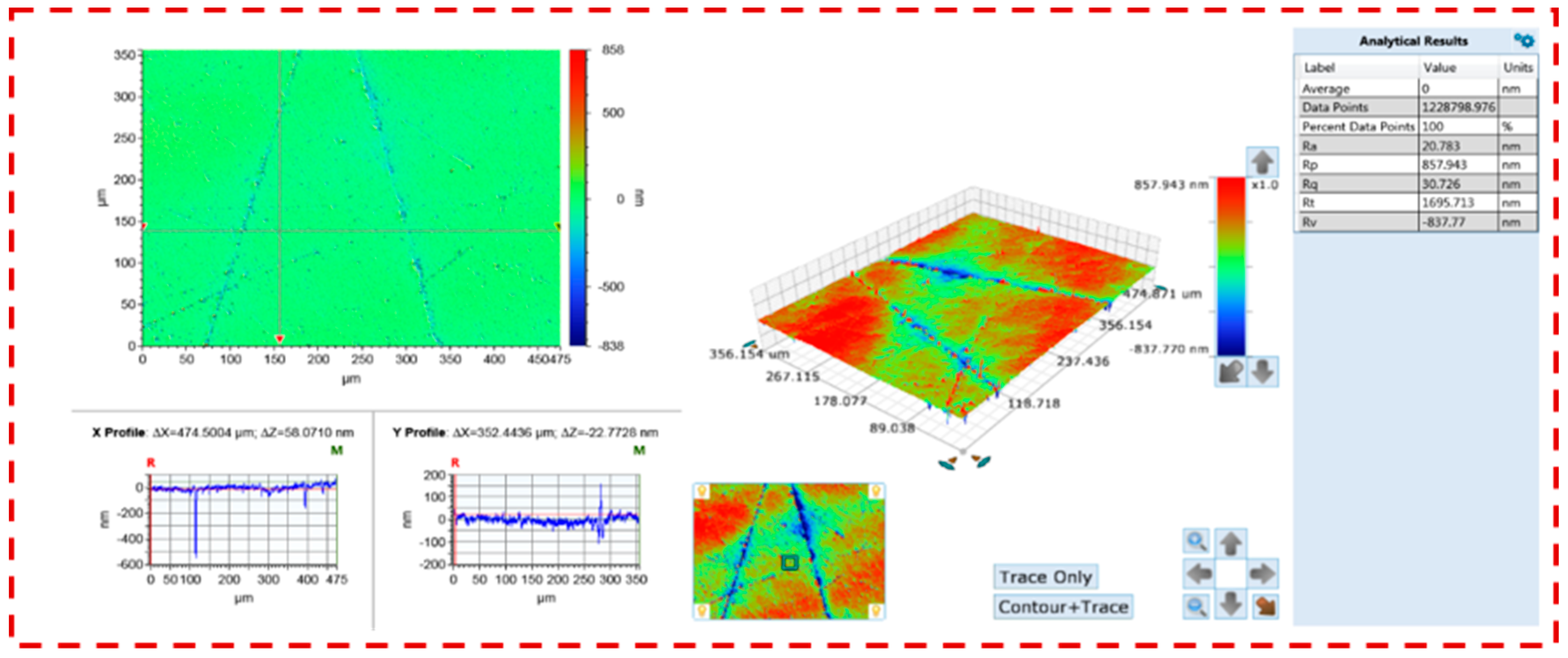

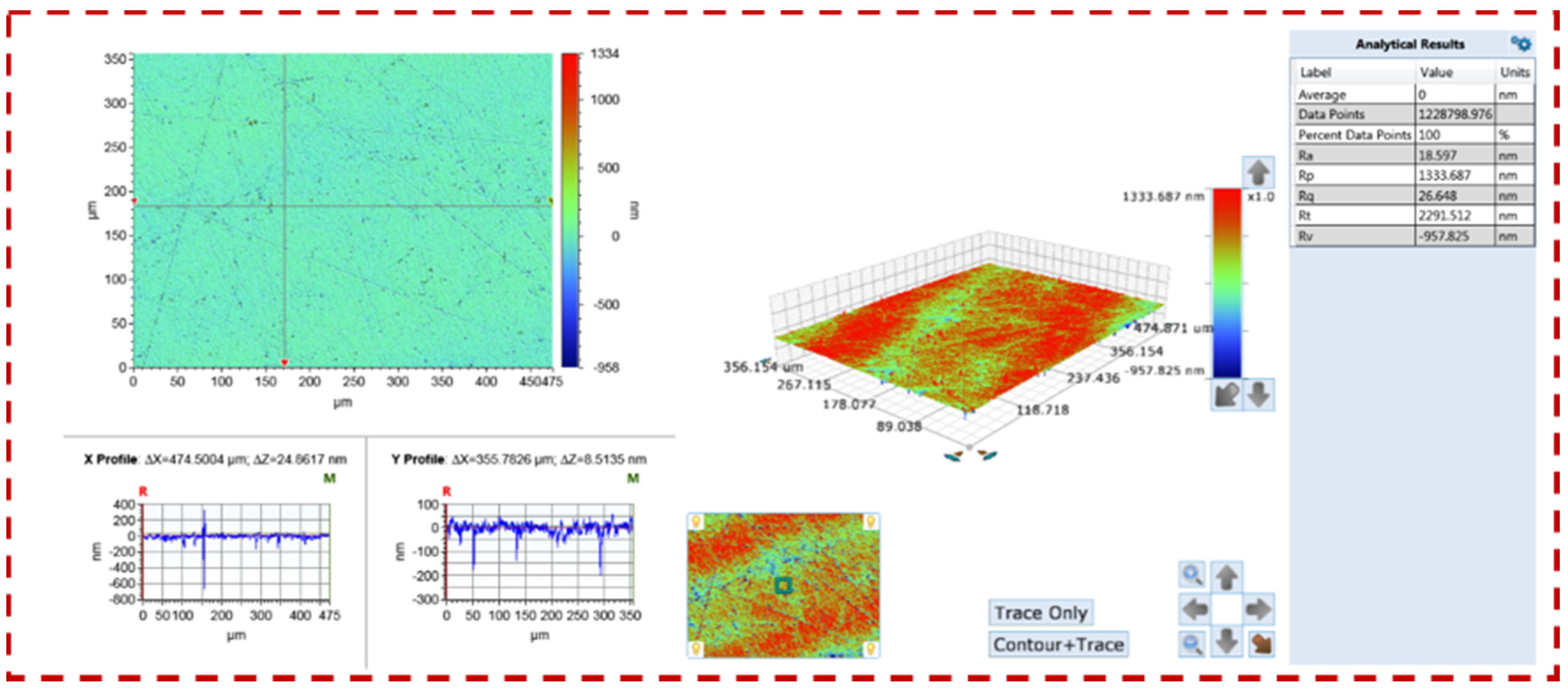

4. Single-Crystal SiC Wafer CMP

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kim, H.; Kim, H.; Jeong, H.; Seo, H.; Lee, S. Self-conditioning of encapsulated abrasive pad in chemical mechanical polishing. J. Mater. Process. Technol. 2003, 142, 614–618. [Google Scholar] [CrossRef]

- Wilson, S.R.; Tracy, C.J. Handbook of Multilevel Metallization for Integrated Circuits; Noyes Publications: Park Ridge, NJ, USA, 1993; pp. 97–107. [Google Scholar]

- Cook, L.M. Chemical processes in glass polishing. J. Non-Cryst. Solids 1990, 120, 152. [Google Scholar] [CrossRef]

- Patrick, W.J.; Guthrie, W.L.; Standley, C.L.; Schiable, P.M. Application of chemical mechanical polishing to the fabrication of VLSI circuitinter connections. J. Electrochem. Soc. 1991, 138, 1778. [Google Scholar] [CrossRef]

- Steigerwald, J.M. Chemical Mechanical Planarization of Microelectronic Materials; Wiley: New York, NY, USA, 1997; p. 48. [Google Scholar]

- Chen, J.; Sun, T.; Su, J.; Li, J.; Zhou, P.; Peng, Y.; Zhu, Y. A novel agglomerated diamond abrasive with excellent micro-cutting and self-sharpening capabilities in fixed abrasive lapping processes. Wear 2021, 464–465, 203531. [Google Scholar] [CrossRef]

- Chen, J.; Zhu, N.; Niu, F.; Peng, Y.; Su, J.; Zhu, Y. Influence of agglomerated diamond abrasive wear on sapphire material removal behavior. Diam. Relat. Mater. 2020, 108, 107965. [Google Scholar] [CrossRef]

- Shi, X.; Xu, L.; Zhou, Y.; Zou, C.; Wang, R.; Pan, G. An in situ study of chemical-mechanical polishing behaviours on sapphire (0001) via simulating the chemical product-removal process by AFM-tapping mode in both liquid and air environments. Nanoscale 2018, 10, 19692–19700. [Google Scholar] [CrossRef]

- Zhang, Z.; Cui, J.; Zhang, J.; Liu, D.; Yu, Z.; Guo, D. Environment friendly chemical mechanical polishing of copper. Appl. Surf. Sci. 2019, 467–468, 5–11. [Google Scholar] [CrossRef]

- Zhang, Z.; Liao, L.; Wang, X.; Xie, W.; Guo, D. Development of a novel chemical mechanical polishing slurry and its polishing mechanisms on a nickel alloy. Appl. Surf. Sci. 2020, 506, 144670. [Google Scholar] [CrossRef]

- Zhang, Z.; Shi, Z.; Yue, F.; Guo, Z.; Guo, L.; Guo, D. A novel approach of chemical mechanical polishing for a titanium alloy using an environment-friendly slurry. Appl. Surf. Sci. 2018, 427, 409–415. [Google Scholar] [CrossRef]

- Xie, W. Green chemical mechanical polishing of sapphire wafers using a novel slurry. Nanoscale 2021, 12, 22518–22526. [Google Scholar] [CrossRef]

- Dong, Y.; Lei, H.; Liu, W.; Chen, Y. Preparation of ellipsoidal rod-shaped silica nanocomposite abrasives by Chromium ion/PEG200 induced method for sapphire substrates chemical mechanical polishing. J. Alloys Compd. 2019, 777, 1294–1303. [Google Scholar] [CrossRef]

- Wang, Z.; Niu, F.; Wang, Z.; Li, J.; Sun, T.; Zhu, Y. Friction and wear characteristics of agglomerated diamond abrasives and lapping performance of fixed agglomerated diamond pads. Wear 2021, 470–471, 203598. [Google Scholar] [CrossRef]

- Wang, Z.; Niu, F.; Zhu, Y.; Li, J.; Wang, J. Comparison of lapping performance between fixed agglomerated diamond pad and fixed single crystal diamond pad. Wear 2019, 432–433, 202963. [Google Scholar] [CrossRef]

- Runnel, S.R.; Eyman, L.M. Tribology analysis of chemical mechanical polishing. J. Electrochem. Soc. 1994, 141, 1698. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, S.; Ding, Y.; Yang, Y.; Ma, L.; Pang, M.; Han, J.; Su, J. Process parameter modeling and optimization of abrasive water jet dressing fixed-abrasive pad based on box-behnken design. Materials 2022, 15, 5251. [Google Scholar] [CrossRef] [PubMed]

- Zefang, Z.; Shiyue, P. A Polyurethane Composite Polishing Pad and Its Preparation Method. CN 111205430A, 23 June 2020. [Google Scholar]

- Huajun, W. A Non-Woven Polyurethane Polishing Pad. CN 210909505U, 3 July 2020. [Google Scholar]

- Huajun, W. A Polyurethane Fiber Polishing Pad. CN 211220222U, 11 August 2020. [Google Scholar]

- Jianxiu, S.; Yu, F.; Jiaxi, D.; Xiqu, C.; Xueliang, Z.; Dongming, G. Analysis of polishing pad surface characteristics. Semicond. Technol. 2007, 32, 957–960. [Google Scholar]

- Chunyu, L. Research and analysis of the groove shape on the surface of the polishing pad for chemical mechanical polishing. China Sci. Technol. 2014, 19, 61. [Google Scholar]

- Kim, S.; Saka, N.; Chun, J. The Role of Pad Topography in Chemical-Mechanical Polishing. IEEE Trans. Semicond. Manuf. 2014, 27, 431–442. [Google Scholar] [CrossRef]

- Zhankui, W.; Minghua, P.; Mingchao, L.; Jianbin, W.; Lijie, M.; Haixu, L.; Jianhai, H.; Yongwei, Z.; Jianxiu, S. Effect of material structure on spinel machinability in its fixed abrasive lapping. J. Manuf. Process 2021, 68, 141–153. [Google Scholar] [CrossRef]

- Jianguo, Y.; Jiejing, L.; Haixu, L.; Zhankui, W.; Yongwei, Z.; Jianxiu, S. Tribochemical action on the tribochemical mechanical lapping (0001) C plane of the SiC single-crystal substrate. Int. J. Mod. Phys. B 2022, 36, 2240027. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, Z.; Wang, S.; Pang, M.; Ma, L.; Su, J. Study on wavelet packet energy characteristics on friction signal of lapping with fixed abrasive pad. Micromachines 2022, 13, 981. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Yang, Y.; Pang, M.; Li, Y.; Ma, L.; Yao, J.; Zhu, Y.; Su, J. Response surface model of processing parameters for lapping quartz glass with a fifixed abrasive pad. Surf. Technol. 2021, 50, 376–385. [Google Scholar]

- Niu, F.; Wang, K.; Sun, T.; Zhou, P.; Hu, W.; Zhu, Y. Lapping performance of mixed-size agglomerated diamond abrasives in fifixed abrasives pads. Diam. Relat. Mater. 2021, 118, 108499. [Google Scholar] [CrossRef]

- Wang, Z.K.; Wang, Z.K.; Zhu, Y.W.; Su, J.X. Effect of lapping slurry on critical cutting depth of spinel. Appl. Surf. Sci. 2015, 347, 849–855. [Google Scholar] [CrossRef]

- Neslen, C.L.; Mitchel, W.C.; Hengehold, R.L. Effects of process parameter variations on the removal rate in chemical mechanical polishing of 4H-SiC. J. Electron. Mater. 2001, 30, 1271–1275. [Google Scholar] [CrossRef]

- Min, Z.; Renjiang, Y.; Xiaobing, L.; Jianfeng, C.; Wenhu, X. Effects of abrasive particle and polishing pad characteristics on ultrasonic chemical mechanical polishing of sapphire. China Surf. Eng. 2018, 153, 131–138. [Google Scholar]

- Zhou, Y.; Luo, H.; Pan, G.; Zou, C.; Luo, G.; Chen, G.; Kang, C. Study on Pad Performance Deterioration in Chemical Mechanical Polishing (CMP) of Fused Silica. Ecs J. Solid State Sci. Technol. 2018, 7, 295–298. [Google Scholar] [CrossRef]

- Yuan, J.; Wang, Z.; Hong, T. A semi-fixed abrasive machining technique. J. Micromech. Microeng. 2009, 19, 054006. [Google Scholar] [CrossRef]

- Luo, Q.; Lu, J.; Xu, X. Study on the processing characteristics of SiC and sapphire substrates polished by semi-fixed and fixed abrasive tools. Tribol. Int. 2016, 104, 191–203. [Google Scholar] [CrossRef]

- Luo, Q.; Lu, J.; Xu, X. A comparative study on the material removal mechanisms of 6H-SiC polished by semi-fixed and fixed diamond abrasive tools. Wear 2016, 350–351, 99–106. [Google Scholar] [CrossRef]

- Lu, J.; Li, Y.; Xu, X. The effects of abrasive yielding on the polishing of SiC wafers using asemi-fixed flexible pad. Proc. Inst. Mech. Eng. Part B-J. Eng. Manuf. 2015, 229, 170–177. [Google Scholar] [CrossRef]

| Factor | Swelling Rate/% | Young’s Modulus/MPa | Porosity/% | Aperture/μm | Hole Depth/μm | Roughness/μm | |

|---|---|---|---|---|---|---|---|

| Polishing Pad | |||||||

| Polyurethane pad | 1.9066 | 528.316 | 65 | 216.432 | 325.925 | 14.726 | |

| Self-made polishing pad | 14.434 | 2094.897 | 44 | 71.898 | 471.823 | 7.527 | |

| CMP1 | CMP2 | ||

|---|---|---|---|

| Pressure (psi) | 2 | 2 | |

| Rotational speed (r/min) | 60 | 60 | |

| Time (t) | 30 | 30 | |

| Polishing pad | Polyurethane | Polyurethane | SR-FAPP |

| SR-FAPP | |||

| Polishing solution | Al2O3 Oxidant Dispersing agent | Oxidant Dispersing agent | |

| PH | 9–10 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yao, J.; Liu, H.; Wang, Z.; Zhu, Y.; Su, J. Study on the Preparation and Performance of Self-Regressive Fixed Abrasive Chemical Mechanical Polishing Pad. Machines 2022, 10, 999. https://doi.org/10.3390/machines10110999

Yao J, Liu H, Wang Z, Zhu Y, Su J. Study on the Preparation and Performance of Self-Regressive Fixed Abrasive Chemical Mechanical Polishing Pad. Machines. 2022; 10(11):999. https://doi.org/10.3390/machines10110999

Chicago/Turabian StyleYao, Jianguo, Haixu Liu, Zhankui Wang, Yongwei Zhu, and Jianxiu Su. 2022. "Study on the Preparation and Performance of Self-Regressive Fixed Abrasive Chemical Mechanical Polishing Pad" Machines 10, no. 11: 999. https://doi.org/10.3390/machines10110999

APA StyleYao, J., Liu, H., Wang, Z., Zhu, Y., & Su, J. (2022). Study on the Preparation and Performance of Self-Regressive Fixed Abrasive Chemical Mechanical Polishing Pad. Machines, 10(11), 999. https://doi.org/10.3390/machines10110999